The Definitive Guide to Pasteles Machine: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for pasteles machine

In an increasingly competitive global market, sourcing efficient pasteles machines that enhance productivity while maintaining authenticity can be a daunting challenge for international B2B buyers. As culinary traditions face the pressures of modernization, the need for reliable equipment that streamlines production without compromising quality becomes paramount. This guide serves as a comprehensive resource for businesses looking to navigate the diverse landscape of pasteles machines.

From understanding the different types of machines available—ranging from manual graters to advanced electric models—to exploring their applications in various culinary settings, this guide covers all essential aspects. We also delve into critical topics such as supplier vetting processes, cost analysis, and maintenance tips, ensuring that buyers are equipped with the knowledge necessary to make informed purchasing decisions.

Designed specifically for international markets, particularly in Africa, South America, the Middle East, and Europe (including Germany and Vietnam), this guide empowers businesses to identify the best pasteles machines that align with their operational needs. By providing actionable insights and expert recommendations, we aim to simplify the sourcing process, helping you to not only enhance your culinary offerings but also to elevate your business’s efficiency and customer satisfaction.

Understanding pasteles machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Grater | High-speed grating, consistent texture, easy to clean | Restaurants, catering services, food production | Pros: Time-efficient, authentic texture, durable. Cons: Higher initial cost. |

| Manual Grater | Hand-operated, portable, typically less expensive | Small food vendors, home use | Pros: Cost-effective, simple design. Cons: Labor-intensive, slower processing. |

| Commercial Pasteles Machine | Multi-functional, designed for large volumes, automated | Food manufacturing, large-scale catering | Pros: High capacity, versatile. Cons: Requires more space, higher maintenance. |

| Industrial Shredder | Heavy-duty, capable of processing various ingredients quickly | Large-scale food processing plants | Pros: Extremely efficient, robust. Cons: Expensive, complex operation. |

| Specialty Pasteles Press | Designed specifically for shaping and pressing pasteles | Specialty restaurants, ethnic food markets | Pros: Perfect shape and consistency, enhances presentation. Cons: Limited versatility. |

What Are the Key Characteristics of Electric Graters for Pasteles?

Electric graters are designed for high-speed, high-efficiency grating. They excel in producing consistent textures necessary for authentic pasteles. Ideal for restaurants and catering businesses, these machines can grate large quantities of ingredients like yuca and green bananas in minutes, significantly reducing labor time. When considering an electric grater, businesses should evaluate durability, ease of cleaning, and the availability of replacement parts, as these factors directly influence long-term operational efficiency.

How Do Manual Graters Compare for Smaller Operations?

Manual graters provide a portable and cost-effective solution for small food vendors and home chefs. While they require physical effort and time to operate, they are simpler and less expensive than electric models. Manual graters are suitable for businesses that do not require high volumes of production and can benefit from the hands-on approach to food preparation. Buyers should assess the balance between labor costs and production speed when opting for manual equipment.

What Benefits Do Commercial Pasteles Machines Offer?

Commercial pasteles machines are designed for high-volume production, integrating multiple functions such as grating, mixing, and shaping. They are perfect for food manufacturing and large-scale catering operations that demand efficiency and consistency. These machines can handle various ingredients, allowing for versatility in menu offerings. However, potential buyers must consider the space requirements and maintenance needs, as these machines can be more complex and costly than their smaller counterparts.

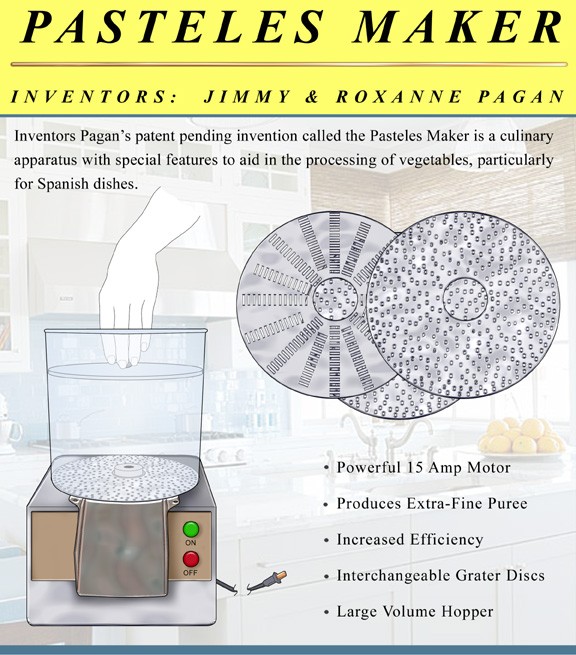

Illustrative image related to pasteles machine

Why Choose an Industrial Shredder for Large-Scale Processing?

Industrial shredders are built for heavy-duty applications, capable of processing vast amounts of ingredients quickly. They are ideal for large-scale food processing plants that require continuous operation. While they offer exceptional efficiency and robustness, the initial investment can be significant. Businesses should assess their production needs and budget constraints, as well as the complexity of operation and maintenance before purchasing.

What Are the Advantages of Specialty Pasteles Presses?

Specialty pasteles presses are tailored for shaping and pressing pasteles, ensuring consistent size and presentation. These machines are particularly beneficial for specialty restaurants and ethnic food markets that focus on authenticity and quality. While they enhance the aesthetic appeal of dishes, their limited versatility means that buyers should consider their specific production needs and how often they will utilize this specialized equipment.

Key Industrial Applications of pasteles machine

| Industry/Sector | Specific Application of pasteles machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | High-volume production of pasteles | Increases efficiency, reduces labor costs, and enhances product consistency | Reliability of the machine, ease of cleaning, and maintenance support |

| Catering and Events | On-site preparation for large gatherings | Allows for quick preparation of traditional dishes for events, ensuring freshness and flavor | Portability, power supply requirements, and ingredient compatibility |

| Ethnic Food Manufacturing | Production of frozen pasteles for retail | Expands product line, meets consumer demand for authentic ethnic foods | Scale of production, storage capabilities, and compliance with local food safety regulations |

| Restaurant Chains | Streamlined menu item preparation | Reduces prep time, enabling faster service and higher customer satisfaction | Durability, ease of use, and adaptability for various recipes |

| Culinary Schools | Teaching traditional cooking techniques | Provides students with hands-on experience in authentic food preparation | Educational support, warranty options, and training resources |

How is the Pasteles Machine Used in the Food Service Industry?

In the food service industry, the pasteles machine is instrumental for restaurants and kitchens that specialize in traditional dishes. It allows for the high-volume production of pasteles, significantly increasing efficiency while reducing labor costs. This machine can process large quantities of ingredients quickly, thus maintaining the consistency and quality of the product. B2B buyers in this sector should focus on the reliability of the machine, ease of cleaning, and the availability of maintenance support to ensure uninterrupted kitchen operations.

What Role Does the Pasteles Machine Play in Catering and Events?

Catering companies leverage pasteles machines to prepare traditional dishes on-site for large gatherings and events. This capability ensures that the food served is fresh and retains its authentic flavor, which is critical for client satisfaction. The portability of the machine and its power supply requirements are essential considerations for buyers in this sector, as they must ensure that equipment can be easily transported and operated in various locations.

How Does the Pasteles Machine Benefit Ethnic Food Manufacturing?

For ethnic food manufacturers, the pasteles machine is vital for producing frozen pasteles for retail distribution. This application allows businesses to expand their product lines while meeting consumer demand for authentic ethnic foods. Buyers in this industry should consider the scale of production the machine can handle, storage capabilities for the finished products, and compliance with local food safety regulations to ensure quality and safety in their offerings.

Why is the Pasteles Machine Essential for Restaurant Chains?

Restaurant chains utilize pasteles machines to streamline the preparation of menu items, leading to reduced prep time and enhanced customer satisfaction. By incorporating this equipment into their operations, chains can serve more customers efficiently without compromising on the authenticity of their dishes. Key considerations for buyers include the durability of the machine, ease of use, and its adaptability for various recipes to ensure it meets diverse culinary needs.

How Can Culinary Schools Benefit from Using a Pasteles Machine?

Culinary schools can enhance their teaching methods by incorporating pasteles machines into their curriculum, providing students with hands-on experience in traditional cooking techniques. This exposure is invaluable for students learning about authentic food preparation. When sourcing these machines, schools should prioritize educational support, warranty options, and training resources to facilitate effective learning experiences for their students.

3 Common User Pain Points for ‘pasteles machine’ & Their Solutions

Scenario 1: Struggling with Labor Costs and Time Management in Production

The Problem: Many B2B buyers in the food industry, particularly those specializing in traditional dishes, face the significant challenge of high labor costs and time inefficiencies when preparing pasteles. Traditional methods require extensive manual labor, leading to increased payroll expenses and production delays. For businesses aiming to scale operations or maintain competitive pricing, these factors can severely impact profitability and growth.

Illustrative image related to pasteles machine

The Solution: Investing in an efficient pasteles machine can dramatically reduce both labor costs and preparation time. Buyers should look for machines that are specifically designed for high-volume production, such as electric graters or automated masa makers. For instance, a machine that can grate ingredients like yuca and green bananas in a matter of minutes can cut down prep time from hours to just a few minutes. When sourcing these machines, ensure that they are durable, easy to clean, and capable of delivering the authentic texture required for traditional recipes. Collaborating with reliable suppliers who offer warranties and support can also provide peace of mind, ensuring that your investment pays off in the long run.

Scenario 2: Ensuring Consistent Quality and Authenticity

The Problem: Maintaining the authentic taste and texture of pasteles is crucial for businesses that pride themselves on traditional recipes. B2B buyers often struggle with equipment that doesn’t deliver consistent results, leading to variations in product quality. This inconsistency can alienate loyal customers who expect a certain standard, potentially harming brand reputation and sales.

The Solution: To overcome this challenge, buyers should prioritize machines that are designed to replicate the hand-grated texture of traditional pasteles. A machine like Grandma Ann’s Electric Grater is engineered to provide uniform results, which is essential for achieving that authentic flavor and texture that customers crave. When purchasing, consider machines with adjustable settings to fine-tune the grating size according to recipe requirements. Additionally, conducting regular training for staff on how to operate and maintain the machines can help ensure consistent output and quality.

Scenario 3: Navigating Supply Chain and Sourcing Challenges

The Problem: B2B buyers often encounter difficulties in sourcing reliable pasteles machines due to varying international standards, shipping delays, and a lack of local suppliers. This can be particularly challenging for businesses in regions like Africa or South America, where access to high-quality kitchen equipment may be limited. The inability to find the right machinery can hinder production capabilities and affect the overall business operation.

The Solution: To effectively navigate these supply chain challenges, B2B buyers should consider partnering with established manufacturers or distributors that specialize in kitchen equipment for ethnic cuisines. Researching suppliers that offer international shipping and have a proven track record can also alleviate concerns about sourcing. Additionally, opting for versatile machines that can handle multiple types of ingredients will provide long-term value and adaptability to changing menu offerings. Buyers may also explore local trade shows or industry expos to connect with suppliers directly, allowing for firsthand assessments of equipment and establishing reliable business relationships.

Strategic Material Selection Guide for pasteles machine

When selecting materials for pasteles machines, it’s crucial to consider both the performance characteristics and the operational environment. The right material can significantly impact the efficiency, durability, and overall effectiveness of the machine, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in the construction of pasteles machines.

What Are the Key Properties of Stainless Steel for Pasteles Machines?

Stainless steel is a popular choice for pasteles machines due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for cooking applications. Additionally, stainless steel is easy to clean, ensuring hygiene in food preparation environments.

Pros: Stainless steel is highly durable and resistant to rust and staining, which is essential for machines that process moist ingredients. Its aesthetic appeal also makes it a preferred choice for commercial kitchens.

Cons: The primary drawback is its cost, which can be higher than other materials. Manufacturing complexity can also be a concern, as stainless steel requires specialized equipment for shaping and welding.

Illustrative image related to pasteles machine

Impact on Application: Stainless steel is compatible with a wide range of food products, ensuring that the flavor and quality of pasteles are preserved.

Considerations for International Buyers: Compliance with international food safety standards (e.g., FDA, EU regulations) is essential. Buyers should also consider local standards such as DIN in Germany or ASTM in the U.S. to ensure the material meets safety and quality benchmarks.

How Does Aluminum Compare as a Material for Pasteles Machines?

Aluminum is another material frequently used in pasteles machines. It is lightweight and has good thermal conductivity, which can enhance cooking efficiency.

Illustrative image related to pasteles machine

Pros: The lightweight nature of aluminum makes machines easier to handle and transport. It is also generally less expensive than stainless steel, which can lower initial costs.

Cons: Aluminum is less durable than stainless steel and can be prone to scratching and denting. It also has lower corrosion resistance unless anodized, which can add to manufacturing costs.

Impact on Application: Aluminum is suitable for applications where weight is a concern, but it may not be ideal for high-moisture environments unless treated properly.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local regulations regarding food safety and material standards, such as JIS in Japan or ASTM in the U.S.

What Role Does Plastic Play in Pasteles Machines?

Plastic components are often used in non-structural parts of pasteles machines, such as hoppers or handles.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs. They are also resistant to corrosion and can be made food-safe.

Cons: Plastic may not withstand high temperatures as well as metals, limiting its use in certain machine components. Additionally, some plastics can degrade over time, especially when exposed to certain food acids.

Impact on Application: Plastic is suitable for parts that do not require high strength or heat resistance, making it ideal for user-friendly components.

Considerations for International Buyers: Ensure that any plastic used complies with food safety standards, as certain types may not be suitable for food contact.

How Effective is Cast Iron for Pasteles Machines?

Cast iron is less common but can be used in specific applications within pasteles machines, especially for components that require high durability and heat retention.

Pros: Cast iron is incredibly durable and has excellent heat retention properties, which can enhance cooking efficiency.

Cons: It is heavy and can be prone to rust if not properly maintained. The manufacturing process can also be more complex and costly.

Illustrative image related to pasteles machine

Impact on Application: Cast iron is ideal for components that require high durability, but its weight can be a disadvantage in portable machines.

Considerations for International Buyers: Buyers should check for compliance with local safety standards and consider the maintenance requirements for cast iron, especially in humid environments.

Summary Table of Material Selection for Pasteles Machines

| Material | Typical Use Case for pasteles machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, blades | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight parts, heat exchangers | Lightweight and cost-effective | Less durable, lower corrosion resistance | Medium |

| Plastic | Non-structural parts, handles | Lightweight and moldable | Temperature limitations and degradation potential | Low |

| Cast Iron | Heavy-duty components | Excellent heat retention and durability | Heavy and prone to rust | Medium |

In conclusion, selecting the right material for pasteles machines involves balancing performance, cost, and compliance with international standards. Each material has its unique advantages and limitations, making it essential for B2B buyers to consider their specific operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for pasteles machine

What Are the Key Stages in the Manufacturing Process of Pasteles Machines?

The manufacturing process of pasteles machines involves several critical stages, each designed to ensure efficiency, durability, and performance. Understanding these stages is essential for B2B buyers who are looking to invest in high-quality equipment.

Material Preparation

The first stage in manufacturing pasteles machines involves selecting the right materials. Common materials include high-grade stainless steel for the body and components, which ensures durability and resistance to corrosion. The selection process often includes sourcing materials that meet international standards for food safety, particularly for machines used in food production. Suppliers typically conduct a thorough assessment of material specifications to ensure compliance with safety regulations.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. These may include stamping, welding, and machining, depending on the specific design and functionality of the machine. Advanced technologies such as CNC (Computer Numerical Control) machining are frequently employed to achieve precision in the shaping of components. This precision is critical, as any misalignment can affect the machine’s performance and the quality of the pasteles produced.

Assembly Process

The assembly stage is where all components come together. Skilled technicians carefully fit and assemble the various parts, ensuring that each machine operates smoothly. This stage often employs lean manufacturing principles to minimize waste and optimize efficiency. Assembly lines are designed to facilitate quick assembly while maintaining high standards of quality control. Each machine is typically tested for functionality during this phase to catch any potential issues early.

Finishing Touches

Finishing processes, such as polishing, coating, and packaging, finalize the machines. The finishing not only enhances the aesthetic appeal but also adds a layer of protection against wear and tear. For food-related equipment, finishes must comply with health and safety regulations to ensure that no harmful substances can contaminate food products. This stage may also include branding and labeling, which are essential for marketing the machines internationally.

How Is Quality Assurance Integrated into Pasteles Machine Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets both international and industry-specific standards. B2B buyers should be aware of the quality control measures that are typically in place.

What International Standards Should B2B Buyers Look For?

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards indicates that a manufacturer has processes in place to ensure consistent quality and customer satisfaction. Additionally, specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain industrial applications can be critical for ensuring product safety and reliability.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process, commonly categorized into three phases: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not pass this inspection are rejected or sent back to the supplier.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are conducted to monitor the production process. This includes verifying dimensions, functionality, and assembly accuracy at various points in the production line.

-

Final Quality Control (FQC): Once the machines are fully assembled, they undergo a final inspection to assess overall performance, safety features, and compliance with relevant standards. This stage may also include functional testing to ensure that the machine operates correctly under expected conditions.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure that pasteles machines meet quality standards. These may include:

-

Performance Testing: Assessing the machine’s efficiency in processing ingredients, such as grating or mixing, to ensure it meets specified output levels.

-

Durability Testing: Subjecting the machine to prolonged use conditions to evaluate its longevity and resistance to wear and tear.

-

Safety Testing: Ensuring that all safety features function correctly, such as emergency shut-off mechanisms, to protect users during operation.

-

Compliance Testing: Verifying that the machine meets all relevant regulatory standards, which may vary by region.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards. Here are several methods to verify supplier quality control:

Illustrative image related to pasteles machine

Conducting Audits

One effective way to assess a supplier’s quality control measures is through on-site audits. These audits allow buyers to evaluate the manufacturing processes, quality control checkpoints, and overall operational practices. Buyers should inquire about the frequency of these audits and any corrective actions taken in response to previous findings.

Reviewing Quality Reports

Suppliers should provide comprehensive quality reports that detail their quality control processes and outcomes. These reports may include data on defect rates, compliance with international standards, and results from various testing methods.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These services often conduct inspections at various stages of the manufacturing process and can provide certification that the products meet specified standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial, especially when sourcing from different regions like Africa, South America, the Middle East, and Europe.

Regional Compliance Requirements

Different regions may have varying compliance requirements and standards. For example, European markets require CE certification, while certain African nations may have local standards that need to be met. Buyers should familiarize themselves with these requirements to avoid issues with importation or product usage.

Illustrative image related to pasteles machine

Language and Cultural Considerations

Language barriers and cultural differences can impact communication regarding quality standards and expectations. B2B buyers should consider working with local representatives or consultants who understand the regional market and can facilitate clear communication with suppliers.

Logistics and Supply Chain Management

Quality assurance extends beyond manufacturing; it also includes logistics and supply chain management. International buyers should ensure that suppliers have robust systems in place for tracking and managing shipments, as well as handling any quality issues that may arise during transportation.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for pasteles machines is essential for B2B buyers. By focusing on the key stages of manufacturing, quality control checkpoints, and verification methods, buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pasteles machine’

In the competitive world of food production, sourcing the right pasteles machine is essential for efficiency and quality. This guide outlines a practical checklist for B2B buyers looking to procure machines that can streamline the preparation of pasteles and other traditional dishes. Follow these steps to ensure you make an informed purchasing decision.

1. Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a pasteles machine. Consider the volume of production you anticipate and the specific types of ingredients you will be processing. This will help you determine the required capacity, power, and features of the machine, ensuring it meets your operational needs.

- Capacity: Assess how much product you need to process per hour or day.

- Versatility: Look for machines that can handle various ingredients like yuca, green bananas, and more.

2. Research Potential Suppliers

Conduct thorough research on potential suppliers to identify those with a strong reputation in the industry. Look for manufacturers that specialize in food processing equipment and have experience supplying machines for traditional cooking methods.

- Reviews and Ratings: Check customer testimonials and ratings on platforms like Alibaba or industry-specific forums.

- Industry Presence: Evaluate their history and presence in the market, focusing on suppliers who have served similar markets or regions.

3. Evaluate Machine Features and Functionality

When considering specific models, evaluate their features and functionality. Look for machines that are easy to use, clean, and maintain, as well as those that offer consistent performance.

Illustrative image related to pasteles machine

- Ease of Use: The machine should require minimal training for staff to operate efficiently.

- Cleaning and Maintenance: Machines with fewer parts or those that are dishwasher-safe can save time and labor costs.

4. Verify Supplier Certifications

Before making a purchase, it is crucial to verify the supplier’s certifications. Compliance with international safety and quality standards is essential, especially if you plan to export your products.

- Quality Assurance: Look for ISO certifications or similar endorsements that demonstrate the supplier’s commitment to quality.

- Safety Standards: Ensure that the machines meet relevant food safety regulations in your target market.

5. Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the pasteles machine. This allows you to assess the machine’s performance firsthand and verify that it meets your expectations.

- Trial Runs: If feasible, conduct trial runs to evaluate the machine’s output and ease of use.

- Ingredient Compatibility: Ensure the machine works effectively with the specific ingredients you will be using.

6. Compare Pricing and Warranty Options

Once you have narrowed down your options, compare pricing and warranty terms from different suppliers. A well-structured warranty can save you significant costs in case of malfunctions or defects.

- Total Cost of Ownership: Consider not only the initial purchase price but also the long-term costs associated with maintenance and parts replacement.

- Warranty Length: A longer warranty often indicates a supplier’s confidence in their product quality.

7. Finalize the Purchase Agreement

After selecting the ideal pasteles machine, finalize the purchase agreement carefully. Ensure that all terms, including delivery timelines, payment terms, and after-sales support, are clearly outlined.

- Clear Terms: Specify any additional costs, such as shipping or installation fees.

- After-Sales Support: Confirm the availability of technical support and spare parts in your region.

By following this checklist, you can ensure that you make a well-informed decision when sourcing a pasteles machine that aligns with your production needs and business goals.

Comprehensive Cost and Pricing Analysis for pasteles machine Sourcing

What are the Key Cost Components in Sourcing a Pasteles Machine?

When sourcing a pasteles machine, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality stainless steel or food-grade plastics are often used for durability and safety, which can raise the price. Sourcing materials locally versus internationally can also influence costs due to varying prices and availability.

-

Labor: Labor costs vary depending on the manufacturing location. In regions with lower labor costs, such as parts of Asia or South America, the overall cost of the machine may decrease. However, this can also lead to variations in quality, which is crucial for food processing equipment.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower overhead costs, making it essential for buyers to evaluate supplier operations.

-

Tooling: The initial investment in tooling can be substantial, especially for custom machines. Buyers should consider whether they need standard machines or if customization is necessary, as this can affect lead times and costs.

-

Quality Control (QC): Ensuring that machines meet food safety and operational standards is vital. The costs associated with QC processes should be factored into the pricing, as rigorous testing can add to the overall expense.

-

Logistics: Shipping costs depend on the distance and method of transportation. International buyers must also consider duties and taxes that may apply upon importation, affecting the total cost.

-

Margin: Suppliers will typically add a markup to cover their costs and ensure profitability. Understanding typical margins in the industry can help buyers gauge whether they are getting a fair price.

What Factors Influence Pricing for Pasteles Machines?

Several factors influence the pricing of pasteles machines, particularly for B2B transactions.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the per-unit cost. Buyers should negotiate MOQs to ensure they are not over-committing while still benefiting from bulk pricing.

-

Specifications and Customization: Custom features can significantly increase costs. Buyers need to assess whether specific functionalities justify the additional expense, especially if standard machines can meet their needs.

-

Material Quality and Certifications: Machines that comply with international food safety standards may cost more but offer assurance regarding safety and durability. Certifications can also play a role in market acceptance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer or less reputable suppliers might offer lower prices but with higher risks.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms define the responsibilities of buyers and sellers in shipping costs and risks, which can significantly impact the total landed cost.

How Can Buyers Negotiate for Better Pricing?

To achieve cost efficiency, buyers should focus on several negotiation strategies:

-

Research and Benchmarking: Gather data on pricing trends and competitor offerings to establish a baseline for negotiations. This information can empower buyers during discussions.

-

Total Cost of Ownership (TCO): Consider the TCO beyond the initial purchase price. Include maintenance, operational costs, and potential downtime in your calculations to evaluate the true value of the machine.

-

Flexibility in Specifications: Being open to slight modifications in machine specifications may yield cost savings. Suppliers often have more flexibility in pricing when customization is limited.

-

Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Suppliers are often more willing to negotiate with buyers who demonstrate loyalty and consistent purchasing.

-

Understanding Pricing Nuances for International Buyers: Be aware of local market conditions, currency fluctuations, and trade agreements that may affect pricing. This knowledge can aid in negotiations and help mitigate risks.

Conclusion

While the indicative prices for pasteles machines can vary widely based on the factors mentioned above, B2B buyers must conduct thorough due diligence. By understanding the cost components, pricing influencers, and effective negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing pasteles machine With Other Solutions

When considering options for food preparation, particularly in the context of producing pasteles, it’s essential to evaluate various alternatives available in the market. Understanding the strengths and weaknesses of each solution can significantly impact operational efficiency, cost management, and overall productivity for businesses in the food industry.

| Comparison Aspect | Pasteles Machine | Grandma Ann’s Electric Grater | Manual Grating Method |

|---|---|---|---|

| Performance | High efficiency, can process large quantities quickly | Quick preparation, hand-grated texture | Labor-intensive, slow, inconsistent results |

| Cost | Varies, generally higher upfront investment | Approximately $479, cost-effective for small operations | No initial cost, but high labor costs |

| Ease of Implementation | Requires initial setup and training | Plug-and-play, minimal training needed | No setup required, but requires skilled labor |

| Maintenance | Regular cleaning, parts may need replacement | Easy to clean, durable | No maintenance costs, but physical strain on workers |

| Best Use Case | High-volume production environments | Small to medium-scale production | Home cooking or occasional use |

What Are the Benefits and Drawbacks of Grandma Ann’s Electric Grater?

Grandma Ann’s Electric Grater is a strong alternative for businesses seeking to streamline their food preparation process. It excels in performance, allowing users to grate a substantial amount of ingredients in a short time, making it ideal for restaurants with moderate demand. The cost is relatively reasonable, especially when considering the time saved compared to manual methods. However, while it is easy to use, the grater may not be suitable for extremely high-volume production environments where a pasteles machine would excel.

Why Might Manual Grating Still Be a Consideration?

The manual grating method, while outdated, offers certain advantages for small-scale operations or home kitchens. It incurs no upfront costs and can be done without the need for machinery. However, this method is labor-intensive and may lead to inconsistencies in texture and quality, which can affect the final product. Additionally, the physical demands placed on workers can lead to fatigue and decreased productivity, making it less viable for businesses aiming for efficiency.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating the right solution for food preparation, B2B buyers should consider their operational scale, budget constraints, and the quality of output required. For high-volume production needs, investing in a pasteles machine may be justified despite the higher initial costs due to its efficiency and output quality. Alternatively, for smaller operations or those just starting, Grandma Ann’s Electric Grater may provide a balanced solution, offering both efficiency and affordability. Ultimately, understanding specific business needs and production goals will guide buyers in selecting the most effective food preparation method.

Illustrative image related to pasteles machine

Essential Technical Properties and Trade Terminology for pasteles machine

What Are the Key Technical Properties of a Pasteles Machine?

When considering the purchase of a pasteles machine, understanding its technical specifications is crucial for ensuring it meets production needs. Here are several essential properties to evaluate:

-

Material Grade

The material grade of a pasteles machine, often stainless steel or food-grade plastic, determines its durability and resistance to corrosion. High-quality materials ensure longevity, which is vital for businesses aiming to maintain consistent production without frequent replacements. -

Power Rating (Wattage)

The power rating indicates the machine’s efficiency and performance. A higher wattage typically means faster processing times, allowing for greater output. For businesses, this translates to improved productivity and the ability to meet high demand during peak seasons. -

Capacity

This specification refers to the amount of masa (dough) the machine can process in a single batch, usually measured in pounds or kilograms. A machine with a larger capacity can significantly reduce preparation time, making it ideal for larger operations or those looking to scale their production. -

Speed Settings

Adjustable speed settings allow operators to customize the grating and mixing process based on specific recipes or ingredient types. This versatility is important for maintaining the authenticity of traditional pasteles while optimizing production efficiency. -

Ease of Cleaning

Machines designed for easy disassembly and cleaning save time and labor costs, crucial in a commercial kitchen environment. Features such as removable blades and smooth surfaces facilitate thorough sanitation, which is vital for food safety compliance. -

Warranty and Support

A robust warranty and reliable customer support indicate a manufacturer’s confidence in their product. For B2B buyers, this aspect is essential for long-term operational stability, as it ensures assistance in case of technical issues or maintenance needs.

What Are Common Trade Terminology and Jargon in the Pasteles Machine Industry?

Familiarizing yourself with industry terminology can enhance negotiations and purchasing processes. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for sourcing reliable machines and components, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and planning inventory, particularly for bulk purchases that can reduce costs per unit. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products. This is a crucial step in the procurement process, allowing buyers to compare prices and terms from different manufacturers. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and risk management aspects of their transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory management and ensuring timely production schedules. -

Certification Standards

These are regulations or guidelines set by authorities to ensure product safety and quality. For food processing equipment, compliance with health and safety standards is critical, and knowing which certifications to look for can guide purchasing decisions.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their production capabilities and operational efficiency in the pasteles market.

Navigating Market Dynamics and Sourcing Trends in the pasteles machine Sector

What Are the Key Market Trends Influencing the Pasteles Machine Sector?

The pasteles machine sector is experiencing transformative growth, driven by the increasing demand for traditional culinary experiences across global markets. The rise of ethnic cuisine popularity, particularly in regions like Africa, South America, and the Middle East, is pushing restaurants and food manufacturers to seek efficient solutions for authentic food preparation. In Europe, especially in countries like Germany and Vietnam, there is a growing appreciation for diverse culinary offerings, further fueling the demand for specialized equipment like pasteles machines.

Illustrative image related to pasteles machine

Emerging technologies are reshaping sourcing strategies. Automation and digitization are key trends, enabling manufacturers to streamline operations and reduce costs. For B2B buyers, this means sourcing from suppliers who can offer advanced machinery that enhances production speed and maintains quality. Additionally, the integration of smart technologies, such as IoT-enabled machines, allows for real-time monitoring and maintenance, providing insights that can lead to operational efficiencies.

Moreover, international buyers should be aware of shifting trade dynamics, including tariffs and trade agreements that can impact sourcing costs. As businesses navigate these complexities, it’s essential to establish relationships with reliable suppliers who understand local market conditions and can provide adaptive solutions tailored to specific regional needs.

How Important Is Sustainability and Ethical Sourcing in the Pasteles Machine Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the pasteles machine sector. As global awareness of environmental issues rises, businesses are increasingly held accountable for their supply chain practices. This shift is particularly relevant for machinery that consumes significant resources or generates waste during production.

Investing in energy-efficient machines not only reduces operational costs but also aligns with a growing consumer preference for sustainable practices. Buyers should prioritize suppliers who utilize environmentally friendly materials and processes in their manufacturing. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to pasteles machine

Moreover, ethical sourcing practices ensure that the materials used in pasteles machines are obtained responsibly, minimizing negative impacts on local communities and ecosystems. By fostering relationships with suppliers who prioritize ethical practices, businesses can enhance their brand reputation and appeal to a broader customer base that values corporate responsibility.

How Has the Pasteles Machine Sector Evolved Over Time?

The evolution of the pasteles machine sector reflects broader trends in food production and technology. Historically, the preparation of pasteles—a traditional Puerto Rican dish—relied heavily on manual labor, with chefs spending hours grating and preparing ingredients. As demand for these dishes grew, particularly in the restaurant industry, the need for more efficient production methods became evident.

The introduction of electric graters and specialized pasteles machines revolutionized this process, significantly reducing preparation time while maintaining the authenticity of the dish. Today, advancements in automation and smart technology continue to shape the sector, enabling manufacturers to produce high-quality machines that cater to the evolving needs of international markets. As the industry moves forward, the focus on efficiency, sustainability, and authenticity will remain paramount for B2B buyers seeking to thrive in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of pasteles machine

-

How do I solve the challenge of high labor costs when producing pasteles?

Investing in a high-efficiency pasteles machine can significantly reduce labor costs. These machines automate the grating and mixing processes, allowing your team to focus on other critical tasks. Additionally, the speed and consistency of machine processing can increase production capacity, ultimately enhancing profitability. When sourcing, consider machines with versatile functionalities to handle various ingredients, which can further optimize labor use and streamline operations. -

What is the best machine for producing authentic pasteles?

The best machine for producing authentic pasteles is one that replicates the traditional hand-grating technique while offering efficiency and speed. Look for machines equipped with sharp, durable blades that can handle tough ingredients like yuca and green bananas, ensuring the texture remains true to the traditional recipe. Also, consider user-friendly features such as easy assembly, disassembly, and cleaning, which are crucial for maintaining hygiene in a commercial kitchen. -

How can I ensure the quality of pasteles machines from international suppliers?

To ensure quality, start by vetting suppliers through industry certifications and customer reviews. Request product samples to assess performance and durability before making bulk purchases. Additionally, consider suppliers that offer warranties and after-sales support, as this can be an indicator of their commitment to quality. Establishing a strong line of communication with suppliers will also help clarify your quality expectations and any customization needs. -

What customization options are available for pasteles machines?

Many manufacturers offer customization options to meet specific operational needs. You can request modifications in blade types, machine size, or even electrical specifications for different voltages. Customization can also include features that enhance usability, such as automatic shut-off or adjustable speed settings. Before placing an order, clearly communicate your requirements and check if the supplier can accommodate them within your budget. -

What is the minimum order quantity (MOQ) when sourcing pasteles machines?

The MOQ can vary widely among suppliers, typically ranging from one unit for custom orders to several dozen for bulk purchases. It is essential to discuss your production scale with potential suppliers, as some may offer lower MOQs for established businesses or first-time customers. Additionally, some manufacturers may provide flexibility on MOQs if you are willing to pay a premium for smaller orders. -

What payment terms should I expect when purchasing pasteles machines?

Payment terms can vary significantly depending on the supplier and your relationship with them. Common options include upfront payment, a deposit followed by the balance upon delivery, or net terms (e.g., net 30 or 60 days). Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Negotiating favorable terms can help manage cash flow, especially for larger purchases. -

How do I handle logistics and shipping for pasteles machines?

Logistics and shipping are critical considerations when sourcing pasteles machines internationally. Confirm the shipping methods offered by your supplier, such as sea freight or air freight, based on your budget and urgency. Additionally, inquire about customs clearance processes and whether the supplier provides assistance in navigating import regulations in your country. Establishing a reliable logistics partner can streamline the shipping process and mitigate delays. -

What should I include in my quality assurance (QA) process for pasteles machines?

Your QA process should encompass several key steps: initial inspection upon receipt, functionality testing, and ongoing maintenance checks. Ensure that you have a checklist for evaluating the machine’s performance, including speed, texture consistency, and ease of operation. Additionally, establish a feedback loop with your team to address any operational challenges quickly. Regular maintenance schedules will also prolong the machine’s lifespan and ensure consistent quality in production.

Top 4 Pasteles Machine Manufacturers & Suppliers List

1. Freakin Rican – Pasteles Grater

Domain: thefreakinricanrestaurant.com

Registered: 2013 (12 years)

Introduction: Pasteles Grater – Grandma Ann’s Electric Grater. This machine allows for mass production of Freakin Rican Pasteles. Promo code ‘FREAKIN’ for free shipping and a complimentary set of blades. Accepts all credit cards.

2. Grandma Ann’s – Freakin Rican Bundle

Domain: grandma-anns.com

Registered: 2010 (15 years)

Introduction: Freakin Rican Bundle – Grandma Ann’s Electric Grater

Regular price: $479.00 USD (previously $539.00 USD)

Pre-order available with FREE shipping

Shipping starts: First week of March 2025

Key Features:

1. Grating made effortless: Prep 10 pounds of ingredients in under 2 minutes.

2. Perfect hand-grated texture every time.

3. Versatile for various dishes including desserts and sauces.

4. Easy to clean…

3. Etsy – Puerto Rican Pasteles Machine

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Puerto Rican Pasteles Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hamilton Beach – Blender with Grinder/Shredder Attachment

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Hamilton Beach – Blender with Grinder/Shredder Attachment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pasteles machine

In the evolving landscape of food production, the strategic sourcing of pasteles machines is crucial for businesses aiming to enhance efficiency and maintain quality. Leveraging high-performance equipment like Grandma Ann’s Electric Grater can significantly reduce preparation time, ensuring that traditional flavors are preserved without compromising on authenticity. These machines not only streamline operations but also empower businesses to scale their production capabilities, allowing them to meet growing consumer demand.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, investing in reliable and versatile pasteles machines is essential. The ability to produce authentic dishes quickly and efficiently can set a business apart in competitive markets. Furthermore, sourcing equipment that offers durability and ease of use can lead to long-term cost savings and operational stability.

As you consider your sourcing strategies, remember that the right pasteles machine can be a game-changer for your culinary operations. Explore options that align with your business goals and take the next step towards enhancing your production capabilities. Don’t hesitate to reach out to suppliers who understand your needs and can provide tailored solutions for your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.