Choosing Your Broom With Metal Bristles: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for broom with metal bristles

In today’s global marketplace, sourcing brooms with metal bristles presents unique challenges for B2B buyers, particularly those operating in demanding environments like manufacturing, construction, and commercial cleaning. Metal-bristled brooms are renowned for their durability and effectiveness in tackling heavy-duty cleaning tasks. However, navigating the complexities of supplier selection, product specifications, and pricing can be daunting. This guide offers a comprehensive resource designed to empower international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia.

Throughout this guide, we delve into various types of metal-bristled brooms, exploring their applications across different industries. From push brooms to specialty cleaning brushes, we cover the essential features that make these tools indispensable. Additionally, we provide actionable insights on supplier vetting processes, helping you identify reliable manufacturers and distributors that meet your quality and compliance standards.

Moreover, we analyze cost factors to ensure you can make informed purchasing decisions that align with your budgetary constraints. By equipping you with this knowledge, our guide aims to streamline your procurement process, enabling you to select the best broom solutions tailored to your specific operational needs. Whether you’re looking to enhance your cleaning efficiency or reduce downtime, understanding the global market for brooms with metal bristles is crucial for your success.

Understanding broom with metal bristles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Push Broom | Sturdy construction, wide head, metal bristles for heavy debris | Warehouses, factories, outdoor areas | Pros: Efficient for large areas; Cons: Can be heavy to maneuver. |

| Lobby Broom | Compact design, fine bristles, ideal for tight spaces | Restaurants, malls, offices | Pros: Great for quick clean-ups; Cons: Less effective on larger debris. |

| Wire Broom Brush | Metal wire bristles, excellent for tough scrubbing | Industrial cleaning, garages | Pros: Durable and long-lasting; Cons: May scratch delicate surfaces. |

| Stiff Bristle Broom | Stiff, durable bristles for heavy scrubbing and trapping debris | Construction sites, outdoor cleaning | Pros: Effective on rough surfaces; Cons: Not suitable for delicate floors. |

| Metal-Top Broom | Reinforced metal top, ideal for wet and rough surfaces | Agricultural settings, heavy-duty cleaning | Pros: High durability; Cons: Can be cumbersome for light tasks. |

What Are the Key Characteristics of Heavy-Duty Push Brooms?

Heavy-duty push brooms are designed for extensive cleaning tasks, often featuring a wide head and robust metal bristles. These brooms excel in environments such as warehouses and factories, where they can efficiently clear large debris from floors. When considering a purchase, businesses should evaluate the broom’s width and bristle stiffness to ensure it meets their specific cleaning needs.

How Do Lobby Brooms Enhance Cleaning in Commercial Settings?

Lobby brooms are compact and easy to handle, making them ideal for quick clean-ups in restaurants, malls, and offices. With fine bristles, these brooms are effective at trapping dust and small particles, especially in tight spaces. Buyers should consider the broom’s size and bristle material to match the cleaning tasks they encounter regularly.

Why Choose Wire Broom Brushes for Tough Cleaning Jobs?

Wire broom brushes are equipped with metal wire bristles, which are perfect for heavy scrubbing tasks. They are commonly used in industrial cleaning settings and garages where tough debris is present. Buyers must weigh the durability of wire bristles against the potential risk of scratching delicate surfaces, which may limit their application in certain environments.

What Makes Stiff Bristle Brooms Suitable for Rough Surfaces?

Stiff bristle brooms are characterized by their robust and durable bristles, ideal for heavy scrubbing and trapping debris on rough surfaces. They are commonly used in construction sites and for outdoor cleaning. Businesses should assess the broom’s bristle stiffness and handle length to ensure it suits their operational requirements.

How Do Metal-Top Brooms Stand Out in Agricultural Cleaning?

Metal-top brooms feature a reinforced design that enhances durability, making them suitable for wet and rough surfaces often found in agricultural settings. They are effective for heavy-duty cleaning tasks. When purchasing, businesses should consider the broom’s weight and ease of use, particularly in environments where maneuverability is crucial.

Key Industrial Applications of broom with metal bristles

| Industry/Sector | Specific Application of broom with metal bristles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Cleaning production floors and machinery areas | Enhances safety by removing debris | Durability of bristles; compatibility with floor types |

| Agriculture | Sweeping grain storage facilities and silos | Prevents contamination and spoilage | Resistance to moisture; ease of handling in tight spaces |

| Construction | Removing debris from job sites | Increases efficiency and safety on-site | Bristle strength; handle length for maneuverability |

| Food Processing | Cleaning processing and packaging areas | Ensures hygiene and compliance | Non-reactive materials; ease of cleaning |

| Transportation & Logistics | Maintaining cleanliness in warehouses and loading docks | Improves operational efficiency | Weight and size for ease of storage; bristle material durability |

How is a broom with metal bristles utilized in manufacturing environments?

In manufacturing settings, broom with metal bristles is essential for maintaining clean production floors and machinery areas. The robust bristles effectively sweep away metal shavings, dust, and other debris that can pose safety hazards. This not only enhances workplace safety but also ensures operational efficiency by preventing machine malfunctions caused by accumulated waste. International buyers should consider the durability of the broom, as well as its compatibility with various floor types, to ensure long-term use in demanding environments.

What role does a broom with metal bristles play in agriculture?

In the agricultural sector, these brooms are often used to clean grain storage facilities and silos. By effectively removing debris and spills, they help prevent contamination and spoilage of stored grains, which is critical for maintaining product quality. Buyers in this sector should look for brooms that are resistant to moisture and designed for easy handling in tight spaces, as these features will enhance the broom’s effectiveness in managing agricultural environments.

How does a broom with metal bristles contribute to construction site safety?

Construction sites generate a significant amount of debris, making the use of a broom with metal bristles vital for maintaining cleanliness. These brooms are ideal for sweeping up heavy materials like gravel and dust, thus increasing safety and efficiency on-site. When sourcing for construction applications, businesses should prioritize bristle strength and handle length, as these factors contribute to the broom’s maneuverability and effectiveness in various site conditions.

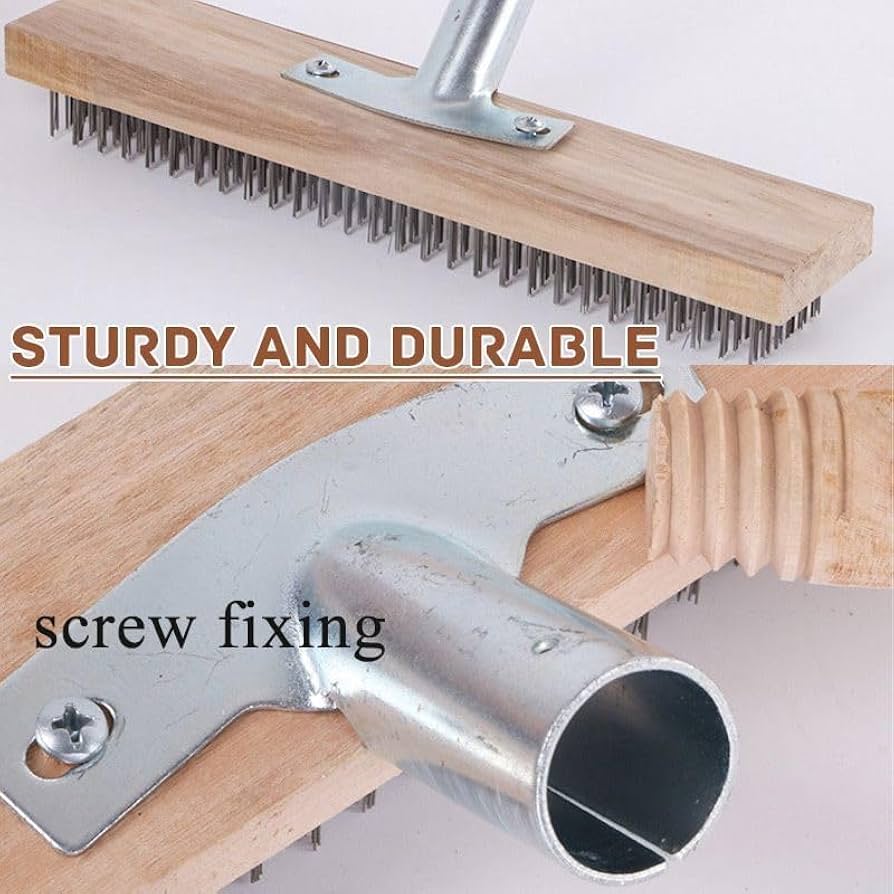

Illustrative image related to broom with metal bristles

Why is a broom with metal bristles important in food processing facilities?

In food processing environments, hygiene is paramount. Brooms with metal bristles are used to clean processing and packaging areas, ensuring that all surfaces are free from contaminants. This not only helps in compliance with health regulations but also protects product quality. Buyers should seek brooms made from non-reactive materials that are easy to clean, as these will meet the stringent hygiene standards required in food processing.

How does a broom with metal bristles enhance operations in transportation and logistics?

In warehouses and loading docks, maintaining cleanliness is essential for operational efficiency. Brooms with metal bristles are effective in sweeping away debris that can obstruct workflow. They help improve safety and reduce the risk of accidents. When sourcing for these applications, businesses should consider the broom’s weight and size for ease of storage, as well as the durability of the bristle material to withstand the rigors of a busy logistics environment.

3 Common User Pain Points for ‘broom with metal bristles’ & Their Solutions

Scenario 1: Ineffective Cleaning on Tough Surfaces

The Problem: B2B buyers in industries like construction, manufacturing, or agriculture often face the challenge of cleaning heavy debris, dust, and materials from tough surfaces. Traditional brooms may not provide the required effectiveness, leading to time-consuming cleanup processes and potential safety hazards. For example, a factory manager may find that standard brooms struggle to remove metal shavings or sawdust, resulting in a hazardous work environment and increased downtime.

The Solution: To address this issue, buyers should consider sourcing brooms with metal bristles specifically designed for heavy-duty applications. These brooms are equipped with durable, stiff bristles that can penetrate rough surfaces and effectively sweep away debris. When purchasing, look for brooms with a suitable width for your workspace and an appropriate handle length for comfort and reach. It’s also advisable to choose a broom with a metal handle for added durability. Additionally, implementing regular maintenance schedules for cleaning tools will ensure that these brooms remain effective over time, thereby maximizing productivity and safety on the worksite.

Illustrative image related to broom with metal bristles

Scenario 2: Quick Wear and Tear of Cleaning Equipment

The Problem: In sectors such as hospitality or food service, where cleanliness is paramount, the longevity of cleaning tools like brooms can significantly impact operational efficiency. Buyers often experience frustration when metal-bristled brooms wear out quickly or fail to maintain their effectiveness, leading to increased replacement costs and disruptions in service. For instance, a restaurant owner may find that their brooms become ineffective after only a few weeks of use, resulting in compromised cleanliness and a poor customer experience.

The Solution: To mitigate this problem, buyers should invest in high-quality brooms that feature heavy-duty bristles and reinforced construction. Prioritize brooms made from materials that resist wear, such as stainless steel bristles that maintain their shape and functionality longer than other materials. Additionally, consider brooms with replaceable heads or parts, which can extend the product’s lifespan and reduce overall costs. Educating staff on proper usage techniques—such as sweeping at appropriate angles and avoiding excessive force—can also help maintain the broom’s condition and effectiveness over time.

Scenario 3: Difficulty in Managing Diverse Cleaning Needs

The Problem: Many businesses encounter the challenge of managing various cleaning tasks that require different tools. A single broom may not be suitable for all surfaces, leading to inefficiencies and missed opportunities for thorough cleaning. For example, a facility manager in a warehouse might struggle with the decision of whether to use a metal-bristled broom for sweeping concrete floors or a softer-bristled option for cleaning sensitive areas like carpets or polished surfaces.

The Solution: To effectively address diverse cleaning needs, buyers should adopt a multipurpose strategy by sourcing a range of brooms with varying bristle types and hardness levels. Metal-bristled brooms can be designated for heavy-duty applications, while softer bristle options can be reserved for delicate surfaces. This strategic selection ensures that each area can be cleaned effectively without risking damage or inefficiency. Additionally, investing in a color-coded system for different broom types can help staff easily identify the right tool for the job, streamlining the cleaning process and enhancing overall operational efficiency. Regular training sessions can also reinforce the importance of using the appropriate broom for each task, ultimately leading to a cleaner and safer environment.

Strategic Material Selection Guide for broom with metal bristles

What Are the Key Materials for Brooms with Metal Bristles?

When selecting materials for brooms with metal bristles, it’s essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in the construction of these brooms, focusing on their performance characteristics and implications for international B2B buyers.

How Does Steel Perform as a Material for Broom Bristles?

Steel is a popular choice for metal bristles due to its strength and durability. It offers excellent resistance to wear and can withstand high pressures, making it suitable for heavy-duty applications. Steel bristles are particularly effective for sweeping rough surfaces and can easily dislodge stubborn debris.

Pros: Steel bristles are highly durable and can endure extensive use without significant wear. They are also relatively cost-effective compared to other metals.

Cons: Steel is prone to rust and corrosion if not properly treated, which can limit its lifespan in humid or wet environments. Additionally, manufacturing steel bristles can involve complex processes, which may increase production costs.

Impact on Application: Steel bristles are ideal for industrial settings where heavy debris removal is necessary, such as construction sites or warehouses. However, they may not be suitable for use on delicate surfaces, as they can scratch or damage them.

What Advantages Do Stainless Steel Bristles Offer?

Stainless steel bristles provide a corrosion-resistant alternative to regular steel. They maintain their integrity in various environmental conditions, making them ideal for both indoor and outdoor use.

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, ensuring a longer lifespan. This material also maintains its strength and performance over time.

Cons: Stainless steel is generally more expensive than regular steel, which can impact overall product pricing. The manufacturing process can also be more complex, potentially leading to higher costs for buyers.

Illustrative image related to broom with metal bristles

Impact on Application: Stainless steel bristles are suitable for applications requiring hygiene and cleanliness, such as food processing or healthcare settings. They can withstand exposure to moisture without degrading.

How Do Aluminum Bristles Compare in Terms of Performance?

Aluminum bristles are lightweight and resistant to corrosion, making them a practical choice for various applications. Their lightweight nature allows for easy maneuverability, which is beneficial in environments requiring frequent sweeping.

Pros: The lightweight characteristic of aluminum makes it easy to handle, reducing user fatigue during prolonged use. Additionally, aluminum does not rust, making it suitable for wet environments.

Cons: While aluminum is resistant to corrosion, it is less durable than steel, which may lead to quicker wear in heavy-duty applications. This can necessitate more frequent replacements.

Illustrative image related to broom with metal bristles

Impact on Application: Aluminum bristles are ideal for light to medium-duty tasks, such as cleaning in retail spaces or offices. They may not be suitable for heavy industrial applications where tougher bristle materials are required.

What Role Does Polypropylene Play in Broom Bristle Construction?

While not a metal, polypropylene is often used in conjunction with metal bristles for added flexibility and functionality. It is a synthetic material that can enhance the broom’s performance by providing softness and flexibility.

Pros: Polypropylene bristles are resistant to moisture and chemicals, making them suitable for various cleaning applications. They are also less likely to scratch surfaces, which is beneficial for delicate flooring.

Cons: Polypropylene bristles may not provide the same level of durability as metal bristles, especially in heavy-duty applications. They can wear out faster under rigorous use.

Illustrative image related to broom with metal bristles

Impact on Application: This material is ideal for applications requiring gentle cleaning, such as in homes or offices. It can be effectively used in combination with metal bristles to create a versatile broom suitable for multiple surfaces.

Summary Table of Material Selection for Brooms with Metal Bristles

| Material | Typical Use Case for broom with metal bristles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial sweeping | High durability | Prone to rust | Low |

| Stainless Steel | Hygiene-sensitive environments | Corrosion resistance | Higher cost | High |

| Aluminum | Light to medium-duty cleaning | Lightweight and easy to handle | Less durable | Medium |

| Polypropylene | Gentle cleaning applications | Moisture and chemical resistance | Less durable than metal | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in brooms with metal bristles, helping them make informed purchasing decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for broom with metal bristles

What Are the Main Stages of Manufacturing Brooms with Metal Bristles?

The manufacturing process for brooms with metal bristles involves several key stages, each critical to ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Metal-Bristled Brooms?

Material preparation begins with sourcing high-quality raw materials. Metal bristles are typically made from stainless steel or galvanized steel, chosen for their durability and resistance to rust. The handles are often constructed from various materials, including aluminum or other metals, which provide strength and longevity.

After sourcing, the materials undergo processing to achieve the desired specifications. This may involve cutting, bending, and treating the metal to enhance its properties. For instance, the metal bristles may be treated to improve their rigidity or coated to prevent corrosion.

What Techniques Are Used in Forming the Broom Components?

Forming is the next stage, where the prepared materials are shaped into broom components. Key techniques include:

- Stamping and Cutting: Metal sheets are stamped to create the bristle bases, while handles are cut to predetermined lengths.

- Bristle Insertion: In this step, the metal bristles are inserted into the broom head, which may involve techniques like heat treatment or adhesive bonding to ensure they remain securely in place.

- Molding: For brooms with plastic components, injection molding may be used to create the broom head or other attachments.

These techniques ensure that each component fits perfectly and functions as intended, contributing to the overall effectiveness of the broom.

How Are Brooms Assembled for Optimal Performance?

Assembly is a crucial phase where all components come together. The process often involves:

- Joining Components: Metal handles are affixed to the broom head, using rivets or screws to ensure a tight fit. The choice of joining method can affect the broom’s durability and ease of use.

- Quality Checks During Assembly: As components are joined, quality control checks are often performed to detect any misalignments or defects early in the process.

This attention to detail during assembly is vital, as it directly impacts the broom’s usability and lifespan.

What Finishing Processes Enhance the Quality of Metal-Bristled Brooms?

Finishing processes add the final touches to the broom, enhancing both aesthetics and functionality. These processes may include:

Illustrative image related to broom with metal bristles

- Surface Treatment: Metal components are often polished or coated to enhance corrosion resistance and improve appearance.

- Final Assembly and Packaging: After finishing, the brooms undergo a final assembly check before being packaged for distribution. This may include labeling and barcoding for inventory management.

The finishing stage not only improves the broom’s durability but also its market appeal, which is crucial for B2B buyers focused on product presentation.

What Quality Assurance Measures Are Essential for Brooms with Metal Bristles?

Quality assurance (QA) is paramount in the manufacturing process of brooms with metal bristles. Implementing effective QA measures ensures that products meet both international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

For brooms with metal bristles, adherence to international standards such as ISO 9001 is critical. This standard emphasizes a quality management system that focuses on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking may be relevant, indicating compliance with European health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control (QC) checkpoints are established at various stages of production:

- Incoming Quality Control (IQC): This initial stage checks the quality of raw materials upon receipt. Suppliers must provide documentation proving compliance with standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are tested to ensure ongoing compliance with specifications. This may involve testing the strength of bristles or the durability of handles.

- Final Quality Control (FQC): Before packaging, finished products undergo a comprehensive inspection to verify that they meet all quality standards and specifications.

These checkpoints help to catch defects early, reducing the risk of non-compliant products reaching the market.

What Common Testing Methods Are Used in Quality Control?

Common testing methods employed during QC include:

- Mechanical Testing: This assesses the strength and durability of the broom components, particularly the bristles and handles.

- Visual Inspection: A thorough visual examination checks for defects such as uneven bristle distribution or handle misalignment.

- Performance Testing: Brooms may be tested in real-world conditions to evaluate their effectiveness in various cleaning scenarios.

These testing methods provide an assurance of quality, ensuring that the brooms perform as expected in diverse environments.

Illustrative image related to broom with metal bristles

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure quality in their broom procurement should consider several verification strategies:

What Steps Can Buyers Take to Audit Suppliers?

Conducting audits of suppliers is a proactive approach. Buyers can request to visit manufacturing facilities or review quality management system certifications. This provides insight into the supplier’s commitment to quality and compliance with international standards.

How Important Are Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers is essential. These documents should detail results from IQC, IPQC, and FQC, giving buyers confidence in the product quality. Additionally, engaging third-party inspectors can provide an unbiased assessment of the manufacturing processes and products.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific certification requirements in their markets. For instance, compliance with local regulations and standards is crucial when importing goods. Understanding these nuances helps buyers avoid potential legal issues and ensures that products meet local market demands.

In conclusion, understanding the manufacturing processes and quality assurance measures for brooms with metal bristles is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust QC practices, buyers can ensure they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘broom with metal bristles’

Introduction

Sourcing a broom with metal bristles requires careful consideration to ensure that you procure a product that meets your operational needs while also aligning with quality standards. This step-by-step checklist is designed to guide B2B buyers through the essential actions necessary for successful procurement, from defining specifications to evaluating suppliers. By following these steps, you can ensure a seamless purchasing process that results in high-quality products for your business.

Step 1: Define Your Technical Specifications

Clearly define the specifications for the broom you need. Consider factors such as bristle material (e.g., steel or aluminum), handle length, and broom width. This step is crucial because the right specifications will determine the broom’s effectiveness for your intended use, whether for industrial cleaning, outdoor applications, or fine particle collection.

Illustrative image related to broom with metal bristles

- Bristle Type: Choose between stiff or flexible metal bristles based on the surfaces you will be cleaning.

- Handle Length: Ensure the handle length is ergonomic for your workforce, reducing fatigue during use.

Step 2: Identify Your Target Market and Distribution Channels

Understanding your target market and distribution channels is vital for aligning your product offerings with customer needs. Identify whether you are selling to commercial sectors like hospitality, manufacturing, or retail, as this will influence the type of broom you should source.

- Market Analysis: Research specific needs in different regions, such as Africa or Europe, to tailor your offerings.

- Distribution Strategy: Decide whether to sell directly to end-users or through distributors, which may affect your pricing strategy.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and product quality. Request company profiles, product samples, and references from other buyers in similar industries or regions.

- Supplier Reputation: Look for suppliers with positive reviews and proven experience in manufacturing metal-bristled brooms.

- Certifications: Check for industry certifications that indicate adherence to quality and safety standards.

Step 4: Compare Pricing and Terms of Sale

Gather quotes from multiple suppliers to compare pricing structures and terms of sale. This step is essential to ensure you are getting a competitive rate without compromising on quality.

Illustrative image related to broom with metal bristles

- Bulk Discounts: Inquire about bulk purchase discounts or loyalty programs that could reduce costs.

- Payment Terms: Assess payment terms and conditions, including deposits, credit options, and return policies.

Step 5: Assess Logistics and Shipping Options

Evaluate the logistics involved in sourcing your brooms, including shipping times and costs. Efficient logistics can significantly impact your overall procurement strategy.

- Shipping Costs: Analyze the shipping costs based on your location and the supplier’s location to avoid unexpected expenses.

- Delivery Times: Confirm estimated delivery times to ensure they align with your operational timelines.

Step 6: Establish Quality Control Measures

Implement quality control measures to ensure that the products received meet your specifications and standards. This is crucial for maintaining customer satisfaction and minimizing returns.

- Inspection Protocols: Develop protocols for inspecting received brooms, focusing on bristle quality and handle integrity.

- Feedback Loop: Create a system for collecting feedback from your team on broom performance to inform future sourcing decisions.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, finalize contracts and agreements to formalize the relationship. This step protects both parties and clarifies expectations.

- Legal Review: Have legal counsel review the contract to ensure all terms are fair and clearly defined.

- Performance Metrics: Establish performance metrics to evaluate the supplier’s adherence to quality and delivery standards over time.

By following this comprehensive checklist, B2B buyers can navigate the procurement process for brooms with metal bristles effectively, ensuring they make informed decisions that benefit their operations.

Comprehensive Cost and Pricing Analysis for broom with metal bristles Sourcing

What Are the Key Cost Components in Sourcing Brooms with Metal Bristles?

When sourcing brooms with metal bristles, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type and quality of materials significantly influence the cost. Metal bristles can range from stainless steel to more economical options, impacting durability and performance. The handle materials, whether wood or various metals, also add to the overall cost.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with higher wages will naturally result in higher production costs. It’s essential to consider the skill level required for production, as skilled labor may command higher wages.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses associated with running a manufacturing facility. Efficient production practices can help mitigate these costs.

-

Tooling: Initial setup costs for molds and tools specific to the broom design can be substantial. For customized or specialized designs, these costs can increase significantly.

-

Quality Control: Ensuring product quality through rigorous testing and inspection processes can add to costs. However, investing in QC can reduce long-term costs associated with returns and customer dissatisfaction.

-

Logistics: Transportation costs, including shipping and handling, play a crucial role, especially for international trade. Factors such as distance, freight rates, and customs duties must be accounted for.

-

Margin: Suppliers typically include a margin that reflects their business objectives and market conditions. Understanding the margin will help buyers gauge the price competitiveness of various suppliers.

How Do Price Influencers Affect Broom Sourcing?

Several factors can influence the pricing of brooms with metal bristles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often secure lower prices per unit due to economies of scale. Establishing a long-term relationship with suppliers can also lead to better pricing structures.

-

Specifications and Customization: Customization requests, such as specific handle lengths or bristle types, can raise costs. Standardized products typically have lower price points.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or other industry-specific standards) can increase the price but may enhance product durability and performance, providing better value over time.

-

Supplier Factors: Supplier reputation, location, and reliability can impact pricing. Established suppliers may charge a premium but offer better service and product assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They dictate responsibilities for shipping, insurance, and tariffs, directly affecting the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers?

To achieve cost efficiency when sourcing brooms with metal bristles, B2B buyers should consider the following strategies:

Illustrative image related to broom with metal bristles

-

Leverage Volume Discounts: When feasible, consolidate orders to meet higher volume thresholds that qualify for discounts.

-

Request Multiple Quotes: Engaging multiple suppliers allows for comparison and can strengthen negotiation leverage. Highlighting competitive offers can lead to better pricing.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider factors like durability, maintenance, and potential for replacement. A higher upfront cost may result in lower long-term expenses.

-

Be Aware of Regional Pricing Nuances: Prices can vary significantly across regions due to local economic conditions, tariffs, and currency fluctuations. Understanding these factors can help in negotiations.

-

Build Strong Relationships: Establishing rapport with suppliers can lead to better terms, pricing, and priority treatment during peak seasons.

What Should International Buyers Consider in Pricing Nuances?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it’s crucial to be aware of:

-

Currency Fluctuations: Exchange rates can impact the final cost significantly, so locking in prices or negotiating in a stable currency can mitigate risks.

-

Import Duties and Taxes: Understanding local regulations regarding import duties and taxes can prevent unexpected costs and assist in accurate budgeting.

-

Shipping Logistics: Consider the reliability of shipping methods and potential delays, which can affect inventory management and cash flow.

-

Cultural Considerations: Different cultures have varying negotiation styles and expectations, so adapting to these nuances can lead to more fruitful discussions.

This comprehensive analysis provides a roadmap for B2B buyers to navigate the complexities of sourcing brooms with metal bristles effectively. By understanding cost components, price influencers, and negotiation strategies, buyers can make informed decisions that contribute to their overall operational efficiency.

Alternatives Analysis: Comparing broom with metal bristles With Other Solutions

Introduction to Alternatives in Sweeping Solutions

When it comes to maintaining cleanliness in industrial and commercial environments, choosing the right cleaning tool is crucial. Broom with metal bristles offers robust performance for tough sweeping tasks; however, it is essential to evaluate other viable alternatives that may suit specific needs better. This analysis compares the broom with metal bristles against two alternative solutions: mechanical sweepers and brooms with synthetic bristles, providing insight into their respective advantages and disadvantages.

Illustrative image related to broom with metal bristles

Comparison Table

| Comparison Aspect | Broom With Metal Bristles | Mechanical Sweeper | Synthetic Bristle Broom |

|---|---|---|---|

| Performance | Excellent for heavy debris and rough surfaces | High efficiency, covers large areas quickly | Good for fine particles, less effective on heavy debris |

| Cost | Moderate ($20 – $50) | High initial investment ($2,000 – $10,000) | Low ($10 – $30) |

| Ease of Implementation | Simple and manual | Requires training and setup | Easy to use, similar to metal broom |

| Maintenance | Low, occasional bristle replacement | Moderate, regular upkeep needed | Low, occasional bristle replacement |

| Best Use Case | Industrial settings, outdoor areas | Large warehouses, parking lots | Indoor spaces, light cleaning tasks |

Detailed Breakdown of Alternatives

1. Mechanical Sweepers

Mechanical sweepers are advanced cleaning machines designed for large-scale operations. They significantly enhance productivity by covering expansive areas quickly and efficiently. Their high capacity for collecting debris makes them ideal for warehouses, parking lots, and other vast outdoor spaces. However, they come with a high initial cost and may require specialized training for operators. Regular maintenance is also necessary to ensure optimal performance, making them less accessible for smaller businesses or those with limited budgets.

2. Synthetic Bristle Broom

The synthetic bristle broom is an economical alternative that utilizes materials like polypropylene or polyester for sweeping. This type of broom is lightweight and easy to handle, making it ideal for indoor environments and light cleaning tasks. While they excel at picking up fine particles, synthetic brooms may struggle with heavy debris and rough surfaces, which can limit their effectiveness in certain industrial applications. Their lower cost makes them appealing for businesses seeking budget-friendly solutions, but they may need to be replaced more frequently than metal bristle brooms.

Conclusion: Choosing the Right Sweeping Solution

Selecting the appropriate sweeping solution depends on the specific cleaning needs of a business. For environments requiring robust performance against heavy debris, the broom with metal bristles stands out as a reliable choice. However, for larger areas that demand efficiency, mechanical sweepers may be worth the investment despite their higher costs. Conversely, for routine light cleaning in indoor settings, synthetic bristle brooms provide a cost-effective and easy-to-use option. B2B buyers should carefully assess their operational requirements, budget constraints, and maintenance capabilities when deciding on the best solution for their cleaning needs.

Illustrative image related to broom with metal bristles

Essential Technical Properties and Trade Terminology for broom with metal bristles

What are the Key Technical Properties of Brooms with Metal Bristles?

Understanding the technical specifications of brooms with metal bristles is essential for B2B buyers to make informed purchasing decisions. Here are some critical properties to consider:

-

Bristle Material

The bristles of metal brooms are typically made from heavy-duty materials such as stainless steel or galvanized wire. These materials provide excellent durability and resistance to corrosion, making them suitable for harsh cleaning environments. For businesses in industries like construction or agriculture, the strength of the bristles ensures longevity and effective cleaning performance, reducing the need for frequent replacements. -

Handle Material and Length

Handles can be constructed from various materials, including metal, fiberglass, or wood. Metal handles are preferred for their strength and resistance to bending or breaking under heavy use. The length of the handle is also important, as it affects the broom’s maneuverability. A longer handle (usually between 48 to 60 inches) allows for better reach and reduces strain on the user’s back, particularly beneficial in large industrial or outdoor spaces. -

Head Width

The width of the broom head can vary significantly, typically ranging from 9 to 24 inches. A wider head allows for sweeping larger areas more efficiently, which can be advantageous in warehouses or outdoor settings. Conversely, narrower heads are ideal for tight spaces and detailed cleaning. Understanding the intended application will guide buyers in selecting the right broom width for their needs. -

Bristle Stiffness

Metal bristles come in various stiffness levels, affecting their cleaning effectiveness. Stiffer bristles are ideal for heavy-duty scrubbing and can effectively dislodge dirt and debris from rough surfaces. Softer bristles, on the other hand, are better suited for delicate surfaces where scratching could be a concern. Knowing the appropriate stiffness for specific applications can enhance cleaning efficiency. -

Weight

The overall weight of the broom can impact user comfort and effectiveness. Heavier brooms may provide better contact with the surface, while lighter models may be easier to maneuver. Buyers should consider who will be using the broom and for what purposes, as this can influence the choice of weight.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms relevant to brooms with metal bristles:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with an OEM can ensure high-quality products that meet specific needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they can meet their operational needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. This allows buyers to compare pricing and terms from different suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms can help buyers understand shipping costs, risk management, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For businesses, shorter lead times can improve inventory management and operational efficiency.

By understanding these technical specifications and trade terms, B2B buyers can make better-informed decisions when sourcing brooms with metal bristles, ultimately enhancing their operational effectiveness.

Navigating Market Dynamics and Sourcing Trends in the broom with metal bristles Sector

What Are the Key Trends Driving the Broom with Metal Bristles Market?

The broom with metal bristles market is witnessing significant growth, driven by increasing demand for durable cleaning tools across various industries. Key trends include the rise of automation in cleaning processes, which is leading to the integration of advanced materials and designs into broom manufacturing. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking brooms that can withstand rigorous use in industrial and commercial settings. The focus on efficiency and performance is pushing manufacturers to innovate, with features such as ergonomic designs and enhanced bristle technology that improve cleaning effectiveness and reduce labor costs.

Illustrative image related to broom with metal bristles

Emerging technologies, such as e-commerce platforms and digital supply chain management, are reshaping sourcing strategies for B2B buyers. These platforms facilitate direct interactions between manufacturers and buyers, allowing for better price negotiations and streamlined procurement processes. Additionally, global supply chain disruptions have prompted businesses to diversify their sourcing strategies, prioritizing local suppliers to mitigate risks associated with international shipping. This trend is particularly relevant for buyers in regions like Nigeria and Saudi Arabia, where local sourcing can enhance supply chain resilience.

How Is Sustainability Influencing Sourcing Decisions in the Broom with Metal Bristles Sector?

Sustainability has become a critical consideration for B2B buyers in the broom with metal bristles sector. The environmental impact of cleaning products, including the materials used in manufacturing brooms, is prompting companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers that offer eco-friendly materials, such as recycled plastics or sustainably sourced wood for handles, as part of their commitment to reducing their carbon footprint.

Moreover, the demand for ethical sourcing is growing, with businesses seeking suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) certification for wood products are becoming essential criteria for procurement decisions. This shift towards sustainable sourcing not only addresses environmental concerns but also enhances the brand reputation of companies in competitive markets.

What Is the Historical Context of the Broom with Metal Bristles?

The broom with metal bristles has evolved significantly since its inception, reflecting changes in cleaning technology and consumer needs. Initially used primarily in agricultural settings, metal-bristled brooms were designed for their durability and effectiveness in sweeping rough surfaces. Over time, advancements in material science led to the introduction of synthetic bristles, enhancing performance while maintaining the robustness associated with metal.

In recent decades, as industries expanded and cleaning standards became more stringent, the design and functionality of brooms evolved further. The introduction of ergonomic handles and specialized bristle types has made these cleaning tools more versatile, catering to a broader range of applications from industrial cleaning to household use. Today, the focus on sustainability and efficiency continues to shape the future of broom design, ensuring that they meet the needs of modern buyers while minimizing environmental impact.

Frequently Asked Questions (FAQs) for B2B Buyers of broom with metal bristles

1. How do I choose the right broom with metal bristles for my business needs?

Selecting the right broom with metal bristles depends on the specific cleaning tasks you need to address. Consider the surface type—metal bristles are ideal for tough surfaces like concrete or rough flooring where heavy debris is common. Assess the broom’s head width and handle length to ensure it fits your workspace efficiently. Additionally, review the bristle material; options like polypropylene offer durability and resistance to wear, making them suitable for industrial applications. Engage with suppliers to discuss your requirements and request samples for testing before making a bulk purchase.

2. What advantages do metal bristle brooms offer compared to traditional brooms?

Metal bristle brooms provide several advantages over traditional brooms. They are exceptionally durable, making them ideal for heavy-duty cleaning tasks and outdoor applications. The rigidity of metal bristles allows for better penetration into cracks and crevices, effectively capturing larger debris and dirt. Furthermore, they do not absorb moisture, reducing the risk of mold and bacteria buildup, which is essential in environments like warehouses and factories. Overall, their longevity and efficiency can lead to lower replacement costs and improved cleaning performance.

3. What are the typical minimum order quantities (MOQs) for bulk purchases of metal bristle brooms?

Minimum order quantities (MOQs) for metal bristle brooms can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from as low as 50 units to over 500 units for specialized or customized brooms. It’s essential to communicate your needs directly with suppliers to negotiate terms that suit your business requirements. Additionally, consider the potential for discounts on larger orders, which can enhance cost-effectiveness for your procurement strategy.

4. How can I ensure the quality of metal bristle brooms from suppliers?

To ensure the quality of metal bristle brooms, conduct thorough due diligence on potential suppliers. Request product samples to assess material quality and construction. Check for certifications or compliance with industry standards, as these can indicate a commitment to quality. Reviews and testimonials from other buyers can provide insight into the supplier’s reliability and product performance. Establishing clear quality assurance protocols and agreements with suppliers can further ensure that the products meet your specifications consistently.

5. What payment terms should I consider when sourcing brooms internationally?

When sourcing brooms internationally, it’s essential to establish clear payment terms to protect your investment. Common options include advance payments, letters of credit, and net payment terms (e.g., 30, 60, or 90 days post-delivery). Evaluate the risks associated with each method based on your relationship with the supplier and their reputation. Using escrow services can provide additional security. Always negotiate terms that align with your cash flow needs while ensuring that you maintain a good relationship with the supplier.

Illustrative image related to broom with metal bristles

6. How do shipping and logistics work for international orders of metal bristle brooms?

Shipping and logistics for international orders of metal bristle brooms typically involve several steps, including selecting a freight forwarder and determining the best shipping method (air or sea). It’s crucial to understand the incoterms (International Commercial Terms) that define who is responsible for shipping costs, insurance, and customs clearance. Ensure that you have all necessary documentation ready, including invoices, packing lists, and certificates of origin. Partnering with logistics experts can streamline the process, helping you navigate customs regulations and ensuring timely delivery.

7. Can I customize the design or branding of metal bristle brooms for my business?

Yes, many suppliers offer customization options for metal bristle brooms, including branding with your company logo and specific design features. Customization can enhance brand visibility and create a more professional appearance for your cleaning services. Discuss your design ideas with potential suppliers and inquire about the minimum order quantities and costs associated with customization. It’s advisable to request prototypes to evaluate the final product before committing to a larger order.

8. What factors should I consider when vetting suppliers of metal bristle brooms?

When vetting suppliers for metal bristle brooms, consider their experience and reputation in the industry. Look for suppliers with a proven track record of delivering high-quality products and reliable service. Assess their production capabilities, including the technology used and their ability to meet your order specifications. Additionally, evaluate their customer service responsiveness and willingness to address concerns. Trade certifications and participation in industry associations can also indicate a commitment to quality and ethical practices.

Top 5 Broom With Metal Bristles Manufacturers & Suppliers List

1. {product_details:MSC Direct – Industrial Supplies}

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: CRITICAL: You MUST output ONLY the JSON object, with no other text, commentary, or markdown formatting. The entire response must be a single, valid JSON object like this: {“product_details”: “string”}. If no info is found, use an empty string for the value.

2. Aramsco – 18 Stiff Bristle Broom

Domain: aramsco.com

Registered: 1996 (29 years)

Introduction: Aramsco 18″ Stiff Bristle Broom with 60″ Metal Threaded Wood Handle, SKU: 57080

3. Gemplers – Metal-Top Broom 1361

4. Rubbermaid® – Lobby Pro Broom

Domain: bramespecialty.com

Registered: 2001 (24 years)

Introduction: {‘product_name’: ‘Lobby Pro Broom, Poly Bristles, 35″ Metal Handle, Black’, ‘sku’: ‘1570355’, ‘vendor_sku’: ‘FG637400BLA’, ‘brand_name’: ‘Rubbermaid® Commercial’, ‘description’: ‘The Rubbermaid Commercial Products Executive Lobby Broom with Vinyl Handle is great for use in restaurants, malls, lobbies, and more. These push brooms are ideal for one-handed sweeping and cleaning under tables, fixtures…

5. Blackford – 24 Push Broom Head

Domain: arizonabag.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “24” Blackford Push Broom Head, Wire Center”, “product_number”: “”, “price”: “$6.70”, “description”: “This 24″ wide Tampico Push Broom has a center row of steel bristles. The medium stiff tampico bristles will pick up smaller particles while the steel bristles will push heavier or wet debris.”, “features”: [“24″ width”, “center row of steel bristles”, “medium stiff tampico bristle…

Strategic Sourcing Conclusion and Outlook for broom with metal bristles

The strategic sourcing of brooms with metal bristles presents a unique opportunity for businesses looking to enhance their cleaning efficiency and durability. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly prioritize quality and cost-effectiveness, investing in robust cleaning tools becomes essential. Metal-bristled brooms offer superior performance on tough surfaces, making them ideal for various industrial and commercial applications, from construction sites to food processing facilities.

Illustrative image related to broom with metal bristles

Key takeaways emphasize the importance of evaluating suppliers based on product quality, bristle durability, and handle materials. Engaging with manufacturers who provide customization options can further meet specific market needs, ensuring your operations maintain high standards of cleanliness and safety.

Looking ahead, the demand for efficient cleaning solutions will continue to rise, driven by stringent hygiene regulations and a growing emphasis on sustainability. International buyers are encouraged to explore partnerships that not only promise product reliability but also align with eco-friendly practices. By prioritizing strategic sourcing now, businesses can position themselves for success in an evolving market landscape. Consider reaching out to reputable suppliers today to secure the best solutions for your cleaning challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to broom with metal bristles

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.