A B2B Buyer’s Guide to Drive Shaft Coupling: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for drive shaft coupling

In today’s dynamic global marketplace, sourcing reliable drive shaft couplings presents a significant challenge for B2B buyers. Companies across various industries, from manufacturing to automotive, require these critical components to ensure efficient power transmission and equipment reliability. This comprehensive guide delves into the intricacies of drive shaft couplings, exploring different types, their specific applications, and essential factors for supplier vetting.

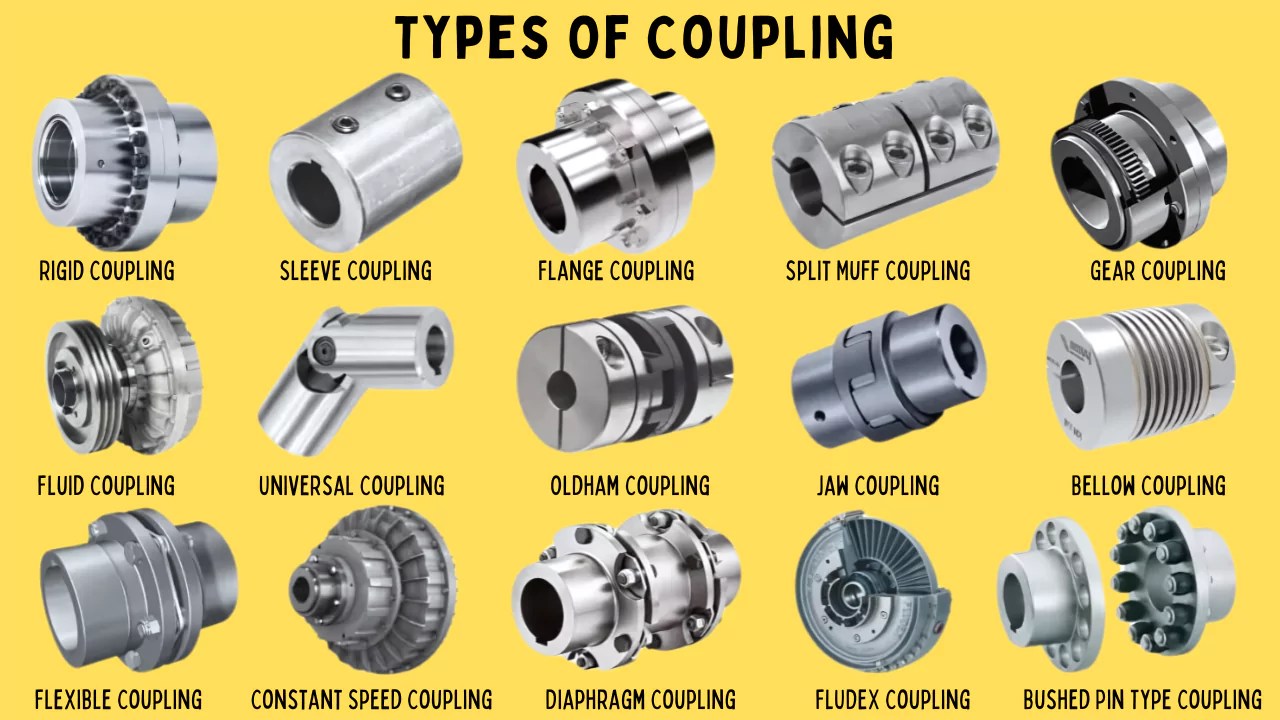

Understanding the diverse range of couplings available, including flexible, rigid, and universal joints, is crucial for making informed purchasing decisions. Additionally, we will cover cost considerations and the importance of aligning your selection with operational requirements, such as torque ratings and misalignment compensation.

For international B2B buyers from Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria, navigating the complexities of sourcing drive shaft couplings can be daunting. This guide aims to empower you with actionable insights and practical strategies to streamline your procurement process. By equipping you with the knowledge to evaluate suppliers and assess product specifications, we help ensure that your organization can confidently invest in high-quality drive shaft couplings that meet your operational needs.

Understanding drive shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Couplings | Dampen vibrations, accommodate misalignment | Manufacturing, automotive | Pros: Compensates for misalignment; reduces wear. Cons: Limited torque capacity. |

| Rigid Couplings | Transmit maximum torque with minimal damping | Robotics, precision machinery | Pros: High torque transmission; reliable for aligned systems. Cons: Cannot accommodate misalignment. |

| Universal Joints | Allow for angular misalignment between shafts | Automotive, heavy machinery | Pros: Versatile for various angles; smooth operation. Cons: More complex installation. |

| Spacer Couplings | Self-supporting design for extended lengths | Industrial machinery, conveyors | Pros: Compact and robust; accommodates axial misalignment. Cons: Requires careful alignment. |

| Precision Motion Control Couplings | Zero backlash for high-accuracy applications | Robotics, CNC machines | Pros: Ensures precise positioning; high performance. Cons: Generally more expensive. |

What Are the Characteristics of Flexible Couplings?

Flexible couplings are designed to accommodate misalignment and dampen vibrations in rotating machinery. They are commonly used in manufacturing and automotive applications where slight misalignment is inevitable. When purchasing flexible couplings, buyers should consider factors such as torque ratings, material compatibility, and the specific types of misalignment they need to accommodate. These couplings are advantageous for extending the lifespan of connected components but may have limitations in terms of torque capacity.

Illustrative image related to drive shaft coupling

How Do Rigid Couplings Differ from Other Types?

Rigid couplings are engineered to provide a solid connection between two aligned shafts, enabling maximum torque transmission with minimal vibration dampening. They are prevalent in applications requiring precise alignment, such as robotics and precision machinery. B2B buyers should focus on the torque rating and the alignment precision of their systems when selecting rigid couplings. While they provide reliable performance, they do not compensate for misalignment, which can lead to increased wear if not properly aligned.

What Makes Universal Joints a Versatile Option?

Universal joints are essential for applications where shafts are not perfectly aligned, allowing for angular misalignment between them. They are widely used in the automotive sector and heavy machinery where movement occurs at various angles. Buyers should assess the joint’s operating angles and load capacities, as well as the complexity of installation. While they offer versatility and smooth operation, universal joints can complicate maintenance due to their intricate design.

Why Choose Spacer Couplings for Industrial Applications?

Spacer couplings feature a self-supporting design that allows for longer shaft lengths without the need for additional support. This makes them ideal for use in industrial machinery and conveyor systems. When purchasing spacer couplings, consider the required torque ratings and the potential for axial misalignment. They are robust and compact, but proper alignment is crucial to avoid premature wear and failure.

What Are the Advantages of Precision Motion Control Couplings?

Precision motion control couplings are designed for applications requiring zero backlash, such as robotics and CNC machines. These couplings ensure high accuracy and performance, making them ideal for precision applications. Buyers should evaluate the coupling’s backlash specifications and torque ratings. Although they offer superior performance, precision couplings often come at a higher cost, which should be justified by the application requirements.

Key Industrial Applications of drive shaft coupling

| Industry/Sector | Specific Application of drive shaft coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to conveyor systems | Ensures efficient power transmission with minimal downtime | Torque ratings, misalignment tolerance, and material durability |

| Agriculture | Powering irrigation pumps and machinery | Enhances operational efficiency and reduces maintenance costs | Compatibility with existing equipment and environmental resistance |

| Oil & Gas | Connecting pumps and compressors in extraction and processing | Increases reliability and safety in high-stress environments | Ability to withstand extreme temperatures and pressures |

| Automotive | Linking engine components to drivetrain systems | Improves vehicle performance and reduces vibration | Precision in dimensions and material specifications |

| Mining | Connecting machinery for ore extraction and processing | Enhances durability and reduces operational failures | Heavy-duty specifications and resistance to harsh conditions |

In the manufacturing sector, drive shaft couplings are critical for connecting motors to conveyor systems, ensuring smooth and efficient power transmission. They reduce downtime by minimizing the risk of mechanical failure, which is vital for continuous production. Buyers should focus on torque ratings and misalignment tolerance to ensure compatibility with their systems.

In agriculture, these couplings are essential for powering irrigation pumps and various machinery. By enabling efficient energy transfer, they help optimize irrigation processes and reduce maintenance costs. Buyers should consider the compatibility of couplings with existing equipment and their resistance to environmental factors like moisture and dust.

The oil and gas industry utilizes drive shaft couplings to connect pumps and compressors, particularly in extraction and processing applications. These couplings enhance reliability and safety in high-stress environments, where equipment failure can lead to significant operational disruptions. Buyers must prioritize couplings that can withstand extreme temperatures and pressures, ensuring operational integrity.

In the automotive industry, drive shaft couplings link engine components to the drivetrain, improving vehicle performance and minimizing vibration. Precision in dimensions is crucial for proper fit and function, while material specifications can affect durability and performance under varying conditions. Buyers should assess the specific requirements based on vehicle types and applications.

Finally, in the mining sector, drive shaft couplings connect machinery used for ore extraction and processing. These couplings must be robust to handle heavy-duty operations, enhancing durability and reducing the likelihood of operational failures. Buyers should focus on specifications that ensure resistance to harsh conditions, including dust, moisture, and mechanical stress, to maintain productivity.

3 Common User Pain Points for ‘drive shaft coupling’ & Their Solutions

Scenario 1: Ensuring Compatibility in Diverse Applications

The Problem: A B2B buyer in a manufacturing plant often faces compatibility issues when selecting drive shaft couplings for different machinery. With various applications demanding specific torque ratings, misalignment tolerances, and material properties, it can be overwhelming to ensure that the selected coupling will perform optimally. In regions like Africa or South America, where supply chains may be less reliable, sourcing the right part can lead to significant downtime if the wrong coupling is ordered.

The Solution: To overcome compatibility challenges, it is crucial to conduct a thorough assessment of the operational requirements before sourcing drive shaft couplings. This includes analyzing the torque transmission needs, the type of misalignment (angular, parallel, or axial) present in the application, and the environmental conditions (such as temperature extremes and exposure to chemicals). Engage with suppliers who offer comprehensive technical support and can provide detailed specifications for their couplings. Furthermore, consider utilizing CAD configurators or technical guides provided by manufacturers to visualize and assess compatibility with existing systems. This proactive approach not only minimizes the risk of mismatched components but also streamlines the procurement process, ensuring the correct couplings are sourced efficiently.

Scenario 2: Dealing with Vibration and Shock Issues

The Problem: In industrial settings, excessive vibration and shock can lead to premature wear and tear of drive shaft couplings, resulting in unexpected failures and costly repairs. Buyers often struggle to identify the right coupling that can effectively dampen these vibrations while maintaining performance. This challenge is particularly pronounced in sectors like mining and construction, where heavy machinery operates under strenuous conditions, and reliability is paramount.

The Solution: Buyers should prioritize flexible couplings designed to absorb shocks and dampen vibrations. When selecting a coupling, consider those with elastomeric elements or other damping materials that can handle the specific frequency and amplitude of vibrations encountered in your application. Additionally, it is essential to evaluate the coupling’s construction and material properties for resistance to fatigue and wear. Engaging with manufacturers who provide application analysis services can help identify the right coupling type. Moreover, conducting regular maintenance checks and monitoring the condition of the couplings can preemptively address potential issues, ensuring continuous operation and reducing downtime.

Scenario 3: Reducing Installation Complexity and Time

The Problem: Installation of drive shaft couplings can often be a complex and time-consuming task, particularly in environments where space is limited or precision is required. Buyers frequently face challenges related to alignment, which can lead to additional labor costs and extended project timelines. This issue is exacerbated in regions with less access to skilled technicians, making it even more critical to simplify the installation process.

The Solution: To alleviate installation complexities, opt for couplings that are designed for quick and easy installation. Look for features such as quick-fit designs or couplings that do not require lubrication, which can save significant time during setup. Additionally, consider using couplings with integrated alignment indicators that assist in achieving optimal alignment during installation. Providing clear installation guidelines and training for technicians can also enhance efficiency. Suppliers who offer comprehensive support, including installation training or detailed manuals, can be invaluable in ensuring that your team is well-prepared. By streamlining the installation process, businesses can reduce labor costs and enhance overall operational efficiency.

Strategic Material Selection Guide for drive shaft coupling

What Are the Key Properties of Common Materials Used in Drive Shaft Couplings?

When selecting materials for drive shaft couplings, it is essential to consider the specific properties that will influence performance in various applications. Here, we analyze four common materials: steel, aluminum, rubber, and composite materials.

Steel: The Traditional Choice for Durability

Steel is one of the most widely used materials for drive shaft couplings due to its high strength and durability. It offers excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel couplings can withstand significant torque and are resistant to wear and fatigue.

Pros: Steel is highly durable, offers excellent torque transmission, and is cost-effective for large-scale manufacturing.

Cons: The primary drawbacks include susceptibility to corrosion unless treated and a relatively high weight compared to other materials.

Impact on Application: Steel couplings are ideal for applications requiring high strength and reliability, such as in industrial machinery and automotive systems. However, they may not be suitable for environments with high corrosion risk unless coated or treated.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100. In regions like Europe and the Middle East, specifications for corrosion resistance may be particularly stringent.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is increasingly popular in applications where weight savings are critical. It has a good strength-to-weight ratio and excellent corrosion resistance, making it suitable for various environments.

Pros: Lightweight, corrosion-resistant, and easy to manufacture, aluminum couplings can reduce the overall weight of machinery and improve fuel efficiency in automotive applications.

Cons: While aluminum is strong, it is not as durable as steel under high torque conditions and can be more expensive.

Impact on Application: Aluminum is ideal for lightweight applications, such as in aerospace and automotive sectors, where reducing weight is essential. However, it may not be suitable for high-torque applications without reinforcement.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM B221 and consider the availability of aluminum alloys that meet regional specifications.

Rubber: Flexible Couplings for Vibration Damping

Rubber is often used in flexible couplings due to its ability to dampen vibrations and compensate for misalignment. It is particularly effective in applications requiring shock absorption.

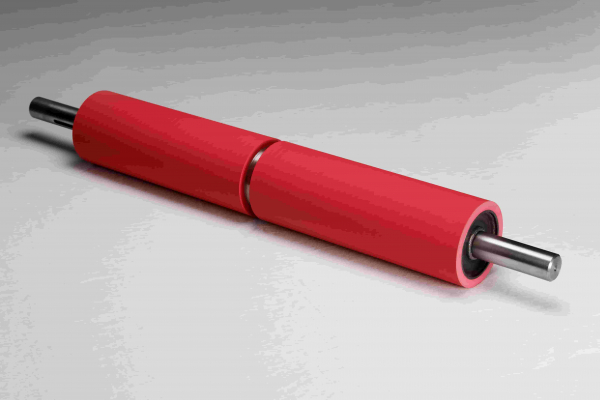

Illustrative image related to drive shaft coupling

Pros: Rubber couplings are excellent for reducing noise and vibration, making them suitable for sensitive machinery.

Cons: They have lower temperature and pressure ratings compared to metals and can degrade over time when exposed to certain chemicals or extreme temperatures.

Impact on Application: Rubber couplings are commonly used in automotive applications and machinery where vibration dampening is crucial. However, they may not be suitable for high-load applications.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 is essential, especially in regions with strict quality control measures.

Composite Materials: The Future of Lightweight Couplings

Composite materials, such as reinforced plastics, are emerging as a viable option for drive shaft couplings. They offer a unique combination of strength, lightweight properties, and corrosion resistance.

Pros: Composites can be engineered for specific applications, providing tailored performance characteristics while being lightweight.

Cons: They can be more expensive and may require specialized manufacturing processes, which can complicate supply chains.

Impact on Application: Composites are suitable for high-tech applications, including aerospace and advanced automotive systems. Their performance can be optimized for specific requirements, but they may not yet be as widely accepted in traditional industries.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards such as ASTM D638 and be aware of the specific certifications required in their region.

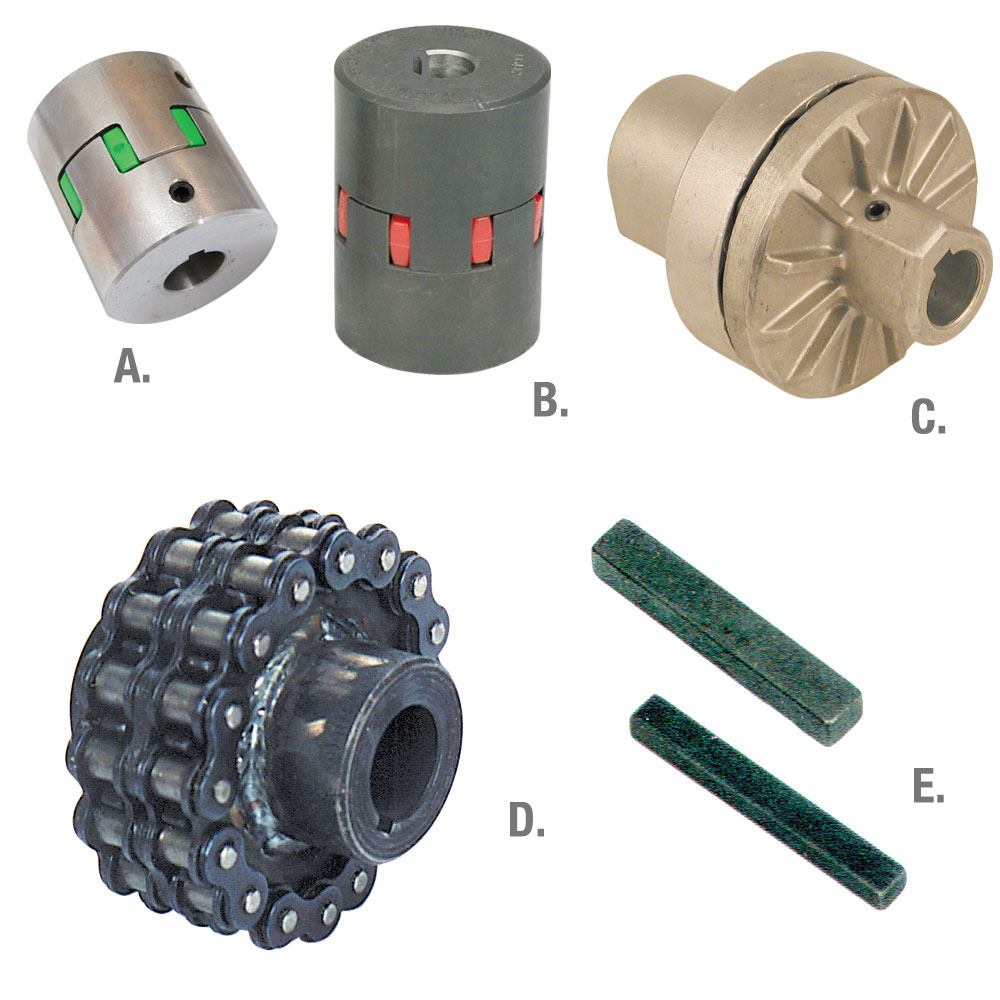

Illustrative image related to drive shaft coupling

Summary Table of Material Selection for Drive Shaft Couplings

| Material | Typical Use Case for drive shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial machinery | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower torque capacity than steel | High |

| Rubber | Automotive and machinery requiring dampening | Excellent vibration dampening | Lower temperature and pressure ratings | Low |

| Composite | Advanced automotive and aerospace systems | Tailored performance and lightweight | Higher cost and complex manufacturing | High |

This strategic material selection guide provides an overview of the key properties, pros and cons, and considerations for international B2B buyers, ensuring informed decisions in selecting the right drive shaft coupling material for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for drive shaft coupling

What Are the Key Stages in Manufacturing Drive Shaft Couplings?

The manufacturing process for drive shaft couplings is a systematic approach that ensures the final product meets rigorous performance standards. The main stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques that enhance the durability and efficiency of the couplings.

How Is Material Prepared for Drive Shaft Couplings?

Material selection is critical in the manufacturing of drive shaft couplings. Typically, high-strength alloys, such as steel or aluminum, are chosen based on their mechanical properties and compatibility with the intended application.

Illustrative image related to drive shaft coupling

-

Material Sourcing: Suppliers must provide materials that meet international standards, such as ASTM or ISO specifications. This initial verification is crucial for ensuring quality.

-

Cutting and Shaping: The raw materials are cut into appropriate sizes using precision cutting tools. Techniques such as CNC machining allow for high precision in shaping the components required for couplings.

-

Heat Treatment: Depending on the material, heat treatment processes, like annealing or quenching, may be applied to enhance the mechanical properties, such as toughness and hardness.

What Techniques Are Utilized in Forming Drive Shaft Couplings?

Forming techniques vary depending on the complexity and specifications of the coupling design. Common methods include:

-

Machining: Components are often machined to achieve precise dimensions. This can include turning, milling, and drilling operations to create features like keyways and bolt holes.

-

Forging: For high-strength applications, forging techniques may be used to shape the couplings while improving their structural integrity. This process aligns the grain structure of the metal, making it more durable.

-

Casting: In some cases, especially for complex geometries, casting methods are employed. This involves pouring molten metal into molds to create the desired shape, followed by finishing processes to achieve the final specifications.

How Are Drive Shaft Couplings Assembled?

Assembly is a crucial stage that ensures all components fit together correctly for optimal performance.

-

Component Integration: Various parts, such as hubs, elastomeric elements, and spiders, are assembled according to the design specifications. Precision in this stage is vital to prevent misalignment during operation.

-

Fastening: Bolts and nuts are used to secure the components. This step may involve torque application to ensure that the fasteners are tight enough to withstand operational stresses without damaging the components.

-

Alignment Checks: After assembly, alignment checks are performed to ensure that the couplings will function correctly under operational conditions. This is particularly important for applications with strict alignment requirements.

What Finishing Processes Are Used in Drive Shaft Coupling Production?

Finishing processes enhance the aesthetic and functional properties of drive shaft couplings. These include:

Illustrative image related to drive shaft coupling

-

Surface Treatment: Techniques such as anodizing, painting, or coating are applied to protect against corrosion and wear. For example, black oxide coatings are popular for their aesthetic appeal and protective qualities.

-

Quality Inspection: Each coupling undergoes rigorous inspection to ensure it meets specifications. This may include visual inspections, dimensional checks, and functional testing to verify performance under load.

-

Packaging: Finally, the finished couplings are carefully packaged to prevent damage during transportation. Proper packaging is essential for international shipping, ensuring that products arrive in perfect condition.

What Quality Assurance Practices Are Critical for Drive Shaft Couplings?

Quality assurance is integral to the manufacturing process of drive shaft couplings. Adherence to international standards, such as ISO 9001, ensures that manufacturers maintain a consistent quality management system.

What International Standards Should B2B Buyers Consider?

-

ISO 9001: This standard outlines criteria for a quality management system and is essential for manufacturers aiming to ensure product quality and customer satisfaction.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: In industries like oil and gas, adherence to API standards is crucial for ensuring that components can withstand harsh operational environments.

How Are Quality Control Checkpoints Established?

Quality control checkpoints throughout the manufacturing process help maintain high standards:

-

Incoming Quality Control (IQC): Inspect raw materials upon arrival to verify compliance with specifications. This step prevents defective materials from entering the production process.

-

In-Process Quality Control (IPQC): Conduct regular inspections during manufacturing to monitor adherence to specifications and identify any deviations early in the process.

-

Final Quality Control (FQC): Before shipment, a comprehensive inspection is conducted to ensure that the finished product meets all design and performance standards.

What Testing Methods Are Commonly Used in Drive Shaft Coupling Quality Assurance?

Testing methods play a crucial role in validating the performance of drive shaft couplings:

-

Torque Testing: This assesses the coupling’s ability to transmit torque without failure. It ensures that the product can handle the specified loads in real-world applications.

-

Vibration Testing: Evaluating how well the coupling performs under operational vibrations helps identify potential issues related to misalignment or imbalance.

-

Fatigue Testing: This simulates long-term use and assesses how the coupling withstands repeated loading and unloading cycles, ensuring durability over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers helps verify their compliance with quality standards. This process may include reviewing manufacturing processes, quality control measures, and product certifications.

-

Requesting Reports: Buyers should ask for detailed quality assurance reports, including testing results and compliance certifications. This documentation provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. This is particularly valuable for international transactions, where buyers may not have direct oversight.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers must navigate additional complexities in quality control:

-

Cultural and Regulatory Differences: Understanding the local regulations and standards in the supplier’s country is crucial. This knowledge helps buyers ensure compliance and avoid potential legal issues.

-

Logistical Challenges: Shipping and handling can affect product quality. Buyers should ensure that suppliers have robust packaging and transportation processes to minimize damage during transit.

-

Language Barriers: Effective communication is essential for quality assurance. Buyers should consider suppliers who provide documentation and support in a language they understand to facilitate clearer exchanges.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for drive shaft couplings, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drive shaft coupling’

Introduction

Sourcing drive shaft couplings can be a complex process, especially for international B2B buyers who must navigate various technical specifications, supplier evaluations, and logistical considerations. This guide provides a practical checklist to streamline your procurement process, ensuring you acquire the right coupling for your applications while minimizing risks and maximizing efficiency.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your drive shaft coupling. Consider factors such as torque ratings, misalignment tolerances, and material compatibility. This step is critical as it ensures that the coupling will meet the operational demands of your machinery and prevent costly failures in the field.

- Torque Ratings: Verify that the coupling can handle the maximum torque your application will produce.

- Misalignment Tolerances: Determine the types of misalignment (angular, parallel, axial) that the coupling must accommodate.

Step 2: Research Different Coupling Types

Familiarize yourself with the various types of drive shaft couplings available in the market. Understanding the differences between flexible, rigid, and universal couplings will help you choose the right product for your application needs.

- Flexible Couplings: Ideal for applications with slight misalignments and vibrations.

- Rigid Couplings: Best suited for applications requiring maximum torque transmission with minimal movement.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure reliability and quality. Request product certifications, company profiles, and customer references. This step is essential to mitigate risks associated with supplier reliability and product quality.

- Certifications: Look for ISO or industry-specific certifications that demonstrate adherence to quality standards.

- Customer References: Reach out to other businesses within your industry to gauge their experiences with the supplier.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the drive shaft couplings you are considering. Testing samples allows you to verify that the product meets your specifications and performs well under operational conditions.

- Performance Testing: Evaluate the coupling’s performance in real-world conditions to ensure it meets your operational requirements.

- Fit and Compatibility: Confirm that the sample fits seamlessly with your existing machinery.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures and payment terms from different suppliers. Understanding the cost implications and payment flexibility is crucial for maintaining your budget while ensuring quality.

- Bulk Discounts: Inquire about bulk purchasing discounts to reduce costs.

- Payment Terms: Evaluate payment options, such as net terms or upfront payments, to find a solution that fits your financial strategy.

Step 6: Verify Shipping and Delivery Options

Ensure that the supplier can meet your logistical needs by verifying shipping and delivery options. Timely delivery is critical to maintaining your production schedules.

- Lead Times: Confirm the expected lead times and factor this into your project timelines.

- Shipping Costs: Assess shipping costs and options for international delivery, particularly if you are sourcing from overseas.

Step 7: Finalize Your Order and Establish Communication

Once you have selected a supplier, finalize your order and establish clear communication channels. This step helps to ensure that any issues can be addressed promptly throughout the fulfillment process.

- Order Confirmation: Get a written confirmation detailing the order specifications, pricing, and delivery timelines.

- Point of Contact: Identify a point of contact within the supplier’s organization for ongoing communication regarding your order.

By following this checklist, international B2B buyers can effectively navigate the complexities of sourcing drive shaft couplings, ensuring they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for drive shaft coupling Sourcing

In the competitive landscape of drive shaft coupling sourcing, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the components of cost, pricing influencers, and strategic buyer tips to facilitate informed purchasing decisions.

What Are the Key Cost Components for Drive Shaft Couplings?

The cost structure for drive shaft couplings is multifaceted, encompassing several critical components:

-

Materials: The choice of materials significantly affects pricing. Common materials include aluminum, steel, and high-strength alloys, each varying in cost based on market fluctuations and availability. High-performance materials designed for specific applications may incur additional costs.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes. Automated production methods can reduce labor expenses, while manual assembly may increase costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient production practices can minimize overhead costs, ultimately impacting pricing.

-

Tooling: The initial investment in specialized tooling for production can be substantial. Custom tooling for unique designs or specifications increases upfront costs but can lead to economies of scale for larger orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which is essential for applications in industries such as automotive and industrial machinery. Higher QC standards can result in increased costs but also enhance the product’s value.

-

Logistics: Shipping and handling costs vary based on the destination and volume of the order. International shipments may incur customs duties and tariffs, affecting the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on competition and market demand.

What Influences Pricing in Drive Shaft Coupling Procurement?

Several factors influence the pricing of drive shaft couplings:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk discounts, reducing the per-unit cost. Understanding a supplier’s MOQ policy can help buyers negotiate better terms.

-

Specifications and Customization: Custom designs or specific performance requirements may lead to higher costs. Buyers should weigh the necessity of customization against budget constraints.

-

Quality and Certifications: Couplings that meet international quality standards or certifications (e.g., ISO, CE) may command higher prices. However, investing in certified products can reduce long-term maintenance costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge more due to their quality assurance and customer service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly influence the overall cost.

What Tips Can Buyers Use for Effective Negotiation and Cost-Efficiency?

To maximize cost-efficiency and ensure favorable pricing, buyers should consider the following strategies:

Illustrative image related to drive shaft coupling

-

Negotiate Terms: Engaging in open discussions with suppliers about pricing, payment terms, and lead times can lead to more favorable conditions. Be prepared to leverage volume commitments for better rates.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, downtime, and reliability. A slightly higher initial investment in quality couplings can yield significant savings over time.

-

Research Market Trends: Stay informed about market trends and material costs. Understanding current pricing dynamics can provide leverage during negotiations.

-

Consider Regional Differences: For buyers in regions like Africa, South America, the Middle East, and Europe, it’s essential to understand local market conditions and regulations that may affect pricing.

Conclusion

Navigating the cost and pricing landscape of drive shaft couplings requires a comprehensive understanding of various components and influencers. By employing strategic negotiation tactics and considering the total cost of ownership, international B2B buyers can make informed decisions that align with their operational needs and budgetary constraints. Always remember that the prices mentioned are indicative and can vary based on numerous factors, including market conditions and supplier capabilities.

Alternatives Analysis: Comparing drive shaft coupling With Other Solutions

Exploring Alternative Solutions to Drive Shaft Couplings

In the realm of mechanical power transmission, drive shaft couplings play a critical role in connecting two shafts and allowing for the transfer of torque and motion. However, there are alternative technologies and methods available that may better suit specific applications or operational requirements. This analysis compares drive shaft couplings against two viable alternatives: universal joints and flexible couplings, providing valuable insights for B2B buyers looking to optimize their systems.

Comparison Table

| Comparison Aspect | Drive Shaft Coupling | Universal Joint | Flexible Coupling |

|---|---|---|---|

| Performance | High torque transmission; effective for aligned shafts | Excellent for angular misalignment; versatile | Damps vibrations; compensates for minor misalignments |

| Cost | Moderate (varies by material) | Generally low to moderate | Moderate to high (depends on design) |

| Ease of Implementation | Simple installation; requires alignment | Requires precise alignment; more complex installation | Easy to install; minimal alignment needed |

| Maintenance | Low maintenance; durable | Moderate; potential for wear over time | Low; typically maintenance-free |

| Best Use Case | High torque applications in aligned systems | Applications with significant angular misalignment | Applications needing vibration damping and flexibility |

Detailed Breakdown of Alternatives

Universal Joint

Universal joints are designed to connect two shafts that are not aligned in a straight line, allowing for angular movement. This flexibility makes them ideal for applications where shafts may be offset or experience variable angles. The primary advantage of universal joints is their ability to handle angular misalignment effectively. However, they can introduce backlash and may require more frequent maintenance due to wear on the joint surfaces. In terms of cost, universal joints are generally more affordable, making them a popular choice for a variety of applications, particularly in automotive and heavy machinery sectors.

Flexible Coupling

Flexible couplings are another alternative that excels in applications requiring the dampening of vibrations and the accommodation of minor misalignments. They are designed to absorb shocks and reduce the risk of damage due to misalignment, making them suitable for sensitive machinery and high-speed applications. The installation process is straightforward, and they often require minimal alignment. However, flexible couplings can be more expensive than traditional drive shaft couplings, particularly when high-performance models are selected. Their maintenance is typically low, as they are designed to withstand various operational stresses.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right coupling solution ultimately depends on your specific application requirements. If you are dealing with high torque and aligned shafts, a drive shaft coupling may be your best option due to its durability and performance. Conversely, if your application involves significant angular misalignment, a universal joint might provide the necessary flexibility without compromising functionality. For scenarios where vibration dampening is critical, a flexible coupling could enhance system reliability and longevity. By carefully assessing the performance needs, cost implications, and maintenance considerations of each option, B2B buyers can make informed decisions that optimize their mechanical systems and operational efficiency.

Illustrative image related to drive shaft coupling

Essential Technical Properties and Trade Terminology for drive shaft coupling

When considering the procurement of drive shaft couplings, it’s crucial for B2B buyers to understand the essential technical properties and trade terminology that influence performance, compatibility, and overall value. This knowledge aids in making informed decisions that align with operational requirements and industry standards.

What Are the Key Technical Properties of Drive Shaft Couplings?

-

Material Grade

Drive shaft couplings are typically manufactured from materials such as aluminum, steel, or high-tensile alloys. The choice of material impacts strength, weight, and corrosion resistance. For instance, aluminum is lightweight and resistant to corrosion but may not withstand high torque applications compared to steel. Understanding material grades is critical for ensuring the coupling can handle the specific demands of the intended application. -

Torque Rating

This specification indicates the maximum torque the coupling can transmit without failure. It is essential to select couplings that match or exceed the torque requirements of your machinery. Underestimating torque ratings can lead to premature failure, downtime, and increased maintenance costs, making this a vital consideration for B2B buyers. -

Misalignment Compensation

Drive shaft couplings are designed to accommodate various types of misalignment, including angular, parallel, and axial misalignment. Understanding the coupling’s ability to compensate for these misalignments is crucial for ensuring operational efficiency and longevity of the equipment. This characteristic helps prevent excessive wear and tear on components, reducing the likelihood of costly repairs. -

Backlash

Backlash refers to the slight movement that occurs in a coupling when torque is applied. Some applications, particularly in precision machinery, require backlash-free couplings to maintain accuracy. For B2B buyers, knowing the acceptable levels of backlash for specific applications can influence coupling selection, particularly in fields such as robotics or CNC machining. -

Dimensions and Tolerances

The physical dimensions of a coupling, including diameter, length, and tolerance levels, dictate how well it fits within the existing machinery. Precision in tolerances is crucial for maintaining alignment and performance. B2B buyers must ensure that the selected coupling meets the dimensional requirements of the equipment to prevent issues related to fit and function. -

Temperature and Environmental Resistance

Couplings may be exposed to various environmental conditions, including extreme temperatures, chemicals, and moisture. Selecting couplings with suitable temperature ratings and environmental resistance properties is essential for ensuring durability and operational reliability. This consideration is particularly important in industries such as manufacturing, oil and gas, and automotive.

What Are Common Trade Terms Related to Drive Shaft Couplings?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of drive shaft couplings, OEM parts are designed to meet specific standards set by the original equipment, ensuring compatibility and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to manage inventory and budget effectively. It can influence purchasing decisions, especially for smaller companies or those with limited storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For drive shaft couplings, submitting an RFQ can help buyers compare options and negotiate better deals based on their technical requirements. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for B2B buyers as it helps define costs, risk, and delivery responsibilities, ensuring smooth transactions across borders. -

Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled, from the moment it is placed until the goods are delivered. Understanding lead times is critical for production planning and inventory management, particularly in industries where timing is essential. -

Custom Fabrication

This term denotes the process of creating products tailored to specific requirements. For drive shaft couplings, custom fabrication might be necessary for unique applications or machinery configurations, allowing B2B buyers to optimize performance for their specific needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing drive shaft couplings, ensuring that they meet their operational needs while maximizing value and performance.

Navigating Market Dynamics and Sourcing Trends in the drive shaft coupling Sector

What Are the Current Market Dynamics and Key Trends in the Drive Shaft Coupling Sector?

The drive shaft coupling sector is experiencing significant growth, driven by advancements in industrial automation, increasing demand from the automotive sector, and rising infrastructure investments across emerging markets. Key trends include the integration of smart technologies, such as IoT-enabled couplings that provide real-time monitoring and predictive maintenance capabilities. This technology allows international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to enhance operational efficiency and reduce downtime.

Moreover, the market is witnessing a shift towards lightweight and high-strength materials, such as composite and advanced alloys, which improve performance and fuel efficiency in automotive applications. The demand for flexible couplings is also rising, as they accommodate various misalignments and reduce vibration, essential for enhancing the longevity of machinery in sectors like manufacturing and construction.

B2B buyers must navigate a complex landscape characterized by fluctuating raw material prices and supply chain disruptions. It is crucial to establish relationships with reliable suppliers who can provide quality products and adapt to changing market conditions. Additionally, understanding regional market dynamics, such as regulatory environments and local manufacturing capabilities, can provide a competitive edge in sourcing strategies.

How Is Sustainability and Ethical Sourcing Influencing Drive Shaft Coupling Procurement?

Sustainability and ethical sourcing are becoming pivotal in the drive shaft coupling sector, reflecting a broader trend in B2B procurement practices. The environmental impact of manufacturing processes, including emissions and waste generation, is prompting buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials and energy-efficient production methods, which not only reduce the carbon footprint but can also lead to cost savings in the long term.

Buyers are increasingly demanding transparency in supply chains, seeking partners who can demonstrate ethical sourcing of materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming benchmarks for evaluating suppliers. Additionally, the adoption of ‘green’ materials, such as bio-based plastics or sustainably sourced metals, is gaining traction, aligning with global efforts to reduce environmental impact.

For international buyers, especially those in regions like Europe and North America, aligning procurement strategies with sustainability goals can enhance brand reputation and meet regulatory requirements. Establishing partnerships with suppliers who prioritize sustainability can also lead to innovation and improved product offerings, ultimately benefiting the buyer’s operational efficiency.

How Has the Drive Shaft Coupling Sector Evolved Over Time?

The evolution of the drive shaft coupling sector has been marked by significant technological advancements and shifts in manufacturing practices. Initially, couplings were primarily designed for basic mechanical connectivity. However, as industries evolved, the need for more sophisticated solutions became evident. This led to the development of various coupling types, including flexible and rigid couplings, designed to accommodate misalignments and reduce wear in machinery.

The introduction of advanced materials and manufacturing techniques, such as computer-aided design (CAD) and 3D printing, has revolutionized the industry. These innovations allow for the production of lighter, stronger couplings tailored to specific applications, enhancing performance across sectors like automotive, aerospace, and industrial machinery.

Moreover, the focus on efficiency and reliability has driven the integration of smart technologies, paving the way for future developments. As the market continues to grow, understanding this historical context is essential for international B2B buyers to make informed sourcing decisions that align with both current and future industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of drive shaft coupling

-

How do I solve misalignment issues with drive shaft couplings?

To address misalignment, first identify the type: angular, parallel, or axial. For minor misalignments, flexible couplings are often suitable as they can accommodate slight deviations without compromising performance. If misalignments are significant, consider adjustable couplings or spacer couplings designed to handle larger tolerances. Always ensure that the selected coupling matches the torque requirements and operational speeds to maintain reliability and prevent premature wear. -

What is the best type of drive shaft coupling for high-torque applications?

For high-torque applications, steel gear flexible couplings are highly recommended due to their robust design and high torque ratings. These couplings provide improved torque transmission and longer service life, making them ideal for demanding industrial settings. Additionally, consider full-flex couplings if some misalignment is anticipated, as they can handle vibrations and shocks efficiently while maintaining torque integrity. -

How do I vet potential suppliers for drive shaft couplings?

Begin by researching suppliers’ reputations through customer reviews and industry certifications. Request product samples to assess quality and performance. Check if the supplier has experience in your specific industry and offers technical support. It’s also beneficial to inquire about their manufacturing processes, quality assurance protocols, and after-sales service. Building a relationship with suppliers who have a proven track record can ensure reliability in your sourcing process. -

What customization options are typically available for drive shaft couplings?

Many manufacturers offer customization options such as specific dimensions, torque ratings, and materials to suit unique application requirements. You can request variations in bore sizes, keyway configurations, and even the use of specialized elastomeric elements for enhanced performance in extreme conditions. Always communicate your specific needs during the inquiry phase to ensure that the final product meets your operational criteria. -

What are the minimum order quantities (MOQs) for drive shaft couplings?

MOQs can vary significantly between suppliers, typically ranging from a few units to several hundred, depending on the type and complexity of the couplings. Custom couplings often have higher MOQs due to additional manufacturing processes. Always clarify MOQs during negotiations to ensure that your purchasing needs align with the supplier’s capabilities. Consider discussing bulk purchasing discounts if you anticipate needing larger quantities in the future. -

What payment terms should I expect when sourcing drive shaft couplings?

Payment terms vary by supplier but generally include options like advance payment, net 30, or letter of credit for larger transactions. For international purchases, consider factors such as currency fluctuations and transfer fees. Establish clear terms before finalizing orders to avoid any misunderstandings. Some suppliers may also offer flexible payment plans for long-term contracts, which can enhance cash flow management. -

How is the quality of drive shaft couplings ensured during manufacturing?

Quality assurance processes typically include material inspections, in-process checks, and final product testing against industry standards. Many reputable manufacturers adhere to ISO certifications, ensuring consistent quality control. Requesting documentation of these processes can provide additional confidence in the product’s reliability. Additionally, inquire about warranty options as they often reflect the manufacturer’s commitment to quality. -

What logistics considerations should I be aware of when importing drive shaft couplings?

When importing, consider shipping methods, customs regulations, and lead times. Ensure that your supplier provides all necessary documentation for customs clearance to avoid delays. Familiarize yourself with import duties and taxes applicable in your country. It’s also wise to use freight forwarders who can assist with logistics planning, ensuring timely delivery and compliance with international shipping standards.

Top 3 Drive Shaft Coupling Manufacturers & Suppliers List

1. Wadsworth Controls – Drive Shaft Coupling 1-3/8

Domain: wadsworthcontrols.com

Registered: 1998 (27 years)

Introduction: {“name”:”Drive Shaft Coupling 1-3/8″, “price”:”$17.00″, “description”:”Coupling to join two lengths of 1-3/8″ drive tube. Nuts and bolts included.”, “SKU”:”S-9109″, “category”:”Vent Automation”, “weight”:”1.62 lbs”, “reviews”:”No reviews yet.”}

2. Power Jacks – Key Features of Couplings and Drive Shafts

Domain: powerjacks.com

Registered: 1996 (29 years)

Introduction: Key Features of Couplings and Drive Shafts:

1. Curved jaw design with torque ratings from 10Nm to 3300Nm.

2. No lubrication required; quick and simple installation.

3. Reliable, rugged, and compact design.

4. Four standard spider types available.

5. Elastomeric element resistant to heat (-40°C to +90°C), grease, oil, and chemicals.

6. Hubs made from aluminium and sintered iron.

7. Full-Flex…

3. Strange Engineering – Solid Driveshafts & C-Clip Eliminator Kits

Domain: strangeengineering.net

Registered: 2002 (23 years)

Introduction: Solid Driveshafts & Couplers from Strange Engineering include a range of high-performance components designed for various applications. Key products include: 1. **Solid Driveshafts** – Engineered for durability and performance in drag racing and street applications. 2. **C-Clip Eliminator Kits** – Designed to enhance safety and durability with low-friction ball bearings and a lightweight aluminum …

Strategic Sourcing Conclusion and Outlook for drive shaft coupling

As the demand for drive shaft couplings continues to rise across global markets, strategic sourcing emerges as a critical factor for B2B buyers seeking quality and reliability. Understanding the nuances of different coupling types—be it flexible, rigid, or specialized designs—enables businesses to make informed decisions that align with their operational needs. Moreover, considering factors such as torque ratings, misalignment capabilities, and materials can significantly enhance equipment performance and longevity.

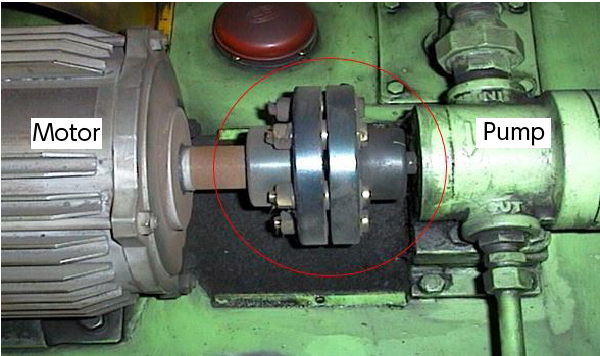

Illustrative image related to drive shaft coupling

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize establishing relationships with reputable suppliers who can provide tailored solutions and robust support. This proactive approach not only mitigates risks associated with sourcing but also fosters innovation and competitive advantage in diverse markets.

Looking ahead, the drive shaft coupling market is poised for growth, driven by advancements in technology and increasing industrial activities. By leveraging strategic sourcing practices, businesses can position themselves to capitalize on emerging opportunities. Engage with suppliers now to secure the best solutions for your specific applications and ensure your operations run smoothly and efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.