The Definitive Guide to Kangaroo Jumper: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for kangaroo jumper

In the competitive landscape of recreational equipment, sourcing a reliable kangaroo jumper can pose significant challenges for international B2B buyers. As playgrounds and recreational facilities increasingly seek to enhance their offerings, understanding the diverse applications and advantages of kangaroo jumpers becomes crucial. This guide serves as a comprehensive resource, exploring various types of kangaroo jumpers, their applications across different markets—including campgrounds, agritourism, and day camps—and the essential considerations for supplier vetting.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries such as Saudi Arabia and Nigeria—will find valuable insights into cost structures, safety standards, and customization options that can differentiate their offerings. With a focus on high-quality materials, innovative designs, and installation methods, this guide empowers stakeholders to make informed purchasing decisions that enhance customer satisfaction and drive business growth.

By delving into the intricacies of the kangaroo jumper market, you will gain the knowledge needed to navigate supplier relationships, ensure compliance with safety regulations, and ultimately secure a product that stands out in a crowded marketplace. Whether you are looking to add a new attraction to a family entertainment center or enhance the experience at a camp, this guide is your key to unlocking the potential of kangaroo jumpers.

Understanding kangaroo jumper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Air Pillow | Basic design, durable PVC material, suitable for outdoor use | Campgrounds, outdoor parks, schools | Pros: Cost-effective, easy installation. Cons: Limited customization options. |

| Elite Land Bouncer | High UV-resistant material, antimicrobial properties, vibrant colors | Agritourism, family entertainment centers | Pros: Long-lasting, visually appealing. Cons: Higher initial investment. |

| Indoor Jumpers | Designed for indoor use, often smaller in size | Day camps, indoor recreation centers | Pros: Year-round use, safe for various age groups. Cons: Requires specific installation considerations. |

| Custom-Sized Jumpers | Tailored dimensions and designs based on client specifications | Theme parks, large event venues | Pros: Maximizes space efficiency, unique branding options. Cons: Longer lead time for production. |

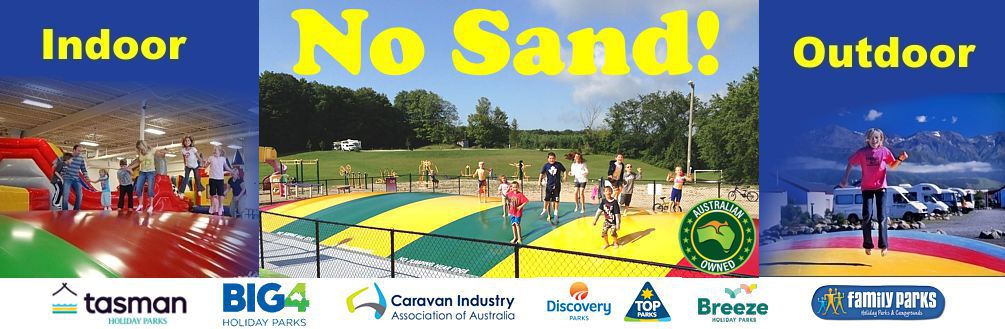

| No-Sand Option Jumpers | Cleaner installation with no sand, easier maintenance | Urban parks, facilities with strict cleanliness standards | Pros: Safer for children, less environmental impact. Cons: May require specialized installation techniques. |

What Are the Key Characteristics of Standard Air Pillows?

Standard air pillows are the foundational type of kangaroo jumper. Made from durable PVC material, they are designed primarily for outdoor use in settings like campgrounds and parks. Their straightforward design allows for easy installation and maintenance. B2B buyers should consider the cost-effectiveness and ease of setup, although they may find limited customization options compared to more advanced models.

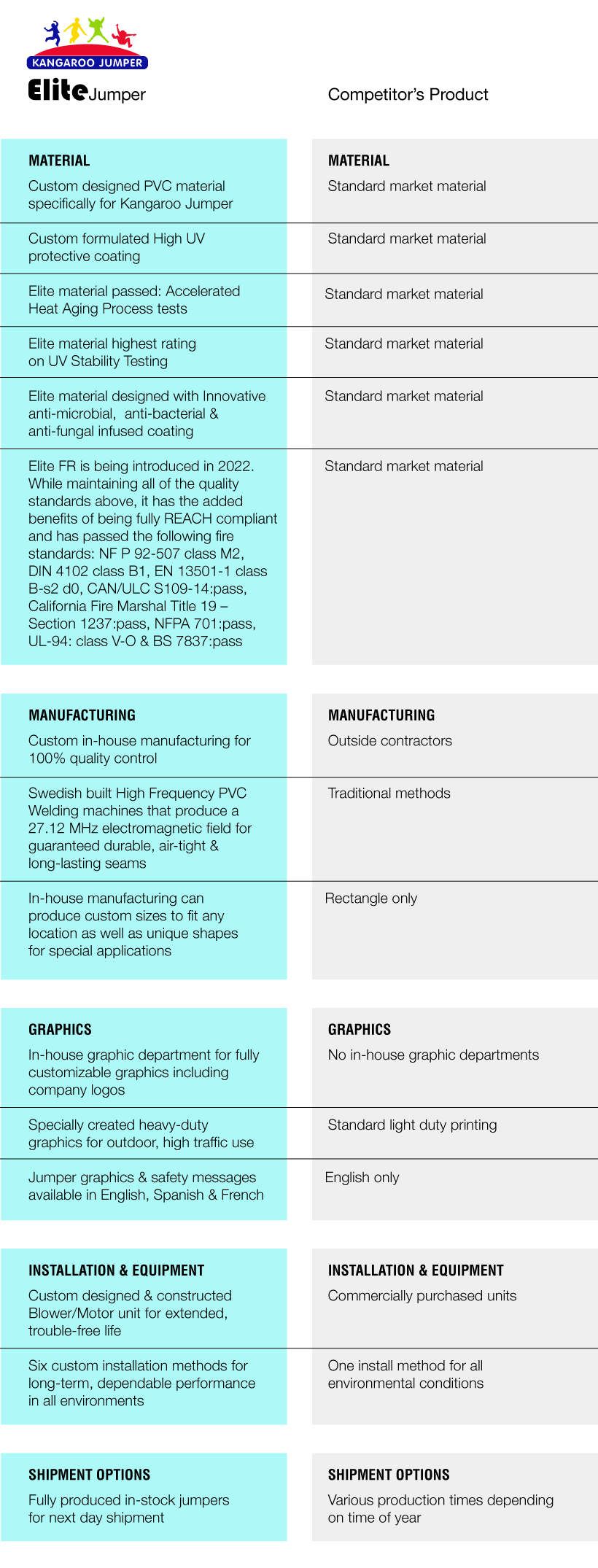

How Do Elite Land Bouncers Stand Out?

Elite Land Bouncers feature high UV-resistant fabric, which helps maintain vibrant colors and prolongs their lifespan. This type is particularly suited for agritourism and family entertainment centers, where visual appeal is crucial. The antimicrobial properties enhance safety, making it an attractive option for high-traffic areas. While the initial investment is higher, the durability and aesthetic benefits can lead to a solid return on investment.

What Are the Benefits of Indoor Jumpers?

Indoor jumpers are specifically designed for indoor environments, often being smaller to fit within various spaces. They are ideal for day camps and indoor recreation centers, providing a safe and fun environment for children year-round. When considering this option, buyers should focus on the safety features and the ability to cater to different age groups. However, installation may require specific considerations due to space constraints.

Why Choose Custom-Sized Jumpers?

Custom-sized jumpers are tailored to meet the specific needs of businesses, making them suitable for theme parks and large event venues. These jumpers allow for unique branding opportunities and can maximize space efficiency. While they may involve a longer lead time for production and higher costs, the ability to create a one-of-a-kind attraction can significantly enhance customer engagement and satisfaction.

What Makes No-Sand Option Jumpers a Safer Choice?

No-sand option jumpers provide a cleaner installation method that eliminates the need for sand, making them easier to maintain. This feature is particularly beneficial for urban parks and facilities with strict cleanliness standards. Buyers should consider the enhanced safety for children and the reduced environmental impact. However, specialized installation techniques may be required, which could complicate the setup process.

Key Industrial Applications of kangaroo jumper

| Industry/Sector | Specific Application of kangaroo jumper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Campgrounds | Installation of outdoor bounce pillows for kids | Attracts families, enhances visitor experience | Durability, weather resistance, and safety standards |

| Agritourism | Adding jumpers to farms for family-friendly activities | Increases foot traffic and engagement on the farm | Custom branding options and compliance with local regulations |

| Day Camps | Indoor and outdoor jumpers for summer programs | Provides unique recreational options to attract attendees | Installation flexibility and safety certifications |

| Amusement Parks | Large-scale jumpers as a main attraction | Differentiates from competitors, boosts revenue | High capacity design and maintenance support |

| Educational Institutions | Recreational areas with bounce pillows for students | Promotes physical activity and social interaction | Safety features, ease of installation, and warranty options |

How Do Campgrounds Benefit from Kangaroo Jumpers?

Campgrounds often seek innovative ways to keep children entertained, making kangaroo jumpers an ideal addition. These inflatable bounce pillows can be installed outdoors, providing a safe and enjoyable environment for kids to play. The presence of a kangaroo jumper can significantly enhance the overall visitor experience, encouraging families to spend more time at the site and potentially leading to increased revenue. For international buyers, considerations such as weather resistance and compliance with local safety standards are crucial for ensuring longevity and safety.

What Role Do Kangaroo Jumpers Play in Agritourism?

In the agritourism sector, kangaroo jumpers serve as an engaging attraction for families visiting farms. By incorporating bounce pillows, farms can create a fun atmosphere that keeps children occupied while parents enjoy other activities. This not only increases foot traffic but also enhances the overall experience, making farms more appealing to visitors. Buyers should consider custom branding options to align the jumpers with their farm’s identity, as well as ensure compliance with local regulations regarding amusement equipment.

How Can Day Camps Leverage Kangaroo Jumpers?

Day camps can utilize kangaroo jumpers to offer unique recreational opportunities for children, whether indoors or outdoors. These jumpers can be pivotal in attracting attendees, providing a fun physical activity that promotes social interaction. When sourcing for day camps, it’s essential to consider the jumper’s installation flexibility and safety certifications to meet the specific needs of children and ensure a safe environment.

Why Are Kangaroo Jumpers Essential for Amusement Parks?

Amusement parks can greatly benefit from incorporating large-scale kangaroo jumpers as a central attraction. These bounce pillows can differentiate a park from competitors and draw families looking for unique experiences. The ability to accommodate multiple jumpers at once enhances the park’s capacity and revenue potential. For B2B buyers in this sector, focusing on high-capacity designs and reliable maintenance support is vital for operational success.

Illustrative image related to kangaroo jumper

How Do Educational Institutions Use Kangaroo Jumpers?

Educational institutions can integrate kangaroo jumpers into their recreational areas to promote physical activity among students. These jumpers encourage outdoor play and social interaction, vital for child development. When sourcing for schools, it’s important to prioritize safety features, ease of installation, and warranty options to ensure long-term use and compliance with educational safety standards.

3 Common User Pain Points for ‘kangaroo jumper’ & Their Solutions

Scenario 1: Safety Concerns Regarding Bounce Pillow Use

The Problem: As playground and recreational facility operators expand their offerings, safety remains a top concern. B2B buyers often worry about the potential for injuries associated with inflatable products like the Kangaroo Jumper, particularly in high-traffic environments where children of varying ages use the equipment simultaneously. Accidents can lead to serious liability issues, damaged reputations, and costly insurance claims, making safety a crucial factor in purchasing decisions.

The Solution: To mitigate safety concerns, buyers should prioritize sourcing Kangaroo Jumpers that feature high-volume, low-pressure technology, which minimizes the risk of injuries related to the “catapult effect” commonly associated with traditional bounce houses. Moreover, prospective buyers should ensure that the product meets safety standards specific to their region, such as ASTM or EN standards. It’s advisable to work closely with the manufacturer to understand the installation requirements and safety recommendations. Additionally, implementing regular maintenance checks and staff training on proper usage can significantly enhance safety. Establishing clear guidelines for usage, including age restrictions and maximum jumper capacity, will further ensure a safe environment for all users.

Scenario 2: Durability in Diverse Environments

The Problem: Buyers in regions with extreme weather conditions, such as intense sunlight in the Middle East or heavy rainfall in South America, often face challenges regarding the durability of playground equipment. They need products that withstand harsh environmental factors without compromising safety or aesthetics. The risk of premature wear and fading can lead to additional costs for replacements or repairs, making it crucial to select a product designed for longevity.

The Solution: When sourcing Kangaroo Jumpers, buyers should opt for models constructed from high UV-resistant materials, such as the Elite fabric offered by Kangaroo Jumper. This material not only prolongs the lifespan of the inflatable but also keeps colors vibrant, reducing fading. Additionally, buyers should inquire about the product’s warranty and maintenance requirements to ensure long-term performance. For outdoor installations, consider using ground covers designed to resist mold and mildew, further enhancing durability. Buyers should also explore custom options that suit their specific environmental conditions, such as reinforced seams or weatherproof coatings, ensuring that their investment remains viable through various weather scenarios.

Scenario 3: Installation and Space Requirements

The Problem: Many B2B buyers face difficulties when it comes to the installation of Kangaroo Jumpers, especially in locations with limited space or unique ground conditions. Miscalculating the installation requirements can lead to costly delays or unsuitable setups that fail to meet safety standards. Furthermore, the complexity of installation may deter some buyers from considering inflatable options altogether.

The Solution: To address installation challenges, buyers should engage directly with the manufacturer or authorized dealers to discuss specific site conditions and requirements. Kangaroo Jumper offers various installation methods tailored to different ground types, including concrete, rocky soil, and flood-prone areas. Buyers should request a detailed site assessment, which can help determine the best installation method for their location. Additionally, consider hiring professional installers experienced in setting up inflatable structures, as they can ensure compliance with safety guidelines and local regulations. By understanding and preparing for the unique challenges of their site, buyers can facilitate a smooth installation process and maximize the utility of their Kangaroo Jumper investment.

Strategic Material Selection Guide for kangaroo jumper

What Are the Key Materials Used in Kangaroo Jumpers?

When selecting materials for kangaroo jumpers, it is essential to consider various factors that impact performance, safety, and longevity. Here, we analyze four common materials used in the manufacturing of kangaroo jumpers, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of PVC Vinyl in Kangaroo Jumpers?

PVC (Polyvinyl Chloride) vinyl is the most commonly used material for kangaroo jumpers. It offers excellent durability and resistance to wear and tear, making it suitable for high-traffic environments. Key properties include high tensile strength, flexibility, and a temperature rating that allows for use in various climates. PVC is also resistant to corrosion and UV degradation, ensuring that colors remain vibrant over time.

Illustrative image related to kangaroo jumper

Pros: PVC is relatively low-cost compared to other materials, easy to manufacture, and can be customized for different designs and sizes. Its lightweight nature simplifies installation.

Cons: While PVC is durable, it can become brittle over time when exposed to extreme temperatures, particularly in colder climates. Additionally, it may not be as environmentally friendly as other alternatives.

Impact on Application: PVC is compatible with various media, including air and water, making it a versatile choice for different environments. However, international buyers should ensure that the PVC used complies with local regulations, such as REACH in Europe.

How Does the New Elite FR (Fire Retardant) Material Enhance Safety?

The Elite FR material is a specialized version of PVC designed to meet fire safety standards. This material is treated with fire-retardant chemicals to reduce flammability, making it a safer option for playgrounds and campsites.

Pros: The primary advantage of Elite FR is enhanced safety, which can be a significant selling point for B2B buyers. It also retains the durability and flexibility of standard PVC.

Cons: The manufacturing process for fire-retardant materials can be more complex, potentially leading to higher costs. Additionally, the availability of this material may vary by region.

Impact on Application: Fire safety is a critical concern in many regions, especially in areas prone to wildfires or where regulations are stringent. Buyers in the Middle East, for instance, may prioritize this material due to local safety standards.

What Advantages Does Antimicrobial Material Offer for Kangaroo Jumpers?

Antimicrobial materials are designed to inhibit the growth of bacteria, mold, and fungi, making them ideal for environments where hygiene is a priority, such as day camps and indoor play areas.

Illustrative image related to kangaroo jumper

Pros: The use of antimicrobial materials can significantly enhance the safety and cleanliness of a kangaroo jumper, providing peace of mind for operators and parents alike. This feature may also extend the lifespan of the product by preventing degradation caused by microbial growth.

Cons: Antimicrobial treatments can add to the cost of manufacturing and may not be necessary for all applications, particularly in less humid regions.

Impact on Application: In regions like Africa and South America, where humidity levels can be high, antimicrobial properties are particularly beneficial. Buyers should verify that the antimicrobial treatments used comply with local health regulations.

How Does the Use of High UV-Resistant Material Affect Longevity?

High UV-resistant materials are specifically formulated to withstand prolonged exposure to sunlight without significant degradation. This is particularly important for outdoor installations.

Pros: These materials prolong the life of the kangaroo jumper and keep colors vibrant, which can enhance the aesthetic appeal of playgrounds and campsites.

Cons: High UV-resistant materials can be more expensive than standard options, and their manufacturing may require specialized processes.

Impact on Application: Buyers in sunny regions, such as parts of Europe and the Middle East, should prioritize UV-resistant materials to ensure longevity and maintain the visual appeal of their installations.

Illustrative image related to kangaroo jumper

Summary Table of Material Selection for Kangaroo Jumpers

| Material | Typical Use Case for kangaroo jumper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Vinyl | General playgrounds | Cost-effective and durable | Can become brittle in extreme temps | Low |

| Elite FR | Safety-focused environments | Enhanced fire safety | Higher manufacturing complexity | Med |

| Antimicrobial Material | Indoor play areas | Improved hygiene and safety | Increased manufacturing cost | Med |

| High UV-Resistant Material | Outdoor installations | Prolongs lifespan and maintains color | Higher cost and specialized processes | High |

This strategic material selection guide provides B2B buyers with valuable insights into the materials used in kangaroo jumpers, helping them make informed decisions that align with their operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for kangaroo jumper

What Are the Main Stages of the Manufacturing Process for Kangaroo Jumpers?

The manufacturing process for Kangaroo Jumpers involves several critical stages that ensure the final product is safe, durable, and visually appealing. These stages are material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary material used in the production of Kangaroo Jumpers is high-quality PVC vinyl, chosen for its durability and flexibility. During this stage, the PVC is tested for quality and compliance with international standards, ensuring that it meets specifications for strength and UV resistance. This is crucial as the jumpers are often exposed to varying weather conditions, especially in regions like Africa and the Middle East where UV exposure can be intense.

-

Forming: The PVC sheets are then cut into specific shapes and sizes based on customer specifications. Advanced cutting techniques, such as laser cutting, may be employed to ensure precision. Additionally, the sheets are prepared for welding, which involves cleaning and treating the edges to ensure a strong bond during the welding process.

-

Assembly: High-frequency welding machines are utilized to create airtight seams, a technique that guarantees durability and longevity. This method is essential to prevent air leaks and ensure the safety of the product. The assembly process may also include the integration of custom graphics or branding, which is done using heavy-duty graphic inks that are resistant to fading and wear.

-

Finishing: Once assembled, the Kangaroo Jumpers undergo a thorough inspection to ensure they meet design specifications. This stage may include adding safety features, such as reinforced edges and anti-slip surfaces. The final product is then cleaned and prepared for packaging.

What Quality Control Measures Are Implemented During Manufacturing?

Quality control (QC) is an integral part of the manufacturing process for Kangaroo Jumpers. Several international and industry-specific standards guide these practices, ensuring that products are safe and reliable.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001 standards, which focus on quality management systems and continuous improvement. Compliance with these standards assures buyers of the manufacturer’s commitment to quality and customer satisfaction.

-

Industry-Specific Certifications: In addition to ISO 9001, Kangaroo Jumpers may also meet CE certification requirements, indicating compliance with European health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe who must ensure products meet stringent safety regulations.

-

Quality Control Checkpoints: Quality checks are conducted at various stages of the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet specified quality standards.

– In-Process Quality Control (IPQC): Ongoing checks are performed during the manufacturing stages to identify and rectify issues immediately.

– Final Quality Control (FQC): The finished products undergo rigorous testing, including pressure tests and visual inspections, to ensure they are free from defects and meet all safety standards.

What Common Testing Methods Are Used for Quality Assurance?

Several testing methods are employed to ensure the safety and performance of Kangaroo Jumpers:

-

Tensile Strength Testing: This measures the material’s ability to withstand pulling forces, ensuring that the jumper can handle the weight and activity of multiple users.

-

UV Resistance Testing: Given the outdoor usage of Kangaroo Jumpers, UV resistance testing is crucial to assess how well the material can withstand prolonged exposure to sunlight without degrading.

-

Leak Testing: This involves checking for air leaks in the seams and connections to ensure that the jumper maintains its inflation during use.

-

Safety Testing: Compliance with safety standards may involve additional testing for flammability and chemical safety, particularly for regions with strict regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source Kangaroo Jumpers should take proactive steps to verify the quality control measures of their suppliers:

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the quality control processes in place. This allows buyers to assess the adherence to international standards firsthand.

-

Requesting Quality Reports: Buyers should request detailed QC reports, including results from various tests performed on the products. This documentation should reflect compliance with relevant international and industry-specific standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and final products. This is especially important for buyers in regions with strict import regulations, such as Saudi Arabia and Nigeria, where compliance is crucial.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

-

Regional Regulations: Different countries may have varying requirements for product safety and quality. Buyers should familiarize themselves with local regulations to ensure compliance when importing products.

-

Documentation Requirements: Importing goods often necessitates specific documentation, including certificates of conformity and quality assurance. Buyers should ensure that their suppliers provide all necessary paperwork to facilitate smooth customs clearance.

-

Cultural Considerations: Understanding cultural differences in business practices can help in negotiations and establishing trust with suppliers. Buyers should be prepared to engage in thorough discussions about quality expectations and standards.

In conclusion, the manufacturing processes and quality assurance measures for Kangaroo Jumpers are designed to deliver safe, durable, and high-quality products. By understanding these processes and taking steps to verify supplier quality control, international B2B buyers can make informed purchasing decisions that enhance their business offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kangaroo jumper’

This guide serves as a practical checklist for international B2B buyers interested in procuring Kangaroo Jumpers. It outlines essential steps to ensure a successful sourcing process, enabling you to make informed decisions that align with your business needs and local market requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your requirements for the Kangaroo Jumper. Consider factors such as size, weight capacity, material specifications (e.g., fire retardant and antimicrobial features), and intended use (indoor vs. outdoor). Establishing these parameters upfront will streamline your sourcing process and ensure you receive appropriate product options.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in Kangaroo Jumpers. Look for companies with a solid track record, positive customer testimonials, and experience in your target market. Utilize online resources, industry reports, and trade shows to gather information and make a list of potential vendors.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that your chosen suppliers have the necessary certifications and compliance with safety standards. Check for certifications such as REACH compliance, which ensures that the materials used are safe for both human health and the environment. This step not only protects your business but also enhances the credibility of your offerings.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that include pricing, delivery timelines, and warranty information. Ensure the proposal outlines all features, including the durability of materials and installation methods. Comparing these proposals will help you assess which supplier offers the best value for your investment.

Illustrative image related to kangaroo jumper

Step 5: Visit Supplier Facilities (if possible)

If feasible, visit the suppliers’ manufacturing facilities to assess their production capabilities and quality control processes. This firsthand experience can provide valuable insights into their operations, including the technology used for welding seams and material quality. It also fosters stronger relationships with suppliers, which can be beneficial for future negotiations.

Step 6: Check for Customization Options

Inquire about customization capabilities, such as unique sizes, colors, or branding options. Many suppliers offer tailored solutions that can differentiate your product offerings in the market. Customization can enhance customer engagement and satisfaction, making it a critical factor in your decision-making process.

Step 7: Confirm After-Sales Support

Finally, ensure that the supplier provides comprehensive after-sales support, including installation services, maintenance guidelines, and customer service availability. Having reliable support can greatly enhance the longevity and performance of your Kangaroo Jumper, ensuring that you deliver a safe and enjoyable experience to your customers.

Illustrative image related to kangaroo jumper

By following this checklist, B2B buyers can navigate the procurement process effectively, ensuring they select the right Kangaroo Jumper that meets their operational needs and enhances their business offerings.

Comprehensive Cost and Pricing Analysis for kangaroo jumper Sourcing

What Are the Key Cost Components for Sourcing Kangaroo Jumpers?

When sourcing kangaroo jumpers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary material used in kangaroo jumpers is PVC vinyl, known for its durability and safety. The quality of the PVC can significantly influence the cost, with premium options like fire retardant and antimicrobial fabrics commanding higher prices.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is required for the assembly of the jumpers, especially when custom designs or specific installation methods are needed.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. A manufacturer with advanced technology, such as high-frequency welding machines, may have higher overhead but can offer superior product quality.

-

Tooling: Initial costs for molds and machinery can be significant, particularly for customized designs. These costs are usually amortized over large production runs, impacting the price per unit.

-

Quality Control (QC): Ensuring that products meet safety and quality standards involves additional costs for testing and inspections. Certifications, especially for international markets, can increase expenses but enhance the product’s marketability.

-

Logistics: Shipping costs can vary greatly depending on the destination, mode of transport, and Incoterms. For international buyers, understanding these logistics costs is essential, as they can affect the total landed cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Kangaroo Jumper Sourcing?

Several factors can influence the pricing of kangaroo jumpers, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Negotiating better pricing terms can be beneficial for buyers looking to purchase in bulk.

-

Specifications/Customization: Custom sizes, colors, and branding options can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality: Higher quality materials and certifications can raise the price. Buyers should consider the long-term benefits of investing in superior products, such as durability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers may offer better warranties and support but could charge more.

-

Incoterms: Understanding shipping terms is vital. Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, which can significantly influence overall costs.

What Are the Best Buyer Tips for Sourcing Kangaroo Jumpers Internationally?

-

Negotiate Smartly: Leverage your purchasing volume to negotiate better pricing. Building a long-term relationship with suppliers can also lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential replacement costs over time. A more expensive jumper with a longer lifespan may be more cost-effective.

-

Understand Pricing Nuances: Be aware of currency fluctuations and tariffs that may affect pricing, especially for international transactions. This is particularly important for buyers from regions like Africa, South America, the Middle East, and Europe.

-

Research Suppliers Thoroughly: Look for suppliers who offer comprehensive service, including installation and support. Check for certifications and customer testimonials to ensure quality.

-

Plan for Logistics: Factor in shipping times and costs when making purchasing decisions. Understanding the logistics involved can help in budgeting and planning for installation.

Disclaimer

The prices mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing kangaroo jumper With Other Solutions

Introduction: Exploring Alternatives to the Kangaroo Jumper

In the realm of recreational equipment for playgrounds and entertainment venues, the Kangaroo Jumper stands out as a unique solution. However, several alternatives exist that can offer similar benefits in terms of fun and engagement for children. This analysis compares the Kangaroo Jumper against other viable solutions, helping international B2B buyers determine the best fit for their specific needs.

Comparison Table

| Comparison Aspect | Kangaroo Jumper | Trampoline Park | Inflatable Bounce House |

|---|---|---|---|

| Performance | High bounce, multi-user | High bounce, multi-user | Moderate bounce, single-user |

| Cost | $9,300 for large units | Varies; typically higher setup | $1,500 – $5,000 |

| Ease of Implementation | Requires professional setup | Requires extensive space, permits | Easy setup, portable |

| Maintenance | Moderate, durable materials | High, regular inspections needed | Low, but requires regular cleaning |

| Best Use Case | Camps, farms, large venues | Dedicated recreation centers | Birthday parties, small events |

Detailed Breakdown of Alternatives

Trampoline Park

Trampoline parks are designed for high-energy activities, featuring interconnected trampolines that allow for various jumps and flips. They offer a thrilling experience and can accommodate multiple users simultaneously, similar to the Kangaroo Jumper. However, the initial setup cost is typically higher due to the need for extensive space, safety measures, and potential permits. Maintenance also demands regular inspections and repairs to ensure safety compliance. While trampoline parks may draw larger crowds, they require significant investment and ongoing operational costs, making them a less feasible option for smaller businesses or those with limited budgets.

Illustrative image related to kangaroo jumper

Inflatable Bounce House

Inflatable bounce houses are another popular choice for providing entertainment at events and gatherings. They are generally more affordable than Kangaroo Jumpers and can be easily transported and set up at various locations. Bounce houses are particularly suited for birthday parties and smaller events, offering a good alternative for businesses focusing on short-term rentals. However, they typically have a lower bounce quality compared to the Kangaroo Jumper and may not accommodate as many jumpers at once. Maintenance is relatively low, but regular cleaning is necessary to keep the equipment hygienic. Additionally, they may not provide the same long-lasting durability as the materials used in Kangaroo Jumpers.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between the Kangaroo Jumper and its alternatives, buyers should carefully consider their specific business model, target audience, and budget constraints. The Kangaroo Jumper excels in providing a unique and durable solution for larger venues, making it ideal for campgrounds and agritourism sites. In contrast, trampoline parks may appeal to those looking for a high-energy, dedicated recreational facility, while inflatable bounce houses offer flexibility and affordability for smaller events. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals and customer needs.

Essential Technical Properties and Trade Terminology for kangaroo jumper

What Are the Key Technical Properties of a Kangaroo Jumper?

Understanding the essential technical specifications of a Kangaroo Jumper is critical for B2B buyers, particularly those aiming to invest in playground equipment that maximizes safety and durability. Here are some key properties to consider:

1. Material Grade: PVC Vinyl

The primary material used in Kangaroo Jumpers is high-quality PVC vinyl, typically rated at 900 grams per square meter (gr/m²). This robust material ensures durability and resistance to wear, making it suitable for both indoor and outdoor installations. For B2B buyers, selecting a product with superior material quality translates to lower maintenance costs and a longer lifespan, thereby maximizing ROI.

2. UV Resistance

Kangaroo Jumpers often feature a custom UV protective coating designed to withstand intense sun exposure. This property is crucial for outdoor installations, especially in regions with high solar intensity. By investing in products with high UV resistance, buyers can ensure that colors remain vibrant and the material does not degrade quickly, which is particularly important for maintaining aesthetics and functionality in competitive markets.

Illustrative image related to kangaroo jumper

3. Antimicrobial Properties

Recent innovations have introduced antimicrobial and antifungal treatments into the manufacturing process of Kangaroo Jumpers. This feature is essential for maintaining hygiene, especially in high-traffic areas like playgrounds and campgrounds. B2B clients can benefit from offering a cleaner and safer play environment, which can be a strong selling point to customers concerned about health and safety.

4. Installation Flexibility

Kangaroo Jumpers can be installed using multiple methods, including standard soil, rocky soil, and concrete surface installations. This versatility allows buyers to choose the best installation method based on their specific site conditions, enhancing operational efficiency. Understanding installation options helps B2B buyers plan their projects more effectively and avoid unexpected costs.

5. Warranty and Quality Assurance

Most manufacturers offer warranties ranging from five years and above, reflecting their confidence in product durability and performance. A strong warranty not only provides peace of mind for buyers but also indicates the manufacturer’s commitment to quality. B2B buyers should prioritize products with solid warranty terms as a safeguard against potential future costs.

Illustrative image related to kangaroo jumper

What Are Common Trade Terms Related to Kangaroo Jumpers?

Familiarity with trade terminology is vital for B2B transactions, ensuring clear communication and understanding between buyers and suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are then marketed under another brand’s name. For B2B buyers, understanding OEM relationships can help in negotiating better pricing and ensuring product quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to know as it affects inventory management and cash flow. Understanding the MOQ helps businesses plan their purchases more strategically.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can lead to competitive pricing and better negotiation leverage.

Illustrative image related to kangaroo jumper

4. Incoterms (International Commercial Terms)

These are predefined commercial terms that define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping and insurance. Familiarity with Incoterms helps B2B buyers mitigate risks and understand their obligations in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage their supply chains effectively and meet customer demands without delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when investing in Kangaroo Jumpers, ensuring they choose the right products for their markets.

Illustrative image related to kangaroo jumper

Navigating Market Dynamics and Sourcing Trends in the kangaroo jumper Sector

What are the Key Market Trends Affecting the Kangaroo Jumper Sector?

The global kangaroo jumper market is witnessing significant growth driven by rising demand for recreational facilities and outdoor activities. Countries across Africa, South America, the Middle East, and Europe are increasingly investing in recreational spaces such as amusement parks, campgrounds, and agritourism sites, which incorporate kangaroo jumpers to enhance visitor experiences. The shift towards experiential entertainment is propelling the adoption of these inflatable playground features, as they offer unique, safe, and engaging activities for children of all ages.

Emerging trends in the B2B sourcing landscape include the integration of technology in product offerings. For instance, advancements in materials technology have led to the development of high UV-resistant and antimicrobial fabrics, ensuring longer-lasting, safer, and cleaner products. Additionally, the customization of jumpers—tailored sizes, colors, and branding options—has become a significant selling point for businesses aiming to differentiate themselves in competitive markets. International buyers should also be aware of logistical considerations, such as installation methods adaptable to various terrains and environmental conditions, which are critical for successful project execution.

Furthermore, the rise of e-commerce platforms has streamlined procurement processes, allowing B2B buyers to compare products, request quotes, and secure orders more efficiently. As more suppliers embrace online sales, international buyers can benefit from competitive pricing and faster access to the latest innovations in the kangaroo jumper sector.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Kangaroo Jumper Market?

Sustainability has become a pivotal concern in the kangaroo jumper sector, influencing purchasing decisions and supplier relationships. The environmental impact of recreational products, particularly in terms of material sourcing and manufacturing processes, is under scrutiny. B2B buyers are increasingly seeking products that utilize environmentally friendly materials and processes. For example, kangaroo jumpers made from PVC that is REACH compliant ensure safety for both users and the environment.

Ethical sourcing practices are also gaining traction. Companies that prioritize transparent supply chains and adhere to sustainable practices are more likely to attract conscientious buyers. For instance, the introduction of antimicrobial and antifungal materials not only enhances the longevity of jumpers but also supports public health by reducing the risk of germs. Certifications that demonstrate a commitment to sustainability, such as those for lead-free materials or reduced carbon footprints, can significantly enhance a supplier’s marketability.

In regions like Africa and South America, where environmental regulations are evolving, buyers are encouraged to engage with suppliers who demonstrate a commitment to sustainability. This not only meets regulatory requirements but also aligns with the growing consumer demand for responsible business practices.

What is the Historical Context of Kangaroo Jumpers in the B2B Market?

The kangaroo jumper, originally introduced to the U.S. market over 15 years ago, has evolved significantly from its inception as a niche product to a staple in recreational facilities worldwide. The initial focus was on providing a safe, interactive space for children to play, which has now expanded to encompass a variety of applications, including indoor and outdoor installations across diverse settings, from campgrounds to amusement parks.

As the market matured, manufacturers began to innovate, focusing on durability and safety enhancements, such as high-frequency welded seams and advanced material compositions. This evolution has positioned kangaroo jumpers as not only a fun addition to recreational spaces but also a competitive advantage for businesses aiming to attract families and children. The continuous investment in product development reflects the industry’s responsiveness to changing consumer preferences and the need for sustainable, high-quality recreational solutions.

Illustrative image related to kangaroo jumper

This historical perspective underscores the importance of understanding market dynamics and sourcing trends for international B2B buyers looking to capitalize on the growing demand for kangaroo jumpers.

Frequently Asked Questions (FAQs) for B2B Buyers of kangaroo jumper

-

How do I ensure the safety of a Kangaroo Jumper installation?

To ensure the safety of your Kangaroo Jumper installation, it’s essential to follow the manufacturer’s guidelines for setup and maintenance. Regularly check the inflation levels and inspect the sand barrier to prevent accidents. Additionally, consider the safety of the installation site, ensuring it is free from hazards. It’s also advisable to conduct periodic safety audits and have trained staff supervise the area where the jumper is installed. Compliance with local safety regulations will further enhance safety for all users. -

What is the best Kangaroo Jumper model for my business needs?

Choosing the right Kangaroo Jumper model depends on your target market and space availability. For campgrounds, larger models that can accommodate multiple jumpers at once are ideal. If you are operating in a smaller indoor space, consider compact models designed for year-round use. The Elite model offers enhanced durability and UV protection, making it suitable for outdoor settings in sunny regions. Assess your customer demographics and intended usage frequency to determine the best fit for your business. -

What customization options are available for Kangaroo Jumpers?

Kangaroo Jumpers can be customized in various ways, including size, color, and branding. Clients can request specific dimensions to fit their location and can choose vibrant color options to enhance visual appeal. Additionally, custom graphics and logos can be printed on the jumpers, allowing businesses to promote their brand effectively. This level of customization helps businesses create a unique attraction that stands out in competitive markets. -

What are the minimum order quantities (MOQs) for purchasing a Kangaroo Jumper?

Minimum order quantities can vary based on the supplier and specific product configurations. Generally, for Kangaroo Jumpers, the MOQ is one unit, making it accessible for small businesses looking to enhance their offerings. However, bulk orders may qualify for discounts, so it’s worth discussing your needs directly with the supplier to explore pricing options that fit your budget and inventory requirements. -

What payment terms can I expect when sourcing a Kangaroo Jumper?

Payment terms for purchasing a Kangaroo Jumper typically vary by supplier but commonly include options such as upfront payment, a deposit followed by balance upon delivery, or payment upon receipt. International buyers may also encounter different terms based on their location. It’s crucial to negotiate terms that are favorable for your cash flow while ensuring the supplier’s confidence in the transaction. -

How do I vet suppliers of Kangaroo Jumpers?

When vetting suppliers for Kangaroo Jumpers, consider their industry experience, customer reviews, and product quality certifications. Request references from previous clients and inquire about their warranty and support services. It’s also beneficial to check if the supplier complies with international safety standards and regulations, which is particularly important for playground equipment. Engaging in direct communication and potentially visiting their facilities can also provide insights into their operational capabilities. -

What logistics considerations should I keep in mind when importing Kangaroo Jumpers?

Logistics for importing Kangaroo Jumpers involve understanding shipping methods, costs, and customs regulations specific to your country. Ensure that you have a reliable freight forwarder familiar with the import process for inflatable products. It’s also important to factor in lead times for production and shipping, as well as any potential tariffs or taxes that may apply. Proper planning will help minimize delays and additional costs upon arrival. -

What quality assurance measures should I expect for Kangaroo Jumpers?

Quality assurance for Kangaroo Jumpers should include thorough inspections during manufacturing, testing for durability and safety, and compliance with international standards. Suppliers should provide documentation proving that their products meet safety regulations and material specifications. Additionally, inquire about the warranty period and what it covers, as this reflects the manufacturer’s confidence in the product’s quality. Regular maintenance and service support from the supplier can further ensure long-term performance.

Top 4 Kangaroo Jumper Manufacturers & Suppliers List

1. Kangaroo Jumper – Air Pillow for Playgrounds

Domain: kangaroojumper.com

Registered: 2009 (16 years)

Introduction: Kangaroo Jumper is an air pillow designed for playgrounds, available in both indoor and outdoor options. It is made from ELITE PLUS PVC material and is now offered in fire retardant (FR) and antimicrobial versions. The product is suitable for various markets including campgrounds, agritourism, and day camps. Bounce pillows typically last between 5 to 10 years and are designed for safety with prope…

2. Light As Air – Kangaroo Jumper Elite Bouncer

Domain: lightasairboats.com

Registered: 2019 (6 years)

Introduction: Kangaroo Jumper Elite Land Bouncer Air Pillows

3. Kangaroo Jumper – Air-Filled Bouncy Pillow

Domain: crs4rec.com

Registered: 2001 (24 years)

Introduction: Kangaroo Jumper is a large, air-filled bouncy pillow designed for interactive fun for kids of all ages, allowing multiple jumpers at once. It features indoor/outdoor installation options and comes in various sizes to fit any location. The product utilizes high-volume, low-pressure technology for safety, eliminating the catapult effect. Made from durable, superior-quality PVC material with high-fre…

4. Kangaroo Jumper – Safety and Longevity Redefined

Domain: kangaroojumper.com.au

Introduction: The Kangaroo Jumper is designed for safety and longevity, addressing shortcomings of traditional jumping products. Key features include:

– UV resistant material for enhanced life expectancy

– Sand Depth Indicator for easy monitoring of sand depth

– Upgraded signage compliant with insurance requirements

– New installation method for increased stability and lower jumping height

– Over 2500 inst…

Strategic Sourcing Conclusion and Outlook for kangaroo jumper

In the competitive landscape of recreational equipment, Kangaroo Jumper stands out as a premier choice for international B2B buyers seeking innovative, durable, and engaging products. The strategic sourcing of Kangaroo Jumpers offers significant advantages, including enhanced customer satisfaction through unique play experiences and the ability to differentiate your offerings in crowded markets. With features like antimicrobial materials, versatile installation options, and customization capabilities, these jumping pillows not only provide entertainment but also prioritize safety and cleanliness.

The growing demand for outdoor recreational activities in regions such as Africa, South America, the Middle East, and Europe highlights the need for businesses to invest in quality products that cater to families and children. As more operators recognize the value of Kangaroo Jumpers in enhancing their facilities, there’s a tremendous opportunity for B2B buyers to tap into this expanding market.

Looking ahead, now is the ideal time to explore how Kangaroo Jumpers can elevate your business. By investing in these innovative products, you can create unforgettable experiences for your customers while ensuring a safe and enjoyable environment. Take the next step in your strategic sourcing journey and consider adding Kangaroo Jumpers to your portfolio today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to kangaroo jumper

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.