Choosing Your Motor Electric Dc: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for motor electric dc

In today’s rapidly evolving industrial landscape, sourcing reliable and efficient motor electric DC solutions presents a significant challenge for international B2B buyers. As businesses increasingly prioritize performance and energy efficiency, understanding the diverse range of DC motors available—from permanent magnet options to gearmotors—becomes crucial. This comprehensive guide addresses key considerations such as application suitability, supplier vetting processes, and cost analysis, ensuring that decision-makers can navigate the complexities of the global market with confidence.

The guide delves into various types of DC motors, highlighting their applications across sectors such as agriculture, warehouse automation, and renewable energy. Buyers will find insights into selecting the right motor for specific needs, including high starting torque requirements and adjustable speed capabilities. Furthermore, we provide practical tips on evaluating suppliers, ensuring that B2B buyers from regions like Africa, South America, the Middle East, and Europe—such as Brazil and Germany—can make informed purchasing decisions that align with their operational goals.

By empowering buyers with detailed knowledge and actionable insights, this guide serves as a vital resource for those looking to enhance their procurement strategies in the competitive landscape of motor electric DC products. Whether you’re exploring low-voltage options for off-grid applications or high-performance motors for industrial use, this guide equips you to make choices that drive efficiency and reliability in your operations.

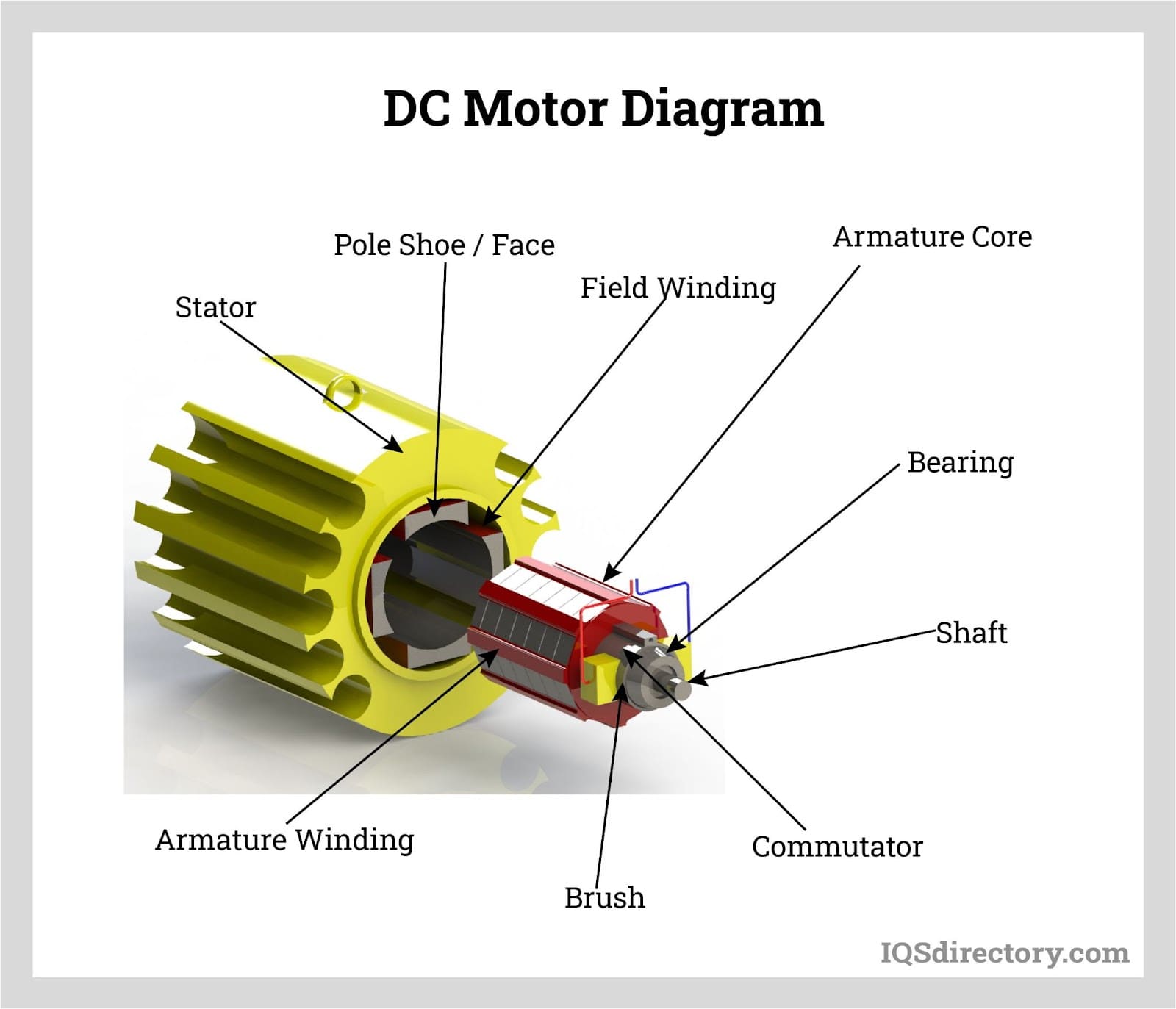

Understanding motor electric dc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnet DC Motors | High efficiency, compact size, and excellent torque performance | Robotics, medical devices, agricultural equipment | Pros: High efficiency, low maintenance. Cons: Limited to lower power applications. |

| Series DC Motors | High starting torque, simple construction | Elevators, cranes, and other heavy machinery | Pros: High torque at low speeds. Cons: Less efficient at higher speeds. |

| Shunt DC Motors | Adjustable speed control, stable operation | Conveyor systems, fans, and pumps | Pros: Good speed regulation. Cons: More complex and costly. |

| Brushless DC Motors | No brushes, high reliability, and longer lifespan | Electric vehicles, drones, and HVAC systems | Pros: High efficiency and low wear. Cons: Higher initial cost and complexity. |

| Gearmotors (DC) | Integrated gearbox for torque multiplication | Automation, robotics, and material handling | Pros: Space-saving and enhanced torque. Cons: Increased weight and potential backlash. |

What Are Permanent Magnet DC Motors and Their B2B Relevance?

Permanent Magnet DC (PMDC) motors are characterized by their compact design and high efficiency, making them ideal for applications requiring significant torque in a limited space. They are commonly used in robotics, medical devices, and agricultural machinery. When considering PMDC motors, buyers should evaluate their power requirements, efficiency ratings, and potential applications in battery-powered or solar environments. The low maintenance needs of PMDC motors can lead to reduced operational costs, making them a cost-effective choice for many businesses.

How Do Series DC Motors Operate and Where Are They Used?

Series DC motors are known for their robust construction and high starting torque, which makes them suitable for heavy-duty applications such as elevators and cranes. Their design allows for high torque at low speeds, but they are less efficient at higher speeds. B2B buyers should consider the specific torque requirements of their applications and weigh the benefits of simplicity against the potential for lower efficiency. While they are generally more affordable, their limitations in speed may affect their suitability for certain modern applications.

What Advantages Do Shunt DC Motors Offer for Businesses?

Shunt DC motors provide excellent speed regulation and are used in applications where adjustable speed is crucial, such as conveyor systems and fans. Their ability to maintain a stable operation under varying loads makes them a preferred choice in many industrial settings. However, the complexity and cost of shunt motors may deter some buyers. When purchasing, businesses should assess their need for precise speed control against the associated costs and maintenance requirements.

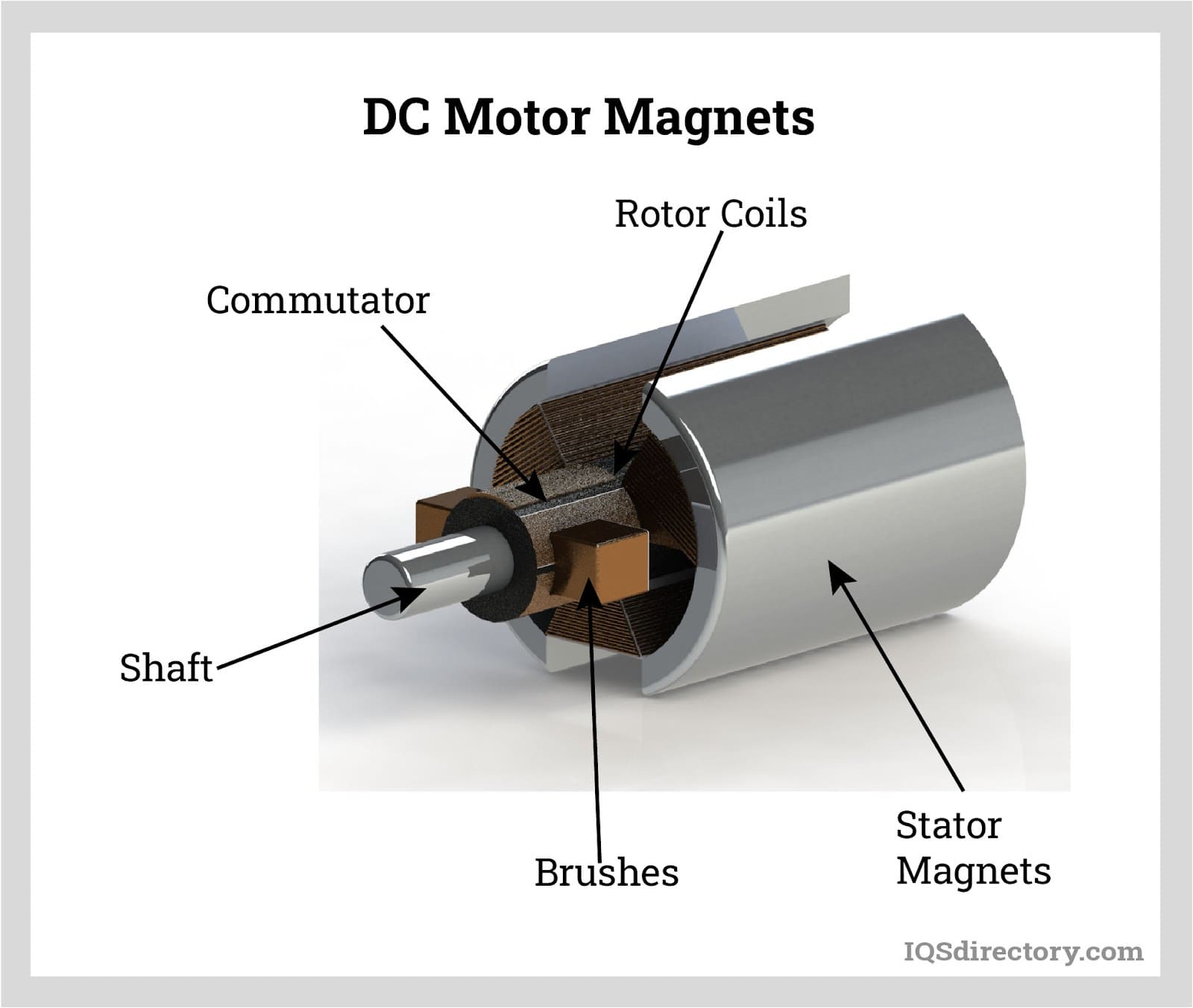

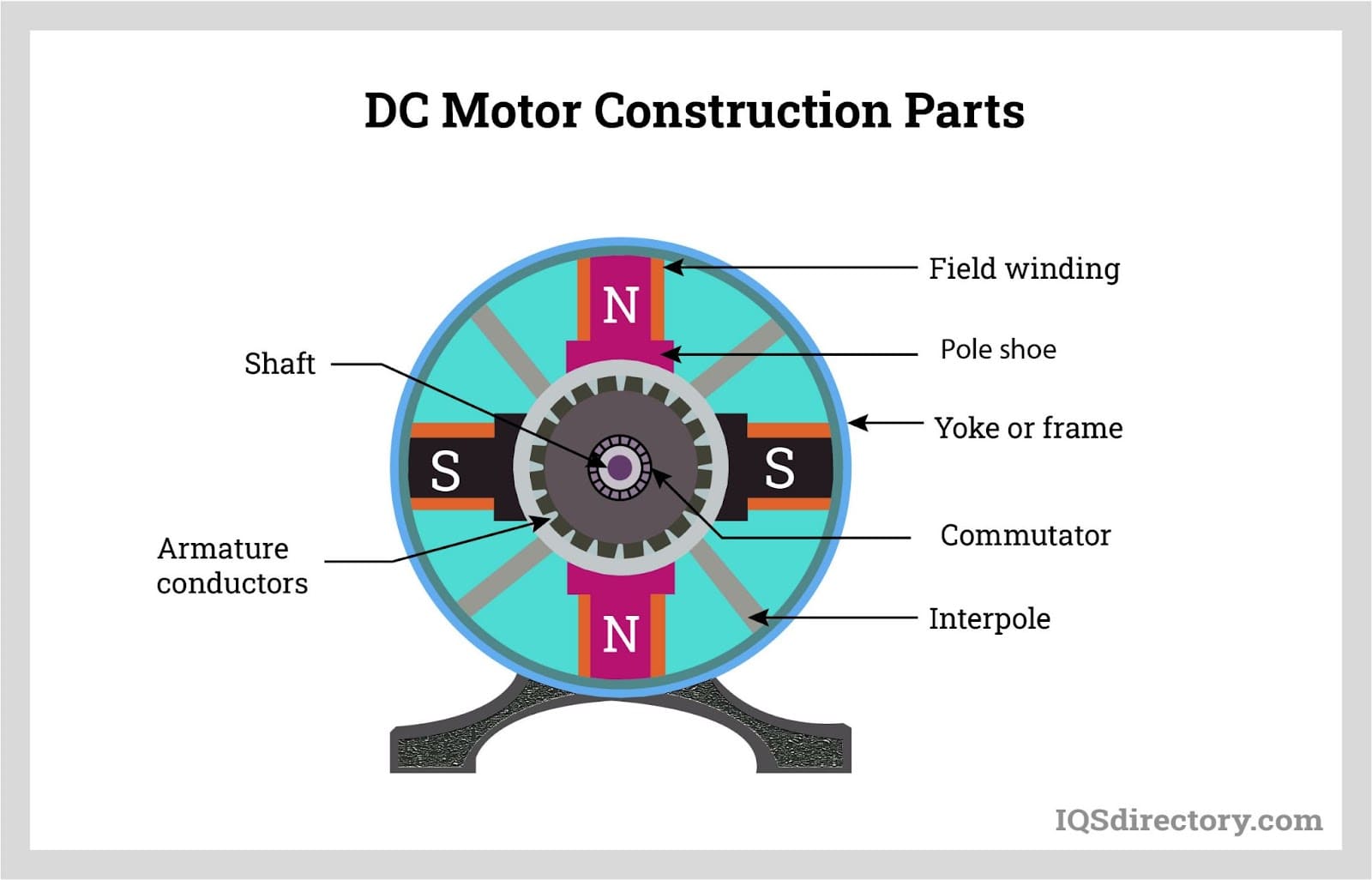

Illustrative image related to motor electric dc

Why Choose Brushless DC Motors for Your Operations?

Brushless DC motors are designed for high reliability and longer lifespans due to their lack of brushes, which minimizes wear and maintenance. They are commonly found in electric vehicles, drones, and HVAC systems. While the initial investment may be higher, the long-term savings from reduced maintenance and increased efficiency can justify the cost. Buyers should evaluate their operational requirements and consider the benefits of efficiency and longevity when selecting brushless DC motors for their applications.

How Do Gearmotors Enhance Performance in DC Motor Applications?

Gearmotors combine DC motors with integrated gearboxes to provide enhanced torque and efficiency, making them ideal for automation, robotics, and material handling applications. They save space and offer torque multiplication, which is crucial in many industrial processes. However, the added weight and potential for backlash may be drawbacks. Buyers should consider the specific torque and space requirements of their applications to determine if gearmotors are the right fit for their operational needs.

Key Industrial Applications of motor electric dc

| Industry/Sector | Specific Application of motor electric dc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated Irrigation Systems | Improved efficiency and reduced labor costs | Durability in harsh environments and low maintenance needs |

| Warehouse Automation | Automated Guided Vehicles (AGVs) | Enhanced productivity and operational efficiency | Compatibility with existing systems and power management |

| Healthcare | Portable Medical Devices | Reliability and precision in critical care | Compliance with medical standards and battery compatibility |

| Manufacturing | Conveyor Systems | Streamlined processes and reduced downtime | Customization options and speed control requirements |

| Renewable Energy | Solar-Powered Equipment | Sustainable operations and energy efficiency | Voltage specifications and integration with solar systems |

How Are DC Motors Used in Agriculture for Automated Irrigation Systems?

In agriculture, motor electric DC is crucial for automated irrigation systems, which enable precise water delivery to crops. By utilizing DC motors, these systems can operate efficiently, minimizing water waste and labor costs. For international buyers, especially in regions like Africa and South America, sourcing motors that can withstand harsh weather conditions and require minimal maintenance is essential. Additionally, low-voltage options are ideal for solar-powered setups, enhancing sustainability in farming practices.

What Role Do DC Motors Play in Warehouse Automation with Automated Guided Vehicles (AGVs)?

DC motors are integral to the operation of Automated Guided Vehicles (AGVs) in warehouses. These vehicles rely on precise speed control and high starting torque, provided by DC motors, to navigate and transport goods efficiently. For B2B buyers in Europe and the Middle East, ensuring that the motors can integrate seamlessly with existing warehouse management systems is vital. Additionally, sourcing motors that offer adjustable speed and high durability can significantly enhance operational productivity.

How Are DC Motors Essential for Portable Medical Devices in Healthcare?

In the healthcare sector, portable medical devices such as infusion pumps and portable ventilators utilize DC motors for their reliability and precision. These motors must meet stringent medical standards and provide consistent performance, particularly in critical care settings. International buyers should prioritize sourcing motors that are compatible with battery systems and ensure compliance with health regulations. This focus on quality can lead to improved patient outcomes and operational efficiency in healthcare facilities.

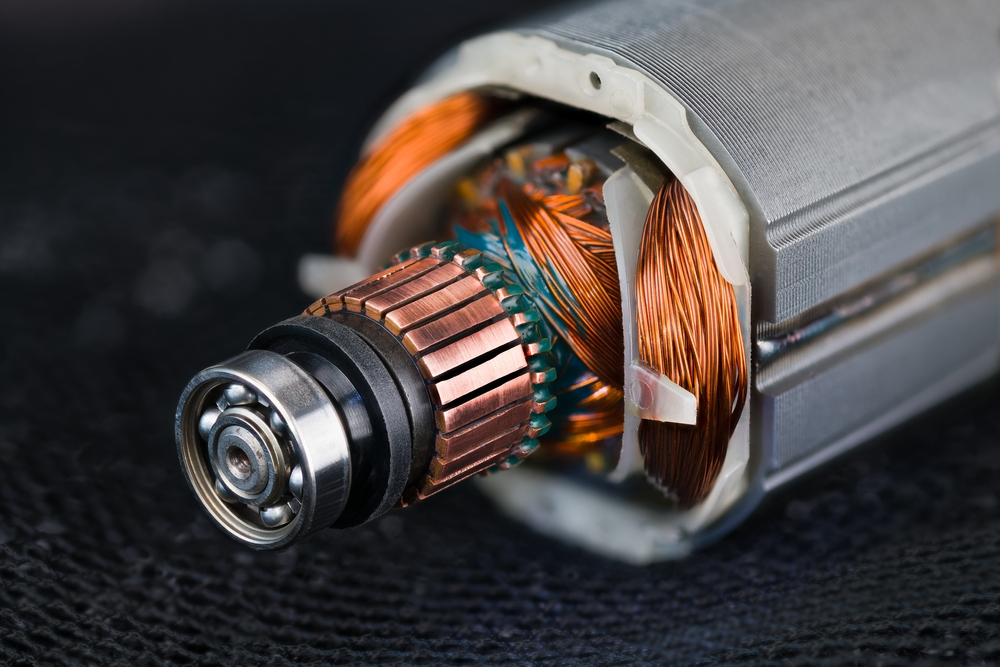

Illustrative image related to motor electric dc

What Benefits Do DC Motors Provide in Manufacturing Conveyor Systems?

DC motors are widely used in manufacturing conveyor systems, where they facilitate the movement of materials and products along production lines. The ability to customize speed and torque makes DC motors an attractive option for manufacturers looking to streamline processes and minimize downtime. Buyers should consider sourcing motors that offer robust performance and adaptability to various conveyor configurations. This ensures that manufacturing operations remain efficient and responsive to changing production demands.

How Do DC Motors Enhance Sustainability in Renewable Energy Applications?

In renewable energy, particularly in solar-powered equipment, motor electric DC plays a pivotal role. These motors enable efficient operation of devices like solar pumps and trackers, optimizing energy usage and supporting sustainable practices. For buyers in regions focusing on renewable energy, such as parts of Europe and Africa, it is crucial to source motors that align with specific voltage requirements and can operate effectively in off-grid conditions. This not only supports energy efficiency but also contributes to broader sustainability goals.

3 Common User Pain Points for ‘motor electric dc’ & Their Solutions

Scenario 1: Inconsistent Performance in Variable Load Applications

The Problem: Many B2B buyers face the challenge of sourcing DC motors that can handle variable load conditions without compromising performance. For instance, in agricultural applications, motors may need to adjust to different loads when powering equipment like harvesters or irrigation systems. If the motor isn’t capable of handling these fluctuations, it can lead to inefficiencies, increased wear and tear, and ultimately, equipment failure. This inconsistency not only affects productivity but also leads to higher maintenance costs and downtime.

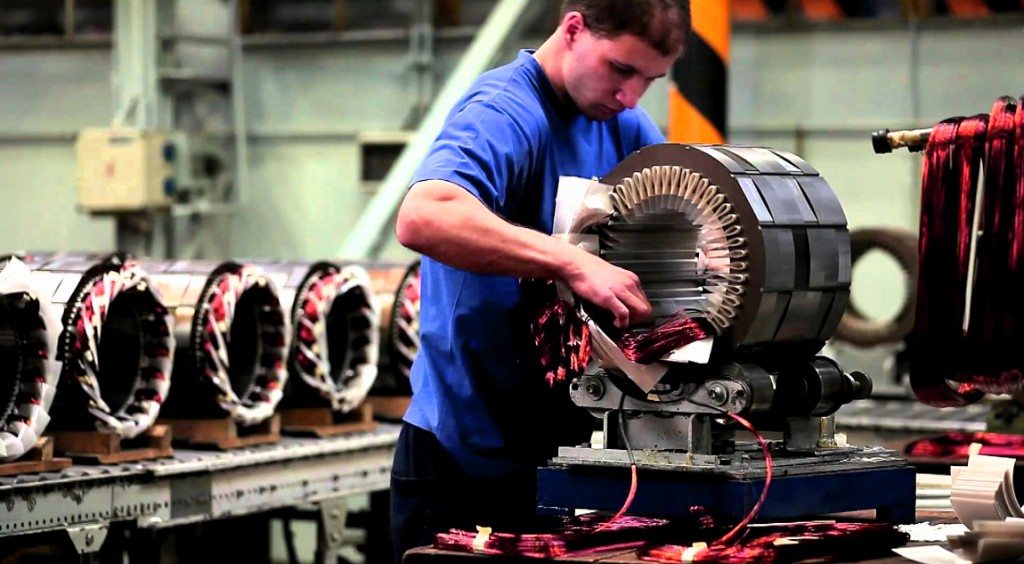

Illustrative image related to motor electric dc

The Solution: To ensure consistent performance in variable load applications, buyers should look for permanent magnet DC (PMDC) motors that feature adjustable speed controls. Selecting a motor with a broader torque range allows it to adapt effectively to changing loads. Additionally, it’s crucial to analyze the application requirements thoroughly, including load profiles and operational environments. Buyers should collaborate with suppliers to specify motors that offer features like high starting torque and continuous duty operation. This proactive approach will help mitigate performance issues and enhance overall system reliability.

Scenario 2: Difficulty in Sourcing Compatible Components

The Problem: Another common pain point for B2B buyers is the challenge of sourcing compatible components for DC motors, such as controllers and gearboxes. This issue often arises when companies attempt to retrofit older systems or integrate new technologies into existing operations. Incompatible components can lead to suboptimal performance, increased installation times, and higher costs due to the need for additional modifications or replacements.

The Solution: Buyers can overcome this challenge by adopting a systems approach when sourcing motor electric DC components. It’s essential to work with suppliers who provide comprehensive product lines, including motors, controllers, and gearboxes that are designed to work seamlessly together. Establishing clear specifications for voltage, torque, and speed requirements will help ensure compatibility. Furthermore, engaging in pre-purchase consultations with manufacturers can provide insights into the best configurations for specific applications. This strategy not only streamlines procurement but also minimizes risks associated with compatibility issues.

Illustrative image related to motor electric dc

Scenario 3: Managing Power Efficiency and Cost

The Problem: For international buyers, particularly in regions with fluctuating energy prices, managing power efficiency in DC motor applications is a pressing concern. Poorly chosen motors can lead to excessive energy consumption, resulting in inflated operational costs. This is particularly critical in applications like warehouse automation or transportation systems, where efficiency directly impacts the bottom line.

The Solution: To tackle this issue, buyers should prioritize sourcing high-efficiency DC motors that align with their specific operational needs. Focus on motors that feature low-voltage options, which are often more energy-efficient and suitable for battery or solar-powered applications. Additionally, consider implementing advanced control systems that optimize motor performance based on real-time data. For example, using pulse-width modulation (PWM) controllers can enhance energy efficiency by adjusting the motor speed according to load demands. Buyers should also conduct a cost-benefit analysis to evaluate the long-term savings associated with investing in high-efficiency motors versus cheaper, less efficient alternatives. This approach not only reduces energy costs but also contributes to a more sustainable operational model.

Strategic Material Selection Guide for motor electric dc

What Are the Key Materials Used in DC Motors and Their Properties?

When selecting materials for electric DC motors, several factors come into play, including performance characteristics, manufacturing complexity, and regional compliance standards. Here, we analyze four common materials used in the construction of DC motors: copper, aluminum, steel, and plastic composites.

How Does Copper Impact the Performance of DC Motors?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for windings in DC motors. Its high thermal conductivity allows for efficient heat dissipation, which is crucial in maintaining performance under continuous duty operations. However, copper can be susceptible to corrosion, particularly in humid environments, which may be a concern for applications in regions like Africa and South America.

Illustrative image related to motor electric dc

Pros: High conductivity, good thermal properties, and durability.

Cons: Higher cost compared to alternatives, potential corrosion issues.

Impact on Application: Ideal for high-performance applications requiring efficient power transfer.

Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper may be necessary, especially in markets like Germany where material quality is strictly regulated.

What Role Does Aluminum Play in DC Motor Manufacturing?

Aluminum is increasingly used in DC motors due to its lightweight nature and good electrical conductivity, albeit lower than copper. Its resistance to corrosion makes it suitable for outdoor applications, particularly in the Middle East where environmental conditions can be harsh. However, aluminum’s lower strength compared to copper may limit its use in high-torque applications.

Pros: Lightweight, corrosion-resistant, cost-effective.

Cons: Lower conductivity and strength than copper, which may affect performance.

Impact on Application: Suitable for applications where weight is a critical factor, such as portable devices.

Considerations for International Buyers: Ensure compliance with local standards like DIN 1725 for aluminum, particularly in European markets.

How Does Steel Contribute to the Structural Integrity of DC Motors?

Steel is often used for the motor casing and structural components due to its high strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. However, steel is prone to rust and corrosion, necessitating protective coatings, especially in humid or coastal regions.

Illustrative image related to motor electric dc

Pros: High strength, good durability, and thermal resistance.

Cons: Heavier than aluminum and susceptible to corrosion without proper treatment.

Impact on Application: Best for industrial applications where robustness is essential.

Considerations for International Buyers: Compliance with ASTM A36 for structural steel may be required, particularly in the U.S. and Europe.

What Advantages Do Plastic Composites Offer in DC Motor Design?

Plastic composites are increasingly being utilized in DC motors for non-structural components due to their lightweight and corrosion-resistant properties. They are also less expensive to manufacture compared to metals. However, their thermal stability may not match that of metals, limiting their use in high-temperature environments.

Pros: Lightweight, corrosion-resistant, and cost-effective.

Cons: Limited thermal stability and potential for lower mechanical strength.

Impact on Application: Ideal for low-stress applications and environments where corrosion is a concern.

Considerations for International Buyers: Ensure compliance with relevant standards like ISO 9001 for quality management systems, especially in markets with stringent regulations.

Illustrative image related to motor electric dc

Summary Table of Material Selection for DC Motors

| Material | Typical Use Case for motor electric dc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and electrical connections | Excellent conductivity | Higher cost, corrosion potential | High |

| Aluminum | Lightweight motor housings | Lightweight and corrosion-resistant | Lower strength than copper | Medium |

| Steel | Structural components and casings | High strength and durability | Heavier, corrosion risk | Medium |

| Plastic Composites | Non-structural components | Lightweight and cost-effective | Limited thermal stability | Low |

This strategic material selection guide aims to provide B2B buyers with actionable insights into the materials used in DC motors, facilitating informed purchasing decisions tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for motor electric dc

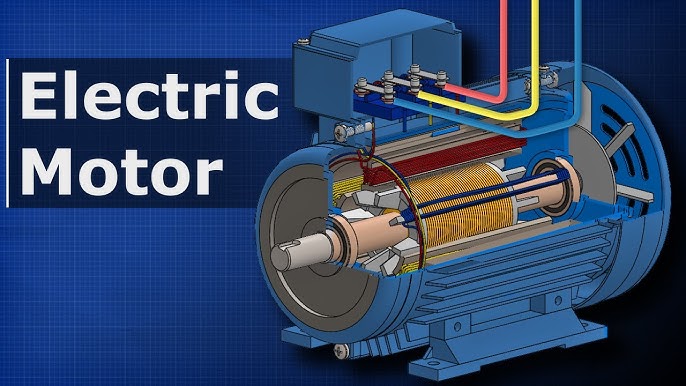

What Are the Main Stages in the Manufacturing Process of Electric DC Motors?

The manufacturing process of electric DC motors involves several critical stages, each designed to ensure efficiency, performance, and reliability. Here’s a breakdown of these stages:

-

Material Preparation: The initial step involves sourcing high-quality raw materials such as copper for windings, steel for the motor casing, and magnets for permanent magnet motors. Suppliers often utilize specific grades of materials to ensure that the motors meet performance standards.

-

Forming: This stage encompasses the shaping of raw materials into components. Techniques such as stamping, forging, and machining are commonly employed. For instance, stator and rotor components are typically stamped from sheets of electrical steel, which enhances magnetic efficiency. Precision machining ensures that parts fit together accurately, which is essential for minimizing friction and maximizing performance.

-

Assembly: In the assembly phase, individual components are brought together. This can include winding the coils around the stator, inserting bearings, and securing the rotor in place. Automated assembly lines are increasingly common, allowing for high-speed production while maintaining consistency. Skilled technicians oversee this process to address any anomalies that may arise.

-

Finishing: The final stage involves testing and applying protective coatings. Finishing processes might include painting, plating, or varnishing to enhance durability and prevent corrosion. Quality assurance tests are conducted to verify that each motor meets specified performance metrics, such as torque and speed.

Which Key Techniques Are Used in Manufacturing Electric DC Motors?

Manufacturers employ a variety of techniques tailored to the specific requirements of electric DC motors:

-

Winding Techniques: Different winding techniques, such as lap winding or wave winding, influence the motor’s characteristics. Choosing the right technique is crucial for achieving the desired torque and efficiency.

-

Magnetization: In permanent magnet DC motors, the magnetization process is critical. Techniques such as pulse magnetization ensure that magnets are charged uniformly, which is vital for optimal performance.

-

Precision Machining: Using CNC (Computer Numerical Control) machines allows for high precision in producing rotor and stator components. This reduces variability in production and enhances the motor’s overall performance.

What International Standards Govern Quality Assurance for Electric DC Motors?

Quality assurance in the manufacturing of electric DC motors is governed by several international standards, ensuring that products meet global benchmarks:

-

ISO 9001: This is a fundamental quality management standard that applies to organizations seeking to enhance customer satisfaction through effective quality management systems. Compliance with ISO 9001 demonstrates a commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is essential for B2B buyers in Europe to ensure that their suppliers have CE certification.

-

API Standards: For motors used in oil and gas applications, adherence to American Petroleum Institute (API) standards may be required. This ensures that products meet industry-specific performance and safety requirements.

How Do Quality Control Checkpoints Ensure Product Reliability?

Quality control (QC) is integral to the manufacturing process, and several checkpoints are established to monitor quality throughout production:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials before they enter the production line. It involves inspecting raw materials for defects and ensuring they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves ongoing inspections and testing to catch defects early. This may include measuring dimensions, checking assembly integrity, and monitoring the winding process.

-

Final Quality Control (FQC): Once assembly is complete, FQC involves comprehensive testing of finished motors. Common tests include performance evaluations under load, noise level measurements, and insulation resistance tests. Motors that fail to meet standards are either reworked or discarded.

What Common Testing Methods Are Used for Electric DC Motors?

Testing methods play a crucial role in validating the performance and reliability of electric DC motors:

-

Performance Testing: This involves running the motor under specified conditions to measure torque, speed, and efficiency. Load testing helps simulate real-world conditions, ensuring that the motor performs as expected.

-

Thermal Testing: Motors are subjected to thermal cycling tests to assess their performance under varying temperature conditions. This is vital for applications in extreme environments.

-

Electrical Testing: Insulation resistance tests and current draw measurements ensure that the motor operates safely without risk of overheating or failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can adopt several strategies to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their compliance with quality standards and operational procedures. This can include on-site visits to observe production and QC processes.

-

Quality Reports: Requesting detailed quality reports from suppliers provides insights into their QC practices, including results from IQC, IPQC, and FQC. This transparency is crucial for establishing trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can verify compliance with international standards and ensure that products meet specified criteria.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, particularly from regions such as Africa, South America, the Middle East, and Europe, B2B buyers should be aware of several nuances:

Illustrative image related to motor electric dc

-

Cultural Differences: Understanding cultural nuances can facilitate better communication and negotiation regarding quality expectations. Buyers should be aware of varying standards and practices across regions.

-

Regulatory Compliance: Different countries may have unique regulatory requirements affecting motor design and manufacturing. Buyers must ensure that their suppliers are aware of and comply with these regulations.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can impact quality. Buyers should consider how transportation and handling might affect the motors during shipment, and ensure that suppliers use appropriate packaging and handling procedures to mitigate risks.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and select reliable suppliers for electric DC motors, ensuring that they receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motor electric dc’

In the competitive landscape of B2B procurement, sourcing the right DC electric motor is crucial for ensuring operational efficiency and reliability. This guide provides a step-by-step checklist to assist international buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your application. Consider factors such as voltage ratings (e.g., 12V, 24V, 90V), torque requirements, speed ranges (RPM), and whether you need features like adjustable speed or reversible operation. Documenting these specifications helps streamline your search and ensures suppliers understand your needs.

Step 2: Identify Suitable Applications

Understanding the specific applications for which you need DC motors is essential. Different motors excel in various environments, such as agricultural machinery, warehouse automation, or medical devices. By identifying the application, you can narrow your focus to motors that are proven to perform effectively in similar conditions, thus enhancing reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and customer references to assess their capabilities. Look for suppliers with a proven track record in your industry and those that can demonstrate successful deployments in similar applications. This step minimizes risks associated with product performance and service quality.

Step 4: Verify Compliance and Certifications

Ensure that the motors you are considering meet relevant industry standards and certifications. Check for compliance with international standards such as ISO, CE, or UL, which indicate product quality and safety. Verifying certifications not only safeguards your investment but also ensures that the motors are suitable for international markets, particularly in regions with strict regulations.

Step 5: Request and Compare Quotations

Once you have identified potential suppliers, request detailed quotations. Ensure that these quotes include all relevant information such as pricing, lead times, and terms of sale. Comparing quotations allows you to assess the total cost of ownership, including potential shipping costs and duties, which is vital for budgeting and financial planning.

Step 6: Discuss After-Sales Support and Warranty

Engage with suppliers about their after-sales support and warranty policies. A robust support structure is crucial for resolving issues that may arise post-purchase. Inquire about the duration of the warranty and what it covers, as well as the availability of spare parts and service options. Strong after-sales support can significantly reduce downtime and maintenance costs.

Step 7: Finalize Purchase and Monitor Delivery

After selecting the supplier, finalize your purchase agreement and monitor the delivery process closely. Ensure that the shipment is tracked and that all documentation is complete for customs clearance if applicable. Maintaining open lines of communication with your supplier during this phase can help address any potential issues swiftly, ensuring timely receipt of your motors.

By following this structured approach, B2B buyers can confidently navigate the complexities of sourcing DC electric motors, ultimately securing the best solutions for their operational needs.

Comprehensive Cost and Pricing Analysis for motor electric dc Sourcing

What Are the Key Cost Components in Sourcing DC Motors?

When sourcing electric DC motors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. High-quality magnets, copper windings, and durable casings are essential for performance and longevity but can increase the price. Buyers should evaluate whether lower-cost alternatives can meet their application requirements without sacrificing quality.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Countries with lower wage rates may provide cost savings, but this can also impact the quality of workmanship. It’s vital to consider the skill level and training of the workforce involved in production.

-

Manufacturing Overhead: This includes factory expenses such as utilities, maintenance, and administrative costs. Suppliers with streamlined operations may offer more competitive pricing, so it’s beneficial to assess their operational efficiency.

-

Tooling: Custom tooling for specific motor designs can be a significant upfront cost. Buyers should inquire about tooling costs, especially for unique specifications, as these can impact the overall price.

-

Quality Control (QC): Rigorous QC processes ensure that motors meet safety and performance standards. While this adds to the cost, it is essential for reducing long-term risks associated with product failures.

-

Logistics: Shipping and handling costs can vary based on the origin, destination, and shipping methods. International buyers should consider these expenses when calculating the total cost of ownership.

-

Margin: Supplier profit margins can vary widely. Understanding the pricing strategy of suppliers can help buyers negotiate better deals.

How Do Price Influencers Affect DC Motor Costs?

Several factors influence the pricing of DC motors, and recognizing these can help buyers make informed purchasing decisions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. International buyers should evaluate their needs and consider bulk purchasing to achieve better pricing.

-

Specifications and Customization: Custom specifications often lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses for features that may not be essential.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can justify premium pricing. Buyers should balance the need for quality against budget constraints.

-

Supplier Factors: Established suppliers with a strong reputation may charge more but offer reliability and better customer service. Assessing supplier capabilities and histories can be beneficial in the long run.

-

Incoterms: Understanding Incoterms is essential for managing logistics costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can significantly affect pricing and risk exposure.

What Buyer Tips Can Help Negotiate Better Prices?

International B2B buyers can leverage several strategies to enhance cost-efficiency when sourcing DC motors:

-

Negotiation: Always negotiate prices, especially for larger orders. Suppliers may have flexibility, particularly in competitive markets. Presenting a long-term partnership can also encourage better pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost over the product’s lifecycle, including maintenance, energy consumption, and potential downtime. A lower initial cost may lead to higher TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes, as these can impact the final costs significantly. Working with local experts can provide insights into market conditions and pricing trends.

Conclusion

When sourcing electric DC motors, a comprehensive understanding of the cost structure and pricing influencers is essential for making informed purchasing decisions. By employing effective negotiation strategies and considering the total cost of ownership, international buyers can optimize their sourcing processes, ensuring they achieve both quality and value. Always keep in mind that indicative prices may vary, so thorough research and supplier discussions are crucial for accurate budgeting.

Alternatives Analysis: Comparing motor electric dc With Other Solutions

Exploring Alternatives to Motor Electric DC: A Comparative Analysis

When considering motor solutions for various applications, it is essential for B2B buyers to evaluate alternatives to Motor Electric DC (Direct Current) motors. Understanding the strengths and weaknesses of competing technologies can help businesses make informed decisions that align with their operational needs and financial constraints. This section provides a detailed comparison of Motor Electric DC motors against two viable alternatives: AC (Alternating Current) Motors and Stepper Motors.

| Comparison Aspect | Motor Electric DC | AC Motors | Stepper Motors |

|---|---|---|---|

| Performance | High starting torque, good for variable speed applications | Efficient for constant speed, typically higher RPM | Precise positioning, excellent for controlled movement |

| Cost | Generally cost-competitive, especially for low-voltage applications | Higher initial costs, but lower operational costs | Moderate cost, often higher than DC for similar power |

| Ease of Implementation | Relatively simple installation, requires compatible controllers | May require additional components for speed control | More complex installation due to control systems |

| Maintenance | Low maintenance, but brushes may require periodic replacement | Generally low maintenance, robust design | Requires careful calibration and can wear over time |

| Best Use Case | Ideal for applications needing variable speed and torque, like robotics and conveyors | Best for constant-speed applications such as fans and pumps | Excellent for precise positioning tasks in automation and CNC machinery |

What Are the Advantages and Disadvantages of AC Motors?

AC motors are widely used in industrial applications due to their efficiency and reliability. They can operate at higher speeds than DC motors and are generally more efficient in converting electrical energy into mechanical energy. However, they often come with higher initial costs and may require additional components like variable frequency drives (VFDs) for speed control. This makes them less appealing for applications requiring variable speed or torque.

Illustrative image related to motor electric dc

How Do Stepper Motors Compare to Motor Electric DC?

Stepper motors offer unique advantages, particularly in applications requiring precise control and positioning. They can move in discrete steps, allowing for exact movements, which is crucial in automation and CNC machinery. However, their complexity in installation and control systems can be a drawback. Additionally, stepper motors can experience wear and require calibration, making them less suitable for high-load continuous operations compared to DC motors.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right motor technology hinges on understanding specific application requirements, including performance needs, budget constraints, and maintenance considerations. For applications demanding variable speed and torque, Motor Electric DC motors are often the best choice due to their efficiency and simplicity. On the other hand, if the need is for high-speed, constant applications, AC motors may provide a more cost-effective long-term solution. Finally, for applications requiring precise control, stepper motors should be considered despite their complexity.

In conclusion, evaluating these alternatives enables B2B buyers to align their motor solutions with operational demands while optimizing costs and performance. By carefully weighing the pros and cons of each option, businesses can make informed decisions that drive efficiency and productivity in their operations.

Essential Technical Properties and Trade Terminology for motor electric dc

What Are the Key Technical Properties of DC Motors That B2B Buyers Should Consider?

When sourcing DC motors, understanding their essential technical properties is crucial for making informed purchasing decisions. Here are several critical specifications to keep in mind:

-

Voltage Rating

The voltage rating indicates the electric potential required to operate the motor. Common ratings for DC motors include low voltage (12V or 24V) and higher voltage options (90V, 130V). Selecting the appropriate voltage is essential, especially for applications reliant on battery or solar power, as it directly impacts performance and efficiency. -

Torque

Torque measures the rotational force produced by the motor, typically expressed in oz-in or Nm. High starting torque is particularly important for applications requiring quick acceleration or heavy loads. Understanding torque specifications helps ensure the motor can handle the mechanical demands of specific applications, such as conveyors or agricultural equipment. -

Speed (RPM)

The speed rating, measured in revolutions per minute (RPM), indicates how quickly the motor can rotate. For instance, some DC motors can operate between 1,750 to 11,500 RPM. The required speed will vary depending on the application, making it crucial to match motor speed with operational needs to optimize efficiency and performance. -

Duty Cycle

The duty cycle defines the motor’s operational time relative to its resting time. Continuous duty motors can operate for long periods without overheating, while intermittent duty motors are designed for short bursts of use. Understanding duty cycle is vital for ensuring that the selected motor aligns with operational requirements and prevents premature failure. -

Control Type

DC motors can be controlled via various methods, including SCR (Silicon Controlled Rectifier) or PWM (Pulse Width Modulation). These control types affect the motor’s performance in terms of speed regulation and efficiency. Choosing the right control type is essential for applications that require precise speed adjustments or energy efficiency. -

Frame Size

The frame size indicates the physical dimensions of the motor, which can affect installation and integration into existing systems. Ensuring that the motor fits within the designated space is critical, especially in compact applications like robotics or portable medical devices.

What Are Common Trade Terms in the DC Motor Industry That Buyers Should Know?

Familiarizing yourself with industry terminology can facilitate smoother transactions and negotiations. Here are several essential terms used in the DC motor sector:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial for B2B buyers who need to source components that will be integrated into larger systems or products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers to manage inventory and cash flow effectively, especially when sourcing components for large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. It outlines the specifications and quantities required. Utilizing RFQs can help buyers compare prices and terms from multiple suppliers to ensure they receive the best value. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for understanding shipping costs, risks, and responsibilities in cross-border trade. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is essential for project planning and inventory management, particularly in industries where timely delivery is critical. -

Warranty Period

The warranty period specifies the duration during which the manufacturer guarantees the product against defects. Knowing the warranty terms can help buyers assess the reliability of the motor and plan for potential replacements or repairs.

By grasping these technical properties and industry terms, B2B buyers can make well-informed decisions when sourcing DC motors, ensuring that their applications function efficiently and reliably.

Navigating Market Dynamics and Sourcing Trends in the motor electric dc Sector

What Are the Global Drivers and Key Trends in the Motor Electric DC Market?

The motor electric DC sector is experiencing robust growth, driven by the increasing demand for energy-efficient solutions across various industries. Key markets in Africa, South America, the Middle East, and Europe are particularly focused on sustainable energy sources, which are enhancing the appeal of DC motors. The push towards automation and digital transformation in sectors such as manufacturing, logistics, and agriculture is propelling the adoption of DC motors, which are known for their high efficiency, compact size, and adaptability in various applications.

Emerging technologies, including IoT and Industry 4.0, are reshaping sourcing strategies, with businesses seeking suppliers that offer smart motor solutions integrated with real-time monitoring and control capabilities. Moreover, the growing trend of electrification in transportation, notably electric vehicles (EVs), is creating new opportunities for DC motors, especially those optimized for battery applications. International B2B buyers must remain vigilant to these trends, as they influence pricing, supply chain dynamics, and product specifications.

How Do Sustainability and Ethical Sourcing Impact the Motor Electric DC Industry?

Sustainability is becoming a paramount concern for B2B buyers in the motor electric DC sector. The environmental impact of manufacturing processes and materials used in motor production is under scrutiny, leading to a demand for greener alternatives. Ethical sourcing is no longer just a marketing strategy; it is a critical factor in supplier selection. Buyers are increasingly looking for manufacturers that demonstrate a commitment to reducing their carbon footprint and use sustainable materials.

Illustrative image related to motor electric dc

Certifications such as ISO 14001 for environmental management and adherence to the RoHS (Restriction of Hazardous Substances) directive are becoming essential for suppliers aiming to compete in the global market. The use of recyclable components and energy-efficient manufacturing practices not only meets regulatory requirements but also aligns with the values of conscientious consumers and businesses. By prioritizing suppliers with strong sustainability credentials, B2B buyers can enhance their brand reputation and contribute to broader environmental goals.

How Has the Motor Electric DC Sector Evolved Over Time?

The evolution of the motor electric DC sector dates back to the early 19th century when the first DC motors were developed. Initially used in applications like telegraphs and early machinery, these motors have undergone significant advancements in design and efficiency. The introduction of permanent magnet technology in the 1960s marked a turning point, allowing for smaller, lighter, and more efficient motors.

Over the decades, as the demand for automation and precision control increased, the DC motor technology evolved to include variable speed drives and advanced control systems. Today, they are integral components in diverse applications ranging from industrial machinery to consumer electronics. The ongoing development of smart technologies and the shift towards renewable energy sources signal that the sector will continue to innovate, providing exciting opportunities for B2B buyers looking for reliable, efficient, and sustainable motor solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of motor electric dc

-

How do I solve performance issues with DC motors in my application?

Performance issues with DC motors can stem from various factors such as inadequate power supply, incorrect voltage ratings, or improper installation. To resolve these issues, first, ensure that the motor is rated for the application’s voltage and current requirements. Check connections for tightness and corrosion, and verify that the power supply is stable. If the motor is underperforming, consider whether the load exceeds the motor’s specifications or if the motor requires a different type of speed control. Regular maintenance and monitoring can help prevent performance degradation over time. -

What is the best DC motor type for adjustable speed applications?

For adjustable speed applications, permanent magnet DC (PMDC) motors are often the best choice. They provide high efficiency, excellent starting torque, and smooth speed control, making them ideal for applications such as conveyors and warehouse automation. PMDC motors can be used with various speed control methods, including PWM (Pulse Width Modulation) and SCR (Silicon Controlled Rectifier) controls, allowing for precise adjustments. When selecting a motor, consider the application’s specific torque and speed requirements to ensure optimal performance. -

What are the key factors to consider when sourcing DC motors internationally?

When sourcing DC motors internationally, key factors include supplier reliability, quality certifications, and compliance with local regulations. Investigate the supplier’s track record by checking reviews and requesting references. Additionally, confirm that the motors meet industry standards such as ISO or CE certifications. Consider logistics, including shipping costs, lead times, and customs regulations, to avoid unexpected delays. Finally, assess the supplier’s ability to provide after-sales support, which is crucial for resolving any operational issues that may arise. -

How can I ensure the quality of DC motors from international suppliers?

To ensure quality when sourcing DC motors, it’s vital to conduct thorough supplier vetting. Request samples for testing before placing a bulk order, and consider visiting the manufacturing facility if feasible. Implement quality assurance protocols such as pre-shipment inspections and third-party audits. Additionally, establish clear quality specifications in your purchase agreement, including performance metrics and warranty terms. By maintaining open communication with the supplier, you can address potential issues proactively, ensuring the motors meet your operational standards. -

What customization options are available for DC motors?

Many suppliers offer customization options for DC motors, including voltage ratings, torque specifications, and physical dimensions. Customization can also extend to features such as encoders for feedback control, gear ratios for specific applications, and unique mounting configurations. When discussing customization with a supplier, be clear about your application requirements and performance expectations. Keep in mind that customization may affect lead times and pricing, so it’s essential to balance these factors against your project timelines and budget. -

What is the minimum order quantity (MOQ) for DC motors when sourcing internationally?

Minimum order quantities (MOQs) for DC motors can vary significantly by supplier and product type. Some suppliers may allow orders as low as one unit, especially for standard models, while others may require higher quantities for customized motors or bulk orders. It’s essential to discuss MOQs upfront to understand how they align with your project needs. If the MOQ is higher than desired, consider negotiating with the supplier or exploring other manufacturers who can accommodate smaller orders without compromising quality. -

What payment terms should I expect when purchasing DC motors from international suppliers?

Payment terms can vary widely among international suppliers, but common arrangements include partial upfront payments, letters of credit, or payment upon delivery. It is advisable to negotiate payment terms that suit your cash flow while ensuring the supplier feels secure in the transaction. Be mindful of potential currency fluctuations and consider using secure payment methods that provide buyer protection. Establishing a good relationship with the supplier can also lead to more favorable payment terms over time. -

How can I manage logistics when importing DC motors?

Managing logistics when importing DC motors involves careful planning and coordination with suppliers and freight forwarders. Start by understanding the shipping options available, such as air freight for faster delivery or ocean freight for cost savings. Ensure that all necessary documentation, including customs declarations and import permits, is in order to prevent delays at the border. Collaborate with a logistics provider experienced in international shipping to navigate customs regulations and optimize shipping routes. Tracking shipments closely can help you stay informed about delivery times and address any issues that may arise promptly.

Top 6 Motor Electric Dc Manufacturers & Suppliers List

1. Bodine – PMDC Motors

Domain: bodine-electric.com

Registered: 1997 (28 years)

Introduction: Bodine permanent magnet DC (PMDC) motors include 24A, 33A, and 42A frame motors designed for high efficiency, high starting torque, and linear speed/torque performance. They are suitable for adjustable speed applications and available in low-voltage (12 or 24 VDC), SCR rated (90 VDC or 180 VDC), and standard (130 VDC) windings. Applications include agricultural equipment, warehouse automation robo…

2. Johnson Electric – DC Motors

Domain: shop.johnsonelectric.com

Registered: 1996 (29 years)

Introduction: Johnson Electric offers a range of DC motors, including Brushless DC (BLDC) and Permanent Magnet DC (PMDC) motors. These motors are designed for high performance and durability, suitable for applications in automotive, power tools, home appliances, and industrial equipment. Key features include high efficiency, precise speed control, and compact designs. Specific details include various diameters …

3. Surplus Center – Key DC Motors

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for DC Motors include: 1. Types: Base Mount DC Motors, Face Mount DC Motors, DC Fan Motors, Special Purpose DC Motors, Motor Speed Controllers. 2. Example Products: 0.015 HP 26 Volt DC 19000 RPM Motor, .044 HP 27.5 Volt DC 7400 RPM Motor, 1/10 HP 4150 RPM 12 Volt DC Motor, 1/4 HP 24 Volt DC 1500 RPM Motor, 1/3 HP 12 Volt DC 1800 RPM Motor, 90/180 Volt DC Variable Speed Control….

4. Caldwell Motors – DC Motors

Domain: caldwellmotors.com

Registered: 2018 (7 years)

Introduction: This company, Caldwell Motors – DC Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. IQS Directory – DC Motors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: DC motors are electrical devices that convert electrical energy into mechanical energy using a magnetic field powered by direct current. They are categorized into several types based on field winding connections and rotor power methods. Key types include: 1. Brushed DC Motors: Common and cost-effective, featuring a magnetic field generated by current through a commutator and brushes. Subtypes incl…

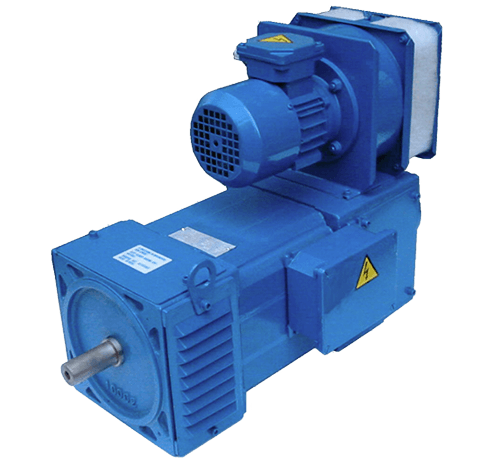

6. T-T Electric – DC Motors for Industrial Applications

Domain: t-telectric.com

Registered: 2005 (20 years)

Introduction: DC Motors from T-T Electric are designed for industrial applications, adaptable to machines, and suitable for small spaces. Key features include:

– Frame sizes: 80 to 450mm

– Outputs: 1500 kW

– Compliance with IEC, VDE, BS, NEMA, and CSA standards

– Protection ratings: IP23-IP55

– Various cooling forms

– Multiple mounting forms

– Extensive accessory options

– Custom mounting interfaces and…

Strategic Sourcing Conclusion and Outlook for motor electric dc

In today’s competitive landscape, strategic sourcing of DC motors presents a significant opportunity for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing high-efficiency, durable, and cost-effective solutions, businesses can enhance operational capabilities while maximizing return on investment. The availability of low-voltage options and advanced control features makes DC motors particularly suitable for diverse applications, ranging from agricultural equipment to automated systems in warehouses.

Investing in reliable suppliers and fostering strong partnerships is crucial to navigating the complexities of the global supply chain. Buyers should focus on manufacturers that offer customized solutions tailored to specific industry needs, ensuring optimal performance and longevity of their motor applications. As the demand for sustainable and efficient energy solutions continues to grow, DC motors will play a pivotal role in driving innovation and productivity.

Looking ahead, it is vital for businesses to stay informed about technological advancements and market trends in the DC motor sector. Embrace the future of electric motor solutions by engaging with trusted suppliers and leveraging strategic sourcing to propel your operations forward. Take action today to secure a competitive edge in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.