Everything You Need to Know About What Is A Isolating Transformer Sourcing in 2025

Introduction: Navigating the Global Market for what is a isolating transformer

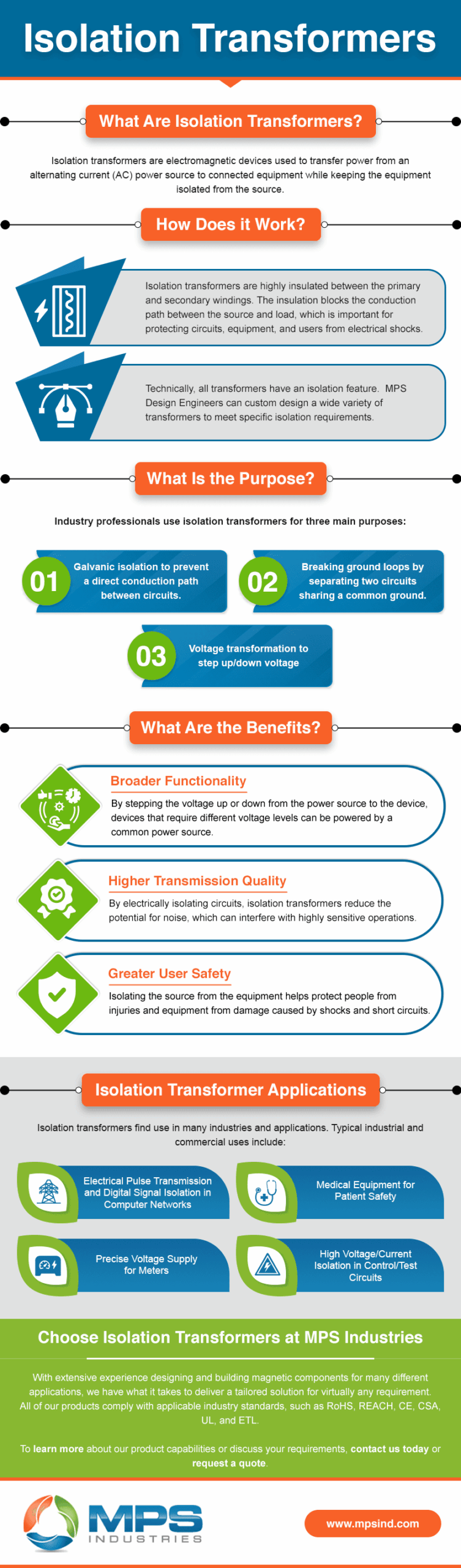

In today’s interconnected global market, sourcing the right electrical components can be daunting, especially when it comes to isolating transformers. These essential devices not only facilitate electrical power transfer between circuits but also ensure safety and minimize interference in various applications. For international B2B buyers—particularly in regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil—understanding the intricacies of isolating transformers is critical for informed procurement.

This comprehensive guide delves into the various types of isolating transformers, their specific applications across industries, and the benefits they offer, such as enhanced power quality and equipment protection. Additionally, we will provide insights into supplier vetting processes, helping you identify reliable manufacturers and distributors that meet your operational needs. Cost considerations will also be explored, enabling you to make budget-conscious decisions without compromising on quality.

By equipping you with actionable insights and in-depth knowledge, this guide empowers international B2B buyers to navigate the complexities of sourcing isolating transformers effectively. Whether you are involved in medical, industrial, or commercial applications, understanding these components will enhance your purchasing strategy and contribute to the success of your projects.

Understanding what is a isolating transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Constant Voltage Transformer | Maintains steady voltage output despite input fluctuations | Industrial equipment, telecommunications | Pros: Reliable voltage; Cons: May be more expensive than standard models. |

| Ultra Isolation Transformer | Offers superior electrical isolation, reducing noise and surges | Medical devices, sensitive research equipment | Pros: High accuracy; Cons: Higher initial cost and complexity. |

| Drive Isolation Transformer | Designed for electric motors, minimizing electrical noise | Manufacturing, automation systems | Pros: Clean power delivery; Cons: Limited to motor applications. |

| Galvanic Isolation Transformer | Prevents electrical current transfer between circuits | Medical, industrial control systems | Pros: Complete isolation; Cons: Can be bulky and costly. |

| Dry Isolation Transformer | Utilizes dry air for insulation, ensuring safety and reliability | Telecom, medical, and industrial applications | Pros: Safe operation; Cons: Performance can be affected by environmental conditions. |

What are the Characteristics of Constant Voltage Transformers?

Constant Voltage Transformers (CVTs) are engineered to maintain a stable voltage output, even when input voltage levels fluctuate. This feature is particularly beneficial in environments with variable power supply conditions, such as industrial settings and telecommunications. Buyers should consider the specific voltage requirements of their equipment and any potential installation challenges, as these transformers can be more expensive than standard options. Additionally, they may require regular maintenance to ensure optimal performance.

How Do Ultra Isolation Transformers Provide Enhanced Protection?

Ultra Isolation Transformers are designed to provide exceptional levels of electrical isolation, making them ideal for sensitive medical and research applications. Their construction minimizes the transfer of electrical noise and prevents surges, ensuring that connected devices operate accurately and reliably. When purchasing, B2B buyers should evaluate the specific isolation requirements of their applications and consider the higher upfront costs and installation complexities associated with these transformers.

What are the Key Features of Drive Isolation Transformers?

Drive Isolation Transformers are specifically tailored for powering electric motors, focusing on reducing electrical noise and interference. These transformers ensure that motors receive clean and consistent power, which is crucial in manufacturing and automation systems. Buyers should assess the compatibility of the transformer with their motor specifications and determine the expected load requirements. While these transformers are effective in their niche, they may not be suitable for other applications outside motor power.

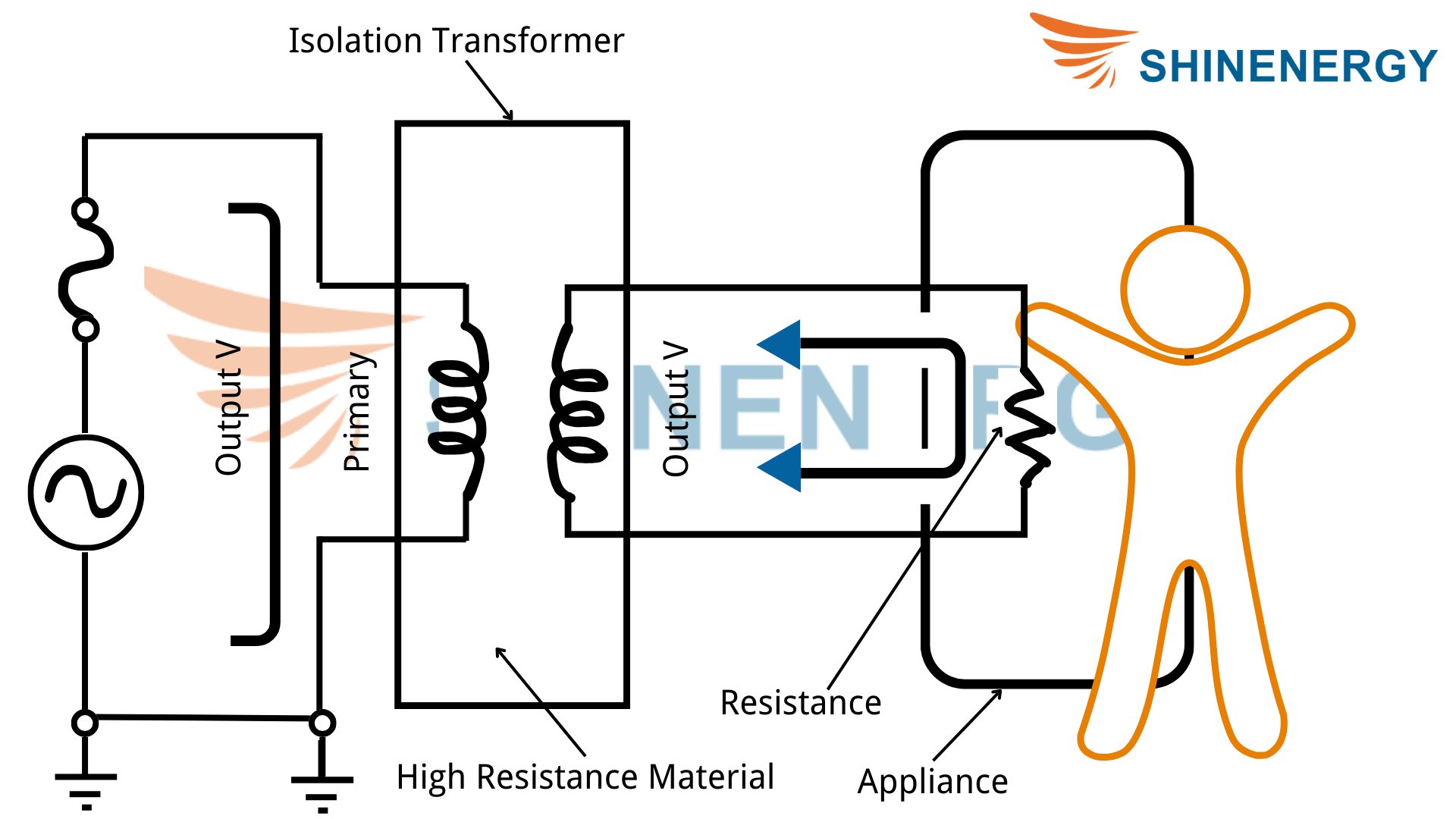

Why Choose Galvanic Isolation Transformers for Safety?

Galvanic Isolation Transformers offer complete electrical insulation between circuits, making them highly effective in protecting sensitive equipment in medical and industrial settings. Their design prevents any electrical current from passing between the primary and secondary coils, safeguarding against potential damage from electrical noise or surges. When considering a purchase, B2B buyers should focus on the safety standards required for their applications, as well as the physical space needed for installation, which may be more substantial compared to other types.

What are the Advantages of Dry Isolation Transformers?

Dry Isolation Transformers utilize dry air for insulation, providing a safe and reliable option for various applications, including telecommunications and industrial uses. Their design helps ensure complete electrical isolation while maintaining safety standards. Buyers should consider environmental factors that may affect performance, such as humidity and temperature variations. While these transformers are generally safe, they may require more careful monitoring in challenging conditions to ensure consistent operation.

Key Industrial Applications of what is a isolating transformer

| Industry/Sector | Specific Application of what is a isolating transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Equipment Isolation | Protects sensitive medical devices from electrical noise, ensuring accurate readings and safe operation. | Compliance with international safety standards and certifications. |

| Manufacturing | Drive Isolation for Motors | Ensures clean power supply to motors, minimizing downtime and maintenance costs due to electrical noise. | Robust insulation materials and voltage ratings suitable for industrial use. |

| Telecommunications | Power Supply for Telecom Equipment | Provides stable voltage and protects against surges, enhancing the reliability of communication systems. | Compatibility with regional power standards and environmental conditions. |

| Research Laboratories | Ultra-Isolation in Sensitive Experiments | Prevents interference in experimental setups, leading to more reliable results and data integrity. | High-quality construction and specialized materials to meet research specifications. |

| Renewable Energy | Integration in Solar and Wind Power Systems | Facilitates safe connection between renewable sources and the grid, enhancing system stability. | Adaptability to varying input conditions and compliance with grid requirements. |

How Are Isolation Transformers Used in Healthcare Applications?

In the healthcare sector, isolation transformers are crucial for protecting sensitive medical equipment such as imaging devices and monitoring systems. By providing electrical isolation, they help mitigate the effects of electrical noise and surges, which can lead to inaccurate readings or device malfunctions. For international B2B buyers, ensuring compliance with safety standards, such as IEC 60601 for medical electrical equipment, is essential when sourcing these transformers to guarantee patient safety and device reliability.

What Role Do Isolation Transformers Play in Manufacturing?

Manufacturing facilities frequently utilize drive isolation transformers to supply electric motors with a clean and stable power source. These transformers reduce electrical noise that can cause fluctuations in motor performance, thereby minimizing wear and tear and lowering maintenance costs. Buyers in this sector should consider the robustness of insulation materials and the voltage ratings of transformers to ensure they can withstand the demanding conditions of industrial environments, especially in regions with fluctuating power quality.

How Do Isolation Transformers Enhance Telecommunications Reliability?

In telecommunications, isolation transformers are used to stabilize the power supply for critical equipment. They protect against voltage surges and electrical noise, ensuring that communication systems remain operational and reliable. When sourcing isolation transformers for telecom applications, buyers should focus on compatibility with local power standards and the ability to withstand environmental factors, such as humidity and temperature fluctuations, common in many regions.

Why Are Ultra-Isolation Transformers Important in Research Laboratories?

Research laboratories often require ultra-isolation transformers to prevent electrical interference in sensitive experiments. These transformers provide a high level of electrical isolation, which is critical for obtaining accurate and reproducible results. International buyers in this field should prioritize sourcing transformers made from high-quality materials that meet stringent specifications, as well as ensuring that they can operate effectively in the unique conditions found in laboratory settings.

How Do Isolation Transformers Support Renewable Energy Integration?

In the renewable energy sector, isolation transformers play a pivotal role in safely connecting solar panels and wind turbines to the electrical grid. They help to manage the varying input voltages generated by these sources, ensuring stable output and enhancing system reliability. For B2B buyers, it’s essential to consider the adaptability of transformers to different energy conditions and their compliance with local grid requirements to ensure seamless integration and operation.

3 Common User Pain Points for ‘what is a isolating transformer’ & Their Solutions

Scenario 1: Ensuring Equipment Safety in Industrial Environments

The Problem: In industrial settings, electrical safety is paramount. Many B2B buyers face challenges related to the risk of electrical shocks and equipment damage caused by ground loops or transient voltage spikes. This concern is particularly pronounced in regions with unstable electrical grids, where fluctuations in voltage can lead to equipment failures and costly downtime. For instance, a manufacturing facility in Brazil may experience regular electrical surges that jeopardize sensitive machinery, resulting in operational inefficiencies and increased maintenance costs.

The Solution: Implementing isolation transformers is an effective way to mitigate these risks. Buyers should prioritize sourcing high-quality isolation transformers that provide galvanic isolation, which prevents direct electrical connections between circuits. When specifying an isolation transformer, consider the specific electrical requirements of your equipment, including voltage ratings and load capacity. Additionally, working with reputable suppliers who understand local electrical standards and conditions can help ensure that the selected transformer is well-suited for the operational environment. Regular maintenance and testing of the transformers will further enhance reliability and safety, providing peace of mind for operations managers.

Scenario 2: Overcoming Electrical Noise in Medical Facilities

The Problem: In medical facilities, the integrity of electronic equipment is critical. B2B buyers in this sector often encounter issues with electrical noise affecting the performance of diagnostic and monitoring devices. For instance, a hospital in Germany may find that its imaging equipment produces inaccurate results due to interference from other electrical devices within the facility. This not only complicates patient care but can also lead to costly legal implications if equipment malfunctions.

The Solution: To combat electrical noise, B2B buyers should invest in ultra-isolation transformers specifically designed for medical applications. These transformers significantly reduce electrical interference, ensuring that sensitive medical equipment operates accurately. When sourcing ultra-isolation transformers, it’s crucial to assess their specifications, such as the level of isolation and frequency response. Additionally, collaborating with manufacturers who specialize in medical-grade transformers will ensure compliance with health and safety regulations. Implementing a comprehensive training program for staff on proper usage and integration of these transformers can further enhance their effectiveness in maintaining equipment integrity.

Scenario 3: Managing Power Quality for Sensitive Electronics

The Problem: Businesses that rely on sensitive electronic equipment, such as telecom companies in South America, often struggle with power quality issues. Voltage fluctuations can lead to data loss or hardware damage, causing significant operational disruptions. This is especially challenging in regions with unreliable power infrastructure, where maintaining consistent voltage levels is crucial for business continuity.

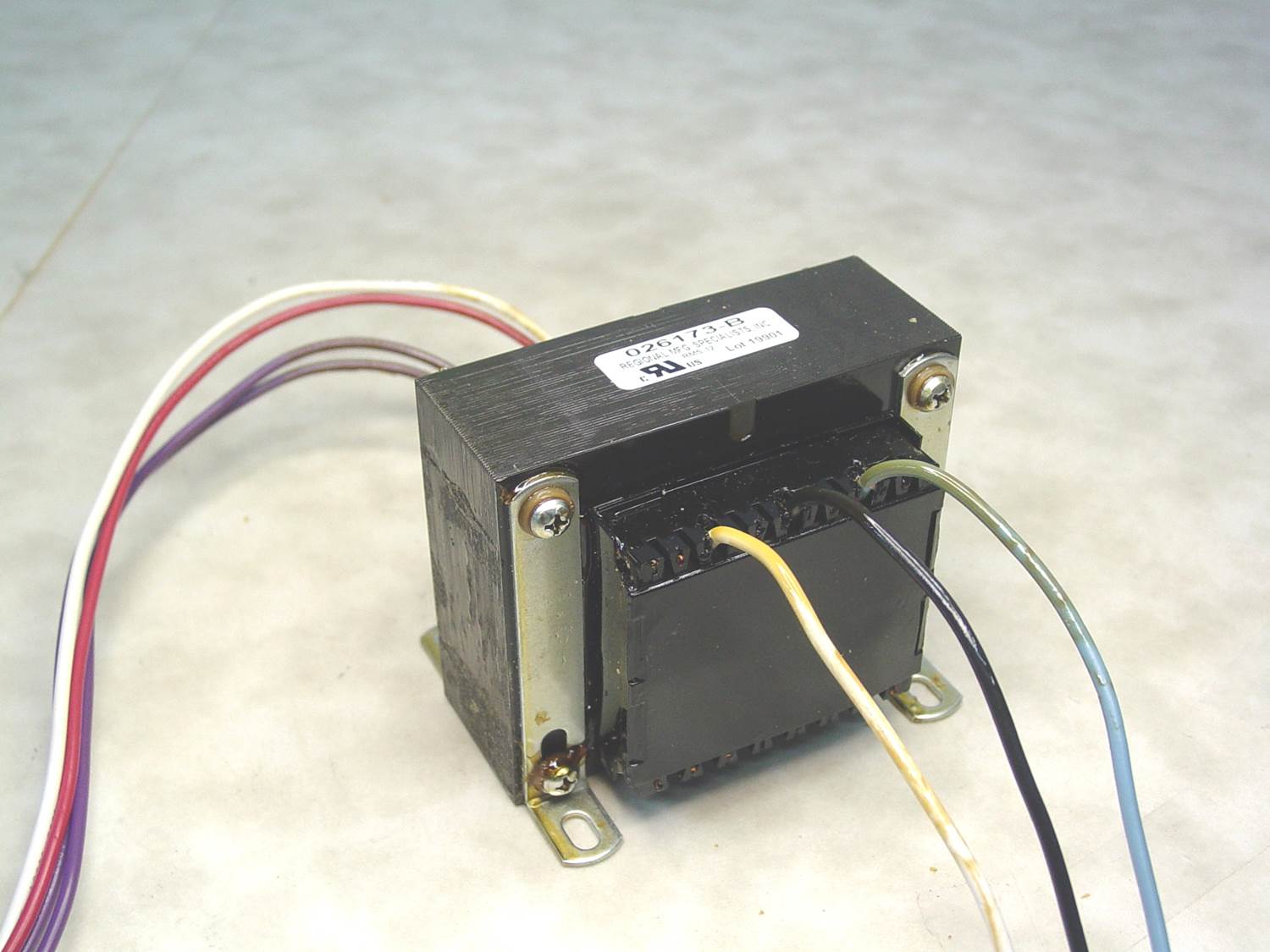

Illustrative image related to what is a isolating transformer

The Solution: Utilizing constant voltage transformers (CVTs) can be a strategic solution for managing power quality. B2B buyers should seek out CVTs that can adapt to varying input voltages while maintaining a steady output. When selecting a CVT, it’s essential to evaluate its voltage regulation capabilities and the specific requirements of the electronic equipment in use. Additionally, consider implementing a monitoring system to track voltage levels and transformer performance over time. This proactive approach not only helps in identifying potential issues before they escalate but also supports informed decision-making regarding maintenance and upgrades, ensuring that sensitive equipment remains operational and efficient.

Strategic Material Selection Guide for what is a isolating transformer

What Materials Are Commonly Used in Isolation Transformers?

When selecting materials for isolation transformers, understanding the properties, advantages, disadvantages, and application impacts is crucial for B2B buyers. Here, we analyze four common materials used in isolation transformers: silicon steel, copper, aluminum, and plastic insulation. Each material has unique characteristics that influence the performance and suitability of the transformer in various applications.

What Are the Key Properties of Silicon Steel in Isolation Transformers?

Silicon steel, often used in the core of isolation transformers, is known for its excellent magnetic properties. It typically has a high permeability, allowing for efficient magnetic flux transfer, which is essential for minimizing energy losses. Silicon steel can withstand high temperatures and has good corrosion resistance, making it suitable for diverse environments.

Pros and Cons: The primary advantage of silicon steel is its efficiency in reducing energy losses, which translates to better performance. However, it can be more expensive than other materials and may require complex manufacturing processes, such as lamination, to enhance its performance.

Impact on Application: Silicon steel is particularly effective in applications where energy efficiency is a priority, such as in industrial settings requiring continuous operation.

Considerations for International Buyers: Buyers from regions like Europe or the Middle East should be aware of compliance with standards such as DIN or IEC, which often specify the quality of materials used in electrical components.

How Does Copper Contribute to the Performance of Isolation Transformers?

Copper is widely used for windings in isolation transformers due to its excellent electrical conductivity. It allows for efficient power transfer and minimizes resistive losses. Copper also has a high melting point, which contributes to its durability in high-temperature applications.

Illustrative image related to what is a isolating transformer

Pros and Cons: The key advantage of copper is its superior conductivity, leading to enhanced performance. However, copper is relatively expensive compared to aluminum, and its weight can be a disadvantage in applications where weight is a critical factor.

Impact on Application: Copper windings are ideal for applications requiring high efficiency and reliability, such as medical equipment and precision instruments.

Considerations for International Buyers: Compliance with international standards such as ASTM for copper quality is essential, particularly for buyers in North America and Europe.

What Role Does Aluminum Play in Isolation Transformers?

Aluminum is increasingly being used as an alternative to copper in transformer windings due to its lower cost and lighter weight. While aluminum has lower conductivity than copper, advancements in technology have made aluminum windings more efficient.

Pros and Cons: The primary advantage of aluminum is its cost-effectiveness, making it an attractive option for large-scale production. However, aluminum is more susceptible to corrosion and requires careful handling to avoid oxidation, which can degrade performance.

Impact on Application: Aluminum is suitable for applications where weight and cost are significant factors, such as in portable transformers or less critical industrial applications.

Considerations for International Buyers: Buyers should consider regional preferences for material quality and compliance with standards like JIS in Japan or EN in Europe.

Why Is Plastic Insulation Important for Isolation Transformers?

Plastic insulation materials, such as PVC or nylon, are essential for providing electrical insulation between the windings and the core. These materials have excellent dielectric properties and can withstand high voltages, ensuring safety and reliability.

Illustrative image related to what is a isolating transformer

Pros and Cons: The main advantage of plastic insulation is its effectiveness in preventing electrical leakage, which is critical for safety. However, some plastics may have lower thermal resistance compared to other insulation materials, limiting their use in high-temperature environments.

Impact on Application: Plastic insulation is commonly used in a variety of applications, including consumer electronics and industrial equipment, where safety and reliability are paramount.

Considerations for International Buyers: Buyers must ensure that the insulation materials comply with local safety standards, such as UL in the United States or CE marking in Europe.

Summary Table of Material Selection for Isolation Transformers

| Material | Typical Use Case for what is a isolating transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Core material for energy-efficient transformers | High magnetic efficiency | Expensive and complex manufacturing | High |

| Copper | Windings in high-performance transformers | Superior electrical conductivity | High cost and weight | High |

| Aluminum | Windings in cost-sensitive applications | Cost-effective and lightweight | Susceptible to corrosion | Medium |

| Plastic Insulation | Insulation for electrical safety | Excellent dielectric properties | Lower thermal resistance | Low |

This comprehensive material selection guide provides valuable insights for B2B buyers in diverse global markets, helping them make informed decisions when sourcing materials for isolation transformers.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a isolating transformer

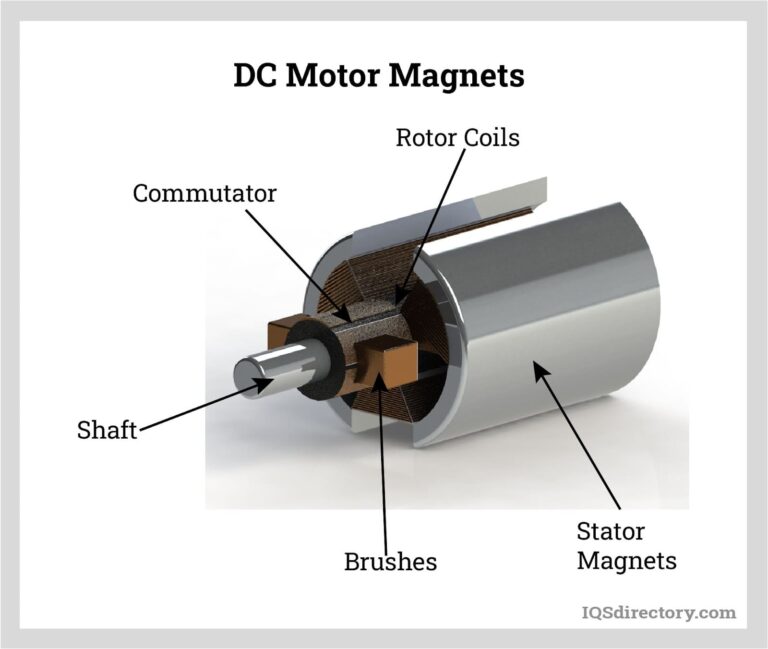

What Are the Main Stages in the Manufacturing Process of an Isolation Transformer?

The manufacturing of isolation transformers involves several key stages, each critical to ensuring the performance and reliability of the final product. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Isolation Transformers?

Material preparation is the first step in the manufacturing process. The core materials typically include high-grade silicon steel for the transformer cores, which are essential for minimizing energy losses. Copper or aluminum wire is used for the windings. Suppliers should ensure that these materials meet industry standards for electrical conductivity and thermal stability.

Before production begins, thorough inspections of raw materials (Incoming Quality Control, or IQC) are essential. This step verifies that materials comply with specifications and international standards. This is particularly important for international buyers who may have specific requirements based on regional regulations.

What Techniques Are Used for Forming Isolation Transformers?

The forming stage involves cutting and shaping the materials into the required dimensions. For the core, various techniques such as stacking and laminating are employed. Stacking involves arranging thin sheets of silicon steel to create a core that reduces eddy current losses. The winding process, where the copper or aluminum wire is wrapped around the core, is performed using automated machines to ensure precision and consistency.

Quality during this stage can be monitored through In-Process Quality Control (IPQC). Regular checks on the dimensions of the windings and the quality of the core assembly help identify any issues early in the process.

How Are Isolation Transformers Assembled?

In the assembly stage, the primary and secondary windings are placed around the core. The connections must be made with utmost care to ensure electrical isolation between the two circuits. This is achieved through careful design and the use of insulating materials.

Proper assembly techniques are vital to prevent issues like short circuits and electrical noise interference. Buyers should inquire about the assembly process and the qualifications of the personnel involved, as skilled technicians are crucial for maintaining quality.

What Finishing Processes Are Applied to Isolation Transformers?

Finishing processes include insulation and protection of the transformer. This may involve applying varnish to the windings and adding protective coatings to the outer casing. The transformers are often tested for dielectric strength to ensure they can withstand electrical stress.

Final Quality Control (FQC) checks are performed to assess the overall quality of the finished product. These checks include visual inspections and performance testing under operational conditions to ensure the transformer meets its specified ratings.

Which International Standards Guide the Quality Assurance of Isolation Transformers?

Quality assurance in the manufacturing of isolation transformers is governed by various international standards. The ISO 9001 standard is a key framework that emphasizes quality management systems and continuous improvement. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent product quality.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in Europe) and API certifications (for certain industrial applications) may also apply. These certifications provide assurance that the transformers meet specific safety and performance criteria relevant to their applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality Control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Conducted during various stages of production, IPQC ensures that the manufacturing process adheres to established protocols and standards.

-

Final Quality Control (FQC): This final stage involves comprehensive testing and inspection of the completed isolation transformers to verify their performance and safety.

Common testing methods include dielectric testing, insulation resistance testing, and load testing, which assesses the transformer’s ability to handle electrical loads under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some recommended approaches:

-

Supplier Audits: Conducting on-site audits can provide deep insights into a manufacturer’s processes, quality control measures, and adherence to international standards.

-

Review of Quality Reports: Requesting detailed quality reports can help buyers understand the frequency of QC checks and the results of performance testing.

-

Third-Party Inspections: Engaging independent inspection agencies can ensure that the transformers meet the specified quality standards before shipment.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may face specific challenges in verifying quality control. Different regions may have varying standards and regulations, necessitating a clear understanding of local compliance requirements.

Additionally, language barriers and logistical challenges can complicate communication with suppliers. It is advisable for buyers to establish strong lines of communication and consider employing local representatives or consultants who can navigate these complexities effectively.

Ensuring that isolation transformers meet both international and regional standards is crucial for minimizing risks and ensuring operational reliability. By focusing on these quality assurance practices, B2B buyers can make informed decisions and foster successful partnerships with manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a isolating transformer’

In the realm of electrical engineering, isolation transformers play a crucial role in ensuring safety and reliability in power distribution. This guide offers a step-by-step checklist for B2B buyers aiming to procure isolation transformers, focusing on key considerations that will aid in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for your isolation transformer. Consider factors such as voltage levels, power ratings, and the specific application (e.g., medical, industrial, telecom). Establishing these specifications early ensures that you select a transformer that meets your operational needs without compromising on performance.

Step 2: Identify the Type of Isolation Transformer Needed

Isolation transformers come in various types, each designed for specific applications. Determine whether you need a constant voltage transformer, ultra-isolation transformer, or another type based on your operational requirements. Each type offers different benefits, such as noise reduction or enhanced electrical isolation, which can be critical depending on the equipment being powered.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request company profiles, product catalogs, and case studies, and check for references from other buyers in your industry or region. Reliable suppliers should also provide certifications that demonstrate compliance with international safety and quality standards, which is crucial for minimizing risks.

Step 4: Assess Quality Assurance Processes

Investigate the quality assurance measures that suppliers implement in their manufacturing processes. Look for details on testing procedures, warranties, and return policies. A robust quality assurance process not only ensures that you receive a reliable product but also protects your investment by reducing the likelihood of equipment failures.

Step 5: Request Samples or Prototypes

Whenever possible, request samples or prototypes of the isolation transformers you are considering. This allows you to evaluate their performance in your specific application before making a bulk purchase. Testing the product in real-world conditions can help identify any potential issues that might not be apparent from specifications alone.

Step 6: Compare Pricing and Total Cost of Ownership

While price is a critical factor, consider the total cost of ownership, which includes installation, maintenance, and energy efficiency. A lower initial cost may not always translate into savings over time. Ensure that you compare similar products and take into account the long-term benefits of investing in a high-quality transformer.

Step 7: Finalize Contracts and Negotiate Terms

Once you have selected a supplier, carefully review the contract terms before finalizing the purchase. Pay attention to delivery timelines, payment terms, and warranty conditions. Effective negotiation can help secure favorable terms and establish a good working relationship with the supplier, which is essential for future collaborations.

By following this checklist, B2B buyers can streamline their procurement process for isolation transformers, ensuring that they choose products that enhance safety and performance in their electrical systems.

Comprehensive Cost and Pricing Analysis for what is a isolating transformer Sourcing

What are the Key Cost Components in Sourcing Isolation Transformers?

When sourcing isolation transformers, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials typically account for a significant portion of the total cost. The choice of core materials (such as silicon steel or amorphous steel) and winding materials (like copper or aluminum) will influence price. High-quality materials may enhance performance and longevity but will also increase costs.

Labor costs are influenced by the complexity of the transformer design and the manufacturing process. Skilled labor may be required for assembly and testing, particularly for specialized transformers such as ultra-isolation types.

Manufacturing overhead includes costs related to factory operations, utilities, and equipment maintenance. These expenses can vary based on the location of the manufacturing facility, which is particularly relevant for international buyers.

Tooling costs are incurred during the initial setup of production and can be substantial for custom designs. For buyers looking for bespoke solutions, these costs will need to be factored into the overall pricing.

Quality Control (QC) is critical in ensuring that transformers meet required specifications and certifications. The more rigorous the QC processes, the higher the associated costs, but this investment often pays off in terms of reliability and performance.

Illustrative image related to what is a isolating transformer

Logistics costs encompass shipping, handling, and any import duties applicable to international transactions. These costs can vary greatly depending on the geographic location of the buyer and supplier, as well as the chosen Incoterms.

Supplier margin is the profit margin that manufacturers add to the base cost. This margin can vary significantly between suppliers based on their market positioning and service levels.

How Do Price Influencers Affect the Cost of Isolation Transformers?

Several factors can influence the pricing of isolation transformers, including volume, specifications, materials, quality certifications, supplier reputation, and Incoterms.

Volume and Minimum Order Quantities (MOQ) play a crucial role in determining price. Higher volumes generally lead to lower per-unit costs due to economies of scale. Conversely, low MOQs can significantly increase the unit price, which is a critical consideration for smaller buyers.

Specifications and customization can greatly impact costs. Standard transformers are typically less expensive than customized solutions, which require additional design and engineering efforts. Buyers should carefully evaluate whether the benefits of customization justify the additional costs.

Material choices can also affect pricing. For instance, opting for premium materials that enhance durability and performance will increase initial costs but may lead to lower maintenance expenses over the product’s lifecycle.

Quality certifications (such as ISO or CE) may increase initial costs but are often necessary for compliance in certain markets. Buyers should consider the long-term benefits of investing in certified products.

Supplier factors, including reputation and reliability, can affect pricing. Established suppliers may command higher prices due to their proven track record and quality assurance processes.

Incoterms impact logistics and overall costs. Understanding the responsibilities for shipping, insurance, and duties is essential for accurate cost calculations.

What Buyer Tips Can Help in Negotiating Isolation Transformer Costs?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, a few strategic tips can enhance cost-efficiency when sourcing isolation transformers.

Illustrative image related to what is a isolating transformer

Negotiation is key. Buyers should be prepared to discuss pricing openly with suppliers, leveraging factors such as order volume or long-term contracts to secure better rates.

Total Cost of Ownership (TCO) is an important consideration. Evaluating the long-term costs associated with maintenance, energy efficiency, and performance can provide a more accurate picture of the value of the investment.

Understanding pricing nuances is crucial for international buyers. Currency fluctuations, tariffs, and local market conditions can all affect pricing. Buyers should factor these elements into their budget and negotiate terms that mitigate these risks.

Lastly, always request indicative prices as a starting point, but recognize that final costs will depend on various factors discussed above. This approach ensures that buyers are well-informed and prepared for negotiations that lead to favorable outcomes.

Alternatives Analysis: Comparing what is a isolating transformer With Other Solutions

When considering the implementation of electrical isolation in various applications, it is essential to evaluate different solutions available on the market. Isolation transformers are widely recognized for their ability to transfer electrical power between circuits without a direct connection. However, there are alternative technologies that can also achieve similar goals, each with its advantages and disadvantages. This analysis will compare isolation transformers with two viable alternatives: DC-DC converters and opto-isolators.

Comparison Table

| Comparison Aspect | What Is A Isolating Transformer | DC-DC Converter | Opto-Isolator |

|---|---|---|---|

| Performance | Excellent at reducing electrical noise and surges | Good for voltage regulation, but less effective for noise reduction | High-speed isolation, but limited to low power applications |

| Cost | Moderate to high initial investment | Generally lower cost | Low-cost, but limited capability |

| Ease of Implementation | Requires proper installation and space | Easy to integrate into existing circuits | Simple to install but needs careful circuit design |

| Maintenance | Low, but requires periodic checks | Low, generally maintenance-free | Low, but may need replacement over time |

| Best Use Case | Medical devices, industrial equipment requiring high isolation | Battery-powered devices and renewable energy systems | Signal isolation in communication systems |

Detailed Breakdown of Alternatives

DC-DC Converters

DC-DC converters are devices that convert one level of DC voltage to another, allowing for efficient power management in battery-operated and renewable energy systems. They excel in providing stable voltage output, making them a solid choice for applications where voltage regulation is crucial. However, while they can offer some level of electrical isolation, they are not as effective as isolation transformers in reducing electrical noise and protecting against surges. Their cost is generally lower, and they are easier to implement, making them attractive for projects with budget constraints.

Opto-Isolators

Opto-isolators, or opto-couplers, utilize light to transmit signals between circuits while maintaining electrical isolation. They are particularly beneficial in communication systems where signal integrity is paramount. Their low cost and ease of integration into existing designs make them a popular choice for many applications. However, their performance is limited to low power situations, and they do not provide the same level of electrical isolation as isolation transformers or DC-DC converters. Additionally, they may require careful circuit design to ensure effective operation.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate solution for electrical isolation depends on specific application requirements, including power needs, budget, and installation capabilities. Isolation transformers are ideal for high-power applications requiring excellent noise reduction and surge protection, particularly in sensitive environments like medical facilities. On the other hand, DC-DC converters are suitable for applications needing efficient voltage regulation with a lower initial investment. For communication systems requiring signal integrity, opto-isolators may be the best choice. By carefully evaluating these factors, B2B buyers can make informed decisions that align with their operational needs and financial constraints.

Essential Technical Properties and Trade Terminology for what is a isolating transformer

What Are the Key Technical Properties of Isolation Transformers?

Understanding the technical specifications of isolation transformers is essential for B2B buyers, especially when making investment decisions in industrial applications. Here are several critical specifications to consider:

1. Voltage Rating

The voltage rating indicates the maximum voltage that the transformer can handle safely. It is crucial for ensuring that the transformer can operate effectively within the electrical system’s parameters. An appropriate voltage rating prevents overheating and potential failure, making it vital for reliable operation in various applications, from medical devices to industrial machinery.

2. Power Rating (kVA)

The power rating, measured in kilovolt-amperes (kVA), denotes the maximum load the transformer can support. Selecting a transformer with the right power rating is essential for efficient operation; an undersized transformer can lead to overheating and premature failure, while an oversized transformer may result in energy inefficiency and increased costs.

3. Insulation Class

The insulation class indicates the temperature rating of the materials used in the transformer. Common classes include A, B, F, and H, with each class representing a different thermal tolerance. A higher insulation class allows for operation in more demanding environments, which is particularly important for industrial applications where temperature fluctuations can occur.

Illustrative image related to what is a isolating transformer

4. Efficiency Rating

The efficiency rating reflects how effectively the transformer converts input power to output power. A higher efficiency rating means lower energy losses during operation, which translates to cost savings over time. For businesses focused on sustainability and operational efficiency, selecting a transformer with a high efficiency rating is a significant factor.

5. Frequency

Isolation transformers typically operate at standard frequencies, such as 50 Hz or 60 Hz. Understanding the frequency is crucial for ensuring compatibility with existing electrical systems. Mismatched frequencies can lead to operational issues and inefficiencies, particularly in regions with varying standards, such as Africa and South America.

6. Cooling Method

Isolation transformers may utilize different cooling methods, such as air-cooled or oil-cooled systems. The choice of cooling method affects the transformer’s performance and longevity. For example, oil-cooled transformers can handle higher loads and are suitable for environments where temperature control is critical.

What Are Common Trade Terms Related to Isolation Transformers?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s end products. When sourcing isolation transformers, understanding the OEM’s reputation for quality can influence purchasing decisions, ensuring that the transformers meet the required specifications and standards.

Illustrative image related to what is a isolating transformer

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is critical for budgeting and inventory management, especially for businesses looking to establish long-term partnerships with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit pricing and terms from suppliers. Crafting a detailed RFQ for isolation transformers ensures that all necessary specifications are considered, allowing for accurate comparisons among potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for managing shipping costs and risks associated with international procurement.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Knowing the lead time for isolation transformers is crucial for project planning and ensuring that equipment is available when needed, particularly in industries where timing is critical.

6. Certification Standards

Certification standards such as ISO, CE, or UL indicate that the transformer meets specific safety and quality regulations. Familiarity with these standards helps buyers ensure compliance and reliability, especially when operating in regulated industries like healthcare or telecommunications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting isolation transformers for their operations, ensuring both efficiency and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the what is a isolating transformer Sector

What Are the Current Market Dynamics and Key Trends Affecting the Isolation Transformer Sector?

The global isolation transformer market is witnessing significant growth, driven by an increasing demand for electrical safety and improved power quality across various industries. As businesses worldwide become more reliant on sensitive electronic equipment, the need for isolation transformers—capable of providing electrical separation between circuits—grows. This demand is particularly pronounced in sectors such as healthcare, telecommunications, and manufacturing, where operational continuity and equipment protection are paramount.

Emerging trends in sourcing and technology are shaping the landscape for international B2B buyers. The rise of smart grid technologies and renewable energy systems is pushing manufacturers to innovate, leading to the development of more efficient, compact, and cost-effective isolation transformers. Additionally, the integration of IoT devices in industrial settings is enhancing the need for advanced monitoring and control features, making it essential for buyers to consider transformers that can support these functionalities.

For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Buyers should be aware of varying regulations and standards that impact the design and application of isolation transformers. Collaborating with suppliers who have a strong local presence can facilitate compliance and ensure that products meet regional specifications.

How Can Sustainability and Ethical Sourcing Impact the Isolation Transformer Sector?

In the context of isolation transformers, sustainability is becoming an increasingly significant factor for B2B buyers. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek suppliers committed to sustainable practices. Buyers should prioritize partnerships with manufacturers that demonstrate transparency in their supply chains and have certifications for eco-friendly practices.

Ethical sourcing is also crucial, especially in regions where supply chain integrity may be compromised. Buyers should look for suppliers who adhere to international labor standards and engage in fair trade practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the use of green materials in the production of isolation transformers, such as recyclable components and environmentally friendly insulation materials, can further enhance a buyer’s sustainability profile. By investing in ethically sourced and sustainably produced isolation transformers, companies not only mitigate environmental risks but also strengthen their brand reputation in an increasingly eco-conscious market.

What Is the Historical Context of Isolation Transformers and Their Evolution?

The concept of isolation transformers dates back to the early days of electrical engineering in the late 19th century. Initially designed to enhance the safety of electrical systems, these transformers have evolved significantly over the years. Early models primarily focused on basic electrical isolation to prevent shocks and equipment damage. However, as technology advanced, so did the applications of isolation transformers.

In the mid-20th century, with the rise of electronic devices and sensitive equipment, the demand for high-quality isolation transformers surged. Innovations such as constant voltage transformers and ultra-isolation transformers emerged, catering to the specific needs of medical and industrial applications. Today, isolation transformers are integral components in various sectors, reflecting a continuous evolution driven by technological advancements and the growing emphasis on electrical safety and performance.

Understanding this historical context can provide B2B buyers with insight into the reliability and safety benefits that isolation transformers offer, reinforcing their importance in contemporary electrical systems.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a isolating transformer

-

How do I choose the right isolation transformer for my application?

When selecting an isolation transformer, consider the specific requirements of your application, including voltage, power rating, and the type of isolation needed (e.g., galvanic, ultra-isolation). Evaluate the environment in which the transformer will operate, as factors like humidity and temperature may affect performance. Additionally, assess your need for features such as constant voltage regulation or noise reduction. Consulting with suppliers who can provide technical specifications and application support can help ensure you make an informed choice. -

What are the primary benefits of using an isolation transformer?

Isolation transformers offer several advantages, including enhanced safety through electrical isolation, improved power quality by reducing electrical noise, and protection against voltage spikes. They are crucial in sensitive applications like medical devices and industrial equipment, where consistent power delivery is essential. Furthermore, isolation transformers can help extend the lifespan of connected equipment by minimizing wear and tear caused by electrical interference, making them a valuable investment for any business. -

What customization options are available for isolation transformers?

Many manufacturers offer customization options for isolation transformers, allowing buyers to specify factors such as power ratings, input/output voltages, and insulation materials. Custom designs can also include specific winding techniques for enhanced performance or unique physical dimensions to fit within existing equipment layouts. When sourcing, discuss your precise requirements with suppliers to ensure they can accommodate your needs and deliver a transformer that meets your operational demands. -

What is the typical minimum order quantity (MOQ) for isolation transformers?

Minimum order quantities for isolation transformers can vary significantly among suppliers, typically ranging from a single unit for custom orders to larger quantities for standard models. It’s essential to communicate your requirements and project scope to potential suppliers, as they may offer flexible terms based on your specific needs. Bulk purchasing can often lead to cost savings, so consider your long-term plans when negotiating MOQs. -

How do I verify the quality of isolation transformers from international suppliers?

To ensure quality, request certifications and compliance documents from suppliers, such as ISO 9001 or UL certification. Evaluate their manufacturing processes and quality control measures by asking about testing protocols and production standards. Additionally, consider seeking references or customer testimonials from other businesses in your region. If possible, request samples to assess performance before placing a larger order. -

What payment terms are common for international purchases of isolation transformers?

Payment terms for international orders may include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to negotiate terms that protect your interests while providing the supplier with confidence. Consider using escrow services for large transactions to mitigate risks. Always clarify currency exchange rates and any additional fees related to international transactions to avoid unexpected costs. -

What logistics considerations should I keep in mind when sourcing isolation transformers?

When sourcing isolation transformers internationally, consider shipping methods, lead times, and customs regulations in your country. Ensure your supplier is experienced in exporting goods and can provide necessary documentation for customs clearance. Discuss packaging options to protect the transformers during transit and inquire about insurance coverage for your shipment. Planning for potential delays in shipping can help mitigate disruptions to your operations. -

How can I assess the after-sales support offered by isolation transformer suppliers?

Evaluate suppliers by asking about their after-sales support services, including warranty policies, technical assistance, and availability of replacement parts. Inquire if they provide training for installation and maintenance, as well as remote support options. A reputable supplier should have a responsive customer service team to address any issues that arise post-purchase. Engaging with suppliers who prioritize after-sales support can significantly enhance your operational reliability.

Top 6 What Is A Isolating Transformer Manufacturers & Suppliers List

1. IQS Directory – Isolation Transformers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Isolation transformers are immobile devices designed to electrically and physically separate primary and secondary windings, ensuring complete isolation between circuits. They function by transferring energy through magnetic induction, adjusting voltage levels, and mitigating voltage spikes in supply lines. Key features include: 1. **Types of Isolation Transformers**: – Ultra Isolation Transformer…

2. Payton Group – Isolation Transformers

Domain: paytongroup.com

Registered: 1997 (28 years)

Introduction: An isolation transformer is a type of transformer that transfers electrical power between two circuits without direct electrical connection, providing complete electrical isolation. Key types include: 1. Constant Voltage Transformers (CVTs) – maintain steady voltage output despite input fluctuations. 2. Ultra Isolation Transformers – offer higher levels of isolation to prevent electrical noise, us…

3. Reddit – Isolation Transformers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Isolation transformers are used to create two separate isolated circuits, isolate grounding systems, break ground loops, and help eliminate noise such as 60Hz hum in audio applications. They provide a level of galvanic isolation suitable for safety devices, making it harder for a person to become part of the circuit. While they do not block all AC spikes, they can block DC shorts and reduce the ri…

4. Hammond Power Solutions – Isolation Transformers

Domain: americas.hammondpowersolutions.com

Registered: 2000 (25 years)

Introduction: An isolation transformer is a type of transformer where the primary and secondary windings are physically isolated from each other, meaning they are not directly connected. The transformation of voltage and current occurs through mutual inductance in the core’s shared magnetic field. Most transformers, except for autotransformers, function as isolation transformers.

5. Digi-Key – Isolation Transformers

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, Digi-Key – Isolation Transformers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Block – Isolating Transformers

Domain: block.eu

Introduction: Isolating transformers with galvanic isolation provide a reliable supply to circuits with the safety measures “protective separation”. They offer double or reinforced isolation between the primary and secondary sides. The secondary side can be configured flexibly, whether as a monitored isolated system or a grounded system with fuse elements. The output voltage ranges from 50 Vac to 1,000 Vac or 1…

Strategic Sourcing Conclusion and Outlook for what is a isolating transformer

In today’s global marketplace, understanding the intricacies of isolation transformers is essential for businesses aiming to enhance operational efficiency and protect sensitive equipment. These transformers offer significant advantages, including improved power quality and enhanced electrical safety, making them a vital component in sectors such as healthcare, industrial manufacturing, and telecommunications.

For international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and established economies like Germany and Brazil, strategic sourcing of isolation transformers can lead to substantial cost savings and performance improvements. By leveraging reliable suppliers, companies can ensure they receive high-quality products that meet their specific needs while minimizing risks associated with electrical surges and noise.

Looking ahead, businesses should prioritize partnerships with manufacturers who understand regional compliance standards and technological advancements in transformer design. Investing in isolation transformers today not only safeguards equipment but also positions companies for sustainable growth. Engage with suppliers now to explore tailored solutions that align with your operational goals and contribute to your competitive advantage in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.