Unlocking Value: A Strategic Analysis of the Thermoformed Trays Market

Introduction: Navigating the Global Market for thermoformed trays

In today’s fast-paced global market, sourcing the right thermoformed trays can be a daunting challenge for international B2B buyers. As businesses across industries—from electronics to pharmaceuticals—seek efficient packaging solutions, understanding the nuances of thermoformed trays becomes crucial. This comprehensive guide delves into the various types of thermoformed trays, their applications, and key factors to consider when selecting suppliers.

With a focus on the needs of buyers in regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—this guide equips you with actionable insights to navigate the complexities of procurement. From identifying the right materials to evaluating cost-effectiveness and supplier reliability, we cover all aspects that influence your purchasing decisions.

Moreover, we provide strategies for vetting suppliers and understanding the latest industry trends, enabling you to make informed choices that enhance your operational efficiency. Whether you are looking for standard options or custom solutions, this guide empowers you to find the ideal thermoformed tray that meets your business needs while ensuring product protection and reducing shipping costs.

Understanding thermoformed trays Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shipping Trays | Designed for safe transport, often stackable | Electronics, automotive, general manufacturing | Pros: Cost-effective, durable. Cons: Limited customization options. |

| ESD (Electrostatic Discharge) Trays | Conductive materials prevent static damage | Electronics, telecommunications | Pros: Protects sensitive components. Cons: Higher material cost. |

| Medical Trays | Designed for sterility, often with compartments | Medical devices, pharmaceuticals | Pros: Ensures hygiene and safety. Cons: May require specialized materials. |

| Insert Trays | Customizable cavities for specific components | Precision parts, optics, and delicate items | Pros: Tailored fit enhances protection. Cons: Longer lead times for custom orders. |

| Clamshell Trays | Hinged design for easy access, often transparent | Retail packaging, food items | Pros: Visibility of contents, reusable. Cons: Less protection during transport. |

What Are Shipping Trays and Their B2B Relevance?

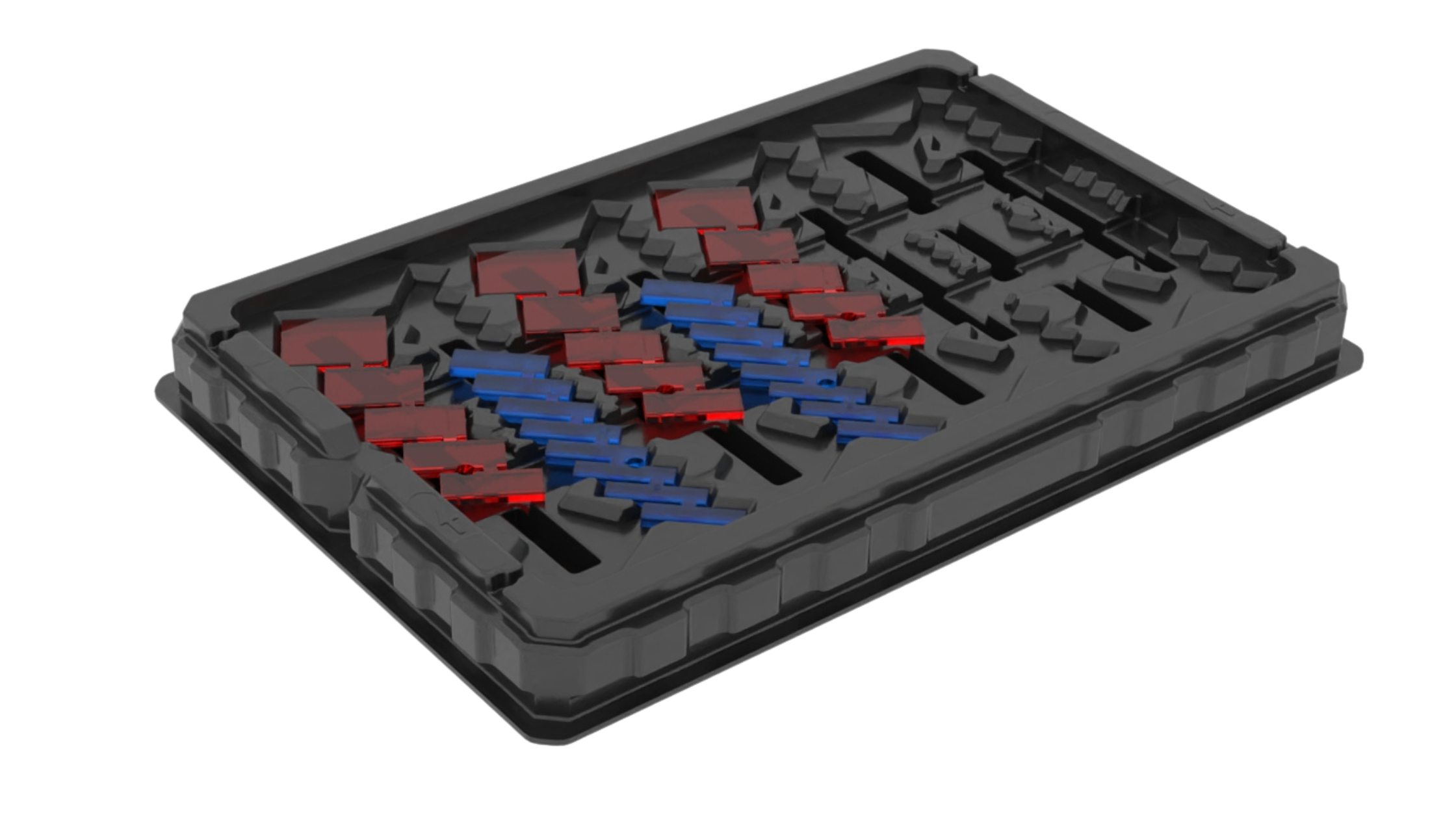

Shipping trays are primarily designed to facilitate the safe transport of products, often featuring a stackable design that maximizes storage efficiency. Commonly used in industries such as electronics and automotive manufacturing, these trays are made from durable materials like PVC and PETG. When purchasing shipping trays, B2B buyers should consider factors such as load capacity, compatibility with existing packaging systems, and bulk purchase discounts to optimize logistics and costs.

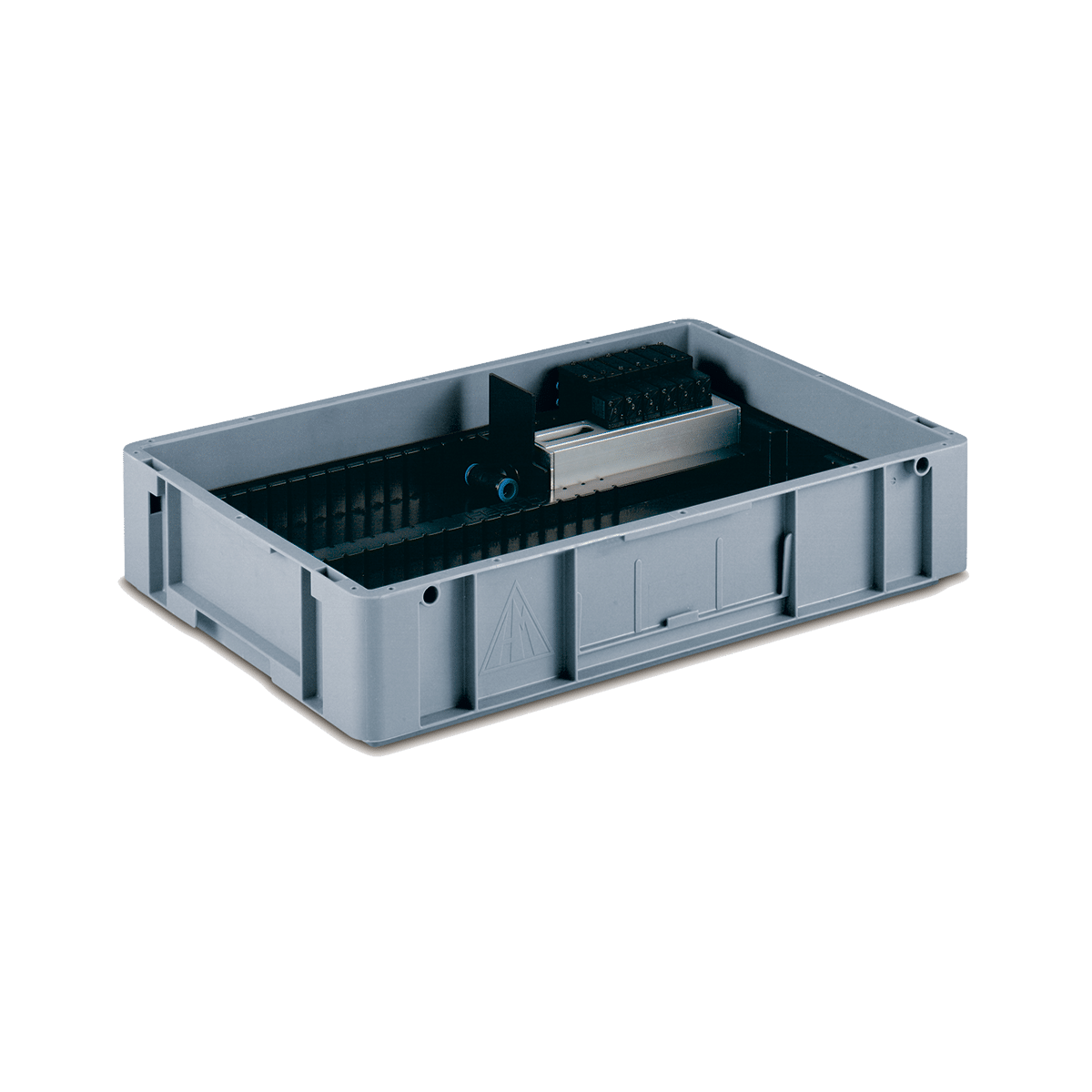

Illustrative image related to thermoformed trays

How Do ESD Trays Protect Sensitive Components?

ESD trays are specifically engineered to safeguard electronic components from electrostatic discharge, which can cause significant damage. These trays are made from conductive materials that dissipate static electricity, making them essential in electronics and telecommunications sectors. Buyers should evaluate the specific ESD ratings, tray designs, and how they integrate with existing workflows to ensure the protection of sensitive items during storage and transit.

What Are the Key Features of Medical Trays?

Medical trays are designed with a focus on sterility and safety, often incorporating individual compartments for different medical devices or pharmaceuticals. They are crucial in the healthcare industry to maintain hygiene and ensure the safe handling of sensitive items. B2B buyers should consider regulatory compliance, material safety certifications, and the ability to provide customized solutions for specific medical applications when choosing these trays.

Why Choose Insert Trays for Precision Parts?

Insert trays are customizable solutions that feature cavities specifically designed to hold particular components securely. This design is ideal for industries dealing with precision parts, such as optics and delicate instruments. When considering insert trays, buyers should focus on the customization capabilities, lead times, and the ability to enhance product protection during shipping and handling.

What Advantages Do Clamshell Trays Offer in Retail Packaging?

Clamshell trays feature a hinged design that allows for easy access to the contents while providing a clear view, making them popular in retail packaging for food and consumer products. While they offer visibility and can be reused, buyers must consider their protective capabilities during transport. Assessing the balance between visibility, ease of access, and protection will be essential for businesses looking to enhance their packaging solutions.

Key Industrial Applications of thermoformed trays

| Industry/Sector | Specific Application of thermoformed trays | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | ESD (Electrostatic Discharge) Trays | Protect sensitive components during shipping and storage | Ensure compliance with ESD standards and material quality |

| Medical | Medical Shipping Trays | Safeguard delicate medical instruments and devices | Look for FDA-approved materials and sterilization options |

| Automotive | Custom Parts Trays | Streamline assembly lines and reduce handling errors | Consider tray design for specific components and stackability |

| Food & Beverage | Food-grade Thermoformed Trays | Enhance food safety and extend shelf life | Verify compliance with food safety regulations and materials |

| Aerospace | Custom Trays for Precision Components | Ensure safe transport of high-value components | Focus on lightweight yet durable materials for shipping |

How Are Thermoformed Trays Utilized in the Electronics Sector?

In the electronics industry, ESD trays are essential for packaging sensitive components such as circuit boards and semiconductors. These trays are designed to dissipate static electricity, protecting the components from damage during shipping and storage. For international buyers, sourcing ESD trays involves ensuring compliance with strict ESD standards and selecting high-quality materials that maintain their protective properties. Buyers should also consider the tray’s design and compatibility with existing packaging systems to optimize logistics.

What Role Do Thermoformed Trays Play in the Medical Industry?

Medical shipping trays are crucial for the safe transport of delicate instruments, devices, and pharmaceuticals. These trays are often custom-designed to fit specific products, ensuring they are securely held in place during transit. International buyers must prioritize sourcing trays made from FDA-approved materials that can withstand sterilization processes. Additionally, understanding the regulatory requirements in their region is vital to ensure compliance and safety in medical packaging.

How Are Thermoformed Trays Beneficial in the Automotive Sector?

In the automotive industry, custom parts trays facilitate efficient assembly line processes by organizing components and reducing handling errors. These trays can be tailored to fit unique parts, enhancing productivity and minimizing the risk of damage. For B2B buyers, it is important to consider the design and material specifications that align with their production needs, including stackability and durability during transportation. Sourcing from manufacturers with experience in automotive applications can ensure high-quality solutions.

Illustrative image related to thermoformed trays

Why Are Food-Grade Thermoformed Trays Important in the Food & Beverage Sector?

Food-grade thermoformed trays are critical for maintaining food safety and quality during packaging and distribution. These trays are designed to meet stringent food safety regulations, ensuring that they do not contaminate food products. Buyers in this sector should verify that the materials used are compliant with local and international food safety standards. Additionally, sourcing trays that enhance shelf life through proper sealing and ventilation can provide a competitive advantage in the market.

How Do Aerospace Applications Benefit from Custom Thermoformed Trays?

In the aerospace sector, custom trays are designed to securely transport high-value components, such as avionics and engine parts. The lightweight yet durable nature of thermoformed trays makes them ideal for reducing shipping costs while ensuring product safety. International buyers should focus on sourcing trays that meet aerospace industry standards for quality and performance. Customization options, including specific cavity shapes and stacking features, are also critical to accommodate the unique requirements of aerospace components.

3 Common User Pain Points for ‘thermoformed trays’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face challenges when sourcing thermoformed trays due to inconsistent quality among different suppliers. This inconsistency can lead to product damage during shipping, increased return rates, and ultimately a negative impact on brand reputation. For instance, a buyer may receive trays that do not meet the required specifications, either being too fragile or lacking the necessary dimensions for their components. This variability can cause delays in production and a lack of trust in the supply chain.

The Solution: To mitigate quality issues, buyers should prioritize suppliers with a proven track record and industry certifications. Engaging in direct communication regarding specific requirements and expected standards is crucial. Conducting a thorough supplier audit and requesting samples before placing bulk orders can help ensure that the trays meet the desired specifications. Additionally, consider establishing a quality assurance protocol, where trays are inspected upon arrival, allowing for immediate feedback to the supplier if discrepancies arise. This proactive approach not only safeguards the product but also fosters a stronger partnership with the supplier.

Scenario 2: Lack of Customization Options

The Problem: Many businesses find that standard thermoformed trays do not adequately meet their unique packaging needs, leading to inefficiencies in storage and transportation. For example, a company specializing in delicate electronic components may struggle to find trays that provide the necessary protection and fit for their specific products. This lack of tailored solutions can result in increased costs, as companies might resort to using additional materials to compensate for inadequate protection.

The Solution: Buyers should actively seek suppliers that offer customization options for thermoformed trays. This can include varying dimensions, material choices, and design features that cater to specific industry requirements. Engaging with a supplier that provides a collaborative design process can lead to more effective solutions. Buyers should articulate their needs clearly, possibly even providing prototypes or sketches to ensure that the final product aligns with their expectations. Utilizing advanced manufacturing techniques such as CNC machining can also enhance the precision of customized trays, ensuring a perfect fit for sensitive items.

Scenario 3: Inefficient Logistics and High Shipping Costs

The Problem: When sourcing thermoformed trays, B2B buyers often encounter logistical challenges, particularly concerning shipping costs and delays. Thermoformed trays are typically lightweight, yet their dimensions can lead to inefficient packing and increased freight charges. For companies operating in regions with limited shipping options, these logistical inefficiencies can significantly escalate overall costs and delay product launches.

The Solution: To address shipping and logistical issues, buyers should collaborate closely with suppliers who understand the importance of efficient packaging and transportation. It’s advisable to explore suppliers that offer solutions like stackable or nestable tray designs, which optimize shipping space and reduce freight costs. Additionally, buyers can consider consolidating orders to maximize shipping efficiency and take advantage of bulk pricing. Establishing a reliable logistics partnership can also streamline the shipping process, ensuring that products are delivered on time and at a lower cost. Finally, utilizing local suppliers can reduce shipping distances and associated costs, fostering a more sustainable supply chain.

Strategic Material Selection Guide for thermoformed trays

What Are the Key Materials Used in Thermoformed Trays?

When selecting materials for thermoformed trays, B2B buyers must consider factors such as durability, cost, and specific application requirements. The most common materials include Polyvinyl Chloride (PVC), Polyethylene Terephthalate Glycol (PETG), High-Impact Polystyrene (HIPS), and Polypropylene (PP). Each material has distinct properties and suitability for various applications, making it crucial for buyers to understand their advantages and limitations.

How Does Polyvinyl Chloride (PVC) Perform in Thermoformed Trays?

PVC is a widely used material for thermoformed trays due to its versatility and cost-effectiveness. Key properties include good chemical resistance and moderate temperature tolerance, typically ranging from -10°C to 60°C. PVC trays are durable and can withstand rough handling, making them suitable for shipping and storage applications.

Pros: PVC is relatively inexpensive and easy to thermoform, allowing for rapid production. Its durability makes it ideal for various industries, including electronics and medical applications.

Cons: However, PVC has limitations in high-temperature applications and can be less environmentally friendly compared to other materials. Additionally, it may not be suitable for food-grade applications unless specifically treated.

Impact on Application: Buyers in regions with stringent regulations, such as Germany, should ensure that PVC trays meet local compliance standards, including those set by DIN and EU regulations.

What Benefits Does Polyethylene Terephthalate Glycol (PETG) Offer?

PETG is another popular choice for thermoformed trays, known for its excellent clarity and toughness. It has a higher temperature tolerance than PVC, typically up to 70°C, and exhibits good chemical resistance.

Illustrative image related to thermoformed trays

Pros: PETG is more environmentally friendly than PVC, being recyclable. Its clarity makes it ideal for applications where visibility of the product is essential, such as in retail packaging.

Cons: The primary drawback is its higher cost compared to PVC. Additionally, while PETG is durable, it can be more prone to scratching.

Impact on Application: For buyers in emerging markets like Nigeria or South America, the recyclability of PETG may align with growing sustainability initiatives, making it a favorable option.

Why Choose High-Impact Polystyrene (HIPS) for Thermoformed Trays?

HIPS is known for its impact resistance and ease of fabrication. It typically performs well within a temperature range of -20°C to 70°C, making it suitable for various applications, including food packaging and electronic components.

Pros: HIPS is lightweight and offers good dimensional stability. Its cost-effectiveness makes it a popular choice for bulk production.

Cons: However, HIPS may not provide the same level of chemical resistance as PVC or PETG, which can limit its use in certain environments.

Impact on Application: For international buyers, HIPS trays can be an economical option for non-sensitive applications, but they should verify compatibility with specific media, especially in industries like pharmaceuticals.

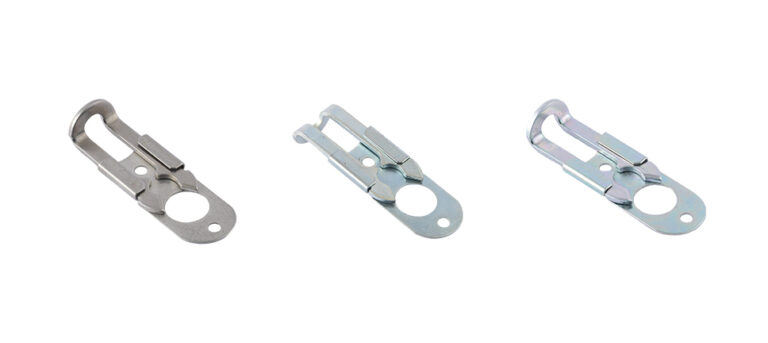

What Role Does Polypropylene (PP) Play in Thermoformed Trays?

Polypropylene is a versatile material known for its excellent chemical resistance and high melting point, typically around 100°C. It is often used in applications requiring sterility, such as medical trays.

Pros: PP is lightweight, durable, and resistant to moisture, making it ideal for various applications. It is also recyclable, aligning with sustainability goals.

Illustrative image related to thermoformed trays

Cons: The main limitation is its higher cost compared to HIPS and PVC. Additionally, it can be more challenging to thermoform due to its rigidity.

Impact on Application: Buyers in the Middle East, where high-temperature resistance is often required, may find PP trays particularly beneficial for specific applications.

Summary of Material Selection for Thermoformed Trays

| Material | Typical Use Case for thermoformed trays | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General packaging, electronics | Cost-effective and durable | Limited high-temperature use | Low |

| PETG | Retail packaging, medical applications | Clarity and recyclability | Higher cost, prone to scratching | Medium |

| HIPS | Food packaging, electronic components | Lightweight and stable | Limited chemical resistance | Low |

| PP | Medical trays, high-temperature applications | Chemical resistance and recyclability | Higher cost, challenging to thermoform | High |

Understanding the properties, advantages, and limitations of these materials will enable B2B buyers to make informed decisions that align with their operational needs and compliance requirements in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for thermoformed trays

What Are the Main Stages of Manufacturing Thermoformed Trays?

The manufacturing process for thermoformed trays involves several key stages, each critical for producing a high-quality product. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate plastic materials, commonly using PVC, PETG, or HIPS. The chosen material is then fed into a sheet feeder, where it is cut into specified dimensions suitable for the desired tray size. Quality control measures at this stage ensure that the materials meet necessary specifications, including thickness and clarity.

-

Forming: During this stage, the plastic sheets are heated until they become pliable. This is typically achieved using a heated oven that maintains precise temperature control. Once the material reaches the required temperature, it is transferred to a mold, where vacuum forming or pressure forming techniques are employed. Vacuum forming is the most common method, where air is removed from the mold to create a tight fit, ensuring that the tray takes on the desired shape accurately.

-

Assembly: After forming, trays are often assembled with additional components, such as lids or inserts. This step may involve welding or adhesive bonding, depending on the design and requirements. For custom trays, this stage allows for the inclusion of features like finger grooves, stackable designs, or numbered cavities for ease of use.

-

Finishing: The final stage includes trimming excess material, polishing edges, and applying any necessary coatings or treatments to enhance functionality, such as anti-static properties for electronics applications. This stage may also involve printing labels or branding directly onto the trays, which is crucial for product identification and marketing.

What Quality Control Measures Are Essential in Thermoformed Tray Production?

Quality assurance is vital in the production of thermoformed trays to meet both international standards and specific industry requirements. Manufacturers typically adhere to several recognized quality control protocols.

-

International Standards: Many manufacturers follow ISO 9001, which emphasizes a process-based approach to quality management. Compliance with this standard signifies that a company consistently meets customer and regulatory requirements, enhancing trust among international B2B buyers.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be required. For example, medical-grade trays might need to comply with the FDA regulations or ISO 13485 for medical devices. Similarly, trays intended for food use may require adherence to food safety standards like FSSC 22000.

-

Quality Control Checkpoints: Quality control is performed at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor the forming process and ensure that production remains within specified tolerances.

– Final Quality Control (FQC): After production, finished trays undergo a thorough inspection to check for defects, dimensions, and functionality before they are packaged for shipment. -

Common Testing Methods: Various testing methods may be employed, including tensile strength tests, impact resistance tests, and visual inspections for surface defects. These tests help ensure the durability and reliability of the trays, which is particularly important in sectors like electronics and medical devices.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, should consider several strategies to verify supplier quality control.

-

Audits and Inspections: Conducting supplier audits is an effective way to assess the quality control measures in place. Buyers can request to visit manufacturing facilities to evaluate processes, equipment, and employee training practices firsthand. This transparency helps establish trust and ensures that suppliers are committed to maintaining high standards.

-

Quality Reports and Certifications: Suppliers should provide documentation of their quality management systems and certifications. These documents can include ISO certificates, quality assurance reports, and test results from third-party laboratories. Reviewing these documents allows buyers to gauge the reliability of the supplier’s quality control processes.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control practices. These inspectors can conduct random checks of production batches and verify compliance with specified standards, ensuring that the trays meet all necessary requirements before shipment.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must navigate specific quality control nuances when sourcing thermoformed trays from global suppliers. Understanding these nuances can significantly impact procurement success.

Illustrative image related to thermoformed trays

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers should familiarize themselves with the regulations applicable in their market, such as CE marking in Europe or FDA compliance in the United States. Ensuring that suppliers meet these requirements is critical for avoiding legal complications and ensuring product acceptance in the target market.

-

Cultural Considerations: Differences in business practices and communication styles can affect quality assurance processes. Buyers should cultivate strong relationships with suppliers and maintain open lines of communication to address any quality concerns proactively. This collaborative approach can enhance understanding and facilitate smoother operations.

-

Logistics and Shipping: Quality assurance doesn’t end at production; it extends to shipping and handling. Buyers should ensure that suppliers have adequate packaging solutions to protect trays during transit. Additionally, understanding the logistics involved in international shipping can help mitigate risks associated with delays or damage, further ensuring product quality upon arrival.

By understanding the manufacturing processes and quality assurance measures for thermoformed trays, B2B buyers can make informed decisions and establish reliable partnerships with suppliers, ultimately enhancing their operational efficiencies and product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermoformed trays’

Introduction

This sourcing guide aims to assist B2B buyers in effectively procuring thermoformed trays, which are essential for various applications, including electronics, medical packaging, and general manufacturing. Following this checklist will ensure that you make informed decisions, streamline your procurement process, and secure high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your thermoformed trays. This includes dimensions, material types (such as PVC, PETG, or Styrene), and any specific features like anti-static properties or stacking capabilities. Defining these specifications upfront helps in identifying suitable suppliers and ensures the trays will adequately protect your products.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers. Look for companies with a proven track record in manufacturing thermoformed trays and those that cater to your industry. Pay attention to customer reviews, case studies, and industry certifications, which can provide insight into the supplier’s reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Production Capabilities: Assess whether the supplier can meet your volume and customization needs.

– Quality Assurance Processes: Inquire about their quality control measures and certifications, such as ISO or food safety certifications.

Illustrative image related to thermoformed trays

Step 4: Request Samples

Always request samples of the thermoformed trays before making a bulk purchase. This allows you to evaluate the quality, durability, and suitability of the trays for your products. Look for:

– Material Quality: Ensure the material meets your requirements for strength and protection.

– Design Accuracy: Check if the design aligns with your specifications and fits your products properly.

Step 5: Review Pricing and Terms

Compare pricing structures among different suppliers while considering bulk discounts and payment terms. Transparency in pricing is essential to avoid hidden costs. Additionally, confirm:

– Minimum Order Quantities: Understand the supplier’s minimum order requirements to ensure they align with your budget.

– Delivery Times: Assess lead times for production and shipping to avoid delays in your supply chain.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications that guarantee product quality and safety. This is particularly important in industries like medical and food packaging. Check for:

– Compliance with Industry Standards: Certifications that validate adherence to safety and quality regulations.

– Sustainability Practices: If relevant, inquire about the supplier’s commitment to environmentally friendly practices.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish clear lines of communication. Effective communication will facilitate quick resolution of any issues and ensure that both parties are aligned throughout the procurement process. Consider setting up regular check-ins to discuss orders, feedback, and any necessary adjustments.

Illustrative image related to thermoformed trays

By following this comprehensive checklist, B2B buyers can ensure they select the right thermoformed trays that meet their operational needs, enhance product safety, and contribute to overall efficiency.

Comprehensive Cost and Pricing Analysis for thermoformed trays Sourcing

When sourcing thermoformed trays, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis explores the various cost components involved, key price influencers, and practical tips for negotiating favorable terms.

What Are the Key Cost Components in Thermoformed Trays?

The total cost of thermoformed trays comprises several essential components:

-

Materials: The choice of materials significantly impacts cost. Common materials include PVC, PETG, and HIPS. Each material has different price points based on availability, quality, and specific applications (e.g., food-safe or ESD-certified).

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can affect the quality and consistency of the product.

-

Manufacturing Overhead: This includes costs related to machinery, utilities, and facility maintenance. Efficient manufacturing processes can help minimize overhead, contributing to lower pricing.

-

Tooling: For custom designs, tooling costs can be significant. This includes the creation of molds and dies, which can range from a few hundred to several thousand dollars depending on complexity. Buyers should consider these costs when evaluating custom tray solutions.

-

Quality Control (QC): Implementing quality assurance measures adds to the cost but is essential for maintaining product integrity, especially in industries like medical and electronics. Certification for quality standards can also influence pricing.

-

Logistics: Shipping and handling costs depend on the supplier’s location and the buyer’s destination. International shipping can introduce additional fees such as customs duties and taxes, which should be factored into the total cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market demand, competition, and the supplier’s business model.

How Do Volume and Customization Affect Pricing?

Volume and customization are critical factors in determining the price of thermoformed trays.

-

Volume/MOQ: Suppliers often offer tiered pricing based on the minimum order quantity (MOQ). Larger orders typically attract discounts, making it more cost-effective for buyers to purchase in bulk.

-

Specifications/Customization: Custom trays tailored to specific requirements (e.g., dimensions, cavity shapes) will incur additional costs due to tooling and design efforts. Buyers should balance the need for customization with budget constraints.

What Quality and Supplier Factors Should Buyers Consider?

Quality certifications (such as ISO or food safety certifications) can influence pricing, as suppliers with certifications often charge more due to their commitment to quality assurance. Additionally, the reputation and reliability of the supplier can affect pricing; established suppliers with a proven track record may command higher prices but offer peace of mind regarding product quality and delivery reliability.

What Are Effective Negotiation Tips for International Buyers?

-

Understand Total Cost of Ownership: Evaluate not just the purchase price but the total cost of ownership, including logistics, maintenance, and potential quality issues. This holistic view helps in making informed purchasing decisions.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs for better pricing. Building a long-term relationship with suppliers can also lead to improved terms over time.

-

Be Clear on Specifications: Clearly define product specifications and quality requirements upfront to avoid misunderstandings that can lead to additional costs later.

-

Negotiate Incoterms: Understand the implications of different Incoterms (e.g., FOB, CIF) on shipping costs and liability. Negotiating favorable terms can significantly impact overall costs.

-

Research Supplier Backgrounds: Conduct due diligence on suppliers to assess their reliability and quality history. This can prevent costly mistakes and ensure that the supplier can meet your needs.

Conclusion

In summary, sourcing thermoformed trays involves a complex interplay of costs and pricing factors. International buyers from regions such as Africa, South America, the Middle East, and Europe should conduct thorough analyses of the cost structure, leverage negotiation strategies, and consider the total cost of ownership to ensure they secure the best value for their investments. Always remember that prices can fluctuate based on market conditions, so maintaining flexibility and open communication with suppliers is key to successful procurement.

Alternatives Analysis: Comparing thermoformed trays With Other Solutions

Exploring Alternatives to Thermoformed Trays for Packaging Solutions

In the competitive landscape of packaging solutions, businesses must consider various options to find the best fit for their specific needs. While thermoformed trays offer numerous advantages, exploring alternatives can provide insights into different methods and technologies that may better align with certain operational requirements. Below, we compare thermoformed trays with two viable alternatives: molded pulp trays and injection-molded containers.

| Comparison Aspect | Thermoformed Trays | Molded Pulp Trays | Injection-Molded Containers |

|---|---|---|---|

| Performance | High durability and customizability | Eco-friendly, but less durable | Excellent durability and precision |

| Cost | Moderate initial investment | Generally low-cost | Higher setup costs, but cost-effective at scale |

| Ease of Implementation | Quick production with standard molds | Requires specific pulp production setup | Complex tooling and setup for large runs |

| Maintenance | Low maintenance | Biodegradable, minimal upkeep | Low maintenance, but depends on material |

| Best Use Case | Electronics, medical, and delicate parts | Food packaging and sustainable products | High-volume manufacturing and bulk storage |

What Are the Pros and Cons of Molded Pulp Trays?

Molded pulp trays are made from recycled paper products and are widely recognized for their eco-friendliness. Their biodegradable nature makes them a favorable choice for companies looking to reduce their environmental impact. However, while they are generally lower in cost and offer decent protection for lightweight items, their durability is inferior compared to thermoformed trays. This makes them less suitable for heavy or fragile products, particularly in industries like electronics or medical device manufacturing.

How Do Injection-Molded Containers Compare?

Injection-molded containers are manufactured through a process that allows for high precision and strength. They can be produced in large quantities, making them cost-effective for mass production. The durability of injection-molded containers is a significant advantage, particularly for industries that require robust packaging solutions. However, the initial setup costs can be substantial, and the complexity of the tooling process may lead to longer lead times for custom designs. This option is best suited for high-volume applications where product consistency is critical.

Making the Right Choice for Your Business Needs

When considering the best packaging solution, B2B buyers should assess their specific requirements, including product type, shipping conditions, and environmental goals. Thermoformed trays excel in customization and protection for sensitive items, making them ideal for electronics and medical applications. Conversely, molded pulp trays offer a sustainable option for less fragile products, while injection-molded containers provide robust solutions for high-volume manufacturing. By understanding the strengths and limitations of each alternative, businesses can make informed decisions that align with their operational needs and market demands.

Essential Technical Properties and Trade Terminology for thermoformed trays

What Are the Key Technical Properties of Thermoformed Trays?

When considering thermoformed trays for your business needs, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications that every B2B buyer should be aware of:

1. Material Grade

Thermoformed trays are commonly made from materials such as Polyvinyl Chloride (PVC), Polyethylene Terephthalate Glycol (PETG), and High Impact Polystyrene (HIPS). Each material has unique properties that affect durability, chemical resistance, and temperature tolerance. For example, PETG is known for its clarity and strength, making it ideal for medical applications, while PVC is often chosen for its cost-effectiveness in general manufacturing. Selecting the right material grade ensures that the trays meet the specific requirements of your products.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In the context of thermoformed trays, tight tolerances are critical for applications where precision is paramount, such as in the electronics or medical sectors. If a tray is too large or small, it may not adequately protect the components it holds, leading to damage during shipping or handling. Understanding tolerance levels allows buyers to ensure that the trays will fit perfectly within their packaging systems.

3. Gauge Thickness

The gauge thickness of a thermoformed tray affects its strength and rigidity. Thicker gauges provide greater durability and resistance to impact, making them suitable for heavy or delicate items. Conversely, thinner gauges may be more cost-effective for lighter products. Buyers should consider the weight and fragility of the items being packaged to determine the appropriate gauge thickness.

Illustrative image related to thermoformed trays

4. Stackability

Stackability is an important design feature that allows trays to be stacked securely without collapsing. This property is crucial for optimizing storage space and reducing shipping costs. Trays designed with stacking capabilities can help streamline logistics, making it easier to manage inventory and minimize waste.

5. Customization Options

Many manufacturers offer customization options for thermoformed trays, including variations in design, size, and color. Custom trays can be tailored to fit specific products or branding requirements, enhancing the overall presentation and protection. This flexibility is particularly valuable for businesses looking to differentiate their products in competitive markets.

What Are Common Trade Terms Used in Thermoformed Trays?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms that buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of thermoformed trays, working with an OEM can ensure that the trays are designed to fit specific machinery or equipment, enhancing compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for buyers as it can impact inventory management and cash flow. Understanding the MOQ helps businesses plan their purchases effectively, ensuring they meet production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. It is a critical step in the procurement process, allowing buyers to compare costs and make informed decisions based on pricing, quality, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit, thereby minimizing misunderstandings.

Illustrative image related to thermoformed trays

5. ESD (Electrostatic Discharge)

ESD refers to the sudden flow of electricity between two electrically charged objects. In the context of thermoformed trays, ESD trays are designed to protect sensitive electronic components from damage caused by static electricity. Understanding this term is crucial for companies in the electronics industry to ensure product safety.

By grasping these technical properties and trade terms, international buyers can make better decisions when sourcing thermoformed trays, ultimately improving their supply chain efficiency and product protection.

Navigating Market Dynamics and Sourcing Trends in the thermoformed trays Sector

What Are the Current Market Dynamics and Key Trends in the Thermoformed Trays Sector?

The global market for thermoformed trays is witnessing significant growth, driven by various factors including the rising demand for packaging solutions across diverse sectors such as electronics, medical, and food industries. Key trends include the increasing adoption of automation in manufacturing processes, which enhances efficiency and reduces costs. Additionally, the integration of advanced technologies such as 3D printing and AI in product design is enabling manufacturers to create custom solutions that meet specific client needs, making sourcing more flexible and responsive.

Emerging markets in Africa, South America, and the Middle East are becoming focal points for international buyers. Countries like Nigeria and Brazil are experiencing a surge in manufacturing activities, creating a demand for durable and cost-effective packaging solutions. In Europe, particularly in Germany, sustainability is becoming a critical factor, influencing purchasing decisions as companies seek eco-friendly materials and processes. As a result, suppliers that can offer both innovation and sustainability are likely to gain a competitive edge.

How Is Sustainability and Ethical Sourcing Impacting the Thermoformed Trays Market?

Sustainability is at the forefront of the thermoformed trays market, with an increasing emphasis on reducing environmental impact. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability practices. This involves the use of recyclable materials, such as PET and HIPS, which not only reduce waste but also appeal to eco-conscious consumers.

Illustrative image related to thermoformed trays

Certifications such as the Food Safety System Certification and other environmental standards are becoming essential for suppliers aiming to establish credibility in the market. Companies that can provide transparent supply chains and demonstrate adherence to green practices are more likely to foster trust with international buyers. Furthermore, incorporating biodegradable materials and adopting energy-efficient manufacturing processes are becoming key differentiators in the sourcing landscape. This trend not only aligns with global sustainability goals but also addresses regulatory pressures in various regions.

What Is the Historical Context of Thermoformed Trays in B2B Sourcing?

The evolution of thermoformed trays can be traced back to the mid-20th century when advancements in plastic manufacturing processes began to emerge. Initially, the focus was on utility and cost-efficiency, with manufacturers primarily catering to the packaging needs of the food and beverage industries. However, as industries evolved, so did the applications for thermoformed trays, expanding into sectors such as electronics, medical devices, and automotive components.

Over the years, the technology behind thermoforming has advanced, allowing for greater customization and design flexibility. Today, manufacturers can produce trays that not only protect products during transit but also enhance branding and consumer appeal. This historical context underscores the importance of innovation and adaptability in meeting the diverse needs of international B2B buyers, as they navigate a marketplace that is continuously evolving.

Frequently Asked Questions (FAQs) for B2B Buyers of thermoformed trays

-

How do I select the right thermoformed trays for my products?

Choosing the right thermoformed trays involves evaluating your product’s size, shape, and weight, as well as the specific protection requirements during shipping and storage. Consider the material of the tray—common options include PVC, PETG, and HIPS—based on the application (e.g., medical, electronic). Additionally, assess whether you need custom designs for complex shapes or standard stock trays for simpler items. Consulting with suppliers can provide insights into the best options tailored to your needs. -

What is the best material for thermoformed trays used in medical applications?

For medical applications, the best materials for thermoformed trays are typically high-quality plastics such as PETG or HIPS, which offer excellent clarity, durability, and chemical resistance. These materials are often chosen for their compliance with health standards and ability to protect sensitive items. It’s essential to verify that the selected material meets relevant safety certifications and regulations in your target market, ensuring it is suitable for its intended use. -

What are the typical lead times for custom thermoformed trays?

Lead times for custom thermoformed trays can vary based on complexity and order volume. Generally, expect 2-4 weeks for prototyping and initial production, with additional time for larger orders or specific customizations. Factors influencing lead time include tooling setup, material availability, and production scheduling. Always discuss timelines with your supplier upfront to plan your inventory and logistics accordingly. -

How can I ensure the quality of thermoformed trays before making a large purchase?

To ensure quality, request samples from potential suppliers before committing to a large order. Evaluate the samples for durability, fit, and overall design. Additionally, inquire about the supplier’s quality assurance processes, including certifications and testing methods. Reviewing customer testimonials and case studies can also provide insights into the supplier’s reliability and product performance. -

What are the minimum order quantities (MOQs) for thermoformed trays?

Minimum order quantities for thermoformed trays vary by supplier and can depend on the complexity of the design and production capabilities. Typically, MOQs range from 100 to several thousand units. Discuss your specific needs with suppliers to see if they can accommodate lower quantities, especially for custom designs, or if they offer bulk discounts for larger orders. -

What payment terms should I expect when sourcing thermoformed trays internationally?

Payment terms for international orders can vary widely, but common practices include upfront payments, deposits, or net payment terms (e.g., net 30 or net 60 days). It’s advisable to negotiate terms that suit your cash flow while ensuring supplier confidence. Consider using secure payment methods such as letters of credit or escrow services to mitigate risks associated with international transactions. -

How do I vet potential suppliers of thermoformed trays?

To vet suppliers, start by checking their industry experience, client references, and certifications. Request information about their manufacturing processes, quality control measures, and material sourcing practices. Conducting site visits, if feasible, or using third-party audits can provide additional assurance of their capabilities and reliability. Engaging in discussions about their logistics and support services will also help gauge their commitment to customer satisfaction. -

What logistics considerations should I keep in mind when importing thermoformed trays?

When importing thermoformed trays, consider shipping methods, customs regulations, and potential tariffs or taxes that may apply to your products. Work with logistics partners experienced in international trade to navigate these complexities. Ensure that your supplier can provide necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance. Planning for potential delays in transit can also help manage your supply chain effectively.

Top 6 Thermoformed Trays Manufacturers & Suppliers List

1. ECP Plastic Trays – Thermoformed Plastic Solutions

Domain: ecpplastictrays.com

Registered: 2012 (13 years)

Introduction: Thermoformed Plastic Trays including Shipping Trays, ESD Trays, Stock Plastic Bins, Plastic Drip Trays, Foam Packaging, Reusable Plastic Trays, Insert Trays, Plastic Hinged Boxes, Molded Pulp Egg Trays, and Custom Trays. Common applications are in electronics, medical, and general manufacturing. Materials used include PVC, PETG, and Styrene. The trays are designed to protect components during tran…

2. Ready-Made – Thermoformed Plastic Trays

Domain: ready-made.com

Registered: 1998 (27 years)

Introduction: Thermoformed Plastic Trays for Packaging & Storage; Available shapes: Rectangle, Square, Round; Pocket Length/Diameter options: 0.36 – 1, 1.03 – 2, 2.05 – 3, 3.1 – 4, 4.1 – 7, 8 – 9.7, 12 – 18.5; Over 150 stock trays and lids ready to ship; Free samples available; Custom trays can be designed in any color with a maximum depth of 2 inches; Domestic and international shipping; Volume discounts for b…

3. Rimco Plastics – Custom Thermoformed Trays and Lids

Domain: rimcoplastics.com

Registered: 2004 (21 years)

Introduction: Rimco Plastics offers custom plastic thermoformed trays and lids in various shapes including rectangle, round, oblong, oval, and square. Their trays can feature special attributes such as finger grooves for easy handling, stackable designs, and numbered cavities for organization. The materials used for production include PVC (Polyvinyl chloride), PETG (Polyethylene terephthalate glycol), and HIPS …

4. Andex – Thermoform Packaging Trays

Domain: andex.net

Registered: 1998 (27 years)

Introduction: Thermoform Packaging Trays available in various shapes, sizes, and configurations including compartments and dividers. Custom thermoformed solutions for industrial equipment, machinery, and electronic enclosures. Material options include clear and colored thermoform trays made from RPET, PETG, and PVC. Antistatic (ESD) options available. Custom designs can be single or multi-cavity with contoured …

5. VisiPak – Thermoformed Plastic Shipping Trays

Domain: visipak.com

Registered: 2000 (25 years)

Introduction: Thermoformed plastic shipping trays are designed for packaging various products, providing superior protection and simplifying the packing process. They are custom designed and manufactured using materials such as PVC, PETG, and PET. Features include a reciprocal snap-perimeter design for excellent sealing, reducing dust and debris exposure. The trays allow for greater packing density, reducing th…

6. OBGYN Care – Women’s Health Services

Domain: obgyncare.com

Registered: 2003 (22 years)

Introduction: OBGYN Care offers a range of women’s health services including obstetrics, gynecology, lactation support, and ultrasound. The practice specializes in non-invasive solutions for pain and bleeding, utilizing the minimally invasive DaVinci robotic system for procedures such as routine surgeries, hysterectomies, and vaginal vault suspension. They deliver babies and provide care at Carle BroMenn Medica…

Strategic Sourcing Conclusion and Outlook for thermoformed trays

In the rapidly evolving landscape of packaging solutions, strategic sourcing of thermoformed trays stands out as a pivotal factor for businesses aiming to enhance efficiency and reduce costs. By leveraging durable materials like PVC, PETG, and HIPS, these trays provide unparalleled protection for components across diverse industries, including medical, electronics, and manufacturing. The ability to customize tray designs ensures that companies can meet specific operational needs, from shipping delicate items to optimizing storage solutions.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing thermoformed trays can lead to significant competitive advantages. Engaging with reliable suppliers who offer rapid production capabilities, bulk discounts, and transparent pricing can streamline logistics and improve supply chain resilience.

As we look toward the future, the demand for innovative and sustainable packaging solutions will continue to rise. It is imperative for businesses to stay ahead of trends and invest in high-quality thermoformed trays. Connect with trusted manufacturers to explore how tailored packaging solutions can transform your operations and drive growth in your market. The time to act is now—ensure your business is equipped with the best packaging strategies to thrive in an increasingly competitive environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to thermoformed trays