Top 3 Shoulder Mount Air Cylinder Suppliers (And How to Choose)

Introduction: Navigating the Global Market for shoulder mount air cylinder

In today’s competitive landscape, sourcing the right shoulder mount air cylinder can pose significant challenges for international B2B buyers. With a myriad of options available, understanding the specific types and applications tailored to your industry is crucial for optimizing operational efficiency. This comprehensive guide delves into the various configurations of shoulder mount air cylinders, their applications across different sectors, and the essential criteria for vetting reliable suppliers. By addressing factors such as cost analysis, installation considerations, and maintenance best practices, this resource equips buyers from Africa, South America, the Middle East, and Europe—specifically in regions like Brazil and Saudi Arabia—with the insights needed to make informed purchasing decisions.

Navigating the global market for shoulder mount air cylinders requires a strategic approach to sourcing, particularly in diverse industrial environments. This guide not only highlights the technical specifications and performance metrics of different cylinder types but also provides actionable recommendations for assessing suppliers and negotiating contracts. With a focus on quality assurance and compatibility, you can enhance your procurement strategy, reduce downtime, and ultimately drive productivity within your operations. Whether you are involved in manufacturing, automotive, or any other sector that relies on pneumatic systems, this resource is designed to empower you with the knowledge necessary to secure the best shoulder mount air cylinders for your specific needs.

Understanding shoulder mount air cylinder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shoulder Mount | Fixed mounting point, typically made of aluminum or steel, designed for high load capacities. | Manufacturing machinery, automation systems | Pros: High durability, cost-effective. Cons: Limited adjustability. |

| Adjustable Shoulder Mount | Features adjustable brackets for varying load conditions, allowing for fine-tuning of positioning. | Robotics, assembly lines | Pros: Versatile and customizable. Cons: More complex installation. |

| Compact Shoulder Mount | Smaller size for tight spaces, lightweight materials like composite plastics. | Aerospace, automotive applications | Pros: Space-saving design, easy to integrate. Cons: Lower load capacity. |

| Heavy-Duty Shoulder Mount | Reinforced structure designed to withstand extreme loads and harsh environments. | Heavy machinery, construction equipment | Pros: Exceptional strength, long lifespan. Cons: Higher cost, bulkier design. |

| Dual-Action Shoulder Mount | Allows for push and pull actions, enhancing operational flexibility. | Material handling, conveyor systems | Pros: Increased functionality, efficient use of space. Cons: More complex mechanism may require specialized maintenance. |

What are the characteristics of Standard Shoulder Mount Air Cylinders?

Standard shoulder mount air cylinders are typically constructed from robust materials such as aluminum or steel, making them suitable for high-load applications. They feature a fixed mounting point, which simplifies installation and ensures stability during operation. These cylinders are ideal for use in manufacturing machinery and automation systems, where reliability and durability are paramount. Buyers should consider their load requirements and the operational environment, as these cylinders may offer limited adjustability.

Why choose Adjustable Shoulder Mount Air Cylinders for specific applications?

Adjustable shoulder mount air cylinders come with brackets that allow for varying load conditions, making them suitable for applications that require fine-tuning of positioning. This adaptability is particularly beneficial in robotics and assembly lines, where precise movements are crucial. While they provide versatility, the installation process can be more complex, requiring skilled technicians. Buyers should weigh the benefits of customization against potential installation challenges.

How do Compact Shoulder Mount Air Cylinders fit into modern designs?

Compact shoulder mount air cylinders are designed for applications where space is at a premium. Their lightweight materials, often composite plastics, enable easy integration into tight spaces, such as in aerospace and automotive industries. While they excel in saving space, buyers should be aware that their load capacity may be lower compared to standard models. It’s essential to assess the specific application needs before selecting a compact model.

What makes Heavy-Duty Shoulder Mount Air Cylinders a preferred choice in tough environments?

Heavy-duty shoulder mount air cylinders are engineered to withstand extreme loads and harsh environmental conditions, making them ideal for heavy machinery and construction equipment. Their reinforced structure ensures long-lasting performance, even under significant stress. However, these cylinders tend to be bulkier and carry a higher price tag. Buyers in demanding industries should evaluate the cost versus the benefits of durability and longevity.

Why consider Dual-Action Shoulder Mount Air Cylinders for enhanced flexibility?

Dual-action shoulder mount air cylinders provide the unique capability of both push and pull actions, making them highly versatile for various applications, including material handling and conveyor systems. This flexibility can lead to more efficient operations, as they can perform multiple functions without needing separate components. However, their more complex mechanisms may require specialized maintenance, which should be considered in the purchasing decision. Buyers should assess their operational needs to determine if the added functionality justifies the potential maintenance requirements.

Key Industrial Applications of shoulder mount air cylinder

| Industry/Sector | Specific Application of Shoulder Mount Air Cylinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Automated Assembly Lines | Increases efficiency and speed in vehicle assembly | Ensure compatibility with existing machinery and standards |

| Food and Beverage | Packaging Machinery | Enhances precision in packaging processes | Consider hygiene standards and material certifications |

| Robotics | Robotic Arm Actuation | Improves accuracy and reliability in robotic tasks | Assess weight capacity and response time requirements |

| Material Handling | Conveyor Systems | Streamlines material movement and handling | Look for durability and maintenance requirements |

| Aerospace | Testing and Simulation Equipment | Provides reliable actuation for testing applications | Verify compliance with industry safety standards |

How is the Shoulder Mount Air Cylinder Used in Automotive Manufacturing?

In the automotive manufacturing sector, shoulder mount air cylinders are integral to automated assembly lines. These cylinders facilitate the precise movement of tools and components, significantly enhancing the speed and efficiency of vehicle assembly. By automating repetitive tasks, businesses can reduce labor costs and minimize human error. Buyers should ensure that the cylinders are compatible with existing machinery and comply with NFPA or ISO standards to guarantee seamless integration into their operations.

What Role Does the Shoulder Mount Air Cylinder Play in Food and Beverage Packaging?

In the food and beverage industry, shoulder mount air cylinders are employed in packaging machinery to ensure accurate and efficient packaging processes. These cylinders allow for precise actuation of packaging components, which is crucial for maintaining product integrity and compliance with hygiene standards. International buyers must consider material certifications and ensure that the cylinders meet local food safety regulations to maintain product quality and safety.

How Does the Shoulder Mount Air Cylinder Enhance Robotics?

Shoulder mount air cylinders are pivotal in robotics, particularly for robotic arm actuation. They provide smooth and controlled movements, essential for tasks that require high precision, such as assembly or handling delicate components. For buyers in this sector, it is crucial to assess the weight capacity and response time of the cylinders to ensure they meet the specific operational demands of their robotic systems.

In What Ways Does the Shoulder Mount Air Cylinder Streamline Material Handling?

In material handling applications, shoulder mount air cylinders are used in conveyor systems to facilitate the movement of goods. These cylinders enable smooth transitions and precise control over the handling of heavy loads, reducing the risk of damage and improving operational efficiency. When sourcing these cylinders, businesses should prioritize durability and consider maintenance requirements to ensure long-term reliability in demanding environments.

What is the Importance of Shoulder Mount Air Cylinders in Aerospace Testing?

In the aerospace industry, shoulder mount air cylinders are utilized in testing and simulation equipment to provide reliable actuation. These cylinders are critical for simulating various flight conditions and testing aircraft components under controlled environments. Buyers in this sector must verify compliance with stringent industry safety standards and ensure that the cylinders can withstand the unique challenges posed by aerospace applications.

3 Common User Pain Points for ‘shoulder mount air cylinder’ & Their Solutions

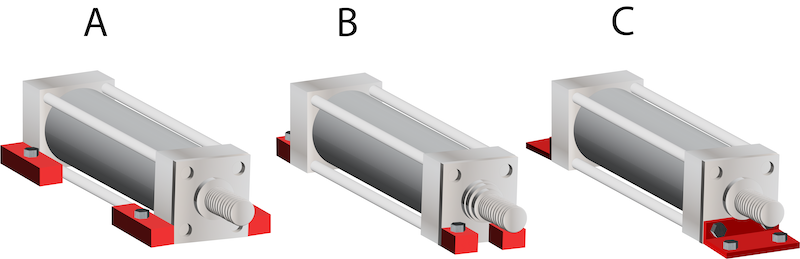

Scenario 1: Installation Challenges with Shoulder Mount Air Cylinders

The Problem: One of the most common challenges B2B buyers face when integrating shoulder mount air cylinders is the complexity of installation. Many manufacturers provide limited guidance, leading to confusion about mounting styles, orientations, and required components. Inadequate installation can result in misalignment, loss of efficiency, and premature wear, which could lead to costly downtime in production. Buyers may feel overwhelmed when trying to determine the correct installation process, especially when dealing with various cylinder models and mounting standards.

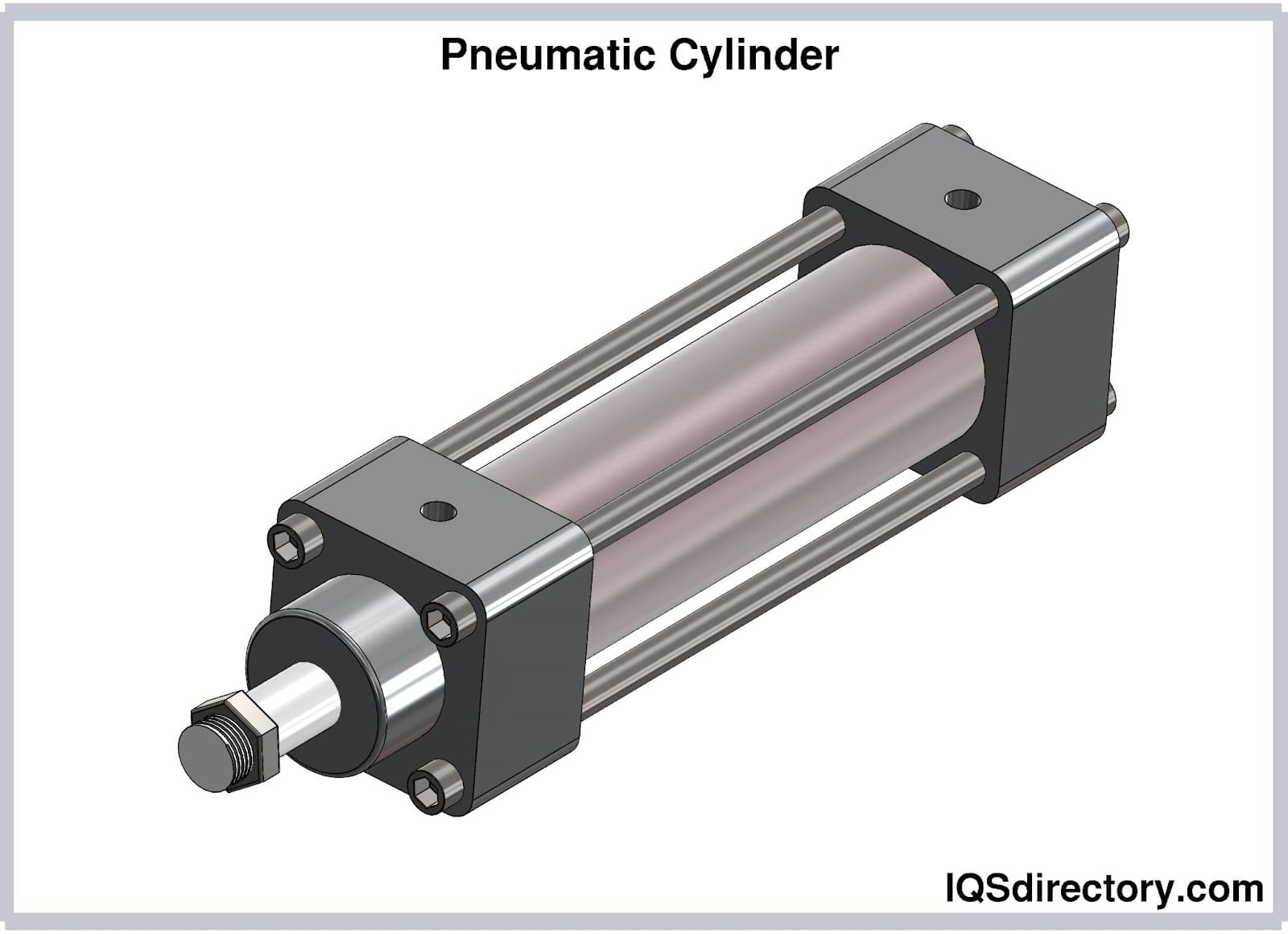

Illustrative image related to shoulder mount air cylinder

The Solution: To overcome installation challenges, buyers should prioritize sourcing shoulder mount air cylinders that adhere to recognized standards, such as NFPA or ISO. This ensures compatibility with existing machinery and simplifies the installation process. Additionally, buyers should invest time in reviewing comprehensive installation guides provided by manufacturers. These guides typically outline step-by-step procedures tailored to specific models. Engaging with supplier technical support can also provide valuable insights, helping buyers clarify any uncertainties before installation. Finally, utilizing mounting kits that come with all necessary components can streamline the process, reducing the risk of errors and enhancing operational efficiency.

Scenario 2: Compatibility Issues with Existing Equipment

The Problem: Compatibility issues often arise when trying to integrate new shoulder mount air cylinders into existing machinery setups. B2B buyers may find that the specifications of the new cylinders do not align with their current systems, which can result in operational inefficiencies or the need for costly modifications. This is particularly relevant for businesses operating in diverse industries, where machinery standards can vary significantly.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough assessment of their existing equipment before selecting a shoulder mount air cylinder. This includes measuring mounting dimensions, understanding the load requirements, and verifying the pneumatic specifications of the current system. Establishing a relationship with a trusted supplier who can provide customizable solutions is beneficial. Many manufacturers offer bespoke cylinder options that can be tailored to meet specific application needs. Furthermore, adopting a modular approach to design can allow for easier upgrades and replacements in the future, enabling businesses to adapt to evolving operational demands without significant overhauls.

Scenario 3: Maintenance and Performance Degradation

The Problem: Over time, shoulder mount air cylinders can experience performance degradation due to wear and tear, leading to reduced efficiency and increased operational costs. B2B buyers often struggle with maintenance schedules and identifying the right maintenance practices that can prolong the lifespan of their air cylinders. The lack of a clear maintenance protocol can result in unexpected breakdowns, further complicating workflow and impacting productivity.

The Solution: Implementing a robust maintenance program is crucial for enhancing the longevity and performance of shoulder mount air cylinders. Buyers should establish a routine maintenance schedule that includes regular inspections for signs of wear, such as leaks or unusual noises. Utilizing condition monitoring tools can also provide real-time data on the performance of the cylinders, allowing for timely interventions. Additionally, training staff on proper usage and maintenance protocols can help prevent operational mistakes that lead to accelerated wear. Collaborating with suppliers for ongoing support and access to replacement parts can ensure that businesses can promptly address any issues, minimizing downtime and maintaining optimal performance.

Strategic Material Selection Guide for shoulder mount air cylinder

What Are the Common Materials Used for Shoulder Mount Air Cylinders?

When selecting materials for shoulder mount air cylinders, it’s essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Here’s an analysis of four common materials used in the manufacturing of these components.

How Does Aluminum Perform as a Material for Shoulder Mount Air Cylinders?

Aluminum is a popular choice for shoulder mount air cylinders due to its lightweight nature and good strength-to-weight ratio. It typically has a temperature rating of up to 150°C and can withstand moderate pressures, making it suitable for various pneumatic applications.

Pros: Aluminum is resistant to corrosion, making it ideal for environments that may expose the cylinder to moisture or chemicals. Additionally, its lightweight nature allows for easier handling and installation.

Illustrative image related to shoulder mount air cylinder

Cons: While aluminum is durable, it is not as strong as steel, which may limit its use in high-stress applications. The manufacturing complexity can also be higher due to the need for specialized machining techniques.

Impact on Application: Aluminum is compatible with a wide range of media, including air and inert gases, but may not perform well with aggressive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM or ISO is crucial. Buyers in regions like Europe and the Middle East may prefer aluminum due to its lightweight properties, especially for applications in automotive and aerospace sectors.

What Advantages Does Steel Offer for Shoulder Mount Air Cylinders?

Steel is another widely used material for shoulder mount air cylinders, known for its exceptional strength and durability. It can handle high pressures (up to 300 psi) and has a temperature rating that can exceed 200°C, making it suitable for demanding applications.

Illustrative image related to shoulder mount air cylinder

Pros: Steel’s high strength makes it ideal for heavy-duty applications, ensuring long-term reliability. It also has excellent wear resistance, which is beneficial in high-friction environments.

Cons: The primary drawback of steel is its susceptibility to corrosion, particularly in humid or chemically aggressive environments. This may necessitate additional protective coatings, increasing manufacturing complexity and costs.

Impact on Application: Steel is compatible with a variety of media, including air and hydraulic fluids, but may require careful selection of protective coatings when used in corrosive environments.

Considerations for International Buyers: Compliance with standards like DIN or JIS is important, especially in regions such as Brazil and Saudi Arabia, where industrial applications are prevalent.

How Does Stainless Steel Compare for Shoulder Mount Air Cylinders?

Stainless steel is favored for its corrosion resistance and aesthetic appeal, making it suitable for applications where appearance matters, such as in food processing or pharmaceutical industries. It can withstand high temperatures (up to 300°C) and pressures.

Pros: Its corrosion resistance is superior to that of regular steel, allowing for use in harsh environments. Stainless steel also has good mechanical properties, ensuring durability.

Cons: The cost of stainless steel is significantly higher than that of aluminum or regular steel, which may not be justifiable for all applications. The machining process can also be more complex and time-consuming.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive chemicals, making it ideal for specialized applications.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer stainless steel for its compliance with food safety standards and regulations, making it a common choice in these regions.

What Role Does Plastic Play in Shoulder Mount Air Cylinders?

Plastic, particularly engineering plastics like polyamide (nylon) or polycarbonate, is sometimes used in shoulder mount air cylinders for lightweight applications. These materials can handle moderate pressures and temperatures (up to 80°C).

Pros: Plastic is lightweight and resistant to corrosion, making it suitable for applications where weight savings are critical. It also offers good insulation properties.

Cons: The primary limitation of plastic is its lower strength compared to metals, which may restrict its use in high-load applications. Additionally, its temperature and pressure ratings are lower, limiting its versatility.

Impact on Application: Plastic is suitable for pneumatic applications with non-corrosive media but may not be appropriate for high-stress environments.

Considerations for International Buyers: In regions like Africa and South America, where cost sensitivity is higher, plastic may be an attractive option for low-cost applications, provided that it meets relevant compliance standards.

Summary Table of Material Selection for Shoulder Mount Air Cylinders

| Material | Typical Use Case for shoulder mount air cylinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications in automotive sectors | Corrosion-resistant and lightweight | Lower strength than steel | Medium |

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to corrosion | Medium |

| Stainless Steel | Food processing and pharmaceutical applications | Superior corrosion resistance | Higher cost and complex machining | High |

| Plastic | Lightweight pneumatic applications | Lightweight and corrosion-resistant | Lower strength and durability | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shoulder mount air cylinder

What Are the Key Manufacturing Processes for Shoulder Mount Air Cylinders?

The manufacturing of shoulder mount air cylinders involves several critical stages that ensure the final product meets the required specifications and performance standards.

How Is Material Prepared for Shoulder Mount Air Cylinders?

The first step in the manufacturing process is material preparation. High-quality materials, typically aluminum or stainless steel, are selected for their strength, durability, and resistance to corrosion. The raw materials undergo rigorous inspection to ensure they meet the specified grades and standards.

Cutting the materials to the required lengths is the next step, often using automated CNC machines for precision. This process minimizes waste and ensures consistency across production batches.

What Forming Techniques Are Used in the Production of Air Cylinders?

After material preparation, the forming stage begins. This typically involves processes such as extrusion, machining, and forging.

-

Extrusion: In this method, the raw material is forced through a die to create a cylindrical shape. This technique is efficient for producing long, uniform sections that can later be machined to exact specifications.

-

Machining: Precision machining is employed to create the necessary features, such as mounting holes and grooves, ensuring that each component fits seamlessly within the assembly.

-

Forging: For components requiring high strength, forging techniques are utilized. This process alters the material structure at high temperatures, enhancing its mechanical properties.

How Are Shoulder Mount Air Cylinders Assembled?

Once the individual components are formed, assembly follows. This phase involves the careful integration of the piston, cylinder body, and shoulder mount.

-

Assembly Techniques: Typically, assembly is performed using automated systems that enhance efficiency and accuracy. Each component is fitted together, and fasteners are applied to secure the assembly.

-

Sealing and Testing: After assembly, seals are installed to ensure airtight integrity. This is crucial for the performance of the air cylinder.

What Quality Assurance Measures Are Essential for Shoulder Mount Air Cylinders?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the shoulder mount air cylinders meet both regulatory and customer standards.

Which International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that adhere to international standards such as ISO 9001, which establishes a framework for quality management systems. Additionally, certifications like CE mark (European Conformity) and API (American Petroleum Institute) may be relevant depending on the application of the air cylinders.

These certifications indicate that the manufacturer complies with stringent quality and safety standards, which is particularly important in regions with strict regulatory environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before they are processed.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of the components being produced. This includes dimensional checks and visual inspections to catch defects early.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is conducted. This includes testing the air cylinders for performance under pressure, verifying seal integrity, and ensuring that all components function correctly.

What Common Testing Methods Are Employed for Quality Assurance?

Several testing methods are commonly used to validate the performance and durability of shoulder mount air cylinders:

-

Pressure Testing: This method assesses the strength and leak integrity of the air cylinder by subjecting it to high-pressure conditions.

-

Functionality Testing: This involves actuating the cylinder to ensure it operates smoothly and responds as expected under various conditions.

-

Fatigue Testing: To simulate long-term use, fatigue testing evaluates how the cylinder withstands repeated cycles of operation.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers can take proactive steps to ensure that their suppliers maintain high-quality standards:

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into the quality control processes in place. This includes reviewing documentation related to quality standards and testing results.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation that outlines their quality control processes, including results from testing and inspection.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can verify that the products meet the required specifications before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality standards and practices. Buyers should familiarize themselves with local regulations and compliance requirements.

-

Supply Chain Considerations: Logistics can impact quality assurance, particularly in transportation. Understanding how products are handled during shipping can help mitigate risks of damage or quality degradation.

-

Communication: Clear communication with suppliers regarding quality expectations is crucial. This includes detailing specifications, testing requirements, and deadlines.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing shoulder mount air cylinders, ensuring they receive reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoulder mount air cylinder’

Introduction

This guide is designed to assist international B2B buyers in sourcing shoulder mount air cylinders effectively. The procurement process can be complex, especially when considering various technical specifications, supplier capabilities, and compliance requirements. This checklist will help streamline your decision-making and ensure you select the right products for your applications.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your shoulder mount air cylinder. This includes dimensions, mounting styles, and performance characteristics such as load capacity and stroke length.

- Consider application requirements: Ensure the specifications align with the specific needs of your machinery or equipment.

- Account for environmental factors: Be aware of factors like temperature, humidity, and potential exposure to chemicals that could affect performance.

Step 2: Research Industry Standards

Familiarize yourself with relevant industry standards that govern pneumatic cylinders, such as NFPA and ISO norms.

- Ensure compatibility: Understanding these standards will help you select products that fit seamlessly into your existing systems.

- Safety regulations: Compliance with industry standards is crucial for safety and reliability, especially in high-stakes applications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers.

- Request documentation: Ask for company profiles, certifications, and case studies that demonstrate their experience in your industry.

- Seek references: Contact other buyers in similar markets to gauge the supplier’s reliability and product quality.

Step 4: Assess Manufacturing Capabilities

Investigate the manufacturing processes and capabilities of shortlisted suppliers.

- Look for quality assurance: Ensure that the supplier has robust quality control measures in place to maintain product consistency.

- Evaluate production capacity: Confirm that the supplier can meet your order volumes, especially for large or recurring purchases.

Step 5: Verify Supplier Certifications

Check for relevant certifications that validate the supplier’s quality management systems, such as ISO 9001 or other industry-specific accreditations.

- Importance of certifications: Certifications indicate a commitment to quality and reliability, which is essential in B2B transactions.

- Regulatory compliance: Ensure the supplier adheres to local and international regulations, particularly if you are importing products.

Step 6: Request Samples and Testing

Before finalizing your order, request product samples to evaluate performance firsthand.

- Conduct trials: Test the samples in your operational environment to assess their functionality and durability.

- Evaluate customer support: Observe the supplier’s responsiveness to your inquiries during this phase, as it reflects their commitment to customer satisfaction.

Step 7: Negotiate Terms and Conditions

Finally, engage in negotiations regarding pricing, delivery schedules, and warranty terms.

- Establish clear expectations: Ensure that both parties are aligned on pricing structures, payment terms, and delivery timelines to avoid future disputes.

- Consider long-term partnerships: Look for suppliers willing to build a long-term relationship, which can lead to better pricing and service in future transactions.

By following this checklist, B2B buyers can make informed decisions when sourcing shoulder mount air cylinders, ensuring they select high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for shoulder mount air cylinder Sourcing

What Are the Key Cost Components in Sourcing Shoulder Mount Air Cylinders?

When sourcing shoulder mount air cylinders, buyers must consider several cost components that contribute to the overall pricing structure. The primary cost factors include:

-

Materials: The choice of materials significantly influences the cost. Common materials for air cylinders include aluminum and stainless steel, which offer durability and resistance to corrosion. High-grade materials may increase upfront costs but can reduce long-term maintenance expenses.

-

Labor: Labor costs encompass the expenses related to manufacturing the air cylinders, including machining, assembly, and quality control. Labor rates can vary significantly based on the country of origin, impacting the final price.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in tooling and molds can be substantial, particularly for customized or high-specification cylinders. However, these costs can be amortized over large production runs, leading to lower per-unit costs.

-

Quality Control (QC): Ensuring the air cylinders meet quality standards is essential, especially in industries where reliability is critical. QC processes may involve testing and certification, which add to the overall cost.

-

Logistics: Transportation and handling costs are crucial, especially for international shipments. Factors such as distance, shipping method, and import duties can significantly affect logistics expenses.

-

Margin: Suppliers typically build a margin into their pricing to ensure profitability. This margin can vary based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect Shoulder Mount Air Cylinder Costs?

Several factors influence the pricing of shoulder mount air cylinders, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Custom-designed cylinders or those with unique specifications typically incur additional costs. Buyers should be clear about their requirements and understand how customization affects pricing.

-

Material Quality and Certifications: Cylinders made from higher-quality materials or those that meet specific industry certifications may command a premium price. Buyers should consider the long-term benefits of investing in higher-quality products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer more competitive rates due to their experience and efficient processes.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting overall costs.

What Are the Best Buyer Tips for Negotiating Costs?

To ensure cost efficiency when sourcing shoulder mount air cylinders, buyers should consider the following strategies:

Illustrative image related to shoulder mount air cylinder

-

Negotiation: Engage suppliers in discussions about pricing, particularly for bulk orders. Establishing long-term relationships can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Assess the total cost of ownership rather than just the initial purchase price. Consider factors like maintenance, longevity, and energy efficiency, which can significantly impact overall costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of potential pricing fluctuations due to currency exchange rates, tariffs, and regional demand. Understanding these nuances can inform better purchasing decisions.

-

Conduct Market Research: Researching market trends and competitor pricing can provide leverage during negotiations. Staying informed about industry standards and innovations can also help in identifying the best suppliers.

Conclusion

Sourcing shoulder mount air cylinders involves a complex interplay of costs and pricing influencers. By understanding these components, B2B buyers can make informed decisions that optimize their procurement strategies. It is crucial to approach sourcing with a comprehensive perspective, considering both immediate costs and long-term value. As always, prices can fluctuate, and it is advisable to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing shoulder mount air cylinder With Other Solutions

Exploring Alternatives to Shoulder Mount Air Cylinders

In the realm of industrial automation and machinery, selecting the right actuation solution is critical. Shoulder mount air cylinders are popular for their precision and efficiency in various applications, but several alternatives may be more suitable depending on specific operational requirements. This analysis compares shoulder mount air cylinders with other viable solutions, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Shoulder Mount Air Cylinder | Linear Actuator | Electric Actuator |

|---|---|---|---|

| Performance | High precision, fast response | Moderate precision, slower than pneumatic | High precision, variable speed |

| Cost | Moderate (dependent on specifications) | Moderate to high (depending on type and brand) | High initial investment, lower long-term operating costs |

| Ease of Implementation | Requires specific mounting and pneumatic setup | Generally easy to install, requires electrical connections | Requires electrical setup and control systems |

| Maintenance | Moderate (periodic checks for leaks and wear) | Low (minimal moving parts) | Low to moderate (depends on the complexity of the system) |

| Best Use Case | High-performance applications like motorsports | General automation, material handling | Applications requiring precise control and positioning |

Detailed Breakdown of Alternatives

Linear Actuator

Linear actuators convert rotational motion into linear motion, making them suitable for various applications, including material handling and assembly processes. They are generally easier to install than shoulder mount air cylinders due to their simpler setup and can be powered by pneumatic, hydraulic, or electric means. However, they typically offer moderate precision and speed, which may not meet the demands of high-performance applications. The cost can vary, but they are often more affordable than pneumatic systems when considering long-term maintenance.

Electric Actuator

Electric actuators provide precise control over motion and speed, making them ideal for applications requiring variable positioning, such as robotic assembly or automated machinery. They tend to have a higher initial investment compared to shoulder mount air cylinders but can offer lower operational costs over time due to reduced energy consumption and minimal maintenance requirements. The complexity of installation can be a drawback, as electric actuators often require additional electrical control systems, which may not be suitable for all applications. Their flexibility and precision can outweigh the initial costs, particularly in environments where accuracy is paramount.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting an actuation solution, B2B buyers should assess their specific operational needs, including performance requirements, budget constraints, and installation capabilities. Shoulder mount air cylinders excel in high-speed, high-precision scenarios, while linear actuators provide a more straightforward and often cost-effective solution for general automation tasks. Electric actuators offer unparalleled precision and control, making them suitable for advanced applications despite their higher initial costs. By carefully considering these factors, buyers can choose the most appropriate technology to enhance their operational efficiency and productivity.

Essential Technical Properties and Trade Terminology for shoulder mount air cylinder

What Are the Key Technical Properties of a Shoulder Mount Air Cylinder?

When selecting a shoulder mount air cylinder, understanding its technical specifications is crucial for ensuring optimal performance in your applications. Here are some essential properties to consider:

1. Material Grade

The material used in manufacturing shoulder mount air cylinders, such as aluminum, steel, or composite materials, significantly impacts durability, weight, and resistance to corrosion. For example, 6061-T6 aluminum is often favored for its strength-to-weight ratio and corrosion resistance, making it ideal for high-performance environments. B2B buyers should prioritize material grade to ensure the cylinder meets the specific demands of their operational environment.

2. Bore Size

The bore size, which is the internal diameter of the cylinder, directly influences the force output and efficiency of the air cylinder. Larger bore sizes can generate greater force, which is critical in applications requiring heavy lifting or rapid actuation. When sourcing, consider the bore size that aligns with your application requirements to avoid performance bottlenecks.

3. Stroke Length

The stroke length is the distance the piston travels within the cylinder. Selecting the appropriate stroke length is vital for applications that require specific movement ranges. Understanding the required stroke can prevent underperformance or mechanical failure, ensuring the air cylinder fulfills its intended function without compromise.

4. Operating Pressure

Operating pressure ratings indicate the maximum pressure the cylinder can safely handle. This specification is critical for maintaining safety and performance standards. B2B buyers should assess their application’s pressure requirements to choose a cylinder that can operate efficiently within those parameters, reducing the risk of failure or accidents.

5. Tolerance Levels

Tolerance levels refer to the allowable variations in dimensions and performance characteristics. High tolerance levels are essential for applications requiring precise movements and consistent performance. Understanding tolerance specifications helps buyers ensure compatibility with existing systems and reduces the likelihood of operational disruptions.

6. Mounting Style

The mounting style of the shoulder mount air cylinder determines how it will be installed within a system. Common styles include flange, foot, and trunnion mounts. Selecting the correct mounting style ensures ease of installation and optimal alignment, which are crucial for maintaining the efficiency and longevity of the cylinder.

What Are Common Trade Terms Related to Shoulder Mount Air Cylinders?

Familiarity with industry jargon enhances communication and negotiation between suppliers and buyers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships is crucial for ensuring product quality and compatibility in your supply chain.

Illustrative image related to shoulder mount air cylinder

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers to understand as it affects inventory management and purchasing strategies. Knowing the MOQ helps in budgeting and planning for stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. It’s an essential tool for B2B buyers looking to compare costs and negotiate better deals, ensuring they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps in understanding shipping costs and responsibilities, which is crucial for international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for effective project planning and inventory management, ensuring that operations run smoothly without delays.

6. Certification Standards

Certifications such as ISO or CE indicate that products meet specific safety and quality standards. Knowledge of certification standards is important for B2B buyers to ensure compliance and reliability in their supply chains, particularly when dealing with international suppliers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing shoulder mount air cylinders, enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the shoulder mount air cylinder Sector

What Are the Current Market Dynamics and Key Trends in the Shoulder Mount Air Cylinder Sector?

The shoulder mount air cylinder sector is experiencing significant growth driven by advancements in automation and the increasing demand for precision engineering in various industries such as automotive, manufacturing, and robotics. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, seek reliable and efficient pneumatic solutions, the market is adapting to meet these needs. Key trends include the integration of smart technologies, such as IoT capabilities, allowing for real-time monitoring and predictive maintenance, which enhances operational efficiency.

Additionally, the shift towards modular designs is gaining traction. Modular air cylinders facilitate easier installation and maintenance, catering to the diverse needs of manufacturers who require adaptable solutions. This trend is particularly beneficial for businesses in emerging markets, where rapid scalability is essential. Moreover, increasing investments in renewable energy projects in regions like Africa and South America are spurring demand for pneumatic systems that can operate efficiently in varied environmental conditions.

B2B buyers must also consider the competitive landscape, which is marked by a mix of established manufacturers and emerging players. The latter often leverage innovative technologies and cost-effective manufacturing processes, thus providing buyers with a broader range of options. Understanding local market conditions, regulatory requirements, and cultural nuances is crucial for successful sourcing strategies.

How Are Sustainability and Ethical Sourcing Influencing the Shoulder Mount Air Cylinder Market?

Sustainability has become a pivotal factor in B2B sourcing decisions, particularly in the shoulder mount air cylinder sector. The environmental impact of pneumatic systems, including energy consumption and material waste, is under scrutiny. As a result, manufacturers are increasingly adopting sustainable practices, such as using recyclable materials and energy-efficient production processes. This not only reduces carbon footprints but also meets the growing expectations of environmentally conscious buyers.

Ethical sourcing is equally important, as it encompasses fair labor practices and responsible supply chain management. B2B buyers are now prioritizing suppliers who demonstrate transparency in their sourcing processes and adhere to international labor standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for manufacturers aiming to enhance their market appeal.

Furthermore, the use of “green” materials in the production of shoulder mount air cylinders is gaining popularity. Buyers are encouraged to inquire about suppliers’ commitment to sustainability and ethical sourcing. This includes understanding the lifecycle of products, from raw material extraction to end-of-life recycling. By aligning with suppliers who prioritize these values, businesses not only enhance their brand reputation but also contribute to a more sustainable industrial ecosystem.

What Is the Brief Evolution and History of the Shoulder Mount Air Cylinder?

The shoulder mount air cylinder has evolved significantly since its inception, driven by the need for more efficient and reliable pneumatic systems. Initially used in simple applications, these cylinders have transformed into sophisticated components equipped with advanced features such as adjustable stroke lengths and integrated sensors. The introduction of standardized mounting configurations, such as those specified by NFPA and ISO, has further facilitated compatibility and ease of installation across various industries.

Over the decades, technological advancements have led to the integration of computer-aided design (CAD) and simulation tools, enabling manufacturers to optimize cylinder designs for performance and durability. As industries embraced automation, the demand for shoulder mount air cylinders surged, prompting manufacturers to innovate continuously. This evolution reflects the broader trends of increased automation and the need for high-performance components in modern manufacturing processes, positioning shoulder mount air cylinders as critical components in today’s industrial landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of shoulder mount air cylinder

-

How do I choose the right shoulder mount air cylinder for my application?

Selecting the right shoulder mount air cylinder involves understanding your specific application requirements, including load capacity, stroke length, and environmental conditions. Consider the mounting style that best fits your machinery, whether it’s fixed centerline or non-centerline. Additionally, check for compatibility with existing equipment and ensure the cylinder adheres to relevant industry standards, such as NFPA or ISO. Consulting with suppliers about customization options can also help tailor the cylinder to your needs. -

What are the benefits of using a shoulder mount air cylinder in industrial applications?

Shoulder mount air cylinders provide several advantages in industrial settings, including improved space efficiency and ease of installation. They allow for cleaner setups without the need for extensive modifications, such as drilling into the frame. Their design facilitates quick and precise actuation, making them ideal for high-speed applications like automated assembly lines and robotic systems. Moreover, these cylinders can enhance the overall reliability of the machinery due to their robust construction and stable performance. -

What is the typical lead time for ordering shoulder mount air cylinders from international suppliers?

Lead times for shoulder mount air cylinders can vary significantly based on the supplier’s location, production capacity, and whether the order is customized. Generally, standard products may have a lead time of 2-4 weeks, while custom orders can take 6-12 weeks or more. It’s essential to communicate your project timelines clearly with suppliers and inquire about their production schedules and shipping methods to avoid delays. -

How can I ensure the quality of shoulder mount air cylinders from international suppliers?

To ensure quality, start by vetting potential suppliers through reviews, certifications, and their track record in the industry. Request product samples to assess their performance and durability firsthand. Additionally, inquire about their quality assurance processes, such as adherence to ISO standards and testing protocols. Establishing a clear communication line regarding your quality expectations and conducting regular audits can also help maintain standards throughout the supply chain. -

What are the minimum order quantities (MOQ) for shoulder mount air cylinders?

Minimum order quantities for shoulder mount air cylinders can vary widely depending on the manufacturer and whether the items are standard or custom. Typically, MOQs range from 50 to 100 units for standard products, while custom orders may require higher quantities. When negotiating with suppliers, it’s beneficial to discuss your needs upfront to find a suitable arrangement, especially if you’re looking to test the market with a smaller initial order. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can differ based on supplier policies and your negotiation outcomes. Common terms include upfront payments, partial payments before shipping, or net 30/60 days after delivery. Always clarify the accepted payment methods, such as wire transfers, letters of credit, or online payment platforms, to ensure a smooth transaction. Establishing a secure payment arrangement can mitigate risks associated with international trade. -

How do I handle shipping and logistics for shoulder mount air cylinders?

When sourcing shoulder mount air cylinders internationally, it’s crucial to discuss shipping options with your supplier. Factors to consider include freight costs, delivery times, and customs duties. Utilize freight forwarders who specialize in international shipping to streamline the process. Ensure that you have all necessary documentation, such as invoices and import permits, to facilitate customs clearance and avoid delays. -

Can shoulder mount air cylinders be customized for specific applications?

Yes, many manufacturers offer customization options for shoulder mount air cylinders to meet specific application needs. This can include modifications in size, stroke length, mounting styles, and materials used. When discussing customization with suppliers, provide detailed specifications about your requirements and ask for design recommendations. This collaboration can lead to a tailored solution that enhances the efficiency and effectiveness of your operations.

Top 3 Shoulder Mount Air Cylinder Manufacturers & Suppliers List

1. SMC – CD75R Air Cylinder

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “CD75R Air Cylinder”, “type”: “Direct Mount”, “action”: “Double Acting”, “rod_type”: “Single Rod”, “standard”: “Standard”}

2. JH Foster – Pneumatic Cylinders & Mounting Solutions

Domain: jhfoster.com

Registered: 1998 (27 years)

Introduction: Pneumatic cylinders, mounting configurations, NFPA and ISO standards, fixed centerline mountings, fixed non-centerline mountings, pivoted centerline mountings, cylinder stroke, plane of motion, load size and condition, column strength of piston rod, installation space, material properties, pressure ratings, mounting terminology, mounting types (MX1, MX2, MS1, MP1, etc.), benefits and limitations o…

3. SMC – Compact Air Cylinders

Domain: smcworld.com

Registered: 1998 (27 years)

Introduction: Compact Air Cylinders include models such as CUJ/CDUJ, CUJ-XB24, CU/CDU, CU-XB24, CDU-X3178, CQS/CDQS, CQS-XB24, JCQ/JCDQ, CQ2/CDQ2, CQ2-XB24, CQE, CDQ2B-X3166, CDQ2B-X3150, CDQ2B-X3205, CDQ2B-X3206, CDQ2B-X3207, CDQ2A-X3260, RQ/RDQ, CQM/CDQM, CQU, MU/MDU, C55/CD55, NCQ8.

Strategic Sourcing Conclusion and Outlook for shoulder mount air cylinder

In conclusion, the strategic sourcing of shoulder mount air cylinders is crucial for businesses aiming to optimize their operations and enhance productivity. By focusing on quality, compatibility, and innovation, international buyers can ensure they select the right components that not only meet their specific needs but also align with industry standards. The integration of advanced pneumatic technology can significantly improve efficiency, reduce downtime, and lead to cost savings in the long run.

As the global market continues to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, staying ahead of sourcing trends becomes essential. Engaging with reliable suppliers who adhere to international standards can foster robust partnerships that enhance supply chain resilience and adaptability.

Looking forward, businesses should consider not only the immediate benefits of sourcing but also the long-term value derived from investing in cutting-edge technologies and sustainable practices. Now is the time to act—evaluate your sourcing strategies, explore new suppliers, and invest in high-quality shoulder mount air cylinders that will drive your business forward. Embrace the future of pneumatic solutions and position your company as a leader in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.