A B2B Buyer’s Guide to Three Prong European Plug: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for three prong european plug

In today’s increasingly interconnected world, international B2B buyers face the challenge of sourcing reliable three prong European plugs that meet diverse regional standards and regulations. With the proliferation of electronic devices and the need for seamless connectivity across borders, understanding the specifications and compliance requirements of these plugs is essential. This guide offers a comprehensive overview of the various types of three prong European plugs, their applications, and essential factors to consider when selecting the right products for your business needs.

Throughout this resource, we will delve into the intricacies of plug types, including the CEE7/7 standard commonly used in Europe and other regions. We’ll explore the importance of supplier vetting to ensure product quality and reliability, as well as cost considerations that can impact your bottom line. By equipping B2B buyers from Africa, South America, the Middle East, and Europe—countries such as Saudi Arabia and Vietnam—with actionable insights, this guide empowers you to make informed purchasing decisions.

Navigating the global market for three prong European plugs does not have to be daunting. Armed with the right knowledge, you can confidently source products that not only meet compliance standards but also enhance the operational efficiency of your business. Whether you are expanding your product line or optimizing your supply chain, this guide serves as your essential roadmap.

Understanding three prong european plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CEE 7/7 (Schuko) | Round pins, grounding clip, compatible with CEE 7/16 | General appliances, industrial equipment | Pros: High safety; versatile. Cons: Bulky design may not fit all outlets. |

| CEE 7/4 (Europlug) | Two round pins, no grounding, compact design | Small electronics, lightweight devices | Pros: Space-saving; easy to carry. Cons: Limited to devices without grounding. |

| CEE 7/5 (Type F) | Similar to Schuko, with grounding, suitable for higher loads | Heavy machinery, power tools | Pros: Robust; supports higher current. Cons: Heavier; may require specific outlets. |

| BS 1363 (UK plug) | Rectangular pins, fused for safety | Consumer electronics, home appliances | Pros: Enhanced safety with fuses; widely used in the UK. Cons: Not compatible with all European sockets. |

| NEMA 5-15 (USA to Europe Adapter) | Adapts NEMA 5-15 plugs to European outlets | Travel, temporary setups | Pros: Convenient for travelers; versatile. Cons: Not for permanent installations; wattage limitations. |

What are the Characteristics of the CEE 7/7 (Schuko) Plug?

The CEE 7/7 plug, commonly referred to as the Schuko plug, features two round pins and a grounding clip, making it suitable for a variety of appliances across Europe and many African countries. Its design allows for a secure fit in compatible sockets, enhancing safety during use. B2B buyers should consider the Schuko plug for industrial equipment and general appliances due to its versatility and high safety standards. However, its bulkiness can be a disadvantage in tight spaces or when dealing with portable devices.

How Does the CEE 7/4 (Europlug) Differ from Other Plugs?

The CEE 7/4 Europlug is distinguished by its two round pins and compact design, making it ideal for lightweight devices such as small electronics. This plug is particularly useful for B2B buyers looking for space-saving solutions in electronics manufacturing or distribution. Its lack of grounding makes it unsuitable for high-power appliances, which is an important consideration when sourcing products that require safety compliance.

What Makes the CEE 7/5 (Type F) Plug Suitable for Heavy Machinery?

The CEE 7/5 Type F plug shares similarities with the Schuko but is designed to support higher electrical loads, making it ideal for heavy machinery and power tools. This robust plug is often used in industrial settings, where durability and reliability are critical. B2B buyers should prioritize the Type F plug for applications that demand high current, but they must also be aware of its weight and the need for compatible outlets.

Why is the BS 1363 Plug Popular in the UK?

The BS 1363 plug features three rectangular pins and includes a fuse for added safety, making it a standard in the UK. Its widespread use in consumer electronics and home appliances presents a reliable option for B2B buyers targeting the UK market. However, its incompatibility with many European sockets can be a drawback for businesses that operate across multiple regions.

What are the Benefits of Using NEMA 5-15 Adapters for European Travel?

NEMA 5-15 to European plug adapters facilitate the use of American devices in Europe, catering to travelers and businesses with temporary setups. While these adapters offer convenience, they are not designed for permanent installations and come with wattage limitations. B2B buyers should consider these factors when sourcing travel accessories, ensuring they meet the power requirements of their devices.

Key Industrial Applications of three prong european plug

| Industry/Sector | Specific Application of three prong european plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and tools in production lines | Ensures reliable operation of heavy equipment | Certification for safety standards (e.g., CE, UL) |

| Hospitality | Connecting appliances in hotels and restaurants | Facilitates seamless operation of kitchen and service equipment | Compatibility with local electrical systems |

| Construction | Temporary power solutions at construction sites | Provides safe and efficient power supply for tools | Durability and weather resistance for outdoor use |

| Telecommunications | Powering communication equipment | Ensures uninterrupted connectivity and service | Voltage rating to match local grid requirements |

| Healthcare | Connecting medical devices in clinics and hospitals | Supports critical healthcare operations | Compliance with health and safety regulations |

How is the Three Prong European Plug Used in Manufacturing?

In the manufacturing sector, the three prong European plug is essential for powering various machinery and tools used in production lines. These plugs ensure a secure connection to the electrical supply, which is critical for maintaining operational efficiency and safety. Businesses in this sector require plugs that comply with safety standards such as CE and UL, ensuring that they can withstand the rigors of heavy-duty use. Additionally, international buyers must consider the voltage compatibility based on their local electrical grid to avoid equipment damage.

What Role Does the Three Prong European Plug Play in the Hospitality Industry?

In hospitality, the three prong European plug is commonly used to connect kitchen appliances, cleaning equipment, and other essential devices in hotels and restaurants. This plug type facilitates the seamless operation of equipment that is vital for service delivery, such as ovens, refrigerators, and coffee machines. For businesses sourcing these plugs, it is crucial to ensure compatibility with local electrical systems and to consider the durability of the plugs, given the high usage rates in busy establishments.

How is the Three Prong European Plug Utilized on Construction Sites?

Construction sites often require temporary power solutions, making the three prong European plug a valuable asset for connecting tools and equipment. These plugs provide a safe and efficient power supply for various construction tools, ensuring that work can proceed without interruptions. Buyers in this sector should prioritize sourcing plugs that are durable and weather-resistant, as they will often be exposed to harsh conditions. Additionally, compliance with local safety regulations is paramount to mitigate risks on-site.

In What Way Does the Three Prong European Plug Support Telecommunications?

In the telecommunications industry, the three prong European plug is used to power communication equipment, including routers, switches, and servers. Ensuring an uninterrupted power supply is critical for maintaining connectivity and service reliability, which directly impacts business operations. When sourcing these plugs, businesses should focus on the voltage ratings to match their local grid requirements, as mismatches can lead to equipment failure and costly downtimes.

How is the Three Prong European Plug Essential in Healthcare Settings?

Healthcare facilities rely on the three prong European plug to connect medical devices such as diagnostic machines, monitoring equipment, and surgical instruments. The reliability and safety of these connections are crucial for supporting patient care and operational efficiency. Sourcing considerations for healthcare applications include compliance with health and safety regulations, as well as ensuring that the plugs can handle the specific voltage and current requirements of sensitive medical equipment.

3 Common User Pain Points for ‘three prong european plug’ & Their Solutions

Scenario 1: Incompatibility with Local Power Outlets

The Problem: B2B buyers often encounter significant hurdles when attempting to use American devices in regions with three-prong European plugs. For example, a company in South America sourcing equipment from the USA may find that their devices do not fit local outlets. This issue can lead to operational delays, increased costs, and frustration among employees who need to adapt to different power standards quickly. The lack of compatibility can disrupt workflows, especially in environments where time is critical.

The Solution: To mitigate these compatibility issues, B2B buyers should prioritize sourcing high-quality three-prong European plug adapters that comply with local standards, such as the CEE7/7. When selecting adapters, ensure they are rated for the necessary voltage (typically 250V) and amperage (around 10A) to prevent device damage. Collaborating with suppliers who understand local regulations can also help streamline this process. For example, purchasing adapters in bulk can provide significant savings and ensure that all devices can be used seamlessly in the target market. Additionally, it’s prudent to invest in multi-region power strips that can accommodate various plug types, providing flexibility for future expansions or travel.

Scenario 2: Risk of Electrical Damage to Devices

The Problem: One of the critical concerns for B2B buyers is the risk of electrical damage when using devices designed for different voltages and plug types. An organization importing electronics from Europe to Africa may find that their devices are not rated for the local voltage, leading to potential malfunctions or permanent damage. This situation can result in costly repairs or replacements, impacting budgets and timelines.

The Solution: To address this issue, buyers must conduct thorough research on the voltage and frequency requirements of their devices before purchase. When sourcing three-prong European plugs or adapters, it’s crucial to ensure that they are equipped with built-in voltage converters or that the devices themselves are rated for dual voltage operation (e.g., 125/250V). Consulting with manufacturers or suppliers who specialize in international electrical standards can provide insights into safe practices. Additionally, implementing a testing protocol for new devices upon arrival can help catch compatibility issues early, thus avoiding damage and ensuring that all equipment operates efficiently.

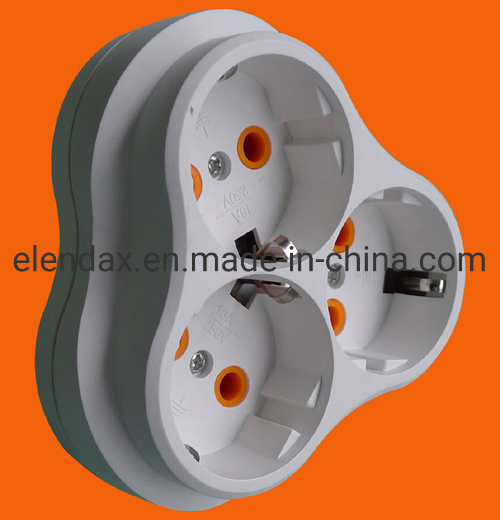

Illustrative image related to three prong european plug

Scenario 3: Inadequate Product Information and Certifications

The Problem: B2B buyers often struggle with insufficient product information when sourcing three-prong European plugs. For example, an importer may receive plugs that lack necessary certifications or detailed specifications, which can lead to compliance issues and safety risks. This lack of information can create uncertainty regarding the quality and safety of the products, ultimately affecting the buyer’s reputation in the market.

The Solution: To overcome this challenge, it is essential for buyers to establish clear communication channels with suppliers and demand comprehensive product specifications, including certifications such as UL or CE. Investing time in due diligence when selecting suppliers can prevent future issues. Buyers should also seek out vendors who provide documentation on environmental compliance (e.g., RoHS, REACH) to ensure that their products meet local regulations. Building a relationship with reputable manufacturers that offer robust customer support can facilitate access to necessary information and certification documents, ensuring that buyers can make informed purchasing decisions. Regular audits of supplier practices can also help maintain quality standards over time.

Strategic Material Selection Guide for three prong european plug

What are the Key Materials Used in Manufacturing Three Prong European Plugs?

When selecting materials for three prong European plugs, it is essential to consider their properties, advantages, and limitations. The choice of material directly impacts the plug’s performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these plugs.

What are the Benefits and Drawbacks of Using Polycarbonate for Three Prong European Plugs?

Polycarbonate is a popular choice for the casing of three prong European plugs due to its excellent impact resistance and electrical insulating properties. It can withstand high temperatures, typically rated up to 120°C, making it suitable for various applications.

Illustrative image related to three prong european plug

Pros: Polycarbonate is lightweight, durable, and offers good resistance to UV radiation and chemicals. Its transparency allows for visual inspection of internal components, ensuring quality control during manufacturing.

Cons: The primary limitation of polycarbonate is its susceptibility to scratching and potential degradation over time when exposed to harsh environmental conditions. Additionally, it can be more expensive than other plastic materials.

Impact on Application: Polycarbonate plugs are ideal for indoor and outdoor use, particularly in regions with extreme weather conditions. However, buyers should ensure that the plugs meet compliance standards such as IEC 60884-1.

How Does PVC Compare as a Material for Three Prong European Plugs?

Polyvinyl chloride (PVC) is another commonly used material for three prong European plugs, particularly for the insulation of wires. It is known for its flexibility and resistance to moisture and chemicals.

Pros: PVC is cost-effective and has good electrical insulation properties. It is also highly resistant to corrosion and can withstand a wide range of temperatures, typically between -15°C to 70°C.

Cons: While PVC is durable, it can become brittle over time, especially when exposed to UV light. This brittleness can lead to cracking, making it less suitable for outdoor applications.

Impact on Application: PVC-insulated plugs are widely used in various industries, but international buyers must ensure compliance with local regulations regarding material safety and environmental impact, such as RoHS and REACH.

What are the Advantages of Using Metal Components in Three Prong European Plugs?

Metal components, particularly brass or copper, are often used for the prongs in three prong European plugs due to their excellent conductivity and strength.

Pros: Metals like brass provide superior electrical conductivity, which is crucial for efficient power transfer. They are also durable and resistant to corrosion when properly plated.

Cons: The primary drawback of using metals is their susceptibility to oxidation over time, which can lead to reduced conductivity. Additionally, metal components can increase the overall weight of the plug.

Impact on Application: Metal prongs are essential for high-performance applications, especially in industrial settings. Buyers from regions with high humidity or salt exposure, such as coastal areas in Africa and South America, should prioritize corrosion-resistant finishes.

Why is Thermoplastic Elastomer (TPE) a Good Choice for Three Prong European Plugs?

Thermoplastic elastomer (TPE) is increasingly being used for the flexible parts of three prong European plugs, such as strain reliefs and grips.

Pros: TPE combines the advantages of rubber and plastic, offering flexibility, resilience, and excellent grip. It is also resistant to chemicals and UV light, making it suitable for various environments.

Cons: TPE can be more expensive than traditional plastics and may require specialized processing techniques, which can complicate manufacturing.

Illustrative image related to three prong european plug

Impact on Application: TPE is particularly beneficial for plugs used in portable devices or in environments where flexibility and durability are crucial. International buyers should ensure that TPE materials comply with relevant safety standards.

Summary Table of Material Selection for Three Prong European Plugs

| Material | Typical Use Case for three prong european plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Plug casing for indoor/outdoor applications | Excellent impact resistance and insulation | Susceptible to scratching and UV degradation | Medium |

| PVC | Wire insulation in plugs | Cost-effective and moisture-resistant | Can become brittle over time | Low |

| Metal (Brass/Copper) | Prongs for high-performance applications | Superior electrical conductivity | Susceptible to oxidation | Medium |

| Thermoplastic Elastomer (TPE) | Flexible components like grips and strain reliefs | Combines flexibility with durability | Higher cost and manufacturing complexity | High |

This comprehensive analysis of materials provides B2B buyers with actionable insights to make informed decisions regarding the selection of three prong European plugs, ensuring compliance with international standards and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for three prong european plug

What Are the Main Stages in the Manufacturing Process of a Three Prong European Plug?

The manufacturing of a three prong European plug involves several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials used in the production of three prong plugs include high-quality thermoplastics for the casing and copper or brass for the conductive pins. Suppliers must ensure that materials meet international standards for safety and durability, such as RoHS compliance, which restricts hazardous substances. Advanced material testing is often performed to verify properties such as electrical conductivity and thermal resistance.

-

Forming: During this stage, the raw materials are shaped into the various components of the plug. The casing is typically manufactured using injection molding, which allows for precise control over dimensions and surface finish. The conductive pins are formed through processes like stamping or extrusion, ensuring that they meet strict dimensional tolerances.

-

Assembly: Once all components are formed, the assembly process begins. This usually involves inserting the conductive pins into the molded casing and ensuring that they are securely attached. Automated assembly lines are often utilized for efficiency, but manual checks are essential to guarantee that each plug functions correctly.

-

Finishing: The final stage includes quality checks and surface finishing. This may involve polishing the casing, applying protective coatings, or adding branding elements. The plugs are then packaged for distribution, ensuring that they are protected from damage during transport.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is vital in ensuring that three prong plugs meet safety and performance standards. This process is typically broken down into several checkpoints:

-

Incoming Quality Control (IQC): Before production begins, materials are inspected to ensure they comply with specifications. This includes checking for certifications like UL approval and RoHS compliance. Any materials that do not meet standards are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, QC personnel monitor production closely. This includes measuring component dimensions, checking assembly procedures, and ensuring that machinery operates correctly. Statistical process control (SPC) methods are often used to analyze production data in real-time and identify potential issues before they escalate.

-

Final Quality Control (FQC): Once production is complete, each plug undergoes a final inspection. This involves testing for electrical safety, insulation resistance, and mechanical durability. Common testing methods include high-voltage tests, thermal cycling tests, and drop tests to ensure reliability.

What International Standards and Certifications Should B2B Buyers Consider?

For B2B buyers, understanding the relevant international standards and certifications is crucial for ensuring product quality and safety. Key standards include:

-

ISO 9001: This international standard focuses on quality management systems and ensures that manufacturers adhere to consistent quality practices throughout their processes.

-

CE Marking: Required for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

-

UL Certification: This certification is essential for electrical products in the USA, indicating that the product has been tested for safety.

-

RoHS and REACH Compliance: These regulations ensure that products are free from hazardous substances and meet environmental safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to high-quality standards, B2B buyers can implement several verification strategies:

-

Supplier Audits: Conducting audits at the supplier’s facility can provide valuable insights into their manufacturing and quality control processes. Audits can assess compliance with international standards and the effectiveness of their quality management systems.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC. These reports can help buyers understand the consistency and reliability of the supplier’s production.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification. These organizations can perform unannounced inspections and provide unbiased assessments of the supplier’s quality control processes.

What Are the QC Nuances for International B2B Buyers, Especially from Africa, South America, and the Middle East?

International buyers, particularly those from regions such as Africa, South America, and the Middle East, face unique challenges when sourcing three prong European plugs. These nuances include:

-

Understanding Regional Regulations: Different regions may have specific regulatory requirements that must be met. Buyers should familiarize themselves with local standards and ensure that their suppliers are compliant.

-

Logistical Considerations: Shipping and customs regulations can vary significantly between countries. Buyers should work with suppliers who have experience in international shipping and can navigate these complexities efficiently.

-

Cultural Differences in Business Practices: Effective communication is key in international transactions. Buyers should be aware of cultural differences that may impact negotiations, timelines, and expectations regarding quality and delivery.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing three prong European plugs, ensuring that they obtain high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three prong european plug’

Introduction

Sourcing a three prong European plug can be a complex task, especially for international B2B buyers. This guide provides a structured checklist to streamline your procurement process, ensuring you select high-quality products that meet your technical requirements and compliance standards. By following these steps, you can make informed decisions that enhance your supply chain efficiency.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the three prong European plug. Consider factors such as voltage ratings (typically 250V), amperage (usually 10A), and compliance with relevant standards like CEE7/7. This clarity will guide your search and help you communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in electrical components, particularly plugs and adapters. Utilize online marketplaces, industry directories, and trade shows to compile a list of reputable manufacturers. Pay attention to their experience and market presence, as these factors often correlate with product quality and reliability.

Step 3: Verify Supplier Certifications

Confirm that your shortlisted suppliers possess the necessary certifications and approvals for their products. Look for compliance with international standards such as UL, RoHS, and REACH, which ensure safety and environmental responsibility. Valid certifications not only guarantee product quality but also mitigate risks associated with regulatory non-compliance.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the three prong European plugs to evaluate their quality firsthand. Inspect the materials, construction, and overall design to ensure they meet your specifications. Testing samples in real-world applications can help identify potential issues early, saving you from costly mistakes.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among different suppliers while considering the total cost of ownership, including shipping and customs duties. Be sure to clarify payment terms, such as deposits and payment methods, to ensure they align with your budgeting process. Negotiating favorable terms can significantly enhance your cash flow management.

Illustrative image related to three prong european plug

Step 6: Evaluate Supplier Support and Warranty Policies

Understanding the level of support and warranty offered by suppliers is crucial. Inquire about their customer service responsiveness and the warranty terms for defective products. A reliable supplier should provide prompt assistance and a clear return policy, which can be vital for maintaining operational continuity.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, draft a purchase agreement that outlines all terms and conditions, including delivery schedules, payment terms, and quality assurances. Ensure both parties understand and agree to these terms to prevent misunderstandings. A well-structured agreement protects your interests and fosters a healthy supplier relationship.

By following this comprehensive checklist, you can navigate the complexities of sourcing three prong European plugs with confidence, ensuring you secure high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for three prong european plug Sourcing

What Are the Key Cost Components in Sourcing Three Prong European Plugs?

When sourcing three prong European plugs, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

Illustrative image related to three prong european plug

-

Materials: The choice of raw materials significantly impacts overall costs. High-quality plastics and metals that comply with international safety standards can raise initial costs but enhance product durability and safety.

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Countries with lower labor costs may offer cheaper products, but this can come at the expense of quality.

-

Manufacturing Overhead: This includes costs associated with facility operations, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Custom molds and tooling for specific plug designs can entail significant upfront costs. However, amortizing these costs over large production runs can lead to lower unit prices.

-

Quality Control (QC): Implementing strict quality control measures is vital to ensure compliance with international safety standards. While this adds to the overall cost, it protects against returns and reputational damage.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. Factors such as distance, shipping method, and international tariffs need to be accounted for.

-

Margin: Finally, the supplier’s profit margin is a crucial component. This varies by supplier and can be influenced by market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of Three Prong European Plugs?

Several factors can influence the pricing of three prong European plugs, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers typically offer discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs or additional features (like surge protection) can increase costs. Buyers should balance their needs with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., UL, RoHS) can increase costs but are essential for compliance in many markets.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Suppliers from regions with advanced manufacturing capabilities might command higher prices but offer superior quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Are the Best Practices for Negotiating Pricing on Three Prong European Plugs?

B2B buyers should employ strategic negotiation tactics to secure favorable pricing:

-

Research and Benchmarking: Conduct thorough market research to understand competitive pricing. Knowing the average price can empower buyers during negotiations.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront cost. This includes shipping, tariffs, and potential costs related to quality issues. A lower initial price might lead to higher long-term costs.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Trust can facilitate more effective negotiations and open the door for future collaborations.

-

Flexibility on Payment Terms: Offering flexible payment terms can be attractive to suppliers. This may lead to discounts or better pricing structures.

What Pricing Nuances Should International Buyers Consider?

For buyers from Africa, South America, the Middle East, and Europe, several nuances should be considered:

-

Currency Fluctuations: Be aware of exchange rate volatility, which can affect pricing. Locking in exchange rates or negotiating in stable currencies can mitigate risks.

-

Import Tariffs and Duties: Understand the import regulations and potential tariffs that may apply in your country. This can dramatically affect the total cost of procurement.

-

Cultural Differences: Be mindful of cultural differences in negotiation styles and business practices. Tailoring your approach can lead to more successful outcomes.

Disclaimer on Indicative Prices

The prices mentioned throughout this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always consult directly with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing three prong european plug With Other Solutions

In the realm of electrical connectivity, the three-prong European plug (CEE7/7) serves as a robust and widely accepted standard. However, there are alternative solutions available that cater to different needs and preferences in various international markets. This section explores these alternatives, providing B2B buyers with insights to make informed decisions.

Comparison Table

| Comparison Aspect | Three Prong European Plug | Universal Travel Adapter | Two-Prong Euro Plug |

|---|---|---|---|

| Performance | High voltage and current rating; robust design | Variable performance based on device compatibility; may not support high wattage | Moderate voltage rating; suitable for low-power devices |

| Cost | Moderate, typically around $3.99 – $6.49 | Higher initial investment, typically $20-$50 | Lower, generally $1.50 – $4.00 |

| Ease of Implementation | Simple plug-and-play functionality | Requires understanding of compatibility; may need adjustment for different devices | Easy to use, but limited to devices without grounding requirements |

| Maintenance | Low maintenance, durable construction | Low maintenance, but requires careful handling | Very low maintenance, fewer components |

| Best Use Case | Ideal for permanent installations in Europe and compatible regions | Best for travelers using multiple devices across various countries | Suitable for low-power appliances in regions where grounding is not a concern |

Detailed Breakdown of Alternatives

Universal Travel Adapter

Universal travel adapters offer a versatile solution for international travelers. They are designed to accommodate various plug types from around the world, making them ideal for those who frequently travel or do business in multiple countries. The primary advantage of a universal travel adapter is its ability to support a wide range of devices, ensuring connectivity regardless of the plug type. However, the cost is significantly higher compared to a standard three-prong European plug, and the performance can vary based on the specific device being used. Additionally, they may not handle high-wattage devices effectively, which could lead to compatibility issues.

Two-Prong Euro Plug

The two-prong Euro plug is a simpler alternative that lacks the grounding feature of the three-prong design. While it is typically less expensive and easy to use, it is limited in application. This plug is suitable for low-power devices, such as phone chargers and small appliances, but it poses risks when used with devices that require grounding for safety. Consequently, the two-prong Euro plug is best for users who do not need the enhanced safety features provided by the three-prong design and are operating in environments where grounding is less critical.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between the three-prong European plug and its alternatives, B2B buyers should assess their specific needs based on performance, cost, and application. For businesses operating in Europe or regions using the CEE7/7 standard, the three-prong plug is often the best choice due to its durability and safety features. Conversely, companies that prioritize versatility and travel may find universal travel adapters more beneficial, despite the higher cost. Lastly, if the application is limited to low-power devices, the two-prong Euro plug could be a cost-effective solution. Ultimately, the decision should align with the operational requirements, safety standards, and budget considerations of the business.

Essential Technical Properties and Trade Terminology for three prong european plug

What Are the Key Technical Properties of a Three Prong European Plug?

Understanding the technical specifications of a three prong European plug is crucial for B2B buyers to ensure compatibility and safety in their operations. Here are some essential properties to consider:

-

Voltage Rating

– The voltage rating indicates the maximum voltage the plug can handle, typically ranging from 125V to 250V. For three prong European plugs, the standard is often 250V. It is vital for buyers to confirm that their devices are compatible with this voltage to prevent damage. -

Current Rating (Amperage)

– This specification reflects the maximum current the plug can safely carry, generally rated at 10A for standard plugs. Understanding the amperage is crucial for ensuring that the electrical load does not exceed the plug’s capacity, which can lead to overheating and potential hazards. -

Material Composition

– The materials used in the construction of the plug, such as thermoplastic for the casing and copper for the prongs, affect durability and safety. High-quality materials can withstand wear and tear while ensuring electrical conductivity. Buyers should prioritize plugs made from certified materials to comply with safety regulations. -

Certification Standards

– Certifications like UL, RoHS, and REACH signify that the plug meets international safety and environmental standards. These certifications are critical for B2B buyers who must adhere to compliance regulations in their respective markets, ensuring that products are safe for use. -

Environmental Compliance

– Many countries have specific environmental regulations regarding electrical products. Compliance with standards such as ISO 14001:2015 indicates that the manufacturer follows processes that reduce environmental impact. B2B buyers should consider this aspect to align with corporate sustainability goals.

What Trade Terms Should B2B Buyers Know for Three Prong European Plugs?

Familiarity with industry jargon can streamline negotiations and purchasing processes. Here are some common terms relevant to the three prong European plug market:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality components that meet specific technical requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest order size that a supplier will accept. Knowing the MOQ is essential for B2B buyers to plan inventory and cash flow. It can also affect pricing strategies, as larger orders often lead to better discounts. -

RFQ (Request for Quotation)

– An RFQ is a document that solicits price quotes from suppliers. It typically includes detailed specifications of the product required. B2B buyers should use RFQs to ensure that they receive competitive pricing and terms for their orders. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, which are crucial for international transactions. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is important for B2B buyers to manage supply chain expectations and ensure that they can meet their operational deadlines.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed purchasing decisions regarding three prong European plugs, enhancing their operational efficiency and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the three prong european plug Sector

What are the Current Market Dynamics and Key Trends for the Three Prong European Plug?

The global market for three prong European plugs is experiencing robust growth, driven by increasing international trade, globalization, and a rising demand for electronic devices. Key trends include the surge in cross-border travel, which necessitates the use of plug adapters, and the growth of e-commerce, enabling easier access to a variety of electrical products. Additionally, as businesses expand into emerging markets in Africa and South America, the need for reliable and standardized electrical solutions becomes more pronounced.

Illustrative image related to three prong european plug

Technological advancements are also influencing the market, with innovations in materials and design leading to more efficient and user-friendly products. For instance, the introduction of smart plugs that integrate IoT capabilities is gaining traction, particularly in regions like Europe and the Middle East, where tech adoption is high. Furthermore, regulatory changes related to safety standards and environmental compliance are shaping sourcing strategies. International B2B buyers should stay informed about these developments to leverage opportunities and mitigate risks associated with regulatory non-compliance.

How Important is Sustainability and Ethical Sourcing in the Three Prong European Plug Sector?

Sustainability and ethical sourcing are becoming paramount in the three prong European plug sector. As global awareness of environmental issues increases, buyers are prioritizing suppliers that adhere to sustainable practices. The production of electrical components can have significant environmental impacts, from resource extraction to manufacturing processes. Therefore, sourcing from suppliers who utilize eco-friendly materials and sustainable manufacturing practices is critical.

Buyers should look for products that carry certifications such as RoHS and REACH, which indicate compliance with environmental standards. Additionally, manufacturers that demonstrate a commitment to reducing their carbon footprint and employing ethical labor practices are increasingly favored. B2B buyers, particularly those in regions like Africa and the Middle East, are recognizing that sustainable sourcing not only enhances brand reputation but also aligns with their corporate social responsibility goals, ultimately leading to stronger customer loyalty and market differentiation.

What is the Brief Evolution and History of the Three Prong European Plug?

The three prong European plug, commonly referred to as the Schuko plug (CEE7/7), has its origins in the early 20th century as European countries sought standardized electrical solutions to accommodate the growing demand for electricity in homes and businesses. The Schuko design, characterized by its grounding pin and rounded shape, was developed in the 1920s to enhance safety and reduce electrical hazards.

Over the decades, this plug design has evolved to meet changing technological standards and safety regulations. With the rise of international travel and trade, the three prong plug has become a critical component for travelers and businesses alike, facilitating the seamless operation of electrical devices across borders. Today, the plug is widely used not only in Europe but also in many countries in Africa and Asia, underscoring its importance in the global electrical landscape. Understanding this evolution is essential for B2B buyers as they navigate sourcing decisions and adapt to the needs of diverse markets.

Illustrative image related to three prong european plug

Frequently Asked Questions (FAQs) for B2B Buyers of three prong european plug

-

How do I solve compatibility issues with three prong European plugs?

To solve compatibility issues, ensure that your devices are rated for the appropriate voltage and amperage for the region you are operating in. The CEE7/7 standard European plug operates at 250V and is compatible with various devices from regions like the USA (NEMA 5-15R). If your device is not rated for this voltage, using a step-down transformer may be necessary. Additionally, consider sourcing high-quality adapters that provide a secure fit in both the plug and outlet to avoid connection issues. -

What is the best way to source three prong European plugs for bulk orders?

The best way to source three prong European plugs for bulk orders is to establish relationships with manufacturers or reputable distributors who specialize in electrical components. Look for suppliers with certifications such as UL, RoHS, and ISO standards to ensure product quality and safety. Utilize platforms like Alibaba or Global Sources to find verified suppliers, and consider requesting samples before committing to larger orders to assess quality and compatibility with your requirements. -

What are the typical minimum order quantities (MOQs) for three prong European plugs?

Minimum order quantities (MOQs) for three prong European plugs can vary significantly depending on the supplier and the specific product. Generally, MOQs range from 100 to 1,000 units for bulk orders. It’s advisable to negotiate with suppliers, especially if you are a new buyer or require a trial order. Some manufacturers may offer flexibility on MOQs for first-time customers or bulk orders, so it’s beneficial to communicate your needs clearly during negotiations. -

What payment terms should I expect when purchasing three prong European plugs internationally?

When purchasing three prong European plugs internationally, payment terms can vary by supplier but often include options such as wire transfer (T/T), letters of credit (L/C), and PayPal for smaller orders. Many suppliers may request a deposit (typically 30-50%) upfront, with the balance due before shipping. Ensure to clarify payment terms during negotiations and consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. -

How can I ensure the quality of three prong European plugs from my supplier?

To ensure the quality of three prong European plugs, request product certifications such as CE, UL, and RoHS from your supplier. Conduct factory audits if possible, or utilize third-party inspection services to verify product quality before shipment. Additionally, review customer feedback and ratings about the supplier’s products to gauge reliability. Establishing a clear quality assurance process and maintaining open communication with your supplier will also help mitigate risks. -

What are the shipping options available for three prong European plugs?

Shipping options for three prong European plugs include air freight, sea freight, and express courier services like DHL or FedEx. The choice of shipping method will depend on your budget, timeline, and order size. Air freight is faster but more expensive, making it suitable for urgent orders, while sea freight is cost-effective for larger shipments but takes longer. Always confirm the shipping terms with your supplier, including delivery times, tracking options, and insurance coverage. -

Are there customization options available for three prong European plugs?

Many suppliers offer customization options for three prong European plugs, including branding, color, and packaging. Customization can enhance your product’s market appeal and differentiate it from competitors. Discuss your specific requirements with your supplier, including design specifications and any necessary certifications. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly. -

What are the common regulatory compliance requirements for importing three prong European plugs?

When importing three prong European plugs, ensure compliance with local regulations and standards, which may include CE marking in Europe and UL certification in the USA. Research the specific import regulations in your country, as they can vary widely. You may need to provide documentation for safety testing and environmental compliance. Engaging a customs broker or legal expert can facilitate the import process and help navigate any regulatory challenges.

Top 3 Three Prong European Plug Manufacturers & Suppliers List

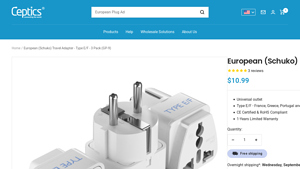

1. Ceptics – European Travel Adapter – Type E/F – 3 Pack

Domain: ceptics.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “European (Schuko) Travel Adapter – Type E/F – 3 Pack (GP-9)”, “Sale Price”: “$10.99”, “Key Features”: {“Connects Up To”: “1 Device”, “Standard”: “Type E/F plug, CEE 7/4, CEE 7/5, CEE 7/17”, “Grounded”: “3-Prong plug”, “Universal Socket”: “Accepts plugs from all countries except South Africa”, “Safety”: “Safe and fully grounded connection from input to output”, “Product Dimensions…

2. Reddit – Portable USB Charger & Voltage Adapter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: US three prong plug, EU two prong outlet, portable USB charger/extension, voltage compatibility (220/240v), safety concerns regarding grounding and potential electrocution.

3. Rick Steves – Travel Adapters

Domain: community.ricksteves.com

Registered: 1996 (29 years)

Introduction: Travel adapter options include 2-prong and 3-prong types. 2-prong adapters are suitable for most cell phone and laptop chargers, while 3-prong adapters are needed for grounded items. Italian 3-prong plugs differ from other European plugs, featuring 3 pins in a line. It’s advisable to carry both types of adapters, especially since some accommodations may not have 3-prong outlets. Adapters can be pu…

Strategic Sourcing Conclusion and Outlook for three prong european plug

In conclusion, the strategic sourcing of three-prong European plugs presents a significant opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the diverse applications and standards across regions can lead to more informed purchasing decisions. Buyers should prioritize sourcing from manufacturers that meet high-quality certifications such as UL, RoHS, and REACH, ensuring compliance with international safety standards.

Moreover, leveraging bulk purchasing options can enhance cost-effectiveness while fostering long-term partnerships with suppliers. As global trade continues to evolve, staying ahead of market trends and technological advancements in electrical components will be crucial for maintaining a competitive edge.

Moving forward, we encourage international buyers to explore the vast potential within this market. Engaging with reputable suppliers who offer comprehensive support and innovative solutions can drive growth and efficiency in your operations. Take action today to secure reliable sourcing channels and elevate your business capabilities in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.