Choosing Your Foundries In Florida: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for foundries in florida

In the quest for high-quality castings, international B2B buyers face a significant challenge: navigating the myriad foundries in Florida that offer diverse capabilities and products. This guide is designed to streamline the sourcing process for those interested in leveraging Florida’s robust foundry market, which specializes in aluminum, copper, iron, and unique artistic castings. By exploring various types of foundries, their applications across industries, and methods for vetting suppliers, this resource empowers decision-makers from regions such as Africa, South America, the Middle East, and Europe—specifically buyers from Nigeria and Saudi Arabia—to make informed purchasing choices.

Florida’s foundries are renowned for their advanced technologies and capabilities, including sand casting, permanent mold casting, and even 3D-printed molds. These facilities serve critical sectors like aerospace, automotive, and defense, ensuring that buyers can find tailored solutions to meet their specific needs. Additionally, this guide will delve into cost considerations and quality assurance practices, enabling buyers to evaluate their options effectively.

With a focus on actionable insights, this comprehensive resource equips international buyers with the knowledge necessary to navigate Florida’s foundry landscape confidently, ensuring that they secure the best products for their business applications. Whether you are a seasoned procurement professional or new to sourcing castings, this guide will enhance your understanding and facilitate successful partnerships within this dynamic market.

Understanding foundries in florida Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Sand Casting | Utilizes sand molds; cost-effective for complex shapes | Automotive, Aerospace, Marine | Pros: Versatile, quick turnaround; Cons: Surface finish may require additional machining. |

| Permanent Mold Casting | Metal molds for high precision; suitable for high-volume runs | Industrial Equipment, Defense, Medical | Pros: Excellent dimensional accuracy; Cons: Higher initial costs for mold creation. |

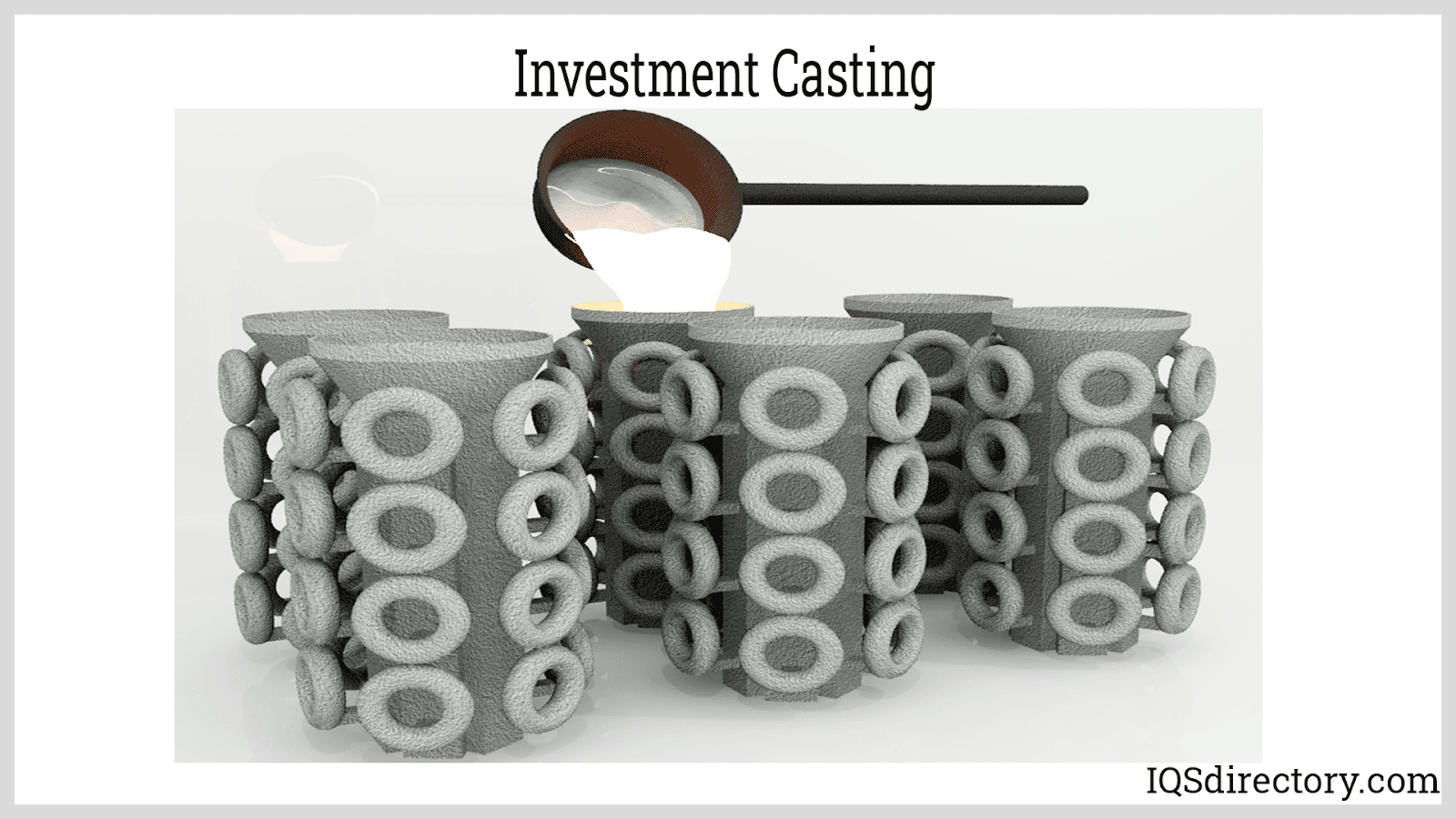

| Investment Casting | Uses wax patterns; ideal for intricate designs | Aerospace, Automotive, Medical | Pros: High precision and finish; Cons: Longer lead times, higher costs. |

| Grey Iron Casting | Known for strength and durability; uses advanced techniques | Construction, Industrial Equipment, Automotive | Pros: Robust and wear-resistant; Cons: Limited to specific applications due to material properties. |

| Brass and Copper Alloy Casting | Combines aesthetic appeal with functionality; various methods available | Decorative Items, Plumbing, Electrical Components | Pros: Excellent corrosion resistance; Cons: Higher material costs compared to alternatives. |

What Are the Key Characteristics of Aluminum Sand Casting Foundries?

Aluminum sand casting foundries are characterized by their use of sand molds, which allow for the economical production of complex shapes. This method is particularly suitable for low to medium volume production, making it a favorite in industries such as automotive and aerospace. Buyers should consider the foundry’s capabilities in terms of turnaround time and surface finish, as additional machining may be required for optimal results. The flexibility of this casting type makes it ideal for prototyping and custom parts.

How Does Permanent Mold Casting Differ from Other Methods?

Permanent mold casting involves the use of reusable metal molds, which provides exceptional dimensional accuracy and surface finish. This method is well-suited for high-volume production runs in industries like defense and medical equipment manufacturing. While the initial costs for creating molds can be higher, the long-term savings in production efficiency often justify the investment. Buyers should evaluate the foundry’s experience with precision casting and the specific alloys available.

What Makes Investment Casting a Preferred Choice for Complex Designs?

Investment casting is known for its ability to produce highly intricate designs using wax patterns that are melted away during the process. This method is particularly advantageous for industries requiring high precision, such as aerospace and medical device manufacturing. Although lead times can be longer and costs higher compared to other casting methods, the superior finish and detail make it a valuable option for specialized applications. Buyers should assess the foundry’s technology and experience in investment casting to ensure quality outcomes.

Why Is Grey Iron Casting Popular in Heavy Industries?

Grey iron casting is renowned for its strength, durability, and resistance to wear, making it a staple in construction and industrial equipment sectors. This type of casting employs advanced techniques to produce high-quality components. While the material’s properties limit its application range, its robustness is unmatched for heavy-duty uses. Buyers should consider the foundry’s ability to meet specific quality standards and their experience in producing grey iron components.

What Are the Advantages of Brass and Copper Alloy Casting for Decorative Applications?

Brass and copper alloy casting foundries focus on combining aesthetic appeal with functional applications. This casting type is often used in decorative items and plumbing fixtures due to its corrosion resistance and attractive finish. While the material costs can be higher, the longevity and visual appeal often justify the investment for buyers in decorative and electrical component markets. Evaluating the foundry’s expertise in different casting methods and finishing techniques is crucial for achieving the desired results.

Key Industrial Applications of foundries in florida

| Industry/Sector | Specific Application of foundries in Florida | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of aluminum and titanium castings | Lightweight components improve fuel efficiency | Compliance with aerospace standards (e.g., AMS) |

| Automotive | Manufacturing of engine blocks and structural components | Enhanced performance and durability of vehicles | Need for precise tolerances and material specifications |

| Defense and Military | Fabrication of critical parts for military vehicles and equipment | High-quality, reliable components for safety and performance | Adherence to military specifications and testing |

| Construction and Infrastructure | Production of heavy-duty castings for machinery and tools | Increased efficiency and reduced downtime in projects | Material strength and durability are critical factors |

| Marine | Creation of marine engine components and fittings | Resistance to corrosion and enhanced performance at sea | Consideration of marine-grade materials and treatments |

How Are Foundries in Florida Meeting Aerospace Industry Needs?

Foundries in Florida play a crucial role in the aerospace sector by producing lightweight aluminum and titanium castings. These materials are essential for manufacturing aircraft components that require both strength and reduced weight, ultimately enhancing fuel efficiency. International buyers should prioritize suppliers that comply with rigorous aerospace standards, such as AMS (Aerospace Material Specifications), to ensure quality and reliability in their components.

What Applications Do Foundries Serve in the Automotive Sector?

In the automotive industry, Florida foundries specialize in manufacturing engine blocks and structural components that are vital for vehicle performance. These castings are designed to withstand high stress and temperature variations, ensuring durability and efficiency. Buyers from regions like Africa and South America should seek foundries that can deliver precise tolerances and meet specific material specifications to ensure seamless integration into their vehicle designs.

How Do Foundries Support Defense and Military Applications?

Florida foundries provide critical manufacturing services for the defense sector, producing components for military vehicles and equipment. The emphasis on high-quality, reliable castings is paramount, as these parts must perform under extreme conditions. Buyers in the Middle East and Europe should focus on suppliers that adhere to military specifications and offer robust testing protocols to guarantee the safety and performance of their products.

What Are the Benefits of Foundries for Construction and Infrastructure?

In construction and infrastructure, foundries in Florida produce heavy-duty castings used in machinery and tools that enhance project efficiency. These castings are engineered for strength and durability, minimizing downtime and maintenance costs. B2B buyers should consider the material strength and durability of castings when sourcing, as these factors significantly impact project timelines and costs.

How Do Foundries Cater to the Marine Industry?

Foundries in Florida are instrumental in the marine sector, creating engine components and fittings that require resistance to corrosion and high performance in marine environments. The use of marine-grade materials is essential for ensuring the longevity and reliability of these components. Buyers should prioritize foundries that specialize in marine applications and understand the specific requirements for material treatments to withstand harsh sea conditions.

3 Common User Pain Points for ‘foundries in florida’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Casting

The Problem: B2B buyers often face significant challenges related to the quality of castings when sourcing from foundries in Florida. This is especially pertinent when working with critical applications such as aerospace, automotive, or defense. Buyers may experience frustration when the castings do not meet specific industry standards or specifications, leading to costly delays and rework. Moreover, the lack of transparency about the foundry’s quality control processes can leave buyers feeling uncertain about their investment.

The Solution: To mitigate quality control issues, buyers should conduct thorough due diligence before partnering with a foundry. This includes requesting documentation of quality certifications such as ISO 9001:2015 or specific industry standards like AMS-STD-2175. Engaging in a pre-production meeting can also be beneficial, allowing buyers to discuss their exact specifications, tolerances, and quality expectations directly with foundry engineers. Additionally, incorporating a rigorous inspection plan that includes non-destructive testing (NDT) methods can help ensure that the castings meet all necessary criteria before they are shipped. Establishing a strong communication channel with the foundry will facilitate real-time updates and allow for quick resolutions to any quality concerns that may arise.

Scenario 2: Overcoming Lead Time Constraints in Production

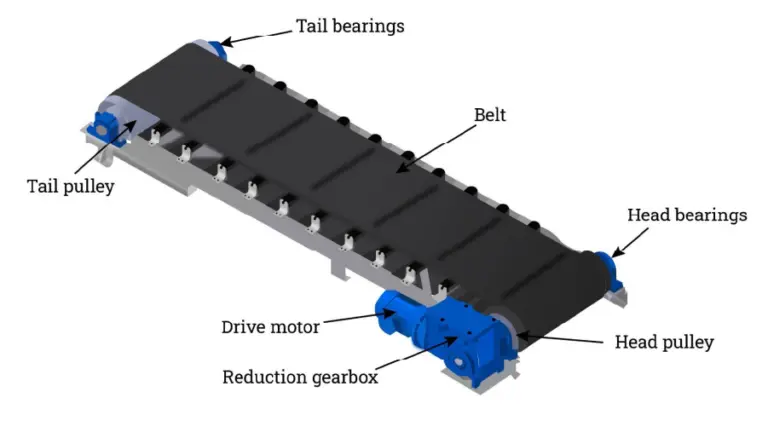

The Problem: International B2B buyers often encounter lengthy lead times when sourcing castings from foundries in Florida, which can disrupt their supply chains and project timelines. Factors such as high demand, production capacity limits, and logistical delays can exacerbate this issue, making it difficult for companies to meet their customers’ expectations and adhere to project deadlines. This can be particularly detrimental for buyers in industries where time-to-market is crucial.

Illustrative image related to foundries in florida

The Solution: To effectively manage lead time constraints, buyers should prioritize collaboration with foundries that offer flexible production capabilities and clear timelines. It is advisable to engage in discussions about production capacity and potential bottlenecks early in the sourcing process. Establishing long-term partnerships with foundries can also result in more favorable lead times, as these relationships often lead to prioritized service. Furthermore, buyers can consider utilizing advanced technologies like 3D printing for rapid prototyping, which can help accelerate the development process and reduce overall lead times. By maintaining an open dialogue with the foundry regarding production schedules and potential delays, buyers can better align their supply chain strategies and expectations.

Scenario 3: Addressing Cost Management and Budget Constraints

The Problem: Cost management is a critical concern for B2B buyers when dealing with foundries in Florida. Fluctuating material costs, unexpected price increases, and additional expenses for custom designs or specialized services can strain budgets, particularly for international buyers operating in competitive markets. This financial pressure can lead to difficult decisions regarding quality versus cost, potentially compromising the integrity of the final product.

The Solution: To effectively manage costs, buyers should engage in comprehensive market research to understand the pricing landscape of foundry services in Florida. Requesting detailed quotes that break down material, labor, and overhead costs can provide better visibility into pricing structures and help identify areas for potential savings. Additionally, buyers should explore alternative materials or casting methods that may offer a more cost-effective solution without sacrificing quality. Utilizing a fixed-price contract can also protect against unexpected cost increases, allowing for better financial planning. Lastly, establishing a long-term relationship with a foundry can lead to negotiated pricing structures that benefit both parties, making it easier to manage costs over time.

Strategic Material Selection Guide for foundries in florida

What Are the Common Materials Used in Florida Foundries?

In Florida’s foundries, several materials are frequently utilized for casting processes, each with distinct properties and applications. Understanding these materials is crucial for international B2B buyers to make informed decisions that align with their specific needs and compliance requirements.

Aluminum Alloys: Versatility and Lightweight Performance

Aluminum alloys are a staple in Florida foundries, known for their lightweight nature and excellent corrosion resistance. They typically exhibit good mechanical properties and can withstand moderate temperatures, making them suitable for various applications, from automotive components to aerospace parts.

Pros: The primary advantages of aluminum alloys include their lightweight characteristics, which contribute to fuel efficiency in transportation applications. They are also relatively easy to cast and machine, reducing manufacturing complexity.

Cons: On the downside, aluminum alloys can be more expensive than other materials like iron. They also have lower strength compared to some steel alloys, which may limit their use in high-stress applications.

Impact on Application: Aluminum’s compatibility with various media, such as water and certain chemicals, makes it ideal for automotive and marine applications.

Illustrative image related to foundries in florida

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should be aware of compliance with ASTM standards, particularly for aerospace and automotive applications, where specifications like AMS-STD-2175 are crucial.

Grey Iron: Strength and Durability for Heavy Applications

Grey iron is another commonly used material in Florida foundries, particularly for applications requiring high strength and wear resistance. Its excellent castability allows for complex shapes, making it ideal for engine blocks, machine bases, and heavy-duty components.

Pros: The key advantage of grey iron is its high wear resistance and ability to absorb vibrations, which is beneficial in heavy machinery applications. It is also cost-effective due to the abundance of raw materials.

Illustrative image related to foundries in florida

Cons: However, grey iron’s brittleness can be a significant drawback, making it less suitable for applications requiring high tensile strength. Additionally, its corrosion resistance is lower compared to aluminum.

Impact on Application: Grey iron’s durability makes it suitable for applications exposed to high stress and wear, such as automotive and industrial machinery.

Considerations for International Buyers: Buyers should consider the common standards for grey iron castings, such as ASTM A48, to ensure compliance with international quality benchmarks.

Illustrative image related to foundries in florida

Copper Alloys: Corrosion Resistance and Electrical Conductivity

Copper alloys, including bronze and brass, are often used in specialized applications due to their excellent corrosion resistance and electrical conductivity. They are commonly employed in marine environments and electrical components.

Pros: The primary advantage of copper alloys is their superior corrosion resistance, making them ideal for applications in harsh environments. They also offer excellent machinability and aesthetic appeal.

Cons: The main disadvantage is the higher cost of copper alloys compared to aluminum and iron. Additionally, they require more complex manufacturing processes, which can increase lead times.

Impact on Application: Copper alloys are particularly suited for applications involving electrical components, plumbing, and marine hardware due to their resistance to corrosion.

Considerations for International Buyers: Buyers from Europe and South America should ensure compliance with standards like ASTM B271 for copper alloy castings, which can affect material selection and sourcing.

Steel Alloys: Strength and Versatility

Steel alloys are widely used in Florida foundries for their high strength and versatility. They can be tailored to meet specific performance requirements, making them suitable for a range of applications, from construction to automotive.

Pros: The key advantage of steel alloys is their high tensile strength and durability, which make them suitable for heavy-duty applications. They can also be heat-treated to enhance performance characteristics.

Cons: However, steel alloys can be heavier and more expensive than alternatives like aluminum. They also require more complex processing techniques, which can impact production timelines.

Impact on Application: Steel alloys are ideal for applications requiring high strength and durability, such as structural components and heavy machinery.

Illustrative image related to foundries in florida

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM A36 for structural steel, ensuring that their products meet the necessary quality and performance criteria.

Summary Table of Material Selection

| Material | Typical Use Case for foundries in florida | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Automotive, aerospace components | Lightweight and corrosion resistant | Higher cost and lower strength | Medium |

| Grey Iron | Engine blocks, heavy machinery components | High wear resistance and cost-effective | Brittleness and lower corrosion resistance | Low |

| Copper Alloys | Marine hardware, electrical components | Superior corrosion resistance | Higher cost and complex manufacturing | High |

| Steel Alloys | Structural components, heavy machinery | High strength and versatility | Heavier and more complex processing | Medium |

This strategic material selection guide equips international B2B buyers with essential insights into the materials commonly used in Florida foundries, enabling them to make informed decisions that align with their operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for foundries in florida

What Are the Key Manufacturing Processes in Florida Foundries?

In Florida, foundries typically follow a structured manufacturing process that encompasses several key stages. Understanding these stages is essential for international B2B buyers seeking quality castings.

Material Preparation: How Are Raw Materials Processed?

The manufacturing process begins with material preparation, where raw materials such as aluminum, copper alloys, iron, and steel are sourced. Foundries often rely on specific alloys tailored to meet industry requirements, such as aerospace or automotive standards. The materials undergo sorting and testing to ensure they meet the necessary specifications before being introduced into the casting process.

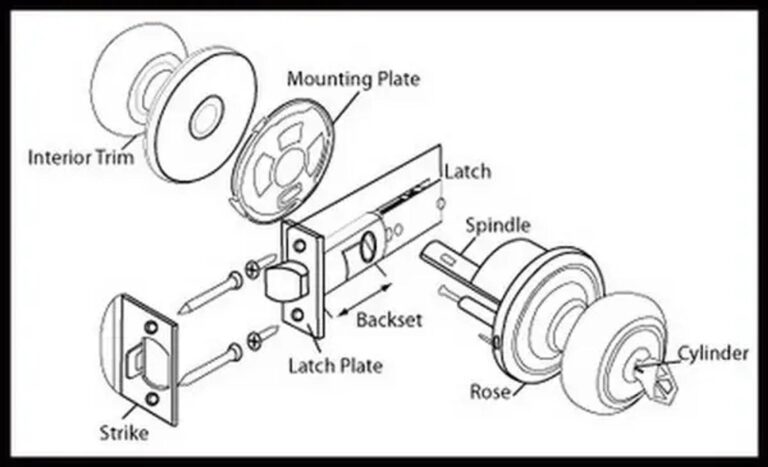

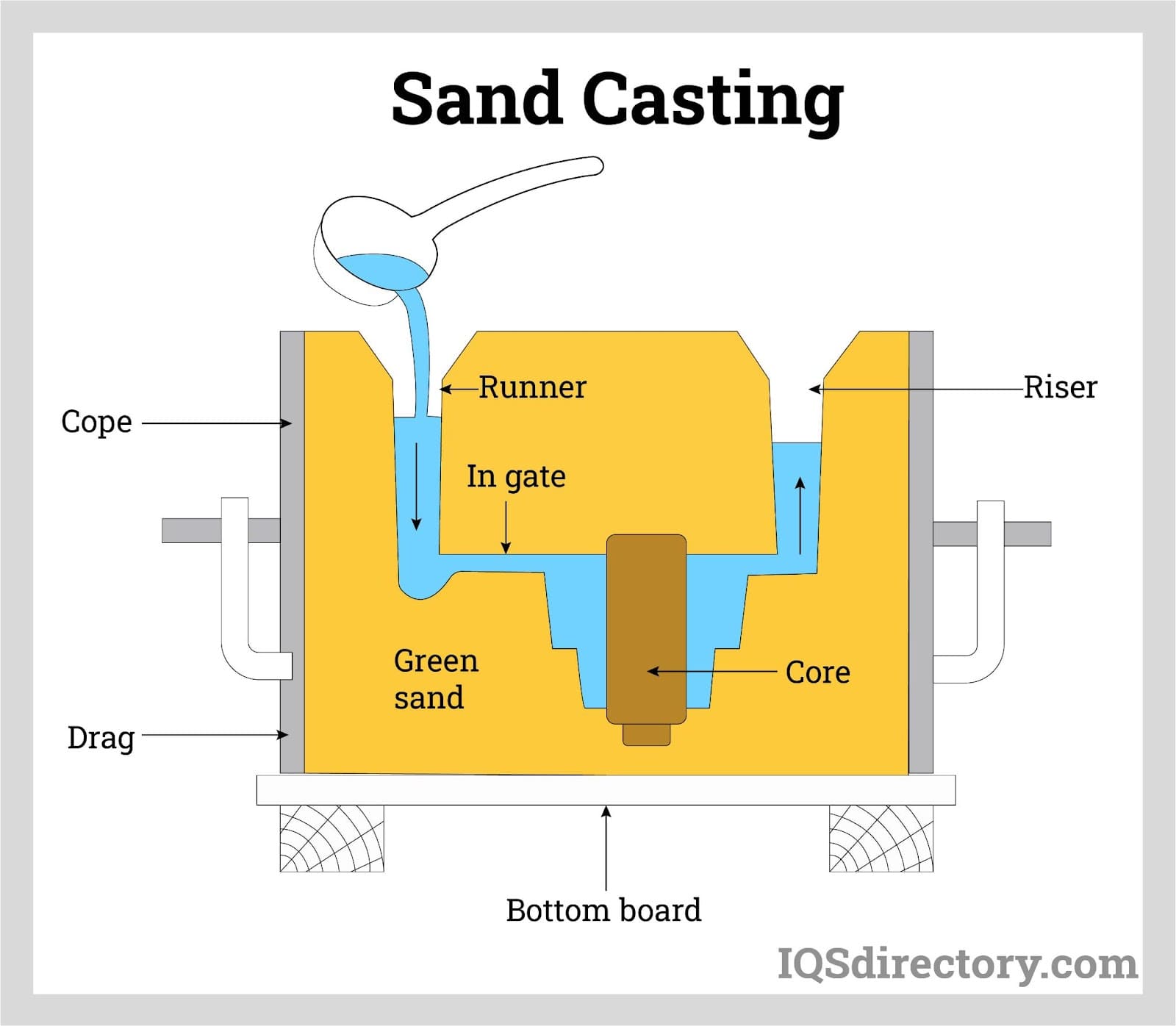

What Forming Techniques Are Commonly Used in Florida Foundries?

The forming stage is where the actual casting takes place. Florida foundries utilize various techniques, including:

Illustrative image related to foundries in florida

-

Sand Casting: A widely used method where sand is packed around a pattern to create a mold. This technique is favored for its flexibility and cost-effectiveness, especially for small to medium production runs.

-

Permanent Mold Casting: This method involves creating reusable molds, allowing for better surface finish and dimensional accuracy. It is commonly used for aluminum and copper alloy castings.

-

Investment Casting: Also known as lost-wax casting, this technique is ideal for producing intricate shapes and fine details, often used in aerospace and medical applications.

-

3D-Printed Molds: Emerging technologies, such as 3D printing, are increasingly being utilized for creating molds, reducing lead times and costs associated with traditional pattern-making.

Each of these techniques has specific applications and advantages, depending on the desired properties of the final product.

How Is Assembly Managed in the Foundry Process?

Once the casting is completed, the assembly phase may involve additional processes such as machining, which includes drilling, milling, and turning to achieve precise dimensions. Foundries like Florida Machine & Casting provide machining capabilities alongside casting, enhancing efficiency by offering a one-stop solution for buyers. This integration reduces lead times and enhances communication between the foundry and the buyer.

What Quality Assurance Practices Are Implemented in Florida Foundries?

Quality assurance (QA) is critical in foundries to ensure that products meet both international standards and customer expectations.

Which International Standards Govern Quality Control in Foundries?

Many Florida foundries adhere to international quality standards such as ISO 9001:2015, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to maintaining high-quality processes and continuous improvement.

In addition to ISO certifications, foundries may also comply with industry-specific standards such as:

- AMS (Aerospace Material Specifications): Essential for industries requiring stringent quality and material specifications.

- API (American Petroleum Institute): Important for foundries supplying the oil and gas sector, ensuring products meet safety and performance standards.

- CE Marking: Relevant for products sold in European markets, indicating conformity with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control in foundries typically involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the specified requirements before processing begins.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself. Techniques such as process audits and real-time inspections are employed to catch defects early.

-

Final Quality Control (FQC): After production, finished products undergo rigorous testing and inspection. Common testing methods include dimensional inspections, non-destructive testing (NDT), and mechanical property evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of potential suppliers is crucial. Here are actionable steps to ensure compliance and quality:

-

Conduct Supplier Audits: Engaging in regular audits can provide insights into the foundry’s operations, quality control processes, and adherence to industry standards.

-

Request Quality Reports: Buyers should request detailed quality assurance reports, including inspection records, testing results, and compliance certifications. This documentation can help assess the supplier’s reliability.

-

Engage Third-Party Inspectors: Employing third-party inspection services can add an extra layer of verification. These inspectors can assess the foundry’s processes and products independently, ensuring they meet the required standards.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control. Regulatory requirements may vary significantly by country, affecting import standards and product certifications.

Illustrative image related to foundries in florida

Understanding the local regulations in the buyer’s home country is essential, as compliance may require additional documentation or certifications beyond what the supplier typically provides. Moreover, language barriers can pose challenges during negotiations and audits, making it crucial for buyers to have representatives who understand both technical and regulatory terminologies.

Conclusion: Why Quality Assurance Is Critical for B2B Success in Florida Foundries

In summary, Florida foundries employ a comprehensive approach to manufacturing and quality assurance. By understanding the key processes and standards, international B2B buyers can make informed decisions when selecting suppliers. Rigorous quality control practices not only ensure the reliability of the products but also foster long-term partnerships based on trust and performance. Buyers are encouraged to actively engage with suppliers to verify quality control measures, ensuring that their needs are met with the highest standards of craftsmanship and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘foundries in florida’

Introduction

This guide is designed to assist international B2B buyers in navigating the procurement process for foundry services in Florida. By following these steps, you can ensure that you select the right foundry to meet your specific needs, whether it be for aluminum, iron, or copper alloy castings. Understanding the unique aspects of Florida’s foundry market will help streamline your sourcing efforts and lead to successful partnerships.

Step 1: Identify Your Casting Requirements

Before reaching out to foundries, clearly define your technical specifications, including the type of material (e.g., aluminum, iron), casting method (e.g., sand casting, permanent mold), and any industry standards that must be met. This clarity will streamline your communication with potential suppliers and help them provide accurate quotes and timelines.

- Consider volume needs: Are you looking for prototypes, small runs, or large-scale production?

- Quality standards: Ensure that your specifications align with necessary certifications, such as ASTM or military specifications.

Step 2: Research Foundry Capabilities

Investigate the capabilities of various foundries in Florida. Look for facilities that specialize in the type of castings you require and have a proven track record in your industry.

- Technology and equipment: Assess whether they utilize modern technologies like 3D-printed molds or CAD design support.

- Material expertise: Ensure that the foundry has experience with the specific alloys or materials you need.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This helps establish credibility and reliability.

Illustrative image related to foundries in florida

- Visit the facility: If possible, arrange a visit to see the operation firsthand and evaluate their quality control processes.

- Ask for samples: Request samples of previous work to assess quality and craftsmanship.

Step 4: Verify Supplier Certifications

Confirm that the foundries you are considering hold relevant certifications, such as ISO 9001:2015, which indicates a commitment to quality management systems. This step is critical for ensuring that the products meet international quality standards.

- Check industry affiliations: Membership in organizations like the Non-Ferrous Founders’ Society can indicate a commitment to industry best practices.

- Review quality control measures: Understand their testing procedures to ensure that your castings will meet required specifications.

Step 5: Assess Lead Times and Flexibility

Inquire about the lead times for production and the foundry’s ability to adapt to changing demands. A responsive supplier can be invaluable, especially in industries where timelines are critical.

- Understand their production schedule: Determine how busy they are and how that might impact your project.

- Flexibility for changes: Ask how they handle modifications in design or volume adjustments during production.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms early in the process. Transparency in these areas can prevent misunderstandings later on.

- Get detailed quotes: Ensure quotes include all costs, such as tooling, machining, and shipping.

- Review payment options: Discuss payment methods and terms to find an arrangement that suits both parties.

Step 7: Establish Clear Communication Channels

Set up effective communication channels to facilitate ongoing dialogue throughout the sourcing and production process. Clear communication can prevent issues and foster a productive partnership.

- Assign points of contact: Designate specific individuals for both sides to streamline discussions.

- Utilize technology: Consider using project management tools to track progress and share updates in real time.

By following this checklist, B2B buyers can navigate the complexities of sourcing foundry services in Florida effectively, ensuring that they find the right partner for their casting needs.

Comprehensive Cost and Pricing Analysis for foundries in florida Sourcing

What Are the Key Cost Components in Florida Foundry Operations?

When sourcing from foundries in Florida, understanding the cost structure is crucial. The main components include:

-

Materials: The choice of raw materials significantly affects costs. Common materials in Florida foundries include aluminum, copper alloys, and grey iron. Prices fluctuate based on market demand and availability. Sourcing locally may reduce transportation costs but could be impacted by regional supply issues.

-

Labor: Skilled labor is essential for precision in casting and machining processes. Labor costs in Florida can vary, reflecting local wage rates and the availability of skilled workers. Foundries often invest in training to enhance productivity and maintain high-quality standards.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Foundries in Florida may face higher overhead due to climate-related energy costs (e.g., air conditioning) and compliance with environmental regulations.

-

Tooling: Tooling costs include the design and manufacturing of patterns and molds. The complexity of the design and the materials used can lead to significant cost variations. Foundries that offer advanced technologies like 3D printing for mold production may provide cost advantages.

-

Quality Control (QC): Ensuring that castings meet industry standards often involves rigorous testing and inspection, which adds to costs. Certifications such as ISO 9001 or compliance with military specifications can further influence pricing due to the additional quality assurance processes.

-

Logistics: Transporting castings to international buyers involves various costs, including freight, customs duties, and insurance. Effective logistics management can mitigate some of these expenses.

-

Margin: Foundries typically include a profit margin in their pricing. This margin can vary based on the foundry’s market positioning, competitive landscape, and the perceived value of their services.

What Influences Pricing for Foundries in Florida?

Several factors can influence the pricing strategies of foundries:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, making it beneficial for buyers to consolidate their needs. Understanding the MOQ can help negotiate better terms.

-

Specifications and Customization: Custom designs or specialized materials can lead to higher costs due to the increased complexity in production. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Quality and Certifications: Higher quality standards and certifications typically result in increased pricing. Buyers should assess whether the additional costs align with their project requirements.

-

Supplier Factors: The reputation and experience of the foundry can affect pricing. Established suppliers with a proven track record may command higher prices due to their reliability and expertise.

-

Incoterms: The choice of Incoterms can significantly impact overall costs. Buyers should be aware of the responsibilities regarding shipping, insurance, and customs clearance to avoid hidden fees.

How Can International Buyers Optimize Their Sourcing Strategy?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Establish clear communication with suppliers about pricing, delivery schedules, and payment terms. Negotiation can lead to better prices, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with logistics, maintenance, and potential rework. A lower initial cost might lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances: Be aware that prices may vary based on currency fluctuations, local economic conditions, and geopolitical factors. Regularly review market trends to make informed purchasing decisions.

-

Build Relationships: Long-term relationships with foundries can lead to better pricing and priority service. Engaging in regular communication and providing feedback can foster a collaborative partnership.

Disclaimer on Pricing Information

The pricing insights provided here are indicative and may vary based on specific project requirements, market conditions, and negotiation outcomes. Buyers are encouraged to request quotes from multiple foundries to obtain a comprehensive understanding of the costs involved in their specific sourcing needs.

Alternatives Analysis: Comparing foundries in florida With Other Solutions

Understanding Alternatives in Foundry Solutions

In the competitive landscape of manufacturing, particularly in casting and foundry services, buyers often explore various solutions to meet their production needs. While foundries in Florida offer a range of services and materials, alternative methods and technologies may provide different advantages. This analysis compares foundries in Florida with two viable alternatives: overseas foundries and additive manufacturing (3D printing). Each option has distinct features that can impact performance, cost, and suitability for specific applications.

Comparison Table

| Comparison Aspect | Foundries In Florida | Overseas Foundries | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High-quality castings with local support | Varies; potential for lower quality | Excellent for complex geometries |

| Cost | Moderate to high; competitive locally | Often lower due to lower labor costs | Higher initial costs, but savings on waste |

| Ease of Implementation | Straightforward logistics and communication | Longer lead times and shipping complexities | Requires skilled personnel |

| Maintenance | Regular maintenance standards | Varies; less oversight | Minimal maintenance, but requires expertise |

| Best Use Case | Custom castings, prototyping, local industries | High-volume production, cost-sensitive projects | Complex designs, rapid prototyping |

Detailed Breakdown of Alternatives

1. Overseas Foundries

Overseas foundries typically offer lower production costs due to cheaper labor and materials. This can make them an attractive option for large-scale orders where budget constraints are critical. However, buyers must consider the potential for inconsistent quality and longer lead times due to shipping logistics. Communication barriers and time zone differences can also complicate project management. Thus, while overseas foundries may be suitable for high-volume, cost-sensitive projects, they may not be the best choice for businesses requiring close collaboration and quality assurance.

2. Additive Manufacturing (3D Printing)

Additive manufacturing presents a modern alternative to traditional casting methods, enabling the production of complex geometries that would be challenging or impossible to achieve with conventional foundries. This method minimizes material waste, allowing for more sustainable production practices. However, the initial investment in 3D printing technology can be high, and the process may not be suitable for large-scale production runs. Additionally, skilled personnel are required to operate the technology effectively, which can add to operational costs. Despite these challenges, additive manufacturing excels in rapid prototyping and creating custom parts, making it ideal for innovative projects and small batches.

Illustrative image related to foundries in florida

Conclusion: Choosing the Right Foundry Solution

When deciding on the best foundry solution, B2B buyers should consider their specific requirements, including budget constraints, desired quality, and production timelines. Foundries in Florida provide reliable local services with a focus on quality and customer support, making them a strong choice for custom and complex casting projects. Conversely, overseas foundries may offer significant cost savings for large-scale orders, while additive manufacturing serves well for innovative designs and rapid prototyping. By assessing these alternatives against their operational needs, buyers can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for foundries in florida

What Are the Key Technical Properties Relevant to Foundries in Florida?

Understanding the technical properties of castings is essential for international B2B buyers when sourcing from Florida foundries. Here are some critical specifications that influence the quality and applicability of castings:

-

Material Grade: The classification of materials used, such as aluminum alloys (e.g., 300 series, 500 series) and copper alloys, defines the mechanical properties of the final product. Material grades affect strength, ductility, and corrosion resistance, which are crucial in industries like aerospace and automotive.

-

Tolerance Levels: This refers to the permissible limits of variation in dimensions. Tight tolerances ensure that parts fit together correctly, which is vital for machinery and structural applications. Understanding tolerance levels helps buyers assess whether a foundry can meet specific engineering requirements.

-

Casting Process: Different casting methods—such as sand casting, permanent mold, and die casting—offer unique advantages. For example, sand casting is flexible for complex shapes, while die casting is suitable for high-volume production with tighter tolerances. Buyers should match the casting process with their project needs to optimize cost and quality.

-

Weight and Size Limits: Foundries often have specifications regarding the maximum weight and dimensions of castings. For instance, some facilities may handle castings up to 600 pounds, while others may focus on lighter components. Understanding these limits is essential for ensuring that your project can be accommodated within the foundry’s capabilities.

-

Surface Finish Standards: The finish of a casting can impact its performance and aesthetic quality. Foundries may offer various surface treatments, from rough to polished finishes. Buyers should specify their surface finish requirements to ensure compatibility with their product applications.

-

Quality Assurance Standards: Compliance with industry standards, such as AMS STD 2175, is crucial for ensuring that castings meet safety and performance requirements. Buyers should inquire about a foundry’s quality control processes, including non-destructive testing and certification, to ensure reliability.

What Are Common Trade Terms Used in the Foundry Industry?

Familiarity with industry jargon can enhance communication and negotiation between buyers and foundries. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that may be marketed under another company’s brand. Understanding OEM relationships is vital for buyers looking to source components for final assembly.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategies and assess cost-effectiveness, especially for large-scale projects.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for price estimates on specified products or services. Submitting an RFQ is a standard practice for buyers to compare costs and capabilities among different foundries.

-

Incoterms (International Commercial Terms): These are a set of predefined international trade terms that outline the responsibilities of buyers and sellers. Familiarity with Incoterms helps clarify shipping, insurance, and payment obligations, which can prevent misunderstandings in cross-border transactions.

-

Lead Time: This refers to the time it takes from placing an order to receiving the finished product. Understanding lead times is crucial for project planning, especially in industries with tight deadlines.

-

Casting Design: This term refers to the blueprint or specifications for creating a casting. Effective casting design considers factors such as material properties, weight, and tolerances, making it essential for successful product outcomes.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when engaging with foundries in Florida, ensuring that their sourcing aligns with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the foundries in florida Sector

What Are the Current Market Dynamics and Sourcing Trends in Florida’s Foundries?

The foundry sector in Florida is experiencing notable growth, driven by global demand for high-quality castings and advancements in manufacturing technologies. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking to Florida’s foundries for their diverse capabilities, including aluminum and copper alloy castings, sand casting, and advanced machining services. Key trends include a shift towards digital transformation in operations, such as the adoption of 3D printing for mold production, which allows for rapid prototyping and cost-effective production runs. Additionally, the growing emphasis on supply chain transparency and efficiency is prompting foundries to enhance their logistics and operational frameworks, ensuring timely delivery and quality assurance.

Illustrative image related to foundries in florida

The increasing focus on sustainability is another vital driver of change. Buyers are more inclined to partner with foundries that demonstrate a commitment to reducing their environmental footprint and adhering to ethical sourcing practices. As a result, Florida’s foundries are investing in energy-efficient technologies and sustainable materials, aligning with global market expectations.

How Is Sustainability Shaping Ethical Sourcing Practices in Florida’s Foundries?

Sustainability is becoming a cornerstone of sourcing practices within Florida’s foundry sector, with a significant emphasis on minimizing environmental impacts. Foundries are adopting eco-friendly materials and processes, including the use of recycled metals and energy-efficient casting techniques. This shift is not only beneficial for the environment but also appeals to international buyers who prioritize sustainability in their supply chains.

Ethical sourcing practices are increasingly relevant, as companies strive to ensure that their suppliers adhere to responsible labor and environmental standards. Certifications such as ISO 14001 for environmental management systems and adherence to green manufacturing practices are becoming prerequisites for doing business with reputable foundries. B2B buyers are encouraged to seek partnerships with foundries that can demonstrate compliance with such standards, ensuring that their sourcing aligns with corporate social responsibility goals.

What Is the Historical Context of Florida’s Foundry Industry?

The history of Florida’s foundry industry dates back to the mid-20th century, with companies like Florida Aluminum Casting Company established in 1946. Over the decades, the sector has evolved significantly, responding to changing market demands and technological advancements. The acquisition and transformation of legacy foundries into modern manufacturing hubs reflect the industry’s adaptability. Companies have diversified their offerings, moving from traditional casting methods to incorporating advanced technologies such as CAD design and 3D printing.

Today, Florida’s foundries not only serve regional markets but are also positioned as key players in the global supply chain, catering to various industries, including aerospace, automotive, and defense. This evolution illustrates a robust foundation upon which international buyers can build successful partnerships, leveraging Florida’s expertise and innovative capabilities.

Illustrative image related to foundries in florida

Frequently Asked Questions (FAQs) for B2B Buyers of foundries in florida

-

How do I ensure quality when sourcing from foundries in Florida?

To ensure quality, start by verifying the foundry’s certifications, such as ISO 9001:2015 or compliance with ASTM and military specifications. Request samples of previous work to assess their craftsmanship. Additionally, inquire about their quality control processes, including non-destructive testing and inspections. Establish a clear communication channel for ongoing updates and feedback during the production process. Building a relationship with the supplier can also help in maintaining quality throughout the project. -

What is the typical lead time for custom castings from Florida foundries?

Lead times can vary based on the complexity of the casting and the foundry’s current workload. Generally, standard aluminum castings may take 4-8 weeks, while more complex or larger orders could extend to 10-12 weeks. It’s advisable to discuss timelines upfront and consider any potential delays due to logistics or material sourcing. To avoid disruptions, plan your procurement schedule with buffer time for unexpected delays. -

What customization options are available for castings from Florida foundries?

Florida foundries typically offer a range of customization options, including material selection (e.g., aluminum, copper alloys), casting methods (sand, permanent mold, investment), and finishing processes (machining, heat treating). Many foundries also provide design assistance, using technologies like CAD and 3D printing for prototyping. Discuss your specific needs with the foundry to explore all available options and ensure the final product aligns with your requirements. -

What are the minimum order quantities (MOQs) for foundries in Florida?

Minimum order quantities (MOQs) can vary significantly between foundries and depend on the type of casting and process used. For instance, smaller foundries may have MOQs as low as 50 pieces for standard products, while larger operations might require orders of several hundred units for cost-effectiveness. Always clarify MOQs during initial discussions to ensure they align with your project needs and budget. -

What payment terms should I expect when working with Florida foundries?

Payment terms vary by foundry but commonly include a deposit upfront (often 30-50% of the total order value) with the balance due upon completion or prior to shipping. Some foundries may offer flexible terms, including payment plans for larger orders or credit options for established clients. Discuss payment terms early in the negotiation process to avoid misunderstandings later on. -

How do logistics and shipping work for international orders from Florida foundries?

Logistics for international orders typically involve coordination with freight forwarders and customs brokers. Foundries in Florida can assist in arranging shipping, but it’s crucial to clarify responsibilities regarding shipping costs, insurance, and customs duties. Ensure that all shipping documentation is in order to prevent delays at customs. Discuss lead times and potential shipping methods (air, sea) to choose the best option for your timeline and budget. -

What should I consider when vetting foundry suppliers in Florida?

When vetting foundry suppliers, assess their experience, industry reputation, and client references. Investigate their manufacturing capabilities, including available technologies and processes. Check for certifications that demonstrate quality assurance, and inquire about their customer service approach. Establishing a relationship with the supplier can also provide insights into their reliability and commitment to meeting your needs. -

How can I address language and cultural barriers when sourcing from Florida foundries?

To address language and cultural barriers, consider working with a local agent or representative who understands both your language and the local business culture. Utilize clear and concise communication, and confirm understanding through summaries or follow-up questions. Many foundries are accustomed to working with international clients and may have multilingual staff. Establishing a rapport can also help bridge any cultural gaps and facilitate smoother negotiations.

Top 6 Foundries In Florida Manufacturers & Suppliers List

1. IQS Directory – Casting Foundries

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Casting foundries in Florida offer a variety of services including design, engineering, and manufacturing of castings tailored to specific qualifications. Key products include aluminum die castings, magnesium die castings, and zinc die castings. The directory provides detailed company profiles, including website links, locations, phone numbers, product videos, and customer reviews.

2. Tampa Brass – Non-Ferrous Castings

Domain: tampabrass.com

Registered: 2000 (25 years)

Introduction: Non-ferrous sand and permanent mold castings including aluminum and copper alloy castings. Capabilities for prototype and production runs. Casting methods include Hunter, Permanent Mold, Squeezer, No-bake, and Rotolift. Castings meet ASTM and military specifications with quality to AMS STD 2175. Maximum casting size up to 500 lbs. Pattern shop capabilities include wood, plastic, and metal.

3. TriState Cast – Aluminum and Iron Castings

Domain: tristatecast.com

Registered: 1998 (27 years)

Introduction: Products available include aluminum castings (sand, permanent mold, die cast), iron sand castings, steel forgings, and steel investment castings. Most products shipped include added value such as machining and non-destructive testing. Castings frequently supplied meet AMS-Std-2175 Class 1 and Class 2 and other critical specifications.

4. Hawver Aluminum Foundry – Aluminum Sand Castings

Domain: hawvercastings.com

Registered: 2007 (18 years)

Introduction: Hawver Aluminum Foundry Inc. specializes in aluminum sand castings ranging from several ounces to over 600 pounds. They service various industries including automotive, marine, machine manufacturers, and architectural. Their capabilities include casting design and prototyping, utilizing technologies such as 3D-printed sand molds, No-Bake (Airset) molds and cores, heat treating, and CAD design.

5. Maddox Foundry – Local Machine Shop

Domain: cityofarcher.com

Registered: 2007 (18 years)

Introduction: Maddox Foundry, established in 1905, originally served the local mining industry as a machine shop. It has been in operation for over a century and is recognized for its support to the city of Archer, Florida.

6. Miami-Cast – Grey Iron Castings

Domain: grey-iron-castings.com

Registered: 2001 (24 years)

Introduction: Miami-Cast, Inc. is a leading manufacturer of high-quality Grey Iron Castings with over 25 years of experience. The company is based in Miami, Florida, and operates a state-of-the-art foundry and machine shop. Their Grey Iron Castings are known for superior strength, durability, and wear resistance, making them suitable for automotive, construction, agricultural, and industrial equipment applicati…

Strategic Sourcing Conclusion and Outlook for foundries in florida

In conclusion, Florida’s foundries present a unique opportunity for international B2B buyers seeking high-quality casting solutions. With a diverse range of capabilities—including aluminum and copper alloy castings, advanced machining, and compliance with rigorous military and industry specifications—these foundries are well-equipped to meet the demands of various sectors, from aerospace to automotive. The strategic sourcing approach in Florida not only ensures access to superior craftsmanship but also fosters strong partnerships that can enhance supply chain efficiency.

As the global market continues to evolve, leveraging the capabilities of Florida’s foundries can significantly benefit businesses looking to innovate and expand. The emphasis on advanced technologies, such as 3D printing and precision machining, positions these foundries as leaders in quality and cost-effectiveness.

For B2B buyers from Africa, South America, the Middle East, and Europe—countries like Nigeria and Saudi Arabia—now is the time to explore collaboration with Florida’s foundries. Engage with these manufacturers to capitalize on their expertise and drive your business forward. The future of manufacturing is here, and it starts with strategic partnerships that prioritize quality and innovation. Reach out today to discover how Florida’s foundries can support your sourcing needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to foundries in florida

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.