Bundler Machine: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for bundler machine

In the fast-paced world of global commerce, sourcing an effective bundler machine can pose a significant challenge for international B2B buyers. As manufacturers and distributors strive to enhance packaging efficiency, the need for reliable and versatile bundling solutions has never been greater. This comprehensive guide delves into the intricacies of bundler machines, covering various types such as automatic, semi-automatic, and shrink bundlers, alongside their diverse applications across industries.

From understanding the technical specifications that influence performance to evaluating the cost implications of different models, this guide equips buyers with the essential knowledge to make informed purchasing decisions. Key considerations include supplier vetting processes, ensuring compliance with international standards, and identifying the right machine for specific operational needs.

Whether you are a business in Africa aiming to streamline your packaging process, a distributor in South America seeking to meet customer demands, or a manufacturer in Europe looking to enhance operational efficiency, this guide provides actionable insights tailored to your market. By addressing common challenges and offering practical solutions, we empower B2B buyers to navigate the complexities of sourcing bundler machines effectively, ultimately fostering sustainable business growth in an increasingly competitive landscape.

Understanding bundler machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Bundlers | PLC touchscreen controls, hot knife seal system, adjustable height | High-volume packaging in manufacturing | Pros: High efficiency, minimal labor needed. Cons: Higher initial investment. |

| Semi-Automatic Bundlers | Manual loading, adjustable settings, lower throughput | Small to medium-sized operations | Pros: Lower cost, flexibility in operation. Cons: Requires more manual labor. |

| Inline Bundlers | Compact design, integrates with existing conveyor systems | Automated assembly lines | Pros: Space-saving, efficient integration. Cons: May require additional conveyor setup. |

| Shrink Bundlers | Heat shrink film application, creates tight seals | Food packaging, consumer goods | Pros: Excellent product protection, aesthetic appeal. Cons: Limited to compatible films. |

| Tray and Pad Bundlers | Supports larger products, optional collation modules | Packaging of stable products over 4 inches | Pros: Versatile, handles a range of product types. Cons: May be overkill for smaller items. |

What Are the Characteristics of Automatic Bundlers?

Automatic bundlers are designed for high-volume operations, featuring advanced technology such as PLC touchscreen controls that allow for precise adjustments. With options for hot knife sealing and adjustable product pass-through heights, these machines cater to various product sizes and shapes. They are ideal for industries where speed and efficiency are critical, such as manufacturing and distribution. Buyers should consider their production volume and the machine’s compatibility with their specific packaging materials before investing.

How Do Semi-Automatic Bundlers Differ?

Semi-automatic bundlers provide a more manual approach to packaging, allowing operators to load products into the machine while maintaining adjustable settings for different applications. These machines are suitable for small to medium-sized operations where flexibility is valued over speed. The lower initial investment is attractive for businesses that may not require continuous high-volume output. However, buyers should assess the trade-off between labor costs and operational efficiency when considering this option.

What Are the Benefits of Inline Bundlers?

Inline bundlers are designed to seamlessly integrate with existing conveyor systems, making them an excellent choice for automated assembly lines. Their compact design allows for efficient use of space, which is particularly beneficial in facilities with limited floor space. These machines can significantly enhance workflow efficiency. Buyers should evaluate their current production line setup to ensure compatibility and consider any additional conveyor systems that may be needed for optimal performance.

Why Choose Shrink Bundlers for Packaging?

Shrink bundlers are favored for their ability to apply heat shrink film, creating a tight and secure seal around products. This method is particularly effective for food packaging and consumer goods, where product protection and presentation are paramount. While they offer aesthetic benefits, buyers must ensure that the bundler is compatible with the films they intend to use, as this can limit options. Cost considerations related to film types and machine maintenance should also be factored in.

What Makes Tray and Pad Bundlers Ideal for Larger Products?

Tray and pad bundlers are specifically designed for larger, stable products, providing optional collation modules to enhance packaging efficiency. They are particularly useful in industries where products are often packaged together, such as in food and beverage. The versatility of these machines allows for a range of product types to be handled, making them a valuable asset for businesses with diverse packaging needs. However, buyers should assess the necessity of such capabilities against their product range to avoid over-investment.

Key Industrial Applications of bundler machine

| Industry/Sector | Specific Application of bundler machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Bundling of packaged snacks and beverages | Increases shelf appeal and reduces packaging costs | Ensure compliance with food safety standards and select heat-resistant films. |

| Consumer Goods | Packaging personal care products in multipacks | Enhances product visibility and facilitates retail display | Consider machine compatibility with various product sizes and shapes. |

| Building Materials | Bundling tiles, lumber, or other construction materials | Improves shipping efficiency and reduces damage during transit | Evaluate durability and robustness of the bundler for heavy items. |

| Pharmaceuticals | Packaging medical supplies and over-the-counter products | Ensures product integrity and compliance with industry regulations | Look for machines that can handle sterile packaging processes. |

| Electronics | Bundling electronic components or devices for shipping | Protects sensitive items and reduces shipping costs | Assess for precision in bundling to avoid damage to fragile components. |

How Are Bundler Machines Used in the Food & Beverage Industry?

In the food and beverage sector, bundler machines are employed to package snacks and bottled drinks efficiently. By creating secure multipacks, these machines enhance shelf appeal while reducing overall packaging costs. International buyers must prioritize compliance with food safety standards, ensuring that the materials used are suitable for direct contact with food and capable of withstanding various temperature conditions during storage and transportation.

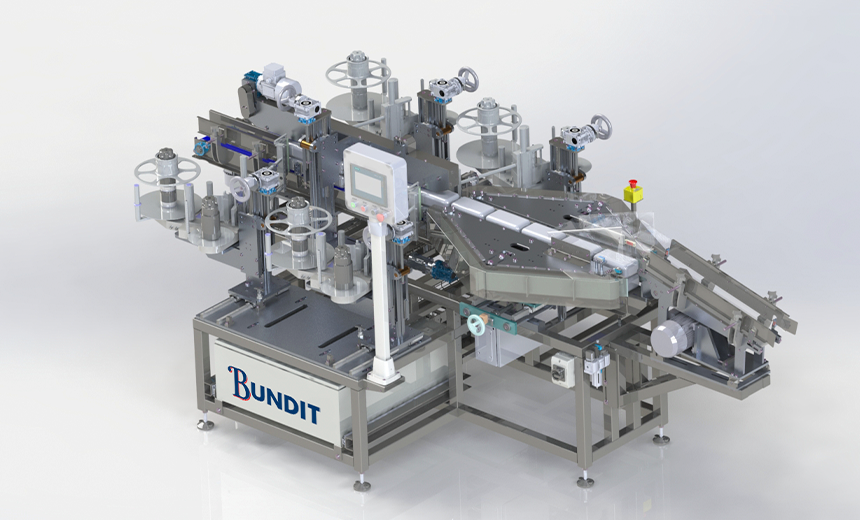

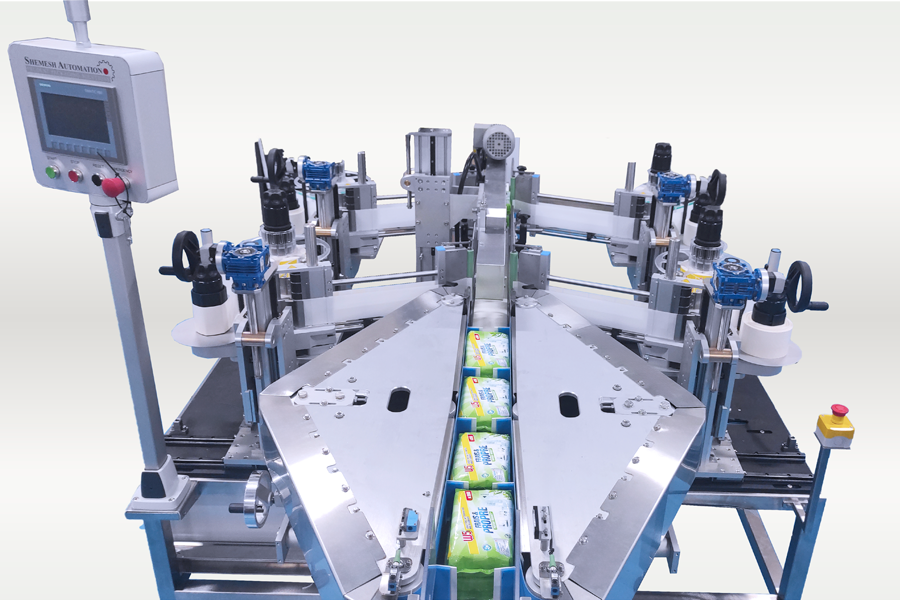

Illustrative image related to bundler machine

What Role Do Bundler Machines Play in Consumer Goods Packaging?

Bundler machines are critical in the consumer goods industry, particularly for personal care products that are often sold in multipacks. These machines enable manufacturers to bundle products, improving visibility on retail shelves and facilitating easier handling during distribution. Buyers should consider the machine’s adaptability to different product sizes and shapes, ensuring seamless integration into existing production lines.

How Are Bundler Machines Beneficial for Building Materials?

In the building materials industry, bundler machines are used to package heavy items like tiles and lumber, improving shipping efficiency and minimizing damage during transit. These machines can handle large volumes and are designed to provide robust support for heavy loads. Buyers must evaluate the durability and robustness of bundler machines to ensure they can withstand the rigors of packaging heavy construction materials.

What Are the Applications of Bundler Machines in Pharmaceuticals?

Bundler machines are essential in the pharmaceutical sector for packaging medical supplies and over-the-counter products. They ensure that products remain intact and compliant with stringent industry regulations. Buyers should focus on sourcing machines that can accommodate sterile packaging processes, as this is critical for maintaining product integrity and meeting health standards in various markets.

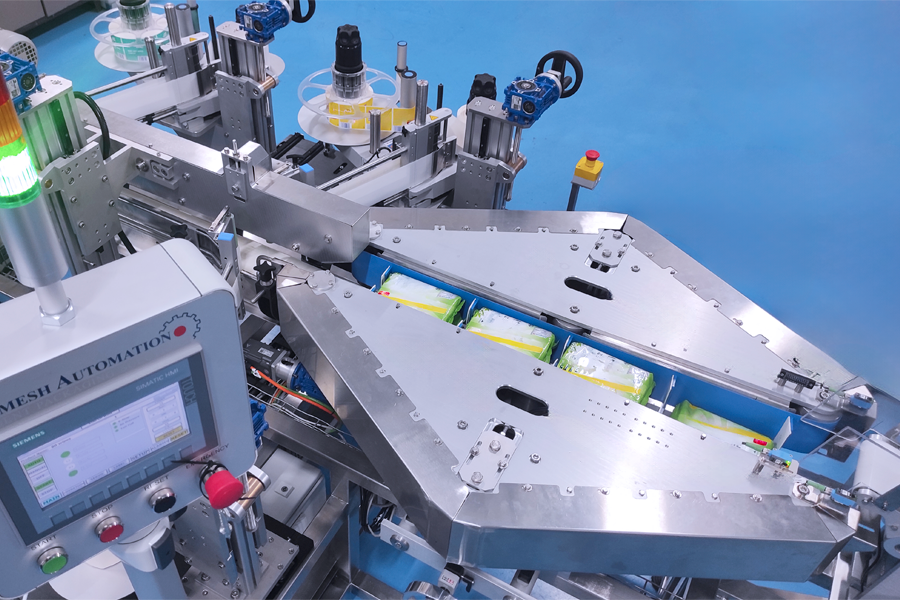

Illustrative image related to bundler machine

How Do Bundler Machines Enhance Efficiency in Electronics Packaging?

In the electronics industry, bundler machines are utilized to package sensitive components or finished devices for shipping. These machines protect fragile items from damage and help reduce shipping costs by efficiently bundling products together. Buyers should assess the precision of bundler machines to ensure they can handle delicate items without compromising quality, while also considering the need for customization based on specific product requirements.

3 Common User Pain Points for ‘bundler machine’ & Their Solutions

Scenario 1: Inefficient Packaging Process Leading to Delays

The Problem: Many B2B buyers face significant challenges with the speed and efficiency of their packaging processes. An outdated bundler machine may be unable to keep up with production demands, leading to bottlenecks in the packaging line. This inefficiency not only results in delayed order fulfillment but also increases labor costs as workers struggle to manage the backlog. Furthermore, if the bundling process is slow, it can affect overall operational efficiency, causing frustration among staff and dissatisfaction among clients waiting for their products.

The Solution: To address these issues, businesses should consider investing in a high-speed bundler machine that features automated processes. Look for models that offer options for continuous motion, such as the Polypack CMS series, which can significantly enhance throughput. Conduct a thorough assessment of your production needs and choose a bundler that allows for quick changeovers and easy integration with existing conveyor systems. By prioritizing machines with user-friendly interfaces, such as PLC touchscreens, operators can quickly adjust settings for different products, minimizing downtime. Additionally, evaluate the machine’s ability to handle various packaging materials, ensuring flexibility to adapt to changing market demands.

Scenario 2: Product Damage During Bundling

The Problem: Another common pain point for B2B buyers is product damage during the bundling process. Fragile items may get crushed or misaligned, leading to costly returns, unhappy customers, and a tarnished reputation. This issue can stem from inadequate adjustments in the bundling machine, poor handling, or improper sealing techniques. When products are not securely wrapped, they are susceptible to damage during transit, ultimately affecting the bottom line.

The Solution: To mitigate the risk of damage, it’s crucial to select a bundler machine that provides adjustable settings for sealing pressure and temperature, ensuring that the packaging is tailored to the specific product type. Machines with features such as powered film unwind and self-tracking conveyor belts, like the Eastey EB series, help maintain consistent product alignment and minimize handling errors. Implementing regular training for operators on how to adjust machine settings based on the products being processed can further reduce the chances of damage. Additionally, consider bundlers that allow for product guides and hold-downs to stabilize items during the wrapping process.

Illustrative image related to bundler machine

Scenario 3: High Operating Costs Due to Maintenance Issues

The Problem: B2B buyers often encounter high operational costs due to frequent breakdowns or maintenance requirements of their bundler machines. Outdated or poorly designed machines can lead to increased downtime and the need for costly repairs, impacting productivity and profitability. For companies operating in competitive markets, the ability to maintain a streamlined and cost-effective packaging process is crucial for sustaining business growth.

The Solution: To reduce maintenance costs, invest in a bundler machine with a robust and durable design, such as those built with heavy-gauge stainless steel frames. Machines with fewer moving parts and engineered for easy access to components can significantly lower maintenance time and costs. It’s advisable to choose models from reputable manufacturers that offer warranties and reliable customer support, ensuring that any issues can be resolved quickly. Regularly schedule preventative maintenance checks and train staff on basic troubleshooting techniques to minimize downtime. Also, consider machines that provide diagnostic features, allowing operators to identify and address potential issues before they escalate into major problems.

Strategic Material Selection Guide for bundler machine

What are the Key Materials Used in Bundler Machines?

When selecting a bundler machine, the choice of materials significantly impacts performance, durability, and overall cost. Below, we analyze four common materials used in bundler machines, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Stainless Steel Benefit Bundler Machines?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and is resistant to various chemicals, making it suitable for diverse environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which is crucial in humid or chemically aggressive environments. However, it can be more expensive than other materials, and its manufacturing complexity can lead to higher production costs.

Impact on Application: Stainless steel is ideal for bundler machines that handle food or pharmaceutical products, where hygiene is paramount. Its compatibility with cleaning agents ensures compliance with safety standards.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer stainless steel due to stringent hygiene regulations. Compliance with standards such as ASTM and DIN is essential for ensuring product safety and quality.

What Role Does Aluminum Play in Bundler Machine Design?

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can withstand moderate temperatures. It typically has a temperature rating of up to 400°F (204°C) and offers decent strength-to-weight ratios.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can reduce shipping costs and make installation easier. However, it is less durable than stainless steel and may require protective coatings to enhance its corrosion resistance.

Impact on Application: Aluminum is suitable for bundler machines used in less demanding environments, such as packaging non-perishable goods. Its lightweight properties make it ideal for portable bundler machines.

Illustrative image related to bundler machine

Considerations for International Buyers: Buyers in regions like Africa and South America may find aluminum bundler machines appealing due to lower initial costs. However, they should consider the potential need for additional coatings to maintain performance in humid conditions.

How Does Plastic Material Enhance Bundler Machine Functionality?

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polypropylene (PP), offer good chemical resistance and flexibility. They can withstand moderate temperatures, typically up to 180°F (82°C), and are lightweight.

Pros & Cons: The primary advantage of plastics is their cost-effectiveness and ease of manufacturing. However, they may not be suitable for high-temperature applications and can be less durable than metals.

Impact on Application: Plastic components are often used in bundler machines for film guides and other non-structural parts. Their flexibility allows for customization in various packaging applications.

Illustrative image related to bundler machine

Considerations for International Buyers: Buyers should be aware of the recycling and disposal regulations for plastics in their regions. Compliance with local environmental standards is crucial for sustainable operations.

Why is Carbon Steel a Viable Option for Bundler Machines?

Key Properties: Carbon steel is known for its high strength and durability, with temperature ratings typically up to 500°F (260°C). However, it is prone to rust and corrosion without proper treatment.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for heavy-duty applications. Conversely, its susceptibility to corrosion can lead to higher maintenance costs over time.

Impact on Application: Carbon steel is often used in the frames of bundler machines, providing robust support for high-volume operations. However, it may not be suitable for environments with high humidity or corrosive substances.

Considerations for International Buyers: Buyers in industrial sectors, particularly in South America and Africa, may prefer carbon steel due to its lower cost. However, they must consider the need for protective coatings to enhance longevity.

Summary Table of Material Properties for Bundler Machines

| Material | Typical Use Case for bundler machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical packaging | Excellent corrosion resistance | Higher initial cost | High |

| Aluminum | Portable bundler machines | Lightweight, reduces shipping costs | Less durable than steel | Medium |

| Plastic | Non-structural components | Cost-effective and easy to manufacture | Limited temperature resistance | Low |

| Carbon Steel | Heavy-duty bundler machine frames | Cost-effective and strong | Prone to rust without treatment | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bundler machine

What Are the Key Stages in the Manufacturing Process of Bundler Machines?

The manufacturing of bundler machines involves several critical stages, each designed to ensure the final product meets the rigorous demands of the packaging industry. The primary stages include material preparation, forming, assembly, and finishing.

How Does Material Preparation Impact Bundler Machine Quality?

Material preparation is foundational to the production of bundler machines. Manufacturers typically source high-quality materials such as cold-rolled steel for the frame and durable plastics for components that come into contact with the film. This stage includes cutting, welding, and machining processes, ensuring that all parts meet precise specifications. Rigorous material testing is often conducted to verify strength, durability, and compatibility with operational demands. The quality of materials directly influences the machine’s longevity and performance, making this an essential phase in the manufacturing process.

What Forming Techniques Are Used in Bundler Machine Production?

The forming stage encompasses the shaping of the machine components. Advanced techniques such as CNC machining, laser cutting, and press forming are commonly employed. For instance, CNC machines ensure high precision in cutting metal sheets for the frame, while laser cutting can create intricate designs for the film guides. Each component is formed to exact specifications to guarantee seamless assembly and operation. This precision minimizes the risk of operational failures and enhances the machine’s overall efficiency.

How Is Assembly Conducted for Optimal Bundler Machine Performance?

The assembly process involves the integration of all prepared components into a cohesive unit. Skilled technicians typically follow detailed assembly protocols to ensure that each machine is built according to design specifications. This stage may include installing electrical systems, control panels, and mechanical parts such as conveyors and sealing mechanisms. Quality assurance checkpoints during assembly, such as inspections for alignment and functionality, are crucial to ensuring that the machine operates as intended. Employing modular assembly techniques allows for easier troubleshooting and maintenance, enhancing the machine’s longevity.

What Finishing Processes Are Essential in Bundler Machine Manufacturing?

Finishing processes, including painting and coating, are vital for protecting bundler machines from environmental factors and wear. A durable, custom two-part epoxy finish is often applied to resist scratching and corrosion. Additionally, the application of protective coatings can enhance the machine’s aesthetic appeal, which is important for maintaining a professional appearance in customer-facing environments. Final inspections at this stage ensure that all components are functioning properly and that the machine meets industry standards.

What Quality Assurance Practices Are Essential for Bundler Machines?

Quality assurance (QA) is crucial in the manufacturing of bundler machines, ensuring that each unit meets established standards and customer expectations. International standards such as ISO 9001, alongside industry-specific certifications like CE and API, play a significant role in establishing quality benchmarks.

Which International Standards Should B2B Buyers Consider?

B2B buyers should look for manufacturers that comply with international standards like ISO 9001, which outlines a framework for quality management systems. Compliance with CE marking indicates that the product meets EU safety, health, and environmental protection standards, which is particularly important for buyers in Europe. For buyers in industries with specific regulatory requirements, such as pharmaceuticals or food and beverage, certifications from organizations like the American Petroleum Institute (API) may also be relevant.

What Are the Key Quality Control Checkpoints in Bundler Machine Production?

Quality control (QC) involves systematic inspections throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the assembly process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the assembled bundler machine to ensure it operates correctly and meets performance specifications.

These checkpoints help to maintain consistent quality and reduce the likelihood of defects reaching the customer.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers must take proactive steps to verify the quality assurance practices of potential suppliers. Here are key strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational capabilities of the supplier.

-

Quality Reports: Requesting detailed quality reports and documentation can provide insights into a supplier’s QC history, including failure rates, corrective actions taken, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s adherence to quality standards. This is particularly beneficial for buyers unfamiliar with the supplier’s local market.

-

Certifications Verification: Buyers should verify the authenticity of certifications claimed by suppliers. This can often be done through industry associations or regulatory bodies.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of regional regulatory differences. For instance, while CE marking is essential for products sold in Europe, other regions may have distinct standards that must be met. Understanding these nuances is crucial to ensure compliance and avoid potential legal issues or product recalls.

Furthermore, cultural differences may influence communication and negotiation styles, which can affect quality assurance agreements. B2B buyers should approach discussions with an understanding of local practices and expectations.

Illustrative image related to bundler machine

In summary, the manufacturing processes and quality assurance practices for bundler machines are complex and multi-faceted. By understanding these processes, B2B buyers can make informed decisions that ensure they procure reliable, high-quality bundler machines tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bundler machine’

This guide is designed to assist B2B buyers in navigating the procurement process for bundler machines, ensuring that you make informed decisions that align with your operational needs. Bundler machines are essential for efficiently packaging products, and careful consideration during the sourcing process can significantly impact your production efficiency and cost-effectiveness.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for your bundling operations. Consider factors such as the size of products to be bundled, the type of film used (polyethylene, PVC, etc.), and the desired speed of operation.

– Product Dimensions: Ensure the machine can accommodate the maximum dimensions of your products.

– Film Compatibility: Verify that the machine can handle the specific types and sizes of film you intend to use.

Illustrative image related to bundler machine

Step 2: Assess Production Volume Needs

Evaluate your production capacity requirements to determine the appropriate bundler machine type. Machines vary in speed and throughput, so understanding your volume needs will guide your selection.

– Daily Output: Estimate the number of bundles you need to produce daily.

– Future Scalability: Consider whether you may need to scale operations in the future and choose a machine that can adapt to increased demands.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your technical and service needs. Request detailed company profiles, product catalogs, and references from other customers in your industry or region.

– Industry Experience: Look for suppliers with a proven track record in bundling solutions.

– Customer Testimonials: Seek out reviews or case studies that highlight their customer service and machine performance.

Step 4: Review Machine Features and Specifications

Examine the features of the bundler machines that interest you. Essential features can impact both operation and maintenance efficiency.

– Control Systems: Look for machines with user-friendly interfaces such as PLC touchscreens for easy operation.

– Durability and Build Quality: Ensure that the machine’s frame is made from robust materials, such as cold-rolled steel, to withstand daily use.

Step 5: Understand Maintenance Requirements

Inquire about the maintenance needs of the bundler machines you are considering. A machine that requires frequent maintenance can disrupt production and incur additional costs.

– Service Support: Check if the supplier offers comprehensive service contracts or support for repairs.

– Parts Availability: Ensure that replacement parts are readily available and that the supplier has a strong support network.

Step 6: Check for Compliance and Certifications

Verify that the bundler machine complies with relevant industry standards and regulations. Compliance ensures safety and reliability in operation, which is crucial for maintaining production quality.

– Safety Standards: Look for certifications such as CE or UL to ensure the machine meets safety regulations.

– Quality Assurance: Ask about the supplier’s quality control processes during manufacturing.

Step 7: Negotiate Pricing and Terms

Finally, engage in negotiations regarding pricing and terms of purchase. Transparency in costs and clear terms can prevent misunderstandings later in the procurement process.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

– Payment Terms: Ensure that payment terms are reasonable and align with your budget.

By following this checklist, you can effectively navigate the sourcing process for bundler machines, ensuring that you select a solution that meets your operational needs while providing value to your business.

Comprehensive Cost and Pricing Analysis for bundler machine Sourcing

What Are the Key Cost Components of Bundler Machines?

When sourcing bundler machines, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used significantly affects the overall cost. High-grade steel frames, advanced PLC touchscreen controls, and energy-efficient components drive up costs but also enhance durability and efficiency. For instance, machines with cold-rolled steel frames may have a higher upfront cost but often result in lower maintenance expenses.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor for machine assembly and quality assurance processes can increase initial costs. Depending on the region, labor costs can vary dramatically; for example, sourcing from Europe may be pricier compared to regions in Asia or South America.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and facility costs. These overheads can add 15-30% to the total cost of a bundler machine.

-

Tooling: Custom tooling for specific bundler configurations can be a significant investment. The complexity of the design and the need for specialized parts can lead to higher tooling costs, especially if the buyer requires unique specifications or adaptations.

-

Quality Control (QC): Investing in QC processes ensures that the machines meet industry standards and function effectively. Companies that prioritize QC may charge a premium, but this can prevent costly downtimes and failures in the long run.

-

Logistics: Shipping costs vary based on the machine’s size and weight, as well as the distance from the supplier. International buyers should consider the impact of tariffs, customs duties, and shipping insurance on their overall budget.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can range from 10% to 30% depending on the market and competition.

How Do Price Influencers Impact Bundler Machine Costs?

Several factors influence the pricing of bundler machines, including:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts. Suppliers often have tiered pricing structures that favor larger orders, which is crucial for businesses with high-volume needs.

-

Specifications and Customization: Custom features, such as size, speed, and automation capabilities, can considerably affect pricing. Standard models are typically more economical than bespoke machines.

-

Materials and Quality Certifications: Machines made from premium materials or those that meet specific industry certifications (like UL or CE) may carry higher price tags. Buyers should weigh the benefits of these certifications against their operational requirements.

-

Supplier Factors: The reputation, location, and reliability of the supplier can influence pricing. Established suppliers with a strong track record may charge more, but they often provide better support and warranty options.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) can affect the total landed cost. Terms like FOB (Free On Board) can shift shipping responsibilities and costs, impacting the buyer’s final expense.

What Are Some Buyer Tips for Cost-Efficient Bundler Machine Sourcing?

International B2B buyers should consider the following strategies for effective sourcing:

-

Negotiate Effectively: Leverage volume purchases and long-term commitments to negotiate better pricing. Establishing a relationship with suppliers can also yield more favorable terms over time.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess ongoing costs, including maintenance, energy consumption, and potential downtime, to understand the machine’s true cost over its lifespan.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, import duties, and local taxes that can affect the total cost. Engaging with local experts or consultants can provide insights into the specific market conditions in regions like Africa, South America, the Middle East, and Europe.

-

Request Multiple Quotes: Comparing offers from different suppliers can highlight discrepancies in pricing and features. This competitive analysis can help you secure the best deal.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding bundler machine costs and pricing, prices can vary widely based on specific configurations, market conditions, and regional factors. Buyers should conduct thorough research and consult with multiple suppliers to obtain accurate and relevant pricing information tailored to their needs.

Alternatives Analysis: Comparing bundler machine With Other Solutions

Exploring Alternatives to Bundler Machines for Packaging Solutions

In the competitive landscape of packaging solutions, businesses often seek alternatives to bundler machines that can meet specific operational requirements and budgets. Understanding the various options available can help B2B buyers make informed decisions tailored to their unique needs. Below, we compare bundler machines against two viable alternatives: shrink wrapping machines and manual packaging methods.

| Comparison Aspect | Bundler Machine | Shrink Wrapping Machine | Manual Packaging Method |

|---|---|---|---|

| Performance | High throughput, consistent results | Moderate throughput, suitable for smaller batches | Low throughput, variable quality |

| Cost | Higher initial investment, cost-effective long-term | Lower initial cost, may require more labor | Lowest initial cost, high labor costs |

| Ease of Implementation | Requires installation and training | Easier to set up, less training needed | Simple, no setup required |

| Maintenance | Requires regular maintenance | Minimal maintenance required | Minimal maintenance |

| Best Use Case | High-volume production, uniform packaging | Smaller, irregularly shaped products, low volume | Custom, small batch packaging |

Shrink Wrapping Machines: Advantages and Disadvantages

Shrink wrapping machines, such as the Polypack IL/CMS series, offer a flexible solution for packaging stable products. They excel in creating a tight, protective seal around items, making them suitable for distribution-ready packaging. The key advantages include lower initial costs and ease of use, especially for small to medium-sized operations. However, their throughput is generally lower than that of bundler machines, making them less ideal for high-volume production lines. Additionally, they may require more manual labor, which can lead to higher long-term operational costs.

Manual Packaging Methods: Pros and Cons

Manual packaging methods involve labor-intensive processes where workers package products by hand. This approach is highly customizable, allowing for tailored solutions to unique product specifications. The primary advantage is the low initial investment required, making it accessible for startups or small businesses. However, the drawbacks are significant; manual methods typically yield low throughput and inconsistent quality, as they rely heavily on human performance. Moreover, as production scales, labor costs can quickly escalate, making this option less viable for growing companies.

Conclusion: How to Choose the Right Packaging Solution

When selecting a packaging solution, B2B buyers should consider their specific needs, including production volume, budget constraints, and product characteristics. Bundler machines are ideal for high-volume operations requiring consistent quality and efficiency. In contrast, shrink wrapping machines serve well for smaller batches and flexible applications, while manual packaging may be suitable for businesses with unique, low-volume needs. Assessing these factors will enable buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for bundler machine

What Are the Key Technical Properties of Bundler Machines?

When selecting a bundler machine, understanding its technical specifications is crucial for ensuring operational efficiency and compatibility with your packaging needs. Here are some essential technical properties to consider:

1. Material Grade

Bundler machines are typically constructed from high-quality materials such as cold-rolled steel or stainless steel. The material grade affects durability, corrosion resistance, and maintenance requirements. A robust construction is vital for machines operating in demanding environments, as it minimizes downtime and extends the lifespan of the equipment.

2. Film Width and Type

Bundler machines often accommodate various film widths, commonly ranging from 35” to 80”. The choice of film type—such as polyethylene or PVC—also plays a significant role in the final packaging quality. A machine that can handle multiple film types increases versatility and allows businesses to adapt to changing product specifications or market demands.

3. Seal Type and Technology

The sealing method is critical for ensuring product integrity. Most bundler machines utilize a hot knife seal system, which provides a strong, clean seal that is essential for maintaining package stability during transport. Understanding the seal’s effectiveness and the machine’s temperature control capabilities can prevent product spoilage and enhance customer satisfaction.

4. Automation Level

Bundler machines can be fully automatic or semi-automatic, affecting their operational efficiency. Fully automatic systems, which often feature PLC touchscreen controls, allow for higher throughput and reduced labor costs. In contrast, semi-automatic machines may be more suitable for smaller operations or lower volumes, offering flexibility based on production needs.

5. Conveyor Specifications

The conveyor system’s design, including speed and tracking capabilities, is crucial for ensuring consistent product flow and minimizing jams. Self-tracking conveyor belts and adjustable height features enhance usability and adaptability to different product sizes, which is particularly beneficial for companies with diverse product lines.

6. Power Requirements

Understanding the power specifications, such as voltage (e.g., 220V or 480V), is essential for compatibility with existing electrical systems. Machines that are energy-efficient can help reduce operational costs, making them more appealing to budget-conscious buyers.

What Are Common Trade Terms Related to Bundler Machines?

Navigating the procurement process for bundler machines involves familiarity with specific industry terminology. Here are several key terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trusted suppliers and ensure the quality of the components used in bundler machines.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, especially when assessing whether a supplier can meet production requirements without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for B2B buyers to compare costs, specifications, and service offerings, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, which is essential for budgeting and logistics planning.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a bundler machine, including purchase price, maintenance, energy consumption, and labor. Understanding TCO enables buyers to evaluate the long-term financial impact of their investment, beyond the initial purchase price.

6. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is critical for production planning and inventory management, as longer lead times can affect production schedules and customer satisfaction.

In conclusion, understanding these technical properties and trade terms is essential for B2B buyers to make informed decisions regarding bundler machines. This knowledge not only aids in selecting the right equipment but also enhances communication with suppliers, ultimately leading to more successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the bundler machine Sector

What Are the Current Market Dynamics and Key Trends in the Bundler Machine Sector?

The global bundler machine market is experiencing significant growth, driven by the increasing demand for efficient packaging solutions across various industries such as food and beverage, pharmaceuticals, and consumer goods. The rise of e-commerce and the need for streamlined logistics operations are pushing manufacturers to adopt bundling technologies that enhance product protection and reduce shipping costs. In particular, regions like Africa, South America, the Middle East, and Europe are witnessing a surge in investment in automation technologies, with countries such as Vietnam and Germany leading the way in adopting advanced bundler systems.

Emerging trends include the integration of Industry 4.0 technologies, such as IoT and AI, into bundler machines for improved operational efficiency and predictive maintenance. This shift is enabling manufacturers to monitor machine performance in real-time, significantly reducing downtime and maintenance costs. Additionally, the demand for customizable bundler machines is on the rise, as businesses seek solutions tailored to their specific product dimensions and production requirements. Buyers should also be aware of innovations in sustainable packaging materials, which are becoming increasingly important in the selection of bundling solutions.

How Is Sustainability and Ethical Sourcing Impacting the Bundler Machine Industry?

Sustainability has become a critical factor in the bundler machine sector, with businesses prioritizing environmentally friendly practices throughout their supply chains. The environmental impact of traditional packaging materials, particularly plastics, is prompting companies to seek bundler machines that support the use of recyclable and biodegradable materials. As a result, manufacturers are increasingly offering machines that are compatible with sustainable packaging options, such as compostable films.

Ethical sourcing is also gaining traction among B2B buyers, who are looking for suppliers that adhere to responsible production practices. This includes ensuring that materials used in bundler machines are sourced from suppliers that prioritize fair labor practices and environmental stewardship. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO certifications for manufacturing processes are becoming essential in supplier evaluations. By focusing on sustainability and ethical sourcing, businesses can not only reduce their environmental footprint but also enhance their brand reputation and customer loyalty.

What Is the Evolution of Bundler Machines and Its Relevance to Today’s Buyers?

The evolution of bundler machines can be traced back to the early 20th century when manual wrapping techniques were prevalent. As industries grew and the demand for efficient packaging solutions increased, the transition to semi-automatic and eventually fully automatic bundling systems began. The introduction of heat shrink technology revolutionized the industry, allowing for secure and visually appealing packaging that enhances product protection during transportation.

Today, bundler machines have advanced to include features such as PLC touchscreen interfaces, adjustable configurations for various product sizes, and energy-efficient designs. This evolution is significant for B2B buyers, as it highlights the importance of selecting modern, versatile machines that can adapt to changing market demands. Understanding the history of bundler machines not only informs purchasing decisions but also enables buyers to appreciate the technological advancements that contribute to improved operational efficiency and sustainability in their packaging processes.

Frequently Asked Questions (FAQs) for B2B Buyers of bundler machine

-

1. How do I choose the right bundler machine for my packaging needs?

Selecting the right bundler machine involves assessing your product dimensions, packaging speed requirements, and the type of film you intend to use. Consider whether you need a fully automatic or semi-automatic system based on your production volume. It’s also essential to evaluate the machine’s features, such as adjustable seal height and film unwinding capabilities, to ensure compatibility with your operational workflow. Engaging with suppliers to discuss your specific requirements can provide valuable insights and lead to the best choice for your business. -

2. What are the typical costs associated with purchasing a bundler machine?

The cost of bundler machines can vary significantly based on their specifications, features, and the manufacturer. Basic models may start around a few thousand dollars, while advanced, high-capacity machines can exceed tens of thousands. Additional costs may include shipping, installation, and training. It’s advisable to request detailed quotes from multiple suppliers to understand the total cost of ownership, including maintenance and potential upgrades, ensuring you make a financially sound investment. -

3. How can I ensure the quality of the bundler machine I purchase?

To ensure the quality of a bundler machine, look for suppliers with a strong reputation and positive customer reviews. Request certifications such as ISO to confirm adherence to international quality standards. It’s also beneficial to ask for machine demonstrations or visit the supplier’s facility to observe the manufacturing process. Furthermore, inquire about warranty terms and after-sales support, which can provide reassurance regarding the machine’s reliability and longevity. -

4. What customization options are typically available for bundler machines?

Many manufacturers offer customization options to tailor bundler machines to your specific requirements. Common customizations include modifications to seal bar length, adjustable height for different product sizes, and additional film guides. Some suppliers may also provide options for integrating collation modules or custom-sized machines. Discussing your unique packaging needs with the supplier can help identify the best customization options to enhance operational efficiency. -

5. What are the minimum order quantities (MOQ) for bundler machines?

Minimum order quantities can vary widely among manufacturers, often influenced by the complexity of the machine and the level of customization required. Many manufacturers may have a MOQ of one unit for standard models, while custom machines may require higher quantities. It’s crucial to clarify MOQs during initial discussions with suppliers to ensure they align with your production plans and budget constraints. -

6. What payment terms should I expect when purchasing a bundler machine?

Payment terms can differ significantly between suppliers. Common arrangements include a deposit upfront, with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans, particularly for higher-value machines. Always clarify payment terms before finalizing your order, and consider negotiating terms that provide you with flexibility while ensuring a secure transaction for both parties. -

7. How do I handle logistics and shipping for an international bundler machine purchase?

When purchasing a bundler machine internationally, coordinate closely with your supplier to understand shipping options, costs, and timelines. Ensure that all necessary customs documentation is prepared to facilitate smooth importation. It may be beneficial to work with a freight forwarder experienced in handling industrial equipment to navigate logistical challenges effectively. Additionally, consider insurance for the shipment to protect your investment during transit. -

8. What kind of maintenance is required for bundler machines?

Regular maintenance is crucial for ensuring optimal performance and longevity of bundler machines. This typically includes routine cleaning, lubrication of moving parts, and inspection of seals and film feed mechanisms. Manufacturers often provide maintenance guidelines, and training for your staff can help them identify potential issues early. Establishing a scheduled maintenance plan can minimize downtime and enhance production efficiency, ensuring your investment remains productive over time.

Top 1 Bundler Machine Manufacturers & Suppliers List

1. US Packaging and Wrapping – Shrink Bundling Machines

Domain: uspackagingandwrapping.com

Registered: 2011 (14 years)

Introduction: Shrink Bundling Machines use lay-flat polyethylene shrink bundling film to package heavy bundles of products. Ideal for consumer goods such as beverages, firewood, and canned goods. Key products include: 1. Shrink Bundling Machine – $28,020.45 2. Shrink Bundling Tunnel – $20,159.01 3. Auto Shrink Bundler – $46,748.00. The SW3614 Shrink Bundling Machine features a 36″ wide sealing bar and heavy-dut…

Strategic Sourcing Conclusion and Outlook for bundler machine

In today’s competitive landscape, strategic sourcing of bundler machines is essential for businesses aiming to enhance their packaging efficiency and product presentation. By selecting high-quality, reliable bundling equipment, companies can improve their operational productivity while ensuring a positive return on investment. Features such as adjustable film unwinds, robust construction, and user-friendly interfaces are critical factors that B2B buyers should prioritize when evaluating bundler options.

Understanding the diverse needs of different markets—including Africa, South America, the Middle East, and Europe—enables buyers to tailor their sourcing strategies effectively. Leveraging local suppliers and manufacturers can also provide significant advantages in terms of logistics, cost savings, and support services.

As the packaging industry continues to evolve, investing in advanced bundler machines will not only streamline operations but also enhance product appeal in the marketplace. We encourage international B2B buyers to explore the latest innovations in bundling technology and to engage with suppliers who can offer customized solutions to meet their specific needs. The future of efficient packaging is here—embrace it to stay ahead in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.