The Definitive Guide to Temperature Sensor Applications: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for temperature sensor applications

In today’s rapidly evolving industrial landscape, sourcing reliable temperature sensors can be a daunting challenge for B2B buyers, particularly in emerging markets like Nigeria, Vietnam, and other regions across Africa, South America, the Middle East, and Europe. The diverse range of temperature sensor applications—from monitoring geotechnical structures to ensuring the efficiency of manufacturing processes—requires a nuanced understanding of various types, including thermocouples, RTDs, and thermistors. Each type presents unique advantages and limitations that can significantly impact operational efficiency and product quality.

This comprehensive guide delves into the multifaceted world of temperature sensor applications, providing insights into the types of sensors available, their specific applications across industries, and essential criteria for supplier vetting. Additionally, it outlines cost considerations and strategies for maximizing value while minimizing risk. By addressing the complexities of temperature sensor sourcing, this guide empowers international B2B buyers to make informed purchasing decisions that align with their operational needs and market demands.

Armed with this knowledge, businesses can effectively navigate the global market, ensuring they select the right temperature sensors to enhance productivity, maintain safety standards, and drive innovation. Whether you are a seasoned procurement professional or new to the industry, this guide will serve as your essential resource in making strategic investments in temperature sensor technology.

Understanding temperature sensor applications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermocouples | Made from dissimilar metals; generates voltage based on temperature | Manufacturing, HVAC, automotive, aerospace | Pros: Wide temperature range, fast response time. Cons: Less accurate than RTDs at lower temperatures. |

| RTD Sensors | Resistance changes with temperature; highly accurate and stable | Industrial processes, food and beverage, pharmaceuticals | Pros: High accuracy, stability over time. Cons: More expensive than thermocouples. |

| Thermistors | Resistance changes significantly with temperature; compact size | Consumer electronics, medical devices, HVAC systems | Pros: High sensitivity, low cost. Cons: Limited temperature range compared to RTDs. |

| Infrared Sensors | Non-contact measurement; detects thermal radiation | Medical imaging, building inspections, manufacturing | Pros: Safe for hazardous environments, quick measurements. Cons: Can be affected by environmental factors. |

| Immersion Heaters | Directly placed in liquids; provides efficient heating | Chemical processing, food production, water heating | Pros: Fast and economical heating. Cons: Requires careful installation to avoid damage. |

What Are the Characteristics of Thermocouples and Their B2B Suitability?

Thermocouples are versatile sensors that operate by creating a voltage difference from two different metals. They are ideal for applications requiring a wide temperature range, such as in manufacturing processes, HVAC systems, and automotive industries. Their fast response times make them suitable for dynamic environments. However, businesses should consider their lower accuracy at extreme temperatures compared to other sensors like RTDs, which may be critical in precision-required applications.

Why Choose RTD Sensors for Industrial Applications?

Resistance Temperature Detectors (RTDs) offer high accuracy and stability, making them a preferred choice in industrial settings, including food and beverage processing and pharmaceuticals. They function by measuring the change in electrical resistance as temperature varies. While they tend to be more expensive than thermocouples, their long-term reliability and precision can justify the investment, especially in environments where accurate temperature control is crucial for product quality.

What Makes Thermistors Ideal for Consumer Electronics?

Thermistors, known for their compact size and significant resistance change with temperature, are commonly used in consumer electronics and medical devices. Their high sensitivity allows for precise temperature measurements in smaller devices. However, their limited temperature range means they may not be suitable for all industrial applications. Buyers should assess their specific needs, particularly in terms of temperature extremes, before selecting thermistors.

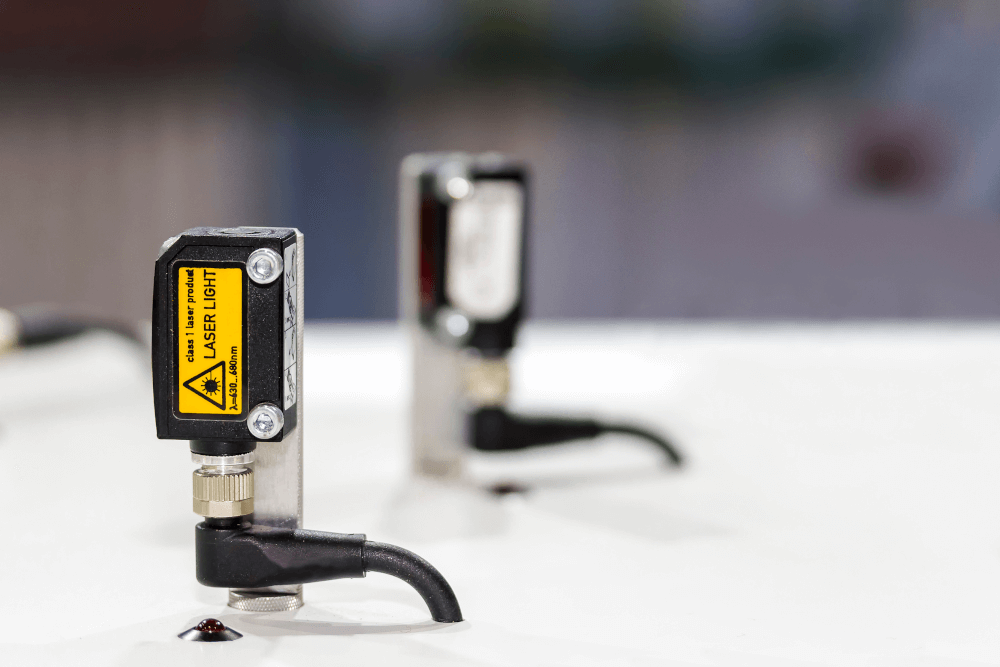

How Do Infrared Sensors Benefit Non-Contact Measurements?

Infrared sensors are unique in that they measure temperature without direct contact, making them ideal for applications in medical imaging, building inspections, and manufacturing. They detect thermal radiation, providing quick and safe measurements, especially in hazardous environments. However, businesses must be aware that environmental factors such as dust or moisture can affect readings, necessitating careful consideration of the operating environment when integrating these sensors.

Why Are Immersion Heaters Essential in Chemical Processing?

Immersion heaters are designed for direct placement in liquids, providing efficient and economical heating solutions for industries like chemical processing and food production. They are particularly effective in heating large volumes of liquid quickly. While their installation is straightforward, proper care is needed to prevent damage to the heater or the surrounding equipment. Buyers should ensure compatibility with their specific liquids and temperature requirements to maximize efficiency.

Key Industrial Applications of temperature sensor applications

| Industry/Sector | Specific Application of temperature sensor applications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Monitoring temperatures during food processing and storage | Ensures food safety, quality, and compliance with regulations | Accuracy, response time, and compatibility with food safety standards |

| Pharmaceutical | Temperature control in storage and transportation of drugs | Maintains drug efficacy and safety, reducing waste | Calibration standards, data logging capabilities, and regulatory compliance |

| Oil and Gas | Wellhead temperature monitoring and pipeline integrity checks | Prevents equipment failure and enhances safety | Durability in harsh environments and resistance to corrosive substances |

| HVAC Systems | Temperature regulation in commercial and residential buildings | Improves energy efficiency and occupant comfort | Integration with building management systems and energy consumption data |

| Geotechnical Engineering | Monitoring temperature in concrete curing and soil conditions | Ensures structural integrity and performance | Long-term stability, resistance to environmental factors, and ease of installation |

How Are Temperature Sensors Used in the Food and Beverage Industry?

In the food and beverage sector, temperature sensors play a crucial role in monitoring temperatures during processing, cooking, and storage. They ensure that food products are maintained at safe temperatures to prevent spoilage and contamination. For international buyers, particularly in regions like Africa and South America, sourcing sensors that meet local food safety regulations is essential. Additionally, sensors need to be accurate and responsive to changes to maintain compliance with international standards.

What Role Do Temperature Sensors Play in Pharmaceuticals?

Temperature sensors are vital in the pharmaceutical industry for monitoring the storage and transportation of temperature-sensitive drugs. Maintaining the correct temperature ensures drug efficacy and safety, minimizing the risk of waste due to spoilage. Buyers from the Middle East and Europe should prioritize sensors with robust calibration standards and data logging capabilities to comply with stringent regulatory requirements, ensuring traceability and accountability in their operations.

How Are Temperature Sensors Applied in Oil and Gas?

In the oil and gas industry, temperature sensors are critical for monitoring wellhead temperatures and pipeline integrity. They help prevent equipment failures and enhance operational safety by providing real-time data that can indicate potential hazards. Buyers in regions like Africa, where harsh environmental conditions are prevalent, should focus on sourcing durable sensors that can withstand corrosive substances and extreme temperatures, ensuring long-term reliability.

What Is the Importance of Temperature Sensors in HVAC Systems?

Temperature sensors in HVAC systems are essential for regulating indoor climate conditions in both commercial and residential buildings. By accurately measuring and controlling temperatures, they contribute to energy efficiency and occupant comfort. For B2B buyers in Europe and the Middle East, integrating sensors with building management systems is crucial, as it allows for better energy consumption tracking and automated adjustments to optimize heating and cooling processes.

How Do Temperature Sensors Aid Geotechnical Engineering?

In geotechnical engineering, temperature sensors are used to monitor temperature changes in concrete curing and soil conditions. This data is vital for ensuring structural integrity and performance, particularly in large-scale infrastructure projects. Buyers, especially from developing regions like Nigeria and Vietnam, should look for sensors that offer long-term stability and resistance to environmental factors, as these characteristics are essential for reliable performance in challenging conditions.

3 Common User Pain Points for ‘temperature sensor applications’ & Their Solutions

Scenario 1: Inaccurate Temperature Readings Affecting Quality Control

The Problem: B2B buyers in manufacturing often face significant challenges when temperature sensors provide inaccurate readings. This can occur due to sensor miscalibration, environmental factors, or faulty equipment. For instance, in a food processing plant, a malfunctioning temperature sensor can lead to improper cooking temperatures, resulting in products that fail to meet safety standards. Such inaccuracies not only jeopardize product quality but also lead to costly recalls and damage to the brand’s reputation.

The Solution: To combat this issue, it is essential to implement a robust calibration and maintenance schedule for all temperature sensors. Buyers should prioritize sourcing high-quality sensors from reputable manufacturers known for their reliability and accuracy. Regularly scheduled calibration checks—ideally, monthly or quarterly—can help ensure that sensors operate within their specified range. Additionally, integrating advanced monitoring systems that provide real-time data can alert operators to any discrepancies, allowing for immediate corrective actions. Investing in training for staff on proper sensor usage and maintenance can further reduce the risk of inaccuracies, ensuring quality control processes remain intact.

Scenario 2: Difficulty in Integrating Sensors with Existing Systems

The Problem: Many businesses struggle with integrating new temperature sensor technology into their existing systems. This issue often arises in industries like pharmaceuticals and energy, where legacy systems may not support the latest sensor technologies. Such integration challenges can lead to increased operational downtime and a steep learning curve for staff, ultimately affecting productivity and profitability.

The Solution: To facilitate smoother integration, buyers should conduct thorough assessments of their current systems before selecting temperature sensors. Opting for sensors that come with compatibility assurances can mitigate potential integration issues. It is also advisable to engage with suppliers who offer comprehensive support services, including installation and training. When implementing new sensors, phased rollouts can minimize disruptions; begin with pilot programs to test compatibility and ease of use before full-scale deployment. Additionally, leveraging cloud-based platforms can provide the necessary flexibility, allowing for seamless data transfer and analytics across various systems, enhancing the overall operational efficiency.

Scenario 3: High Costs of Sensor Maintenance and Replacement

The Problem: The maintenance and replacement costs of temperature sensors can be a significant burden for many organizations, particularly those in high-demand industries such as oil and gas or manufacturing. Frequent sensor failures not only incur direct costs but can also lead to operational delays and lost revenue due to downtime. This financial strain can be especially acute for businesses operating on tight margins.

The Solution: To alleviate these financial pressures, companies should focus on investing in durable, high-quality sensors designed for longevity in harsh environments. Conducting a total cost of ownership analysis can help buyers understand the long-term implications of their choices beyond the initial purchase price. Additionally, considering preventive maintenance programs can significantly reduce unexpected failures; these programs may include regular inspections and timely replacements of sensors showing signs of wear. Collaborating with suppliers who offer warranties and service agreements can also provide financial protection and peace of mind. Finally, utilizing data analytics to monitor sensor performance can help predict failures before they occur, allowing for proactive maintenance and cost management.

By addressing these common pain points with targeted solutions, B2B buyers can enhance the reliability and efficiency of their temperature sensor applications, ultimately leading to improved operational performance and cost savings.

Strategic Material Selection Guide for temperature sensor applications

What Are the Key Properties of Common Materials Used in Temperature Sensors?

When selecting materials for temperature sensors, it’s crucial to consider their properties that directly influence performance. Here, we analyze four common materials: stainless steel, ceramic, glass, and polyimide, focusing on their suitability for various applications.

How Does Stainless Steel Perform in Temperature Sensor Applications?

Stainless steel is widely used in temperature sensor applications, particularly for thermocouples and RTDs. Its key properties include excellent corrosion resistance, high-temperature tolerance (up to 800°C), and good mechanical strength. These characteristics make stainless steel suitable for harsh environments, such as chemical processing and food production.

Pros: Stainless steel is durable, easy to clean, and can withstand high pressures, making it ideal for industrial applications. Its relatively low cost compared to other high-performance materials enhances its appeal.

Cons: While stainless steel is robust, it can be susceptible to certain corrosive environments, particularly chloride-induced corrosion. Additionally, manufacturing processes like welding can add complexity and costs.

Impact on Application: Stainless steel’s compatibility with various media, including liquids and gases, allows it to be used in diverse applications, from HVAC systems to food processing.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East, where regulatory requirements are stringent.

What Are the Advantages of Using Ceramic Materials in Temperature Sensors?

Ceramic materials, particularly those with a positive temperature coefficient (PTC), are increasingly used in temperature sensors due to their stability and resistance to thermal shock. They can operate at high temperatures (up to 1000°C) and have excellent electrical insulation properties.

Pros: Ceramics are highly durable and resistant to chemical corrosion, making them suitable for extreme environments. Their low thermal conductivity allows for precise temperature measurements.

Cons: The brittleness of ceramics can be a limitation, as they may fracture under mechanical stress. Additionally, the manufacturing process can be more complex and expensive than metals.

Impact on Application: Ceramics are particularly effective in applications involving high temperatures, such as in aerospace and automotive industries, where reliability is critical.

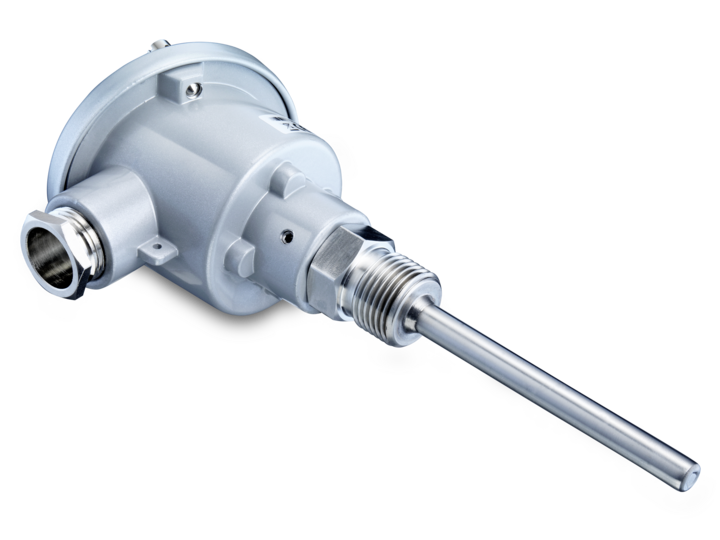

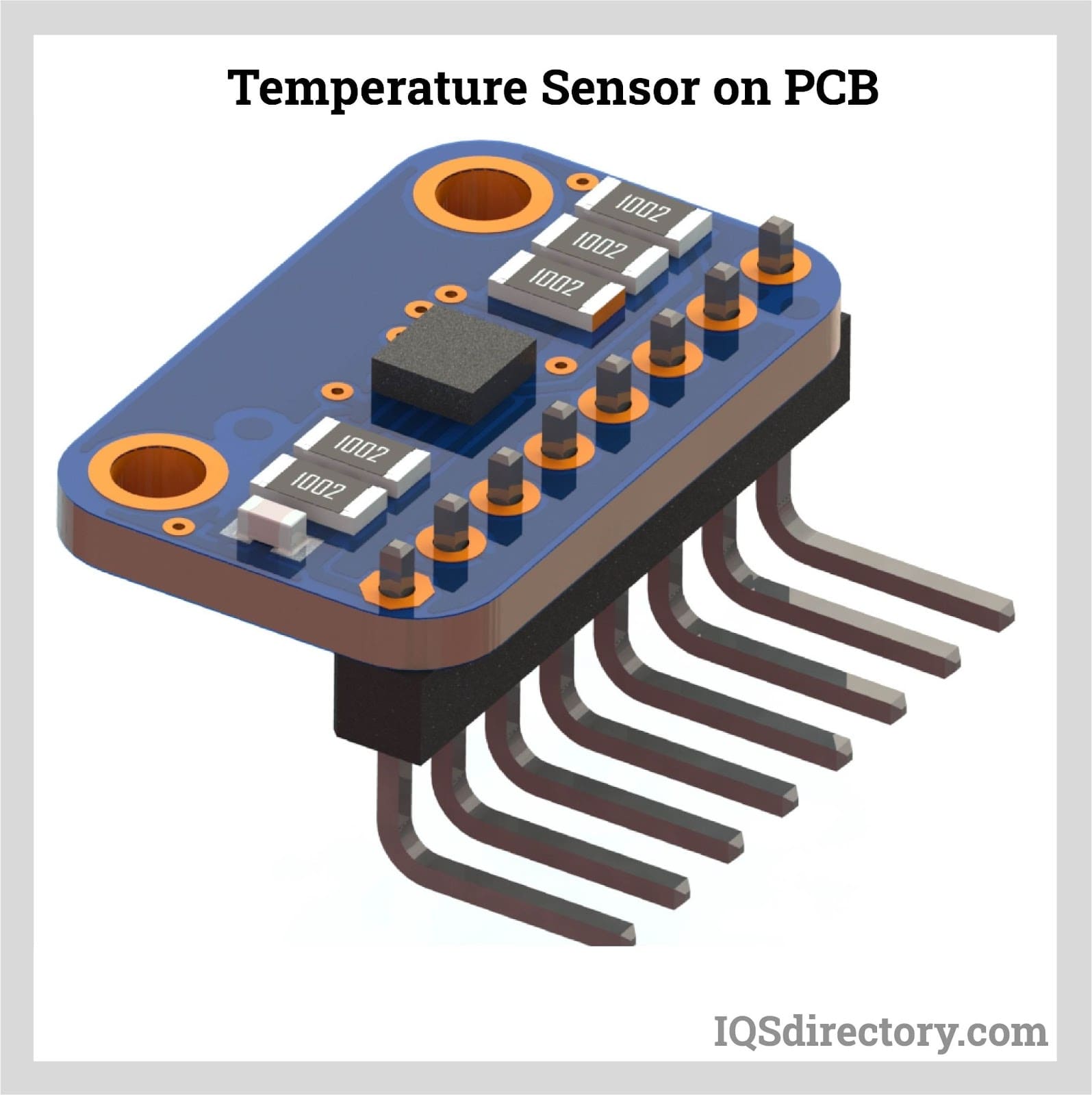

Illustrative image related to temperature sensor applications

Considerations for International Buyers: Buyers should ensure that ceramic materials meet relevant standards, such as JIS in Japan, to guarantee quality and performance.

How Do Glass Materials Compare in Temperature Sensor Applications?

Glass is often used in thermometers and some types of thermocouples. Its key properties include good thermal stability and the ability to withstand a wide range of temperatures (from -200°C to 500°C).

Pros: Glass is non-reactive and can be used in applications involving aggressive chemicals. It also provides excellent visibility for temperature readings in thermometers.

Illustrative image related to temperature sensor applications

Cons: The fragility of glass makes it unsuitable for high-impact environments. Its thermal expansion can also lead to inaccuracies in extreme temperature variations.

Impact on Application: Glass is ideal for laboratory settings and other controlled environments where precise temperature readings are necessary.

Considerations for International Buyers: Compliance with safety standards is crucial, especially in regions with stringent health regulations, such as Europe.

What Role Does Polyimide Play in Temperature Sensor Applications?

Polyimide is a flexible polymer that is often used in the manufacturing of flexible temperature sensors. It can operate effectively at temperatures ranging from -269°C to 260°C.

Illustrative image related to temperature sensor applications

Pros: Polyimide’s flexibility allows it to conform to various surfaces, making it suitable for applications where space is limited. It is also resistant to many chemicals and has excellent thermal stability.

Cons: While polyimide is versatile, it may not be suitable for high-pressure environments. The cost of high-quality polyimide can also be higher than traditional materials.

Impact on Application: Polyimide is particularly useful in aerospace and electronics, where lightweight and flexible solutions are essential.

Considerations for International Buyers: Buyers should be aware of the specific grades of polyimide available and ensure compliance with local standards, particularly in regions like Africa and South America, where material availability may vary.

Summary Table of Material Selection for Temperature Sensors

| Material | Typical Use Case for temperature sensor applications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial applications, food processing | Durable and corrosion-resistant | Susceptible to certain corrosive environments | Low |

| Ceramic | Aerospace, automotive applications | High-temperature stability and chemical resistance | Brittle and can fracture under stress | High |

| Glass | Laboratory thermometers, controlled environments | Non-reactive and precise readings | Fragile and sensitive to thermal expansion | Med |

| Polyimide | Aerospace, electronics, flexible applications | Flexible and lightweight | Not suitable for high-pressure environments | Med |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of common materials used in temperature sensors, helping them make informed decisions tailored to their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for temperature sensor applications

What Are the Key Stages in the Manufacturing Process of Temperature Sensors?

The manufacturing of temperature sensors is a complex process that requires precision and adherence to strict quality control measures. The main stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The choice of materials is critical in the production of temperature sensors. Common materials include metals for thermocouples (such as nickel, copper, and platinum) and ceramics for thermistors. The manufacturing process begins with the selection of high-quality raw materials, which are then subjected to various treatments to ensure optimal electrical and thermal properties.

For instance, metals may undergo processes such as annealing to improve ductility and conductivity. Meanwhile, ceramics often require sintering at high temperatures to achieve the desired density and mechanical strength. The quality of these materials directly affects the sensor’s performance and lifespan.

How Are Temperature Sensors Formed?

The forming stage involves shaping the prepared materials into the desired sensor components. For thermocouples, this includes joining dissimilar metals at specific junctions, which is crucial for generating the voltage needed for temperature measurement.

In the case of Resistance Temperature Detectors (RTDs), thin films of platinum are deposited onto a substrate to create a precise resistance element. Techniques such as photolithography and laser cutting are often employed to ensure high precision in component dimensions.

Illustrative image related to temperature sensor applications

What Does the Assembly Process Entail?

Once formed, the individual components are assembled into complete temperature sensors. This stage includes soldering, welding, or adhesive bonding of the elements, depending on the sensor type. For instance, thermowells, which protect the sensing elements, may be welded onto the sensor body to ensure a robust seal against environmental factors.

Automated assembly lines are frequently utilized to enhance efficiency and consistency, though manual assembly may be necessary for more intricate designs. Proper handling during this stage is crucial to avoid contamination or damage to sensitive components.

What Are the Finishing Techniques Used in Temperature Sensor Manufacturing?

Finishing touches often include protective coatings, calibration, and labeling. Sensors may receive coatings to enhance their resistance to corrosive environments, which is particularly important for applications in harsh industrial settings.

Calibration is a critical step that ensures the accuracy of the sensors. This involves exposing the sensors to known temperature references and adjusting their outputs accordingly. Proper labeling and documentation are also essential for traceability and compliance with regulatory standards.

What Quality Control Measures Are Essential for Temperature Sensors?

Quality control (QC) is a vital aspect of temperature sensor manufacturing, particularly for international B2B buyers who require reliability and compliance with industry standards.

What Are the Relevant International Standards for Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for ensuring product compliance in specific sectors.

These standards help guarantee that the sensors meet safety, performance, and environmental criteria, which is especially important for buyers in diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are identified and rectified promptly. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify issues that may arise during material preparation, forming, or assembly.

-

Final Quality Control (FQC): This final inspection checks the complete product for overall functionality, calibration accuracy, and compliance with safety standards.

What Common Testing Methods Are Utilized for Temperature Sensors?

Several testing methods are employed to validate the performance and reliability of temperature sensors. Common techniques include:

-

Thermal Cycling Tests: These assess the sensor’s response to rapid temperature changes, ensuring stability and reliability in fluctuating conditions.

-

Calibration Tests: These ensure that sensors provide accurate readings across their specified temperature ranges.

-

Environmental Testing: This simulates the operating conditions the sensors will face, such as humidity, pressure, and exposure to corrosive substances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from emerging markets, verifying a supplier’s QC processes is essential for ensuring product reliability.

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers should conduct thorough audits of potential suppliers. This includes reviewing their manufacturing facilities, quality management systems, and compliance with international standards.

On-site visits can provide valuable insights into the supplier’s operational practices and commitment to quality. Additionally, buyers can request documentation of past audits and certifications to assess the supplier’s track record.

How Can Buyers Access Quality Control Reports?

Suppliers should be able to provide detailed quality control reports that outline the results of various tests and inspections. These reports should include data on the materials used, calibration results, and compliance with relevant standards.

Buyers may also consider third-party inspections as an additional layer of assurance. Independent auditors can validate the supplier’s QC processes and confirm adherence to specified standards.

Illustrative image related to temperature sensor applications

What Are the Nuances of Quality Certification for International Buyers?

Navigating quality certification can be complex for international B2B buyers. Different regions may have specific requirements that must be met for successful importation.

Buyers should familiarize themselves with the regulatory landscape in their target markets to ensure compliance with local standards. This may involve understanding specific certifications required for temperature sensors in different industries, such as medical, industrial, or automotive sectors.

Conclusion: Why Is Quality Assurance Critical for Temperature Sensor Applications?

In summary, the manufacturing processes and quality assurance measures for temperature sensors are critical for ensuring product reliability and performance. By understanding the key stages of manufacturing, relevant international standards, and effective quality control practices, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only enhances their procurement strategy but also contributes to the overall success of their applications in various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘temperature sensor applications’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring temperature sensors effectively for various applications. By following these steps, you can ensure that you select the right technology, supplier, and terms to meet your specific operational needs, whether in industrial, geotechnical, or other sectors.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right temperature sensor for your needs. Consider the operational environment, temperature range, accuracy requirements, and sensor type (e.g., thermocouples, RTDs, or thermistors). Ensure your specifications align with industry standards applicable to your sector.

- Operational Environment: Assess whether the sensor will be used in extreme conditions, such as high humidity or corrosive environments.

- Measurement Accuracy: Determine the precision required for your application to avoid costly errors.

Step 2: Identify the Appropriate Sensor Type

Understanding the types of temperature sensors available is essential for making informed decisions. Each type has unique advantages and limitations, impacting performance and cost.

- Contact Sensors: These include thermocouples and RTDs, ideal for direct measurement in solid, liquid, or gas states.

- Non-Contact Sensors: Useful in hazardous environments, these measure thermal radiation and are often employed in industrial applications.

Step 3: Evaluate Potential Suppliers

Before committing, vet potential suppliers thoroughly to ensure they can meet your needs. Request comprehensive company profiles, including their experience in your industry, case studies, and references from other clients.

- Supplier Reputation: Research online reviews and testimonials to gauge reliability and product quality.

- Certifications: Verify that the supplier complies with relevant international standards, such as ISO certifications, to ensure product quality and reliability.

Step 4: Request Samples and Perform Testing

Once you have shortlisted suppliers, request samples of the temperature sensors. Conduct thorough testing to assess their performance in your specific application.

- Performance Testing: Evaluate accuracy, response time, and durability under operational conditions.

- Compatibility Check: Ensure that the sensors integrate seamlessly with your existing systems and infrastructure.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with suppliers to secure favorable pricing and contractual terms. Be transparent about your budget while ensuring you do not compromise on quality.

- Volume Discounts: Inquire about pricing tiers based on order volume to optimize costs.

- Warranty and Support: Discuss warranty periods and after-sales support to safeguard your investment.

Step 6: Plan for Logistics and Supply Chain Management

Effective logistics and supply chain management are essential for timely delivery and installation. Discuss shipping timelines and any potential delays with your supplier.

- Lead Times: Understand the production and delivery timelines to plan your project schedule accordingly.

- Customs and Regulations: If importing sensors, familiarize yourself with local customs regulations to avoid unexpected delays.

Step 7: Establish a Long-Term Relationship

Building a strong, long-term relationship with your supplier can lead to better support and pricing in the future. Regular communication helps ensure ongoing alignment with your needs.

Illustrative image related to temperature sensor applications

- Feedback Loop: Provide feedback on product performance to help suppliers improve their offerings.

- Future Needs: Discuss potential future projects or needs to facilitate better planning on both sides.

By following these steps, B2B buyers can effectively navigate the procurement process for temperature sensors, ensuring that they select the right products for their specific applications while fostering productive supplier relationships.

Comprehensive Cost and Pricing Analysis for temperature sensor applications Sourcing

What Are the Key Cost Components in Temperature Sensor Applications Sourcing?

When sourcing temperature sensors, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The type of temperature sensor significantly influences material costs. For instance, thermocouples require specific metals that may be subject to price volatility. RTDs and thermistors also have unique materials that can affect pricing based on market demand and availability.

-

Labor: Labor costs can vary widely depending on the region of production. Countries with lower labor costs may provide a competitive advantage, but it is essential to consider quality and expertise in manufacturing temperature sensors.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment, and utilities. Efficient manufacturing processes can reduce overhead, impacting the final price of the sensors.

-

Tooling: The initial investment in tooling can be significant, especially for custom sensors. This cost is often amortized over larger production runs, making it essential to consider minimum order quantities (MOQs) when negotiating prices.

-

Quality Control (QC): Ensuring that temperature sensors meet industry standards and certifications adds to the cost. Buyers should prioritize suppliers with rigorous QC processes to mitigate risks associated with faulty sensors.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Consideration of Incoterms can help manage responsibilities and costs associated with transportation.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure business viability. Understanding the competitive landscape can aid buyers in evaluating whether the margins are justified.

How Do Price Influencers Affect Temperature Sensor Costs?

Several factors can influence the pricing of temperature sensors, impacting the overall cost for international B2B buyers.

-

Volume/MOQ: Higher order volumes typically lead to reduced unit prices due to economies of scale. Buyers should negotiate for lower prices based on projected demand.

-

Specifications and Customization: Customized sensors tailored to specific applications can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials Quality and Certifications: Sensors made from high-quality materials and those that comply with international certifications (like ISO or CE) may command higher prices but often provide better reliability and performance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more for their products due to perceived value, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the chosen Incoterms can influence the total landed cost of products. Different terms dictate who bears the risk and cost at various stages of the shipping process, impacting the final price.

What Are Essential Tips for Negotiating Temperature Sensor Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing temperature sensors.

-

Negotiate Based on Volume: Leverage potential future orders to negotiate better terms. Suppliers are often willing to provide discounts for larger commitments.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, energy consumption, and potential failures. Investing in higher-quality sensors may yield lower TCO.

-

Explore Regional Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall value.

-

Understand Pricing Nuances: Be aware of pricing fluctuations based on market conditions, such as raw material prices or geopolitical events that may affect supply chains.

Final Thoughts on Sourcing Temperature Sensors

While indicative prices for temperature sensors can vary widely based on numerous factors, a thorough understanding of cost components and price influencers can empower B2B buyers to make informed decisions. Engaging in strategic negotiations and considering the total cost of ownership can lead to better sourcing outcomes, particularly for international buyers navigating complex markets.

Illustrative image related to temperature sensor applications

Alternatives Analysis: Comparing temperature sensor applications With Other Solutions

Exploring Alternatives to Temperature Sensor Applications

In industrial and commercial settings, temperature sensors play a critical role in monitoring and controlling processes. However, several alternative technologies can also fulfill similar objectives, each with its unique advantages and limitations. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Temperature Sensor Applications | Infrared Thermometers | Bimetallic Temperature Gauges |

|---|---|---|---|

| Performance | High accuracy and reliability across a wide temperature range. | Quick measurements; effective for non-contact applications. | Reliable for general temperature measurement but less precise than electronic sensors. |

| Cost | Moderate to high initial investment, depending on type. | Generally lower cost and easy to find. | Affordable but may require frequent calibration. |

| Ease of Implementation | Requires careful installation and calibration. | Simple to use; point-and-shoot functionality. | Straightforward installation with basic mechanical setup. |

| Maintenance | Requires periodic calibration and maintenance. | Minimal maintenance; infrequent recalibration needed. | Low maintenance, but mechanical wear can affect accuracy over time. |

| Best Use Case | Ideal for continuous monitoring in various industrial applications. | Best for quick, non-contact measurements in hazardous areas. | Suitable for basic temperature monitoring in less critical environments. |

In-Depth Analysis of Alternatives

What are Infrared Thermometers and Their Benefits?

Infrared thermometers provide a non-contact method for measuring temperature by detecting thermal radiation emitted from an object. This technology is particularly advantageous in hazardous environments where direct contact with the material being measured poses risks. Infrared thermometers are generally cost-effective and easy to implement, making them a popular choice for quick assessments. However, they may not offer the same level of accuracy as traditional temperature sensors and can be influenced by environmental factors, such as ambient temperature and distance from the target.

What are Bimetallic Temperature Gauges and Their Advantages?

Bimetallic temperature gauges utilize a mechanical system composed of two different metals bonded together. As temperature increases, the different expansion rates cause the metals to bend, which moves a needle on a dial to indicate the temperature. These gauges are affordable and straightforward to install, making them suitable for basic temperature monitoring tasks. However, they lack the precision of electronic sensors and may require periodic calibration to maintain accuracy. Their mechanical nature also makes them susceptible to wear and tear over time.

How to Choose the Right Solution for Your Needs

When selecting between temperature sensor applications and their alternatives, B2B buyers should consider several factors, including the specific requirements of their industry, the accuracy needed for their applications, and budget constraints. For high-precision and continuous monitoring, temperature sensors remain the best choice. In contrast, for quick assessments or non-contact measurements, infrared thermometers may be more appropriate. Bimetallic gauges serve well in less demanding applications where cost and simplicity are prioritized over precision. By aligning the chosen solution with operational needs, companies can enhance efficiency and maintain effective temperature control.

Essential Technical Properties and Trade Terminology for temperature sensor applications

What Are the Key Technical Properties of Temperature Sensors in B2B Applications?

When selecting temperature sensors for industrial applications, understanding their critical specifications is essential for ensuring reliability and performance. Here are some key properties to consider:

1. Material Grade

The material used in temperature sensors, such as thermocouples or RTDs, significantly impacts their accuracy and durability. Common materials include stainless steel, copper, and specialized alloys, each offering different thermal conductivity and resistance characteristics. For B2B buyers, selecting the right material grade is crucial for compatibility with specific applications and environmental conditions, especially in industries such as food processing or chemical manufacturing where sensor integrity is paramount.

2. Temperature Range

Temperature sensors are designed to operate within specified temperature ranges. Understanding the operational limits—such as the maximum and minimum temperatures a sensor can withstand—helps prevent sensor failure and ensures accurate readings. This property is particularly important for industries like oil and gas, where sensors may be exposed to extreme conditions. Buyers should verify that the sensors meet the requirements of their specific applications to avoid costly downtimes.

3. Accuracy and Tolerance

Accuracy refers to how close a sensor’s reading is to the actual temperature, while tolerance indicates the allowable deviation from the true value. High-accuracy sensors are essential in applications where precise temperature control is necessary, such as in pharmaceuticals or semiconductor manufacturing. B2B buyers should prioritize sensors that meet their accuracy requirements, as this can directly influence product quality and compliance with industry standards.

4. Response Time

Response time is the duration it takes for a temperature sensor to react to temperature changes. This property is critical in applications requiring real-time monitoring and control, such as in HVAC systems or automated manufacturing processes. A shorter response time can lead to better process control and efficiency, making it a vital consideration for B2B decision-makers.

5. IP Rating

The Ingress Protection (IP) rating defines how well a temperature sensor can withstand dust and moisture. For sensors deployed in harsh environments, such as outdoor installations or areas with high humidity, selecting a sensor with an appropriate IP rating is essential for longevity and reliability. Buyers should assess the environmental conditions to determine the necessary IP rating, reducing the risk of sensor failure.

What Are Common Trade Terms in Temperature Sensor Procurement?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions involving temperature sensors. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of temperature sensors, buyers often work directly with OEMs to ensure that the sensors meet their specific needs and integrate seamlessly into their systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and budgeting. Understanding MOQ helps buyers plan their purchases effectively, ensuring they meet production requirements without overcommitting resources.

Illustrative image related to temperature sensor applications

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the temperature sensor market, issuing an RFQ allows buyers to compare costs, specifications, and delivery times from multiple suppliers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and duties, which is essential for managing costs and logistics in cross-border purchases of temperature sensors.

5. Calibration

Calibration is the process of adjusting a sensor to ensure its accuracy against a known standard. Regular calibration is vital for maintaining the performance of temperature sensors, especially in industries where precise measurements are critical. Buyers should inquire about calibration services to ensure ongoing accuracy.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting temperature sensors that align with their operational requirements and industry standards.

Illustrative image related to temperature sensor applications

Navigating Market Dynamics and Sourcing Trends in the temperature sensor applications Sector

What Are the Current Market Dynamics and Key Trends in Temperature Sensor Applications?

The temperature sensor market is witnessing significant growth, driven by increasing demand across various sectors, including automotive, healthcare, and industrial automation. Emerging technologies, such as the Internet of Things (IoT) and Industry 4.0, are reshaping the landscape, enabling real-time data collection and analysis. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

One key trend is the shift towards smart sensors that offer enhanced connectivity and data analytics capabilities. These devices not only measure temperature but also provide insights into operational efficiencies and predictive maintenance. Moreover, the demand for miniaturization is prompting manufacturers to innovate smaller, more efficient sensors suitable for a variety of applications, from wearable technology to embedded systems in machinery.

Another notable trend is the growing focus on customization. Buyers are increasingly seeking sensors tailored to specific industrial needs, such as extreme temperature ranges or chemical resistance, which is particularly relevant in industries like oil and gas and food processing. Additionally, the rising importance of automation and smart factories is accelerating the demand for advanced temperature measurement solutions, compelling suppliers to adapt their offerings.

As B2B buyers navigate these market dynamics, they should also consider regional factors such as local regulations, supply chain stability, and the availability of technology partners. Engaging with local suppliers who understand the unique challenges of these markets can lead to more effective sourcing strategies and successful project outcomes.

How Can Sustainability and Ethical Sourcing Influence Temperature Sensor Applications?

Sustainability and ethical sourcing are increasingly important for B2B buyers in the temperature sensor applications sector. The environmental impact of manufacturing processes and the materials used in sensors can significantly affect a company’s overall sustainability profile. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials.

The importance of ethical supply chains cannot be overstated. As consumers and businesses alike demand greater accountability, suppliers must ensure that their sourcing practices do not exploit workers or harm the environment. This includes sourcing raw materials from certified suppliers who adhere to ethical labor practices and environmental standards.

Illustrative image related to temperature sensor applications

In the context of temperature sensor applications, buyers can look for ‘green’ certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). These certifications indicate that the products comply with stringent environmental regulations and are safer for both users and the planet. Additionally, the use of recyclable and biodegradable materials in sensor production is becoming a vital consideration for B2B buyers aiming to enhance their sustainability credentials.

By adopting a sustainability-first approach and prioritizing ethical sourcing, businesses can not only reduce their environmental impact but also enhance their brand reputation, driving customer loyalty and potentially increasing market share.

What Is the Brief Evolution and History of Temperature Sensors?

Temperature sensors have evolved significantly over the past century, transitioning from simple thermometers to advanced digital sensors that integrate seamlessly into modern technology. The first temperature measurement devices were rudimentary, relying on the physical expansion of liquids, such as mercury in glass thermometers.

With advancements in materials science and electronics, thermocouples and resistance temperature detectors (RTDs) emerged, offering greater accuracy and reliability for industrial applications. As technology continued to advance, the development of smart sensors equipped with IoT capabilities marked a new era, allowing for remote monitoring and data analysis.

Today, temperature sensors are integral to various sectors, including manufacturing, healthcare, and automotive industries. The evolution reflects a continuous pursuit of precision, efficiency, and sustainability, shaping the future landscape for B2B buyers seeking innovative solutions in temperature measurement.

Frequently Asked Questions (FAQs) for B2B Buyers of temperature sensor applications

-

How do I choose the right temperature sensor for my application?

Choosing the right temperature sensor involves understanding your specific application requirements, including temperature range, accuracy, and environmental conditions. For industrial applications, thermocouples and RTDs are popular due to their robustness and accuracy. Consider factors such as whether the sensor needs to be in contact with the material or if a non-contact solution is more appropriate. Additionally, evaluate the sensor’s response time and compatibility with existing equipment to ensure seamless integration. -

What are the key differences between thermocouples, RTDs, and thermistors?

Thermocouples are ideal for high-temperature applications and offer a wide temperature range, but they are less accurate than RTDs. RTDs provide high accuracy and stability, making them suitable for precision measurements in controlled environments. Thermistors are cost-effective and sensitive, often used for moderate temperature ranges. The choice between these sensors should depend on the specific requirements of your application, such as temperature range, sensitivity, and budget. -

What are the minimum order quantities (MOQ) for temperature sensors?

Minimum order quantities for temperature sensors vary by supplier and can depend on the type of sensor and customization requirements. Some manufacturers may have a MOQ as low as 10 units, while others may require orders of 100 or more. It’s advisable to discuss your needs directly with suppliers to find options that fit your budget and requirements, especially if you’re looking to test a new sensor type before committing to larger orders. -

How can I ensure the quality of temperature sensors from suppliers?

To ensure the quality of temperature sensors, request certifications such as ISO 9001 or specific industry-related standards. Conducting supplier audits or visiting their facilities can also provide insights into their manufacturing processes. Additionally, ask for product samples and performance data before making bulk purchases. Utilizing third-party testing labs for validation can further ensure that the sensors meet your quality and performance standards. -

What payment terms should I expect when sourcing temperature sensors internationally?

Payment terms can vary widely among suppliers, particularly in international trade. Common practices include upfront payments, partial payments upon order confirmation, and balance payments upon shipment. It’s crucial to negotiate terms that protect your interests, such as letters of credit or escrow services. Always confirm the currency of payment and any additional fees, including transaction or conversion fees, to avoid surprises during the purchasing process. -

What logistics considerations should I keep in mind when importing temperature sensors?

Logistics considerations include shipping methods, customs duties, and lead times. Choose a reliable shipping partner experienced in handling industrial equipment to ensure timely delivery. Be aware of customs regulations in your country, as these can affect shipping times and costs. It’s also wise to factor in potential delays caused by customs inspections or documentation issues. Planning for these factors can help streamline the import process. -

Are temperature sensors customizable for specific applications?

Yes, many manufacturers offer customization options for temperature sensors to meet specific application needs. Customizations can include size, shape, sensitivity, temperature range, and even the type of connection or output signal. Discuss your requirements with suppliers, who can often provide tailored solutions to enhance performance in your unique operational environment. -

What are the common applications for temperature sensors in various industries?

Temperature sensors are used across diverse industries, including manufacturing, food processing, pharmaceuticals, and construction. In manufacturing, they monitor equipment temperatures to prevent overheating. In food processing, they ensure that products are stored and cooked at safe temperatures. In construction, temperature sensors monitor the curing process of concrete. Understanding the specific needs of your industry can help you select the most effective sensor for your application.

Top 6 Temperature Sensor Applications Manufacturers & Suppliers List

1. Variohm – Temperature Sensors

Domain: variohm.com

Registered: 1997 (28 years)

Introduction: Temperature Sensors from Variohm include a complete range of products such as Temperature Probes, Medical Temperature Probes, RTD Sensors (Platinum and Nickel), and NTC Thermistors. These sensors are utilized in various applications across multiple industries including medical, motorsport, HVAC, agriculture, industrial, aerospace, and automotive. Specific applications include monitoring temperatur…

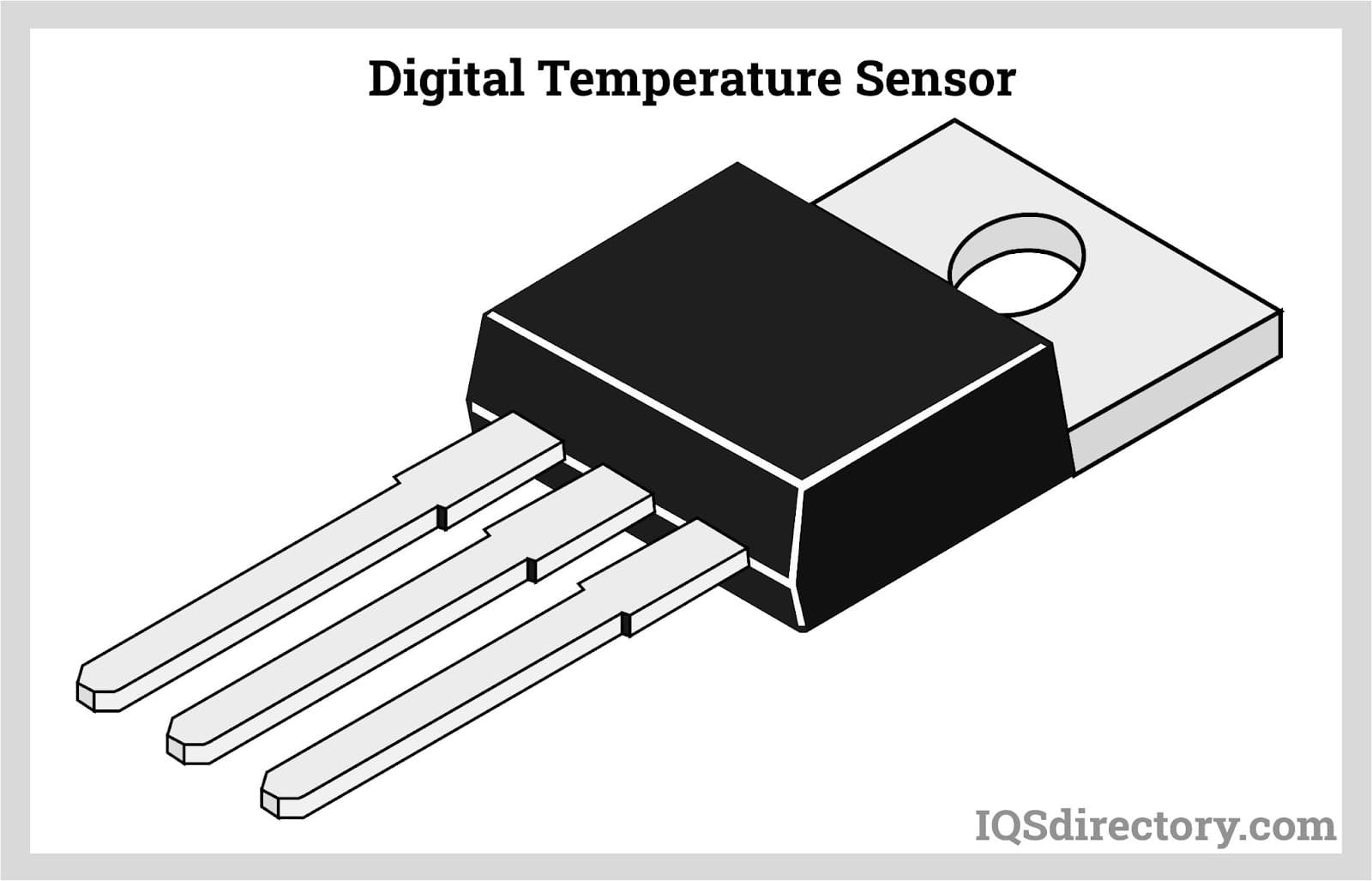

2. IQS Directory – Temperature Sensors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Temperature sensors assess thermal conditions by converting thermal information into electrical outputs. They are used in everyday items like thermometers, microwaves, refrigerators, and water heaters, as well as in applications such as geotechnical monitoring. Temperature sensors can be categorized into contact and non-contact types. Contact sensors include thermistors and thermocouples, which me…

3. Analog – Types of Temperature Sensors

Domain: analog.com

Registered: 1990 (35 years)

Introduction: Types of Temperature Sensors: 1. RTD (Resistance Temperature Detector): Accuracy and stability over -200°C to +850°C. 2. Thermocouple: Wide range -270°C to +1800°C, lower accuracy at high temperatures. 3. Thermistor: Cost-effective, good accuracy over -270°C to +1800°C. 4. Diode-based sensor: Limited range -55°C to +150°C, fast response time, small size. Key Products: 1. ADT7320: Accuracy ±1°C, SP…

4. Upkeep – Temperature Sensors

Domain: upkeep.com

Registered: 1999 (26 years)

Introduction: Temperature sensors are devices that track ambient temperatures, assess readings, and measure the impact of heat conditions. They can be wireless or hardwired into a larger CMMS network. There are six major types of temperature sensors: 1. Thermocouple – measures voltage differences, durable, cost-effective, works across wide temperature ranges. 2. Infrared – senses temperatures of scanned areas, …

5. Master Bond – Specialty Adhesives for Sensor Applications

Domain: masterbond.com

Registered: 1996 (29 years)

Introduction: Master Bond offers a range of one and two component epoxies, silicones, UV-curables, and latex systems designed for sensor applications in various industries including automotive, chemical, electronic, and optical. These products provide protection against harsh environmental conditions such as moisture, abrasion, elevated temperatures, shock, vibration, and corrosion. Key features include:

– Cust…

6. Ashcroft – Temperature Sensors

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: Temperature sensors are used to measure temperature in various applications, including OEM systems and industrial processes. They convert temperature changes into readable output signals for monitoring. Common types include: 1. Thermocouples: Wide temperature range (over 2000 °C or 3632 °F), fast response times, cost-effective but less accurate and stable. Example: Ashcroft® S80 Thermocouple Tempe…

Strategic Sourcing Conclusion and Outlook for temperature sensor applications

In the rapidly evolving landscape of temperature sensor applications, strategic sourcing emerges as a vital component for businesses aiming to optimize their operations and enhance product quality. The diverse array of temperature sensors—including thermocouples, RTDs, and thermistors—offers significant flexibility and accuracy in various industries, from manufacturing to geotechnical monitoring. By leveraging these technologies, businesses can improve process efficiency, ensure compliance with safety standards, and ultimately drive cost savings.

For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, the importance of strategic sourcing cannot be overstated. Establishing reliable partnerships with manufacturers and suppliers not only ensures access to high-quality sensors but also fosters innovation through collaboration. As industries increasingly adopt automation and smart technologies, the demand for precise temperature measurement will continue to grow.

Looking ahead, companies are encouraged to evaluate their sourcing strategies and align them with the latest technological advancements. By doing so, they can position themselves at the forefront of their respective industries. Take the initiative to explore new suppliers, invest in training, and remain agile in your sourcing approach to fully capitalize on the benefits that temperature sensors can provide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.