How to Source Hyd Press Cylinder Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for hyd press cylinder

In today’s dynamic global marketplace, sourcing the right hydraulic press cylinder can present significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The need for reliable, high-performance hydraulic cylinders is paramount across industries, from construction and manufacturing to automotive and aerospace. This guide aims to streamline the procurement process by providing an in-depth analysis of the various types of hydraulic press cylinders available, their specific applications, and essential considerations for supplier vetting.

Understanding the intricacies of hydraulic press cylinders—including single-acting versus double-acting designs, capacity variations, and specialized models—can empower international buyers to make informed purchasing decisions. Furthermore, this guide will cover critical factors such as cost considerations, compliance with international standards, and the importance of durability and maintenance in different environmental conditions.

By equipping B2B buyers with the knowledge to navigate the complexities of the hydraulic press cylinder market, this comprehensive resource will facilitate smarter sourcing strategies and enhance operational efficiencies. Whether you are in Vietnam looking to boost your manufacturing capabilities or in Nigeria seeking reliable equipment for construction projects, this guide is tailored to meet your specific needs and help you achieve your business objectives effectively.

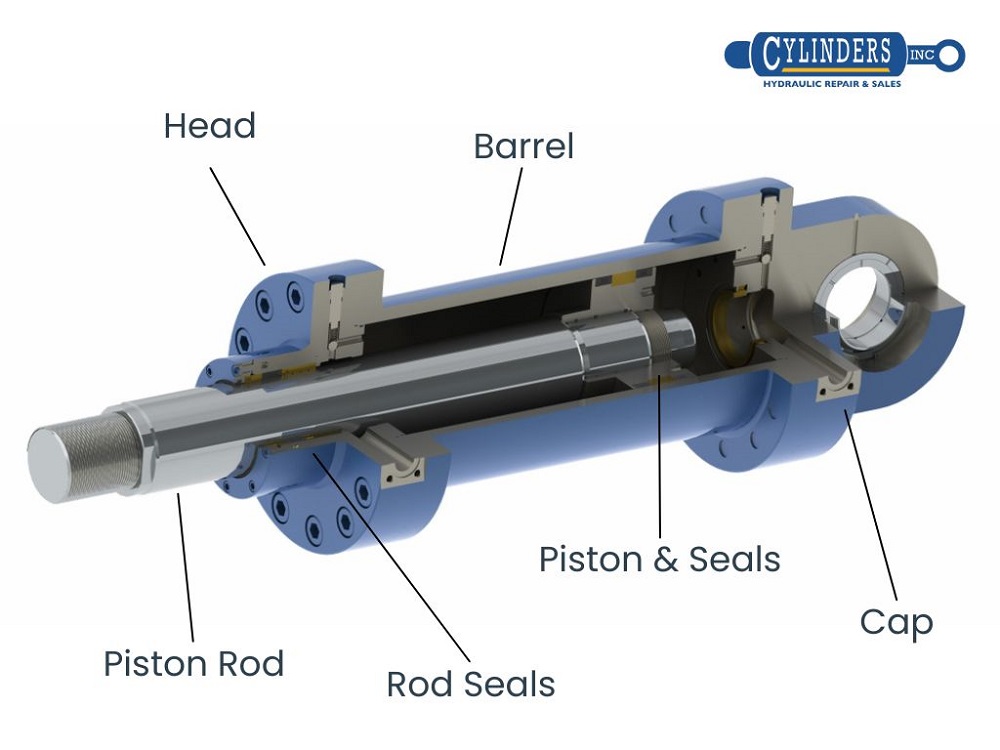

Understanding hyd press cylinder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Acting Cylinder | Operates in one direction; simpler design | General lifting tasks | Pros: Easy to use; lower cost. Cons: Limited functionality; slower operation. |

| Double-Acting Cylinder | Operates in both directions; offers precision | Pressing, bending, and holding applications | Pros: Faster operation; better control. Cons: Higher cost; more complex installation. |

| Hollow Plunger Cylinder | Features a hollow bore for pulling and tensioning | Tensioning applications, cable pulling | Pros: Versatile; allows for pulling applications. Cons: Requires specific setups; limited stroke length. |

| High Tonnage Cylinder | Designed for heavy lifting; robust construction | Industrial machinery and construction | Pros: High capacity; durable. Cons: Heavier; may require more powerful pumps. |

| Telescopic Cylinder | Multi-stage design for extended lift heights | Applications needing significant vertical lift | Pros: Compact when collapsed; versatile. Cons: More complex; potentially higher maintenance. |

What are the Characteristics of Single-Acting Cylinders?

Single-acting cylinders are characterized by their straightforward design, where hydraulic fluid powers the plunger to extend in one direction. They are typically used for general lifting tasks in workshops and construction sites. Buyers should consider the simplicity and cost-effectiveness of these cylinders, making them ideal for applications where the load is only lifted and not lowered using the cylinder. However, their functionality is limited, as they do not retract under hydraulic pressure, which may slow down operations in more complex applications.

How Do Double-Acting Cylinders Enhance Efficiency?

Double-acting cylinders utilize hydraulic pressure to extend and retract the plunger, providing better control and speed. These cylinders are suitable for applications requiring precise movements, such as pressing, bending, and holding materials. B2B buyers should prioritize double-acting cylinders for tasks that demand efficiency and accuracy. While they come at a higher price point and may require more complex installation, the benefits of faster cycle times and improved operational control often justify the investment in high-demand industrial settings.

In What Scenarios are Hollow Plunger Cylinders Most Effective?

Hollow plunger cylinders are uniquely designed with a hollow bore, allowing for pulling and tensioning applications, such as cable or wire tensioning. These cylinders are versatile and can be used in various industries, including construction and manufacturing. When considering a hollow plunger cylinder, buyers should evaluate the specific requirements of their applications, including the need for pulling capabilities. While they offer unique advantages, the limited stroke length and the need for compatible setups may pose challenges in some scenarios.

Why Choose High Tonnage Cylinders for Heavy Lifting?

High tonnage cylinders are built for heavy lifting and are known for their robust construction and capacity, often ranging from 50 to 1,000 tons. They are ideal for industrial machinery, construction projects, and any application where substantial force is required. B2B buyers should consider these cylinders when dealing with significant loads, as they provide durability and reliability. However, the increased weight and the need for more powerful hydraulic pumps may require additional considerations in terms of logistics and installation.

What Advantages Do Telescopic Cylinders Offer?

Telescopic cylinders feature a multi-stage design that allows for extended lift heights while remaining compact when collapsed. These cylinders are particularly beneficial in applications where space is limited but significant vertical lift is necessary, such as in construction or material handling. B2B buyers should consider telescopic cylinders for their versatility and space-saving benefits. However, the complexity of their design may lead to higher maintenance needs and initial costs, which should be evaluated against the operational benefits they provide.

Key Industrial Applications of hyd press cylinder

| Industry/Sector | Specific Application of hyd press cylinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Metal forming and stamping | Increases production efficiency and precision | Assess cylinder tonnage and stroke length needed |

| Construction | Lifting and positioning heavy structural elements | Enhances safety and reduces manual labor | Consider environmental conditions and portability |

| Automotive | Assembly line operations for vehicle manufacturing | Streamlines assembly processes, reducing cycle times | Ensure compatibility with existing machinery |

| Mining and Quarrying | Rock crushing and material handling | Improves operational efficiency and reduces downtime | Evaluate pressure ratings and durability under load |

| Renewable Energy | Wind turbine installation and maintenance | Facilitates heavy lifting operations, ensuring safety | Focus on custom solutions for unique project needs |

How is a Hydraulic Press Cylinder Used in Manufacturing?

In the manufacturing sector, hydraulic press cylinders are crucial for metal forming and stamping processes. These cylinders apply immense pressure to shape or cut metal sheets into desired forms, enhancing production efficiency and precision. For international buyers, it’s essential to consider the cylinder’s tonnage and stroke length to ensure compatibility with their specific machinery. Additionally, understanding the hydraulic system’s maintenance needs can prevent costly downtimes.

What Role Do Hydraulic Press Cylinders Play in Construction?

In construction, hydraulic press cylinders are employed for lifting and positioning heavy structural elements, such as beams and columns. This application significantly enhances safety by minimizing manual lifting and reduces the risk of workplace injuries. Buyers in regions like Africa and South America should evaluate the environmental conditions—such as humidity and dust—which may impact the durability of the cylinders. Portability is another key consideration, especially for projects in remote locations.

How Are Hydraulic Press Cylinders Utilized in the Automotive Industry?

The automotive industry relies heavily on hydraulic press cylinders for assembly line operations. These cylinders streamline processes by precisely applying pressure needed to assemble parts, thereby reducing cycle times and improving overall productivity. For B2B buyers, ensuring compatibility with existing assembly machinery is critical. It’s also advisable to consider the availability of replacement parts and service support to minimize disruptions in production.

What Applications Exist for Hydraulic Press Cylinders in Mining and Quarrying?

In the mining and quarrying sectors, hydraulic press cylinders are used for rock crushing and material handling. They facilitate the crushing of large rocks into manageable sizes, thus improving operational efficiency and reducing downtime. Buyers should evaluate the pressure ratings and durability of the cylinders, as these applications often involve extreme conditions. Additionally, sourcing from suppliers who understand the specific challenges of the mining industry can provide a competitive advantage.

How Do Hydraulic Press Cylinders Support Renewable Energy Initiatives?

Hydraulic press cylinders play a vital role in the installation and maintenance of wind turbines within the renewable energy sector. They are used to lift and position heavy turbine components, ensuring safe and efficient operations. For buyers in Europe and the Middle East, focusing on custom solutions that cater to unique project requirements is essential. Additionally, understanding the lifecycle and maintenance needs of these cylinders can lead to significant cost savings over time.

3 Common User Pain Points for ‘hyd press cylinder’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Cylinder Specifications for Specific Applications

The Problem: B2B buyers often struggle with selecting the correct hydraulic press cylinder that meets their unique operational requirements. Given the vast array of cylinder types, tonnages, and stroke lengths available, buyers may inadvertently choose a cylinder that lacks the necessary capacity or precision for their application. This can lead to inefficiencies, potential damage to machinery, or even safety hazards during operation, particularly in industries like construction or manufacturing where precision is paramount.

The Solution: To navigate this complexity, buyers should begin by conducting a thorough analysis of their specific application needs. This includes understanding the weight of the materials to be lifted or pressed, the required stroke length for the job, and the available space for the cylinder installation. Additionally, consulting with hydraulic system specialists or manufacturers can provide valuable insights into the best cylinder configurations. Once the requirements are clear, utilizing detailed product specifications and load charts from reputable suppliers can aid in making an informed decision. For instance, if a high-tonnage application is needed, selecting a cylinder with a capacity range that exceeds the expected load by at least 20% is advisable to ensure safety and longevity.

Scenario 2: Challenges with Cylinder Compatibility and Replacement Parts

The Problem: Another common pain point for B2B buyers is ensuring compatibility when replacing hydraulic press cylinders or sourcing parts for existing systems. Many manufacturers produce proprietary designs, leading to frustration when trying to find suitable replacement parts or when integrating new cylinders into older systems. This can result in unexpected downtime, increased costs, and operational inefficiencies.

The Solution: To mitigate compatibility issues, buyers should maintain a comprehensive inventory of their hydraulic systems, including detailed specifications and manufacturer information for each component. When sourcing replacement cylinders, it’s critical to verify compatibility by checking mounting dimensions, connection types, and hydraulic fluid compatibility. Buyers can also opt for universal or adaptable hydraulic cylinders that offer greater flexibility. Establishing a relationship with suppliers that provide customer support for compatibility questions can also save time and resources. Furthermore, investing in custom solutions from manufacturers who specialize in bespoke hydraulic cylinders ensures that any specific operational needs are met, thus minimizing the risk of incompatibility.

Scenario 3: Safety Concerns Related to Cylinder Operation and Maintenance

The Problem: Safety is a paramount concern in industries utilizing hydraulic press cylinders, as improper usage or maintenance can lead to catastrophic failures or accidents. B2B buyers may lack adequate training or resources to ensure their team operates and maintains the hydraulic systems safely. This not only jeopardizes employee safety but can also lead to costly equipment damage and regulatory non-compliance.

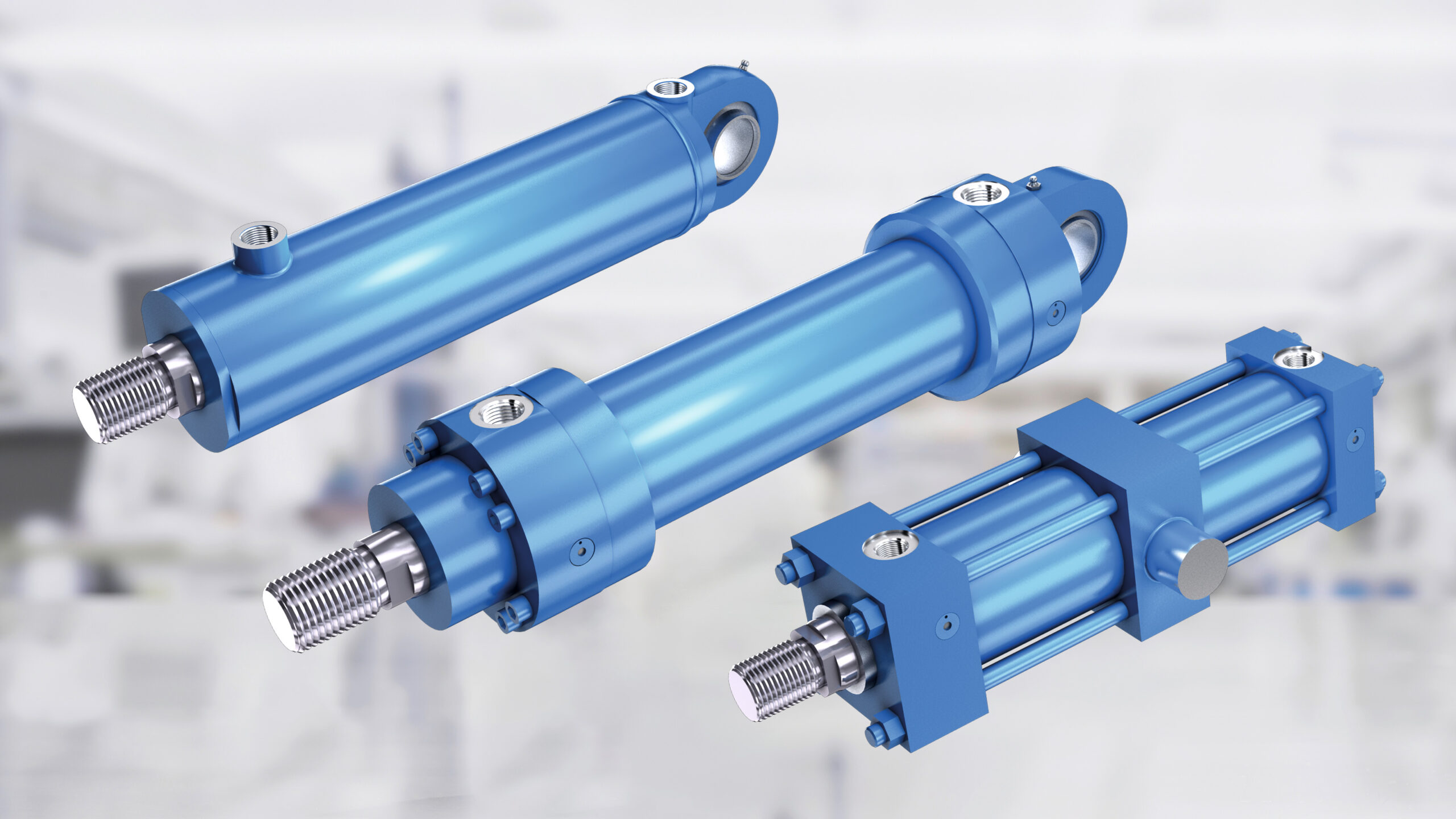

Illustrative image related to hyd press cylinder

The Solution: Implementing a robust training program focused on the safe operation and maintenance of hydraulic press cylinders is essential. Buyers should seek training sessions provided by manufacturers or certified trainers to educate their teams on best practices, including proper cylinder handling, load management, and emergency procedures. Additionally, establishing a routine maintenance schedule that includes regular inspections, fluid checks, and prompt replacement of worn parts is crucial. Buyers can enhance safety by investing in high-quality cylinders equipped with built-in safety features, such as pressure relief valves and locking mechanisms, which provide added protection during operation. Creating a culture of safety that prioritizes ongoing education and proactive maintenance can significantly reduce risks associated with hydraulic press operations.

Strategic Material Selection Guide for hyd press cylinder

What Are the Common Materials Used for Hydraulic Press Cylinders?

When selecting materials for hydraulic press cylinders, several factors come into play, including mechanical properties, environmental resistance, and cost-effectiveness. Understanding the characteristics of various materials can help international B2B buyers make informed decisions that align with their operational needs.

How Does Steel Perform in Hydraulic Press Cylinder Applications?

Key Properties: Steel is renowned for its high tensile strength and durability, making it an ideal choice for hydraulic press cylinders. It typically withstands high pressures (up to 10,000 psi) and has excellent fatigue resistance. Corrosion resistance can be enhanced through coatings or alloying.

Pros & Cons: Steel cylinders are highly durable and can handle extreme conditions, but they can be heavy, impacting portability. Manufacturing processes for steel can be complex, leading to higher costs, especially for custom designs. However, their longevity often justifies the investment.

Impact on Application: Steel is compatible with various hydraulic fluids, including mineral oils and water-based fluids. However, it may require regular maintenance to prevent rust, particularly in humid environments.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial. Buyers from regions like Africa and South America should consider local availability and the potential for corrosion due to environmental factors.

What Advantages Do Aluminum Cylinders Offer?

Key Properties: Aluminum is lightweight and possesses good corrosion resistance, making it suitable for applications where weight is a critical factor. While it has lower tensile strength than steel, advancements in alloy technology have improved its performance.

Pros & Cons: The primary advantage of aluminum is its reduced weight, which enhances maneuverability. However, it is generally less durable than steel and may not be suitable for extremely high-pressure applications. The manufacturing process can also be less complex, leading to lower costs.

Impact on Application: Aluminum cylinders are compatible with a range of hydraulic fluids but may not perform well in high-temperature environments. They are ideal for applications requiring frequent movement or where weight savings are essential.

Considerations for International Buyers: Buyers should ensure that aluminum products meet relevant standards and consider the availability of replacement parts. In regions with high humidity, additional protective coatings may be necessary.

How Do Composite Materials Compare for Hydraulic Press Cylinders?

Key Properties: Composite materials, often a blend of polymers and fibers, offer excellent corrosion resistance and can be engineered for specific mechanical properties. They are typically lighter than metals and can be designed for a variety of applications.

Illustrative image related to hyd press cylinder

Pros & Cons: Composites can be tailored for specific performance characteristics, making them versatile. However, they may not withstand high pressures as effectively as metals, limiting their use in heavy-duty applications. The manufacturing process can also be complex and costly.

Impact on Application: Composites are suitable for environments where corrosion is a significant concern, such as marine applications. They may not be compatible with all hydraulic fluids, requiring careful selection.

Considerations for International Buyers: Compliance with industry standards is essential, especially in regions with stringent regulations. Buyers should also consider the availability of composite materials and their long-term durability in specific applications.

What Role Does Cast Iron Play in Hydraulic Press Cylinder Design?

Key Properties: Cast iron is known for its excellent wear resistance and ability to dampen vibrations. It can handle moderate pressures and is often used in stationary applications.

Pros & Cons: The durability and vibration-damping properties of cast iron make it suitable for specific applications. However, it is heavier and more brittle than other materials, which can limit its use in mobile applications. Manufacturing processes can also lead to higher costs.

Illustrative image related to hyd press cylinder

Impact on Application: Cast iron cylinders are often used in applications where stability is more critical than mobility. They are compatible with many hydraulic fluids but may require protective coatings to prevent corrosion.

Considerations for International Buyers: Buyers should verify that cast iron products meet local standards and consider the implications of weight in their application. In regions with varying climates, additional protective measures may be necessary.

Summary Table of Material Selection for Hydraulic Press Cylinders

| Material | Typical Use Case for hyd press cylinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High tensile strength and durability | Heavy and complex manufacturing | High |

| Aluminum | Lightweight and portable applications | Reduced weight and good corrosion resistance | Lower strength than steel | Medium |

| Composite | Corrosion-sensitive environments | Tailored properties and lightweight | Limited pressure resistance | High |

| Cast Iron | Stationary applications | Excellent wear resistance | Heavy and brittle | Medium |

This guide provides essential insights into material selection for hydraulic press cylinders, enabling B2B buyers to make informed decisions that align with their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hyd press cylinder

What Are the Main Stages of Manufacturing Hydraulic Press Cylinders?

The manufacturing of hydraulic press cylinders involves several critical stages, each designed to ensure the final product meets high-performance and durability standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials, typically high-strength steel or aluminum alloys. These materials are chosen for their excellent mechanical properties, including tensile strength and corrosion resistance. After procurement, materials undergo initial inspections to verify compliance with specifications. This is crucial for B2B buyers who need assurance that their suppliers adhere to international standards.

-

Forming: The forming stage involves cutting, bending, and welding the prepared materials into the cylinder shape. Advanced techniques such as CNC machining and hydraulic pressing are commonly employed to achieve precise dimensions. This stage is vital as it defines the cylinder’s structural integrity. Manufacturers may use simulation software to optimize the design before physical production, reducing waste and ensuring efficiency.

-

Assembly: Once the components are formed, they are assembled, which includes fitting the cylinder body, piston, seals, and other essential parts. This process often employs automated assembly lines to enhance consistency and reduce human error. Special attention is given to the alignment and sealing of components to prevent hydraulic leaks, which can lead to operational failures.

-

Finishing: The final stage includes surface treatment processes such as anodizing or applying corrosion-resistant coatings. These treatments not only enhance the aesthetic appeal but also significantly extend the lifespan of the cylinders in harsh environments. Quality finishing processes help ensure that the cylinders can withstand high pressures and resist wear and tear during operation.

How Is Quality Assurance Implemented in Hydraulic Press Cylinder Manufacturing?

Quality assurance (QA) is a fundamental aspect of hydraulic press cylinder manufacturing, ensuring that products meet safety and performance standards. The QA process typically adheres to several international and industry-specific standards.

-

International Standards: Many manufacturers comply with ISO 9001, which outlines criteria for a quality management system. This certification is globally recognized and signifies that a company consistently meets customer and regulatory requirements. For B2B buyers, selecting suppliers with ISO 9001 certification can mitigate risks associated with product quality.

-

Industry-Specific Standards: In addition to ISO, certifications such as CE marking and API (American Petroleum Institute) standards are relevant for hydraulic press cylinders. CE marking indicates compliance with EU safety, health, and environmental protection standards, which is particularly important for buyers in Europe. API standards ensure that products meet the demands of the oil and gas industry, making them crucial for buyers in those sectors.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential throughout the manufacturing process to identify and rectify issues before the final product reaches the market. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. Materials are tested against specifications to ensure they meet quality standards. For buyers, understanding a supplier’s IQC process can provide insights into the reliability of the materials used in production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring processes such as machining, welding, and assembly. Regular checks are conducted to ensure that production parameters are maintained, and any deviations are corrected promptly. This proactive approach helps prevent defects from progressing to later stages.

-

Final Quality Control (FQC): Before the hydraulic press cylinders are packaged and shipped, they undergo rigorous final inspections. This includes dimensional checks, pressure testing, and performance evaluations to ensure that each cylinder functions as intended. FQC is critical for B2B buyers who require assurance that the products they receive will perform reliably in their applications.

What Testing Methods Are Commonly Used for Hydraulic Press Cylinders?

Various testing methods are employed to validate the performance and safety of hydraulic press cylinders. Common testing techniques include:

-

Hydraulic Pressure Testing: This method involves subjecting the cylinders to high-pressure conditions to verify their structural integrity and leak-tightness. Cylinders are filled with hydraulic fluid and pressurized to ensure they can withstand the maximum operating pressures without failure.

-

Dimensional Inspection: Utilizing tools such as calipers and gauges, manufacturers perform dimensional inspections to ensure that the cylinders meet specified tolerances. This step is crucial for ensuring compatibility with other hydraulic systems and components.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal and surface defects without damaging the cylinders. NDT is essential for identifying potential weaknesses that could compromise the performance of hydraulic cylinders under load.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take an active role in verifying the quality control processes of their suppliers to ensure that they are receiving products that meet their standards. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality control measures, and compliance with international standards. This firsthand assessment can provide valuable insights into the reliability and capabilities of potential suppliers.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand the specific quality measures implemented during production. These reports should outline testing methods, results, and any corrective actions taken to address identified issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s manufacturing and quality assurance processes. These agencies can conduct independent audits and testing, offering additional assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may encounter specific challenges related to quality control. Key considerations include:

-

Regulatory Compliance: Different regions may have varying regulations and standards that affect product certifications. Buyers must ensure that suppliers are compliant with the relevant standards in their target markets to avoid legal issues and ensure product acceptance.

-

Cultural Differences: Variations in business practices and communication styles can impact quality assurance processes. Building strong relationships with suppliers can facilitate better understanding and adherence to quality expectations.

-

Logistical Challenges: International shipping can introduce risks related to product damage or loss of quality during transit. Buyers should discuss packaging and handling procedures with suppliers to minimize these risks and ensure that products arrive in optimal condition.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting suppliers for hydraulic press cylinders, ensuring they receive reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hyd press cylinder’

Introduction

In the competitive landscape of industrial machinery, sourcing the right hydraulic press cylinder is critical for operational efficiency and safety. This guide provides a structured checklist for B2B buyers, ensuring that you make informed decisions while procuring hydraulic press cylinders. By following these steps, you can streamline your sourcing process, minimize risks, and optimize performance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the hydraulic press cylinder meets your operational requirements. Consider factors such as load capacity (tonnage), stroke length, and type (single-acting vs. double-acting). Additionally, assess the working pressure and any specific features needed for your application, such as corrosion resistance or customization options.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to identify those with a strong market reputation. Look for manufacturers that specialize in hydraulic cylinders and have experience in your specific industry. Utilize resources such as industry forums, trade shows, and online directories to gather information about suppliers’ product ranges and capabilities.

Step 3: Evaluate Supplier Certifications

Before proceeding with a purchase, verify that suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO 9001 ensure that the supplier adheres to quality management practices. Additionally, check for compliance with safety regulations specific to your region, which can significantly impact operational safety and liability.

Step 4: Request Product Samples or Demonstrations

When narrowing down your options, request samples or demonstrations of the hydraulic press cylinders. This allows you to assess the quality and performance of the products firsthand. Pay attention to the construction materials, ease of operation, and any unique features that may enhance functionality in your specific application.

Step 5: Analyze Pricing and Payment Terms

Cost is a critical factor in procurement decisions, but it should not be the only consideration. Compare pricing from different suppliers, but also evaluate the total cost of ownership, including shipping, installation, and maintenance. Additionally, negotiate payment terms that align with your cash flow needs, ensuring that they are manageable for your business operations.

Step 6: Check Warranty and After-Sales Support

A robust warranty and reliable after-sales support are essential for long-term satisfaction with your hydraulic press cylinder. Inquire about warranty coverage, including what it entails and the duration. Also, assess the supplier’s customer service reputation and availability of technical support, as this can be crucial for resolving issues quickly and minimizing downtime.

Step 7: Final Approval and Order Placement

Once you have completed the evaluation process, prepare for final approval from your procurement team or stakeholders. Ensure all documentation is in order, including contracts, specifications, and delivery timelines. After approval, place your order and confirm all details with the supplier to ensure a smooth transaction and timely delivery.

Illustrative image related to hyd press cylinder

By following this checklist, B2B buyers can confidently navigate the sourcing process for hydraulic press cylinders, ensuring they select the best products for their operational needs.

Comprehensive Cost and Pricing Analysis for hyd press cylinder Sourcing

What Are the Key Cost Components in Hydraulic Press Cylinder Sourcing?

When sourcing hydraulic press cylinders, understanding the cost structure is crucial for international B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

- Materials: The choice of materials significantly impacts pricing. High-strength steel or aluminum alloys used in manufacturing hydraulic cylinders can vary in cost based on market fluctuations and supplier contracts.

- Labor: Skilled labor is essential for precision machining and assembly. Labor costs can vary widely depending on the region and the level of expertise required.

- Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient operations can help lower these overheads.

- Tooling: Custom tooling for specific applications can add substantial costs. Investing in versatile tooling can mitigate these expenses over time.

- Quality Control: Implementing rigorous QC processes ensures that the cylinders meet safety and performance standards, which can influence the overall cost.

- Logistics: Shipping and handling costs, especially for international transactions, can significantly affect pricing. Understanding Incoterms is vital for calculating total costs.

- Margin: Suppliers will typically mark up their prices to include profit margins. This can vary based on competition and market demand.

What Influences Pricing for Hydraulic Press Cylinders?

Several factors affect the pricing of hydraulic press cylinders, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

- Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounts. Establishing a long-term relationship with suppliers can also secure better pricing.

- Specifications and Customization: Customized cylinders tailored to specific applications may incur additional costs. Providing clear specifications can help suppliers give accurate quotes.

- Materials: The quality and type of materials used can affect both the performance and cost. Higher-quality materials generally command higher prices.

- Quality and Certifications: Certifications such as ISO and ANSI can add credibility but may also increase costs. Buyers should weigh the benefits of certified products against their budget constraints.

- Supplier Factors: Supplier reputation, production capabilities, and geographic location play significant roles in pricing. Established suppliers may charge more due to their quality assurance and customer service.

- Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating the total landed cost.

How Can Buyers Negotiate Cost-Effectively for Hydraulic Press Cylinders?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can employ several strategies to negotiate favorable terms:

- Leverage Volume Discounts: Consider placing larger orders to negotiate better pricing. Suppliers may offer discounts for bulk purchases.

- Request Transparent Pricing: Ask suppliers to break down costs. Understanding the components can help identify areas for negotiation.

- Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, performance, and reliability.

- Timing and Market Trends: Keep an eye on market conditions and material prices. Timing your purchase during favorable market conditions can lead to significant savings.

- Explore Multiple Suppliers: Don’t settle for the first quote. Comparing offers from multiple suppliers can provide leverage in negotiations.

What Pricing Nuances Should International Buyers Be Aware Of?

For international B2B buyers, particularly from emerging markets, there are unique pricing nuances to consider:

Illustrative image related to hyd press cylinder

- Currency Fluctuations: Exchange rates can impact pricing. Locking in rates when negotiating can mitigate this risk.

- Import Duties and Tariffs: Be aware of any applicable tariffs, which can significantly affect the final cost of imported hydraulic cylinders.

- Cultural Factors in Negotiation: Understanding cultural differences in negotiation styles can facilitate smoother discussions and potentially better terms.

Conclusion

In summary, navigating the cost and pricing structure for hydraulic press cylinders requires a comprehensive understanding of various factors. By considering the outlined cost components, pricing influencers, and negotiation strategies, international buyers can make informed purchasing decisions while optimizing their budgets. Always remember to request indicative prices, as final costs can vary based on the specifics of the order and market conditions.

Alternatives Analysis: Comparing hyd press cylinder With Other Solutions

Understanding Alternatives to Hydraulic Press Cylinders

When evaluating solutions for lifting, pressing, or manipulating heavy loads, hydraulic press cylinders often come to mind due to their efficiency and versatility. However, various alternatives also exist that may better suit specific applications or operational needs. This section will explore viable alternatives, comparing their performance, cost, ease of implementation, maintenance requirements, and best use cases.

Comparison Table of Hydraulic Press Cylinder and Alternatives

| Comparison Aspect | Hyd Press Cylinder | Pneumatic Cylinder | Mechanical Press |

|---|---|---|---|

| Performance | High force application; precise control | Good for repetitive tasks; moderate force | High precision; consistent output |

| Cost | Moderate to high initial investment | Generally lower cost | Initial investment can be high |

| Ease of Implementation | Requires hydraulic setup and maintenance | Easier to install; less specialized equipment | More straightforward installation |

| Maintenance | Requires regular inspection and fluid checks | Low maintenance; air filters may need changing | Minimal maintenance; lubrication needed |

| Best Use Case | Heavy industrial applications; custom designs | Assembly lines; automotive industries | Precision tasks; metal forming and stamping |

In-Depth Analysis of Alternatives

Pneumatic Cylinder

Pneumatic cylinders utilize compressed air to create motion and are favored for their speed and simplicity. They are often less expensive than hydraulic systems, making them accessible for small to medium-sized operations. The installation process is generally easier, requiring less specialized equipment and training. However, their performance is limited in terms of force output compared to hydraulic cylinders, making them less suitable for heavy-duty applications. They are ideal for repetitive tasks, such as in assembly lines or packaging operations.

Mechanical Press

Mechanical presses are machines that utilize a mechanical advantage to compress or shape materials. They offer high precision and consistency, making them suitable for tasks that require exact specifications, such as metal stamping or forming. While the initial investment may be significant, mechanical presses often require less maintenance than hydraulic systems, as they have fewer moving parts and do not rely on fluid systems. However, they may not provide the same force output as hydraulic cylinders for heavy lifting applications, limiting their use to lighter tasks or specific types of manufacturing.

How to Choose the Right Solution for Your Needs

When selecting between hydraulic press cylinders and alternative solutions, consider the specific requirements of your operation. If your application demands high force and precision, hydraulic cylinders may be the best fit. For operations focusing on speed and cost-efficiency, pneumatic cylinders could serve as a viable alternative. If precision is paramount, particularly in metalworking, mechanical presses may be the ideal choice. Ultimately, understanding your operational needs, budget constraints, and maintenance capabilities will guide you in making an informed decision that enhances productivity and efficiency in your business operations.

Essential Technical Properties and Trade Terminology for hyd press cylinder

What Are the Key Technical Properties of Hydraulic Press Cylinders?

Hydraulic press cylinders are crucial components in various industrial applications, and understanding their technical specifications is vital for making informed purchasing decisions. Here are several critical specifications to consider:

-

Capacity (Tonnage)

This refers to the maximum load the cylinder can lift, typically expressed in tons. Options often range from 2.5 tons to 1,000 tons. For B2B buyers, selecting the appropriate capacity is essential to ensure the cylinder can handle the intended workload without risking failure or inefficiency. -

Stroke Length

The stroke length indicates how far the cylinder can extend during operation, commonly measured in inches. This measurement is crucial for applications that require specific lifting heights. Buyers should choose a cylinder with a stroke length that meets their operational needs to avoid limitations in production processes. -

Operating Pressure

Operating pressure, usually expressed in psi (pounds per square inch), determines the force the cylinder can exert. Common ratings range from 3,000 psi to 10,000 psi. Understanding the required operating pressure is vital for ensuring that the hydraulic system operates efficiently and safely under expected loads. -

Material Grade

Hydraulic cylinders are often made from high-strength steel or aluminum, which influences durability and weight. Steel offers robustness for heavy-duty applications, while aluminum provides lightweight solutions for mobility. Buyers should consider the environment and application to select the right material that balances strength and weight. -

Type of Cylinder (Single vs. Double Acting)

Single-acting cylinders move in one direction and rely on external forces for retraction, while double-acting cylinders can push and pull, offering greater control and efficiency. This distinction is essential for B2B buyers to match the cylinder type with the operational requirements of their machinery. -

Corrosion Resistance

Many hydraulic cylinders are treated with corrosion-resistant coatings to prolong their lifespan, especially in harsh environments. Buyers should evaluate the environmental conditions in which the cylinder will be used to ensure optimal durability and performance.

Which Trade Terminology Should B2B Buyers Understand in Hydraulic Press Cylinder Transactions?

Familiarizing oneself with industry terminology can streamline the purchasing process and enhance communication. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM specifications ensures they receive components that meet the required standards and compatibility for their machinery. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it affects inventory management and overall purchasing costs. Buyers should negotiate MOQs to align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for specific products. For B2B buyers, issuing an RFQ can help in comparing offers from multiple suppliers, ensuring they secure the best possible deal. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers engaged in cross-border transactions to avoid misunderstandings. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is critical for planning production schedules and ensuring timely project completion. -

Warranty and Service Agreements

Warranty terms and service agreements outline the manufacturer’s responsibilities for defects and maintenance. Buyers should carefully review these agreements to ensure they receive adequate support and protection for their investment.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing hydraulic press cylinders, ultimately enhancing operational efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the hyd press cylinder Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Press Cylinder Sector?

The hydraulic press cylinder market is experiencing significant growth, driven by increased demand across various sectors, including construction, manufacturing, and automotive industries. As global infrastructure projects expand, the need for efficient lifting and pressing solutions rises. Emerging markets in Africa, South America, the Middle East, and Europe are witnessing a surge in construction activities, which further propels the demand for hydraulic cylinders. Additionally, advancements in technology, such as IoT-enabled hydraulic systems and automation, are transforming sourcing practices. These innovations allow for real-time monitoring and enhanced efficiency, making them appealing to international B2B buyers.

Another trend is the growing preference for customized solutions. Businesses increasingly seek hydraulic cylinders tailored to specific applications, enhancing operational efficiency. Moreover, the rise of e-commerce platforms has simplified sourcing, enabling buyers from diverse regions to access a broader range of products and suppliers. This shift towards digital procurement is particularly beneficial for buyers in developing regions like Nigeria and Vietnam, where local suppliers may have limitations in inventory and offerings.

How Does Sustainability Influence Sourcing Decisions in the Hydraulic Press Cylinder Sector?

Sustainability is becoming a critical factor in sourcing decisions within the hydraulic press cylinder sector. As environmental concerns escalate, businesses are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and processes that minimize environmental impact. Ethical sourcing is gaining traction, with companies increasingly seeking to ensure that their supply chains are free from unethical labor practices and that they comply with international labor standards.

B2B buyers should also consider suppliers that hold certifications such as ISO 14001 for environmental management and ISO 9001 for quality assurance. These certifications indicate a supplier’s commitment to sustainability and quality, providing buyers with confidence in their sourcing decisions. Furthermore, incorporating ‘green’ materials, such as recyclable metals and sustainable packaging solutions, can enhance a company’s reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution of Hydraulic Press Cylinders and Its Relevance to Today’s Market?

The hydraulic press cylinder has evolved significantly since its inception in the late 19th century. Initially designed for basic lifting tasks, the technology has advanced to include sophisticated features like double-acting designs, which provide better control and efficiency. Over the decades, hydraulic cylinders have become integral to various industries, from heavy machinery to automotive manufacturing.

Today, the evolution of hydraulic press cylinders reflects broader trends in industrial automation and efficiency. The introduction of smart technology and automation in hydraulic systems has revolutionized the way these products are utilized, allowing for increased productivity and precision. For B2B buyers, understanding this evolution is crucial, as it informs decisions on selecting advanced hydraulic solutions that align with modern operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of hyd press cylinder

-

How do I select the right hydraulic press cylinder for my application?

Choosing the appropriate hydraulic press cylinder involves assessing your specific needs, such as the required lifting capacity, stroke length, and application type. Evaluate whether you need a single-acting or double-acting cylinder based on your operational requirements. Consider the cylinder’s material and finish, particularly in environments prone to corrosion. Additionally, consult with suppliers about customization options, which can help tailor the cylinder to fit your machinery or operational demands. -

What is the best hydraulic press cylinder for heavy-duty applications?

For heavy-duty applications, high-tonnage hydraulic cylinders are ideal. These cylinders, often rated from 50 to 1,000 tons, are designed for durability and reliability under extreme pressures. Look for features such as corrosion-resistant coatings and robust construction materials. Ensure the selected cylinder can accommodate your specific stroke length requirements and is compatible with your existing hydraulic system to maximize efficiency and safety. -

What factors should I consider when vetting suppliers for hydraulic press cylinders?

When vetting suppliers, consider their industry reputation, experience, and certifications such as ISO 9001 for quality assurance. Request references and evaluate customer reviews to gauge reliability and service quality. It’s also essential to assess their product range, including customization options, and inquire about after-sales support, warranty policies, and response times for inquiries or complaints. Engaging in direct communication can also help clarify any concerns. -

What are common payment terms for international purchases of hydraulic cylinders?

Payment terms can vary widely by supplier and region but typically include options like advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60). For international transactions, using a letter of credit can provide security for both parties. Clarify the payment method during negotiations to avoid misunderstandings, and ensure that any exchange rates or transaction fees are clearly stated to manage costs effectively. -

What is the minimum order quantity (MOQ) for hydraulic press cylinders?

Minimum order quantities (MOQ) for hydraulic press cylinders can vary based on the supplier and the type of cylinder required. Some manufacturers may allow orders as low as one unit for standard models, while custom cylinders may have higher MOQs due to production costs. Always inquire about MOQs before placing an order to ensure that your purchasing strategy aligns with supplier capabilities and your operational needs. -

How can I ensure the quality of hydraulic press cylinders before purchase?

To ensure quality, request detailed product specifications, including material certifications and testing results. Ask about the manufacturing process and quality control measures employed by the supplier. Some manufacturers may offer samples or allow for factory visits to observe production standards. Additionally, consider asking for third-party inspection reports to verify that the cylinders meet industry standards and your specific requirements before finalizing the purchase. -

What logistics considerations should I keep in mind when sourcing hydraulic cylinders internationally?

When sourcing hydraulic cylinders internationally, consider shipping methods, lead times, and customs regulations. Ensure that your supplier can handle logistics, including packaging and documentation for export compliance. Be aware of potential duties and tariffs that may apply upon importation. Collaborate with a trusted freight forwarder to facilitate smooth transportation and delivery, and confirm that the shipping terms (Incoterms) align with your business needs. -

What customization options are available for hydraulic press cylinders?

Many suppliers offer customization options for hydraulic press cylinders, including variations in stroke length, bore size, and pressure ratings. You can also request specific mounting configurations, rod end designs, or even unique features tailored to your application. Discuss your requirements with the supplier to understand their capabilities and lead times for custom orders. Customization can enhance performance and compatibility with your existing equipment, so it’s worth exploring these options.

Top 7 Hyd Press Cylinder Manufacturers & Suppliers List

1. Enerpac – Hydraulic Cylinders, Jacks, and Rams

Domain: enerpac.com

Registered: 1995 (30 years)

Introduction: Enerpac hydraulic cylinders, jacks, and rams are available in various configurations. Key product details include:

– Rated up to 10,000 psi (700 bar)

– Capacity ranges from 5 to 1,000 tons

– Stroke lengths up to 48″ (1219 mm)

– Corrosion-resistant coatings (baked enamel, anodized, nitrocarburized)

Product Types:

1. General Purpose Cylinders:

– Capacity: 5 – 500 tons

– Stroke: 0.63 – …

2. Buffalo Hydraulic – Custom Hydraulic Press Cylinder

Domain: buffalohydraulic.com

Registered: 2001 (24 years)

Introduction: Buffalo Hydraulic Custom Hydraulic Press Cylinder – Model: BHDA8.00X4.00-38SPL; Design: Double-acting; Bore: Ø8.00″; Stroke: 38.00″; Rod: Ø4.00″ Precision chrome rod; Working Pressure: 3,500 p.s.i.

3. Temco Industrial – Hydraulic Cylinder Rams

Domain: temcoindustrial.com

Registered: 2012 (13 years)

Introduction: [{‘name’: ‘Hydraulic Cylinder Ram Single Acting 20 TON 6″ Inch Stroke’, ‘standard_price’: ‘$159.81’, ‘sale_price’: ‘$143.83’}, {‘name’: ‘Hollow Hydraulic Cylinder Ram 30 TON 4 Inch Stroke’, ‘standard_price’: ‘$329.16’, ‘sale_price’: ‘$296.25’}, {‘name’: ‘Hydraulic Cylinder Ram Single Acting 50 TON 2″ Inch Stroke’, ‘standard_price’: ‘$220.08’, ‘sale_price’: ‘$198.08’}, {‘name’: ‘Hollow Hydraulic Cy…

4. Tucker Hydraulics – 50 Ton Shop Press Cylinder

Domain: directequipmentsupply.com

Registered: 2009 (16 years)

Introduction: {‘name’: ‘Tucker 50 Ton Shop Press Cylinder’, ‘original_price’: ‘$5,999.00’, ‘current_price’: ‘$699.00’, ‘SKU’: ‘ECC50’, ‘categories’: [‘Hydraulic Shop Presses’, ‘Press Parts and Accessories’], ‘brand’: ‘Tucker Hydraulics’, ‘description’: ‘USA made 50 ton 10,000psi 6″ stroke cylinder with punch and pressure gauge for manual shop presses. (this item is drop shipped from the factory on production ru…

5. Harsle – Hydraulic Cylinders

Domain: harsle.com

Registered: 2014 (11 years)

Introduction: Hydraulic cylinders are core components that provide the force needed to operate a press, converting hydraulic energy into linear mechanical motion for tasks like bending, forming, punching, or compacting. Key factors to consider when choosing hydraulic cylinders include: 1. Load Requirements and Tonnage Capacity: Identify the maximum load your press will handle; select a cylinder that matches or …

6. Practical Machinist – Hydraulic Press Cylinder Rod Materials

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Hydraulic press cylinder rod material options discussed include: 1. Induction hardened rod – hard to machine, typically has a soft core, used for light to moderate impacts. 2. Chrome rod – commonly used in industrial machinery, economical when already chromed. 3. 4140 QT (quenched and tempered) – provides toughness and flexibility, often recommended for press rams. 4. 4340 TGP (turned, ground, and…

7. Macrodyne – Custom Hydraulic Press Cylinders

Domain: macrodynepress.com

Registered: 1998 (27 years)

Introduction: Macrodyne designs & manufactures custom hydraulic press cylinders, including forged tubes, welded tubes, or tie rod-style cylinders. They offer in-house design capabilities to modernize existing cylinders with new packing styles or sealing methods, and can design new cylinders to match or redesign current hydraulic systems. They perform inspection, repair, removal, rebuild, or replacement of hydra…

Strategic Sourcing Conclusion and Outlook for hyd press cylinder

The strategic sourcing of hydraulic press cylinders is essential for businesses aiming to optimize operational efficiency and ensure reliability in heavy-duty applications. By leveraging a diverse range of cylinder types—such as single and double-acting, high tonnage, and custom options—buyers can align their specific needs with the right products. Understanding the nuances of each type, including their capacities and applications, enables businesses to make informed decisions that enhance productivity and safety.

As international buyers from regions like Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is crucial to prioritize suppliers who offer robust support and high-quality products. Establishing strong partnerships with manufacturers ensures not only access to superior hydraulic solutions but also the potential for customized offerings that meet unique project demands.

Looking ahead, the hydraulic cylinder market is poised for innovation, with advancements in technology and materials expected to drive performance improvements. Buyers are encouraged to stay informed about emerging trends and to engage with suppliers who are committed to quality and innovation. By doing so, businesses can secure a competitive edge in their respective industries while ensuring the reliable operation of their hydraulic systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to hyd press cylinder

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.