The Definitive Guide to Burning Barrels For Sale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for burning barrels for sale

In today’s rapidly evolving global marketplace, sourcing reliable burning barrels for sale presents a unique challenge for international B2B buyers. With increasing regulatory scrutiny and diverse applications across various industries—from waste management to agricultural practices—understanding the nuances of product specifications, compliance, and supplier capabilities is crucial. This guide aims to empower buyers by providing comprehensive insights into the types of burning barrels available, their applications, and essential considerations for supplier vetting.

From the traditional 55-gallon drum to more advanced incinerator models, the market offers a range of products tailored to meet specific needs. Buyers will learn about the critical factors influencing cost, including material quality, design features, and compliance with local regulations. Additionally, this guide will delve into the importance of due diligence when selecting suppliers, offering strategies to assess reliability and performance history.

As businesses in Africa, South America, the Middle East, and Europe seek to enhance their operational efficiency and sustainability, informed purchasing decisions become paramount. By equipping decision-makers with actionable insights and practical knowledge, this guide not only simplifies the sourcing process but also fosters confidence in navigating the complexities of the global burning barrel market. Whether you are looking to optimize waste disposal practices or comply with environmental standards, this resource is designed to help you make strategic choices that align with your business objectives.

Understanding burning barrels for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 55-Gallon Burn Barrel | Made from heavy-gauge steel, often with a lid | Waste management, agriculture | Pros: Affordable, widely available. Cons: Limited capacity for larger operations. |

| Incinerator Burn Barrel | Designed for efficient burning with controlled airflow | Industrial waste disposal | Pros: Higher efficiency, reduces smoke. Cons: Higher initial investment. |

| Large Capacity Burn Bin | Larger than standard barrels, often over 100 gallons | Construction, forestry | Pros: Handles larger volumes, durable. Cons: Requires more space and transport considerations. |

| Portable Burn Barrel | Lightweight design, easy to transport | Outdoor events, small farms | Pros: Mobility, versatility. Cons: Smaller capacity, may not withstand heavy use. |

| Custom Fabricated Burn Barrels | Tailored designs to meet specific needs | Specialized industrial applications | Pros: Meets unique requirements. Cons: Longer lead times, potentially higher costs. |

What are the characteristics and suitability of Standard 55-Gallon Burn Barrels?

Standard 55-gallon burn barrels are the most common type, made from heavy-gauge steel with a lid to control smoke and debris. They are suitable for small to medium-sized operations, particularly in waste management and agricultural settings. B2B buyers should consider the barrel’s durability and compliance with local regulations, as proper ventilation and safety features are crucial to prevent fire hazards.

How do Incinerator Burn Barrels enhance waste disposal efficiency?

Incinerator burn barrels are specifically designed to facilitate efficient burning through controlled airflow, which minimizes smoke and maximizes combustion. These barrels are ideal for industrial waste disposal, particularly in sectors that generate hazardous or bulky materials. Buyers should evaluate the initial investment against long-term savings in waste management costs, as the efficiency can significantly reduce the volume of waste needing disposal.

What makes Large Capacity Burn Bins suitable for construction and forestry?

Large capacity burn bins, typically exceeding 100 gallons, are designed for high-volume waste disposal, making them perfect for construction sites and forestry operations. Their robust construction allows them to handle large amounts of waste, and they often feature enhanced safety measures. B2B buyers must consider transportation logistics and site space, as these larger units require more room and careful handling.

Illustrative image related to burning barrels for sale

Why are Portable Burn Barrels favored for outdoor events and small farms?

Portable burn barrels offer a lightweight design that allows for easy transport, making them ideal for outdoor events and small farming operations. Their versatility allows users to manage waste on-the-go, but they typically have a smaller capacity compared to standard barrels. Buyers should assess the need for mobility versus volume, especially if frequent relocation is anticipated.

How can Custom Fabricated Burn Barrels meet unique industrial needs?

Custom fabricated burn barrels are designed to meet specific requirements of various industries, providing tailored solutions for unique waste disposal challenges. These barrels can be constructed with specialized features, such as additional safety measures or specific dimensions. B2B buyers should weigh the benefits of customization against potential longer lead times and costs, ensuring that the tailored solution aligns with operational needs and budget constraints.

Key Industrial Applications of burning barrels for sale

| Industry/Sector | Specific Application of burning barrels for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Incineration of hazardous waste | Safe disposal, compliance with regulations | Material durability, size options, environmental certifications |

| Agriculture | Burning of agricultural waste | Reduces pest habitat, promotes soil health | Size adaptability, local regulations, emission controls |

| Construction | Disposal of construction debris | Efficient waste management, cost savings | Heavy-duty construction, portability, safety features |

| Mining | Disposal of mining by-products | Environmental compliance, resource recovery | Robust design, volume capacity, transportation logistics |

| Forestry | Burning of forest debris and slash | Reduces fire hazards, land clearing | Fire safety standards, size and capacity, local regulations |

How Are Burning Barrels Used in Waste Management and What Problems Do They Solve?

In the waste management sector, burning barrels are essential for the incineration of hazardous waste. These barrels enable businesses to safely dispose of materials while ensuring compliance with local and international regulations. For international B2B buyers, particularly those in Africa and South America, sourcing barrels that meet environmental standards is crucial. Buyers should prioritize materials that are durable and designed to minimize emissions, as well as consider the size of the barrels to fit their operational needs.

What Role Do Burning Barrels Play in Agriculture?

In agriculture, burning barrels are employed for the controlled incineration of agricultural waste, such as crop residues and unwanted plant material. This practice helps in reducing pest habitats and diseases while promoting soil health through the ash produced. For buyers in regions like the Middle East and Europe, understanding local regulations on burning practices is vital. Buyers should look for barrels with features that ensure safety and compliance, such as proper ventilation and size adaptability for various types of waste.

How Are Burning Barrels Utilized in Construction?

Construction companies use burning barrels to dispose of debris, such as wood scraps and packaging materials. This method streamlines waste management processes and can lead to significant cost savings by reducing the need for multiple waste pickups. For international buyers, particularly in Europe, sourcing heavy-duty barrels that can withstand the rigors of construction sites is essential. Safety features, including secure lids and fire-resistant materials, should also be key considerations in the procurement process.

What Applications Are There for Burning Barrels in Mining?

In the mining industry, burning barrels are used for the disposal of mining by-products, such as chemicals and other materials that cannot be recycled. This ensures environmental compliance and aids in resource recovery efforts. For buyers in regions like Africa, sourcing robust barrels that can handle harsh materials and conditions is critical. Additionally, logistics for transporting these barrels to remote mining sites should be factored into sourcing decisions.

How Do Burning Barrels Assist in Forestry Management?

In forestry, burning barrels are utilized for the safe burning of debris and slash left after logging activities. This practice minimizes fire hazards and facilitates land clearing for further development. Buyers from various regions, including South America and Africa, must consider local fire safety regulations and standards when sourcing barrels. Features such as size and capacity to handle large volumes of debris, along with adherence to environmental regulations, are vital in making informed purchasing decisions.

3 Common User Pain Points for ‘burning barrels for sale’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Burning Barrels

The Problem: B2B buyers, particularly in regions like Europe and South America, often face stringent regulations concerning waste disposal and incineration practices. This can create confusion and concern about whether the burning barrels they intend to purchase meet local environmental standards. Non-compliance can lead to hefty fines and reputational damage, making it crucial for buyers to ensure that their chosen products align with legal requirements.

The Solution: To navigate this regulatory landscape, B2B buyers should begin by conducting thorough research on local regulations related to burning barrels and waste management. This includes understanding emission standards and safety requirements. Engage with suppliers who provide detailed documentation of compliance certifications and product specifications. Buyers should also consider investing in barrels designed for enhanced combustion efficiency, which can reduce emissions and align with environmental goals. Moreover, connecting with local industry associations can provide insights into best practices and upcoming regulatory changes, ensuring that your procurement strategy remains proactive.

Scenario 2: Ensuring Quality and Durability of Burn Barrels

The Problem: When sourcing burning barrels, buyers often struggle with the quality and durability of products available in the market. Low-quality barrels may lead to safety hazards, such as leaks or structural failures during use. This is particularly concerning for businesses that rely on burning barrels for waste disposal in outdoor environments, where extreme weather conditions can exacerbate these issues.

The Solution: To ensure the quality and durability of burning barrels, buyers should prioritize suppliers known for their robust manufacturing processes and high-grade materials. Look for barrels made from heavy-gauge steel, which can withstand high temperatures and harsh conditions. Request product samples or visit manufacturing facilities to assess quality firsthand. Additionally, consider the barrel’s design features, such as secure lids and reinforced bases, which contribute to safety and longevity. Establishing long-term relationships with reputable suppliers can also facilitate quality assurance through regular inspections and feedback mechanisms.

Scenario 3: Optimizing Cost-Effectiveness in Sourcing Burning Barrels

The Problem: Cost concerns are a significant pain point for B2B buyers, especially in emerging markets where budgets may be tight. The initial purchase price of burning barrels can vary widely, and buyers may find themselves torn between opting for cheaper, lower-quality options versus investing in more expensive, higher-quality barrels that promise better performance and longevity.

The Solution: To optimize cost-effectiveness, buyers should conduct a comprehensive cost-benefit analysis before making a purchase. This includes not only the initial price of the burning barrels but also considering factors such as maintenance costs, replacement frequency, and potential regulatory fines for non-compliance. Engage multiple suppliers to obtain quotes and compare not just prices but also the total value offered, including warranties, after-sales support, and potential bulk purchase discounts. Additionally, consider the long-term operational costs associated with different barrel types, as investing in higher-quality barrels may lead to lower overall costs due to reduced maintenance and longer lifespans. Creating a clear procurement strategy that aligns with both budgetary constraints and operational needs can lead to smarter purchasing decisions.

Illustrative image related to burning barrels for sale

Strategic Material Selection Guide for burning barrels for sale

What Are the Key Materials Used in Burning Barrels for Sale?

When selecting burning barrels for sale, understanding the materials used in their construction is crucial for ensuring performance, safety, and compliance with international standards. Below, we analyze four common materials used in burning barrels: steel, galvanized steel, stainless steel, and aluminum. Each material has distinct properties and implications for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Burning Barrels?

Key Properties: Steel is renowned for its high strength and durability. It can withstand high temperatures, making it suitable for incineration processes. Standard carbon steel typically has a temperature rating of around 1,500°F (815°C).

Pros & Cons: The primary advantage of steel is its cost-effectiveness and availability. However, it is prone to rust and corrosion if not properly coated or maintained, which can limit its lifespan. Manufacturing steel barrels is relatively straightforward, but the need for protective coatings can increase complexity.

Impact on Application: Steel barrels are compatible with a variety of waste materials, including organic refuse and paper products. However, they may not be suitable for corrosive substances without proper treatment.

Illustrative image related to burning barrels for sale

International Considerations: Buyers should ensure compliance with local regulations regarding materials and emissions. In Europe, for example, barrels must meet specific standards like DIN EN 13501 for fire classification.

What Advantages Does Galvanized Steel Offer for Burning Barrels?

Key Properties: Galvanized steel is coated with a layer of zinc to enhance corrosion resistance. This material can withstand similar temperatures as standard steel but offers better longevity in outdoor conditions.

Pros & Cons: The primary advantage is its resistance to rust, making it ideal for humid or rainy environments. However, the galvanization process can add to production costs and complexity. Additionally, if the coating is damaged, the underlying steel can corrode quickly.

Impact on Application: Galvanized barrels are suitable for various waste types, including those that may cause corrosion in standard steel. However, they should not be used for burning materials that produce toxic fumes, as the zinc coating can release harmful substances when heated.

International Considerations: Compliance with standards like ASTM A123 for zinc coatings is essential, especially for buyers in regions with strict environmental regulations.

Illustrative image related to burning barrels for sale

Why Choose Stainless Steel for Burning Barrels?

Key Properties: Stainless steel is highly resistant to corrosion and can withstand high temperatures, typically rated up to 2,500°F (1,370°C). Its alloy composition provides additional strength and durability.

Pros & Cons: The key advantage of stainless steel is its long lifespan and low maintenance requirements. However, it is significantly more expensive than both carbon and galvanized steel, which may limit its use in budget-sensitive projects.

Impact on Application: Stainless steel barrels are ideal for burning a wide range of materials, including those that are corrosive or produce high emissions. They are particularly suitable for industrial applications where durability is critical.

International Considerations: Buyers should ensure that the stainless steel used meets standards such as ASTM A240 for stainless steel sheets and plates, especially in regions like Germany where compliance is rigorously enforced.

What Role Does Aluminum Play in Burning Barrels?

Key Properties: Aluminum is lightweight and resistant to corrosion, with a melting point around 1,221°F (660°C). While it is not as strong as steel, it is often used in applications where weight is a critical factor.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it easy to transport and handle. However, its lower temperature resistance limits its application for high-heat burning processes, and it can be more expensive than steel alternatives.

Impact on Application: Aluminum barrels are suitable for lighter waste materials but may not be appropriate for heavy-duty incineration. They are often used in smaller, portable applications.

International Considerations: Buyers should be aware of recycling regulations for aluminum in their regions, as many countries have stringent policies regarding the disposal and recycling of materials.

Summary Table of Material Selection for Burning Barrels

| Material | Typical Use Case for burning barrels for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste incineration | Cost-effective and durable | Prone to rust without protection | Low |

| Galvanized Steel | Outdoor waste management | Corrosion-resistant | Higher production costs | Medium |

| Stainless Steel | Industrial waste incineration | Long lifespan and low maintenance | High cost | High |

| Aluminum | Portable incineration applications | Lightweight and easy to handle | Lower temperature resistance | Medium |

This guide provides a comprehensive overview of the materials used in burning barrels, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

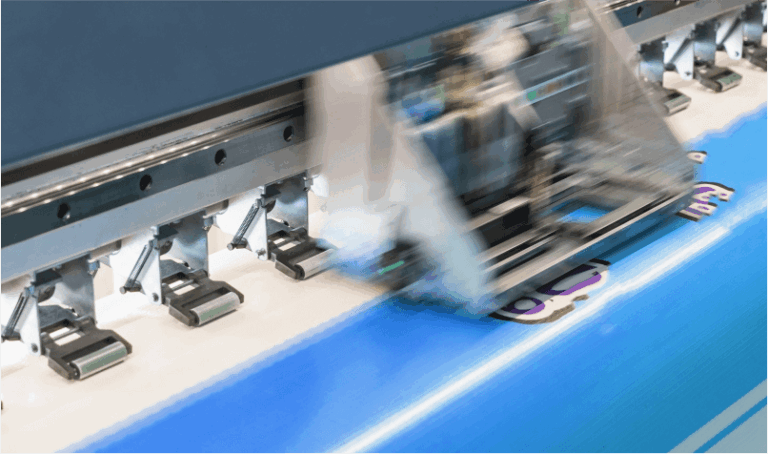

In-depth Look: Manufacturing Processes and Quality Assurance for burning barrels for sale

What Are the Main Stages in the Manufacturing Process of Burning Barrels?

The manufacturing process of burning barrels typically involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to burning barrels for sale

-

Material Preparation: The process starts with selecting high-quality steel, often cold-rolled or galvanized, for durability and resistance to corrosion. Suppliers must ensure that the steel meets specific thickness requirements, commonly 14-gauge or thicker, to withstand high temperatures during burning. Before use, the materials undergo chemical analysis to confirm their composition and strength.

-

Forming: This stage involves shaping the steel into the desired barrel form. Techniques such as stamping or rolling are employed to create the cylindrical body. Advanced machinery may be used to achieve precise dimensions and smooth edges, which are crucial for safety and functionality. The forming process also includes cutting openings for ventilation, which helps control the combustion process.

-

Assembly: Once the components are formed, they are assembled. This involves welding parts together, ensuring that seams are secure to prevent leaks and maintain structural integrity. The use of automated welding technology can enhance precision and efficiency. For barrels with lids, additional hinges and latches are attached during this phase.

-

Finishing: The final stage includes surface treatments to enhance durability and aesthetics. Common methods include powder coating or galvanization, which provide resistance against rust and wear. Quality checks at this stage ensure that all barrels meet the specified surface finish requirements and are free from defects.

What Quality Control Measures Are Implemented in Burning Barrel Manufacturing?

Quality control (QC) is essential to ensure that burning barrels meet international safety and performance standards. The key QC measures typically include adherence to ISO 9001, CE marking, and other industry-specific certifications.

-

International Standards Compliance: ISO 9001 is a widely recognized standard that outlines requirements for a quality management system. Manufacturers aiming for this certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. CE marking signifies compliance with European health, safety, and environmental protection standards, which can be crucial for buyers in Europe.

-

Quality Control Checkpoints: Throughout the manufacturing process, several QC checkpoints are established:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify and rectify any defects in real time.

– Final Quality Control (FQC): After assembly, each barrel undergoes rigorous testing, including pressure tests and visual inspections, to ensure it can withstand operational conditions. -

Common Testing Methods: Manufacturers may employ various testing methods, including:

– Load Testing: Ensures that the barrel can handle the weight of the materials it is designed to burn.

– Heat Resistance Testing: Verifies that the barrel can withstand high temperatures without deforming or releasing harmful substances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers, especially when sourcing internationally.

-

Supplier Audits: Conducting an audit of the manufacturing facility can provide insights into the quality management processes in place. Buyers should request access to the supplier’s quality management system documentation, including certifications and quality assurance protocols.

-

Quality Assurance Reports: Suppliers should provide detailed reports outlining their quality control processes and results from various testing phases. This documentation should include records of compliance with international standards and any third-party inspections conducted.

-

Third-Party Inspections: Engaging a third-party inspection agency can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control measures. These inspections can be particularly beneficial for buyers in regions where local regulations may differ from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in manufacturing is essential.

-

Cultural and Regulatory Differences: Each region may have different regulatory requirements for manufacturing processes and product safety. Buyers should familiarize themselves with local regulations and ensure their suppliers comply with both local and international standards.

-

Material Sourcing: The quality of raw materials can vary significantly between regions. Buyers should inquire about the sourcing of materials and the supplier’s ability to maintain consistent quality across different batches.

-

Logistics and Supply Chain Considerations: International buyers must also consider how logistics and supply chain factors may impact product quality. Delays or mishandling during transport can affect the integrity of the barrels. Ensuring that suppliers have robust logistics management practices can help mitigate these risks.

Conclusion: Ensuring Quality in Burning Barrels for International Markets

In conclusion, the manufacturing processes and quality assurance measures for burning barrels are critical for meeting the diverse needs of international B2B buyers. By understanding the manufacturing stages, quality control practices, and verification methods, buyers can make informed decisions and establish reliable partnerships with suppliers. As the demand for burning barrels continues to grow across various regions, prioritizing quality assurance will be key to successful business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘burning barrels for sale’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure burning barrels. As demand for waste disposal solutions increases across various industries, understanding how to effectively source these products is crucial. This checklist outlines essential steps to help you identify reliable suppliers, assess product quality, and ensure compliance with regional regulations.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the burning barrels you need. Consider aspects such as size (e.g., 55-gallon capacity), material (e.g., steel or aluminum), and design features (e.g., lids, air vents). Defining these criteria helps streamline your sourcing process and ensures you meet your operational requirements.

Illustrative image related to burning barrels for sale

- Size: Ensure the barrel’s capacity aligns with your waste disposal needs.

- Material: Select materials that withstand high temperatures and corrosion for durability.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in manufacturing or distributing burning barrels. Look for companies with a proven track record in your target regions, such as Africa, South America, the Middle East, or Europe.

- Online Reviews: Check platforms like Trustpilot or industry-specific forums for customer feedback.

- Industry Networks: Leverage trade associations or local business networks to find reputable suppliers.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that potential suppliers hold the necessary certifications and comply with local regulations. This step is vital to ensure that the products meet safety and environmental standards.

- Quality Assurance: Look for ISO certifications or similar quality management systems.

- Compliance: Ensure the supplier adheres to local waste management and environmental regulations.

Step 4: Request Samples for Quality Assurance

Always request samples of burning barrels before finalizing your order. This allows you to assess the quality, design, and functionality of the products firsthand.

- Material Inspection: Evaluate the thickness and quality of the metal used.

- Functionality Testing: Check for features like air vents and lids to ensure efficient burning.

Step 5: Assess Pricing and Payment Terms

Gather pricing information from multiple suppliers to understand the market rate for burning barrels. Additionally, review payment terms to ensure they align with your budget and cash flow requirements.

- Bulk Discounts: Inquire about pricing tiers for larger orders to maximize cost efficiency.

- Payment Flexibility: Look for suppliers offering flexible payment options, which can assist in managing cash flow.

Step 6: Confirm Shipping and Delivery Logistics

Discuss shipping options and delivery timelines with potential suppliers. Understanding these logistics is crucial for planning your operations and ensuring timely waste disposal.

- Shipping Costs: Request detailed shipping quotes to avoid unexpected expenses.

- Delivery Times: Clarify lead times to ensure that barrels arrive when needed.

Step 7: Finalize the Contract and Terms

Once you’ve selected a supplier, ensure that all terms are documented in a clear contract. This should include pricing, delivery schedules, and warranty information.

- Legal Review: Consider having a legal expert review the contract to safeguard your interests.

- Clear Terms: Ensure all terms are unambiguous to prevent future disputes.

By following this checklist, B2B buyers can make informed decisions when sourcing burning barrels, ensuring a reliable and efficient procurement process.

Illustrative image related to burning barrels for sale

Comprehensive Cost and Pricing Analysis for burning barrels for sale Sourcing

What Are the Key Cost Components in Sourcing Burning Barrels?

When sourcing burning barrels for sale, it’s essential to understand the multifaceted cost structure involved. The primary components include:

-

Materials: The choice of materials significantly impacts the overall cost. For instance, barrels made from thicker gauge steel will generally be more expensive but offer enhanced durability and safety. Common materials include galvanized steel and standard steel, with galvanized options often costing more due to their corrosion resistance.

-

Labor: Labor costs can vary depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s vital to consider the trade-off in quality. Skilled labor is crucial for the precision required in barrel manufacturing, particularly for safety features and finishing.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and factory operations. Efficient production processes can help keep these costs down, which is an important consideration when evaluating potential suppliers.

-

Tooling and Quality Control (QC): Investment in high-quality tooling can enhance production efficiency and reduce defects. A robust QC process ensures that the barrels meet safety and regulatory standards, which is particularly important for international buyers concerned with compliance.

-

Logistics: Transportation costs can vary greatly based on the shipping method, distance, and volume. International buyers should factor in customs duties, tariffs, and potential delays, which can all impact the final price.

-

Margin: Supplier profit margins can differ, often influenced by market demand, competition, and the supplier’s unique value proposition. Understanding this can aid in negotiations.

How Do Price Influencers Affect the Cost of Burning Barrels?

Several factors can influence the pricing of burning barrels, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Establishing a long-term relationship with a supplier may also yield favorable pricing arrangements.

-

Specifications and Customization: Customized barrels that meet specific regulatory requirements or unique features will typically incur additional costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Quality and Certifications: Barrels that comply with international safety standards or have certifications (like ISO) may come at a premium. However, these certifications can ensure safety and reliability, making them worth the investment.

-

Supplier Factors: Supplier reputation, experience, and their production capacity can affect pricing. Established suppliers may charge higher prices due to their proven track record and reliability.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate who bears the risk and costs during shipping, which can significantly affect the total landed cost of barrels.

What Buyer Tips Can Help in Negotiating Better Prices for Burning Barrels?

To optimize sourcing strategies, consider these actionable tips:

-

Negotiate Terms: Always negotiate pricing, especially if you are placing a large order. Suppliers may have flexibility in pricing that can be leveraged to your advantage.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, safety, and compliance. A lower upfront cost may lead to higher TCO if the barrels require frequent replacement or do not meet safety standards.

-

Understand Pricing Nuances for International Transactions: Be aware of the different economic conditions in your target regions. For instance, fluctuations in currency exchange rates can impact costs. Additionally, familiarize yourself with local regulations that may affect shipping and handling.

-

Research Multiple Suppliers: Obtaining quotes from various suppliers can provide a clearer picture of the market price and help identify the best value. Ensure that you compare apples to apples by considering the same specifications and quality levels.

Disclaimer on Indicative Prices

Prices for burning barrels can fluctuate based on market conditions, supplier negotiations, and changes in material costs. Therefore, the figures obtained during research should be treated as indicative rather than fixed, with a strong recommendation to seek updated quotes directly from suppliers before making purchasing decisions.

Alternatives Analysis: Comparing burning barrels for sale With Other Solutions

Exploring Alternatives to Burning Barrels for Waste Disposal

In the realm of waste disposal, burning barrels are a popular option, particularly for agricultural and industrial sectors. However, there are viable alternatives that can also meet the needs of businesses looking for effective waste management solutions. This analysis compares burning barrels for sale with incinerators and composting systems, providing B2B buyers with insights into their respective advantages and limitations.

Illustrative image related to burning barrels for sale

| Comparison Aspect | Burning Barrels For Sale | Incinerators | Composting Systems |

|---|---|---|---|

| Performance | Effective for small waste | High-temperature combustion | Organic waste processing |

| Cost | $50 – $200 | $1,000 – $10,000+ | $100 – $1,000 |

| Ease of Implementation | Simple setup | Requires installation | Requires space and time |

| Maintenance | Low maintenance | Moderate to high | Low, but requires monitoring |

| Best Use Case | Small-scale waste disposal | Large-scale industrial waste | Organic waste management |

What Are the Pros and Cons of Incinerators as an Alternative to Burning Barrels?

Incinerators offer a more advanced waste disposal method, utilizing high-temperature combustion to reduce waste volume significantly. They are particularly effective for industrial applications where large quantities of hazardous or non-recyclable materials are generated. However, the initial investment is considerably higher than that of burning barrels, with costs ranging from $1,000 to over $10,000, depending on the size and technology. Maintenance can also be more demanding, requiring regular checks and compliance with environmental regulations. Despite these drawbacks, incinerators can be a worthwhile investment for businesses managing large-scale waste streams that require efficient, compliant disposal solutions.

How Do Composting Systems Compare to Burning Barrels for Waste Management?

Composting systems present an environmentally friendly alternative, particularly for businesses that generate organic waste. These systems convert organic materials into nutrient-rich compost, which can be beneficial for agriculture and landscaping. The cost of composting systems can range from $100 for small units to $1,000 for larger setups, making them generally more affordable than incinerators. However, they require a commitment to regular monitoring and space for decomposition, which may not be feasible for all businesses. Composting is ideal for those looking to enhance sustainability efforts while managing organic waste effectively.

Making the Right Choice: How Can B2B Buyers Select the Best Waste Management Solution?

When selecting a waste management solution, B2B buyers should consider their specific needs, including the volume and type of waste generated, budget constraints, and environmental impact. Burning barrels can serve well for smaller operations needing a straightforward disposal method, while incinerators are better suited for larger enterprises handling substantial waste. Composting systems offer an eco-friendly option for those focused on sustainability. Ultimately, the right choice will depend on balancing performance, cost, and operational demands to align with the organization’s waste management goals.

Essential Technical Properties and Trade Terminology for burning barrels for sale

What Are the Key Technical Properties of Burning Barrels for Sale?

When considering the purchase of burning barrels for industrial or commercial use, it is crucial to understand the technical properties that define their quality and functionality. Below are several essential specifications to consider:

Illustrative image related to burning barrels for sale

-

Material Grade

Burning barrels are typically constructed from steel, with common grades including 14-gauge and 16-gauge. The material grade affects durability, resistance to corrosion, and overall weight. Higher gauge numbers indicate thinner steel; thus, a 14-gauge barrel is more robust than a 16-gauge. For B2B buyers, selecting a barrel made from higher-grade steel ensures longevity and reduced maintenance costs. -

Capacity

The capacity of burning barrels is often measured in gallons, with 55-gallon barrels being the standard. Understanding capacity is essential for determining how much waste can be incinerated at one time. This specification influences operational efficiency and compliance with local regulations regarding waste disposal. Buyers should assess their waste volume to select an appropriately sized barrel. -

Burn Rate

This specification refers to the amount of material that can be burned within a specific time frame. A higher burn rate indicates a more efficient barrel, reducing the time required for waste disposal. For businesses with high waste output, choosing a barrel with a favorable burn rate can lead to significant operational savings. -

Design Features

Innovative design elements such as airflow control, bottom gates for ash removal, and reinforced lids can enhance the burning process. Features that prevent debris from escaping during combustion improve safety and efficiency. Buyers should evaluate these features based on their operational needs and safety regulations in their region. -

Weight

The weight of a burning barrel can indicate its sturdiness and material thickness. While lighter barrels may be easier to transport, they may not withstand heavy usage as well as heavier alternatives. This specification is vital for businesses that require mobility or frequent relocation of the barrels. -

Compliance Standards

Many regions have specific regulations governing waste incineration. Compliance with local environmental standards is crucial for legal operation. Buyers should ensure that their chosen burning barrel meets all relevant regulations to avoid fines and operational shutdowns.

What Are Common Trade Terms Related to Burning Barrels?

Understanding industry jargon can significantly enhance communication and negotiation during the purchasing process. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of burning barrels, an OEM might provide barrels that are then sold under a different brand name. Knowing this term can help buyers identify quality products and manufacturers. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers who need to understand the supplier’s constraints and plan their purchasing strategy accordingly. It helps in budgeting and inventory management. -

RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests a price quote from suppliers for specific products. It is a crucial step in procurement, allowing buyers to compare pricing and terms before making a purchasing decision. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers dealing with international suppliers, as they clarify who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the context of burning barrels, understanding lead time is critical for planning waste disposal operations and ensuring that the necessary equipment is available when needed. -

Warranty

A warranty is a guarantee from the manufacturer regarding the quality and lifespan of the product. For burning barrels, a warranty can provide assurance of durability and performance, making it an important consideration for B2B buyers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing burning barrels, ensuring they select products that meet their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the burning barrels for sale Sector

What Are the Key Market Drivers for Burning Barrels?

The global market for burning barrels is shaped by several significant drivers. First, the increasing need for efficient waste disposal methods, particularly in regions with limited access to traditional waste management services, is pushing demand. Countries in Africa and South America are experiencing rapid urbanization, which raises the need for effective waste management solutions. Furthermore, regulatory pressures in Europe and the Middle East are driving businesses to adopt compliant waste disposal methods, including burning barrels, which provide a controlled way to incinerate waste materials.

Emerging technologies are also influencing sourcing trends in the burning barrels sector. The integration of advanced materials and design innovations—such as improved airflow systems that enhance combustion efficiency—are becoming more prevalent. This not only optimizes waste burning processes but also addresses environmental concerns associated with emissions. Moreover, e-commerce platforms are facilitating easier access for international B2B buyers to source burning barrels, allowing for competitive pricing and broader product selections.

Illustrative image related to burning barrels for sale

How Can Sustainability and Ethical Sourcing Impact the Burning Barrels Market?

Sustainability is becoming a critical factor in the B2B purchasing process, particularly for international buyers focused on minimizing environmental impact. The production of burning barrels can contribute to significant environmental concerns if not managed ethically. It is essential for manufacturers to ensure that their processes use sustainably sourced materials, such as recycled steel, which reduces the carbon footprint associated with new material production.

Additionally, the adoption of ‘green’ certifications—such as ISO 14001 for environmental management—can bolster a supplier’s credibility. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability, as this can enhance their own brand reputation in a market that is progressively leaning towards eco-conscious practices. This trend is particularly relevant in Europe, where consumers are demanding greater transparency about the products they purchase.

What Is the Historical Context Behind the Burning Barrels Market?

The use of burning barrels has evolved significantly over the years. Traditionally, these barrels were utilized by households and businesses for simple waste disposal. However, as environmental regulations became stricter, the design and functionality of burning barrels improved to meet compliance standards. Modern burning barrels are now engineered with safety features and efficiency enhancements that align with contemporary environmental guidelines.

As markets continue to develop, particularly in regions with emerging economies, the demand for effective waste management solutions is expected to grow. This historical evolution underscores the importance of innovation and compliance in the burning barrels sector, making it a critical area of focus for B2B buyers seeking reliable and responsible waste disposal options.

Frequently Asked Questions (FAQs) for B2B Buyers of burning barrels for sale

-

How do I ensure compliance with local regulations when purchasing burning barrels?

When sourcing burning barrels, it’s crucial to familiarize yourself with local regulations regarding waste disposal and open burning. Each country or region may have specific laws governing the use of burn barrels, including materials that can be incinerated. To ensure compliance, consult local environmental agencies or legal advisors and request documentation from suppliers that proves their products meet local standards. -

What is the best material for burning barrels?

The best material for burning barrels is heavy-gauge steel, as it can withstand high temperatures and resist corrosion. Look for barrels that are designed specifically for burning, featuring reinforced bottoms and ventilation systems to ensure efficient combustion. Additionally, consider barrels with lids for safety and reduced smoke emissions, which are essential for compliance with environmental regulations. -

What customization options are available for burning barrels?

Many suppliers offer customization options for burning barrels, including size, color, and additional features such as air vents or ash collection systems. When discussing your needs with suppliers, specify the intended use and any particular requirements for your operations. Customization can enhance efficiency and ensure that the barrels meet your specific waste management needs. -

What are the minimum order quantities (MOQ) for burning barrels?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for burning barrels range from a few units to several hundred, depending on the manufacturer’s production capacity and your specific requirements. When negotiating with suppliers, inquire about discounts for larger orders, as bulk purchasing can lead to substantial savings. -

What payment terms should I expect when sourcing burning barrels internationally?

Payment terms for international transactions can vary widely. Common terms include advance payment, partial upfront payments, or payment on delivery. Ensure to clarify these terms before finalizing your order. Additionally, consider using secure payment methods and letters of credit to protect your investment, especially when dealing with new suppliers. -

How can I vet suppliers of burning barrels effectively?

To vet suppliers, start by researching their reputation through reviews and testimonials from other B2B buyers. Request references and verify their business credentials, including certifications for quality and safety standards. Additionally, consider visiting their manufacturing facilities if possible, or request a video tour to assess their production practices and quality control measures. -

What logistics considerations should I keep in mind when importing burning barrels?

Importing burning barrels involves several logistics considerations, including shipping methods, customs clearance, and delivery timelines. Work with a freight forwarder familiar with the regulations of your country to navigate the import process smoothly. Additionally, factor in lead times for manufacturing and shipping, and ensure that you have adequate warehousing solutions upon arrival. -

What quality assurance measures should be in place for burning barrels?

Quality assurance is critical when sourcing burning barrels. Ensure that your supplier adheres to international quality standards, such as ISO certifications. Request documentation that outlines their quality control processes, including testing for durability and performance. Additionally, consider conducting third-party inspections before shipment to guarantee that the products meet your specifications and safety requirements.

Top 2 Burning Barrels For Sale Manufacturers & Suppliers List

1. Innovative Ag – Large Burn Barrel

Domain: innovativeagsd.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Large Burn Barrel”, “sku”: “Medium Burn Large Burn Barrel”, “regular_price”: “$2,250.00”, “sale_price”: “$2,250.00”, “shipping_info”: “Shipping calculated at checkout.”, “description”: “Great for burning items on windy days and containing it. Features a door on the bottom for easy emptying and a filter on the top to keep loose debris in the unit.”, “availability”: “Pre-order item…

2. Huntington Drum – Burn Barrels

Domain: huntingtondrum.com

Registered: 2018 (7 years)

Introduction: {“product_name”:”Burn Barrels”,”regular_price”:”$35.00″,”sale_price”:”$35.00″,”company_name”:”Huntington Drum & Container Inc.”,”contact_number”:”304.525.7496″}

Strategic Sourcing Conclusion and Outlook for burning barrels for sale

In the competitive landscape of burning barrels, strategic sourcing emerges as a critical factor for international buyers aiming to optimize procurement and enhance operational efficiency. By leveraging insights from diverse suppliers across North America, Europe, and emerging markets in Africa and South America, businesses can secure high-quality products that align with their specific needs. Key considerations include assessing material quality, compliance with local regulations, and evaluating supply chain reliability to mitigate risks.

Moreover, fostering relationships with manufacturers can lead to favorable pricing, bulk purchasing options, and customized solutions tailored to unique operational requirements. As demand for burning barrels continues to grow, especially in regions where waste management solutions are crucial, buyers are encouraged to stay informed about innovations in design and materials that enhance safety and efficiency.

Looking ahead, the potential for growth in this sector is significant. International buyers are urged to engage with multiple suppliers, explore emerging markets for competitive pricing, and prioritize sustainable practices. Embracing these strategies will not only streamline procurement but also contribute to long-term business success in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.