The Definitive Guide to Push Pull Cable: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for push pull cable

Navigating the global market for push-pull cables presents a unique challenge for international B2B buyers seeking reliable and efficient control solutions. With applications spanning across industries such as automotive, aerospace, and heavy machinery, sourcing the right push-pull cable requires a thorough understanding of product specifications, supplier capabilities, and regional compliance standards. This guide aims to equip businesses from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Germany—with the insights necessary to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore the various types of push-pull cables available, their specific applications, and key factors to consider when selecting the ideal solution for your needs. Additionally, we will provide valuable information on vetting suppliers, assessing cost-effectiveness, and understanding market trends that may impact your procurement strategy. By leveraging this guide, B2B buyers can navigate the complexities of the global push-pull cable market, ensuring they select high-quality products that enhance operational efficiency and reliability in their applications. Embrace the opportunity to streamline your sourcing process and elevate your business operations with the right push-pull cable solutions.

Understanding push pull cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Push-Pull Cable | Basic design, primarily for pull applications | Automotive, machinery controls | Pros: Cost-effective, simple installation. Cons: Limited in push applications. |

| Cablecraft® Push-Pull | Enhanced durability, supports both push and pull functions | Aerospace, military vehicles, heavy machinery | Pros: High strength, customizable. Cons: Higher cost compared to standard cables. |

| Pull-Only Control Cable | Designed exclusively for pull operations, often with springs | Bicycles, light machinery | Pros: Lightweight, easy to install. Cons: Not suitable for push applications. |

| Multi-Axis Control Cable | Allows for complex movements in multiple directions | Robotics, advanced machinery | Pros: Versatile control options. Cons: More complex installation and higher costs. |

| Custom Push-Pull Cable | Tailored specifications for unique applications | OEMs, specialized machinery | Pros: Perfect fit for specific needs. Cons: Longer lead times and potentially higher costs. |

What are the Characteristics of Standard Push-Pull Cables?

Standard push-pull cables feature a straightforward design primarily focused on pull operations. They are often utilized in automotive and machinery controls where a simple mechanism is sufficient. These cables are cost-effective and easy to install, making them an attractive option for businesses looking for basic functionality. However, their limitations in push applications may necessitate additional solutions for more complex systems.

How Do Cablecraft® Push-Pull Cables Stand Out?

Cablecraft® push-pull cables are engineered for durability and versatility, accommodating both push and pull functions. This makes them ideal for industries such as aerospace and military, where reliability is critical. The ability to customize these cables enhances their appeal, allowing businesses to tailor them to specific requirements. While they offer superior performance, the increased cost may be a consideration for budget-conscious buyers.

What are the Applications of Pull-Only Control Cables?

Pull-only control cables are specifically designed for applications that require pulling action, such as in bicycles and light machinery. These cables often incorporate springs to return to a neutral position when not in use, providing a responsive control experience. Their lightweight construction makes them easy to install, but their limitation to pull functions can restrict their applicability in more complex systems.

What Benefits Do Multi-Axis Control Cables Provide?

Multi-axis control cables are designed for applications requiring intricate movements in multiple directions, making them suitable for robotics and advanced machinery. They offer versatility in control, allowing operators to manage complex tasks with precision. However, their installation can be more complicated, and the higher costs may deter some buyers from investing in these advanced solutions.

Why Consider Custom Push-Pull Cables for Specialized Applications?

Custom push-pull cables are tailored to meet the unique needs of specific applications, making them ideal for original equipment manufacturers (OEMs) and specialized machinery. They ensure a perfect fit and optimal performance, addressing particular operational requirements. However, the longer lead times and potentially higher costs associated with custom solutions should be considered in the purchasing decision.

Key Industrial Applications of push pull cable

| Industry/Sector | Specific Application of Push Pull Cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Throttle and control systems for aircraft | Ensures precise control and safety in flight operations | High strength, corrosion resistance, and compliance with aviation standards |

| Automotive | Transmission and brake control systems | Enhances vehicle performance and safety during operation | Durability under extreme conditions, flexibility for installation |

| Heavy Machinery | Control mechanisms in cranes and excavators | Improves operational efficiency and reliability in tough environments | Customization for specific machinery, resistance to wear and tear |

| Marine | Steering and throttle controls in boats | Provides reliable control in marine environments | Resistance to saltwater corrosion, flexibility in design |

| Military | Actuation systems for ground vehicles like tanks | Critical for operational effectiveness and quick responsiveness | Robustness under harsh conditions, compliance with military specifications |

How is Push Pull Cable Used in Aerospace Applications?

In the aerospace sector, push pull cables are integral to throttle and control systems, facilitating the precise maneuvering of aircraft. These cables must meet stringent safety and durability standards due to the high-stakes environment in which they operate. Buyers from regions such as Europe and the Middle East should ensure that the cables have high tensile strength and corrosion resistance to withstand various atmospheric conditions. Compliance with aviation regulations is paramount, necessitating thorough documentation and certification during procurement.

What Role Does Push Pull Cable Play in Automotive Systems?

In the automotive industry, push pull cables are employed in transmission and brake control systems, crucial for the vehicle’s performance and safety. They allow for smooth gear shifts and responsive braking, enhancing the driving experience. For international buyers, especially in emerging markets in Africa and South America, sourcing durable cables that can handle diverse road conditions and temperatures is essential. Additionally, flexibility in design allows for easier integration into various vehicle models.

Why are Push Pull Cables Important in Heavy Machinery?

Heavy machinery relies on push pull cables for control mechanisms in cranes and excavators, ensuring efficient operation in demanding environments. These cables must be robust and resistant to wear and tear, as they often face heavy loads and harsh conditions. Buyers should consider customization options to match specific machinery requirements, ensuring that the cables can endure the operational stresses without compromising safety or performance.

How Do Push Pull Cables Enhance Marine Operations?

In the marine industry, push pull cables are vital for steering and throttle controls, providing reliable operation in challenging marine environments. These cables must be resistant to saltwater corrosion and designed for flexibility to accommodate various boat designs. International buyers need to prioritize sourcing cables that meet marine industry standards and can withstand the rigors of oceanic conditions, ensuring longevity and reliability.

What is the Military Application of Push Pull Cables?

Military applications utilize push pull cables for actuation systems in ground vehicles, such as tanks. These cables are essential for quick responsiveness and operational effectiveness in combat situations. Buyers in this sector must ensure that the cables are robust enough to withstand extreme conditions and comply with military specifications. The ability to customize cables for specific vehicle models and operational requirements is also critical for effective procurement.

3 Common User Pain Points for ‘push pull cable’ & Their Solutions

Scenario 1: High Failure Rates in Harsh Environments

The Problem: Many B2B buyers face the challenge of push-pull cables failing prematurely in harsh environments, such as those found in heavy machinery or outdoor applications. This can be particularly problematic in regions with extreme temperatures, moisture, or dust, where standard cables may not withstand the rigors of operation. The resulting downtime not only affects productivity but can also lead to costly repairs and replacement, ultimately impacting the bottom line.

The Solution: To mitigate this issue, it is crucial for buyers to select push-pull cables specifically designed for harsh conditions. Sourcing cables with corrosion-resistant materials, such as stainless steel or galvanized steel, is essential. Additionally, opting for cables that feature robust seals to prevent moisture and dust ingress will enhance durability. Buyers should also consider the environment in which the cables will operate and request custom designs if necessary, ensuring that the cables can handle specific load requirements and bend radii. Working with experienced suppliers who understand these environmental factors will enable companies to make informed decisions that boost the longevity of their push-pull cable systems.

Scenario 2: Difficulty in Sourcing Custom Cable Lengths

The Problem: Another prevalent issue is the difficulty buyers encounter when needing custom lengths of push-pull cables for specific applications. Off-the-shelf solutions may not fit perfectly, leading to inefficient operation or installation challenges. This lack of customization can frustrate project timelines and lead to suboptimal performance in the final product.

The Solution: Buyers should seek suppliers that specialize in custom cable manufacturing, ensuring they can accommodate unique length requirements without sacrificing quality. When placing orders, it’s vital to provide detailed specifications regarding the application, including desired length, flexibility, and intended load. Engaging in thorough discussions with suppliers about the intended use can lead to recommendations for the most suitable materials and designs. Additionally, consider suppliers with quick turnaround times for custom orders, enabling companies to maintain project schedules and avoid delays.

Scenario 3: Inadequate Technical Support and Guidance

The Problem: Many buyers experience frustration due to inadequate technical support when selecting and implementing push-pull cables. This lack of guidance can lead to improper installation, incorrect specifications, and ultimately, system failures. For industries relying heavily on precision and reliability, such as aerospace or automotive, this can pose significant risks.

The Solution: To address this concern, buyers should prioritize partnerships with suppliers that offer comprehensive technical support and engineering expertise. This includes access to resources such as detailed product catalogs, installation guides, and responsive customer service teams. When engaging with a supplier, inquire about their ability to provide pre-sales consultations to discuss specific needs and potential challenges. Additionally, some suppliers offer training sessions or detailed documentation that can help teams understand the nuances of cable installation and maintenance. By fostering a collaborative relationship with suppliers, businesses can ensure they receive the guidance necessary for optimal cable performance and reliability.

Strategic Material Selection Guide for push pull cable

What Are the Key Materials Used in Push-Pull Cables?

When selecting materials for push-pull cables, it’s crucial to understand the properties, advantages, and limitations of various materials. The choice of material can significantly influence the cable’s performance, durability, and suitability for specific applications across diverse industries.

How Does Stainless Steel Affect Push-Pull Cable Performance?

Stainless steel is a popular choice for push-pull cables due to its excellent corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for applications in harsh environments, such as marine or aerospace settings. The key properties of stainless steel include a temperature rating of up to 800°F (427°C) and high tensile strength.

Pros: Stainless steel offers exceptional durability and longevity, which reduces maintenance costs over time. Its resistance to rust and corrosion makes it ideal for outdoor or humid environments.

Cons: The primary drawback is its higher cost compared to other materials like galvanized steel. Additionally, manufacturing processes for stainless steel cables can be more complex, potentially leading to longer lead times.

For international buyers, particularly in regions like Europe and the Middle East, compliance with standards such as ASTM A313 or DIN 17440 is essential to ensure quality and performance.

What Role Does Galvanized Steel Play in Push-Pull Cables?

Galvanized steel is another common material used in push-pull cables, known for its cost-effectiveness and strength. The galvanization process involves coating the steel with zinc to enhance corrosion resistance. This material typically has a temperature rating of around 400°F (204°C).

Pros: Galvanized steel is less expensive than stainless steel, making it a budget-friendly option for many applications. It also provides adequate strength for various industrial uses.

Cons: While galvanized steel is resistant to corrosion, it is not as durable as stainless steel in harsh environments. Over time, the zinc coating can wear off, exposing the steel to rust.

International buyers should consider the specific environmental conditions where the cables will be used, as galvanized steel may not be suitable for highly corrosive environments, particularly in coastal regions.

How Do Plastic Materials Impact Push-Pull Cable Applications?

Plastic materials, such as nylon or polyethylene, are increasingly used in push-pull cables, especially in applications requiring flexibility and lightweight solutions. These materials can withstand a temperature range of -40°F to 200°F (-40°C to 93°C).

Pros: The primary advantage of plastic is its lightweight nature, which reduces the overall weight of the assembly. Additionally, plastics are resistant to many chemicals and offer good insulation properties.

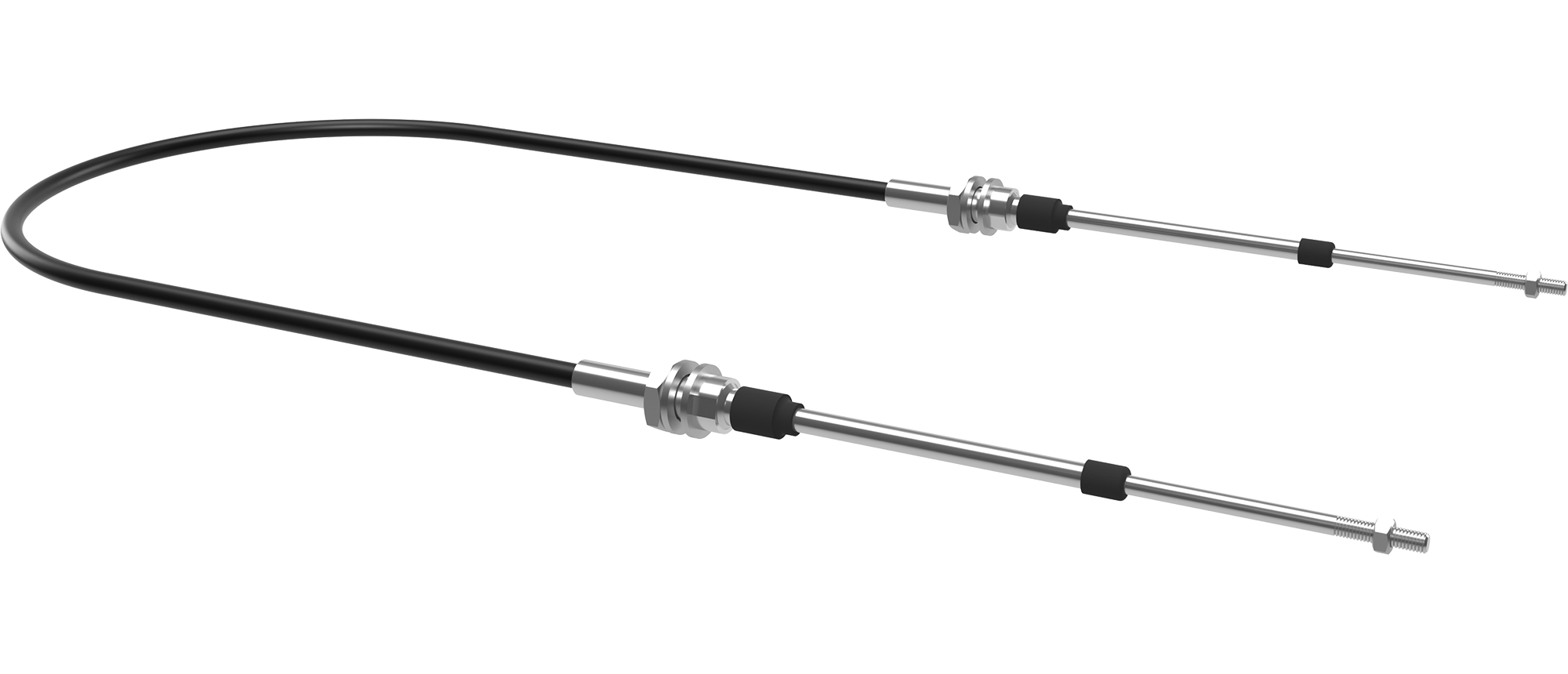

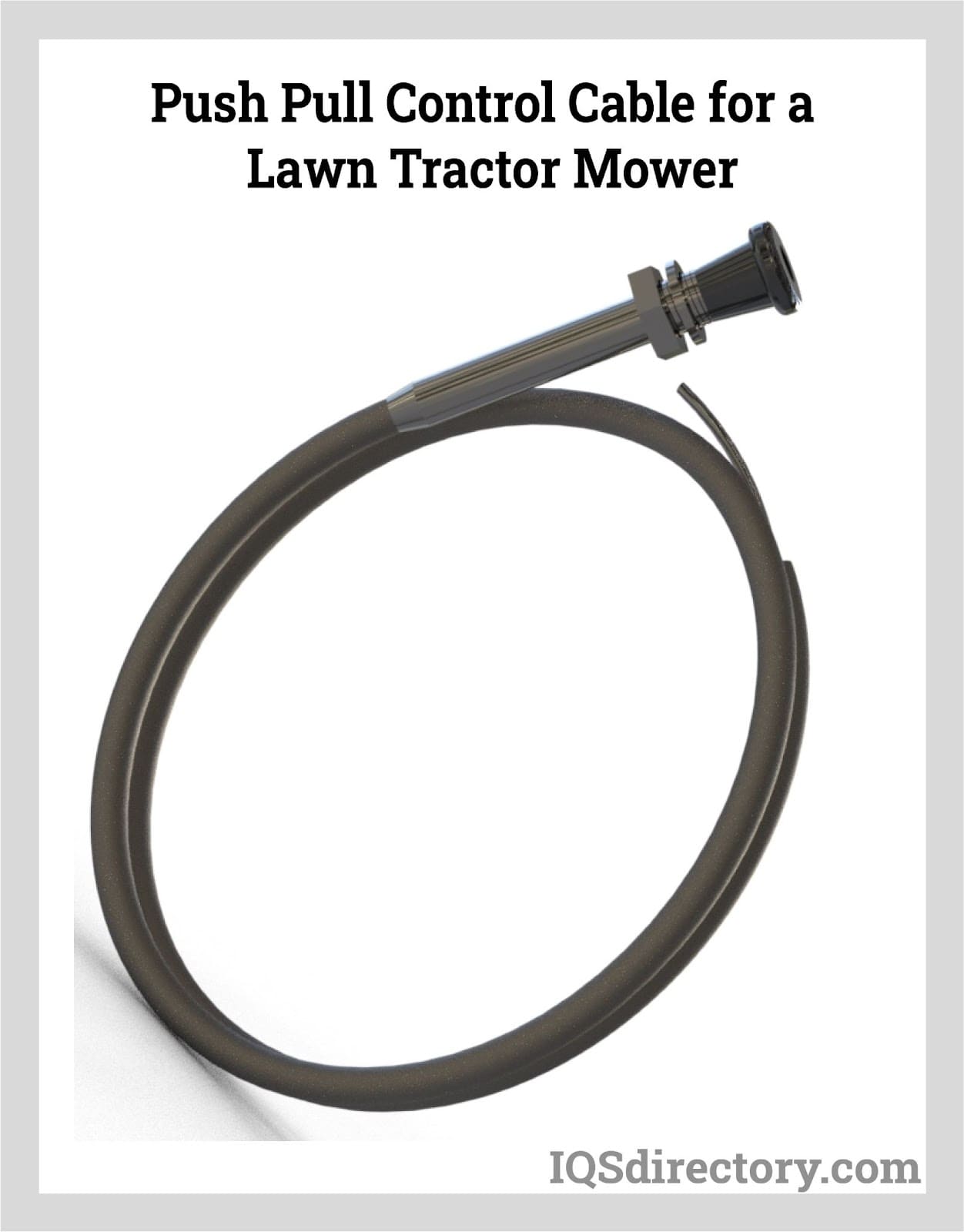

Illustrative image related to push pull cable

Cons: Plastic materials may not provide the same strength and durability as metals, limiting their use in high-load applications. They are also more susceptible to UV degradation and may require additional protective measures in outdoor applications.

For international buyers, understanding the chemical compatibility of plastics with specific media is crucial, especially in industries like chemical processing.

What Benefits Does Composite Material Offer for Push-Pull Cables?

Composite materials, often a combination of plastic and metal, provide a balanced approach to performance and cost. These materials can be engineered to meet specific requirements, such as enhanced strength or flexibility.

Illustrative image related to push pull cable

Pros: Composites can offer significant weight savings while maintaining structural integrity. They are also customizable, allowing for tailored solutions for unique applications.

Cons: The complexity of manufacturing composite materials can lead to higher costs and longer production times. Additionally, the performance of composites can vary widely based on the specific formulation used.

International buyers should be aware of the varying regulations regarding composites in different regions, as compliance with standards like JIS or ASTM may be necessary for certain applications.

Illustrative image related to push pull cable

Summary Table of Material Selection for Push-Pull Cables

| Material | Typical Use Case for push pull cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace, Marine | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | Heavy machinery, Automotive | Cost-effective and strong | Less durable in harsh environments | Medium |

| Plastic | Consumer products, Light machinery | Lightweight and flexible | Limited strength and UV susceptibility | Low |

| Composite | Custom applications, Aerospace | Customizable and weight-saving | Higher costs and variable performance | Medium to High |

This table provides a concise overview of the key materials used in push-pull cables, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for push pull cable

What Are the Main Stages in the Manufacturing Process of Push-Pull Cables?

The manufacturing process for push-pull cables involves several critical stages, each designed to ensure the final product meets the specific demands of various applications. Understanding these stages helps B2B buyers assess the quality and reliability of their suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage involves selecting high-quality raw materials, typically stainless steel or galvanized steel for the inner cable, and various synthetic materials for the conduit. The inner cable must be flexible yet strong enough to withstand significant tension and compression. After material selection, the raw materials undergo processes such as cutting, cleaning, and sometimes pre-coating for corrosion resistance. This preparation is vital as it sets the foundation for the cable’s longevity and performance.

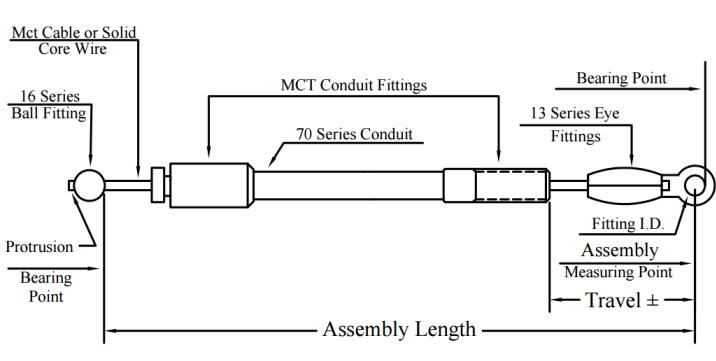

Forming: What Techniques Are Used to Shape and Configure Cables?

Once the materials are prepared, the next step is forming. This stage involves the precise manufacturing of the inner cable and the conduit. Techniques such as wire drawing are employed to produce the desired diameter of the inner cable. Following this, the conduit is formed, ensuring it has a smooth inner liner to facilitate the movement of the cable. Various conduit designs, including rigid and flexible types, are created based on application requirements. This customization is crucial, especially for industries like aerospace and automotive, where specific performance criteria must be met.

Assembly: How Are Components Brought Together?

The assembly stage integrates all components, including the inner cable, conduit, end fittings, and seals. This is typically done using swaging techniques, which involve deforming the metal to create a strong connection. The assembly must be done in a controlled environment to prevent contamination. Additionally, seals are installed to protect against dust and moisture, which is particularly important for applications in harsh environments.

Finishing: What Processes Ensure the Cable Meets Quality Standards?

Finishing processes may include additional coatings or treatments to enhance corrosion resistance and improve aesthetics. The cables are often lubricated to ensure smooth operation. This stage may also involve additional assembly components such as adjustment nuts and end caps, which are customized based on specific customer requirements.

What Quality Assurance Measures Are In Place for Push-Pull Cables?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets both international and industry-specific standards. For B2B buyers, understanding these QA measures is crucial for selecting reliable suppliers.

Illustrative image related to push pull cable

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of push-pull cables often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards assures buyers that the manufacturing processes are consistent and meet customer requirements. Additionally, industry-specific standards like CE marking for European markets and API standards for oil and gas applications may also apply, depending on the cable’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified requirements before production begins. It includes inspections of material certifications and physical properties.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to catch defects as they occur. Techniques such as visual inspections and measurements are common, ensuring that each stage meets predefined specifications.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted. This may include functional testing of the cables, tensile strength tests, and dimensional checks to ensure the product is ready for shipment.

What Testing Methods Are Commonly Used in Quality Assurance?

Testing methods for push-pull cables vary based on application requirements but commonly include:

-

Tensile Testing: This evaluates the maximum load the cable can handle before breaking, which is essential for safety-critical applications.

-

Flex Testing: Cables are bent repeatedly to assess their durability and flexibility over time, mimicking real-world usage conditions.

-

Environmental Testing: Cables may undergo tests to evaluate their performance in extreme temperatures, humidity, and exposure to corrosive substances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should adopt a proactive approach to verify the quality control practices of potential suppliers. Here are some methods to consider:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality management systems. This is an effective way to assess compliance with international standards.

-

Quality Assurance Reports: Requesting detailed QC reports can help buyers understand the testing methods and results. These reports should outline any defects found and corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspectors to evaluate the manufacturing process can provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several nuances to consider:

-

Regulatory Compliance: Understanding local regulations and how they align with international standards is vital. For instance, CE marking is essential for products sold in Europe, while different certifications may apply in other regions.

-

Cultural Differences in Quality Expectations: Be aware that quality expectations may vary across cultures. Engaging in open communication with suppliers can help bridge any gaps in understanding.

-

Logistics and Supply Chain Considerations: Quality control doesn’t end at the factory. Consider how the cables will be transported and whether additional testing is necessary upon arrival to ensure they meet specifications.

By comprehensively understanding the manufacturing processes and quality assurance measures for push-pull cables, B2B buyers can make informed decisions that ensure they procure high-quality products suitable for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘push pull cable’

Introduction

Navigating the procurement process for push-pull cables can be complex, especially for international B2B buyers in diverse industries. This guide provides a structured checklist to help you identify and source the right push-pull cables tailored to your specific application needs. By following these steps, you can streamline your purchasing process and ensure that you select high-quality products that meet your operational requirements.

Step 1: Define Your Technical Specifications

Before starting your procurement process, it is essential to outline the technical specifications of the push-pull cables you need. This includes understanding the operating environment, load requirements, and the specific application for which the cables will be used.

- Application Type: Are the cables for automotive, aerospace, or heavy machinery use?

- Environmental Conditions: Consider factors such as corrosion resistance, temperature extremes, and exposure to moisture or dust.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers with a track record of providing high-quality push-pull cables. Look for suppliers who specialize in the type of cable you require and have experience in your industry.

- Industry Experience: Suppliers with experience in your specific sector are more likely to understand your unique requirements.

- Product Range: Ensure the supplier offers a variety of options, including custom solutions tailored to your needs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and compliance standards that align with your industry requirements. This step is crucial for ensuring product quality and safety.

- Quality Assurance: Look for certifications such as ISO 9001, which indicate adherence to quality management systems.

- Industry Standards: Ensure compliance with any specific industry standards applicable to your application, such as aerospace or automotive standards.

Step 4: Request Samples and Technical Data

Before making a purchase, request samples or detailed technical data sheets from your shortlisted suppliers. This allows you to evaluate the quality and suitability of their products for your specific applications.

- Sample Evaluation: Test the samples under real operating conditions to assess performance.

- Technical Specifications: Review the provided data sheets for information on material properties, load limits, and installation guidelines.

Step 5: Assess Customization Options

Determine if the supplier can provide customization options based on your unique requirements. Custom cables may be necessary for specific applications, and the ability to tailor products can be a significant advantage.

Illustrative image related to push pull cable

- Design Flexibility: Check if the supplier can accommodate design modifications, such as different lengths, materials, or end fittings.

- Manufacturing Capabilities: Ensure they have the capacity to produce custom cables without significant delays.

Step 6: Compare Pricing and Terms

Once you’ve identified potential suppliers and evaluated their offerings, compare pricing and contractual terms. Look beyond just the initial cost to understand the total value provided.

- Total Cost of Ownership: Consider factors like durability, warranty, and after-sales support in your pricing analysis.

- Payment Terms: Review payment options and terms to ensure they align with your budget and cash flow needs.

Step 7: Finalize the Purchase and Establish Communication

After selecting a supplier, finalize your order and establish clear lines of communication. This ensures that any issues can be promptly addressed and that you remain informed throughout the delivery process.

- Order Confirmation: Confirm all specifications, delivery dates, and payment terms in writing.

- Ongoing Support: Establish a point of contact for any future inquiries or support needs.

By following this structured checklist, you can effectively navigate the sourcing process for push-pull cables and secure the best solutions for your operational needs.

Comprehensive Cost and Pricing Analysis for push pull cable Sourcing

When sourcing push-pull cables, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis breaks down the critical components and influencers that affect pricing, providing actionable insights for effective procurement.

What Are the Key Cost Components in Push-Pull Cable Manufacturing?

The cost structure of push-pull cables can be categorized into several key components:

-

Materials: The choice of materials significantly impacts cost. Common materials include galvanized steel for strength and corrosion resistance, stainless steel for marine applications, and various conduit designs that influence flexibility and durability. High-quality materials may increase initial costs but can reduce long-term maintenance expenses.

-

Labor: Labor costs vary by region and complexity of the cable assembly. Skilled labor is required for custom manufacturing, which can increase costs. In regions with higher labor costs, such as parts of Europe, buyers might see higher pricing compared to countries with lower wage structures.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Overhead costs are often distributed across all products, making it crucial for buyers to consider how this impacts the pricing of push-pull cables.

-

Tooling: The initial setup for manufacturing push-pull cables can be significant, particularly for custom designs. Tooling costs are usually amortized over production runs, so larger orders can help spread these costs, reducing the price per unit.

-

Quality Control (QC): Ensuring the reliability of push-pull cables is paramount, especially in critical applications like aerospace and automotive sectors. Implementing rigorous QC processes adds to the overall cost but is essential for maintaining product integrity.

-

Logistics: Shipping costs can vary widely based on the destination and shipping method. International buyers must factor in customs duties and shipping times, which can affect the overall procurement budget.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on competition, demand, and the perceived value of the product.

How Do Price Influencers Affect Push-Pull Cable Costs?

Several factors can influence pricing, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract discounts due to economies of scale. Buyers should negotiate MOQs to ensure they receive competitive pricing.

-

Specifications and Customization: Custom push-pull cables tailored for specific applications may incur higher costs due to unique material requirements or design complexities. Clear communication of specifications can help in obtaining accurate quotes.

-

Quality and Certifications: Products that meet industry-specific certifications (e.g., ISO, ASTM) may command higher prices. Buyers should weigh the benefits of certified products against potential cost savings from non-certified alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more but can offer greater assurance of product performance.

-

Incoterms: The terms of shipping can significantly affect total costs. Understanding Incoterms can help buyers manage risks associated with shipping and customs processes.

What Tips Can Help Buyers Negotiate Better Prices for Push-Pull Cables?

-

Leverage Total Cost of Ownership (TCO): While initial pricing is important, consider the TCO, which includes maintenance, durability, and replacement costs. Investing in higher-quality cables may lead to long-term savings.

-

Negotiate Wisely: Engage in discussions about pricing, especially when placing large orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Research Market Trends: Stay informed about market conditions and pricing trends in the push-pull cable industry. This knowledge can empower negotiations and help identify the best times to purchase.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and potential collaboration on custom projects.

-

Understand Regional Differences: For buyers in Africa, South America, the Middle East, and Europe, being aware of regional variations in pricing and logistics can aid in making informed sourcing decisions.

Disclaimer for Indicative Prices

It is essential to note that prices for push-pull cables can vary widely based on the aforementioned factors and may change over time. Buyers should obtain quotes from multiple suppliers to ensure competitive pricing and assess the total costs involved in their procurement process.

Alternatives Analysis: Comparing push pull cable With Other Solutions

Exploring Alternatives to Push-Pull Cables: A Comparative Analysis

In various industrial applications, the choice of control mechanism is crucial for efficiency and effectiveness. While push-pull cables have established themselves as reliable solutions for precise control, it’s essential to consider alternative technologies that may better suit specific applications. This analysis will compare push-pull cables with two viable alternatives: electric actuators and pneumatic controls.

| Comparison Aspect | Push Pull Cable | Electric Actuator | Pneumatic Control |

|---|---|---|---|

| Performance | High precision in control | Quick response, programmable | Fast, but less precise |

| Cost | Generally low initial cost | Higher upfront costs | Moderate costs, variable |

| Ease of Implementation | Simple installation | Requires electrical setup | Requires compressed air setup |

| Maintenance | Low maintenance needs | Moderate, depends on use | Regular maintenance needed |

| Best Use Case | Mechanical systems, vehicles | Robotics, automated systems | Industrial applications, machinery |

In-depth Analysis of Alternatives

Electric Actuators

Electric actuators convert electrical energy into mechanical motion. They are ideal for applications requiring precise control and programmability. Their quick response times make them suitable for automated systems, such as robotics and conveyor systems. However, they come with higher upfront costs and require careful electrical setup, which can complicate installation. Additionally, while they are reliable, the maintenance needs can be moderate, depending on the operational environment and usage frequency.

Pneumatic Controls

Pneumatic controls utilize compressed air to create motion. They excel in applications that require rapid action and can handle heavier loads, making them popular in industrial machinery. Pneumatic systems are generally faster than push-pull cables but can lack the precision that mechanical cables provide. The initial cost is moderate, but ongoing maintenance is necessary to ensure the system’s integrity and efficiency. Furthermore, pneumatic controls require a reliable compressed air source, which can be a logistical challenge in some settings.

Making the Right Choice for Your Application

When selecting a control mechanism, B2B buyers must consider their specific application requirements, including the environment, the required precision of control, and budget constraints. Push-pull cables are excellent for mechanical systems where reliability and simplicity are key. Electric actuators offer advanced control for automated processes but at a higher cost, while pneumatic controls provide speed and power but demand careful maintenance and air supply management.

Ultimately, the choice between push-pull cables and their alternatives hinges on a thorough assessment of operational needs, budget, and long-term maintenance capabilities. By weighing these factors, buyers can select the most effective solution that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for push pull cable

What Are the Key Technical Properties of Push-Pull Cables?

When selecting push-pull cables for industrial applications, understanding their technical properties is crucial for ensuring performance and longevity. Here are some critical specifications:

1. Material Grade

Push-pull cables are typically constructed from materials like galvanized steel, stainless steel, or plastic composites. The choice of material affects strength, flexibility, and resistance to corrosion. For instance, stainless steel is ideal for marine environments due to its high resistance to rust, making it suitable for applications in humid or saline conditions. B2B buyers should consider the operating environment when selecting materials to avoid premature failure.

2. Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. For push-pull cables, tight tolerances ensure that the cable fits perfectly within its housing, preventing snagging and wear. This is especially important in applications requiring precision, such as aerospace or automotive systems. Buyers should specify tolerances in their order to guarantee compatibility with existing components.

3. Load Capacity

Load capacity indicates the maximum load a cable can handle before failing. It is essential to assess the forces that will act on the cable during operation. Exceeding the load capacity can lead to cable failure, resulting in costly downtime and potential safety hazards. B2B buyers must evaluate their application requirements to select a cable with an appropriate load rating.

4. Flexibility and Bend Radius

Flexibility measures how easily a cable can bend without compromising its integrity. The minimum bend radius is the smallest radius the cable can bend without kinking or breaking. In applications with tight spaces or frequent movement, flexibility is vital to ensure smooth operation. Buyers should consider the installation layout and movement patterns when assessing flexibility.

5. End Fittings and Accessories

End fittings, such as threaded rods or clevis ends, play a critical role in how the cable interfaces with the machinery. Proper end fittings ensure secure connections and allow for easier adjustments. Additionally, accessories like seals and protective covers can enhance the cable’s lifespan by preventing moisture and debris ingress. Understanding the requirements for end fittings is essential for a successful installation.

What Are Common Trade Terms Related to Push-Pull Cables?

Navigating the B2B landscape requires familiarity with specific terminology. Here are some common trade terms related to push-pull cables:

1. OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. In the context of push-pull cables, OEMs often require custom cable assemblies tailored to their specifications. Understanding OEM relationships can help buyers ensure compatibility and quality in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For push-pull cables, MOQs can vary significantly based on customization and material specifications. Buyers should be aware of MOQs to plan their procurement strategies effectively and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When seeking push-pull cables, submitting an RFQ helps buyers compare prices and terms from multiple suppliers. A well-prepared RFQ should include details such as material specifications, dimensions, and required certifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is essential for B2B transactions involving push-pull cables, as they dictate who bears the risk and cost during transportation. Familiarity with these terms can prevent misunderstandings and disputes.

5. Custom Cable Assemblies

Custom cable assemblies refer to cables specifically designed and manufactured to meet unique specifications. This may include alterations in length, material, or configuration. Buyers often require custom solutions to fit specific operational needs, making it crucial to communicate these requirements clearly to suppliers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring push-pull cables, ensuring their applications function smoothly and efficiently.

Navigating Market Dynamics and Sourcing Trends in the push pull cable Sector

What Are the Current Market Dynamics and Key Trends Affecting Push-Pull Cable Sourcing?

The push-pull cable market is experiencing significant growth, driven by advancements in technology and increasing demand across various industries, including automotive, aerospace, and heavy machinery. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia), are increasingly seeking high-performance cable solutions that offer reliability and precision. One of the key trends is the shift towards customization; suppliers are increasingly able to provide tailored solutions that meet specific application requirements. This trend is particularly relevant for industries such as automotive, where performance standards are continually evolving.

Moreover, the integration of smart technology into push-pull systems is on the rise. Features such as sensors and electronic controls are enhancing the functionality of traditional cable systems, making them more efficient and user-friendly. Buyers are advised to stay abreast of these technological advancements to ensure they are sourcing the most effective solutions. Additionally, global supply chain dynamics, influenced by geopolitical factors and the ongoing impact of the COVID-19 pandemic, are prompting buyers to diversify their supplier base. This diversification mitigates risks and ensures a stable supply of high-quality components.

How Can Sustainability and Ethical Sourcing Influence Push-Pull Cable Purchases?

Sustainability is increasingly becoming a focal point for B2B buyers in the push-pull cable sector. The environmental impact of production processes and materials used in cable manufacturing is under scrutiny, making it essential for companies to consider eco-friendly options. Buyers should prioritize suppliers that offer ‘green’ certifications and use sustainable materials in their products. For instance, cables made from recycled materials or those that utilize environmentally friendly coatings can significantly reduce the carbon footprint associated with production.

Ethical sourcing is equally important, as companies are now expected to ensure that their supply chains adhere to fair labor practices and environmental regulations. This consideration not only helps in building brand reputation but also meets the growing consumer demand for responsible business practices. Buyers should engage with manufacturers that are transparent about their sourcing processes and are willing to provide documentation on the ethical standards they uphold.

What Is the Brief History of Push-Pull Cable Technology Relevant to Current B2B Buyers?

The evolution of push-pull cable technology can be traced back to the early 20th century, with initial applications in the automotive industry for throttle controls. Over the decades, the technology has advanced significantly, incorporating materials and design innovations that enhance durability and performance. The introduction of high-strength steel and corrosion-resistant coatings in the 1980s marked a turning point, allowing for broader applications in diverse sectors like aerospace and military.

Today, push-pull cables are integral to numerous control systems, reflecting their versatility and reliability. As international buyers seek cutting-edge solutions, understanding the historical context of these cables provides valuable insights into their development and potential future trends. The continuous adaptation of push-pull cables to meet modern demands highlights the importance of sourcing from manufacturers that are committed to innovation and quality.

Frequently Asked Questions (FAQs) for B2B Buyers of push pull cable

-

How do I select the right push-pull cable for my application?

Selecting the right push-pull cable requires a thorough understanding of your application’s specific needs. Consider factors such as the operating environment (e.g., exposure to moisture or chemicals), load requirements (how much force the cable will need to withstand), and flexibility (the cable’s path and minimum bend radius). Additionally, assess the required end fittings and whether customizations are necessary for your control scheme. Collaborating with a knowledgeable supplier can help ensure you choose a cable that meets all operational demands effectively. -

What types of industries commonly use push-pull cables?

Push-pull cables are utilized across various industries, including automotive, aerospace, military, heavy machinery, and marine applications. In the automotive sector, they control functions like throttle and transmission systems. Aerospace applications may include landing gear and control surfaces. Understanding the specific needs and requirements of your industry is crucial when sourcing these cables, as each application has unique operational challenges and standards. -

Can I customize push-pull cables to meet specific requirements?

Yes, many manufacturers offer extensive customization options for push-pull cables. Customizations can include variations in length, diameter, material (such as stainless steel for corrosion resistance), and end fittings tailored to specific applications. When discussing your needs with suppliers, be clear about the operational environment and any particular features required, such as flexibility or load capacity. This ensures the final product aligns perfectly with your project specifications. -

What is the minimum order quantity (MOQ) for push-pull cables?

Minimum order quantities for push-pull cables can vary significantly between suppliers. Generally, MOQs may range from a few units for standard cables to larger quantities for custom designs. It is advisable to inquire directly with potential suppliers about their MOQ policies, especially if you are testing a new design or application. Some manufacturers may offer flexibility for smaller orders, particularly for businesses looking to establish a long-term relationship. -

What payment terms should I expect when sourcing push-pull cables internationally?

Payment terms can differ based on the supplier’s policies and your negotiation. Common options include upfront payment, partial payment upon order confirmation, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing your order to avoid any misunderstandings that could delay production or shipment. -

How can I ensure quality assurance when purchasing push-pull cables?

To ensure quality assurance, work with reputable suppliers who adhere to industry standards and certifications. Request documentation that outlines the manufacturing process, material specifications, and testing procedures. Inquire about any quality control measures they implement during production. Additionally, consider requesting sample cables for testing to confirm they meet your performance requirements before placing a larger order. -

What logistics considerations should I keep in mind when importing push-pull cables?

Logistics play a vital role in the successful importation of push-pull cables. Factors to consider include shipping methods, customs clearance, and delivery timelines. Ensure that your supplier provides clear shipping terms, including whether they handle customs documentation. It may also be beneficial to work with a freight forwarder who specializes in international shipments to navigate the complexities of logistics and ensure timely delivery. -

How do I vet potential suppliers for push-pull cables?

Vetting potential suppliers involves evaluating their reputation, product quality, and customer service. Start by checking reviews and testimonials from previous clients. Request references and inquire about their experience with the supplier. Additionally, assess their production capabilities and certifications to ensure they can meet your specifications. Establishing a clear line of communication is also essential; a responsive supplier can significantly enhance the purchasing process and address any concerns promptly.

Top 6 Push Pull Cable Manufacturers & Suppliers List

1. McMaster – Push/Pull Control Cables

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Push/Pull Control Cables, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. California Push-Pull – Custom Cables & Wire Rope Assemblies

Domain: push-pull.com

Registered: 1999 (26 years)

Introduction: California Push-Pull, Inc. specializes in custom cables and wire rope assemblies. Key products include: push & pull cables, shift controls, self-locking controls, multi-axis controls, control heads, spool valve adapters, adjustable over center-locking brake levers, accelerator controls, Unidrum lever controls, hydraulic lever systems, and various hardware and accessories. They offer cables for con…

3. CC Cables – Control and Push Pull Cables

Domain: cccables.com

Registered: 2004 (21 years)

Introduction: Control Cables, Push Pull Cables, Push Pull Control Cables, Morse, Bowden, Utility Series (3, 4, 6, 8), Quick Disconnect Series (3, HD 4), Tension PTO Mixer Race Shift, GM Clutch, Kobelt Brake Cables (1/8 PBT, 3/16 PBT), Conduit End Fittings, Strand End Fittings, Clevises, Universal Adjustable Clevises, Clips, Clamps, Springs, Trailer Systems, Light Duty Valve Control Cables (RVO, RVC, SVC), Walvo…

4. Midwest Control – Cables & Push-Pull Solutions

Domain: midwestcontrol.com

Registered: 1996 (29 years)

Introduction: Cables, Push-Pull available in various lengths and diameters. Length options include 30 inches, 36 inches, 40 inches, 48 inches, 60 inches, 72 inches, 84 inches, 96 inches, and many more up to 9000 mm. Diameters include 0.085″ and various metric sizes such as M5, M6, M8, and M10. Specific lengths available in multiple quantities.

5. JB Custom Fabrication – Heavy Duty Push/Pull Cable

Domain: jb-custom-fabrication.myshopify.com

Introduction: {‘title’: ‘Cable, Push/Pull, Heavy Duty’, ‘sku’: ‘S40-36’, ‘available_sizes’: [{‘size’: ’36” CABLE’, ‘price’: 63.0, ‘weight’: 1361}, {‘size’: ’48” CABLE’, ‘price’: 63.0, ‘weight’: 1361}, {‘size’: ’60” CABLE’, ‘price’: 65.0, ‘weight’: 1814}, {‘size’: ’72” CABLE’, ‘price’: 71.0, ‘weight’: 1588}, {‘size’: ’96” CABLE’, ‘price’: 80.0, ‘weight’: 2041}, {‘size’: ‘120″ CABLE’, ‘price’: 89.0, ‘weight’: 226…

6. Pro-Werks – Silver Jacket Ultimate Push Pull Control Cable

Domain: chassisshop.com

Registered: 1997 (28 years)

Introduction: Pro-werks Silver Jacket Ultimate Push Pull Control Cable

Strategic Sourcing Conclusion and Outlook for push pull cable

In summary, the strategic sourcing of push-pull cables is vital for businesses operating in diverse sectors such as automotive, aerospace, and heavy machinery. Understanding the nuances of these cables—including their construction, application-specific requirements, and the importance of durability—can significantly impact operational efficiency and product reliability. Businesses should prioritize sourcing high-quality, customizable solutions that cater to their specific needs, ensuring they remain competitive in their respective markets.

As international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential to engage with reliable suppliers who offer both generic and specialized push-pull cable solutions. By leveraging strategic sourcing, companies can enhance their supply chain resilience, reduce lead times, and ensure compliance with industry standards.

Looking ahead, the demand for innovative control systems is likely to grow, driven by advancements in technology and increasing automation. As you explore your options for push-pull cables, consider reaching out to reputable manufacturers and suppliers to discuss your unique requirements. Together, we can pave the way for improved performance and reliability in your applications.

Illustrative image related to push pull cable

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.