Choosing Your 100Cc Engine Bike Kit: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 100cc engine bike kit

Navigating the complexities of sourcing a 100cc engine bike kit can be a daunting task for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. As the demand for efficient and cost-effective transportation solutions grows, understanding the nuances of this market is crucial. This guide aims to equip you with the knowledge needed to make informed purchasing decisions by exploring various types of 100cc engine bike kits, their applications, and key considerations for supplier vetting.

In the coming sections, we will delve into the distinct categories of 100cc engine bike kits, including 2-stroke and 4-stroke options, highlighting their advantages and ideal use cases. We will also discuss the importance of evaluating suppliers based on reliability, product quality, and customer support—elements that can significantly impact your business operations. Additionally, we will provide insights on cost factors, enabling you to balance quality with budget constraints effectively.

By the end of this guide, you will have a comprehensive understanding of the 100cc engine bike kit landscape, empowering you to navigate your sourcing process with confidence. Whether you are a distributor, retailer, or manufacturer, this resource is designed to enhance your strategic decision-making, ensuring that you remain competitive in a rapidly evolving global market.

Understanding 100cc engine bike kit Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 100cc 2-Stroke Kits | High power-to-weight ratio, compact design | Racing, recreational use | Pros: Lightweight, high performance; Cons: Requires mixing fuel and oil, more maintenance. |

| 100cc 4-Stroke Kits | Quieter operation, more fuel-efficient | Commuting, long-distance travel | Pros: Reliable, lower emissions; Cons: Heavier, more complex repairs. |

| 100cc Friction Drive Kits | Uses friction to drive the wheel, simpler installation | Entry-level markets, hobbyists | Pros: Easy to install, cost-effective; Cons: Lower power, less efficiency on inclines. |

| 100cc Electric Start Kits | Integrated electric start mechanism | Urban commuting, convenience-focused | Pros: User-friendly, reliable starting; Cons: Higher initial cost, potential electrical issues. |

| 100cc Performance Kits | Upgraded components for racing and high performance | Competitive racing, enthusiasts | Pros: Enhanced speed and torque; Cons: Higher investment, may require expert maintenance. |

What Are the Characteristics of 100cc 2-Stroke Kits?

100cc 2-Stroke Kits are known for their compact design and high power-to-weight ratio, making them ideal for racing and recreational use. These kits offer enhanced acceleration and speed, appealing to B2B buyers targeting performance-oriented markets. However, they require the mixing of oil and fuel, leading to increased maintenance needs. Buyers should consider the operational costs and the need for regular upkeep when sourcing these kits.

How Do 100cc 4-Stroke Kits Compare in Terms of Performance?

100cc 4-Stroke Kits are characterized by quieter operation and improved fuel efficiency, making them suitable for commuting and long-distance travel. Their design includes a separate oil reservoir, eliminating the need for oil and fuel mixing, which simplifies maintenance. B2B buyers focused on durability and reliability will find these kits appealing, although they may incur higher repair costs due to their more complex mechanics.

What Are the Advantages of 100cc Friction Drive Kits?

Friction Drive Kits utilize a simple mechanism that drives the wheel through friction, making installation straightforward and cost-effective. These kits are often targeted at entry-level markets and hobbyists. While they are easier to install and less expensive than other types, they typically provide lower power and efficiency, particularly on inclines. B2B buyers should weigh the trade-offs between affordability and performance when considering these kits.

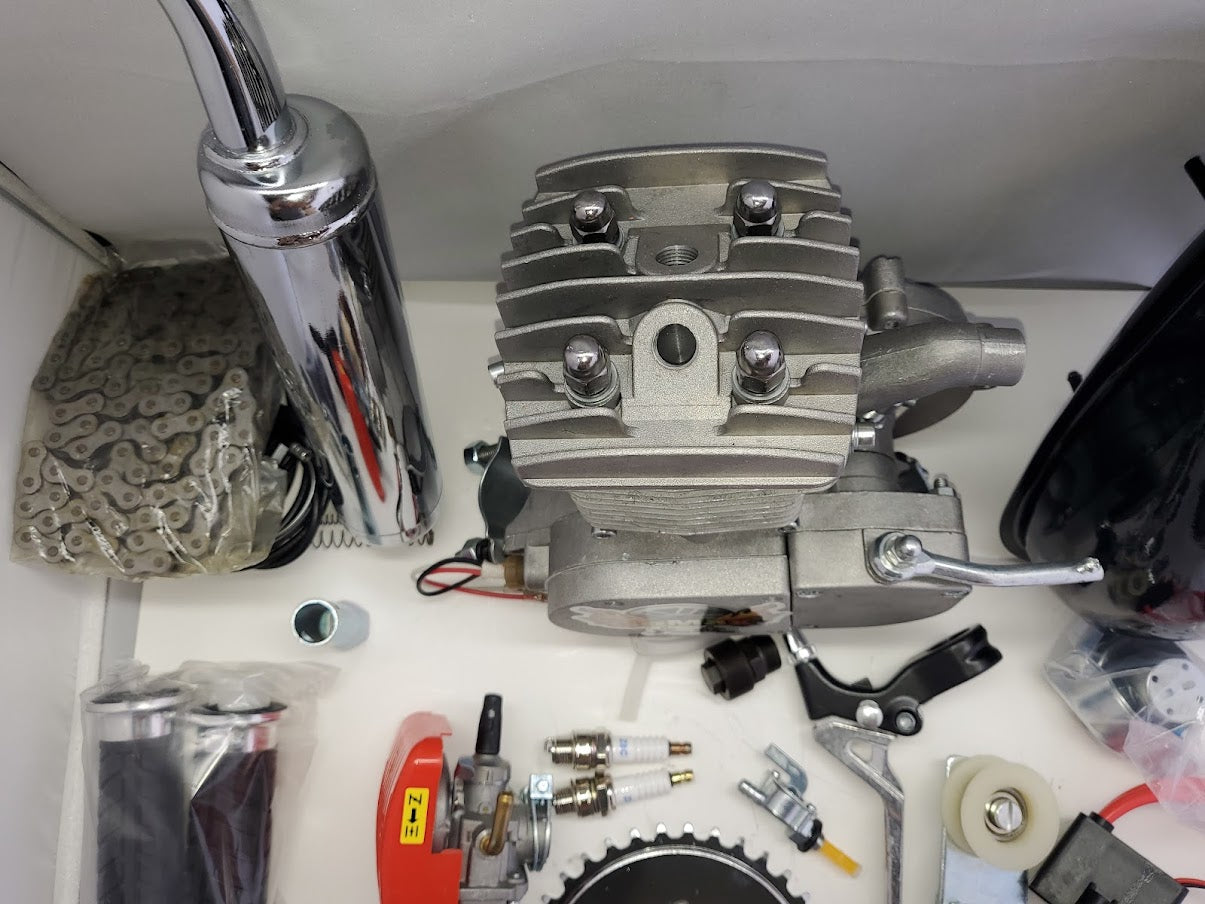

Illustrative image related to 100cc engine bike kit

What Makes 100cc Electric Start Kits Popular?

100cc Electric Start Kits feature an integrated electric starting mechanism, enhancing user convenience, especially for urban commuting. They provide a reliable starting solution that appeals to buyers looking for ease of use. However, the initial investment is generally higher, and potential electrical issues may arise, necessitating careful consideration of warranty and service support. B2B buyers should assess market demand for user-friendly options when evaluating these kits.

Why Choose 100cc Performance Kits for Racing?

100cc Performance Kits are designed with upgraded components to maximize speed and torque, making them ideal for competitive racing and enthusiast markets. These kits often include high-quality parts that enhance overall performance but come at a higher price point. B2B buyers in the racing sector should consider the expected return on investment through performance gains, as well as the need for specialized maintenance to ensure optimal operation.

Key Industrial Applications of 100cc engine bike kit

| Industry/Sector | Specific Application of 100cc engine bike kit | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Transport | Last-mile delivery solutions | Cost-effective transportation for goods in urban areas | Reliability, fuel efficiency, and ease of maintenance |

| Tourism and Leisure | Guided city tours on motorized bicycles | Unique experiences for tourists, increasing customer satisfaction | Customization options, comfort, and safety features |

| Agricultural Support | Transportation for agricultural workers | Efficient mobility for workers in rural areas | Durability, ease of use on rough terrain, and parts availability |

| Logistics and Warehousing | Employee commuting solutions | Reduced commuting costs and improved employee satisfaction | Fuel efficiency, reliability, and capacity for load transport |

| Emergency Services | Rapid response vehicles for local emergencies | Quick access to remote areas, enhancing service efficiency | Performance under various conditions and ease of repair |

How is the 100cc Engine Bike Kit Used in Urban Transport Solutions?

In urban transport, the 100cc engine bike kit is commonly utilized for last-mile delivery solutions. Businesses can convert standard bicycles into motorized vehicles, enabling efficient transportation of goods in congested city areas. This application addresses the rising demand for quick delivery services while offering a cost-effective alternative to traditional vehicles. Buyers in this sector should consider the reliability and fuel efficiency of the kits to ensure optimal performance and minimize operational costs.

Illustrative image related to 100cc engine bike kit

What Role Does the 100cc Engine Bike Kit Play in Tourism and Leisure?

Tourism and leisure industries leverage the 100cc engine bike kit for guided city tours, providing tourists with a unique way to explore attractions. These motorized bicycles enhance the touring experience by allowing participants to cover more ground effortlessly. For B2B buyers in this sector, customization options and safety features are critical considerations to ensure a memorable and secure experience for tourists, ultimately boosting customer satisfaction and loyalty.

How Can Agricultural Support Benefit from 100cc Engine Bike Kits?

In agriculture, the 100cc engine bike kit serves as an effective transportation solution for workers, facilitating mobility in rural areas where traditional vehicles may struggle. This application improves worker efficiency and productivity, as employees can easily navigate fields and transport tools or produce. Buyers in this industry should prioritize durability and ease of use, as well as the availability of replacement parts to maintain the kits over time.

Why Are 100cc Engine Bike Kits Valuable for Logistics and Warehousing?

Logistics and warehousing sectors utilize the 100cc engine bike kit to provide employee commuting solutions. By offering motorized bicycles, businesses can reduce commuting costs and improve employee satisfaction, leading to higher retention rates. When sourcing these kits, companies should focus on fuel efficiency and reliability, as these factors directly impact operational costs and employee productivity.

Illustrative image related to 100cc engine bike kit

How Do Emergency Services Benefit from 100cc Engine Bike Kits?

Emergency services can deploy the 100cc engine bike kit for rapid response vehicles, enhancing their ability to access remote areas quickly. This application is crucial in emergencies where traditional vehicles may face delays due to traffic or terrain. B2B buyers in this sector need to ensure that the kits perform well under various conditions and are easy to repair, ensuring that emergency responders can rely on them during critical situations.

3 Common User Pain Points for ‘100cc engine bike kit’ & Their Solutions

Scenario 1: Navigating Compliance Challenges for 100cc Engine Bike Kits

The Problem: B2B buyers, especially those in regions with strict motor vehicle regulations, often face significant challenges when sourcing 100cc engine bike kits. Many manufacturers may not provide clear information regarding compliance with local laws, leading to potential legal issues or the risk of unsellable inventory. Buyers can find themselves overwhelmed by varying regulations across different countries, especially in Africa and Europe, where standards can differ markedly.

The Solution: To effectively navigate compliance challenges, buyers should prioritize sourcing kits from reputable suppliers who offer comprehensive documentation on regulatory compliance. This includes specifications that align with local laws regarding engine displacement, emissions, and safety features. Buyers can also benefit from establishing a direct line of communication with suppliers to clarify any doubts about compliance. Additionally, investing in training for staff on local regulations can ensure that every purchase decision aligns with legal requirements, minimizing risks and fostering smoother operations.

Scenario 2: Overcoming Performance Variability in 100cc Engine Bike Kits

The Problem: Performance variability is a common pain point for B2B buyers dealing with 100cc engine bike kits. Differences in manufacturing quality, engine specifications, and installation can lead to inconsistent performance, which can frustrate end-users and damage the reputation of businesses that rely on these kits for resale. Buyers may find it challenging to ensure that every engine kit meets the expected performance standards, impacting customer satisfaction and repeat sales.

Illustrative image related to 100cc engine bike kit

The Solution: To overcome performance variability, buyers should adopt a multi-faceted approach. First, they should conduct thorough market research to identify trusted manufacturers with a proven track record for quality and performance. Establishing partnerships with suppliers who offer warranties and performance guarantees can further mitigate risks. Additionally, implementing quality control measures during the installation process, such as standardized testing procedures, can help ensure that each engine kit meets performance expectations. Encouraging customer feedback on performance can also provide valuable insights for ongoing improvements.

Scenario 3: Addressing Maintenance and Repair Knowledge Gaps for 100cc Engine Bike Kits

The Problem: Many B2B buyers encounter difficulties related to the maintenance and repair of 100cc engine bike kits. The complexity of these engines can lead to a knowledge gap among end-users and technicians, resulting in improper maintenance practices that can shorten the lifespan of the kits and increase operational costs. This lack of understanding can create a barrier to customer satisfaction and retention.

The Solution: To address maintenance and repair knowledge gaps, buyers should invest in comprehensive training programs for their staff and end-users. This could include workshops, online training modules, and detailed maintenance manuals that cover common issues and troubleshooting tips for 100cc engine bike kits. Additionally, partnering with suppliers who offer ongoing technical support can help businesses quickly resolve maintenance issues and provide reliable service to their customers. By fostering a culture of knowledge-sharing and continuous learning, businesses can enhance their operational efficiency and customer satisfaction, leading to increased loyalty and sales.

Illustrative image related to 100cc engine bike kit

Strategic Material Selection Guide for 100cc engine bike kit

What Are the Key Materials Used in 100cc Engine Bike Kits?

When selecting materials for a 100cc engine bike kit, it is essential to consider their properties, advantages, and limitations. The choice of materials directly impacts performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in these kits, focusing on their suitability for international B2B buyers.

How Does Aluminum Impact the Performance of 100cc Engine Bike Kits?

Aluminum is a popular choice for various components in 100cc engine bike kits due to its lightweight and excellent corrosion resistance. Key properties include a temperature rating of approximately 150°C and good thermal conductivity, which helps dissipate heat effectively during engine operation.

Pros: Aluminum is highly durable, resistant to rust, and offers a good strength-to-weight ratio. It is also relatively easy to machine, reducing manufacturing complexity.

Cons: The main drawback is its cost, which can be higher compared to steel. Additionally, while it is strong, aluminum may not withstand high-stress applications as well as some steel alloys.

Illustrative image related to 100cc engine bike kit

Impact on Application: Aluminum components are particularly suitable for engine casings and brackets, where weight savings are crucial for performance.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum grades, such as ASTM or EN standards, to guarantee quality and performance.

Why Is Steel a Common Choice for 100cc Engine Bike Kits?

Steel, particularly high-carbon steel, is often used for critical components such as crankshafts and gears due to its high tensile strength and durability. It typically has a temperature rating of around 300°C, making it suitable for high-performance applications.

Illustrative image related to 100cc engine bike kit

Pros: Steel is highly durable and can endure significant stress and strain, making it ideal for load-bearing components. It is also cost-effective compared to other materials.

Cons: Steel is heavier than aluminum, which could affect the overall weight of the bike kit. Additionally, it is prone to corrosion if not properly treated or coated.

Impact on Application: Steel is particularly effective in high-stress components, ensuring reliability and longevity in performance.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should be aware of DIN standards for steel quality, ensuring they select the appropriate grade for their applications.

What Role Does Plastic Play in 100cc Engine Bike Kits?

Plastic materials, such as high-density polyethylene (HDPE) and polycarbonate, are increasingly used in non-structural components like fuel tanks and covers. They offer good chemical resistance and can withstand temperatures up to 80°C.

Illustrative image related to 100cc engine bike kit

Pros: Plastics are lightweight, cost-effective, and resistant to corrosion and chemicals, making them ideal for fuel storage applications.

Cons: While they are suitable for non-load-bearing applications, plastics may not provide the strength required for critical engine components, limiting their use.

Impact on Application: Plastics are particularly effective for components that require chemical resistance, such as fuel tanks, where exposure to gasoline is a concern.

Considerations for International Buyers: Buyers should look for compliance with international standards for plastics (like ASTM D638) to ensure quality and performance.

How Does Composite Material Enhance 100cc Engine Bike Kit Performance?

Composite materials, such as carbon fiber reinforced plastics, are gaining traction in high-performance applications due to their exceptional strength-to-weight ratio. They can withstand temperatures up to 200°C and provide excellent fatigue resistance.

Illustrative image related to 100cc engine bike kit

Pros: Composites are lightweight and can be tailored for specific performance characteristics, making them ideal for high-performance applications.

Cons: The primary limitation is the high cost and manufacturing complexity, which can make them less accessible for budget-conscious buyers.

Impact on Application: Composites are ideal for performance-oriented components, such as body panels or structural reinforcements, where weight savings are crucial.

Considerations for International Buyers: Buyers should ensure compliance with international standards for composite materials to guarantee quality and performance.

Summary Table of Material Selection for 100cc Engine Bike Kits

| Material | Typical Use Case for 100cc engine bike kit | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine casings, brackets | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Steel | Crankshafts, gears | High durability and tensile strength | Heavier than aluminum | Low |

| Plastic | Fuel tanks, covers | Cost-effective and chemical-resistant | Limited strength for critical parts | Low |

| Composite | Performance parts, body panels | Exceptional strength-to-weight ratio | High cost and manufacturing complexity | High |

This comprehensive analysis of materials will assist international B2B buyers in making informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 100cc engine bike kit

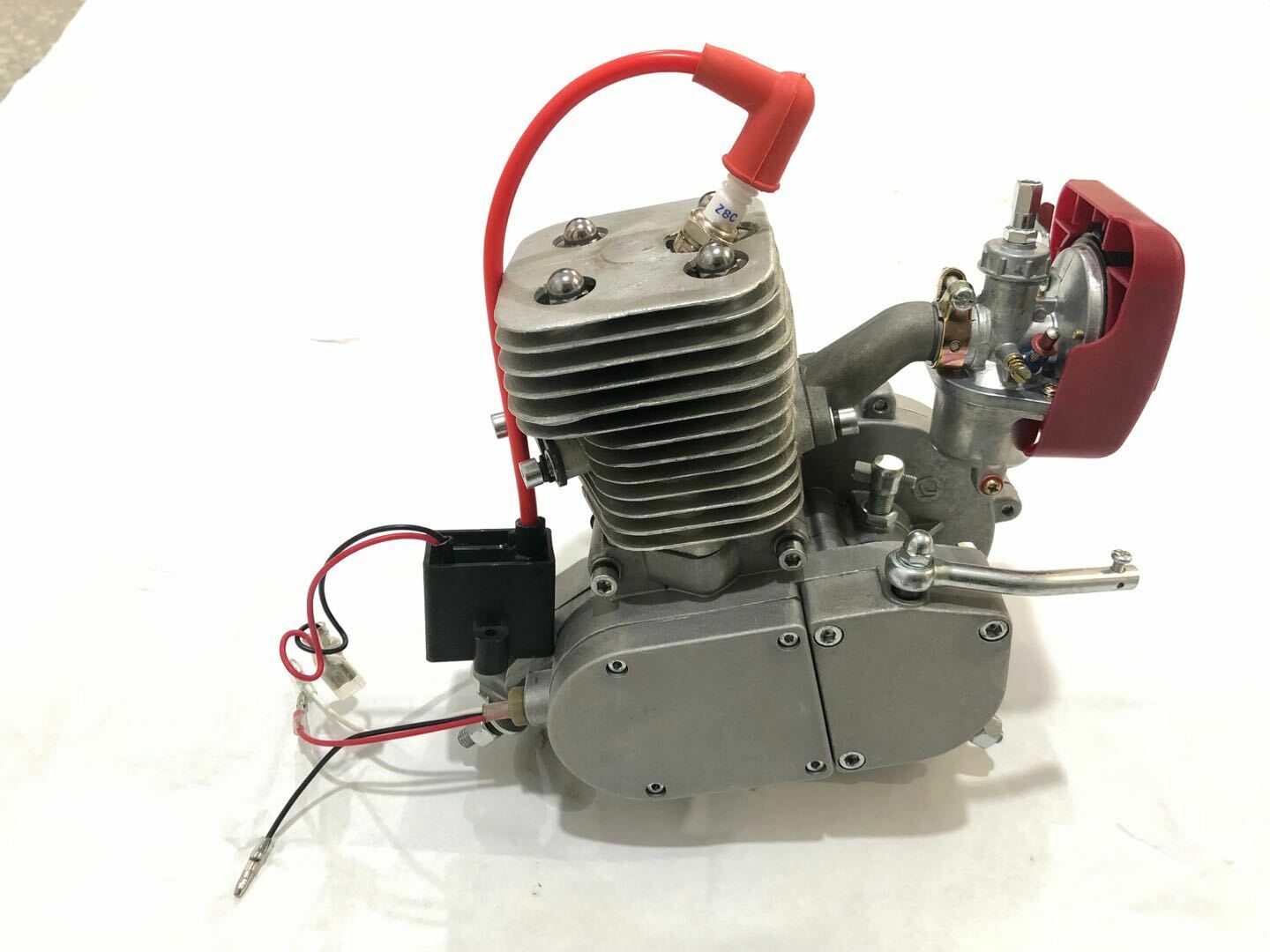

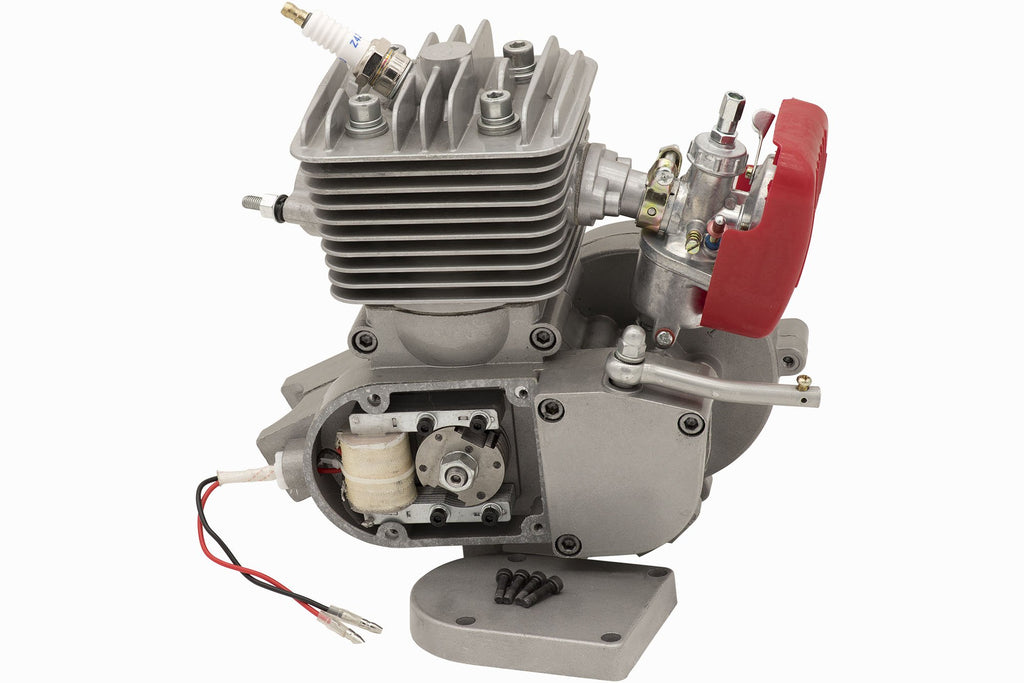

What Are the Key Stages in the Manufacturing Process of a 100cc Engine Bike Kit?

The manufacturing of a 100cc engine bike kit involves several critical stages, each designed to ensure the final product meets high-quality standards while remaining cost-effective. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to 100cc engine bike kit

How Is Material Prepared for Engine Kit Production?

Material preparation is the foundational step in the manufacturing process. High-quality raw materials, such as aluminum for engine casings and steel for internal components, are sourced from reliable suppliers. This stage often involves:

- Material Inspection: Incoming materials undergo rigorous inspections to ensure they meet specified standards. This includes checking for purity, strength, and other mechanical properties.

- Cutting and Shaping: Raw materials are cut into manageable sizes and shapes using CNC machines. This precision reduces waste and ensures that components will fit together correctly during assembly.

What Forming Techniques Are Commonly Used in Engine Manufacturing?

Forming techniques play a crucial role in shaping the engine components. Common methods include:

- Casting: Engine blocks and other complex shapes are often produced through sand or die casting, allowing for intricate designs that are both lightweight and strong.

- Machining: After casting, components are machined to achieve precise dimensions. This includes drilling, turning, and milling operations that ensure tight tolerances, crucial for the engine’s performance.

- Forging: For parts requiring additional strength, such as crankshafts, forging is utilized. This process involves shaping metal under high pressure, resulting in superior mechanical properties.

How Are Components Assembled in the Engine Kit?

Assembly is the stage where individual components come together to form the complete engine. This process typically follows a systematic approach:

- Sub-Assembly: Key components such as the engine block, cylinder head, and crankshaft are assembled separately before being combined into the complete engine assembly.

- Torque Specifications: Each bolt and screw is tightened to specific torque settings, ensuring structural integrity and preventing future failures.

- Quality Checks During Assembly: As components are assembled, quality checks are performed to verify alignment and fit. This includes visual inspections and the use of gauges to ensure dimensional accuracy.

What Finishing Techniques Are Applied to Enhance Engine Quality?

Finishing techniques are employed to enhance the durability and aesthetics of the engine components. Common practices include:

- Surface Treatments: Processes like anodizing or powder coating are applied to protect against corrosion and wear while enhancing appearance.

- Balancing: Engine components, particularly rotating parts, undergo balancing to minimize vibrations, which can affect performance and longevity.

- Final Inspection: Each finished engine kit goes through a final inspection to ensure that all components function correctly and meet the required specifications.

What Are the Quality Control Measures for 100cc Engine Bike Kits?

Quality control (QC) is an integral part of the manufacturing process, ensuring that products meet international and industry-specific standards. The following QC measures are commonly implemented:

Which International Standards Are Relevant for Engine Kit Quality Assurance?

Manufacturers of 100cc engine bike kits often adhere to internationally recognized standards, such as:

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is essential for market access in EU countries.

- API Certification: For certain engine components, especially those related to fuel and lubrication, API certification ensures performance and quality standards are met.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. These typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for quality and compliance with specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, components are regularly inspected to ensure they meet quality standards. This includes checking dimensions, surface finishes, and assembly accuracy.

- Final Quality Control (FQC): The completed engine kits are subjected to rigorous testing, including functionality tests and performance evaluations, to ensure they meet all specifications before shipping.

What Common Testing Methods Are Used to Ensure Engine Performance?

To guarantee the reliability and efficiency of 100cc engine bike kits, various testing methods are employed, including:

- Dyno Testing: This method measures engine power output and efficiency under load, providing insights into performance characteristics.

- Endurance Testing: Engine kits are subjected to prolonged operation under simulated real-world conditions to assess durability and identify potential failure points.

- Vibration Analysis: This testing identifies any issues related to engine balance and component alignment, which can affect performance and lifespan.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some actionable steps:

Illustrative image related to 100cc engine bike kit

- Supplier Audits: Conduct on-site audits to assess the manufacturer’s QC practices, production capabilities, and adherence to international standards.

- Request Quality Reports: Ask suppliers for detailed quality reports, including inspection and testing results, to understand their commitment to quality.

- Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of the manufacturing processes and final products before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe need to be aware of specific nuances in quality control, including:

- Regulatory Compliance: Different regions have varying regulations regarding engine emissions and safety standards. Buyers should verify that the products comply with local laws.

- Cultural Considerations: Understanding cultural differences can impact communication and expectations regarding quality. Establish clear lines of communication to mitigate misunderstandings.

- Supply Chain Transparency: Ensure that the supplier maintains a transparent supply chain, allowing for traceability of materials and components used in the manufacturing process.

By understanding the manufacturing processes and quality assurance measures for 100cc engine bike kits, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘100cc engine bike kit’

To assist B2B buyers in procuring a 100cc engine bike kit, this guide provides a structured checklist aimed at ensuring a smooth and efficient sourcing process. Each step is designed to help you evaluate your needs and assess potential suppliers effectively.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial for sourcing the right 100cc engine bike kit. Consider the intended use of the bike kits—whether for commuting, racing, or recreational purposes—as this will influence the type of engine you need.

– Engine Type: Decide between 2-stroke and 4-stroke engines based on performance and maintenance preferences.

– Power Output: Determine the necessary horsepower and torque to meet your performance expectations.

Illustrative image related to 100cc engine bike kit

Step 2: Research Market Trends

Stay informed about the latest trends in the motorized bicycle industry. Analyzing market dynamics will help you identify popular features and technologies that can enhance your offering.

– Competitive Analysis: Look at what similar businesses are offering and how they position their products.

– Consumer Preferences: Gather insights on what features consumers prioritize, such as fuel efficiency, noise levels, and ease of maintenance.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s vital to conduct thorough due diligence. Assess their reliability and reputation in the market to minimize risks.

– Supplier Background: Request company profiles, product catalogs, and references from previous clients.

– Production Capacity: Ensure that the supplier can meet your volume requirements and delivery timelines.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers comply with relevant industry standards and certifications. This step is essential for ensuring product quality and safety.

– Quality Assurance: Look for ISO certifications or equivalent to gauge their commitment to quality control.

– Environmental Compliance: Check for adherence to environmental regulations, especially if you are sourcing from regions with strict compliance requirements.

Step 5: Request Samples for Testing

Before finalizing your order, obtain samples to evaluate the product’s quality and performance. Testing samples can prevent costly mistakes down the line.

– Performance Testing: Assess the engine’s power output, fuel efficiency, and overall performance under various conditions.

– Durability Assessment: Evaluate the materials and construction quality to ensure they meet your standards.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Effective negotiation can lead to significant cost savings and better service levels.

– Pricing Structure: Discuss bulk pricing, payment terms, and any discounts available for long-term partnerships.

– Warranty and Support: Ensure clarity on warranty terms and after-sales support, which are crucial for customer satisfaction.

Illustrative image related to 100cc engine bike kit

Step 7: Finalize Your Order and Logistics

After reaching an agreement, proceed to finalize your order. Pay attention to logistics to ensure timely delivery of your products.

– Shipping Arrangements: Confirm shipping methods and timelines to align with your inventory management.

– Customs and Import Regulations: Be aware of the import requirements for your region to avoid delays at customs.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing 100cc engine bike kits effectively, ensuring they meet their business needs while maintaining high standards of quality and reliability.

Comprehensive Cost and Pricing Analysis for 100cc engine bike kit Sourcing

What Are the Key Cost Components of a 100cc Engine Bike Kit?

When sourcing a 100cc engine bike kit, understanding the cost structure is critical for effective budgeting and price negotiation. The primary cost components include:

-

Materials: High-quality materials such as aluminum or steel for the frame, specialized components for the engine, and durable plastics for other parts significantly influence costs. Sourcing materials from reliable suppliers can also ensure longevity and performance.

-

Labor: Labor costs vary based on location and the complexity of assembly. In regions with lower labor costs, such as parts of South America and Africa, total production expenses can be reduced, making it an attractive option for international buyers.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient operations can help lower these costs, reflecting in the final price.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or specialized engines. Investing in quality tooling may lead to better-quality products and lower long-term costs.

-

Quality Control (QC): Robust QC processes ensure that products meet industry standards. While this adds to the upfront costs, it can prevent expensive recalls or defects, ultimately saving money.

-

Logistics: Transportation and shipping costs vary widely, depending on the destination and the chosen shipping method. International buyers must consider tariffs and local import duties as part of their logistics budget.

-

Margin: Manufacturers and suppliers typically include a profit margin in their pricing. Understanding standard margins in different markets can provide insight into pricing expectations.

How Do Price Influencers Affect the Cost of 100cc Engine Bike Kits?

Several factors can influence pricing, particularly for B2B transactions:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) with suppliers can result in significant savings.

-

Specifications/Customization: Customizing components or features can lead to higher costs. Buyers should clearly define their specifications to avoid unnecessary expenses while ensuring the product meets their needs.

-

Material Quality/Certifications: Premium materials and certifications (such as ISO or CE) can increase costs but also enhance product reliability. Buyers should weigh the long-term benefits against immediate expenses.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can impact pricing. Partnering with reputable suppliers can lead to better service and product quality.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial. Different terms can shift costs and risks between the buyer and seller, affecting the total landed cost of the product.

What Are the Best Practices for Negotiating Prices on 100cc Engine Bike Kits?

Effective negotiation strategies can lead to better pricing and terms for international buyers:

-

Research Market Prices: Familiarize yourself with market rates for 100cc engine bike kits to negotiate from an informed position.

-

Discuss Total Cost of Ownership: Highlight the importance of long-term costs, including maintenance and reliability, to justify investment in higher-quality products.

-

Leverage Volume: If possible, commit to larger orders for better pricing. Suppliers are often willing to reduce prices for guaranteed bulk purchases.

-

Consider Local Suppliers: Depending on the region, sourcing from local suppliers may reduce logistics costs and tariffs, making it a more cost-effective option.

-

Be Flexible with Payment Terms: Offering upfront payments can sometimes lead to discounts, while extended payment terms can ease cash flow pressures.

What Pricing Nuances Should International Buyers Keep in Mind?

International buyers must navigate various pricing nuances when sourcing 100cc engine bike kits:

-

Currency Fluctuations: Exchange rates can impact the final cost. Locking in prices or using forward contracts may mitigate this risk.

-

Import Duties and Taxes: Understanding local regulations and potential tariffs is essential for accurate budgeting.

-

Cultural Differences: Negotiation styles can vary across cultures. Being culturally sensitive and adapting your approach can foster better relationships with suppliers.

-

Quality vs. Cost: While lower prices may be appealing, they may lead to higher costs in terms of quality issues and reliability. Focus on the total value rather than just the sticker price.

By comprehensively understanding these cost components, price influencers, negotiation strategies, and nuances, international buyers can make informed decisions when sourcing 100cc engine bike kits, ensuring they achieve optimal value for their investments.

Illustrative image related to 100cc engine bike kit

Alternatives Analysis: Comparing 100cc engine bike kit With Other Solutions

Exploring Viable Alternatives to the 100cc Engine Bike Kit

In the realm of motorized bicycles, the 100cc engine bike kit stands as a popular choice due to its balance of power and efficiency. However, various alternatives also provide unique benefits, catering to different operational needs and buyer preferences. This analysis aims to compare the 100cc engine bike kit with two notable alternatives: electric bike conversion kits and 80cc engine bike kits. Each option presents distinct advantages and considerations that B2B buyers should evaluate when making a purchasing decision.

| Comparison Aspect | 100cc Engine Bike Kit | Electric Bike Conversion Kit | 80cc Engine Bike Kit |

|---|---|---|---|

| Performance | Moderate speed and torque, ideal for urban commuting | High torque, instant acceleration, generally quieter | Similar performance to 100cc, often with higher top speeds |

| Cost | Generally priced around $229-$350 | Varies widely, typically $300-$800 depending on features | Typically ranges from $150-$300, budget-friendly |

| Ease of Implementation | Moderate; requires mechanical knowledge for installation | High; often designed for DIY enthusiasts with straightforward instructions | Moderate; similar to 100cc kits, but often simpler |

| Maintenance | Requires regular upkeep and fuel mixing | Minimal maintenance, mainly battery care | Moderate; requires maintenance similar to 100cc |

| Best Use Case | Commuting and leisure riding | Urban commuting, eco-conscious users | Racing and performance-oriented applications |

What Are the Benefits and Drawbacks of Electric Bike Conversion Kits?

Electric bike conversion kits provide an innovative alternative to traditional engine kits. These kits allow users to transform standard bicycles into electric-powered models, which can be particularly advantageous in urban settings. The primary benefits include instant torque and a quieter ride, making them suitable for city commuting. However, the cost can be significantly higher, especially for high-capacity batteries. Additionally, reliance on electrical infrastructure may limit their usability in remote areas without charging stations.

How Do 80cc Engine Bike Kits Compare to 100cc Engine Kits?

The 80cc engine bike kit is often viewed as a stepping stone between lighter 48cc options and the more powerful 100cc kits. With a lower price point and a balance of performance, these kits are particularly attractive for budget-conscious buyers. They provide similar performance metrics to the 100cc kits, often achieving higher top speeds due to lighter weight. However, they may lack some of the torque and power that come with a 100cc engine, making them less ideal for heavy loads or steep terrains.

Illustrative image related to 100cc engine bike kit

Making the Right Choice for Your B2B Needs

Choosing the right motorized bicycle solution hinges on various factors, including target market, operational environment, and budget constraints. For buyers targeting urban commuters or eco-friendly markets, electric bike conversion kits could be the optimal choice, despite their higher initial costs. In contrast, those looking for a balance between performance and affordability may find the 80cc engine bike kit a compelling option. Ultimately, understanding the specific use case and operational requirements will guide B2B buyers toward the most suitable solution for their needs.

Essential Technical Properties and Trade Terminology for 100cc engine bike kit

What are the Key Technical Properties of a 100cc Engine Bike Kit?

When sourcing a 100cc engine bike kit, understanding its technical properties is crucial for making informed purchasing decisions. Here are several essential specifications that buyers should consider:

-

Engine Type (2-Stroke vs. 4-Stroke)

– Definition: The engine type determines the bike’s performance characteristics, fuel efficiency, and maintenance requirements. Two-stroke engines are typically lighter and provide more power for their size, while four-stroke engines are known for their durability and fuel efficiency.

– B2B Importance: Choosing the right engine type can affect end-user satisfaction and operational costs. For businesses targeting commuting markets, four-stroke engines might be more appealing due to their reliability and lower emissions. -

Material Grade of Engine Components

– Definition: The material quality used in engine components (e.g., aluminum alloys for the engine block, stainless steel for fasteners) impacts the kit’s durability and performance.

– B2B Importance: High-grade materials can reduce maintenance costs and improve the lifespan of the engine. Buyers should prioritize suppliers that provide detailed material specifications to ensure product reliability. -

Torque and Power Output

– Definition: Torque refers to the rotational force produced by the engine, while power output measures the engine’s ability to perform work over time.

– B2B Importance: Understanding these metrics helps businesses align their product offerings with customer needs, such as speed versus endurance. A higher torque rating is particularly important for applications requiring heavy loads or uphill performance. -

Mounting Configuration

– Definition: This refers to how the engine is mounted on the bicycle frame (e.g., center mount or rear mount). Different configurations can affect handling and weight distribution.

– B2B Importance: Providing multiple mounting options can cater to diverse customer preferences and enhance the adaptability of the bike kits in different markets. -

Fuel Consumption Rate

– Definition: This metric indicates the amount of fuel consumed per distance traveled. It is crucial for assessing operating costs.

– B2B Importance: Lower fuel consumption rates can be a significant selling point, especially in markets where fuel prices are high. Buyers should evaluate potential fuel savings when comparing different engine kits.

What Common Trade Terms Should B2B Buyers Understand in the 100cc Engine Bike Kit Market?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to the 100cc engine bike kit market:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of engine kits, it refers to manufacturers who create components for branded bicycles.

– Importance: Partnering with recognized OEMs can enhance product credibility and ensure quality standards are met. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for inventory management and cost analysis. Buyers should negotiate MOQs that align with their sales forecasts and cash flow. -

RFQ (Request for Quotation)

– Definition: An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products.

– Importance: Issuing an RFQ allows businesses to compare offers from multiple suppliers, ensuring competitive pricing and terms. -

Incoterms (International Commercial Terms)

– Definition: These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps in understanding shipping responsibilities and costs, which can significantly impact total landed costs. -

Lead Time

– Definition: The time taken from placing an order until the product is delivered.

– Importance: Knowing lead times is vital for planning and inventory management. Longer lead times can affect customer satisfaction and the ability to meet market demand.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, enhance their negotiation strategies, and ultimately improve their market positioning in the competitive landscape of 100cc engine bike kits.

Illustrative image related to 100cc engine bike kit

Navigating Market Dynamics and Sourcing Trends in the 100cc engine bike kit Sector

What Are the Key Trends and Market Dynamics Affecting the 100cc Engine Bike Kit Sector?

The global market for 100cc engine bike kits is experiencing robust growth, driven by several key factors. Urbanization and the demand for cost-effective transportation options are significantly influencing the market, particularly in developing regions such as Africa and South America. The rise of e-commerce platforms has facilitated international trade, enabling B2B buyers to source products from various manufacturers. Additionally, advancements in technology are leading to improved engine performance and efficiency, making 100cc kits an attractive choice for both recreational and commuting purposes.

In Europe and the Middle East, regulatory changes favoring eco-friendly transportation solutions are creating a favorable environment for motorized bicycles. Emerging trends include the integration of smart technology into bike kits, such as GPS tracking and IoT connectivity, which appeal to tech-savvy consumers and enhance the overall user experience. B2B buyers are increasingly looking for suppliers who can offer customizable solutions, enabling them to cater to niche markets or specific customer preferences. Furthermore, competition among manufacturers is prompting innovations in design, durability, and fuel efficiency, ultimately benefiting end-users.

How Is Sustainability Impacting the Sourcing of 100cc Engine Bike Kits?

Sustainability is becoming a central theme in the sourcing and manufacturing of 100cc engine bike kits. As environmental concerns rise globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient production processes, and waste reduction strategies. The market is witnessing a shift towards the adoption of ‘green’ certifications, which provide assurance that products meet certain environmental standards.

Ethical sourcing is equally important; suppliers are expected to maintain transparent supply chains and adhere to fair labor practices. This not only enhances brand reputation but also aligns with consumer expectations in many regions, particularly in Europe and North America. As buyers seek to differentiate themselves in a competitive market, partnering with manufacturers who prioritize sustainability can be a significant value proposition. Overall, integrating sustainability into sourcing strategies is not just about compliance; it can also lead to cost savings, increased customer loyalty, and improved market positioning.

Illustrative image related to 100cc engine bike kit

What Is the Historical Context of the 100cc Engine Bike Kit Market?

The 100cc engine bike kit sector has evolved significantly since its inception. Initially, these kits were primarily used for recreational purposes and were often seen as a niche market. However, as urban congestion increased and the need for efficient transportation solutions became more pressing, the demand for motorized bicycles surged.

In the late 20th century, advancements in engineering and materials science allowed for the development of more efficient and powerful engines. The introduction of 2-stroke and 4-stroke technology broadened the appeal of these kits, making them suitable for a wider audience. Today, 100cc engine bike kits are recognized not only for their performance but also for their potential to reduce carbon footprints, leading to increased interest from environmentally-conscious consumers and B2B buyers alike. This historical trajectory highlights a shift from niche products to essential components in the global transportation landscape, making them a strategic area for investment and sourcing for international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 100cc engine bike kit

-

How do I choose the right 100cc engine bike kit for my market?

Selecting the ideal 100cc engine bike kit involves understanding your target market’s needs. Consider factors like local regulations on engine size, preferred fuel types, and consumer preferences for performance and durability. It’s essential to analyze competitors’ offerings and identify gaps that your product can fill. Additionally, evaluate the price sensitivity of your market to ensure your product remains competitive while meeting quality standards. -

What are the key features to look for in a 100cc engine bike kit?

When sourcing a 100cc engine bike kit, focus on several critical features: engine type (2-stroke vs. 4-stroke), ease of installation, fuel efficiency, and maintenance requirements. Assess the build quality, including materials used and warranty options. It’s also beneficial to consider customization options for branding or performance enhancements, as these can differentiate your product in the market. -

What is the typical minimum order quantity (MOQ) for 100cc engine bike kits?

Minimum order quantities for 100cc engine bike kits can vary significantly between suppliers. Generally, MOQs range from 50 to 500 units, depending on the manufacturer and the complexity of the kit. It’s advisable to communicate directly with suppliers to negotiate MOQs that align with your initial demand forecasts while ensuring they can meet quality and delivery timelines. -

How do I vet suppliers for 100cc engine bike kits?

Vetting suppliers is crucial to ensure product quality and reliability. Start by checking their certifications, production capabilities, and quality control processes. Request samples to evaluate the product firsthand and assess their responsiveness to inquiries. Additionally, review their history with international shipping, payment terms, and after-sales support to ensure they align with your business requirements. -

What payment terms are commonly offered by suppliers of 100cc engine bike kits?

Payment terms can vary widely among suppliers, but common arrangements include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer letters of credit or escrow services for larger orders. Always clarify payment terms before finalizing agreements to avoid misunderstandings, and consider negotiating terms that provide you with favorable cash flow. -

What are the logistics considerations when importing 100cc engine bike kits?

When importing 100cc engine bike kits, consider factors like shipping methods, lead times, and customs regulations in your destination country. Ensure that your logistics provider is experienced in handling motorized components to avoid delays. Additionally, account for potential tariffs and taxes, and assess whether your supplier can assist with documentation to facilitate smooth customs clearance. -

How can I ensure quality assurance for 100cc engine bike kits?

Quality assurance can be established through several methods. Implementing a detailed inspection process during production, including in-line inspections, can help catch defects early. You may also consider third-party quality control services to conduct inspections before shipment. Establish clear quality standards and communicate them to your supplier to ensure that the final product meets your expectations. -

Are there customization options available for 100cc engine bike kits?

Many manufacturers offer customization options for 100cc engine bike kits, including branding, color variations, and specific performance modifications. When discussing customization, consider the implications for cost, lead time, and MOQ. It’s essential to communicate your requirements clearly and understand how customizations will impact the overall production and delivery process to ensure a seamless integration into your product line.

Top 4 100Cc Engine Bike Kit Manufacturers & Suppliers List

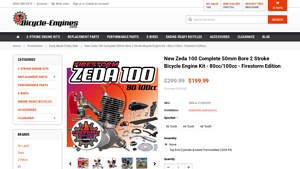

1. Zeda – Complete 50mm Bore 2 Stroke Bicycle Engine Kit

Domain: bicycle-engines.com

Registered: 2007 (18 years)

Introduction: New Zeda 100 Complete 50mm Bore 2 Stroke Bicycle Engine Kit – 80cc/100cc – Firestorm Edition. Price: $299.99 (Discounted to $199.99). SKU: ENGJL-Z100CES. Features: 50mm bore single piece cylinder, upgraded CDI, performance Speed carb, silver anti-corrosion coating, improved magneto, high-end allen bolts, improved gas cap. Engine specifications: 3+ HP, 78.6cc displacement, 40mm stroke, larger intak…

2. California Motorbikes – 100cc Bicycle Engine Kit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 100cc bicycle engine kit, alternatives include 90cc kits, recommended brands include California Motorbikes and CDH Power, parts availability is a concern, suggested to consider 47mm engines for easier maintenance, specific product links shared include GoMaxInd and Bicycle Engines Phantom V3.

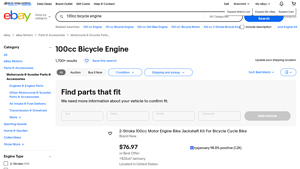

3. eBay – 100cc Bicycle Engine Kits

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 100cc Bicycle Engine

– Type: 2-Stroke and 4-Stroke options available

– Price Range: $20.00 to $273.54

– Features: Motorized petrol/gas engine kits for bicycles

– Delivery: Free delivery options available, typically within 2-4 days

– Locations: Various sellers located in Chino, CA and Cranbury, NJ

– Return Policy: Free returns offered by some sellers

– Ratings: Some products rated 4.0 out of 5 star…

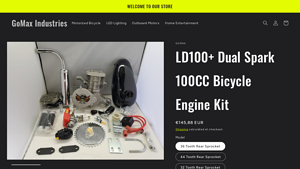

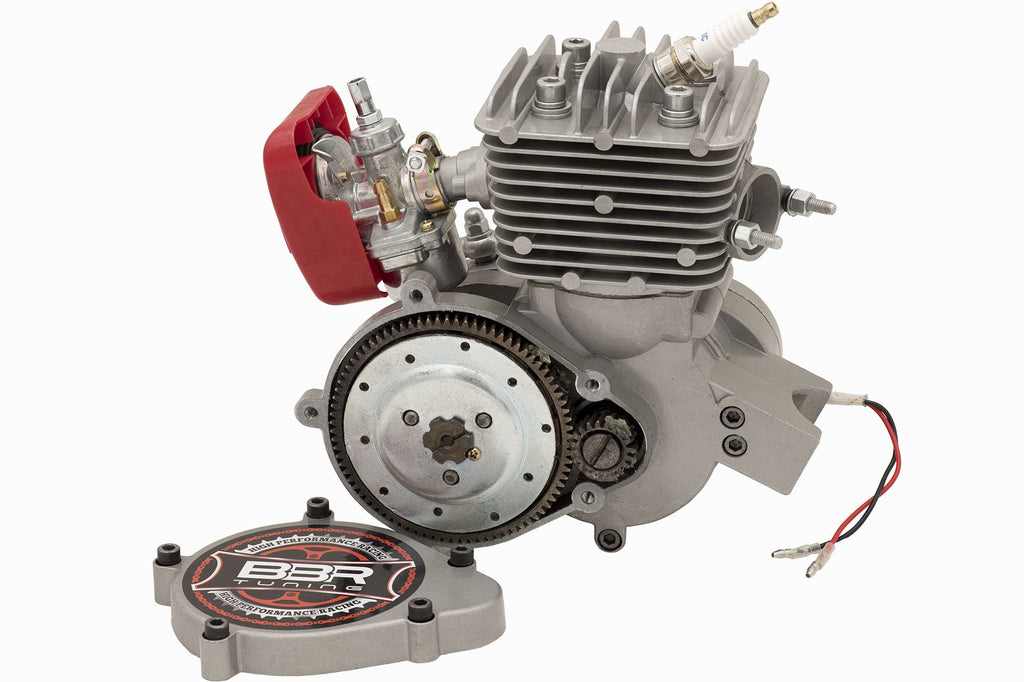

4. GoMax – LD100+ Dual Spark 100CC Bicycle Engine Kit

Domain: gomaxind.com

Registered: 2020 (5 years)

Introduction: LD100+ Dual Spark 100CC Bicycle Engine Kit

– Regular Price: $169.00 USD

– Variants: 36 Tooth Rear Sprocket, 44 Tooth Rear Sprocket, 32 Tooth Rear Sprocket

– Features:

– 100CC Dual Spark Engine

– 50mm bore, 40mm stroke

– Better balanced crank

– Upgraded bearings

– Rare Earth Magnet and Magneto with extra windings

– High performance Red BoFeng Speed carburetor

– Silver anti-corrosion …

Strategic Sourcing Conclusion and Outlook for 100cc engine bike kit

In conclusion, strategic sourcing of 100cc engine bike kits presents a compelling opportunity for international B2B buyers aiming to capitalize on the growing demand for efficient and versatile transportation solutions. By carefully selecting suppliers that offer high-quality kits—such as those with robust 2-stroke and 4-stroke options—businesses can ensure reliability and customer satisfaction.

Moreover, understanding the nuances of engine types, maintenance requirements, and performance features can help buyers tailor their offerings to meet regional needs, particularly in markets across Africa, South America, the Middle East, and Europe.

As the global market continues to evolve, staying ahead of trends and fostering strong supplier relationships will be crucial for success. We encourage B2B buyers to explore partnerships that not only provide competitive pricing but also prioritize innovation and quality. By doing so, you position your business to thrive in a dynamic marketplace, ready to meet the diverse demands of consumers seeking cost-effective and sustainable mobility solutions. Engage with suppliers today to secure your place in this burgeoning sector and drive your business forward.

Illustrative image related to 100cc engine bike kit

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 100cc engine bike kit