Unlocking Value: A Strategic Analysis of the Toroidal Amplifier Market

Introduction: Navigating the Global Market for toroidal amplifier

In today’s competitive landscape, sourcing the right toroidal amplifier can be a daunting task for B2B buyers, especially when navigating the diverse global market. These specialized amplifiers, known for their compact design and superior sound quality, are essential for various applications in industries ranging from audio engineering to renewable energy. However, challenges such as identifying reliable suppliers, understanding pricing structures, and ensuring compliance with international standards can complicate the purchasing process.

This comprehensive guide aims to demystify the intricacies of the toroidal amplifier market. It covers a wide range of topics, including the different types of toroidal amplifiers available, their specific applications across various sectors, and strategies for vetting suppliers to ensure quality and reliability. Additionally, we delve into cost considerations, helping you balance budget constraints with the need for high-performance audio solutions.

By providing actionable insights and expert advice, this guide empowers international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—to make informed purchasing decisions. With a thorough understanding of the toroidal amplifier landscape, you can confidently select the right products to meet your business needs, ultimately enhancing your operational efficiency and product offerings.

Understanding toroidal amplifier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Audio Toroidal Amplifier | High efficiency, low electromagnetic interference, compact size | Professional audio equipment, live sound systems | Pros: Superior sound quality, reduced noise; Cons: Higher initial cost compared to traditional transformers. |

| Medical Grade Toroidal Amplifier | Compliance with strict medical standards, enhanced reliability | Medical devices and equipment | Pros: Meets safety regulations, consistent performance; Cons: Limited customization options. |

| Custom Toroidal Amplifier | Tailored specifications for unique applications | Specialized industrial applications | Pros: Meets specific requirements, optimized performance; Cons: Longer lead times for production. |

| High-Power Toroidal Amplifier | Designed for high current applications, robust construction | Industrial machinery, renewable energy systems | Pros: High efficiency under load, durable; Cons: Bulkier design may limit installation options. |

| Tube Toroidal Amplifier | Combines tube technology with toroidal design for audio warmth | High-end audio systems, audiophile markets | Pros: Rich sound quality, unique tonal characteristics; Cons: Maintenance can be more complex than solid-state options. |

What Are the Characteristics of Audio Toroidal Amplifiers?

Audio toroidal amplifiers are engineered for high efficiency and minimal electromagnetic interference, making them ideal for professional audio applications. Their compact design allows for easy integration into various audio setups, from studio equipment to live sound systems. When purchasing, B2B buyers should consider the initial investment against the long-term benefits of superior sound quality and reduced noise, which can significantly enhance audio experiences in commercial settings.

How Do Medical Grade Toroidal Amplifiers Stand Out?

Medical grade toroidal amplifiers are designed to meet stringent safety and performance standards essential in healthcare applications. These transformers ensure reliable operation in critical medical devices, providing peace of mind for manufacturers and users alike. Buyers in the medical sector should prioritize compliance with industry regulations when selecting these amplifiers, even though customization options may be limited. The trade-off for reliability and safety is worth it for applications where precision is crucial.

What Are the Advantages of Custom Toroidal Amplifiers?

Custom toroidal amplifiers are tailored to meet the specific needs of specialized applications, providing optimized performance that standard models may not offer. They are particularly beneficial for industries requiring unique specifications, such as telecommunications or advanced manufacturing. B2B buyers should consider the lead time for production, as custom solutions may take longer to deliver. However, the ability to meet precise requirements can justify the wait and ensure superior functionality.

Why Choose High-Power Toroidal Amplifiers for Industrial Applications?

High-power toroidal amplifiers are built to handle substantial current loads, making them suitable for industrial machinery and renewable energy systems. Their robust construction and high efficiency under load are significant advantages for businesses aiming to maximize performance while minimizing energy waste. Buyers should evaluate the physical dimensions and installation requirements, as these amplifiers can be bulkier than other types, potentially affecting space and layout.

What Makes Tube Toroidal Amplifiers Unique?

Tube toroidal amplifiers combine the classic warmth of tube technology with the efficiency of toroidal designs, appealing to high-end audio systems and audiophile markets. They provide a rich sound quality that is often preferred in premium audio setups. B2B buyers should consider the maintenance needs of tube amplifiers, as they may require more care than solid-state alternatives. However, the unique tonal characteristics can elevate audio experiences, making them a valuable investment for discerning clients.

Key Industrial Applications of toroidal amplifier

| Industry/Sector | Specific Application of toroidal amplifier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Audio Equipment Manufacturing | Power amplifiers for high-fidelity audio systems | Enhanced sound quality with reduced electromagnetic interference | Customization options for voltage and size requirements |

| Renewable Energy | Inverters for solar power systems | Improved energy efficiency and reduced stray losses | Compliance with local energy regulations and standards |

| Medical Equipment | Medical-grade audio amplifiers | Reliable performance with minimized noise and vibrations | Certification for safety standards (e.g., IEC 60601-1) |

| Industrial Automation | Amplifiers in control systems for machinery | Increased reliability and efficiency in operations | Availability of custom designs for specific industrial needs |

| Telecommunications | Signal amplifiers for communication networks | Higher signal integrity and reduced interference | Robustness against environmental factors in deployment |

How Are Toroidal Amplifiers Used in Audio Equipment Manufacturing?

In the audio equipment manufacturing sector, toroidal amplifiers are crucial for powering high-fidelity audio systems. Their unique design minimizes electromagnetic interference, allowing for superior sound quality and clarity. This is particularly important for businesses focused on high-end audio products, where performance is paramount. Buyers in this sector should consider customization options for voltage specifications and physical dimensions to ensure compatibility with existing systems.

What Role Do Toroidal Amplifiers Play in Renewable Energy?

In renewable energy applications, particularly solar power systems, toroidal amplifiers are used in inverters to convert DC to AC power. Their high efficiency and reduced stray losses contribute to better energy conversion rates, which is essential for maximizing output from solar panels. International buyers should ensure that the products comply with local energy regulations and standards to facilitate seamless integration into their systems.

Why Are Toroidal Amplifiers Important in Medical Equipment?

Medical-grade audio amplifiers that utilize toroidal technology are designed to meet stringent reliability and performance standards. These amplifiers are essential in medical devices where sound quality and clarity can be crucial for diagnostics and monitoring. Buyers in the medical sector must prioritize sourcing from manufacturers with certifications such as IEC 60601-1, ensuring that the products meet safety and performance requirements.

How Do Toroidal Amplifiers Enhance Industrial Automation?

In industrial automation, toroidal amplifiers serve as integral components in control systems for machinery. Their compact size and efficiency allow for streamlined integration into various industrial applications, enhancing operational reliability. Businesses should consider the availability of custom designs to meet specific industrial needs, including tailored voltage requirements and mounting options.

What Are the Benefits of Toroidal Amplifiers in Telecommunications?

In telecommunications, toroidal amplifiers are utilized to boost signal integrity within communication networks. Their ability to reduce interference and enhance signal quality is vital for maintaining reliable communication channels. For B2B buyers in this sector, sourcing robust amplifiers that can withstand environmental factors, such as temperature fluctuations and humidity, is critical for long-term deployment in diverse locations.

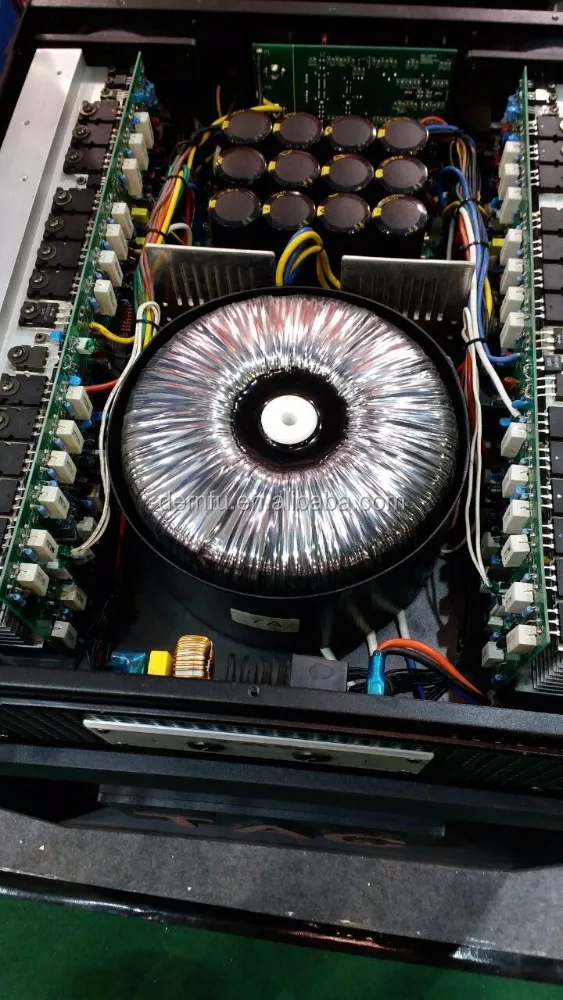

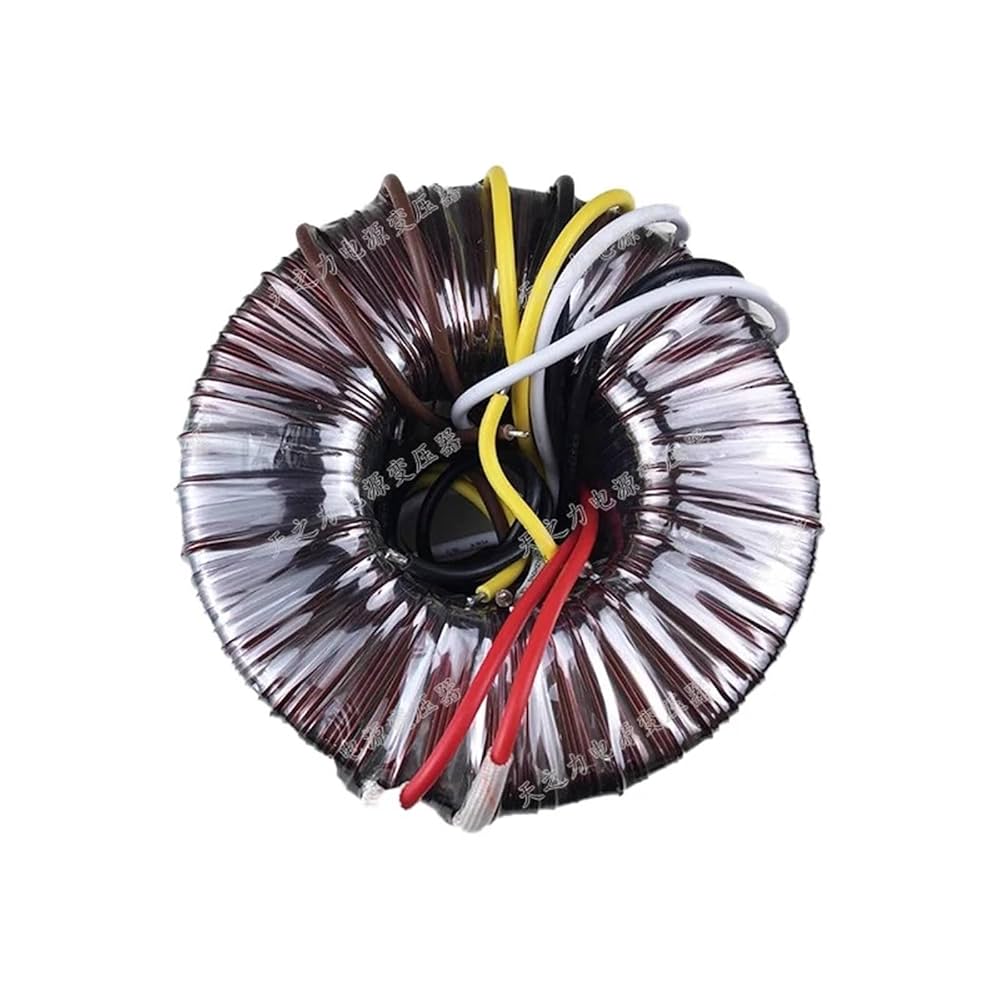

Illustrative image related to toroidal amplifier

3 Common User Pain Points for ‘toroidal amplifier’ & Their Solutions

Scenario 1: Ensuring High-Quality Audio Output for Live Events

The Problem: B2B buyers in the audio equipment industry often face the challenge of ensuring high-quality sound during live events. This is particularly crucial for event organizers and audio engineers who depend on reliable performance from their amplifiers. Traditional transformers can introduce unwanted hum and vibration, compromising sound clarity. This issue is exacerbated in venues with poor acoustic conditions, leading to dissatisfaction among audiences and clients.

The Solution: To overcome this challenge, investing in toroidal amplifiers is key. Their unique design significantly reduces electromagnetic interference (EMI) and mechanical noise, ensuring a clear audio output. Buyers should prioritize sourcing amplifiers that incorporate high-efficiency toroidal transformers, as they provide cleaner power and minimize vibrations. It’s advisable to consult with manufacturers about custom specifications to meet the specific acoustic needs of the venue. Additionally, testing the setup in advance can help identify any potential issues, allowing for adjustments before the event, thus enhancing overall sound quality.

Scenario 2: Space Constraints in Equipment Design

The Problem: Many B2B buyers in sectors such as broadcasting or commercial audio face significant space constraints when designing or upgrading their equipment. Traditional amplifiers with standard transformers can be bulky and heavy, making integration into existing systems challenging. This can lead to additional costs associated with redesigning equipment layouts or purchasing larger enclosures, ultimately impacting project timelines and budgets.

The Solution: The compact nature of toroidal amplifiers presents a practical solution for space-constrained environments. When sourcing toroidal amplifiers, buyers should look for models that offer a low profile and lightweight design. Custom solutions are also available, allowing buyers to specify dimensions that fit their specific installation needs. Collaborating with manufacturers to create tailored transformer solutions can further optimize space while ensuring that performance is not compromised. Additionally, utilizing modular designs can facilitate easier upgrades in the future, accommodating evolving technological requirements without extensive redesign.

Scenario 3: Navigating Compliance and Safety Standards

The Problem: In industries such as medical and industrial applications, B2B buyers must adhere to strict compliance and safety standards. Standard amplifiers may not meet the necessary regulations, which can lead to costly delays and potential legal issues. Ensuring that equipment is certified and reliable is paramount, particularly when it comes to life-saving medical devices or critical industrial machinery.

The Solution: To address compliance challenges, buyers should seek toroidal amplifiers that are specifically designed to meet industry standards. This includes looking for certifications such as IEC 60601-1 for medical-grade transformers. Engaging with reputable suppliers who understand regulatory requirements can streamline the procurement process. Buyers should also invest time in understanding the specific compliance needs of their applications to ensure that the selected amplifiers not only meet but exceed these standards. Regular audits and assessments of the equipment can also help maintain compliance and enhance safety, providing peace of mind to both the buyer and end-users.

Strategic Material Selection Guide for toroidal amplifier

What Materials Are Commonly Used in Toroidal Amplifiers?

When selecting materials for toroidal amplifiers, it is essential to consider the properties and performance implications of various options. Here, we analyze four common materials used in the construction of toroidal transformers, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Silicon Steel

Key Properties: Silicon steel is known for its excellent magnetic properties and is commonly used in transformer cores. It has a high saturation magnetization, which allows for efficient energy transfer, and can withstand temperatures up to 200°C.

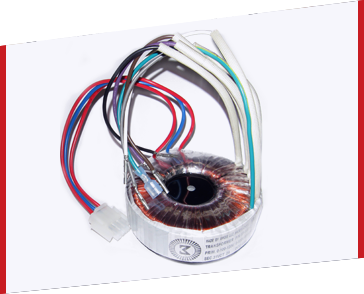

Illustrative image related to toroidal amplifier

Pros & Cons: The primary advantage of silicon steel is its high magnetic permeability, leading to reduced energy losses. However, it can be relatively heavy and requires careful handling during manufacturing, which may increase production costs.

Impact on Application: Silicon steel is suitable for applications where high magnetic efficiency is critical, such as in high-power audio amplifiers. Its performance can be affected by environmental factors like humidity, which may necessitate additional protective coatings.

Considerations for International Buyers: Compliance with international standards such as ASTM A1008 for cold-rolled steel is crucial. Buyers from regions like Europe and the Middle East should ensure that suppliers adhere to these standards to avoid compatibility issues.

2. Ferrite

Key Properties: Ferrite materials are ceramic compounds made of iron oxide mixed with other metals. They exhibit high electrical resistivity and low eddy current losses, making them suitable for high-frequency applications.

Pros & Cons: Ferrite cores are lightweight and compact, allowing for smaller transformer designs. However, they can be brittle and sensitive to mechanical stress, which may limit their use in rugged environments.

Impact on Application: Ferrite is particularly effective in applications requiring high-frequency operation, such as RF amplifiers. Its low loss characteristics make it suitable for energy-efficient designs.

Considerations for International Buyers: Buyers should be aware of the different grades of ferrite materials and their specific applications. Compliance with standards like IEC 60076 for power transformers is essential, especially in regions with stringent regulations like Europe.

3. Copper

Key Properties: Copper is widely used for winding wires in toroidal transformers due to its excellent electrical conductivity and thermal properties. It can operate efficiently at high temperatures and has a melting point of approximately 1,085°C.

Illustrative image related to toroidal amplifier

Pros & Cons: The main advantage of copper is its superior conductivity, which minimizes energy losses. However, copper is relatively expensive compared to aluminum, and its weight can be a consideration in portable applications.

Impact on Application: Copper windings are ideal for high-performance audio amplifiers where minimal resistance is crucial for sound quality. Its compatibility with various media makes it versatile across different applications.

Considerations for International Buyers: Buyers should ensure that the copper used meets international standards such as ASTM B170 for copper wire. In regions like South America and Africa, sourcing high-quality copper can be challenging, necessitating reliable suppliers.

4. Aluminum

Key Properties: Aluminum is a lightweight metal with good electrical conductivity, though not as high as copper. It has a melting point of around 660°C and is resistant to corrosion, making it suitable for various environments.

Pros & Cons: The primary advantage of aluminum is its low cost and lightweight nature, which can reduce shipping and handling costs. However, it has lower conductivity than copper, which may affect performance in high-power applications.

Impact on Application: Aluminum is often used in lower-cost amplifiers where weight and cost savings are priorities. Its corrosion resistance makes it suitable for outdoor applications.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 for aluminum extrusions is important. Buyers in regions with high humidity, like parts of Africa and the Middle East, should consider the long-term durability of aluminum in their applications.

Summary Table of Material Selection for Toroidal Amplifiers

| Material | Typical Use Case for toroidal amplifier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | High-power audio amplifiers | High magnetic permeability | Heavy, higher production costs | Medium |

| Ferrite | RF amplifiers | Lightweight, compact | Brittle, sensitive to mechanical stress | Medium |

| Copper | High-performance audio amplifiers | Superior conductivity | Expensive, heavier than aluminum | High |

| Aluminum | Lower-cost amplifiers | Low cost, lightweight | Lower conductivity than copper | Low |

This analysis provides B2B buyers with crucial insights into material selection for toroidal amplifiers, ensuring informed decisions that align with their specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal amplifier

What Are the Key Stages in the Manufacturing Process of Toroidal Amplifiers?

The manufacturing of toroidal amplifiers involves several critical stages, each designed to ensure the highest quality and efficiency in the final product. Understanding these processes can help B2B buyers make informed decisions when sourcing these components.

How Is Material Prepared for Toroidal Amplifiers?

The first stage of manufacturing begins with material preparation. High-quality electrical steel is often used for the core of toroidal transformers due to its excellent magnetic properties. This steel is typically cut into thin sheets to minimize eddy current losses. The sheets are then stacked and wound into a toroidal shape. Manufacturers may also use copper wire for windings, which is essential for electrical conductivity.

Proper sourcing of raw materials is crucial, as lower-quality materials can lead to inefficiencies and increased noise in the final product. B2B buyers should inquire about the suppliers’ material specifications and sourcing practices.

What Techniques Are Used in Forming Toroidal Transformers?

The forming process involves shaping the prepared materials into the toroidal form. This is generally achieved through automated winding machines that ensure precision in the winding process. The toroidal core is wound with copper wire in a consistent manner to achieve the desired inductance and resistance values.

Advanced techniques such as computer numerical control (CNC) machining may be employed to enhance precision in the winding process. This level of accuracy is vital for achieving the low electromagnetic interference (EMI) that toroidal amplifiers are known for. Buyers should consider suppliers that utilize state-of-the-art machinery to ensure product consistency and quality.

How Is Assembly Conducted in Toroidal Amplifier Manufacturing?

Once the components are formed, the next step is assembly. This involves integrating the toroidal transformers with other components of the amplifier, such as capacitors and circuit boards. The assembly process is typically performed in a cleanroom environment to prevent contamination and ensure optimal performance.

Automated assembly lines are often used to enhance efficiency and reduce human error. Quality control checkpoints during assembly, including visual inspections and functional tests, are essential to catch any potential defects early. B2B buyers should ask about the assembly practices of potential suppliers to ensure they meet industry standards.

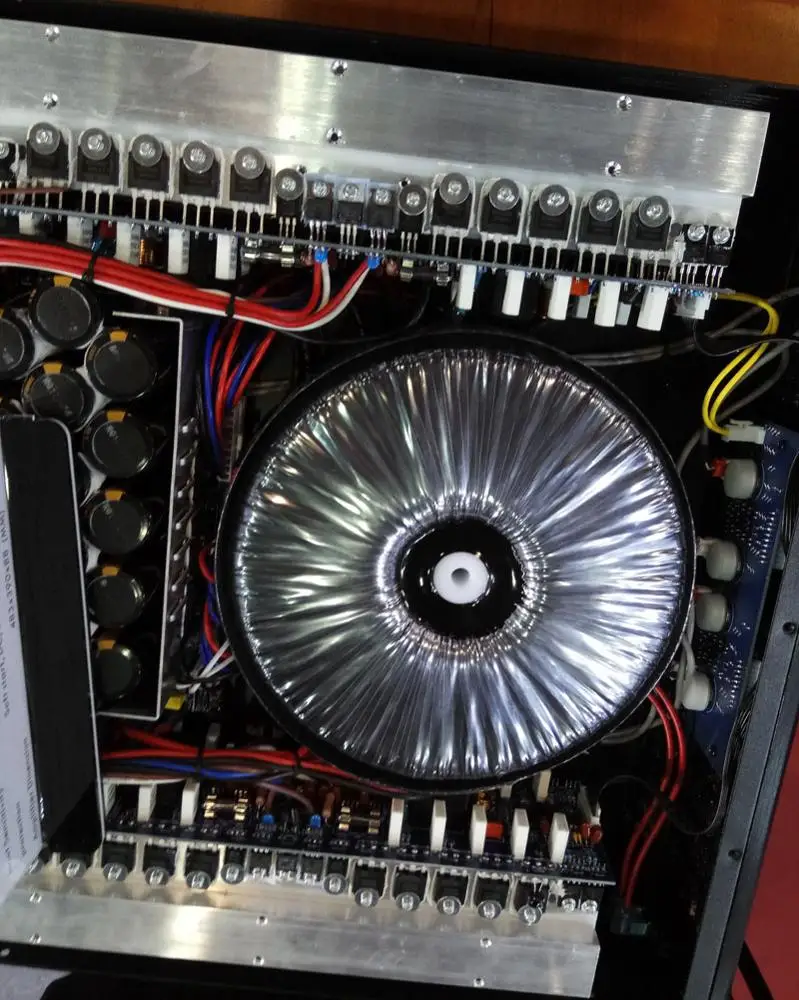

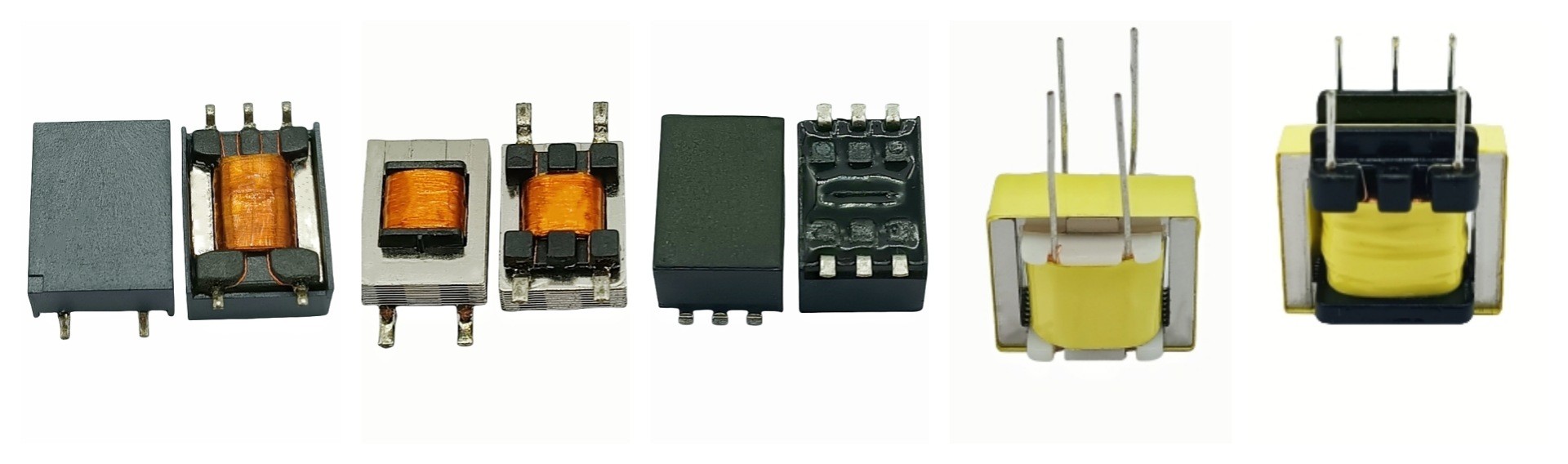

Illustrative image related to toroidal amplifier

What Finishing Techniques Are Used for Toroidal Amplifiers?

Finishing is the final stage in the manufacturing process, where the assembled units undergo testing and cosmetic enhancements. This may include applying protective coatings, labeling, and final inspections. The aim is to ensure that the toroidal amplifiers not only function as intended but also meet aesthetic standards.

This stage often involves rigorous testing protocols to verify performance under various conditions. Buyers should look for suppliers that provide detailed finishing reports, including test results and compliance certifications.

What International Standards Should B2B Buyers Look for in Quality Assurance?

Quality assurance is a critical aspect of the manufacturing process for toroidal amplifiers. International standards, such as ISO 9001, are essential for ensuring consistent quality management systems. Compliance with these standards indicates that a manufacturer has implemented effective quality assurance protocols throughout their processes.

Which Industry-Specific Certifications Are Important for Toroidal Amplifiers?

In addition to general quality management standards, industry-specific certifications can be crucial. For example, CE marking is often necessary for products sold in Europe, indicating conformity with health, safety, and environmental protection standards. Similarly, certifications from organizations like Underwriters Laboratories (UL) and the American National Standards Institute (ANSI) can enhance credibility.

B2B buyers should verify that suppliers possess these certifications, as they can significantly impact product acceptance in different markets.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated at multiple stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): The finished products undergo comprehensive testing to verify functionality and compliance with specifications.

Employing these checkpoints helps manufacturers maintain high standards and reduce the risk of defects. B2B buyers should inquire about the QC processes of potential suppliers to ensure they align with their quality expectations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality control practices, B2B buyers can take several steps:

-

Conduct Audits: Regular audits of potential suppliers can provide insight into their manufacturing processes and QC measures. Audits can be done in person or through third-party services.

-

Request Quality Reports: Suppliers should provide documentation detailing their QC processes, test results, and compliance with relevant standards.

-

Engage Third-Party Inspectors: Utilizing independent inspection agencies can provide an unbiased assessment of the supplier’s manufacturing and QC practices.

-

Check References: Speaking with other customers who have sourced from the supplier can provide valuable insights into their reliability and quality.

What Nuances Should International Buyers Consider Regarding Quality Control?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and standards is vital. Different markets may have varying requirements regarding certifications and compliance, which can affect product acceptance.

Additionally, logistical considerations can influence quality control processes. Ensuring that the supplier has robust logistics and distribution systems can mitigate risks related to product damage during transportation.

B2B buyers should also be aware of the cultural and operational nuances in different regions, as these can impact communication and expectations regarding quality standards.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing toroidal amplifiers, ensuring they acquire high-quality products that meet their specific needs.

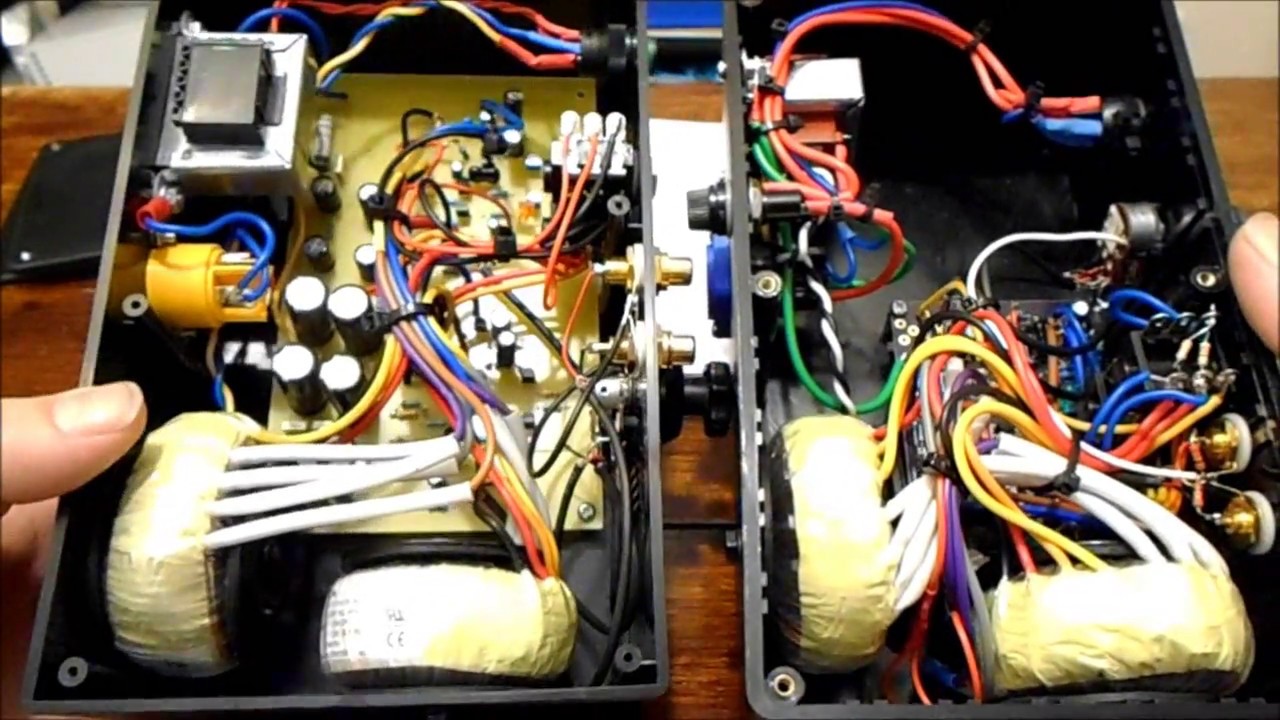

Illustrative image related to toroidal amplifier

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toroidal amplifier’

Introduction

Sourcing a toroidal amplifier requires careful consideration to ensure optimal performance, efficiency, and compatibility with your specific audio applications. This guide provides a step-by-step checklist for B2B buyers, focusing on key factors that will help you make informed procurement decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify your technical requirements. This includes understanding the voltage, power ratings, and specific features needed for your application.

– Consider the application: Are you using the amplifier for professional audio, home theater, or industrial purposes?

– Identify compatibility: Ensure that the amplifier can work seamlessly with existing equipment.

Step 2: Research Supplier Credentials

Establishing trust in your supplier is vital. Research their credentials to verify their expertise and reliability in providing toroidal amplifiers.

– Check certifications: Look for ISO certifications, compliance with industry standards, and any specific certifications relevant to your region.

– Investigate industry reputation: Read reviews and testimonials from other buyers, especially from similar industries or geographical locations.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers thoroughly.

– Request company profiles: Ask for detailed profiles, including their history, production capabilities, and quality assurance processes.

– Seek case studies and references: Contact previous clients to gauge their experiences and satisfaction with the supplier’s products and services.

Step 4: Assess Product Quality and Specifications

Investigate the quality of the toroidal amplifiers being offered by suppliers.

– Inquire about materials and manufacturing processes: High-quality materials will ensure durability and efficiency.

– Request technical data sheets: These documents should outline performance metrics, such as efficiency ratings, temperature rise, and noise levels.

Step 5: Compare Pricing and Terms

Pricing can vary significantly among suppliers, so it’s essential to conduct a thorough comparison.

– Request quotes: Obtain detailed quotes from multiple suppliers, ensuring they include all costs (shipping, taxes, etc.).

– Evaluate warranty and return policies: Understand the terms of warranty and any return policies to mitigate risk.

Step 6: Check Customization Options

If your application requires specific features, inquire about customization capabilities.

– Discuss your needs: Some suppliers may offer tailored solutions, such as custom voltage specifications or unique mounting configurations.

– Understand lead times: Custom solutions may have longer lead times, so factor this into your planning.

Step 7: Finalize and Place Your Order

Once you’ve selected a supplier, ensure that all details are confirmed before placing your order.

– Review the contract: Double-check all specifications, pricing, and terms outlined in the agreement.

– Establish communication channels: Set up clear lines of communication for any follow-up questions or concerns post-order.

By following this checklist, you can navigate the sourcing process for toroidal amplifiers with confidence, ensuring that you select the right product and supplier for your needs.

Illustrative image related to toroidal amplifier

Comprehensive Cost and Pricing Analysis for toroidal amplifier Sourcing

What Are the Key Cost Components for Sourcing Toroidal Amplifiers?

When sourcing toroidal amplifiers, understanding the cost structure is essential for effective budgeting and negotiation. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: The core of a toroidal amplifier is the toroidal transformer, which is made from high-quality magnetic materials. The choice of materials directly impacts performance and price. Higher-grade materials can increase costs but provide better efficiency and longevity.

-

Labor: Labor costs vary depending on the complexity of the design and the location of production. Skilled labor is required for assembly, especially for custom or high-spec models, leading to higher labor costs in regions with stricter labor regulations or higher wage standards.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can mitigate these costs, but they typically constitute a significant portion of the overall price.

-

Tooling: Custom tooling for unique designs can be a substantial upfront investment. However, if the order volume is high, the cost per unit can decrease significantly as the tooling is amortized over a larger production run.

-

Quality Control (QC): Investing in robust QC processes ensures that the amplifiers meet industry standards and certifications, which can affect pricing. For instance, compliance with international standards may require additional testing and documentation, adding to the overall cost.

-

Logistics: Shipping costs are influenced by the destination, order size, and chosen Incoterms. For international buyers, understanding shipping terms is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This can vary widely based on supplier reputation, market demand, and the level of customization required.

What Price Influencers Should B2B Buyers Consider?

Several factors influence the pricing of toroidal amplifiers, especially for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to discounts, while small orders may incur higher per-unit costs.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized materials and labor. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or CE marks) can enhance performance but also lead to higher prices. Buyers should assess the importance of these factors in relation to their specific application.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their expertise and quality assurance, while newer or less-known suppliers may offer lower prices but with increased risk.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting the total landed cost of the amplifiers.

What Are the Best Tips for Negotiating Toroidal Amplifier Prices?

When negotiating prices for toroidal amplifiers, especially in international markets like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher MOQs for better pricing. Suppliers are often more willing to negotiate on larger orders.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like efficiency, longevity, and maintenance costs, which can significantly affect the total cost over the product’s lifecycle.

-

Be Open to Alternatives: If a supplier cannot meet your price expectations, explore other options, such as slightly different specifications or alternative materials that may reduce costs without compromising quality.

-

Establish Clear Communication: Clear and transparent communication about expectations and requirements can facilitate smoother negotiations and minimize misunderstandings that could lead to additional costs.

-

Research Market Trends: Understanding current market trends and pricing benchmarks can empower buyers to negotiate effectively and ensure they are getting a fair deal.

Disclaimer

The prices and specifications mentioned are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always consult suppliers directly for the most accurate and current pricing information.

Alternatives Analysis: Comparing toroidal amplifier With Other Solutions

Exploring Alternatives to Toroidal Amplifiers: A Comprehensive Comparison

In the realm of audio amplification, the choice of technology can significantly impact performance, efficiency, and overall sound quality. While toroidal amplifiers are recognized for their compact design and high efficiency, several alternatives exist that may cater to different needs and budget constraints. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific applications and operational requirements.

Illustrative image related to toroidal amplifier

| Comparison Aspect | Toroidal Amplifier | EL Transformer | R-Core Transformer |

|---|---|---|---|

| Performance | High fidelity; minimal hum and vibration | Good but may produce noise | High performance; low noise |

| Cost | Moderate to high | Low | Moderate |

| Ease of Implementation | Requires specific mounting | Simple installation | Moderate installation complexity |

| Maintenance | Low | Low | Low |

| Best Use Case | Professional audio, medical equipment | Budget audio setups | High-end audio applications |

What Are the Advantages and Disadvantages of EL Transformers?

EL transformers are often the go-to choice for budget-conscious applications. They are less expensive than toroidal amplifiers, making them an attractive option for low-cost audio equipment. However, they tend to be bulkier and heavier, which can pose challenges for installation in compact environments. Additionally, EL transformers may emit higher magnetic fields, which can interfere with audio quality, making them less suitable for high-fidelity applications.

How Do R-Core Transformers Compare?

R-core transformers are another viable alternative, known for their high efficiency and low noise output. They provide better performance than standard laminated transformers but are not as compact as toroidal designs. R-core transformers typically offer good voltage regulation and thermal performance, making them suitable for high-end audio applications. However, their cost is generally moderate, which may be a consideration for budget-sensitive projects. The installation process is more complex than that of EL transformers, potentially requiring specialized mounting solutions.

Conclusion: How Should B2B Buyers Choose the Right Amplifier Solution?

When selecting an amplifier solution, B2B buyers should carefully consider their specific application needs, budget constraints, and desired performance levels. Toroidal amplifiers excel in professional and high-fidelity environments due to their compact size and minimal interference, making them ideal for audiophiles and medical applications. Conversely, EL transformers serve well in budget scenarios, while R-core transformers bridge the gap for those seeking high performance without the premium price tag of toroidal options. Ultimately, the right choice hinges on balancing performance, cost, and application requirements, ensuring that the selected technology aligns with the buyer’s operational goals.

Essential Technical Properties and Trade Terminology for toroidal amplifier

What Are the Key Technical Properties of a Toroidal Amplifier?

1. Efficiency Rating

Efficiency ratings for toroidal transformers typically range from 90% to 97%. This high efficiency means less energy is wasted as heat, resulting in lower operational costs and improved performance. B2B buyers should prioritize high-efficiency models to ensure energy savings and better overall system performance, particularly in applications where power consumption is critical.

2. Magnetic Flux Density

Magnetic flux density is a measure of the magnetic field strength in the transformer core. Toroidal transformers exhibit lower magnetic flux density compared to conventional transformers, which leads to reduced electromagnetic interference (EMI). This property is crucial for applications in sensitive audio environments, where sound quality is paramount. Buyers should consider transformers with optimized flux density to minimize noise and enhance audio fidelity.

3. Size and Weight

The compact design of toroidal transformers allows them to occupy less space and be lighter than traditional transformers. This is particularly beneficial for manufacturers looking to save space in their products or for installations where weight is a constraint. Understanding the size and weight specifications can help buyers choose the right transformer for their applications without compromising on performance or design.

4. Temperature Rise

Temperature rise refers to the increase in temperature of a transformer under full load conditions. A lower temperature rise (generally below 55°C for toroidal transformers) indicates better thermal management and reliability. For B2B buyers, selecting transformers with a low temperature rise is essential to ensure longevity and reduce the risk of thermal-related failures in their applications.

5. Mounting Options

Different toroidal transformers offer various mounting configurations to accommodate specific installation requirements. Many toroidal transformers can be mounted with a single bolt, simplifying the installation process. Understanding the available mounting options can help buyers streamline their assembly processes and ensure compatibility with existing equipment.

6. Material Grade

The materials used in the manufacturing of toroidal transformers, such as core laminations and insulation, affect performance and durability. High-grade materials can enhance efficiency and reduce losses. Buyers should seek products that meet industry standards for material quality to ensure reliability and compliance in their applications.

What Are the Common Trade Terms Associated with Toroidal Amplifiers?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed under another company’s brand name. Understanding OEM relationships is crucial for B2B buyers looking to source toroidal transformers, as it can impact pricing, customization options, and supply chain dynamics.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is important for buyers who need to manage inventory levels or who are working with tight budgets. Knowing the MOQ helps in planning purchases and negotiating favorable terms with suppliers.

Illustrative image related to toroidal amplifier

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. This is a common practice in B2B transactions, especially when sourcing specialized components like toroidal transformers. Submitting an RFQ allows buyers to compare options and ensure they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations when importing toroidal amplifiers from global suppliers.

5. Lead Time

Lead time is the time taken from placing an order to receiving the goods. In the context of toroidal amplifiers, understanding lead times is vital for project planning and inventory management. Buyers should inquire about lead times to ensure they can meet their production schedules.

6. Certification Standards

Certification standards, such as ISO and UL, indicate that a product meets specific safety and quality requirements. For B2B buyers, ensuring that their toroidal transformers comply with relevant certification standards is essential for regulatory compliance and maintaining high-quality production standards.

Navigating Market Dynamics and Sourcing Trends in the toroidal amplifier Sector

What Are the Global Drivers Shaping the Toroidal Amplifier Market?

The toroidal amplifier sector is currently experiencing robust growth, driven by a combination of technological advancements, increasing demand for high-quality audio, and the shift towards compact, efficient designs. The global market is particularly influenced by the rising popularity of home audio systems and professional audio equipment, especially in regions such as Africa, South America, the Middle East, and Europe. These markets are seeing an uptick in consumer spending on premium audio solutions, leading manufacturers to innovate and enhance their offerings.

Emerging trends include the integration of digital technologies into traditional audio equipment, resulting in smarter, more user-friendly products. Additionally, the growing awareness of energy efficiency is pushing buyers towards toroidal amplifiers, which offer higher efficiency ratings (typically between 90% to 97%) compared to traditional transformers. This efficiency not only reduces operational costs but also aligns with the global movement towards sustainable energy practices.

Another key trend is the customization of toroidal transformers to meet specific audio requirements, such as unique voltage levels or compact installation needs. International buyers are increasingly seeking suppliers who can provide tailored solutions that adhere to local regulations and industry standards, ensuring compliance and reliability in diverse applications.

Illustrative image related to toroidal amplifier

How Does Sustainability Influence Sourcing Decisions for Toroidal Amplifiers?

Sustainability is becoming a significant factor in the sourcing of toroidal amplifiers, as businesses and consumers alike are increasingly prioritizing environmental responsibility. The manufacturing of toroidal transformers often involves materials and processes that can have a considerable environmental impact. Therefore, B2B buyers are now looking for suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste in production.

Ethical sourcing is also gaining traction, with companies expected to maintain transparency in their supply chains. Buyers should inquire about the certifications held by manufacturers, such as ISO 14001 for environmental management or similar ‘green’ certifications that ensure compliance with environmental standards. These certifications not only enhance brand reputation but also appeal to eco-conscious consumers.

In addition, the shift towards renewable energy solutions is driving the demand for high-efficiency toroidal transformers that can support sustainable energy systems. As such, suppliers who can showcase their commitment to sustainability and offer products that meet green standards are likely to find favor with international buyers.

What Is the Historical Context of Toroidal Amplifiers in the Market?

The evolution of toroidal amplifiers can be traced back to the introduction of toroidal transformers in the mid-20th century. Initially, these transformers were utilized in industrial applications due to their compact design and efficiency. Over the years, their advantages became apparent in audio applications, where sound quality and low electromagnetic interference are paramount.

Illustrative image related to toroidal amplifier

In the late 1990s and early 2000s, the proliferation of home audio systems and professional sound equipment led to a surge in the demand for high-performance amplifiers. As audio technology advanced, the toroidal transformer became a preferred choice for manufacturers looking to enhance sound quality and reduce noise. Today, the integration of digital technology with traditional audio systems has further solidified the position of toroidal amplifiers in the market, making them a staple in both consumer and professional audio settings.

This historical context not only highlights the advantages of toroidal amplifiers but also underscores their adaptability to changing market needs, making them a reliable choice for international B2B buyers seeking innovative audio solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal amplifier

-

How do I choose the right toroidal amplifier for my audio application?

Selecting the ideal toroidal amplifier involves evaluating your specific audio needs, including power requirements, sound quality, and installation space. Consider the amplifier’s efficiency rating, which should ideally be between 90-97%, and its noise level; toroidal amplifiers are known for their low mechanical noise. Additionally, assess whether you require a standard model or a custom solution that meets unique specifications, such as voltage needs or physical dimensions. -

What advantages do toroidal amplifiers offer compared to traditional transformers?

Toroidal amplifiers provide several benefits, including higher efficiency, reduced hum and electromagnetic interference, and a more compact design. Their unique donut shape minimizes stray losses and vibrations, resulting in clearer sound quality. Additionally, they typically require only a single mounting point, simplifying installation and reducing the footprint in your equipment setup. -

What customization options are available for toroidal amplifiers?

Customization options for toroidal amplifiers can include tailored voltage specifications, unique connector types, specific mounting configurations, and additional shielding requirements. Many manufacturers offer bespoke solutions to meet the unique demands of your audio application. Engaging with a supplier that provides end-to-end support ensures that your specific needs are met, from initial design to final installation. -

What are the typical minimum order quantities (MOQ) for toroidal amplifiers?

Minimum order quantities for toroidal amplifiers can vary significantly based on the manufacturer and the complexity of the product. Standard models may have lower MOQs, while custom designs often require larger orders to justify production costs. It is advisable to discuss your project requirements with suppliers to negotiate favorable terms that align with your purchasing needs. -

How do I vet suppliers for toroidal amplifiers in international markets?

Vetting suppliers involves assessing their certifications, production capabilities, and customer reviews. Look for ISO certifications, which indicate adherence to international quality standards. Additionally, inquire about their experience in your specific market and request references from previous clients. Engaging in direct communication can also help gauge their responsiveness and reliability. -

What payment terms should I expect when sourcing toroidal amplifiers internationally?

Payment terms can vary widely among suppliers and may include options such as upfront payment, 30% deposit with the balance upon shipment, or net 30/60 days post-delivery. It’s essential to clarify these terms early in negotiations and ensure they align with your cash flow capabilities. Using secure payment methods and establishing clear contracts can further protect your investment. -

What quality assurance practices should I look for in toroidal amplifier suppliers?

Look for suppliers that implement stringent quality assurance protocols throughout the production process. This may include regular testing of transformers for efficiency, noise levels, and compliance with international standards. Request documentation of testing procedures and certifications that ensure the amplifiers meet industry regulations, particularly if you are sourcing for sensitive applications like medical or audio equipment. -

How do logistics and shipping impact the sourcing of toroidal amplifiers?

Logistics play a crucial role in the sourcing process, affecting lead times, shipping costs, and overall project timelines. When sourcing internationally, consider the supplier’s location, shipping methods, and customs clearance processes. Opting for suppliers with established logistics networks can streamline the shipping process, while discussing delivery timelines upfront helps manage expectations and ensures timely project execution.

Top 4 Toroidal Amplifier Manufacturers & Suppliers List

1. Sure Electronics – Bluetooth Amplifier Board

Domain: store.sure-electronics.com

Registered: 2006 (19 years)

Introduction: Bluetooth Amplifier Board, Sure Electronics, BCPB, 18650 charger, T-AMP, Volume Control

2. Tortran – Toroidal Power Transformer Stereo Audio Amplifier

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Tortran Series/S Toroidal Power Transformer Stereo Audio Amplifier”, “Condition”: “Used”, “Price”: “$49.99”, “Best Offer”: “Available”, “Payment Options”: “4 interest-free payments of $12.50 available with Klarna”, “Primary Voltage Rating (AC)”: “115 V”, “Primary Current Rating”: “5 A”, “Secondary Voltage Rating (AC)”: “115 V”, “Secondary Current Rating”: “5 A”, “Turns Ratio”: “1…

3. Diyaudio – Toroid vs EI Transformers

Domain: diyaudio.com

Registered: 1999 (26 years)

Introduction: This company, Diyaudio – Toroid vs EI Transformers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Audiogon – Toroidal Transformers in Amplifiers

Domain: forum.audiogon.com

Registered: 1998 (27 years)

Introduction: This company, Audiogon – Toroidal Transformers in Amplifiers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for toroidal amplifier

As businesses increasingly prioritize efficiency and quality, the strategic sourcing of toroidal amplifiers has emerged as a crucial element for international buyers. The unique design of toroidal transformers not only minimizes electromagnetic interference but also enhances audio performance, making them ideal for a wide range of applications from audio equipment to industrial machinery. Their compact size and high efficiency ratings—often exceeding 95%—translate to significant space and cost savings, essential for businesses operating in competitive markets across Africa, South America, the Middle East, and Europe.

Investing in quality toroidal amplifiers ensures that your equipment operates with reduced noise and improved reliability, ultimately enhancing the customer experience. Additionally, the availability of custom solutions allows buyers to meet specific operational needs while adhering to industry standards.

Looking ahead, the demand for advanced audio solutions and efficient power management will only grow. By engaging with trusted suppliers and leveraging strategic sourcing practices, businesses can secure high-quality toroidal amplifiers that align with their operational goals. We encourage you to explore your options and contact reputable manufacturers to discuss tailored solutions that meet your unique requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.