The Definitive Guide to Latch Paddle: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for latch paddle

The global market for latch paddles presents a unique challenge for B2B buyers seeking reliable, secure, and efficient solutions for their operational needs. Sourcing high-quality paddle latches can be daunting due to the diverse range of types, materials, and specifications available. This comprehensive guide aims to demystify the complexities associated with latch paddles by exploring various types, including single-point, multi-point, and rotary paddle latches, while also addressing their specific applications across different industries.

We will delve into essential factors that influence purchasing decisions, such as supplier vetting processes, cost analysis, and quality assurance measures. By equipping international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—with actionable insights, this guide empowers them to make informed purchasing decisions.

Whether you are tasked with enhancing security measures for commercial doors or optimizing access solutions for industrial equipment, understanding the nuances of latch paddles will facilitate better sourcing strategies. The insights provided will ensure that you can navigate the global market with confidence, securing the best products to meet your specific needs.

Understanding latch paddle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Point Paddle Latch | Simple mechanism, typically flush-mounted, easy to operate. | Industrial enclosures, cabinets | Pros: Easy installation; Cons: Limited security features. |

| Multi-Point Paddle Latch | Engages multiple locking points for enhanced security. | Commercial doors, high-security areas | Pros: Increased security; Cons: More complex installation. |

| Rotary Paddle Latch | Rotating mechanism for operation; often used in heavy-duty applications. | Truck and trailer doors, heavy machinery | Pros: Robust design; Cons: Higher cost. |

| Slam Paddle Latch | Self-closing feature; requires minimal effort to operate. | Self-closing doors, quick-access enclosures | Pros: Fast operation; Cons: Less secure than other types. |

| Lockable Paddle Latch | Features a key lock for added security; available in various materials. | Storage units, outdoor equipment | Pros: Enhanced security; Cons: Requires key management. |

What are the characteristics of Single-Point Paddle Latches?

Single-point paddle latches are designed for straightforward operation and installation. They feature a flush-mounted design that integrates seamlessly with the door or enclosure, allowing for easy access. Commonly used in industrial settings, these latches are ideal for cabinets and enclosures where security is less of a concern. When purchasing, buyers should consider the latch’s material for durability and its compatibility with existing door systems.

How do Multi-Point Paddle Latches enhance security?

Multi-point paddle latches engage several locking points along the door frame, significantly increasing security compared to single-point options. These latches are particularly suited for commercial applications, such as office buildings and high-security areas, where theft prevention is critical. Buyers should evaluate the installation complexity and ensure that their doors can accommodate the latch’s multi-point mechanism for optimal performance.

In what scenarios are Rotary Paddle Latches preferred?

Rotary paddle latches are known for their heavy-duty construction and are typically used in applications requiring robust security, such as truck and trailer doors or heavy machinery access. The rotating mechanism allows for secure closure under high-stress conditions. Buyers should consider the latch’s weight capacity and whether it meets the specific demands of their application, as well as installation requirements.

What advantages do Slam Paddle Latches offer?

Slam paddle latches are designed for quick access and self-closing functionality, making them ideal for environments where speed is essential, such as warehouses or service doors. They require minimal effort to operate, allowing for hands-free use in many scenarios. However, buyers should be aware that while these latches are convenient, they may not provide the same level of security as other paddle latch types, making them less suitable for high-security applications.

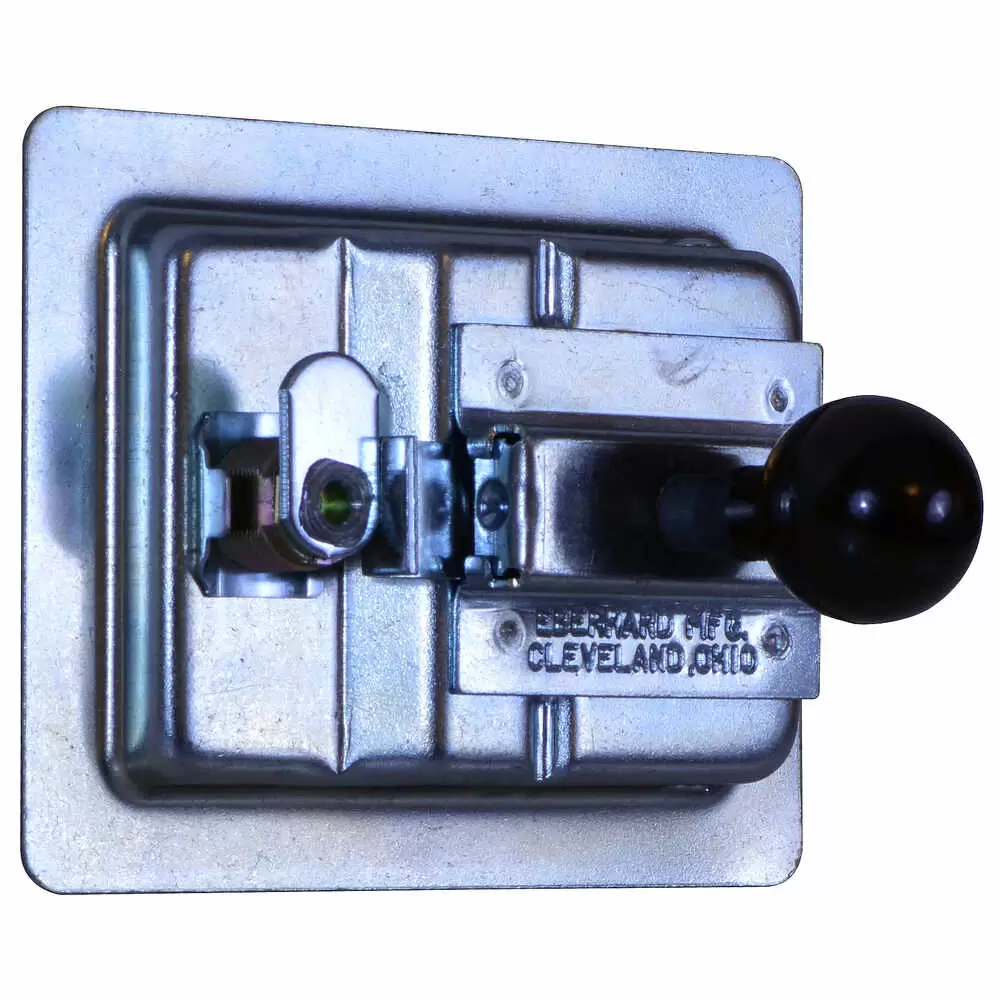

Illustrative image related to latch paddle

Why choose Lockable Paddle Latches for outdoor applications?

Lockable paddle latches provide an added layer of security with key-operated locks, making them suitable for outdoor storage units and equipment. They come in various materials, including stainless steel and powder-coated finishes, offering durability against environmental factors. When selecting these latches, buyers should assess the lock quality and key management aspects to ensure effective security and ease of access.

Key Industrial Applications of latch paddle

| Industry/Sector | Specific Application of latch paddle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Securing truck and trailer compartments | Enhances security and ease of access for cargo | Durability against harsh environments; weight capacity |

| Manufacturing | Access control for machinery enclosures | Streamlines operations and prevents unauthorized access | Compliance with safety standards; material resistance |

| Construction | Locking mechanisms for site storage containers | Protects equipment and materials from theft | Weatherproof finishes; ease of installation |

| Telecommunications | Enclosures for network equipment | Ensures equipment safety while allowing easy access | Compatibility with existing infrastructure; locking options |

| Aerospace | Access to maintenance panels in aircraft | Facilitates quick access for inspections and repairs | Lightweight materials; compliance with aviation standards |

How is a latch paddle utilized in the Transportation & Logistics sector?

In the Transportation & Logistics industry, latch paddles are commonly used to secure compartments in trucks and trailers. Their design allows for quick access while providing robust security against theft or tampering. This is particularly important for businesses that transport high-value goods. Buyers in this sector should consider the durability of the latch paddle, as they must withstand harsh weather conditions and heavy usage. Additionally, they should ensure that the latch has a sufficient weight capacity to support the load being transported.

What role does a latch paddle play in Manufacturing applications?

In manufacturing environments, latch paddles are utilized as access controls for machinery enclosures. This application is crucial for streamlining operations, allowing authorized personnel to quickly access machines while preventing unauthorized entry. Manufacturers must ensure that the latch paddles comply with safety standards to avoid workplace accidents. Buyers should also consider the material resistance to chemicals and wear, as manufacturing processes often involve harsh conditions.

How do latch paddles contribute to security in Construction?

Latch paddles serve as effective locking mechanisms for site storage containers in the construction sector. They protect valuable equipment and materials from theft, which is a significant concern on construction sites. Construction firms should look for latch paddles that feature weatherproof finishes to ensure longevity despite exposure to the elements. Ease of installation is also a key consideration, as quick setup can minimize downtime on projects.

In what ways do latch paddles enhance Telecommunications infrastructure?

In Telecommunications, latch paddles are essential for securing enclosures that house network equipment. They provide a balance between security and accessibility, allowing technicians to quickly access critical equipment while safeguarding it from unauthorized access. Buyers in this sector should prioritize compatibility with existing infrastructure and consider various locking options to enhance security measures. The ability to customize the latch for specific enclosures can also be a significant advantage.

How are latch paddles used in Aerospace applications?

In the Aerospace industry, latch paddles are used to provide access to maintenance panels in aircraft. This application is vital for ensuring that inspections and repairs can be performed quickly and efficiently, which is essential for flight safety. Buyers should focus on lightweight materials that comply with aviation standards, as reducing weight is a critical factor in aircraft design. Additionally, ensuring that the latch paddle operates smoothly under varying pressure conditions is essential for maintaining safety and functionality.

3 Common User Pain Points for ‘latch paddle’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security with Paddle Latches

The Problem: Many B2B buyers face significant challenges in ensuring the security of their facilities, especially when using paddle latches. The concern arises particularly in industries where sensitive materials are stored, such as in logistics or manufacturing. Buyers may find that standard paddle latches do not provide adequate security features, leading to potential unauthorized access and theft, which can result in financial losses and compromised operational integrity.

The Solution: To address security concerns effectively, buyers should consider sourcing paddle latches that come with advanced locking mechanisms, such as key-lockable or padlockable options. For example, selecting a paddle latch with a robust locking system can deter unauthorized access. Additionally, buyers should assess the material and finish of the latch; stainless steel options often offer better durability and resistance to tampering. Buyers can also enhance security by integrating electronic access controls with paddle latches, allowing for remote monitoring and management. This dual approach not only safeguards against physical breaches but also offers a modern solution to access management.

Scenario 2: Incompatibility with Existing Door Hardware

The Problem: In many cases, B2B buyers encounter issues when attempting to retrofit paddle latches onto existing doors. This is particularly prevalent in older facilities where door dimensions and hardware configurations may not align with modern paddle latch specifications. Such incompatibility can lead to installation delays and increased costs, frustrating buyers who need a seamless integration of new hardware into their operational workflow.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough assessment of their existing door hardware before purchasing paddle latches. This includes measuring door thickness, existing latch positions, and the type of materials used. Many manufacturers offer customizable paddle latches that can be adjusted to fit various door specifications. Additionally, buyers should consider consulting with suppliers who provide installation guides and support to facilitate a smooth retrofit process. Involving professional installers can also ensure that the paddle latches are fitted correctly, minimizing the risk of operational disruptions.

Scenario 3: Poor Performance Under Harsh Conditions

The Problem: Paddle latches used in outdoor or industrial environments often face challenges such as corrosion, wear, and failure due to exposure to extreme weather conditions. For buyers in regions with high humidity, salt air, or extreme temperatures, this can lead to frequent replacements and increased maintenance costs, impacting operational efficiency and budget management.

The Solution: To combat performance issues, buyers should prioritize paddle latches designed specifically for harsh environments. Opting for latches made from corrosion-resistant materials, such as marine-grade stainless steel or powder-coated finishes, can significantly enhance longevity and reliability. Additionally, suppliers may offer latches that are weatherproof or equipped with seals to protect internal mechanisms from moisture and debris. Regular maintenance schedules should also be established, including inspections and lubrication, to prolong the life of the latches. By investing in high-quality, environment-specific paddle latches, buyers can reduce downtime and improve overall operational efficiency.

Strategic Material Selection Guide for latch paddle

When selecting materials for latch paddles, B2B buyers must consider various factors that affect performance, durability, and compliance with international standards. Here’s an analysis of four common materials used in latch paddle manufacturing, focusing on their properties, advantages, disadvantages, and implications for specific markets.

What Are the Key Properties of Mild Steel for Latch Paddles?

Mild steel is a popular choice for latch paddles due to its balance of strength and cost-effectiveness. It typically has a tensile strength of around 370 MPa and can withstand moderate temperature variations. However, mild steel is prone to corrosion, particularly in humid or saline environments, unless treated with protective coatings.

Pros and Cons: Mild steel offers high durability and is relatively inexpensive, making it suitable for a wide range of applications. However, its susceptibility to rust limits its use in outdoor or corrosive environments. Additionally, the manufacturing process can be complex due to the need for surface treatments.

Impact on Application: In regions with high humidity or exposure to saltwater, such as coastal areas in Africa and South America, the corrosion risk can significantly impact the longevity of mild steel latch paddles.

How Does Stainless Steel Compare for Latch Paddle Applications?

Stainless steel, particularly type 304, is favored for its excellent corrosion resistance and aesthetic appeal. It can handle higher temperatures and is less likely to deform under stress, with a tensile strength of approximately 520 MPa.

Pros and Cons: The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for outdoor applications and environments with high moisture levels. However, it is more expensive than mild steel and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: In regions like the Middle East, where high temperatures and humidity are common, stainless steel latch paddles provide a reliable solution that meets local demands for durability and performance.

What Are the Benefits of Using Aluminum for Latch Paddles?

Aluminum is lightweight and resistant to corrosion, making it an attractive option for latch paddles. It typically has a tensile strength of around 310 MPa and performs well under moderate temperature conditions.

Pros and Cons: The lightweight nature of aluminum allows for easy installation and reduces the overall weight of the assembly. However, its lower strength compared to steel can be a limitation in heavy-duty applications. Additionally, aluminum can be more expensive due to the cost of raw materials.

Impact on Application: For B2B buyers in Europe, where lightweight materials are preferred for efficiency in transport and installation, aluminum latch paddles can be an ideal choice. However, buyers should consider the specific load requirements of their applications.

Why Choose Plastic for Latch Paddles?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is increasingly being used for latch paddles due to its resistance to corrosion and chemicals. It has a tensile strength of about 30 MPa, which is lower than metals but sufficient for many applications.

Pros and Cons: The primary advantage of plastic is its lightweight nature and resistance to various chemicals, making it suitable for environments where exposure to harsh substances is a concern. However, its lower strength limits its use in heavy-duty applications, and it may not withstand extreme temperatures as effectively as metals.

Impact on Application: In markets like Brazil, where industrial applications may involve exposure to chemicals, plastic latch paddles can provide a viable solution. However, buyers should ensure that the chosen plastic type meets the specific requirements of their application.

Summary of Material Selection for Latch Paddles

| Material | Typical Use Case for latch paddle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General-purpose indoor applications | Cost-effective and durable | Prone to corrosion | Medium |

| Stainless Steel | Outdoor and high-humidity environments | Excellent corrosion resistance | Higher cost and complex machining | High |

| Aluminum | Lightweight applications in Europe | Lightweight and easy to install | Lower strength compared to steel | Medium to High |

| Plastic | Chemical exposure environments | Corrosion-resistant and lightweight | Limited strength and temperature range | Low to Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application requirements and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for latch paddle

What are the Typical Manufacturing Processes for Latch Paddles?

The manufacturing of latch paddles involves a series of well-defined stages that ensure product quality and functionality. Understanding these processes is crucial for B2B buyers seeking reliable suppliers.

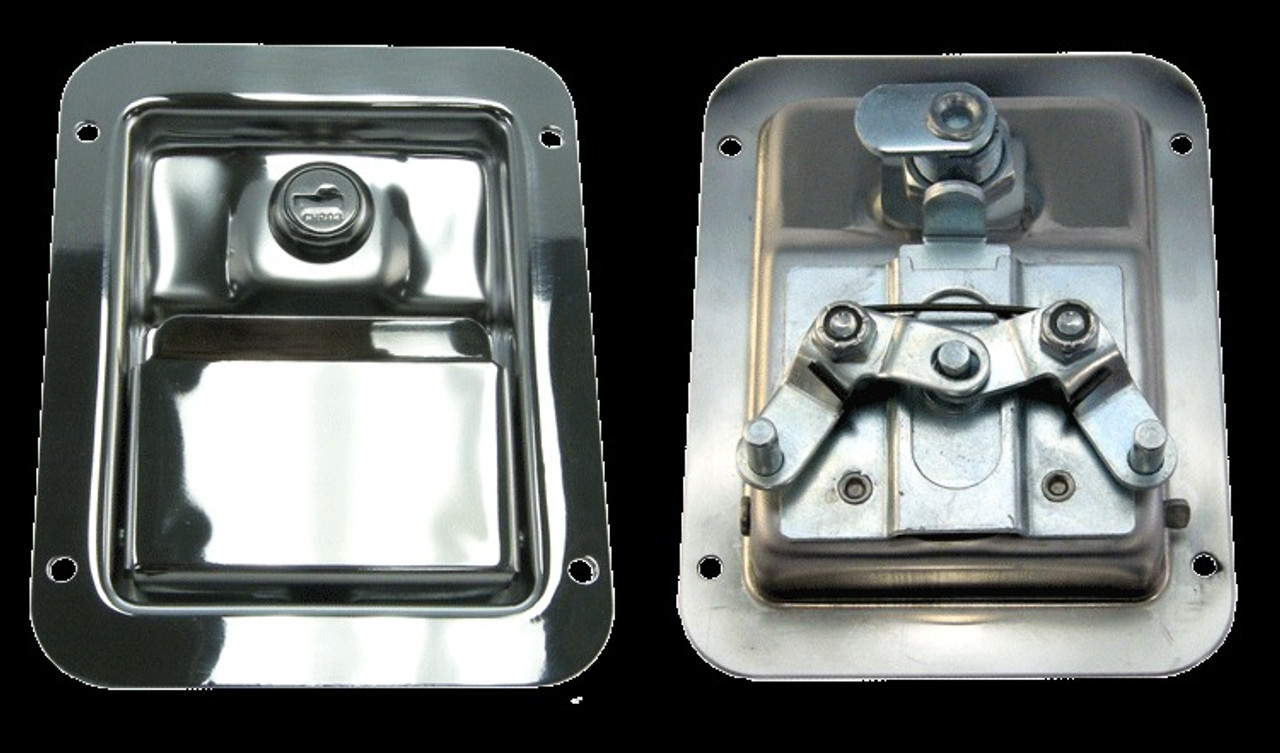

Illustrative image related to latch paddle

What Materials are Used in Latch Paddle Manufacturing?

The primary materials used for latch paddles include mild steel, stainless steel, and various alloys. These materials are chosen for their strength, durability, and resistance to corrosion, which are vital for the performance of the latch in various environments. For instance, stainless steel is often preferred in coastal areas due to its resistance to rust and saltwater.

How is Material Prepared for Latch Paddle Production?

Material preparation begins with sourcing high-quality raw materials that meet international standards. This step includes inspecting the materials for defects and ensuring they conform to specifications. Suppliers often use certified vendors to guarantee material quality. Once the materials are approved, they undergo cutting, shearing, or laser cutting to prepare them for the forming stage.

What Forming Techniques are Commonly Used for Latch Paddles?

Forming is a critical stage where the prepared materials are shaped into the desired latch paddle design. Common techniques include:

- Stamping: This process uses a die to cut and form the metal into specific shapes. It is efficient for producing high volumes of identical parts.

- Bending: Metal sheets are bent to create the contours and features of the latch. Precision bending machines ensure accurate angles and dimensions.

- Machining: For components requiring tight tolerances, machining processes like milling and turning are employed. These processes enhance the precision of critical latch features such as locking mechanisms.

How are Latch Paddles Assembled?

After forming, the components are assembled. This may involve:

- Joining Techniques: Welding, riveting, or using adhesives to connect different parts of the latch paddle. The choice of joining method depends on the design and material.

- Integration of Locking Mechanisms: Many latch paddles include locking features that require precise assembly. This stage ensures that the locking mechanism operates smoothly and securely.

What Finishing Processes are Applied to Latch Paddles?

The finishing stage enhances the latch paddle’s aesthetics and durability. Common finishing techniques include:

- Coating: Powder coating or painting is applied to protect the latch from environmental factors and improve its appearance. For instance, black powder coating is popular for its durability and resistance to wear.

- Plating: Some latches may undergo electroplating to provide a corrosion-resistant layer, which is particularly beneficial for stainless steel components.

- Polishing: This process improves surface smoothness and enhances visual appeal, especially for stainless steel latches.

What Quality Assurance Practices are Essential for Latch Paddle Production?

Quality assurance (QA) is integral to the manufacturing process, ensuring that latch paddles meet both industry standards and customer expectations. A structured QA process helps mitigate risks and ensures product reliability.

Which International Standards Apply to Latch Paddle Manufacturing?

B2B buyers should look for manufacturers that comply with international standards such as ISO 9001, which outlines quality management principles. Compliance with CE marking is also crucial for products sold in Europe, indicating that they meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are vital for maintaining product quality throughout the manufacturing process. The main checkpoints include:

Illustrative image related to latch paddle

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early. This may involve monitoring dimensions, tolerances, and operational functionality.

- Final Quality Control (FQC): The final inspection ensures that the completed latch paddles meet all design specifications and quality standards before shipping.

What Common Testing Methods Are Used for Latch Paddles?

Testing methods vary based on the latch’s intended application, but common techniques include:

- Mechanical Testing: This evaluates the strength and durability of the latch under various loads, ensuring it can withstand operational stresses.

- Corrosion Resistance Testing: Particularly important for latches exposed to harsh environments, this testing assesses the material’s ability to resist rust and degradation.

- Functional Testing: Ensures that all mechanical features operate as intended, including locking mechanisms and ease of use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier QC processes is essential to mitigate risks.

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is a proactive approach to assess manufacturing capabilities and quality systems. Key aspects to evaluate include:

- Certifications: Verify the manufacturer’s compliance with relevant industry standards (e.g., ISO, CE).

- Process Documentation: Request documentation on manufacturing processes, quality control measures, and past audit results.

- Facility Tours: If feasible, visiting the manufacturing facility allows buyers to assess the production environment, equipment, and overall operational efficiency.

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections are an effective way to gain an unbiased evaluation of a supplier’s quality control processes. Independent inspectors can perform random checks on raw materials, in-process components, and finished products. This adds an extra layer of assurance for B2B buyers, especially when sourcing from international suppliers.

Illustrative image related to latch paddle

What Are the Specific QC Considerations for International Buyers?

International buyers should be aware of specific nuances in quality control that may vary by region. For example:

- Regulatory Compliance: Understand the local regulations that may impact product certification and safety standards.

- Cultural Differences: Be mindful of how cultural attitudes towards quality and manufacturing may affect supplier operations.

- Logistics and Shipping: Assess how quality is maintained during shipping and handling, as international transport can pose risks to product integrity.

By understanding the manufacturing processes and quality assurance practices for latch paddles, B2B buyers can make informed decisions and foster successful supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch paddle’

Introduction

Sourcing the right latch paddle for your business needs is critical for ensuring security and functionality in your products. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively. By following these steps, you can make informed decisions that align with your operational requirements and budget constraints.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of effective sourcing. Consider factors such as the paddle latch’s size, material, load capacity, and locking mechanism. For instance, if your application requires high security, a key-lockable option might be essential.

- Material Considerations: Evaluate the durability of materials like stainless steel versus mild steel, especially if the latch will be exposed to harsh environments.

- Load Capacity: Ensure the latch can withstand the maximum weight it will encounter in use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in latch paddles. Look for manufacturers with a strong reputation and a history of supplying to businesses in your industry.

- Supplier Credentials: Verify certifications and industry standards they adhere to, such as ISO certifications.

- Product Range: Assess if they offer a variety of latch paddles to meet different application needs, including specialized options.

Step 3: Evaluate Supplier Certifications

Before committing to any supplier, it is crucial to verify their certifications. This ensures that they meet industry standards for quality and safety.

- Quality Assurance: Look for suppliers that are ISO 9001 certified, which indicates a commitment to quality management.

- Environmental Standards: Suppliers adhering to environmental regulations (such as ISO 14001) can be beneficial if sustainability is a concern for your business.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the latch paddles. Testing these samples will allow you to evaluate their functionality and durability firsthand.

- Field Testing: Consider how the latch performs under real-world conditions, including its ease of use and resilience to wear and tear.

- Feedback Loop: Involve your team in the testing process to gather insights and ensure the product meets operational needs.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and terms. This includes looking at unit costs, bulk discounts, and shipping fees.

Illustrative image related to latch paddle

- Volume Discounts: Many suppliers offer better pricing for larger orders, so consider your purchasing strategy accordingly.

- Payment Terms: Clarify payment terms to avoid cash flow issues, especially if you are importing goods from different regions.

Step 6: Assess After-Sales Support and Warranty

After confirming your choice of supplier, evaluate their after-sales support and warranty policies. This is crucial for addressing any issues that may arise post-purchase.

- Customer Service: Ensure the supplier has a reliable support system for addressing queries or concerns.

- Warranty Coverage: Look for suppliers that offer warranties, as this can provide peace of mind and reduce long-term costs.

Step 7: Finalize the Order and Monitor Delivery

Once all terms are agreed upon, finalize your order and ensure that you have a clear delivery timeline. Monitoring the delivery process is essential to manage your inventory effectively.

- Tracking Systems: Utilize tracking systems provided by suppliers to stay updated on your order status.

- Inspection Upon Arrival: Inspect the goods upon arrival to ensure they meet the agreed specifications and quality standards.

By following this checklist, you can streamline your sourcing process for latch paddles, ensuring that your business acquires high-quality products that meet your operational requirements.

Comprehensive Cost and Pricing Analysis for latch paddle Sourcing

What Are the Key Cost Components in Latch Paddle Sourcing?

When sourcing latch paddles, understanding the cost structure is crucial for B2B buyers. The primary components influencing the total cost include:

-

Materials: The choice of materials, such as mild steel or stainless steel, significantly affects pricing. For example, stainless steel latches typically incur higher costs due to their durability and corrosion resistance.

-

Labor: Labor costs vary depending on the location of manufacturing. Regions with lower labor costs, such as parts of South America or Africa, may offer competitive pricing, but this can also impact quality and delivery timelines.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling for specific latch designs can be a significant upfront investment. Buyers should consider whether the tooling costs can be amortized over a large order quantity.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and safety, which can add to the overall cost but are essential for high-stakes applications.

-

Logistics: Shipping costs are influenced by the distance from the manufacturer to the buyer, shipping methods, and Incoterms. International buyers should be aware of additional tariffs and customs duties that may apply.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. The margin can vary significantly based on supplier reputation, market demand, and the level of service provided.

How Do Pricing Influencers Affect Latch Paddle Costs?

Several factors can influence the pricing of latch paddles, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on order volume. Larger orders can lead to significant savings, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Customized latches designed for specific applications can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (like ISO or ANSI standards) can drive up costs but are essential for ensuring reliability and compliance with industry regulations.

-

Supplier Factors: The experience and reputation of the supplier can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should be clear about who bears the costs and risks during transit to manage their total cost effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Latch Paddle Sourcing?

For B2B buyers, particularly those in regions like Africa, South America, and the Middle East, optimizing sourcing strategies is key to ensuring cost-effectiveness:

-

Negotiation: Engage suppliers in discussions to negotiate better pricing, especially when placing large orders. Building relationships can lead to more favorable terms.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with the latch paddles, including maintenance, replacement, and operational efficiency. A lower initial price may not always equate to overall savings.

-

Pricing Nuances for International Buyers: Be mindful of fluctuations in currency exchange rates, which can impact the final cost when importing products. Also, research local market conditions, as they can affect pricing strategies.

-

Evaluate Multiple Suppliers: Don’t settle for the first offer. Evaluate multiple suppliers to compare prices, quality, and service levels. This approach can help identify the best overall value.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain quotes tailored to your specific needs before making purchasing decisions.

Alternatives Analysis: Comparing latch paddle With Other Solutions

Introduction to Alternative Solutions for Latch Paddle

In the realm of access control and door hardware, the latch paddle serves as a reliable option for securing doors and panels. However, various alternative solutions also exist that can meet similar needs, each with unique characteristics. Understanding these alternatives is crucial for B2B buyers who seek the most efficient, cost-effective, and suitable option for their specific applications.

Comparison of Latch Paddle with Alternative Solutions

| Comparison Aspect | Latch Paddle | Slam Latch | Deadlatch Paddle |

|---|---|---|---|

| Performance | High security; durable design | Moderate security; quick operation | Ergonomic, easy to use |

| Cost | Moderate ($23.49 – $31.32) | Low ($5 – $15) | Moderate ($40 – $60) |

| Ease of Implementation | Requires specific cutouts | Easy to install | Moderate installation complexity |

| Maintenance | Low (occasional lubrication) | Very low (minimal moving parts) | Moderate (requires regular checks) |

| Best Use Case | Heavy-duty applications | Light-duty, self-closing doors | High-traffic areas needing easy access |

Detailed Breakdown of Alternatives

1. Slam Latch

Slam latches are designed for quick engagement and are ideal for self-closing doors. They require minimal force to operate, making them suitable for applications where speed is essential. The low cost and simple installation process are significant advantages, especially for light-duty applications. However, their security level is moderate, making them less suitable for environments where high security is a priority.

2. Deadlatch Paddle

Deadlatch paddles are an ergonomic alternative that allows for easy door operation with a simple push or pull. They are compatible with various deadlatch mechanisms and provide a seamless user experience. While offering a higher security level than slam latches, they tend to be more expensive and require moderate installation effort. Their design is particularly beneficial in high-traffic environments where ease of access is critical.

Illustrative image related to latch paddle

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate access control solution, B2B buyers must consider specific application requirements, including security needs, cost constraints, and ease of installation. The latch paddle is an excellent choice for heavy-duty applications requiring durability and security. Conversely, slam latches may be more suitable for environments where quick access is essential but security is less of a concern. For those needing a balance of accessibility and security, deadlatch paddles present an ergonomic option, albeit at a higher cost. Careful evaluation of these factors will guide buyers toward the optimal solution tailored to their operational demands.

Essential Technical Properties and Trade Terminology for latch paddle

What are the Key Technical Properties of a Paddle Latch?

Understanding the technical specifications of paddle latches is essential for B2B buyers to ensure they select the right product for their applications. Here are critical properties to consider:

-

Material Composition

– Paddle latches are commonly made from materials such as mild steel, stainless steel, or aluminum. Mild steel is often used for its strength and cost-effectiveness, while stainless steel is preferred for its corrosion resistance in harsh environments. The choice of material impacts durability, weight, and the latch’s ability to withstand environmental factors. -

Maximum Working Load

– This specification indicates the maximum force the latch can handle without failure, typically measured in Newtons (N). For instance, a latch with a maximum working load of 560 N ensures that it can securely hold the door or panel under normal operational conditions. Understanding this property helps buyers select latches suitable for their specific application needs, particularly in heavy-duty environments. -

Locking Mechanism

– Many paddle latches feature key lockable or padlockable mechanisms that enhance security. The locking mechanism is critical for applications where access control is paramount. Buyers should consider the security needs of their application, especially in sectors like transportation and storage. -

Installation Compatibility

– Paddle latches come in various configurations and sizes, necessitating compatibility with the door or panel thickness. It is crucial for buyers to check the installation requirements and ensure that the latch fits seamlessly into their existing systems. This prevents issues during installation and ensures reliable operation. -

Finish and Coating

– The finish of a paddle latch can affect its resistance to wear and environmental conditions. Common finishes include powder-coated or anodized options, which provide additional protection against rust and corrosion. Selecting the right finish is vital for longevity, particularly in outdoor or industrial applications. -

Adjustability

– Some paddle latches offer adjustable features, allowing users to modify the latch to fit specific operational requirements. This flexibility can be beneficial for applications with varying door sizes or usage patterns, making the latch more versatile and cost-effective over time.

What are Common Trade Terms Related to Paddle Latches?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures that buyers source compatible paddle latches that meet their equipment requirements. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest order size a supplier is willing to accept. Knowing the MOQ helps buyers plan their purchasing strategy effectively, ensuring they meet supplier requirements while managing inventory levels. -

RFQ (Request for Quotation)

– An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. Issuing an RFQ for paddle latches allows buyers to compare pricing, terms, and conditions, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

– These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks when sourcing paddle latches globally. -

Lead Time

– Lead time refers to the amount of time between placing an order and receiving the product. Understanding lead times is essential for buyers to manage project timelines and ensure that paddle latches are available when needed. -

Technical Data Sheet (TDS)

– A TDS provides detailed information about a product’s specifications, performance, and usage. Reviewing the TDS for paddle latches ensures that buyers understand the product’s capabilities and limitations, aiding in selection and application.

Incorporating this knowledge of technical properties and trade terminology enables B2B buyers to make informed decisions, ensuring they select the right paddle latch solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the latch paddle Sector

What Are the Current Market Dynamics and Key Trends Affecting the Latch Paddle Sector?

The latch paddle sector is experiencing significant transformations driven by globalization, technological advancements, and evolving buyer expectations. One of the primary global drivers is the increasing demand for security solutions across various industries, particularly in regions like Africa and South America, where economic growth is accelerating. These regions are witnessing a surge in infrastructure projects, which in turn fuels the demand for robust and reliable latch paddle systems. International buyers are also influenced by the need for customizable solutions that can cater to diverse applications—from automotive to industrial machinery.

Emerging technologies, such as smart locking systems and IoT-enabled latches, are reshaping the landscape. These innovations not only enhance security but also offer data collection capabilities that can improve operational efficiencies. Additionally, the trend towards e-commerce and online procurement is making it easier for buyers to source latch paddle products globally. This shift necessitates that suppliers optimize their digital presence and supply chain logistics to meet the growing demand.

Buyers should also be aware of regional sourcing trends. In Europe, there is a growing preference for high-quality materials and finishes, driven by stringent safety regulations. Meanwhile, in the Middle East, there is an increasing focus on aesthetic appeal alongside functionality, as consumers seek products that complement their modern architectural designs. Understanding these dynamics is crucial for international B2B buyers to make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Latch Paddle Market?

Sustainability and ethical sourcing are becoming paramount in the latch paddle sector as global awareness of environmental issues rises. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental impact. This includes sourcing materials responsibly and ensuring that manufacturing processes minimize waste and emissions.

Illustrative image related to latch paddle

For instance, latch paddles made from recycled materials or those that utilize eco-friendly coatings are gaining traction among conscientious buyers. Furthermore, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential indicators of a supplier’s dedication to sustainable practices. Buyers should seek out manufacturers who transparently disclose their sustainability efforts and material sourcing.

Ethical supply chains are also critical, particularly in regions where labor practices may not meet international standards. Buyers are encouraged to vet suppliers thoroughly, ensuring that their sourcing practices align with ethical labor standards and contribute positively to local communities. By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable industry overall.

What Is the Brief Evolution and History of the Latch Paddle?

The latch paddle has evolved significantly over the years, adapting to changing market demands and technological advancements. Initially designed for simple mechanical applications, latch paddles have transitioned into sophisticated locking mechanisms that offer enhanced security and user convenience.

The earliest iterations of latch paddles were made from basic metals, primarily focusing on functionality. However, as industries advanced, so did the design and materials used in these products. The introduction of corrosion-resistant finishes and ergonomic designs has made latch paddles more durable and user-friendly.

In recent years, the integration of electronic components and smart technology has revolutionized the latch paddle sector. Today, these devices not only serve as locking mechanisms but also as components of broader security systems that can be monitored and controlled remotely. This evolution highlights the importance of innovation and adaptability in meeting the diverse needs of B2B buyers in a competitive marketplace.

By understanding the market dynamics, sustainability considerations, and the historical context of latch paddles, international B2B buyers can make strategic sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of latch paddle

-

How do I solve issues with paddle latch security?

To enhance the security of paddle latches, consider selecting models with key-lockable features or those that allow for padlock integration. Verify the latch’s material and construction, opting for robust options like stainless steel, which offers better durability and resistance to tampering. Additionally, ensure that the latch is installed correctly to prevent unauthorized access. Regular maintenance and inspection can also help identify potential vulnerabilities before they become security issues. -

What is the best paddle latch for outdoor use?

For outdoor applications, choose paddle latches made from corrosion-resistant materials, such as stainless steel or powder-coated finishes. These materials withstand harsh weather conditions, ensuring longevity and reliability. Look for models with a higher maximum working load and secure locking mechanisms to prevent unauthorized access. Evaluating the latch’s design for ease of use in outdoor environments is also crucial, as it should operate smoothly even in challenging conditions. -

How can I customize paddle latches for my specific needs?

Many manufacturers offer customization options for paddle latches, including variations in size, material, and locking mechanisms. To initiate customization, communicate your specific requirements to potential suppliers, including dimensions, load capacity, and finish preferences. Some suppliers may require a minimum order quantity (MOQ) for custom designs, so it’s essential to confirm this upfront. Collaborating closely with the manufacturer can ensure that the final product meets your operational demands. -

What are the minimum order quantities (MOQs) for paddle latches?

Minimum order quantities for paddle latches can vary significantly between suppliers and depend on factors such as the type of latch and customization options. Typically, MOQs can range from as low as 10 units for standard products to 100 or more for custom orders. When sourcing from international suppliers, it’s advisable to inquire about MOQs early in the negotiation process to plan your procurement strategy effectively. -

What payment terms should I expect when sourcing paddle latches internationally?

Payment terms for international B2B transactions often include options such as advance payment, letter of credit, or payment upon delivery. Suppliers may offer discounts for upfront payments, while others might require partial payments before shipment. It’s crucial to discuss and agree on payment terms before finalizing the order to avoid misunderstandings. Be aware of any additional fees related to currency conversion or international bank transfers that may apply. -

How do I ensure quality assurance for paddle latches?

To ensure quality assurance, request detailed product specifications and certifications from suppliers that demonstrate compliance with international standards. Conducting factory visits or audits can also provide insights into their production processes and quality control measures. Additionally, consider ordering samples before committing to larger quantities to evaluate the latch’s performance and durability. Establishing a clear communication channel with your supplier can help address any quality concerns promptly. -

What logistics considerations should I be aware of when importing paddle latches?

When importing paddle latches, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner familiar with international trade to navigate complexities such as tariffs and import duties. It’s also essential to clarify delivery timelines and any potential delays, especially when sourcing from regions with different shipping infrastructures. Proper documentation, including invoices and shipping manifests, should be prepared to ensure smooth customs clearance. -

How can I vet potential suppliers for paddle latches?

Vetting suppliers involves assessing their reputation, experience, and production capabilities. Start by researching their business history, client testimonials, and industry certifications. Engaging in direct communication can provide insights into their customer service and responsiveness. Requesting references and conducting background checks can further validate their reliability. Additionally, consider visiting their facilities or using third-party inspection services to verify their production quality and ethical practices.

Top 8 Latch Paddle Manufacturers & Suppliers List

1. Southco – PX-64-50-412-50 Paddle Latch Lockable

Domain: protex.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ‘PX-64-50-412-50 Paddle Latch Lockable’, ‘manufacturer’: ‘Southco’, ‘material’: ‘Mild Steel’, ‘finish’: ‘Black Powder Coated’, ‘type’: ‘Pull To Open’, ‘key_lockable’: ‘Yes’, ‘max_working_load’: ‘560 N’, ‘weight’: ‘0.5125 Kg’, ‘supplied_with_keys’: ‘2 keys’, ‘unit_price’: {‘1-19’: ‘$31.32′, ’20-49’: ‘$26.62′, ’50-99’: ‘$25.06’, ‘100+’: ‘$23.49’}, ‘in_stock’: ’48’}

2. McMaster – Paddle Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Paddle Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Buyers Products – Mini Stainless Steel Tear-Drop Paddle Latch

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – Mini Stainless Steel Tear-Drop Paddle Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Essentra Components – Keyed Alike Padlockable Lock

Domain: essentracomponents.com

Registered: 2012 (13 years)

Introduction: {“Item Code”: “016620351”, “Overall Length”: “140.0 mm | 5.512 in”, “Overall Width”: “115.0 mm | 4.528 in”, “Key Type”: “Keyed Alike, Padlockable”, “Body Material”: “Steel”, “Cam Material”: “Steel”, “Color”: “Black”, “Finish”: “Black Powder-Coated”, “Handle Type”: “Push-to-Close, Key Operated”, “Handle Includes”: “1 key supplied with each latch”, “Price”: {“1 – 9 units”: “$37.11”, “10+ units”: “$3…

5. Reid Supply – Paddle Latches

Domain: reidsupply.com

Registered: 2004 (21 years)

Introduction: Paddle latches are recessed release paddle handles mounted on enclosure doors, designed to keep contents secure. They are available in various materials and finishes, and can be key locking or non-locking. Paddle latches operate with a strong spring mechanism that prevents slamming, requiring manual operation to open and close. Types include single-point, multi-point, rotary, and special purpose p…

6. Adams Rite – 4591 Deadlatch Paddle

Domain: adamsrite.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “4591 Deadlatch Paddle”, “manufacturer”: “Adams Rite ASSA ABLOY Group”, “description”: “An ergonomically-friendly alternative to a knob or lever handle that operates with a simple push or pull.”, “function”: “An alternative to knob or lever handles, making opening a latched door as natural as opening an unlatched one.”, “compatibility”: [“Adams Rite 4300 Series Deadlatch”, “Adams …

7. Industrial HWE – Paddle Handle Slam Latch – Spring Loaded Lever – Stainless

Domain: industrialhwe.com

Registered: 1997 (28 years)

Introduction: Paddle Handle Slam Latches available in various styles and finishes. Types include single point, 2-point, flush mount, spring loaded, and options for rods. Materials include Stainless Steel and Zinc. Key products include: 1. PADDLE HANDLE SLAM LATCH-SPRING LOADED LEVER-STAINLESS-EBERHARD, SKU: EB25-4975-SS51, Price: $63.83, 149 in stock. 2. 2 POINT STAINLESS STEEL PADDLE HANDLE LATCH-NON-LOCKING-R…

8. Allegis Corp – Locking Paddle Handle Latch

Domain: allegiscorp.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Locking Paddle Handle Latch – Stainless Steel”, “Part Number”: “4901 SS”, “Finish”: “Stainless Steel”, “Locking Mechanism”: “Key-Locking”, “Operation”: “Easily operated by pulling handle outward 45° slam bolt”, “Construction”: “Heavy-duty welded trigger construction”, “Optional Gasket”: “G5”, “Weight”: “1.160000”, “Pack Size”: “1.0000”, “UOM”: “EA”, “Locking Type”: “Single Point”…

Strategic Sourcing Conclusion and Outlook for latch paddle

In today’s competitive global market, strategic sourcing of latch paddles presents a unique opportunity for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. By understanding the diverse types and functionalities of paddle latches, businesses can make informed decisions that enhance operational efficiency and security.

Illustrative image related to latch paddle

Key takeaways include recognizing the importance of choosing the right material—whether mild steel or stainless steel—and understanding the benefits of features such as key lockability and adjustable designs. Additionally, leveraging volume purchasing can significantly reduce costs, making it essential to consider quantity discounts when sourcing these products.

As the demand for reliable and efficient locking mechanisms continues to rise, companies that invest in strategic sourcing will not only enhance their product offerings but also strengthen their supply chain resilience. This forward-thinking approach will enable businesses to stay ahead of market trends and customer needs.

International buyers are encouraged to explore the available options and suppliers in the market actively. By doing so, they can secure high-quality latch paddles that meet their specific requirements while optimizing their procurement strategies for sustained growth and success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.