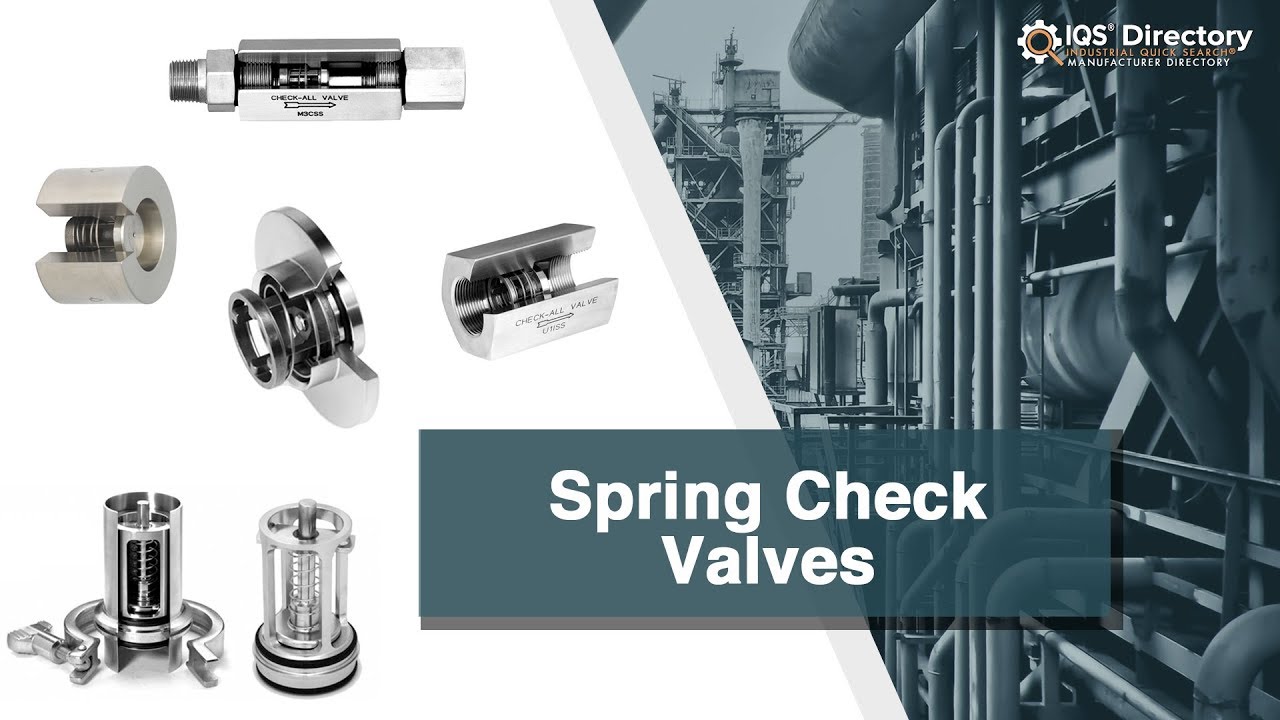

Top 6 Spring Checks Suppliers (And How to Choose)

Introduction: Navigating the Global Market for spring checks

In today’s competitive landscape, sourcing reliable spring check valves presents a pivotal challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Spring check valves are essential for preventing backflow in various applications, ensuring the integrity of fluid systems across industries. As buyers navigate the complexities of the global market, understanding the diverse types of spring check valves, their applications, and the nuances of supplier vetting becomes crucial for making informed purchasing decisions.

This comprehensive guide delves deep into the world of spring check valves, exploring the various types available, including stainless steel and PVC options, as well as their specific applications in industries ranging from HVAC to plumbing. It also highlights key factors influencing cost, helping buyers assess the total value of their investments. Furthermore, the guide provides actionable insights on how to effectively vet suppliers, ensuring quality and reliability in your procurement process.

By equipping B2B buyers with the necessary knowledge and resources, this guide empowers you to confidently navigate the global market for spring check valves. Whether you are based in Vietnam, Germany, or any other part of the world, you’ll find the tools and information needed to optimize your supply chain and enhance operational efficiency.

Understanding spring checks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Spring Check | Corrosion-resistant, high-pressure tolerance | Water treatment, oil & gas, chemical processing | Pros: Durable, versatile; Cons: Higher cost |

| PVC Spring Check | Lightweight, cost-effective, resistant to chemicals | Residential plumbing, irrigation systems | Pros: Affordable, easy to install; Cons: Lower pressure tolerance |

| Brass Spring Check | Excellent durability, good for high-temperature applications | HVAC systems, commercial plumbing | Pros: Strong, reliable; Cons: Heavier, potential corrosion |

| Plastic Spring Check | Lightweight, non-corrosive, suitable for low-pressure | Aquaculture, light-duty applications | Pros: Cost-effective, easy handling; Cons: Limited lifespan |

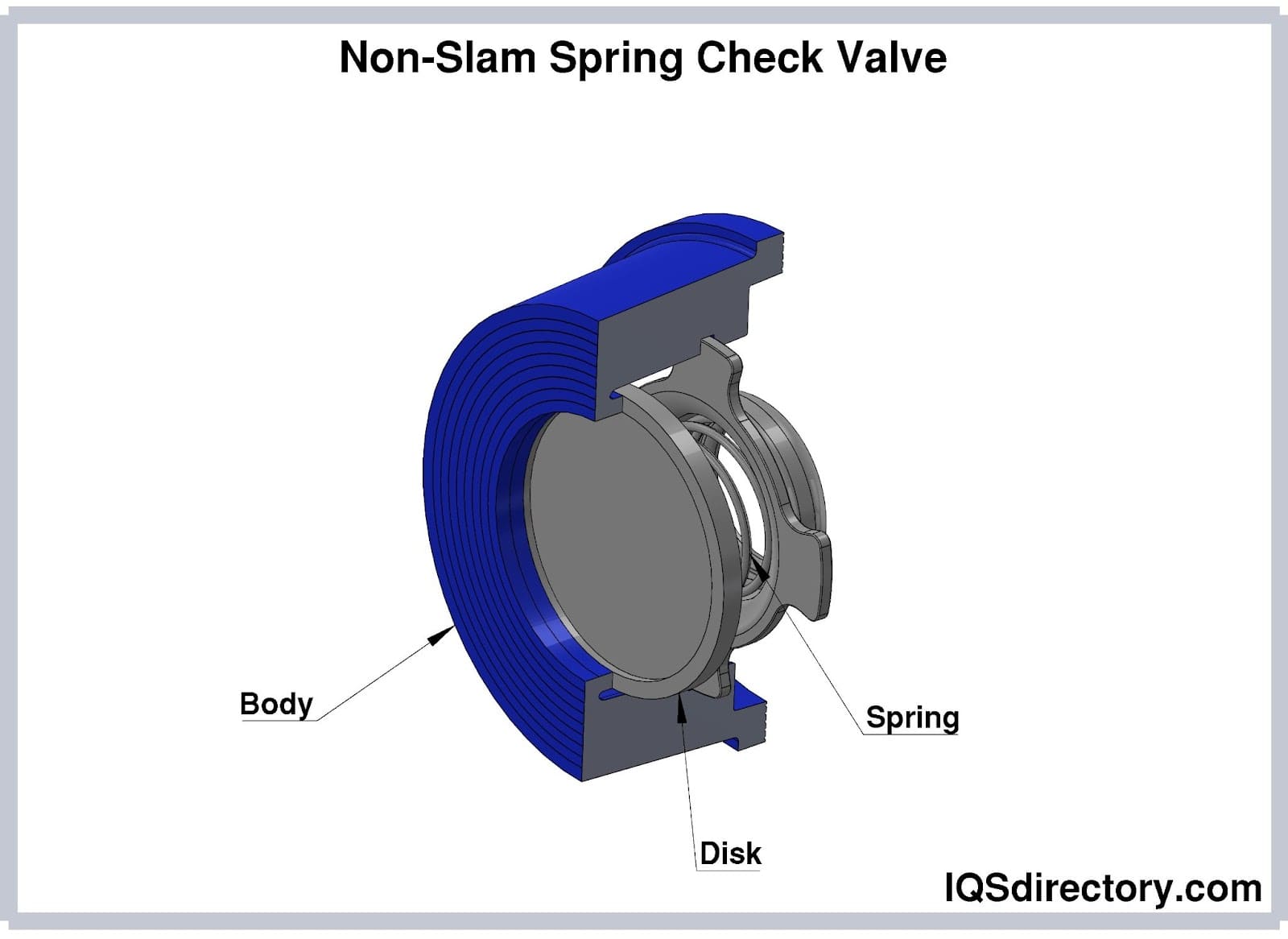

| Dual-Plate Spring Check | Compact design, minimizes space requirements | Industrial applications, water supply systems | Pros: Efficient flow; Cons: More complex installation |

What Are the Key Characteristics of Stainless Steel Spring Check Valves?

Stainless steel spring check valves are known for their robust construction and ability to withstand high pressures, making them ideal for rigorous environments like oil and gas or chemical processing. Their corrosion-resistant properties ensure longevity, which is crucial for industries that require reliable performance over time. When considering a purchase, B2B buyers should evaluate the valve’s pressure ratings and compatibility with specific media to ensure optimal functionality.

How Do PVC Spring Check Valves Compare in Cost and Application?

PVC spring check valves are a popular choice for residential and light commercial applications due to their affordability and ease of installation. They are resistant to a range of chemicals, making them suitable for various plumbing and irrigation systems. However, buyers should be mindful of their lower pressure tolerance compared to metal counterparts, which might limit their use in high-demand scenarios.

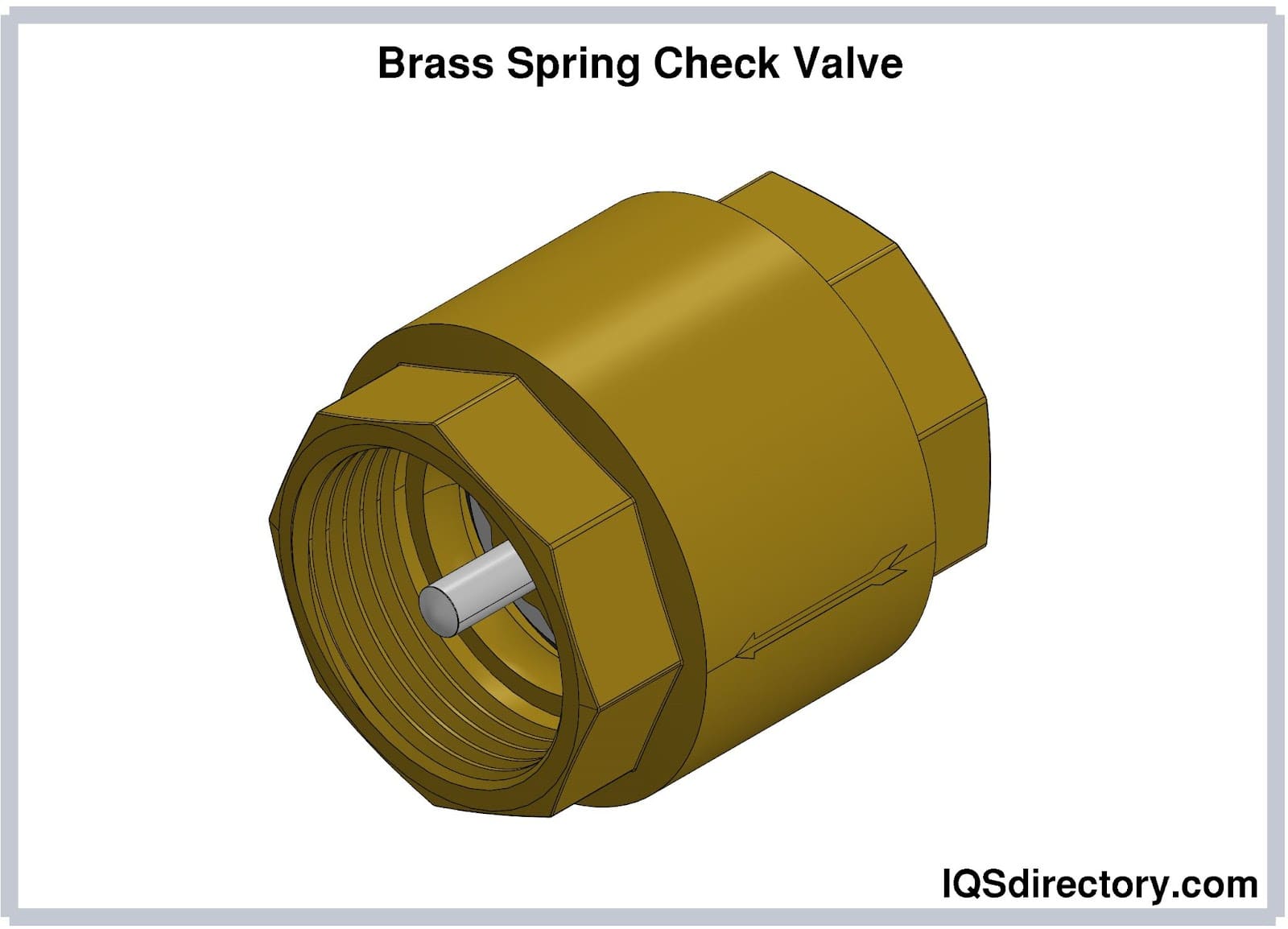

Why Choose Brass Spring Check Valves for HVAC Systems?

Brass spring check valves offer excellent durability and high-temperature resistance, making them particularly well-suited for HVAC systems and commercial plumbing applications. Their robust nature ensures reliability in maintaining system integrity. Buyers should consider the valve’s weight and potential corrosion issues, especially in environments where humidity is a concern.

What Are the Advantages of Plastic Spring Check Valves in Light-Duty Applications?

Plastic spring check valves are lightweight and non-corrosive, making them ideal for low-pressure applications like aquaculture or light-duty plumbing. Their cost-effectiveness and ease of handling are significant advantages for businesses looking to minimize expenses. However, buyers should be aware of their limited lifespan in comparison to metal options, which may affect long-term investment strategies.

How Do Dual-Plate Spring Check Valves Enhance Efficiency?

Dual-plate spring check valves are designed for compactness, allowing for efficient flow in industrial applications and water supply systems. Their design minimizes space requirements while ensuring effective backflow prevention. B2B buyers should consider the installation complexity and maintenance needs when opting for this type of valve, as these factors can influence operational efficiency and costs.

Key Industrial Applications of spring checks

| Industry/Sector | Specific Application of spring checks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Preventing backflow in filtration systems | Ensures clean water supply, reduces contamination risk | Material compatibility, pressure ratings, and certifications |

| Oil and Gas | Protecting pipelines from reverse flow | Minimizes equipment damage and downtime | Temperature tolerance, corrosion resistance, and sizing |

| HVAC Systems | Controlling flow in heating and cooling systems | Enhances system efficiency and longevity | Compatibility with system design and fluid types |

| Food and Beverage | Maintaining hygiene in liquid processing | Prevents contamination, ensuring product safety | Compliance with food-grade materials and industry standards |

| Agricultural Irrigation | Preventing backflow in irrigation systems | Protects crops from contaminated water | Durability in various climates and ease of installation |

How Are Spring Checks Used in Water Treatment Applications?

In water treatment facilities, spring check valves are crucial for preventing backflow in filtration systems. By ensuring that water flows in one direction, these valves help maintain the purity of the water supply, reducing the risk of contamination from stagnant or polluted water. For international buyers, especially from regions with varying water quality challenges, sourcing spring check valves that meet specific material compatibility and certification standards is vital to ensure long-term effectiveness and compliance with local regulations.

What Role Do Spring Checks Play in Oil and Gas Industries?

In the oil and gas sector, spring check valves protect pipelines from reverse flow, which can cause significant equipment damage and costly downtime. These valves are designed to withstand high pressure and temperature variations, making them essential for maintaining operational integrity. Buyers in this industry should consider sourcing valves with robust corrosion resistance and precise sizing to match their specific pipeline configurations, particularly in harsh environments common in regions like the Middle East and South America.

How Are Spring Checks Beneficial in HVAC Systems?

Spring check valves are instrumental in HVAC systems, where they control the flow of fluids in heating and cooling applications. Their ability to minimize noise and water hammer enhances system efficiency and longevity, crucial for maintaining comfortable environments in commercial and industrial buildings. When sourcing these valves, it is important for buyers to ensure compatibility with their system designs and the types of fluids being used, especially in diverse European markets where standards may vary.

Why Are Spring Checks Essential in the Food and Beverage Industry?

In the food and beverage industry, spring check valves play a vital role in maintaining hygiene during liquid processing. By preventing backflow, they ensure that the liquids processed remain uncontaminated, which is critical for product safety and compliance with health regulations. International buyers must prioritize sourcing food-grade materials that meet industry standards to avoid contamination risks and ensure consumer safety, particularly in markets with strict food safety laws like Germany.

How Do Spring Checks Enhance Agricultural Irrigation Systems?

In agricultural irrigation systems, spring check valves prevent backflow, protecting crops from contaminated water sources. This functionality is essential for maintaining healthy crops and optimizing water usage, especially in regions facing water scarcity. Buyers should consider the durability of these valves in various climates and ease of installation to ensure effective and efficient irrigation practices, particularly in developing agricultural sectors in Africa and South America.

3 Common User Pain Points for ‘spring checks’ & Their Solutions

Scenario 1: Backflow Issues in Critical Systems

The Problem: In industries such as pharmaceuticals or food processing, backflow can lead to contamination of products, equipment damage, and potential legal liabilities. B2B buyers in these sectors often face the challenge of ensuring that their piping systems effectively prevent backflow. When traditional swing check valves are used, they may not perform adequately in vertical applications or could be susceptible to water hammer, leading to system inefficiencies and costly downtime.

The Solution: To combat backflow issues, buyers should consider integrating spring check valves, which are designed to function in various orientations, including vertical installations. When sourcing these valves, it’s crucial to assess the specific pressure and temperature requirements of your application. Opt for spring check valves made from materials like stainless steel or PVC with Viton seats and PTFE seals, as these materials offer superior resistance to corrosion and high-pressure environments. Additionally, implementing a routine maintenance schedule that includes regular inspections of the valves will help ensure their reliability and prevent unexpected failures.

Scenario 2: Noise and Vibration Problems

The Problem: In environments such as commercial buildings or manufacturing facilities, excessive noise from valves can lead to complaints from occupants and affect workplace safety. Traditional swing check valves can exacerbate water hammer effects, causing loud thumping sounds and vibrations that not only disrupt operations but also potentially damage piping systems over time. B2B buyers in these settings need a solution that minimizes noise while ensuring the integrity of the system.

The Solution: Buyers should switch to spring check valves, which are engineered to reduce noise levels significantly. When selecting these valves, look for options with concentric spring-loaded designs that mitigate water hammer effects. It’s also advisable to work closely with suppliers to ensure that the chosen valves align with the specific sound dampening requirements of the facility. Regularly scheduled maintenance and monitoring can further help in identifying and addressing any noise issues early on, contributing to a quieter and more efficient operational environment.

Scenario 3: Compatibility with Existing Systems

The Problem: When upgrading or replacing valves in existing piping systems, compatibility is often a major concern for B2B buyers. Many face the dilemma of choosing valves that fit seamlessly into their current infrastructure without requiring extensive modifications. Incompatibility can lead to increased installation costs, prolonged downtime, and operational inefficiencies.

The Solution: To ensure compatibility, B2B buyers should conduct a thorough assessment of their existing systems before sourcing new spring check valves. It’s critical to gather detailed specifications, including pipe sizes, connection types, and flow orientation. Buyers should consider modular valve designs that allow for easy integration into various piping configurations. When sourcing, opt for suppliers that provide comprehensive data sheets and installation instructions to facilitate a smooth transition. Additionally, engaging with a valve expert during the selection process can help in identifying the best options that meet both compatibility and operational needs, ultimately reducing installation time and costs.

Strategic Material Selection Guide for spring checks

What Are the Key Properties of Common Materials Used in Spring Check Valves?

When selecting materials for spring check valves, it is essential to consider their properties, as they directly affect performance, durability, and compatibility with various media. Here, we analyze four common materials: stainless steel, PVC, brass, and carbon steel, focusing on their characteristics relevant to B2B buyers.

How Does Stainless Steel Perform in Spring Check Valves?

Stainless steel, particularly ASTM 316, is widely used in spring check valves due to its excellent corrosion resistance and high-temperature tolerance (up to 356°F or 180°C). This material is well-suited for applications involving aggressive media like chemicals, oils, and water, making it a versatile choice for various industries, including HVAC and plumbing.

Pros: Stainless steel offers exceptional durability and longevity, reducing the need for frequent replacements. Its strength allows it to withstand high pressure (up to 800 PSI), making it ideal for demanding applications.

Cons: The primary drawback is its higher cost compared to other materials, which may be a concern for budget-conscious buyers. Additionally, manufacturing stainless steel components can be complex, requiring specialized equipment.

International Considerations: Compliance with international standards such as ASTM and DIN is crucial for buyers in Europe and other regions. Buyers should ensure that the selected stainless steel meets local regulations regarding corrosion resistance and pressure ratings.

What Advantages Does PVC Offer for Spring Check Valves?

PVC (Polyvinyl Chloride) is a popular choice for spring check valves, particularly in non-corrosive applications. It is lightweight, resistant to many chemicals, and can handle temperatures up to 140°F (60°C). PVC is commonly used in water supply systems and irrigation.

Pros: The affordability of PVC makes it an attractive option for large-scale projects. Its ease of installation and low maintenance requirements further enhance its appeal.

Cons: However, PVC is not suitable for high-temperature applications and can become brittle over time when exposed to UV light. Its pressure ratings are generally lower than those of metals, which may limit its use in high-pressure systems.

International Considerations: Buyers in regions like Africa and South America should be aware of local regulations regarding PVC use, especially concerning environmental impact and safety standards.

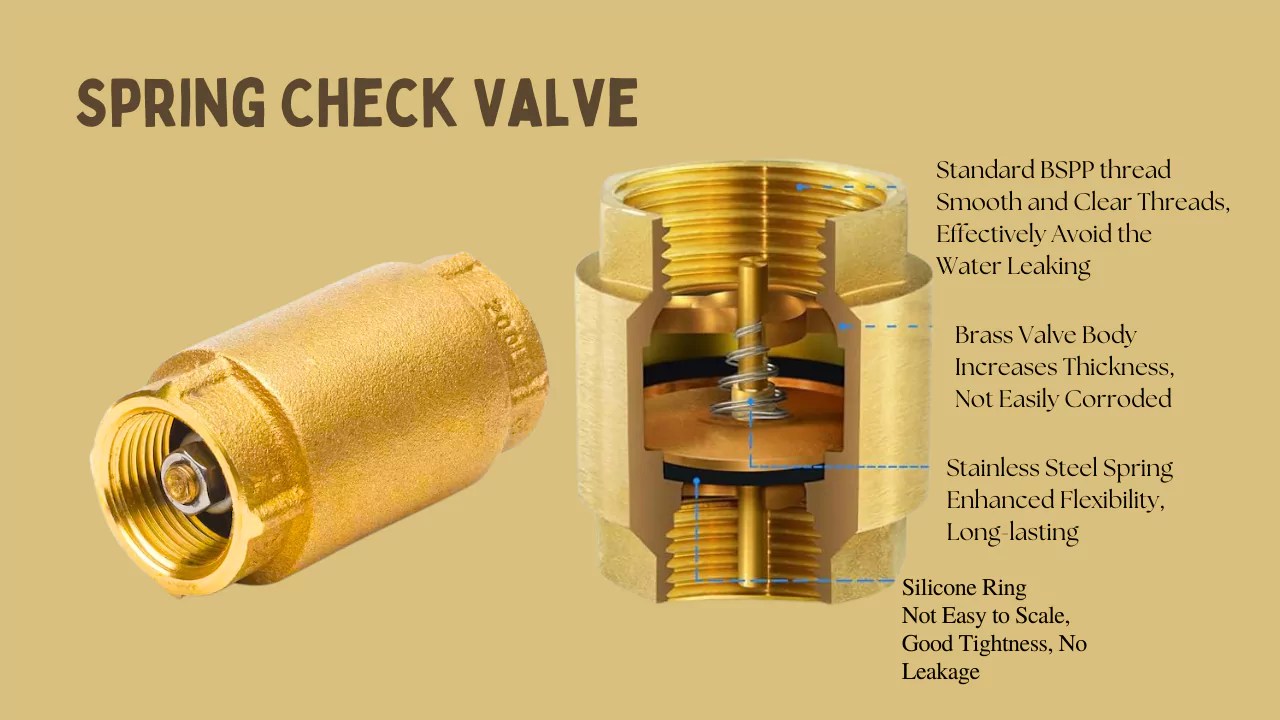

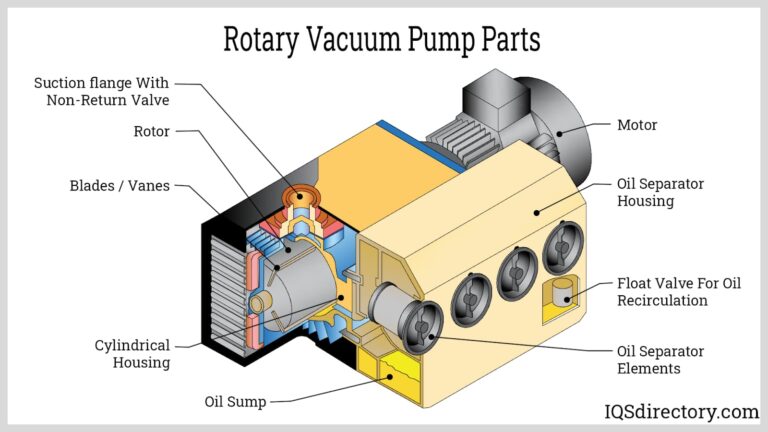

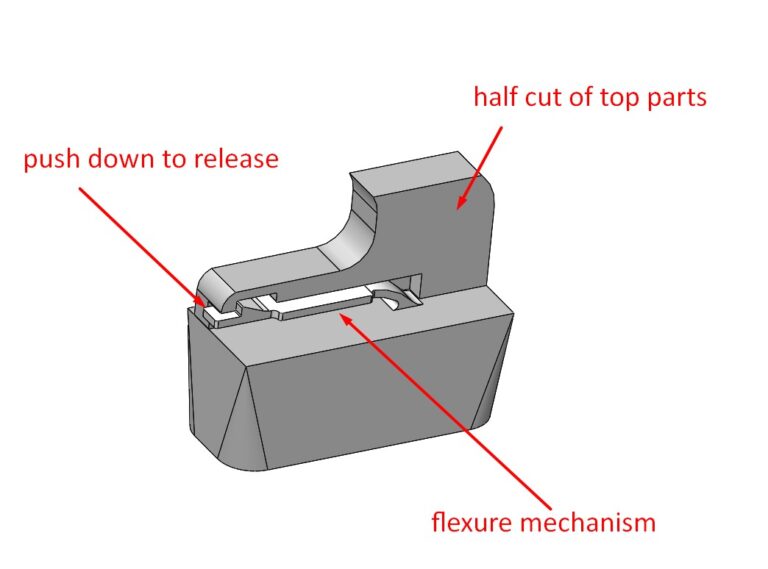

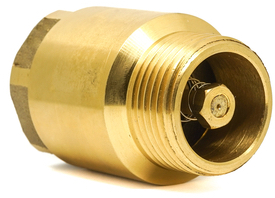

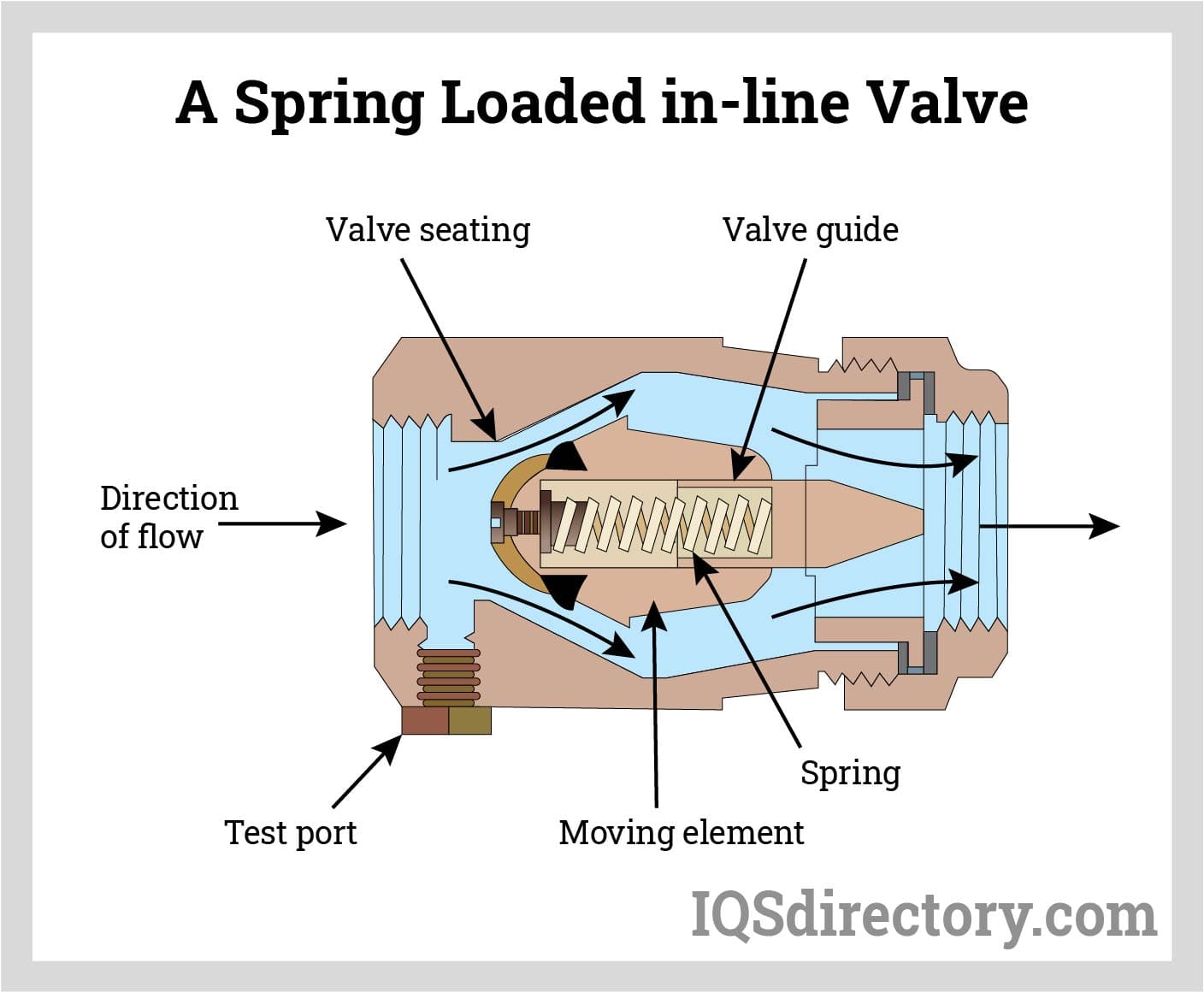

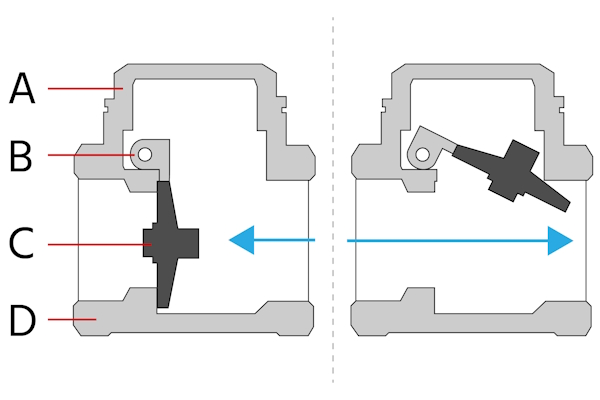

Illustrative image related to spring checks

How Does Brass Compare as a Material for Spring Check Valves?

Brass, an alloy of copper and zinc, is another common material used in spring check valves. It offers good corrosion resistance and can handle moderate temperatures (up to 200°F or 93°C) and pressures.

Pros: Brass is relatively easy to machine, making it a cost-effective option for manufacturers. Its aesthetic appeal also makes it suitable for visible applications.

Cons: The main limitation of brass is its susceptibility to dezincification in certain environments, which can lead to premature failure. Additionally, brass valves may not be suitable for aggressive chemicals.

Illustrative image related to spring checks

International Considerations: Compliance with standards such as JIS and DIN is essential for buyers in Asia and Europe. Buyers should also consider the implications of using brass in potable water applications, as it may be subject to stricter regulations.

What Role Does Carbon Steel Play in Spring Check Valves?

Carbon steel is known for its strength and durability, making it suitable for high-pressure applications. It can handle temperatures up to 400°F (204°C) and is often used in industrial settings.

Pros: The high strength-to-weight ratio of carbon steel allows for the design of robust valves that can withstand significant pressure. It is also generally more affordable than stainless steel.

Illustrative image related to spring checks

Cons: However, carbon steel is prone to corrosion if not properly coated or treated, which can lead to failure in harsh environments. Its heavier weight can also complicate installation.

International Considerations: Buyers in the Middle East and Europe should ensure that carbon steel valves meet local corrosion resistance standards, especially in humid or corrosive environments.

Summary Table of Material Properties for Spring Check Valves

| Material | Typical Use Case for spring checks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, HVAC, plumbing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| PVC | Water supply, irrigation | Affordable and easy to install | Limited temperature and pressure ratings | Low |

| Brass | Plumbing, visible applications | Aesthetic appeal, easy to machine | Susceptible to dezincification | Medium |

| Carbon Steel | Industrial applications, high-pressure | High strength and durability | Prone to corrosion without treatment | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in spring check valves, enabling informed decision-making tailored to specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for spring checks

What Are the Key Stages in the Manufacturing Process of Spring Check Valves?

The manufacturing of spring check valves involves several critical stages that ensure the final product meets both functional and quality requirements. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first step in the manufacturing process is material selection and preparation. Spring check valves are typically constructed from materials such as stainless steel, PVC, or brass, depending on the application and environmental conditions. For instance, stainless steel is favored for its corrosion resistance and strength, making it ideal for applications involving water, oil, and air.

Illustrative image related to spring checks

Once the materials are chosen, they undergo a rigorous quality check to ensure they meet industry standards. This includes assessing mechanical properties, chemical composition, and surface quality. Suppliers often provide material certificates to verify compliance with international standards, which is crucial for B2B buyers seeking reliability.

How Are Spring Check Valves Formed?

The forming stage involves shaping the prepared materials into the desired valve components. This can include processes such as machining, stamping, or molding. For instance, stainless steel parts may be machined to precise dimensions, while PVC components could be produced via injection molding.

Advanced techniques like CNC machining are commonly employed to achieve high precision and repeatability. For B2B buyers, understanding the forming techniques used can provide insights into the supplier’s capabilities and the potential for custom solutions.

Illustrative image related to spring checks

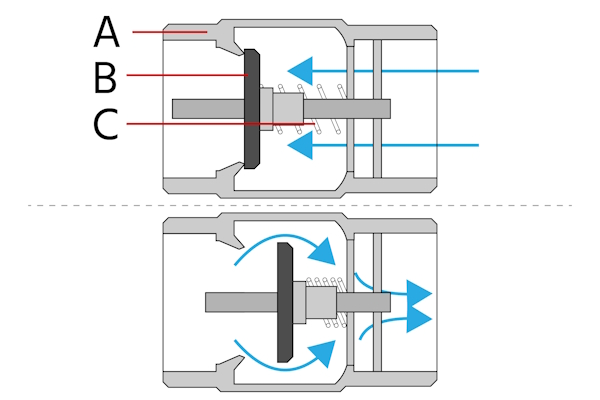

What Does the Assembly Process Entail?

Once the individual components are formed, they are assembled into the final spring check valve. This assembly process can be manual or automated, depending on the scale of production. During assembly, components such as the spring, disc, and body are carefully put together to ensure proper function and sealing.

Quality control is paramount during this stage, as improper assembly can lead to leakage or failure in the field. Suppliers often implement assembly jigs and fixtures to maintain consistent quality. For buyers, asking about the assembly process can reveal a lot about the supplier’s attention to detail and commitment to quality.

What Finishing Techniques Are Used for Spring Check Valves?

The final stage in the manufacturing process is finishing, which includes surface treatments and coatings. Finishing techniques like polishing, anodizing, or applying protective coatings enhance the durability and aesthetics of the spring check valves. These treatments are essential for improving resistance to corrosion and wear, particularly in harsh environments.

B2B buyers should inquire about the specific finishing processes used by suppliers. Understanding these can help assess the longevity and reliability of the valves, which is critical for minimizing maintenance costs and downtime.

Illustrative image related to spring checks

What International Standards Are Relevant for Quality Assurance of Spring Check Valves?

Quality assurance is a crucial aspect of manufacturing spring check valves, ensuring that products meet specific performance and safety standards. Various international standards, such as ISO 9001, provide frameworks for quality management systems.

How Do International Standards Impact Quality Control?

ISO 9001 is a widely recognized standard that outlines requirements for a quality management system. Compliance with ISO 9001 indicates that the manufacturer has established processes for consistent quality control, which is critical for B2B buyers looking for reliable suppliers.

In addition to ISO 9001, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications may also apply, especially for valves used in oil and gas applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process, helping to identify issues before they escalate. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC helps monitor production parameters to ensure compliance with quality standards.

- Final Quality Control (FQC): This involves testing the finished product for functionality, leakage, and performance under specified conditions.

For B2B buyers, understanding these checkpoints can provide confidence in the supplier’s quality assurance processes.

Illustrative image related to spring checks

What Testing Methods Are Commonly Used for Spring Check Valves?

Testing is a critical component of quality assurance in spring check valve manufacturing. Common testing methods include:

- Hydrostatic Testing: This method assesses the valve’s ability to withstand pressure without leaking.

- Functional Testing: This ensures the valve operates correctly under various flow conditions.

- Material Testing: This involves analyzing the mechanical properties of the materials used in the valve construction.

Buyers should request detailed reports on testing methods and results from suppliers to verify the quality and reliability of the valves.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

Verifying a supplier’s quality assurance processes is essential for B2B buyers, particularly when sourcing from international markets. Here are several strategies buyers can employ:

- Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing practices and quality control processes. This can be done directly or through third-party auditing firms.

- Requesting Quality Control Reports: Suppliers should be able to provide documentation detailing their quality control processes, including inspection and testing results.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s capabilities and adherence to quality standards.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification can be complex. Differences in standards and regulations across regions can impact the selection of suppliers. For example, European buyers may prioritize CE certification, while those in the Middle East might focus on compliance with local standards.

Additionally, language barriers and varying levels of transparency in documentation can complicate the verification process. Buyers should establish clear communication channels and expectations with suppliers to navigate these challenges effectively.

Illustrative image related to spring checks

In conclusion, the manufacturing processes and quality assurance for spring check valves are multi-faceted, involving careful material selection, precision forming, diligent assembly, and thorough testing. By understanding these processes and employing effective verification strategies, B2B buyers can make informed decisions and ensure they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring checks’

In the complex landscape of industrial procurement, sourcing spring check valves requires a strategic approach to ensure that you select the right products for your specific applications. This checklist aims to guide international B2B buyers through the necessary steps to effectively source spring check valves, ensuring quality, compatibility, and value.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, establish clear technical specifications for the spring check valves you need. Consider factors such as the medium they will be used with (water, oil, gas), required pressure ratings, temperature ranges, and material compatibility (e.g., stainless steel, PVC). This clarity will help streamline your search and ensure that you receive relevant proposals from suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers with a proven track record in manufacturing spring check valves. Focus on companies that cater to your specific industry needs and geographical location. Check their online presence for product catalogs, technical datasheets, and client testimonials to gauge their reliability and expertise.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that your shortlisted suppliers hold the necessary certifications and comply with international standards, such as ISO 9001 for quality management. These certifications indicate that the supplier adheres to best practices in manufacturing and quality control, minimizing the risk of defects and ensuring product reliability.

Illustrative image related to spring checks

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the spring check valves from your top suppliers. This will allow you to assess the quality, functionality, and compatibility of the products with your existing systems. Pay attention to the materials used, the finish, and the overall design, as these factors can significantly impact performance.

Step 5: Compare Pricing and Terms

Once you have gathered proposals from multiple suppliers, compare pricing alongside other critical factors such as lead times, payment terms, and warranty options. A lower price might be tempting, but it’s crucial to consider the total cost of ownership, including installation, maintenance, and potential downtime due to product failure.

Step 6: Assess After-Sales Support

Effective after-sales support can greatly influence your overall satisfaction and operational efficiency. Inquire about the supplier’s customer service policies, including response times for technical inquiries and their process for handling returns or defective products. A responsive supplier can help mitigate issues that arise post-purchase, ensuring smoother operations.

Step 7: Finalize Your Order and Establish a Relationship

Once you have selected a supplier, finalize your order by ensuring all specifications and terms are clearly documented in a purchase agreement. Establishing a good relationship with your supplier can lead to better pricing, priority service, and insights into new products or technologies that may benefit your operations in the future.

By following these steps, you can navigate the complexities of sourcing spring check valves effectively, securing the best products for your operational needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for spring checks Sourcing

What Are the Key Cost Components in Spring Check Valve Manufacturing?

When sourcing spring check valves, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the cost. Common options include stainless steel, PVC, and other alloys. Higher-grade materials, such as ASTM 316 stainless steel, provide durability and corrosion resistance but come at a premium price.

-

Labor: Labor costs vary based on the region and complexity of the valve design. Skilled labor is essential for quality assurance and precision in manufacturing.

-

Manufacturing Overhead: This includes expenses related to plant operations, utilities, and equipment maintenance. Overhead costs are generally higher in regions with strict environmental and safety regulations.

-

Tooling: The initial investment in tooling can be substantial, especially for custom valve designs. Buyers should consider how these costs are amortized over production volume.

-

Quality Control: Ensuring that valves meet industry standards involves rigorous testing and certification, adding to the overall cost. Buyers should inquire about the QC processes and certifications (e.g., ISO) that suppliers adhere to.

-

Logistics: Shipping costs can vary significantly based on the destination and chosen Incoterms. Buyers should factor in both domestic and international shipping costs when evaluating total expenses.

-

Margin: Supplier margins are influenced by market competition, brand reputation, and the perceived value of the product. Understanding these dynamics can help buyers negotiate better terms.

How Do Volume and Customization Affect Spring Check Valve Pricing?

Pricing for spring check valves is often influenced by order volume and customization requirements.

-

Volume/MOQ: Suppliers typically offer price breaks for larger orders, as higher volumes lead to lower per-unit costs. Understanding the minimum order quantities (MOQs) is essential for buyers looking to optimize their purchasing strategy.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Quality and Certifications: Valves that require specific certifications or meet stringent quality standards may incur additional costs. Buyers must assess whether the added expense aligns with their operational needs.

What Buyer Tips Can Help Optimize Costs and Pricing Negotiation?

B2B buyers should adopt strategic approaches to ensure cost-effectiveness in sourcing spring check valves.

-

Negotiation: Engage suppliers in discussions about pricing structures, especially when placing large orders. Highlighting long-term partnerships can sometimes lead to favorable terms.

-

Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes maintenance, replacement, and operational costs. A lower initial price may not always translate to better long-term value.

-

Pricing Nuances for International Buyers: For buyers from Africa, South America, the Middle East, and Europe, it’s crucial to understand local market dynamics and currency fluctuations. Negotiate Incoterms that minimize risk and ensure cost clarity.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, examining their reputation, quality assurance practices, and past performance. This can prevent costly mistakes and ensure reliable sourcing.

What Should Buyers Keep in Mind Regarding Indicative Pricing?

While indicative pricing provides a benchmark, it’s essential to recognize that actual costs may vary based on specific requirements and market conditions. Factors like regional economic stability, raw material availability, and supplier negotiation strategies can all influence final pricing. Buyers are encouraged to obtain detailed quotes and consider all cost components to ensure comprehensive budgeting.

Illustrative image related to spring checks

Alternatives Analysis: Comparing spring checks With Other Solutions

Exploring Alternatives for Spring Check Valves

In the quest for effective fluid control solutions, B2B buyers often consider various valve technologies. Among these, spring check valves are popular for their ability to prevent backflow efficiently. However, understanding alternative options can provide valuable insights for selecting the right solution tailored to specific applications. Below, we compare spring check valves with two viable alternatives: swing check valves and diaphragm check valves.

| Comparison Aspect | Spring Checks | Swing Check Valves | Diaphragm Check Valves |

|---|---|---|---|

| Performance | Low noise, minimizes water hammer | High flow capacity, but prone to water hammer | Excellent sealing, suitable for low flow |

| Cost | Generally higher upfront costs | Lower cost, budget-friendly | Mid-range cost, depending on materials |

| Ease of Implementation | Versatile in various orientations | Limited to horizontal flows | Requires precise installation and setup |

| Maintenance | Requires periodic checks, low wear | Simple maintenance, but can wear out | Regular diaphragm replacements needed |

| Best Use Case | Water pipelines, protecting equipment | Firefighting systems, sewage | Pharmaceutical, food processing applications |

What Are the Advantages and Disadvantages of Swing Check Valves?

Swing check valves operate using a swinging flap that opens with forward flow and closes automatically to prevent backflow. They are often favored for their low cost and high flow capacity, making them suitable for applications where budget constraints are critical. However, their performance is limited to horizontal or upward vertical flows, which restricts their versatility. Additionally, they can exacerbate water hammer effects, potentially leading to system damage over time. Buyers in industries with fluctuating flow rates may find swing check valves lacking in reliability for sensitive applications.

Why Consider Diaphragm Check Valves?

Diaphragm check valves utilize a flexible diaphragm to regulate flow, providing excellent sealing capabilities even in low-pressure situations. They are particularly effective in applications requiring sanitary conditions, such as in the pharmaceutical and food industries. However, the cost is typically higher than swing check valves, and they may require more frequent maintenance due to diaphragm wear. Their installation also demands precision to ensure optimal performance. B2B buyers in sectors prioritizing hygiene and reliability may find diaphragm check valves to be a superior choice despite the higher upfront costs.

How Can B2B Buyers Choose the Right Valve Solution?

When deciding between spring check valves, swing check valves, and diaphragm check valves, B2B buyers should consider several factors specific to their operational needs. Assessing the nature of the fluid being controlled, flow rates, installation environment, and budget constraints will inform the best choice. For applications requiring silent operation and protection against backflow, spring check valves may be ideal. Conversely, if budget and high flow capacity are priorities, swing check valves could suffice. For niche applications where hygiene is paramount, diaphragm check valves should be the solution of choice. Ultimately, understanding the unique requirements of each application will guide buyers toward the most effective and cost-efficient solution.

Essential Technical Properties and Trade Terminology for spring checks

What Are the Key Technical Properties of Spring Check Valves?

When selecting spring check valves, understanding their technical specifications is crucial for ensuring optimal performance in various applications. Here are some essential properties that should be considered:

1. Material Grade

Spring check valves are commonly constructed from materials such as stainless steel, brass, or PVC. The material grade is significant as it affects the valve’s resistance to corrosion, temperature tolerance, and compatibility with different media (liquids or gases). For instance, ASTM 316 stainless steel is often preferred for its high corrosion resistance, making it suitable for harsh environments.

2. Pressure Rating

This specification indicates the maximum pressure the valve can withstand during operation. Common ratings can range from 150 PSI to 800 PSI or more. Understanding the pressure rating is critical for ensuring that the valve can handle the system’s operational pressures without risk of failure, which could lead to costly downtime and repairs.

3. Cracking Pressure

Cracking pressure is the minimum pressure required to open the valve and allow flow. This specification is vital in applications where precise flow control is necessary. A lower cracking pressure may be desirable in systems with fluctuating pressures, while a higher cracking pressure could be beneficial in high-pressure applications to prevent backflow.

4. Temperature Range

Spring check valves can operate within specific temperature ranges, typically between -13°F to 356°F (-25°C to 180°C). Knowing the temperature limits is essential for ensuring that the valve functions correctly without degrading or failing due to thermal stress, especially in industries like HVAC or chemical processing.

5. Flow Orientation

Spring check valves are versatile and can be installed in various orientations (vertical or horizontal). This flexibility is crucial for B2B buyers who need valves that fit into existing piping configurations without requiring significant modifications. It allows for easier installation and integration into diverse systems.

What Are Common Trade Terms Related to Spring Check Valves?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions in B2B environments. Here are some common terms associated with spring check valves:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of spring check valves, understanding whether a supplier is an OEM can help buyers gauge product quality and reliability, as OEMs typically adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can impact purchasing decisions and inventory management. Understanding the MOQ helps in budgeting and ensures that buyers are not overcommitting to inventory they may not need.

Illustrative image related to spring checks

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. For spring check valves, submitting an RFQ can help buyers compare prices, terms, and conditions from various suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade transactions. Familiarity with these terms is essential for B2B buyers involved in international shipping of spring check valves, as they clarify who is responsible for shipping costs, insurance, and risk during transport.

5. Cv (Flow Coefficient)

The Cv value indicates the flow capacity of a valve. It is a critical parameter for engineers and procurement teams as it helps in selecting the right valve based on the flow requirements of the system. A higher Cv value means a greater capacity for fluid flow, which can be essential for optimizing system performance.

Illustrative image related to spring checks

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing spring check valves, ensuring they select the right products for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the spring checks Sector

What Are the Current Market Dynamics and Key Trends in the Spring Check Valve Sector?

The global market for spring check valves is experiencing significant growth, driven by increasing industrialization and the need for efficient fluid control systems. Key drivers include the rising demand for automation in various sectors such as oil and gas, water treatment, and HVAC systems. Emerging technologies, such as IoT and smart manufacturing, are reshaping how businesses approach sourcing and managing valve systems. For instance, the integration of IoT sensors into valve systems allows for real-time monitoring, enhancing reliability and efficiency.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing valves that not only meet operational requirements but also comply with stringent quality standards. In regions like Vietnam and Germany, there is a growing preference for high-performance materials, such as stainless steel and high-grade plastics, which enhance durability and resistance to corrosion. Moreover, buyers are exploring partnerships with manufacturers that offer customized solutions tailored to specific applications, thus ensuring optimal system performance.

How Are Sustainability and Ethical Sourcing Influencing the Spring Check Valve Market?

Sustainability is becoming a cornerstone of purchasing decisions in the B2B landscape, and the spring check valve sector is no exception. Buyers are increasingly aware of the environmental impact of their sourcing choices, prompting a shift towards sustainable materials and manufacturing practices. The use of eco-friendly certifications, such as ISO 14001, is becoming a common criterion for evaluating suppliers.

Ethical sourcing is crucial in establishing a brand’s reputation and ensuring compliance with global standards. Manufacturers are expected to demonstrate transparency in their supply chains, from raw material extraction to production. This includes the adoption of recyclable materials and energy-efficient manufacturing processes. Buyers are encouraged to prioritize suppliers that not only focus on performance but also uphold sustainability principles, contributing to a reduced carbon footprint and fostering a positive corporate image.

What Is the Brief Evolution of Spring Check Valves in the B2B Context?

The development of spring check valves can be traced back to the increasing need for efficient fluid control systems in the industrial revolution. Initially, basic designs were introduced to prevent backflow in piping systems. Over the decades, innovations in materials and engineering have led to the sophisticated designs we see today.

Modern spring check valves are characterized by advanced features such as low noise operation and enhanced resistance to water hammer, making them suitable for a wide array of applications. The evolution of technology has also allowed for the integration of smart features, enabling more precise control and monitoring. As industries evolve, the demand for reliable, efficient, and sustainable valve solutions continues to shape the landscape, ensuring that spring check valves remain a vital component in various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of spring checks

-

How do I select the right spring check valve for my application?

Choosing the right spring check valve involves evaluating the specific requirements of your system. Consider factors like the type of media (liquid, gas, or both), pressure ratings, and temperature ranges. For instance, stainless steel valves are suitable for high-pressure applications, while PVC valves are ideal for less demanding environments. Additionally, assess installation orientation—spring check valves are versatile for both horizontal and vertical applications. Consulting with manufacturers about your unique needs can help ensure optimal performance and longevity of the valve. -

What are the advantages of using spring check valves over swing check valves?

Spring check valves offer several key advantages compared to swing check valves. They are designed to function effectively in vertical installations and can accommodate various flow orientations, making them more versatile. Spring check valves also minimize noise and reduce the risk of water hammer, which can be damaging in piping systems. Moreover, they provide positive sealing even at lower pressures, ensuring reliable backflow prevention. These features make spring check valves a preferred choice for applications requiring high reliability and operational efficiency. -

What is the typical lead time for ordering spring check valves internationally?

Lead times for international orders of spring check valves can vary based on the manufacturer and the complexity of the order. Generally, you can expect a lead time of 4 to 12 weeks. Custom orders or those requiring specific certifications may take longer. It’s advisable to communicate with your supplier early in the process and confirm production timelines, especially if you have tight project deadlines. Consider requesting expedited shipping options if necessary to ensure timely delivery. -

What are the minimum order quantities (MOQs) for spring check valves?

Minimum order quantities for spring check valves typically range from 10 to 100 units, depending on the supplier and the valve type. Some manufacturers may offer flexibility for smaller orders, especially for standard products. However, larger quantities often result in better pricing per unit. When sourcing, clarify MOQs with your supplier and evaluate how they align with your project needs. This can also impact your budgeting and inventory management strategies. -

How can I ensure the quality of the spring check valves I purchase?

To ensure the quality of spring check valves, consider sourcing from reputable manufacturers with a proven track record. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request detailed product specifications, including material composition and performance testing results. Many suppliers offer warranties or guarantees, which can provide additional assurance. Conducting a factory visit or requesting third-party inspections can also help verify quality before shipment. -

What payment terms should I expect when sourcing spring check valves internationally?

Payment terms for international purchases of spring check valves can vary widely by supplier and region. Common terms include advance payment, letter of credit, or payment upon delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60), allowing you to pay within a specified period after receipt of goods. It’s essential to discuss and negotiate payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

What logistics considerations should I be aware of when importing spring check valves?

When importing spring check valves, consider logistics factors such as shipping method, customs duties, and import regulations. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your timeline and budget. Research the customs clearance process in your country to understand any documentation and fees required. Additionally, working with a logistics partner experienced in international trade can help navigate these complexities, ensuring a smoother import experience. -

Can I customize spring check valves to meet specific requirements?

Yes, many manufacturers offer customization options for spring check valves to meet specific application needs. Customizations may include variations in size, material, sealing options, or pressure ratings. When discussing your requirements with suppliers, provide detailed specifications and application contexts to help them recommend suitable modifications. Be aware that customized valves may have longer lead times and potentially higher costs, so factor these into your planning and budgeting.

Top 6 Spring Checks Manufacturers & Suppliers List

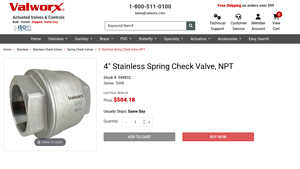

1. Valworx – Stainless Check Valve

2. PVC Fittings Online – PVC Spring Check Valves

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: PVC spring check valves are a type of swing check valve that uses a spring to close the swing flap and are designed to allow flow in only one direction. They are often used in applications where backflow could cause flooding or damage to sensitive components. Utility spring assisted check valves work automatically and are easy to install, making them the valve of choice for stopping backflow. Ther…

3. Dultmeier – Adjustable Spring Check Valve

Domain: dultmeier.com

Registered: 1996 (29 years)

Introduction: {“Type”:”Spring Check Valve”,”Style”:”Adjustable Spring”,”Port Size”:”1 inch”,”Body Length”:”5-1/4 inches”,”Body Material”:”PVC”,”Seal Material”:”EPDM”,”Connection Type”:”1 inch FPT”,”Opening Pressure”:”4 – 17 lbs.”,”Max Working Pressure”:”200 PSI at 72°F”,”Max Temperature Rating”:”140°F”,”SKU”:”JK1205-100″}

4. VNE Stainless – Spring Check Valves

Domain: vnestainless.com

Registered: 1997 (28 years)

Introduction: This company, VNE Stainless – Spring Check Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Empowering Pumps – Check Valves

Domain: empoweringpumps.com

Registered: 2011 (14 years)

Introduction: Spring Check Valves and Swing Check Valves are two types of inline check valves. Swing check valves are the most common and are a lower-cost solution, but they can only be installed in horizontal flow applications, limiting their installation orientation. They offer a larger flow capacity but can exacerbate water hammer effects. In contrast, spring check valves can be mounted in any flow orientati…

6. Check Valves – Spring Check Valves

Domain: check-valves.net

Registered: 2002 (23 years)

Introduction: Spring check valves are essential components in fluid control systems designed to guarantee one-way flow and prevent unwanted reverse flow. They utilize a spring mechanism to close the valve automatically when forward flow ceases or reverses. Key features include unidirectional flow, spring-assisted closure, automatic operation, and low maintenance. Common materials used are stainless steel, brass…

Strategic Sourcing Conclusion and Outlook for spring checks

In conclusion, strategic sourcing of spring check valves is essential for optimizing operational efficiency and ensuring system reliability across various industries. These valves, known for their ability to prevent backflow and minimize water hammer, are versatile in applications ranging from water pipelines to HVAC systems. By understanding the differences between spring check valves and their alternatives, such as swing check valves, buyers can make informed decisions that align with their specific project requirements and budget constraints.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize sourcing high-quality spring check valves that offer durability and performance. Establishing relationships with reputable manufacturers and suppliers is crucial, as it ensures access to the latest innovations and reliable support. As industries continue to evolve, the demand for efficient fluid control solutions will only increase.

Now is the time to leverage strategic sourcing to enhance your supply chain and operational resilience. Engage with trusted valve manufacturers and explore diverse options tailored to your unique needs. Invest in quality solutions that not only protect your systems but also contribute to long-term success in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to spring checks