Everything You Need to Know About Conveyor System Belt Conveyor Diagram Sourcing in 2025

Introduction: Navigating the Global Market for conveyor system belt conveyor diagram

In an increasingly competitive global market, sourcing the right conveyor system belt conveyor diagram can be a daunting challenge for B2B buyers. Understanding the intricacies of various conveyor systems is essential for optimizing material handling operations, ensuring efficiency, and reducing operational costs. This comprehensive guide delves into the types of conveyor systems, their applications across diverse industries, and essential components that constitute effective belt conveyors. Additionally, it will cover critical aspects such as supplier vetting, cost considerations, and maintenance practices tailored for international buyers from Africa, South America, the Middle East, and Europe, including regions like Vietnam and Germany.

By navigating this guide, businesses can make informed purchasing decisions that not only meet their operational requirements but also align with their strategic objectives. With insights into the latest advancements in conveyor technology and best practices for implementation, buyers will be better equipped to enhance productivity and streamline their supply chains. The goal is to empower B2B purchasers with the knowledge needed to select the most suitable conveyor systems, ensuring that they achieve maximum efficiency and return on investment in their material handling processes.

Understanding conveyor system belt conveyor diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Belt Conveyors | Flexible and versatile, suitable for various materials. | Warehousing, assembly lines, and packaging. | Pros: Cost-effective, easy maintenance. Cons: Limited load capacity. |

| Bucket Conveyors | Utilizes buckets attached to a belt to lift materials vertically. | Bulk material handling in agriculture and mining. | Pros: Efficient for vertical transport. Cons: More complex installation. |

| Roller Bed Conveyors | Features rollers that allow items to glide smoothly. | Distribution centers and manufacturing plants. | Pros: Low friction, ideal for heavy loads. Cons: Requires more space. |

| Vibratory Conveyors | Uses vibration to move bulk materials along a trough. | Food processing and recycling industries. | Pros: Gentle handling of materials. Cons: Limited to specific types of materials. |

| Metal Conveyor Belts | Durable belts made of metal mesh or sheets. | High-temperature applications and heavy-duty tasks. | Pros: Excellent durability and strength. Cons: Higher initial cost. |

What Are the Key Characteristics of Flat Belt Conveyors?

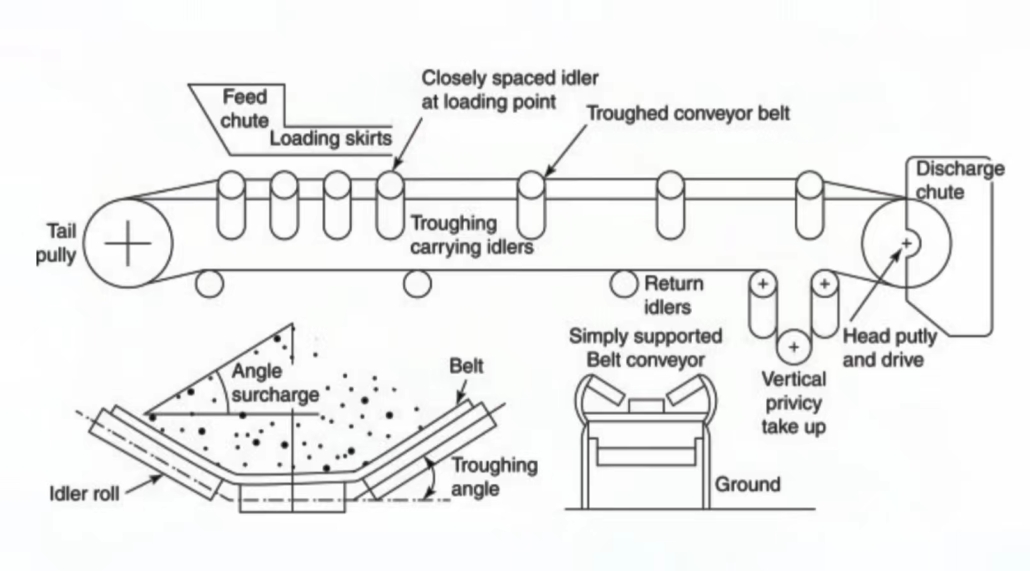

Flat belt conveyors are among the most common types in the industry, characterized by their flat, continuous belts that transport materials horizontally or on a slight incline. They are highly adaptable and can handle various products, from small items to larger packages. When considering a purchase, B2B buyers should evaluate the load capacity, belt material, and overall durability to ensure the conveyor meets their operational requirements. These systems are particularly advantageous for businesses looking for cost-effective solutions with easy maintenance.

How Do Bucket Conveyors Function and Where Are They Used?

Bucket conveyors are specifically designed to move bulk materials vertically. They consist of buckets attached to a belt that lifts materials to higher elevations, making them ideal for applications in agriculture, mining, and food processing. Buyers should consider the conveyor’s height capacity, bucket size, and material compatibility when making purchasing decisions. Although they provide efficient vertical transport, the installation can be more complex compared to other conveyor types.

What Advantages Do Roller Bed Conveyors Offer?

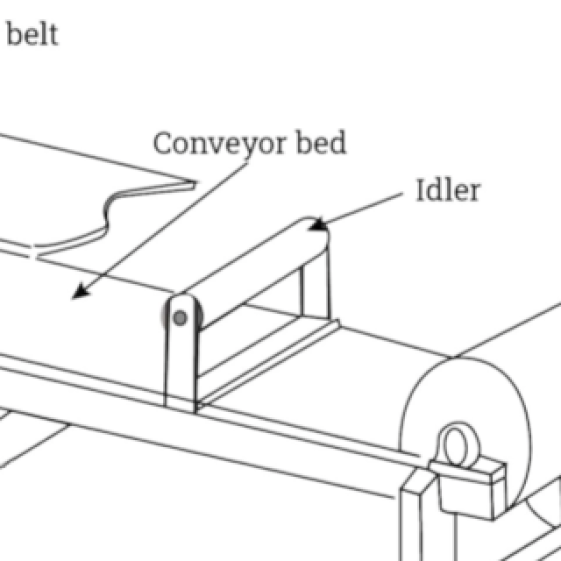

Roller bed conveyors utilize a series of rollers to facilitate the movement of goods, allowing for smooth transport with minimal friction. This type is commonly used in distribution centers and manufacturing plants for heavy loads. B2B buyers should assess the roller spacing, load capacity, and overall design when selecting this type of conveyor. While they excel in handling heavy items, they require more space and can be less flexible in layout compared to flat belt systems.

In What Applications Are Vibratory Conveyors Most Effective?

Vibratory conveyors leverage vibration to move bulk materials along a trough, making them suitable for industries such as food processing and recycling. They are particularly effective for gently handling fragile items or materials that require careful movement. Buyers should focus on the conveyor’s vibration frequency and trough design to ensure compatibility with their specific materials. While vibratory conveyors excel in gentle handling, their application is limited to specific material types, which can restrict versatility.

Why Choose Metal Conveyor Belts for Heavy-Duty Tasks?

Metal conveyor belts are constructed from durable materials like stainless steel or wire mesh, making them ideal for high-temperature or heavy-duty applications. These belts are commonly found in industries that require robust handling, such as automotive and food processing. When considering metal conveyor belts, B2B buyers should evaluate the belt’s strength, thermal resistance, and maintenance requirements. Although they come with a higher initial investment, their longevity and resilience often justify the cost in demanding environments.

Key Industrial Applications of conveyor system belt conveyor diagram

| Industry/Sector | Specific Application of conveyor system belt conveyor diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting packaged goods on production lines | Increases production efficiency and reduces labor costs | Compliance with food safety regulations; material durability |

| Mining and Minerals | Moving bulk materials like ore and coal | Enhances material handling efficiency and reduces downtime | Robust design for heavy loads; resistant materials for wear |

| Automotive Manufacturing | Assembly line integration for parts assembly | Streamlines production processes and improves accuracy | Customization options for different vehicle types; automation integration |

| Warehousing and Logistics | Sorting and distributing packages in fulfillment centers | Optimizes space utilization and accelerates order processing | Flexibility in layout design; compatibility with existing systems |

| Pharmaceuticals and Healthcare | Transporting products between production and packaging areas | Ensures compliance with strict regulatory standards | Material selection for hygiene; traceability features in design |

In the food and beverage industry, conveyor system belt diagrams are essential for transporting packaged goods along production lines. These systems enhance production efficiency by automating the movement of products, which significantly reduces labor costs and minimizes human error. Buyers in this sector must prioritize compliance with food safety regulations, ensuring that the materials used in conveyor belts are durable and suitable for contact with food products.

In mining and minerals, conveyor systems are utilized to move bulk materials like ore and coal from extraction sites to processing areas. These systems are crucial for enhancing material handling efficiency and reducing operational downtime. B2B buyers should consider sourcing conveyors with robust designs capable of handling heavy loads and resistant materials that can withstand the wear and tear of abrasive materials.

The automotive manufacturing sector employs conveyor system belt diagrams for the integration of assembly lines, where parts are transported to various stations for assembly. This automation streamlines production processes, significantly improving accuracy and reducing assembly time. Buyers should seek customizable conveyor solutions that can accommodate different vehicle types and integrate seamlessly with existing automation systems.

In warehousing and logistics, conveyor systems are pivotal for sorting and distributing packages within fulfillment centers. These systems optimize space utilization and accelerate order processing, leading to higher customer satisfaction. When sourcing, companies should look for flexible designs that can be adapted to various layouts and ensure compatibility with current logistics operations.

In the pharmaceutical and healthcare sectors, conveyor systems facilitate the movement of products between production and packaging areas, ensuring compliance with stringent regulatory standards. This application is critical for maintaining product integrity and safety. Buyers must focus on selecting materials that prioritize hygiene and incorporate features that enhance traceability throughout the production process.

3 Common User Pain Points for ‘conveyor system belt conveyor diagram’ & Their Solutions

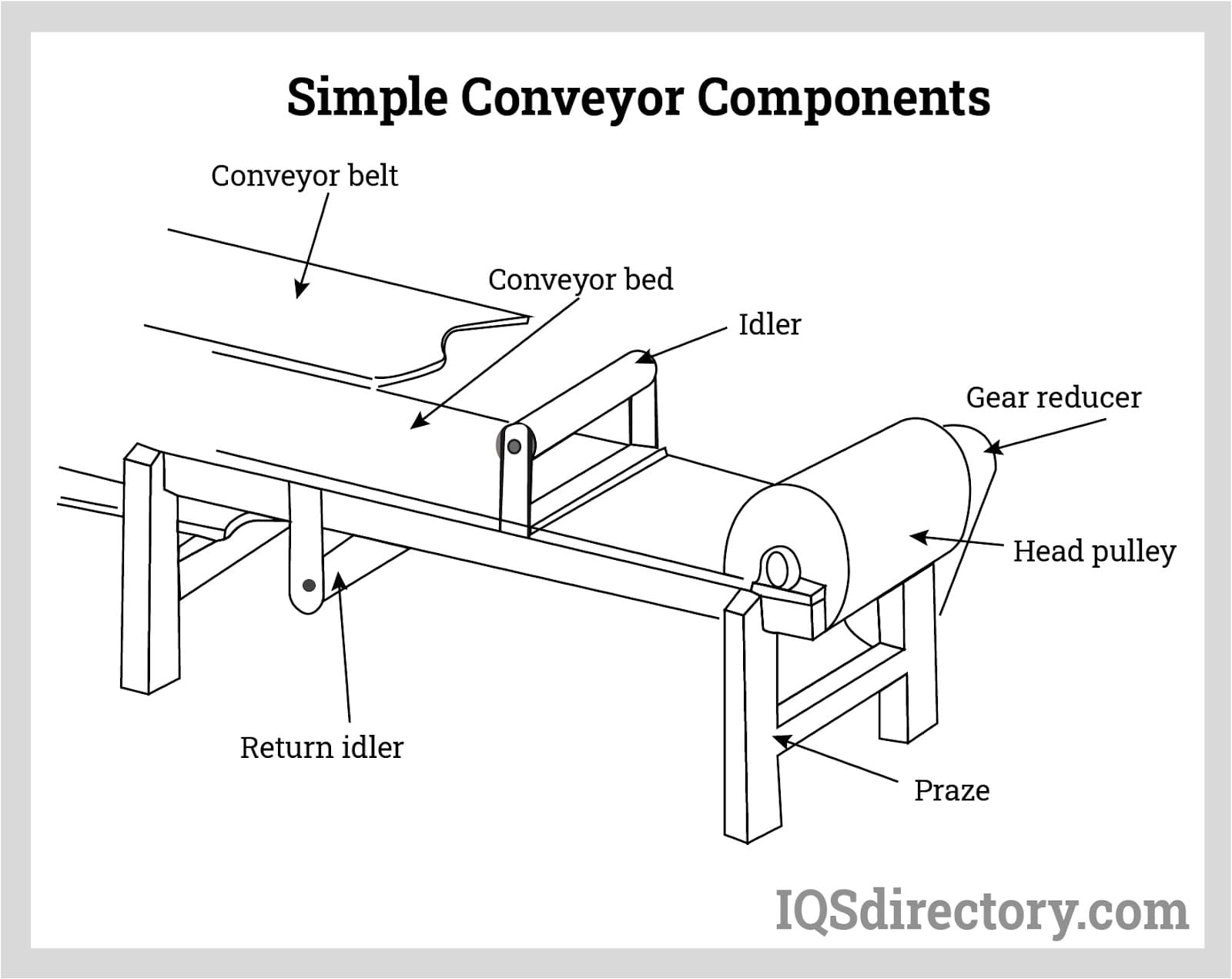

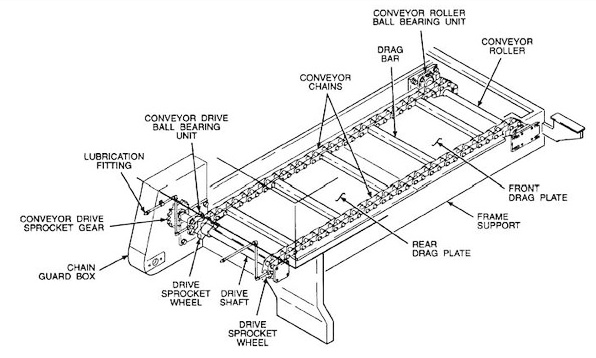

Scenario 1: Difficulty in Understanding Conveyor System Layouts

The Problem: Many B2B buyers encounter challenges when trying to visualize and implement conveyor systems within their operations. A common issue arises when interpreting conveyor system belt diagrams, which can be complex and difficult to understand. This lack of clarity can lead to miscommunication with engineering teams, resulting in inefficient layouts that do not optimize workflow or space. Buyers may also struggle to identify the best configuration for their specific needs, leading to costly mistakes during installation and operation.

The Solution: To overcome this challenge, buyers should prioritize sourcing high-quality, detailed conveyor system belt diagrams from reputable suppliers. When evaluating these diagrams, look for clear labels, dimensions, and annotations that indicate the functionality of each component. Engaging with suppliers who provide comprehensive design consultations can also be invaluable. They can help tailor the diagram to your specific operational needs, ensuring that the layout maximizes efficiency and minimizes waste. Additionally, consider utilizing software tools that allow for simulation and visualization of the conveyor system before implementation, providing a clearer understanding of how the system will operate in practice.

Scenario 2: Misalignment of Conveyor System Components

The Problem: Another common pain point arises from the misalignment of conveyor system components, which can lead to increased wear and tear on the belts, as well as product damage. This issue often stems from inadequate diagrams that do not accurately represent the necessary alignment specifications or tolerances for different components. As a result, B2B buyers may find themselves dealing with frequent breakdowns, increased maintenance costs, and operational delays.

The Solution: To mitigate this issue, B2B buyers should ensure that their conveyor system belt diagrams include detailed specifications for alignment and installation tolerances. When selecting a conveyor system, ask for diagrams that highlight critical alignment points and provide guidelines for installation. Collaborating with experienced engineers during the design phase can further enhance the accuracy of the alignment. Additionally, consider implementing regular training sessions for maintenance personnel on proper alignment techniques and the importance of adhering to the specifications outlined in the diagrams. This proactive approach can significantly reduce the risk of misalignment and extend the lifespan of the conveyor system.

Scenario 3: Inadequate Integration with Existing Systems

The Problem: Many B2B buyers face difficulties when integrating new conveyor systems with their existing equipment and processes. A common issue is the lack of compatibility between the new conveyor system and current machinery, which can lead to operational disruptions. This problem often stems from poor diagramming that fails to account for existing system specifications or operational workflows, resulting in additional costs for retrofitting or replacement.

The Solution: To address this challenge, it is crucial for buyers to conduct a thorough analysis of their current systems before selecting a new conveyor system. When reviewing conveyor system belt diagrams, ensure that they include integration points and compatibility notes with existing machinery. Engage with suppliers who are willing to collaborate on a comprehensive integration plan, taking into consideration the specific requirements of your operations. It may also be beneficial to conduct pilot tests with the new system in a controlled environment to identify potential issues before full implementation. Additionally, investing in modular conveyor systems can provide greater flexibility for future upgrades and adaptations, minimizing the risk of integration challenges.

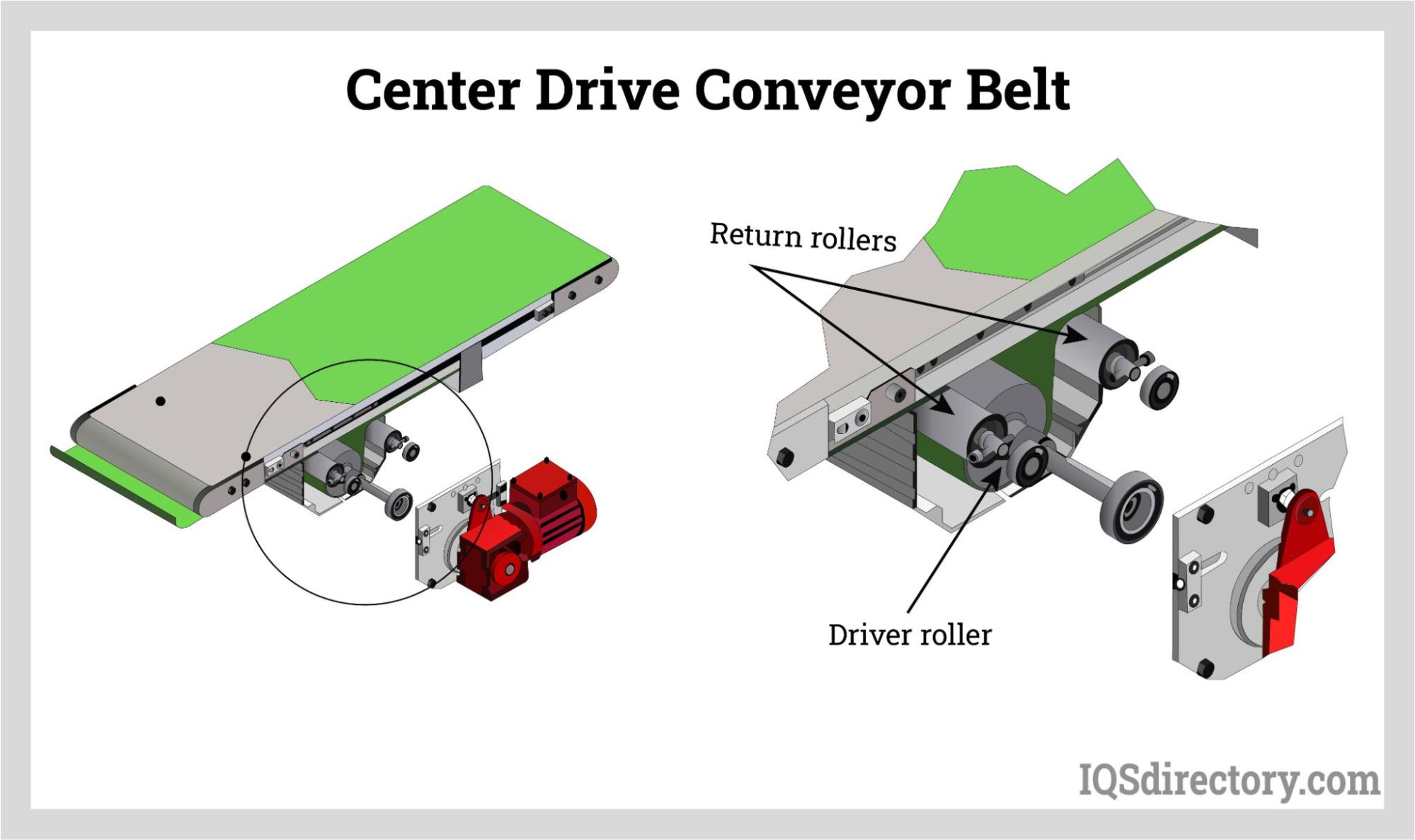

Illustrative image related to conveyor system belt conveyor diagram

Strategic Material Selection Guide for conveyor system belt conveyor diagram

What Are the Key Properties of Different Conveyor Belt Materials?

When selecting materials for conveyor belts, it is crucial to consider their properties, as these directly influence performance in various applications. Below, we analyze four common materials used in conveyor belt systems, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Do Rubber Conveyor Belts Perform in Diverse Conditions?

Rubber conveyor belts are widely recognized for their versatility and durability. They typically exhibit excellent temperature resistance, withstanding temperatures ranging from -30°C to 80°C. Their inherent elasticity provides good shock absorption and flexibility, making them suitable for transporting heavy loads.

Pros: Rubber belts are highly durable and resistant to wear, making them ideal for heavy-duty applications. They also offer good grip and traction, which is essential for inclined or steep conveyor setups.

Cons: The primary drawback is their susceptibility to degradation from oils and certain chemicals, which can limit their use in specific environments. Additionally, rubber belts can be more expensive compared to alternatives like PVC.

Impact on Application: Rubber belts are compatible with a wide range of media, including bulk materials like grains and aggregates. However, buyers in regions with extreme temperatures should consider specific formulations that enhance performance under local conditions.

What Advantages Do PVC Conveyor Belts Offer for Lightweight Applications?

Polyvinyl Chloride (PVC) conveyor belts are known for their lightweight and cost-effective nature. They can handle a variety of temperatures, typically ranging from -10°C to 60°C, making them suitable for moderate conditions.

Pros: PVC belts are resistant to chemicals, oils, and abrasion, which makes them ideal for food processing and packaging applications. Their lower cost compared to rubber makes them attractive for budget-conscious buyers.

Cons: However, PVC belts may not be as durable under heavy loads and can suffer from wear in high-stress applications. Their flexibility is also limited compared to rubber belts.

Impact on Application: PVC belts are particularly well-suited for applications involving light to moderate loads, such as in food processing or packaging. Buyers should ensure compliance with food safety standards, especially in European markets.

How Do Metal Conveyor Belts Enhance Strength and Durability?

Metal conveyor belts, often made from stainless steel or other alloys, are designed for high-temperature and heavy-duty applications. They can withstand extreme temperatures, often exceeding 200°C, and are resistant to corrosion, making them ideal for harsh environments.

Pros: The primary advantage of metal belts is their strength and durability, which allows them to handle heavy loads and extreme conditions. They also have a long lifespan, reducing the need for frequent replacements.

Cons: On the downside, metal belts can be significantly more expensive than rubber or PVC options. They may also require more complex manufacturing processes, increasing lead times.

Impact on Application: Metal belts are commonly used in industries such as food processing, automotive, and mining. International buyers must consider compliance with relevant safety and material standards, such as ASTM or DIN, particularly in Europe and North America.

What Are the Benefits of Fabric Conveyor Belts in Specific Industries?

Fabric conveyor belts, often made from nylon or polyester, are lightweight and flexible, making them suitable for a variety of applications. They typically operate effectively in temperature ranges from -20°C to 80°C.

Pros: These belts are cost-effective and provide good flexibility, which is advantageous in applications requiring bending or turning. They also have a lower weight, which can reduce energy consumption in conveyor systems.

Cons: However, fabric belts may have lower durability compared to rubber or metal options and can be susceptible to moisture and heat damage over time.

Illustrative image related to conveyor system belt conveyor diagram

Impact on Application: Fabric belts are often used in light to medium-duty applications, such as packaging and assembly lines. Buyers in humid regions should consider moisture-resistant options to enhance longevity.

Summary of Material Selection for Conveyor Systems

| Material | Typical Use Case for conveyor system belt conveyor diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Heavy-duty material handling, mining, agriculture | Excellent durability and grip | Susceptible to oils and chemicals | High |

| PVC | Food processing, packaging, light-duty applications | Cost-effective and chemical resistant | Limited durability under heavy loads | Medium |

| Metal | High-temperature, heavy-duty applications | High strength and long lifespan | Expensive and complex to manufacture | High |

| Fabric | Light to medium-duty applications, packaging | Lightweight and flexible | Lower durability and moisture sensitive | Low |

This guide provides a comprehensive overview of material selection for conveyor systems, helping international B2B buyers make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor system belt conveyor diagram

What Are the Main Stages in the Manufacturing Process of Conveyor Belts?

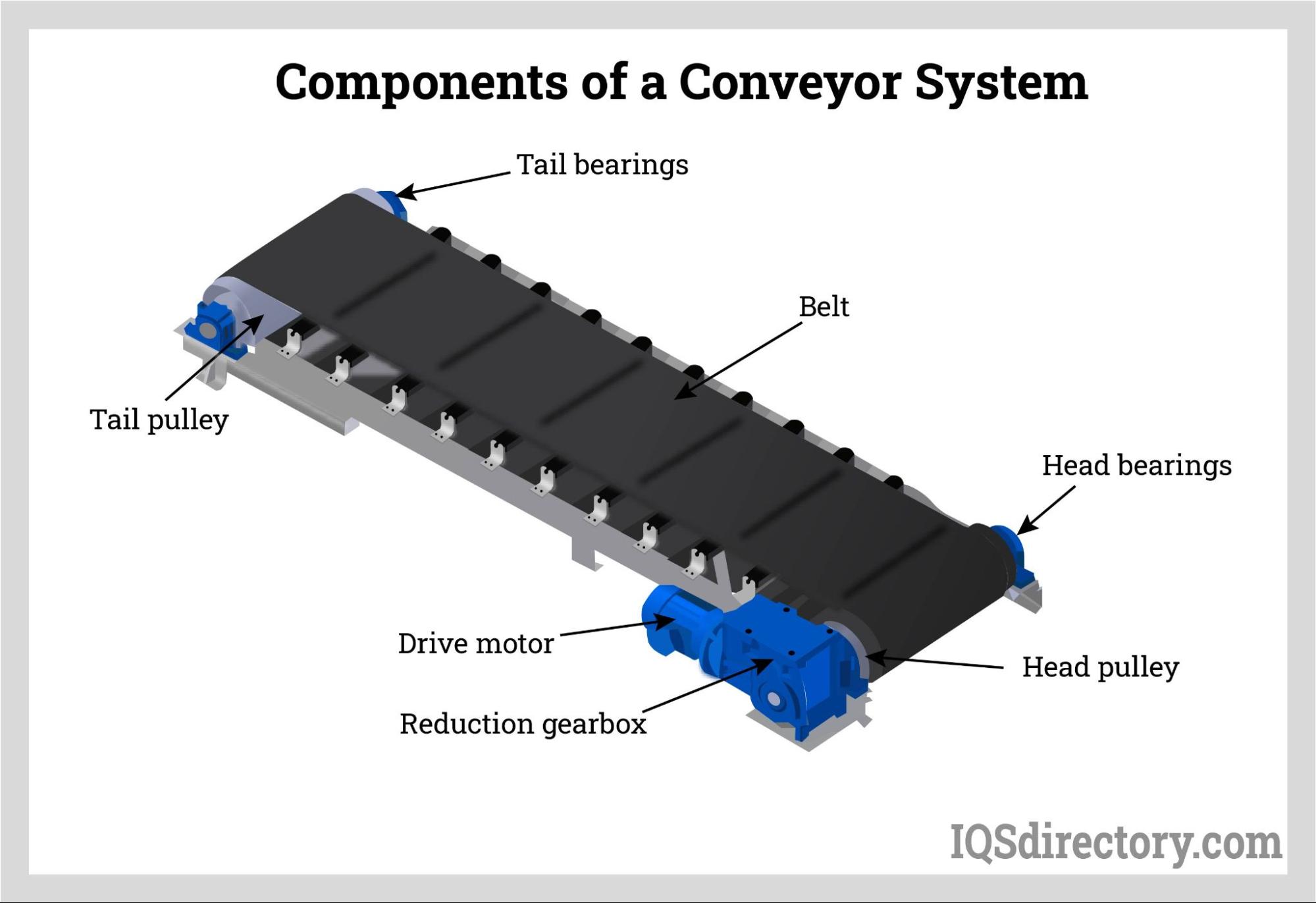

The manufacturing process of conveyor belts involves several critical stages that ensure quality and efficiency. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step is selecting appropriate materials, which can include rubber, PVC, or metal depending on the application. The materials are sourced from trusted suppliers, and their quality is assessed through incoming quality control (IQC) checks. This ensures that the raw materials meet the required specifications for durability and performance.

-

Forming: In this stage, the prepared materials are shaped into the desired form. Techniques such as extrusion or molding are commonly used to create the belt structure. For example, rubber is often extruded to form the basic belt before being cut to size. Advanced techniques such as laser cutting may also be employed for precision.

-

Assembly: After forming, the components are assembled. This includes attaching the belt to pulleys and rollers, which is critical for the operational functionality of the conveyor system. During this stage, attention is paid to alignment and tension, as these factors significantly affect performance. Automated assembly systems may be used to enhance precision and speed.

-

Finishing: The final stage involves applying coatings or treatments to enhance the durability and functionality of the conveyor belt. This may include surface treatments to improve grip or resistance to wear and tear. The finishing process is crucial for ensuring that the conveyor belts perform optimally in their intended environments.

What Are the Key Techniques Used in Conveyor Belt Manufacturing?

Several key techniques are integral to the manufacturing of conveyor belts, ensuring high quality and reliability.

-

Extrusion: This technique is particularly effective for producing rubber and PVC belts. The material is heated and forced through a die to create a continuous length of belt. This method allows for uniform thickness and consistency in material properties.

-

Molding: Used primarily for specialized belts, molding involves shaping materials in a mold to achieve specific designs. This technique is useful for producing belts with unique features, such as cleats or sidewalls.

-

Welding and Joining: Various methods, including heat welding and mechanical fastening, are used to join belt ends. This is a critical step as it determines the strength and longevity of the belt in operation.

-

Quality Coatings: Applying different coatings helps to improve properties such as friction, chemical resistance, and temperature tolerance. These coatings can also provide anti-static properties, which are essential in certain industries.

How Is Quality Assurance Implemented in Conveyor Belt Manufacturing?

Quality assurance (QA) is vital in the manufacturing of conveyor belts to ensure they meet international and industry-specific standards. The following outlines the QA process:

Illustrative image related to conveyor system belt conveyor diagram

-

International Standards Compliance: Compliance with standards such as ISO 9001 is crucial. This standard outlines requirements for a quality management system, ensuring consistent quality in products and services. Other relevant certifications may include CE marking for safety and API standards for specific industrial applications.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints are established to monitor product quality. This includes checking dimensions, material properties, and assembly accuracy.

– Final Quality Control (FQC): At the end of the manufacturing process, a comprehensive inspection is conducted. This may involve testing the belt for strength, flexibility, and operational performance. -

Common Testing Methods: Various testing methods are employed to verify the quality of conveyor belts. These may include:

– Tensile Strength Testing: Measures the belt’s ability to withstand forces without breaking.

– Abrasion Testing: Assesses the wear resistance of the belt material.

– Chemical Resistance Testing: Evaluates how well the belt material holds up against various chemicals it may encounter in its operating environment.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for making informed purchasing decisions.

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to ensure compliance with quality standards. This involves reviewing their manufacturing processes, quality control measures, and adherence to international standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QA processes and results. These reports should outline their testing methods, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can verify that the products meet specified quality standards before shipment.

-

Certifications and Accreditations: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001, CE, or other industry-specific certifications. These documents are indicators of a supplier’s commitment to quality and adherence to international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances that may affect quality control when sourcing conveyor belts:

-

Cultural and Regulatory Differences: Understanding the local regulations and cultural practices regarding quality assurance can help buyers navigate potential challenges. For instance, compliance requirements may vary significantly between regions.

-

Language Barriers: Effective communication is essential for quality assurance. Buyers should ensure that all specifications and quality requirements are clearly communicated and understood by suppliers.

-

Logistics and Shipping Considerations: Quality control does not end with manufacturing. Buyers should consider the logistics involved in transporting products, as handling during shipping can impact product quality. Ensuring that suppliers have robust shipping protocols can mitigate potential issues.

By understanding the manufacturing processes and quality assurance measures involved in conveyor belt production, B2B buyers can make more informed decisions and secure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor system belt conveyor diagram’

In the realm of material handling, the procurement of conveyor systems, particularly belt conveyors, is a critical investment for businesses looking to enhance operational efficiency. This guide provides a practical checklist to help B2B buyers navigate the complexities of sourcing conveyor system belt diagrams, ensuring a well-informed decision-making process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement process. Consider the types of materials you will be handling, the distances they need to be transported, and any specific environmental conditions (e.g., temperature, humidity) that may affect the conveyor’s performance. This clarity will help you communicate effectively with suppliers and ensure that the solutions offered meet your operational needs.

Step 2: Research Available Conveyor Types

Understanding the different types of conveyor systems available is crucial for making an informed choice. Common options include belt conveyors, roller conveyors, and bucket elevators. Each type has its unique applications and advantages, so evaluate which system best aligns with your operational requirements and production goals.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions. Consider their experience with projects of similar scope and complexity to yours, as this can provide valuable insights into their reliability and capabilities.

- Check Certifications: Ensure the supplier has relevant certifications (e.g., ISO, CE) that demonstrate compliance with industry standards.

- Assess Customer Support: Look for suppliers that offer robust customer service and after-sales support to assist with installation and maintenance.

Step 4: Request Detailed Quotations

Once you have a shortlist of potential suppliers, request detailed quotations that outline all costs involved. This should include equipment prices, installation fees, and any recurring maintenance costs. A transparent quotation process will allow you to compare suppliers effectively and avoid unexpected expenses down the line.

- Include Technical Support Costs: Ensure that the quotation specifies costs for ongoing technical support and potential upgrades.

- Ask About Warranty Terms: Understanding warranty coverage can give you peace of mind regarding the longevity and reliability of the equipment.

Step 5: Assess Design and Customization Options

Conveyor systems often require customization to meet specific operational needs. Inquire about the design flexibility of the conveyor systems offered by potential suppliers. A supplier that can provide tailored solutions will better serve your unique business requirements, enhancing overall efficiency and effectiveness.

- Evaluate Layout Compatibility: Ensure that the proposed conveyor design fits seamlessly into your existing operational layout.

- Consider Modularity: A modular design can facilitate future expansions or alterations without significant overhauls.

Step 6: Conduct Site Visits or Virtual Demos

If possible, arrange site visits to existing installations of the conveyor systems you are considering. Observing the equipment in operation can provide insights into its performance and reliability. Alternatively, request virtual demonstrations to see how the system works in a simulated environment.

Illustrative image related to conveyor system belt conveyor diagram

Step 7: Finalize Contracts and Payment Terms

Once you have selected a supplier, review and finalize contracts carefully. Pay attention to payment terms, delivery schedules, and the scope of warranty and maintenance agreements. Clear contractual agreements can prevent misunderstandings and ensure that both parties are aligned on expectations.

Following this checklist will empower B2B buyers to make informed decisions when sourcing conveyor system belt diagrams, ultimately enhancing operational efficiency and productivity in their businesses.

Comprehensive Cost and Pricing Analysis for conveyor system belt conveyor diagram Sourcing

What Are the Key Cost Components in Conveyor System Belt Conveyor Diagram Sourcing?

When sourcing a conveyor system, especially for a belt conveyor diagram, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. Conveyor belts can be made from rubber, PVC, or specialized composites, each varying in price and durability. High-quality materials may lead to higher upfront costs but can reduce maintenance and replacement expenses over time.

-

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and installation. Skilled labor can increase costs, but their expertise can also enhance the quality and efficiency of the conveyor system.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and facility maintenance. Companies that optimize their manufacturing processes can help lower these overhead costs, which may be reflected in the pricing.

-

Tooling: Specialized tooling is often needed for the production of conveyor components. Investment in tooling can raise initial costs but can be amortized over larger production runs, making it more economical for high-volume orders.

-

Quality Control: Ensuring that the conveyor system meets industry standards involves rigorous QC processes. Investing in quality assurance can prevent costly returns and repairs, making it a vital component of the cost structure.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and volume. Effective logistics planning can minimize these costs, particularly for international shipments, where duties and tariffs may also apply.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. Understanding the average margins in the conveyor industry can assist buyers in assessing the fairness of the quoted prices.

How Do Price Influencers Affect Conveyor System Costs?

Several factors influence the pricing of conveyor systems, particularly in international B2B markets.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating higher volumes can provide significant savings.

-

Specifications and Customization: Tailored solutions that meet specific operational needs tend to be more expensive. Buyers should weigh the benefits of customization against the additional costs.

-

Materials: The choice of materials, as mentioned earlier, plays a critical role in pricing. Premium materials may increase upfront costs but can enhance durability and reduce long-term operational costs.

-

Quality and Certifications: Conveyor systems that meet international quality standards and certifications may carry a higher price tag. However, these certifications can be crucial for compliance and reliability, especially in regulated industries.

-

Supplier Factors: The reputation, location, and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more, but they often provide superior service and product reliability.

-

Incoterms: Understanding Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence the total landed cost of the equipment.

What Are the Best Buyer Tips for Negotiating Conveyor System Prices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and understanding of pricing nuances can lead to substantial savings.

-

Negotiate Wisely: Engage suppliers in discussions about pricing, focusing on volume discounts and long-term partnerships. Building a relationship can lead to better terms and conditions.

-

Consider Total Cost of Ownership (TCO): Assess not only the initial purchase price but also maintenance, energy consumption, and potential downtime costs. A lower upfront price may lead to higher long-term costs.

-

Research Market Prices: Conduct thorough market research to understand the average pricing for conveyor systems similar to what you need. This knowledge empowers buyers during negotiations.

-

Be Aware of Regional Differences: Pricing can vary based on geographical factors, including shipping costs and local regulations. Factor these into your overall budget.

-

Request Detailed Quotations: Ask suppliers for itemized quotes that break down costs. This transparency can help identify areas for negotiation and clarify any hidden fees.

Disclaimer

Prices and cost structures can vary widely based on specific project requirements, supplier capabilities, and market conditions. It is advisable for buyers to conduct their own due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing conveyor system belt conveyor diagram With Other Solutions

Introduction: Why Consider Alternatives to Conveyor System Belt Conveyor Diagrams?

In the realm of material handling and logistics, the selection of the right system can significantly impact operational efficiency and cost-effectiveness. While conveyor system belt conveyor diagrams are widely recognized for their utility in transporting goods, several alternative solutions exist that may better suit specific operational needs. Understanding these alternatives is crucial for B2B buyers, particularly when assessing performance, cost, and implementation ease.

Comparison Table

| Comparison Aspect | Conveyor System Belt Conveyor Diagram | Bucket Elevators | Roller Conveyors |

|---|---|---|---|

| Performance | High efficiency for continuous transport of varied goods | Excellent for bulk materials, especially in agriculture | Good for transporting items with a flat base |

| Cost | Moderate initial investment, long-term savings on labor | Higher upfront cost, but durable for heavy loads | Lower initial cost, but may require more maintenance |

| Ease of Implementation | Requires skilled installation, but straightforward setup | Complex setup, often needing specialized knowledge | Easy to install; flexible in design |

| Maintenance | Regular maintenance needed for belts and motors | Low maintenance; robust design | Moderate maintenance; roller wear can be an issue |

| Best Use Case | Ideal for automated warehouses and assembly lines | Best for bulk material handling in agriculture and mining | Suitable for sorting and loading operations in warehouses |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Bucket Elevators?

Bucket elevators are designed to lift bulk materials vertically, making them a viable alternative for industries such as agriculture and mining. Pros include their capacity to handle large volumes and their durability in harsh environments. They are particularly effective for transporting grains, seeds, and other bulk items. However, the cons involve a higher initial investment and a more complex installation process, which may not be ideal for all operations. Furthermore, they are less versatile than belt conveyors, as they are specifically designed for vertical transport.

How Do Roller Conveyors Compare in Terms of Flexibility?

Roller conveyors utilize a series of rollers to facilitate the movement of goods, making them a flexible solution for many B2B applications. Their pros include ease of installation and lower upfront costs, making them accessible for smaller operations. Additionally, they are effective for transporting flat-based items and can be easily configured to suit various layouts. However, the cons include a limitation in handling bulk materials and a potential need for more frequent maintenance as rollers can wear out over time, leading to decreased efficiency.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the right material handling solution hinges on a thorough understanding of your operational requirements. Conveyor system belt conveyor diagrams excel in automated environments where speed and efficiency are paramount. Conversely, bucket elevators are optimal for bulk material handling, while roller conveyors offer flexibility in transporting various goods. B2B buyers should evaluate these alternatives against their specific operational challenges, budget constraints, and maintenance capabilities to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for conveyor system belt conveyor diagram

What Are the Essential Technical Properties of a Conveyor System Belt?

Understanding the critical technical properties of a conveyor system belt is essential for B2B buyers looking to optimize their operations. Here are some key specifications that play a pivotal role in selecting the right conveyor system for your business needs:

-

Material Grade

The material grade of a conveyor belt affects its durability, flexibility, and resistance to wear and tear. Common materials include rubber, PVC, and metal, each suited for different applications. For instance, rubber belts are ideal for heavy loads and harsh environments, while PVC is more suited for lighter, less abrasive materials. Selecting the right material grade ensures longevity and minimizes maintenance costs. -

Belt Width and Length

The dimensions of the conveyor belt directly impact its capacity and efficiency. A wider belt can transport larger volumes of material, while the length determines the distance the material needs to travel. Understanding these dimensions is crucial for designing an efficient workflow, especially in large-scale operations where space and time optimization is essential. -

Load Capacity

Each conveyor belt has a specified load capacity, which dictates how much weight it can safely transport without failure. This property is vital for ensuring operational safety and efficiency. Underestimating load capacity can lead to equipment failure, resulting in costly downtimes and potential hazards in the workplace. -

Tension and Stretch Tolerance

Conveyor belts experience tension during operation, which can lead to stretching over time. Understanding the tension and stretch tolerance of a belt helps in selecting the right components to maintain optimal performance. This aspect is particularly important for systems requiring precise alignment and consistent operation, as excessive stretch can lead to misalignment and increased wear. -

Surface Texture

The surface texture of the conveyor belt plays a significant role in material handling. Smooth surfaces are suitable for transporting packaged goods, while textured surfaces provide better grip for bulk materials. This property is crucial for reducing slippage and ensuring that materials remain securely in place during transport.

What Are Common Terms in the Conveyor Belt Industry?

Familiarizing yourself with industry terminology can streamline communication and negotiations with suppliers and manufacturers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the conveyor industry, working with OEMs ensures that you receive high-quality components that meet specific standards and compatibility requirements, ultimately enhancing the reliability of your conveyor system. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers, as it can affect budgeting and inventory management. Suppliers often set these limits to ensure profitability, so knowing the MOQ can help you negotiate better terms or plan your purchases accordingly. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific goods or services. This formal request allows buyers to compare options from different vendors, facilitating informed decision-making. Crafting a clear RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for clarifying shipping responsibilities, costs, and risks, helping to avoid disputes and ensuring smooth logistics. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. This term is critical for supply chain management, as long lead times can affect production schedules and inventory levels. Knowing the lead times from your suppliers allows for better planning and can prevent delays in operations.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their conveyor systems.

Navigating Market Dynamics and Sourcing Trends in the conveyor system belt conveyor diagram Sector

What are the Current Market Dynamics and Key Trends in the Conveyor System Belt Conveyor Sector?

The global conveyor system market is witnessing a significant transformation driven by technological advancements, the rise of automation, and evolving supply chain dynamics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking efficient solutions that enhance operational productivity. Key drivers include the growing demand for automation in warehouses and manufacturing processes, which is pushing manufacturers to innovate conveyor designs that integrate seamlessly with robotics and smart technologies.

Emerging trends such as Industry 4.0 are reshaping sourcing strategies, with a focus on IoT-enabled conveyor systems that provide real-time monitoring and analytics. This shift not only enhances operational efficiency but also allows for predictive maintenance, reducing downtime and maintenance costs. In regions like Vietnam and Germany, buyers are prioritizing suppliers who can offer customizable solutions tailored to specific industry needs, such as food processing or pharmaceuticals, where hygiene and reliability are paramount.

Furthermore, sustainability is becoming a crucial factor in purchasing decisions. As businesses strive to reduce their carbon footprint, there is an increasing preference for energy-efficient conveyor systems and materials that contribute to sustainable practices. Buyers are actively looking for suppliers who provide transparent sourcing information and demonstrate a commitment to environmental responsibility.

How is Sustainability and Ethical Sourcing Impacting the Conveyor System Belt Conveyor Market?

Sustainability and ethical sourcing are no longer optional; they are essential components of a successful B2B strategy in the conveyor system sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is under scrutiny. B2B buyers are increasingly concerned about the lifecycle of conveyor systems, from production to disposal. This has led to a demand for suppliers who utilize eco-friendly materials and adhere to sustainable manufacturing practices.

Buyers are also prioritizing suppliers with certifications that demonstrate a commitment to sustainability, such as ISO 14001 for environmental management systems. The use of recycled materials in conveyor belt production is gaining traction, alongside innovations like energy-efficient motors that reduce electricity consumption. Additionally, companies are exploring the potential of biodegradable materials and green certifications to enhance their market appeal.

Ethical supply chains are equally important, with buyers seeking transparency in sourcing practices. This includes understanding the labor conditions under which materials are sourced and ensuring compliance with international labor standards. By partnering with suppliers who prioritize ethical practices, companies can enhance their brand reputation and meet the growing consumer demand for responsible business practices.

What is the Evolution of Conveyor Systems and Their Relevance in Today’s B2B Landscape?

The evolution of conveyor systems dates back to the late 18th century, initially designed for simple material transport in manufacturing settings. Over the decades, advancements in engineering and materials science have led to the development of sophisticated conveyor systems capable of handling a diverse range of materials and applications. The introduction of powered conveyor belts in the early 20th century revolutionized manufacturing and logistics, significantly improving efficiency.

Today, conveyor systems are integral to various industries, including automotive, food processing, and e-commerce. The shift towards automation and smart technologies has further transformed the landscape, with modern systems incorporating IoT capabilities, machine learning, and advanced control systems. This evolution is critical for B2B buyers who are looking for solutions that not only meet their current operational needs but also adapt to future technological advancements, ensuring long-term competitiveness and efficiency in their supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor system belt conveyor diagram

-

How do I solve issues with conveyor belt alignment?

Conveyor belt misalignment can lead to increased wear and tear, reduced efficiency, and potential safety hazards. To resolve this issue, first, inspect the idler rollers and pulleys to ensure they are properly aligned and functioning. Adjust the alignment by repositioning the pulleys or adjusting the tension on the belt. Regular maintenance checks and using tracking devices can help prevent misalignment and prolong the lifespan of the conveyor system. -

What is the best material for a conveyor belt in a mining application?

For mining applications, the best material for a conveyor belt is typically rubber or steel-reinforced belts, as they can withstand heavy loads and harsh conditions. Rubber belts provide excellent resistance to wear, impact, and abrasion, while steel-reinforced options offer added strength and durability. Consider the specific materials being transported and the environmental conditions to select the most suitable belt for optimal performance and longevity. -

How can I customize a conveyor system to fit my specific needs?

Customizing a conveyor system involves assessing your operational requirements, including the type of materials handled, load capacity, and available space. Work with your supplier to design a system that incorporates the necessary components, such as belt type, length, width, and speed. Additionally, consider integrating features like sensors, controls, and safety mechanisms to enhance functionality and ensure the system meets your unique production needs. -

What are the minimum order quantities (MOQ) for conveyor systems?

Minimum order quantities for conveyor systems can vary significantly between suppliers and depend on the complexity of the system. Generally, suppliers may require a MOQ of 1-10 units for standard conveyor belts and larger quantities for customized systems. It’s essential to communicate your specific needs to the supplier, as they may offer flexibility on MOQs for first-time orders or long-term partnerships. -

What payment terms should I expect when sourcing conveyor systems internationally?

Payment terms for international transactions typically include options such as upfront payment, net 30/60 days, or letters of credit. The terms can vary based on the supplier’s policies, your negotiation skills, and the relationship built with the supplier. It’s advisable to clarify payment methods and timelines in the contract to avoid any misunderstandings and ensure a smooth transaction process. -

How do I vet suppliers for conveyor systems effectively?

Vetting suppliers involves researching their reputation, production capabilities, and quality assurance processes. Start by checking online reviews, certifications, and industry affiliations. Request references from other B2B clients and assess their responsiveness and communication style. Consider conducting site visits or audits, if possible, to evaluate their manufacturing processes and ensure they meet your quality standards. -

What quality assurance measures should be in place for conveyor systems?

Quality assurance measures should include regular inspections during the manufacturing process, adherence to international standards, and comprehensive testing of the conveyor systems before shipment. Ensure that the supplier provides documentation of quality control processes and certifications. Post-installation, consider implementing a maintenance schedule and monitoring system performance to identify and address any issues promptly. -

What logistics considerations should I keep in mind when importing conveyor systems?

When importing conveyor systems, consider factors such as shipping methods, customs regulations, and lead times. Choose a reliable logistics partner with experience in handling heavy machinery to facilitate smooth transportation. Ensure all necessary documentation, such as import permits and bills of lading, is in order. Additionally, factor in costs related to duties, taxes, and insurance to avoid unexpected expenses.

Top 5 Conveyor System Belt Conveyor Diagram Manufacturers & Suppliers List

1. AutoStore System – Conveyor Belt Solutions

Domain: autostoresystem.com

Registered: 2011 (14 years)

Introduction: Conveyor belts are flexible systems looped over two or more pulleys, designed to transport goods efficiently across various distances. Key components include: 1. Motor drive – provides power to turn the drive pulley; 2. Drive pulley – imparts motion to the belt; 3. Conveyor belt material – made from rubber, PVC, neoprene, urethane, or nylon, affecting durability and friction; 4. Idler rollers – su…

2. Belt Conveyor Design – Key Considerations

Domain: slideshare.net

Introduction: The document describes the design of a belt conveyor system, focusing on key considerations such as continuous material flow, standardization, and minimizing the non-payload weight to payload weight ratio. Important design parameters include belt dimensions and speed, roller diameter, belt power and tension, idler spacing, pulley diameter, motor selection, shaft design, and control systems. The de…

3. Conveyor Rollers – Standard, Heavy-Duty, Coated

Domain: conveyorrollers.com

Registered: 2002 (23 years)

Introduction: Conveyor Rollers: 1. Standard Rollers: Made of steel, versatile for medium load capacity, used in general material handling tasks. 2. Heavy-Duty Rollers: Made of steel, engineered for high load capacities, ideal for industrial settings like mining and construction. 3. Coated Rollers: Made of plastic with a rubber layer for extra grip, medium load capacity, used in food and printing industries. Bea…

4. Accurate Industrial – Conveyor Belting Solutions

Domain: accurateindustrial.com

Registered: 1999 (26 years)

Introduction: Conveyor Belting, Lightweight Conveyor Belting, Food Conveyor Belting, General Conveyor Belting, Incline Conveyor Belting, Machine Tapes / Power Transmission Conveyor Belting, Airport / Distribution Conveyor Belting, Heavy Rubber Conveyor Belting, Modular Belting, Modular Plastic Belting, Table Top Conveyor Chains, Wire Belting, Timing / Drive Belts, Timing Belts, Extruded Profiles, Round Belts, E…

5. Ocado Intelligent Automation – Conveyor Systems

Domain: ocadointelligentautomation.com

Registered: 2023 (2 years)

Introduction: A conveyor system is a mechanical handling apparatus designed for automatically transporting loads and materials within an area. It minimizes human error, lowers workplace risks, and reduces labor costs. Conveyor systems can use belts, wheels, rollers, or chains to transport objects. They consist of a belt stretched across two or more pulleys, with one pulley (the drive pulley) moving the belt to …

Strategic Sourcing Conclusion and Outlook for conveyor system belt conveyor diagram

In the rapidly evolving landscape of material handling, the strategic sourcing of conveyor systems presents a pivotal opportunity for international B2B buyers. Understanding the diverse types of conveyor belts, from flat belts to vacuum conveyors, allows businesses to select systems that align with their operational needs and enhance overall efficiency. The integration of automation and sophisticated control systems further amplifies the benefits of conveyor systems, streamlining processes and reducing operational costs.

Moreover, by investing in high-quality conveyor solutions, companies not only improve productivity but also foster a safer working environment. As industries in Africa, South America, the Middle East, and Europe strive for modernization and efficiency, the importance of strategic sourcing cannot be overstated. It serves as a foundation for building resilient supply chains capable of adapting to market demands.

Looking ahead, it is crucial for international buyers to engage with trusted suppliers who can provide tailored solutions to meet specific challenges. By prioritizing strategic sourcing in conveyor system procurement, businesses can position themselves for long-term success and competitive advantage in their respective markets. Embrace the future of material handling—make informed decisions today to drive operational excellence tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to conveyor system belt conveyor diagram

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.