Filtration Parts Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for filtration parts

In today’s interconnected world, sourcing high-quality filtration parts presents a significant challenge for international B2B buyers. Whether you are operating in Nigeria, Saudi Arabia, or across Europe, the complexity of navigating diverse market standards, varying supplier capabilities, and fluctuating costs can hinder your purchasing decisions. This comprehensive guide delves into the global market for filtration parts, offering insights into various types, applications, and innovative solutions tailored to meet your specific needs.

Throughout this guide, we explore essential topics including supplier vetting processes to ensure reliability, cost considerations for budgeting, and the latest trends in filtration technology. By equipping you with actionable insights and best practices, we empower you to make informed purchasing decisions that align with your operational goals. Understanding the nuances of filtration parts—from injection molded components to advanced carbon block tubes—will enhance your ability to find the right solutions for your projects.

As you navigate the intricate landscape of filtration parts, this guide serves as your strategic resource, facilitating successful sourcing and fostering long-term partnerships with reputable suppliers. Your journey towards effective filtration solutions begins here, enabling you to address challenges head-on and optimize your procurement processes in a competitive global market.

Understanding filtration parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Injection Molded Parts | Customizable shapes, high precision, rapid production | Water filtration systems, HVAC, industrial | Pros: Tailored solutions, quick turnaround. Cons: Initial setup costs can be high. |

| Melt Blown Media | Fine fiber structure, high dirt-holding capacity | Air and liquid filtration | Pros: Excellent filtration efficiency. Cons: Limited lifespan, requires regular replacements. |

| Carbon Block Tubes | High adsorption capacity, customizable dimensions | Water purification, industrial processes | Pros: Effective for chemical removal, versatile. Cons: Can be more expensive than granular filters. |

| Filter Cartridges | Standardized sizes, easy to replace, various filtration grades | Household water filters, commercial systems | Pros: Simple maintenance, wide availability. Cons: Performance can vary by brand. |

| O-Rings | Essential sealing components, available in various materials | All filtration systems | Pros: Cost-effective, crucial for preventing leaks. Cons: Regular inspection needed for wear and tear. |

What are Injection Molded Parts and Their B2B Relevance?

Injection molded parts are manufactured using a process that allows for the creation of complex shapes with high precision. These parts are highly customizable, making them ideal for specific applications in water filtration systems and HVAC units. B2B buyers should consider the initial setup costs against the benefits of rapid production and tailored solutions. The ability to produce large quantities quickly can be advantageous for businesses looking to meet high demand efficiently.

How Does Melt Blown Media Function in Filtration?

Melt blown media consists of fine fibers that create a dense mat, offering high dirt-holding capacity and excellent filtration efficiency. These media are commonly used in air and liquid filtration applications. When purchasing melt blown media, B2B buyers must weigh the high filtration efficiency against the necessity for regular replacements due to their limited lifespan. This type of filtration is particularly suitable for environments with high particulate loads.

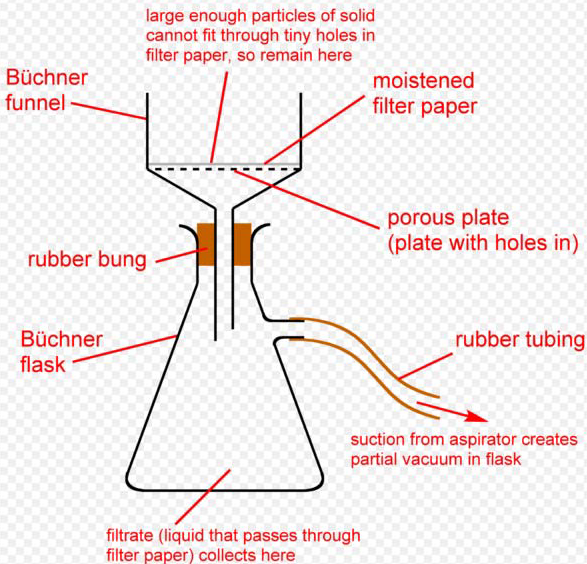

Illustrative image related to filtration parts

What Advantages Do Carbon Block Tubes Offer?

Carbon block tubes are known for their high adsorption capacity, making them effective in removing chemicals and impurities from water. They can be customized to fit various dimensions, which is beneficial for specific industrial processes. Buyers should evaluate the effectiveness of carbon block tubes for their particular applications, keeping in mind that while they can be more expensive than granular filters, their superior performance can justify the investment.

Why Choose Filter Cartridges for Your Filtration Needs?

Filter cartridges are standardized components that are easy to replace and come in various filtration grades. They are widely used in household water filters and commercial systems, making them a convenient choice for B2B buyers. The simplicity of maintenance and the availability of different grades allow businesses to select the best fit for their needs. However, buyers should be cautious about the variability in performance across different brands, which can affect filtration effectiveness.

What Role Do O-Rings Play in Filtration Systems?

O-rings are essential components that ensure the proper sealing of filtration systems, preventing leaks and maintaining system integrity. Available in a range of materials, they are critical for all types of filtration systems. B2B buyers should prioritize regular inspection and replacement of O-rings to avoid operational disruptions. While they are cost-effective, neglecting their condition can lead to significant issues, making them a vital consideration in maintenance strategies.

Key Industrial Applications of filtration parts

| Industry/Sector | Specific Application of filtration parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Replacement filter cartridges for municipal water systems | Ensures clean drinking water, compliance with health standards | Local regulations, compatibility with existing systems, lead times |

| Food & Beverage | Filtration systems for beverage processing | Maintains product quality, extends shelf life | Material safety certifications, customization options, delivery schedules |

| Pharmaceutical | Air and liquid filtration in drug manufacturing | Reduces contamination risk, ensures product efficacy | Regulatory compliance, high-performance standards, traceability of materials |

| Oil & Gas | Filtration for crude oil and natural gas processing | Enhances operational efficiency, reduces maintenance costs | Durability under extreme conditions, compatibility with various fluids, supplier reliability |

| Automotive | Filtration in fuel systems and engine components | Improves engine performance, reduces emissions | OEM specifications, availability of replacement parts, warranty considerations |

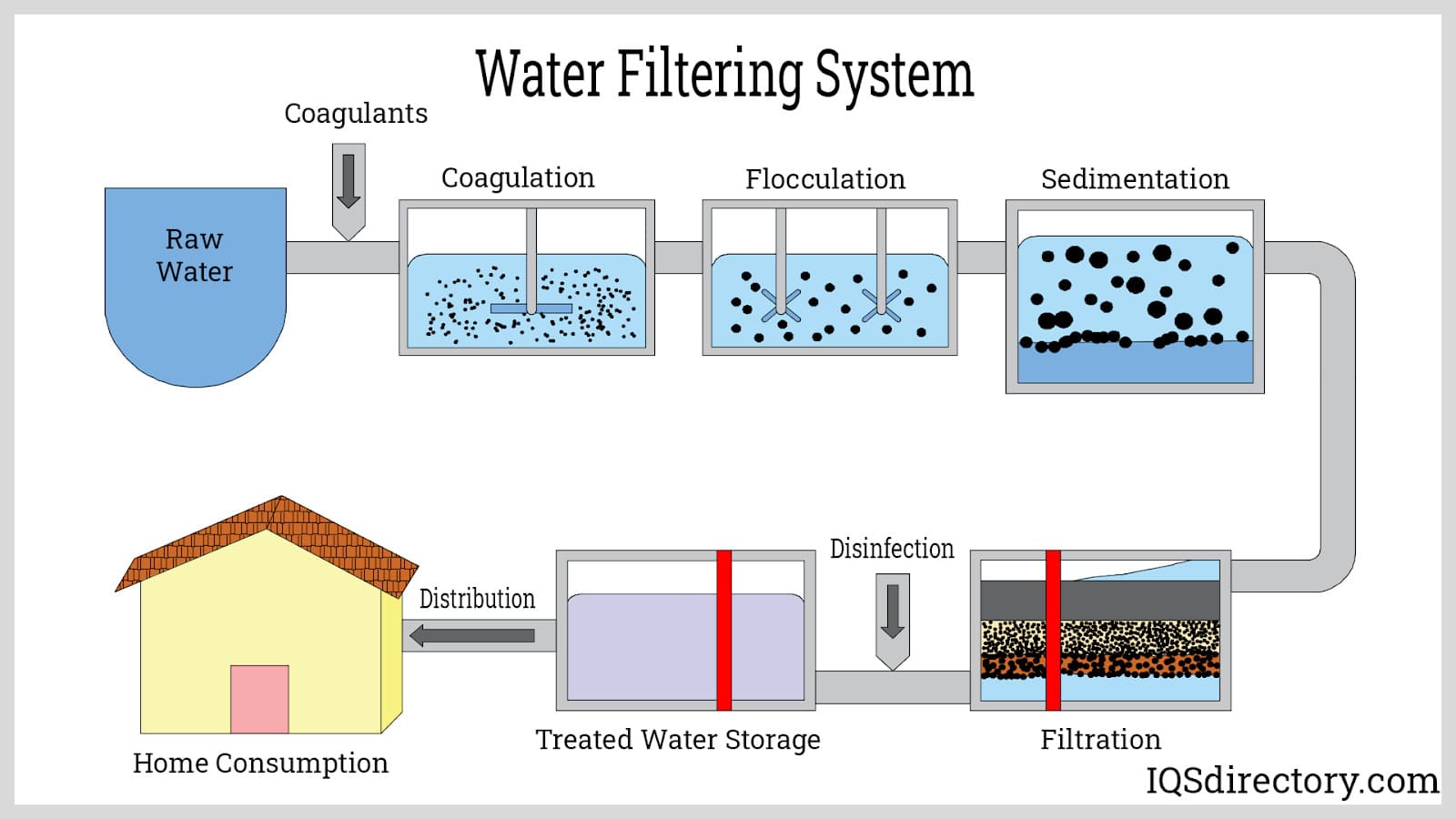

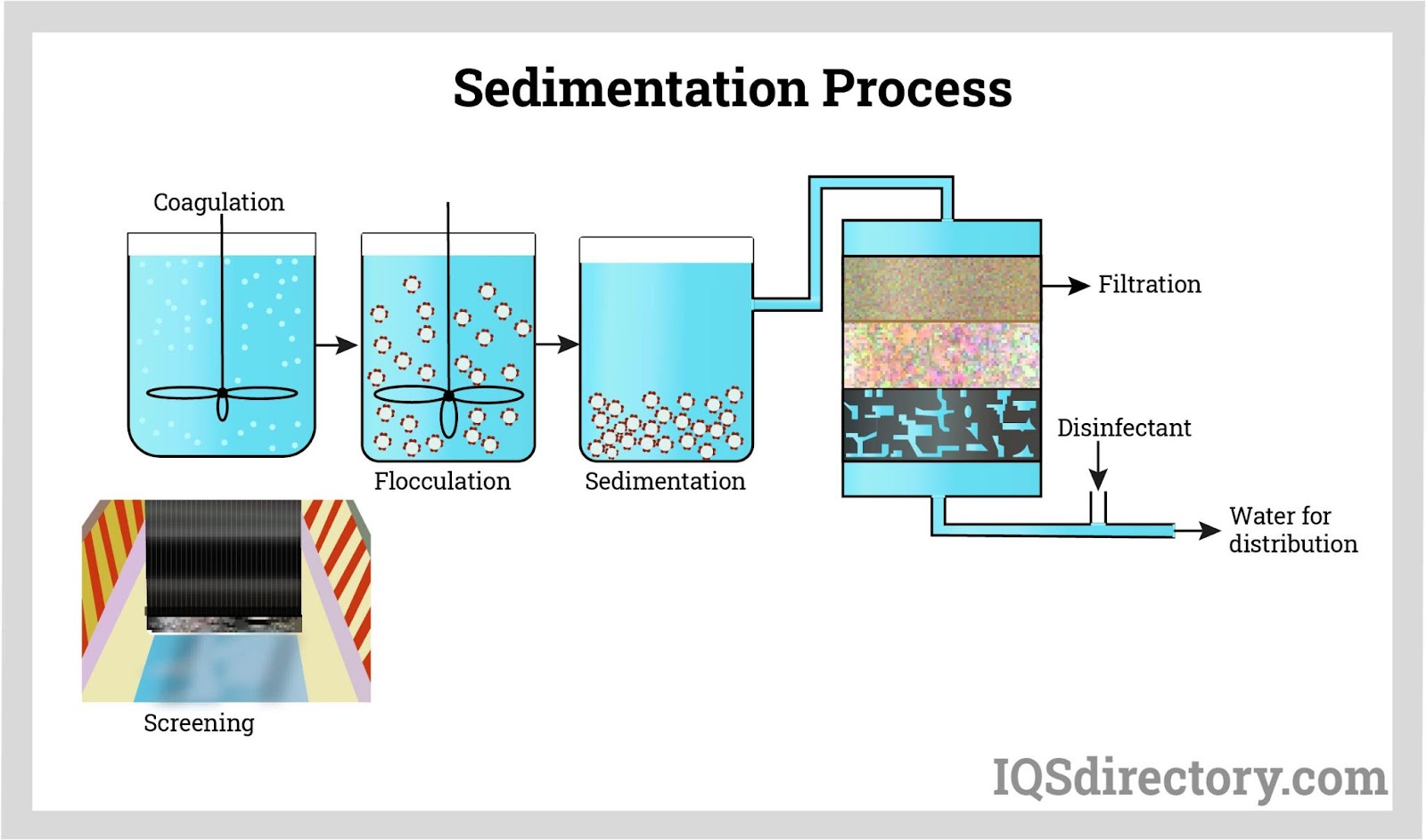

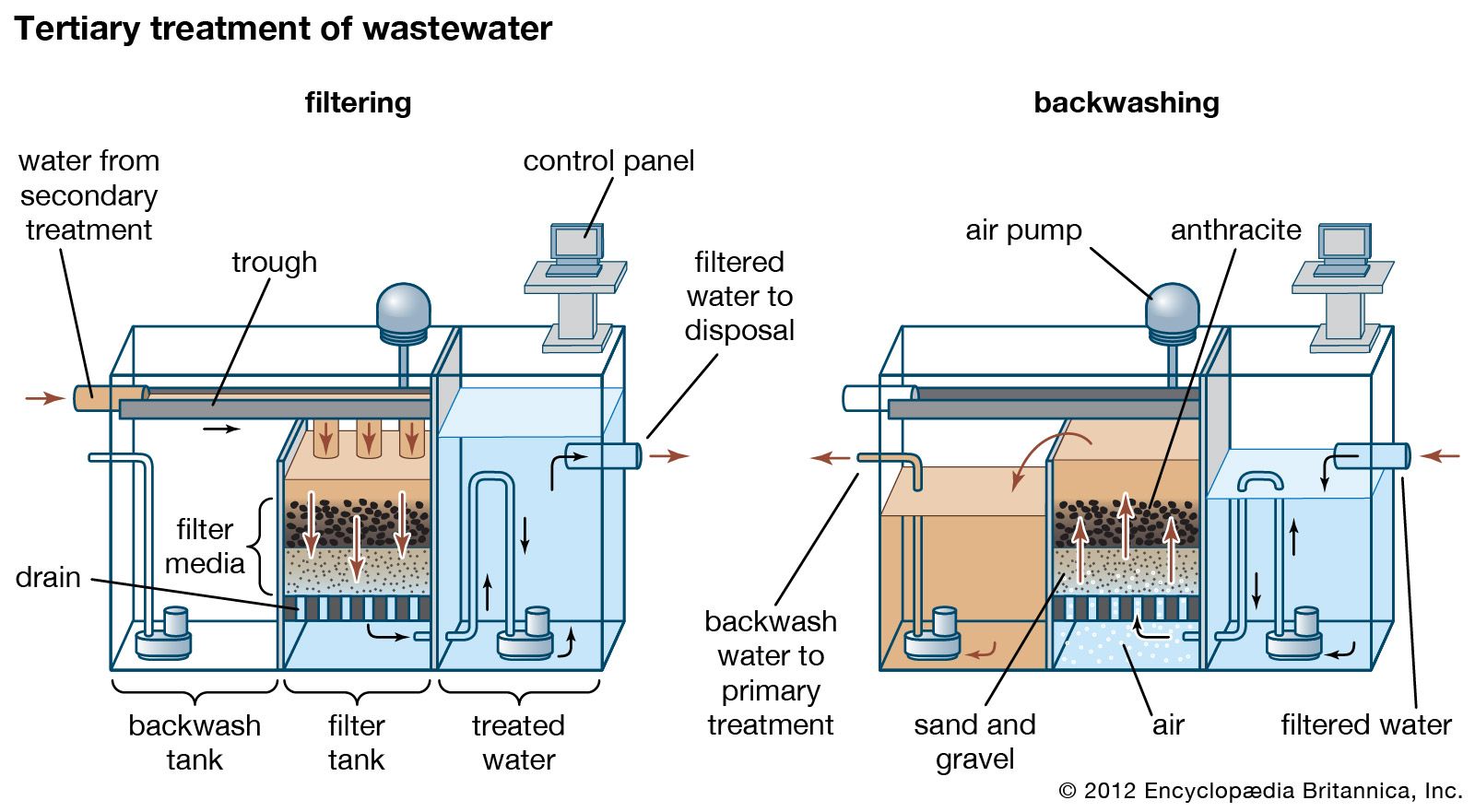

How are Filtration Parts Used in Water Treatment Applications?

In the water treatment industry, filtration parts such as replacement filter cartridges play a crucial role in ensuring that municipal water systems provide clean and safe drinking water. These components are designed to meet local health regulations and can address issues such as sediment, chlorine, and other contaminants. For international buyers, particularly in regions like Africa and South America, sourcing these parts requires an understanding of local regulations and the compatibility of filters with existing systems, as well as considerations around lead times for delivery.

Illustrative image related to filtration parts

What Role Do Filtration Parts Play in the Food & Beverage Sector?

The food and beverage industry relies heavily on filtration systems to ensure product quality during processing. Filtration parts are used to remove impurities and contaminants from liquids, which is essential for maintaining the integrity of beverages and extending their shelf life. Buyers in this sector must prioritize material safety certifications to comply with health standards, as well as customization options to adapt to specific processing needs. Timely delivery is also critical to avoid production delays.

Why Are Filtration Parts Essential in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, filtration parts are integral to maintaining the purity of both air and liquid used in drug production. These components minimize contamination risks, which is vital for ensuring product efficacy and patient safety. Buyers in this sector must focus on regulatory compliance and high-performance standards, as well as traceability of materials to meet stringent industry regulations. Sourcing from reputable suppliers is essential to guarantee the reliability of filtration systems.

How Do Filtration Parts Enhance Operations in Oil & Gas?

Filtration parts are essential in the oil and gas industry, particularly for the filtration of crude oil and natural gas. These components help enhance operational efficiency by removing impurities that could cause damage to equipment and reduce maintenance costs. Buyers should consider the durability of filtration parts under extreme conditions and their compatibility with various fluids. Supplier reliability is also a key factor, as operational downtime can be costly.

What is the Importance of Filtration Parts in Automotive Applications?

In the automotive sector, filtration parts are critical for fuel systems and engine components. They improve engine performance by preventing contaminants from entering sensitive areas, thus reducing emissions and enhancing overall vehicle efficiency. Buyers must ensure that the filtration parts meet OEM specifications and consider the availability of replacement parts to maintain vehicle performance. Warranty considerations are also important when selecting suppliers for these components.

3 Common User Pain Points for ‘filtration parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Filtration Parts

The Problem: B2B buyers often face challenges when trying to source filtration parts that are compatible with their existing systems. This issue can arise from a lack of standardization across different manufacturers, leading to confusion about specifications such as size, material composition, and performance capabilities. For instance, a company in Nigeria might need to replace a specific filter cartridge but finds that the available options do not meet the original equipment manufacturer (OEM) specifications, resulting in delays and potential downtime.

Illustrative image related to filtration parts

The Solution: To mitigate this issue, buyers should conduct thorough research on the specifications of their existing filtration systems before placing orders. This includes understanding the dimensions, material types, and performance ratings of the required parts. Utilizing digital resources, such as manufacturer websites or industry-specific forums, can provide valuable insights into which parts are compatible. Additionally, establishing strong relationships with reliable suppliers who specialize in filtration parts can streamline the sourcing process. Suppliers often have extensive catalogs and can offer custom solutions tailored to specific needs, ensuring that the right parts are delivered on time.

Scenario 2: Inadequate Knowledge of Maintenance Schedules

The Problem: Another common pain point is the inadequate knowledge of maintenance schedules for filtration systems. Many B2B buyers might not be fully aware of how often they should replace various parts, such as filter cartridges or O-rings, which can lead to inefficient filtration and system failures. For example, a manufacturing facility in Saudi Arabia might experience a drop in product quality because filters were not replaced timely, resulting in increased operational costs and potential loss of clients.

The Solution: To address this challenge, companies should implement a proactive maintenance program that includes a detailed schedule for replacing filtration parts. This program should be based on usage patterns, water quality, and manufacturer recommendations. Buyers can utilize inventory management software or maintenance tracking systems to alert them when parts are due for replacement. Additionally, training staff on the importance of regular maintenance and how to identify signs of wear can further enhance system efficiency. Regularly consulting with filtration experts or suppliers can also help companies stay updated on best practices and innovations in filtration technology.

Scenario 3: Cost Concerns with High-Quality Filtration Parts

The Problem: Cost is a significant concern for many B2B buyers, especially in regions like South America and Africa, where budget constraints are often tight. Buyers may struggle to balance the need for high-quality filtration parts with the pressure to minimize expenses. This can lead to the temptation to purchase lower-quality components, which might save money in the short term but could result in greater costs down the line due to increased maintenance needs and system inefficiencies.

The Solution: To navigate cost concerns, buyers should evaluate the total cost of ownership (TCO) rather than just the upfront price of filtration parts. This includes considering factors such as longevity, maintenance frequency, and the efficiency of the filtration system. Investing in higher-quality parts may yield better performance and longer lifespans, ultimately reducing overall costs. Moreover, buyers can explore bulk purchasing options or long-term contracts with suppliers to secure better pricing. Engaging in discussions about performance guarantees or warranties can also provide added assurance that the investment in higher-quality parts will pay off in the long run.

Strategic Material Selection Guide for filtration parts

When selecting materials for filtration parts, it is crucial to consider the properties, advantages, and limitations of each material. This ensures optimal performance, compliance with international standards, and suitability for specific applications. Below, we analyze four common materials used in filtration parts, focusing on their key properties, pros and cons, and the implications for international B2B buyers.

What Are the Key Properties of Polypropylene in Filtration Parts?

Polypropylene (PP) is a widely used thermoplastic polymer known for its excellent chemical resistance and low moisture absorption. It has a temperature rating of up to 100°C (212°F) and can withstand moderate pressures, making it suitable for various filtration applications. Its lightweight nature contributes to ease of handling and installation.

Pros and Cons: Polypropylene is durable and cost-effective, making it a popular choice for manufacturers. However, it has limitations in high-temperature applications and can become brittle over time when exposed to UV light. This may affect its longevity in outdoor or harsh environments.

Impact on Application: Polypropylene is compatible with a range of filtration media, including melt-blown and pleated filters. Its chemical resistance makes it suitable for water and air filtration systems.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that polypropylene parts comply with local regulations and standards, such as ASTM or DIN. The material’s cost-effectiveness can be a significant advantage in price-sensitive markets.

How Does Polyester Compare as a Material for Filtration Parts?

Polyester (PET) is another common material used in filtration applications, particularly for filter media. It boasts excellent tensile strength and is resistant to a wide range of chemicals. Polyester can operate effectively at temperatures up to 150°C (302°F), making it suitable for high-temperature applications.

Pros and Cons: The durability of polyester enhances the lifespan of filtration parts. However, it can be more expensive than polypropylene and may require more complex manufacturing processes, which could impact lead times.

Impact on Application: Polyester is ideal for applications requiring high filtration efficiency, such as in industrial and commercial settings. Its compatibility with various filter designs, including pleated and bag filters, makes it versatile.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific compliance requirements for polyester materials, including certifications for environmental impact. Understanding local preferences for filtration efficiency can also guide material selection.

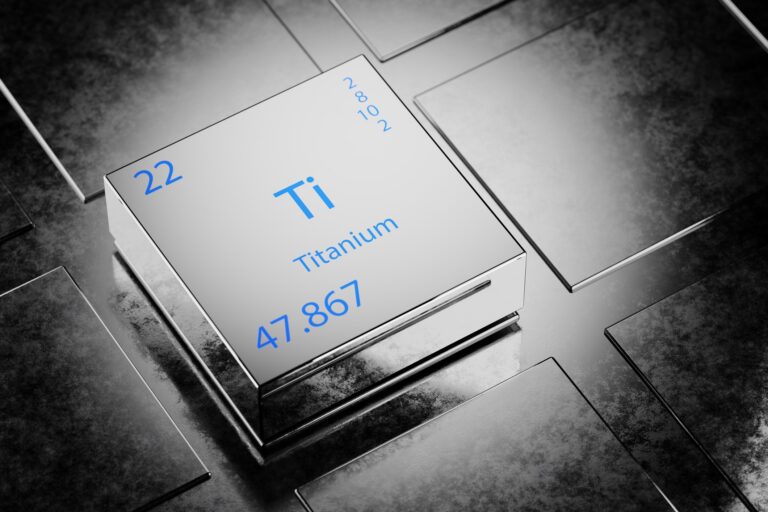

What Role Does Carbon Play in Filtration Parts?

Carbon-based materials, particularly activated carbon, are essential for adsorption processes in filtration systems. They effectively remove contaminants such as volatile organic compounds (VOCs) and chlorine from water and air. Activated carbon can handle high temperatures and pressures, depending on its form and treatment.

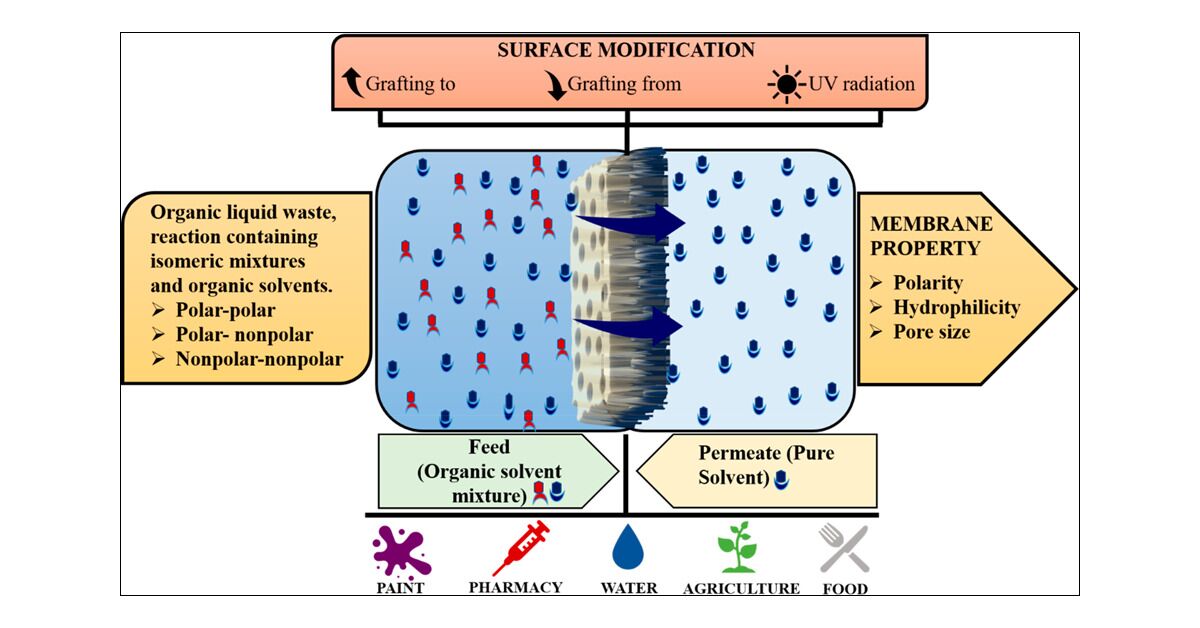

Illustrative image related to filtration parts

Pros and Cons: The primary advantage of carbon is its superior adsorption capacity, making it highly effective in various filtration applications. However, it can be more expensive than synthetic materials and may require regular replacement to maintain performance.

Impact on Application: Carbon is particularly beneficial in water treatment and air purification applications, where the removal of specific contaminants is critical. Its use in combination with other materials can enhance overall filtration efficiency.

Considerations for International Buyers: Buyers from regions like Saudi Arabia and Nigeria should consider the availability of carbon materials and their compliance with local environmental regulations. Understanding the specific contaminants prevalent in local water sources can also inform the choice of carbon type.

How Effective Is Stainless Steel in Filtration Systems?

Stainless steel is often used in filtration systems for its strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for harsh environments. Stainless steel components are often used in industrial filtration applications, such as oil and gas.

Pros and Cons: The durability and longevity of stainless steel are significant advantages, but its higher cost and weight can be limiting factors for some applications. Additionally, the manufacturing process can be more complex compared to plastic materials.

Impact on Application: Stainless steel is particularly effective in applications where hygiene and cleanliness are paramount, such as food and beverage processing. Its resistance to corrosion makes it ideal for harsh chemical environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that stainless steel components meet specific industry standards, such as those set by the FDA or local health authorities. The initial investment may be higher, but the long-term savings from durability can be significant.

Summary Table of Material Selection for Filtration Parts

| Material | Typical Use Case for filtration parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Water and air filtration systems | Cost-effective and durable | Limited high-temperature resistance | Low |

| Polyester | Industrial and commercial filtration | High tensile strength and thermal stability | More expensive and complex to manufacture | Medium |

| Carbon | Water treatment and air purification | Superior adsorption capacity | Higher cost and requires regular replacement | High |

| Stainless Steel | Industrial filtration in harsh environments | Excellent durability and corrosion resistance | Higher cost and weight | High |

This guide provides actionable insights for B2B buyers in selecting the appropriate materials for filtration parts, ensuring compliance with international standards and suitability for specific applications.

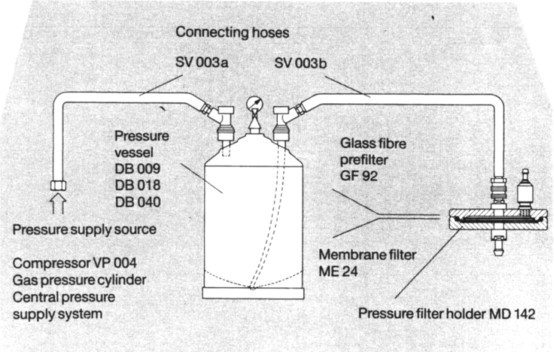

Illustrative image related to filtration parts

In-depth Look: Manufacturing Processes and Quality Assurance for filtration parts

What Are the Main Stages in the Manufacturing Process of Filtration Parts?

The manufacturing process for filtration parts involves several critical stages that ensure the production of high-quality components tailored to industry specifications. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage involves selecting the right raw materials, which can range from polypropylene and polyester for media to various resins for carbon block tubes. Suppliers often perform a series of quality checks on these materials to ensure they meet industry standards and specifications before proceeding to the next step.

-

Forming: The forming process can vary based on the type of filtration part being produced. Common techniques include injection molding for plastic components and extrusion for carbon block tubes. Advanced machinery is utilized to achieve precise dimensions and configurations, which are crucial for the performance of the filtration system.

-

Assembly: Once individual components are formed, they are assembled to create the final product. This may involve integrating various parts such as cores, end caps, and media layers. Effective assembly techniques ensure that each part functions seamlessly within the overall filtration system.

-

Finishing: The finishing stage involves surface treatment and quality checks to enhance the durability and aesthetic appeal of the filtration parts. This may include processes like coating, polishing, or additional molding to eliminate any defects that could affect performance.

What Key Techniques Are Used in Manufacturing Filtration Parts?

Key techniques in the manufacturing of filtration parts are centered around precision and efficiency. These include:

-

Injection Molding: Widely used for creating complex shapes with high precision, injection molding allows for rapid production of parts like filter housings and end caps. It ensures consistency and reduces waste.

-

Extrusion: This technique is particularly important for producing carbon block tubes. Extrusion involves forcing heated material through a die to create long shapes, which can then be cut to desired lengths. This method is efficient and allows for the customization of pore structures for specific filtration applications.

-

Melt Blown Technology: For producing filtration media, melt blown technology is a key process that creates fine fibers from thermoplastic materials. This method provides high filtration efficiency and is often used for pleated filters.

How is Quality Assurance Implemented in Filtration Parts Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for filtration parts, ensuring that products meet international and industry-specific standards.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards helps ensure consistent quality, safety, and efficiency in production. Additionally, certifications such as CE mark indicate that the products meet EU safety and environmental requirements.

-

Industry-Specific Standards: Depending on the application, filtration parts may also need to comply with standards set by organizations such as the American Petroleum Institute (API) or the National Sanitation Foundation (NSF). These certifications are crucial for parts used in critical sectors like oil and gas or water purification.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified criteria.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to catch defects early. This includes monitoring machinery performance and product dimensions.

– Final Quality Control (FQC): The finished products undergo rigorous testing to ensure they function as intended and meet all regulatory requirements.

What Common Testing Methods Are Used to Ensure Quality in Filtration Parts?

Testing methods play a crucial role in validating the performance and reliability of filtration parts. Some common testing methods include:

-

Flow Rate Testing: This measures the efficiency of the filtration system by assessing the flow of fluid through the filter, ensuring it meets the required specifications.

-

Pressure Drop Testing: Assessing the pressure drop across the filter helps determine its resistance to flow and overall effectiveness in contaminant removal.

-

Chemical Compatibility Testing: Particularly important for filtration parts used in various industries, this testing ensures that materials can withstand exposure to different chemicals without degrading.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should implement several strategies to verify supplier quality control processes:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This can include reviewing their certifications, production facilities, and quality management systems.

-

Requesting Quality Reports: Buyers should request detailed quality reports from suppliers, which document the results of various tests and inspections. This transparency can help buyers assess the reliability of the products.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly valuable for buyers unfamiliar with local suppliers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification in international trade can be challenging. B2B buyers should be aware of the following nuances:

-

Understanding Local Regulations: Each region may have different regulations regarding filtration parts. Buyers should familiarize themselves with local compliance requirements to ensure their products meet all necessary standards.

-

Navigating Certification Processes: Obtaining certifications can vary by country. For instance, while ISO certifications are globally recognized, local markets may have specific certifications that are equally important. Buyers should verify that their suppliers hold the necessary certifications relevant to their target market.

-

Managing Supply Chain Risks: International buyers should consider the implications of geopolitical factors, supply chain disruptions, and quality assurance challenges that can arise from sourcing parts from different countries. Establishing strong relationships with suppliers and having contingency plans can mitigate these risks.

In summary, understanding the manufacturing processes and quality assurance measures in the production of filtration parts is essential for B2B buyers. By focusing on these aspects, companies can ensure they procure high-quality components that meet their specific needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘filtration parts’

This guide serves as a comprehensive checklist for B2B buyers looking to procure filtration parts. By following these steps, you can ensure that you choose the right components to meet your specific needs, while also aligning with industry standards and supplier capabilities.

Illustrative image related to filtration parts

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it’s essential to clearly outline your technical requirements. This includes understanding the type of filtration system you are using and the specific parts needed, such as membranes, cartridges, or housings. Additionally, consider factors like material compatibility, dimensions, and any certifications required for your industry.

- Key Considerations:

- Performance metrics (e.g., flow rate, filtration efficiency)

- Environmental conditions (e.g., temperature, pressure)

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is critical to ensuring quality and consistency in your filtration parts. Start by researching potential manufacturers and distributors who specialize in filtration technologies. Look for companies with a proven track record and positive customer reviews.

- Where to Look:

- Industry trade shows and expos

- Online supplier directories and marketplaces

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This will give you insights into their reliability and performance history.

- Assessment Criteria:

- Manufacturing capabilities and technology

- Delivery timelines and flexibility

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that comply with industry standards. Certifications such as ISO 9001 or specific environmental compliance labels indicate a commitment to quality and sustainability.

- Why It Matters:

- Compliance with international standards

- Assurance of product quality and safety

Step 5: Request Samples for Testing

Before placing a large order, request samples of the filtration parts you intend to purchase. Testing these samples in your specific application can help you assess their performance and compatibility with your systems.

- Testing Focus Areas:

- Filtration efficiency and flow rates

- Durability under expected operating conditions

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, enter negotiations to finalize pricing, payment terms, and delivery schedules. Clear communication during this stage can help prevent misunderstandings later.

- Important Negotiation Points:

- Minimum order quantities and lead times

- Warranty and return policies

Step 7: Establish a Long-Term Partnership

Consider building a long-term relationship with your selected supplier. This can lead to better pricing, priority service, and collaborative development of custom parts tailored to your needs.

Illustrative image related to filtration parts

- Benefits of Partnership:

- Improved supply chain reliability

- Access to innovative products and technologies

By following this checklist, you can streamline your procurement process for filtration parts, ensuring that you make informed decisions that align with your business objectives and operational requirements.

Comprehensive Cost and Pricing Analysis for filtration parts Sourcing

What Are the Key Cost Components in Filtration Parts Manufacturing?

Understanding the cost structure for filtration parts is essential for B2B buyers looking to optimize their sourcing strategy. The main cost components include:

-

Materials: The choice of materials significantly impacts overall costs. Common materials like polypropylene and polyester are often less expensive than specialized resins or advanced carbon composites. Buyers should evaluate their specific needs and determine if premium materials are necessary for their applications.

-

Labor: Labor costs can vary depending on the region and the complexity of the manufacturing processes involved. Automated processes can reduce labor costs but may require higher initial investment in machinery.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, maintenance, and facility costs. Buyers should consider suppliers with efficient operations to minimize these overheads.

-

Tooling: The initial cost of molds and tooling can be significant, especially for custom parts. Buyers should assess whether they can share costs with other orders or negotiate tooling costs as part of a larger contract.

-

Quality Control (QC): Quality assurance processes are vital to ensure product performance and compliance with industry standards. This can add to costs but is essential for maintaining reliability in filtration applications.

-

Logistics: Shipping and handling can add considerable expense, particularly for international shipments. Factors such as distance, shipping method, and packaging requirements all influence logistics costs.

-

Margin: Supplier margins vary widely based on market conditions and competition. Buyers should seek suppliers who offer a transparent pricing structure to understand the margins involved.

How Do Price Influencers Affect Filtration Parts Pricing?

Several factors can influence the pricing of filtration parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their needs to achieve better pricing.

-

Specifications and Customization: Customized parts often incur higher costs due to unique tooling and manufacturing processes. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Quality and Certifications: Higher quality materials or those that meet specific certifications can raise costs. Buyers should consider the long-term benefits of investing in quality versus initial costs.

-

Supplier Factors: Supplier reliability, lead times, and their financial stability can influence pricing. Building strong relationships with suppliers can lead to better pricing and service.

-

Incoterms: Understanding the Incoterms agreed upon can significantly affect total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting the final price.

What Are the Best Negotiation Tips for B2B Buyers in Filtration Parts Sourcing?

B2B buyers should consider the following strategies to improve cost-efficiency when sourcing filtration parts:

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and pricing. Flexibility on either side can lead to mutually beneficial agreements.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs to consider maintenance, replacement, and operational costs over the product’s lifecycle. A lower upfront price may result in higher long-term expenses.

-

Research Market Prices: Understanding the market landscape can provide leverage during negotiations. Buyers should gather data on comparable products and suppliers to inform their discussions.

-

Consider Regional Factors: For international buyers, factors such as tariffs, import duties, and local regulations can affect pricing. Being aware of these can help in negotiations and budgeting.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Loyal customers often receive preferential treatment in terms of pricing and availability.

Disclaimer on Pricing

Prices for filtration parts can vary widely based on specifications, supplier capabilities, and market conditions. The figures provided in this analysis are indicative and may not reflect current market rates. Buyers are encouraged to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to filtration parts

Alternatives Analysis: Comparing filtration parts With Other Solutions

Exploring Alternatives to Filtration Parts for Effective Filtration Solutions

In the filtration industry, selecting the right components is crucial for achieving optimal performance. While filtration parts such as injection-molded components and carbon block tubes offer robust solutions, buyers should consider alternative methods that may suit their specific needs better. This analysis compares filtration parts with other viable solutions: Reverse Osmosis Systems and Ultraviolet (UV) Purification.

| Comparison Aspect | Filtration Parts | Reverse Osmosis Systems | Ultraviolet (UV) Purification |

|---|---|---|---|

| Performance | High efficiency for particulate removal | Excellent for dissolved solids | Effective for microbial contamination |

| Cost | Moderate initial investment, variable based on customization | Higher upfront costs due to complex systems | Lower initial investment, but ongoing bulb replacement costs |

| Ease of Implementation | Straightforward installation; may require customization | Requires professional installation and maintenance | Easy to install; requires minimal setup |

| Maintenance | Regular checks and timely replacement recommended | Regular filter and membrane replacements needed | Routine bulb changes and system cleaning necessary |

| Best Use Case | Industrial applications, custom solutions | Residential and commercial water purification | Water treatment for disinfection, aquariums, and pools |

Understanding the Pros and Cons of Reverse Osmosis Systems

Reverse Osmosis (RO) systems are renowned for their ability to remove a wide range of contaminants, including heavy metals and salts. The process involves pushing water through a semi-permeable membrane, which effectively filters out impurities.

Pros: RO systems provide high purification levels, making them ideal for locations with poor water quality. They are versatile, suitable for both residential and commercial applications, and can produce high volumes of purified water.

Cons: The initial investment is significant, as RO systems can be complex and may require professional installation. Additionally, they require ongoing maintenance, including regular filter and membrane replacements, which can increase long-term costs.

Evaluating Ultraviolet (UV) Purification Systems

Ultraviolet purification uses UV light to eliminate bacteria and viruses in water, making it a popular choice for disinfection purposes. This method is particularly effective in ensuring microbiological safety.

Pros: UV systems have a relatively low initial cost and are easy to install. They require minimal maintenance, with most systems only needing bulb replacements once a year.

Cons: While UV purification is effective against microorganisms, it does not remove dissolved solids or chemicals, which may necessitate additional filtration steps. Additionally, the effectiveness of UV systems can be compromised by water turbidity or high levels of particulate matter.

Making the Right Choice for Your Filtration Needs

When considering filtration solutions, B2B buyers must assess their specific requirements, including water quality, usage volume, and budget constraints. Filtration parts are an excellent choice for tailored solutions in industrial applications, while reverse osmosis systems excel in comprehensive purification needs. UV systems serve as a strong complementary option for disinfection purposes.

Ultimately, the decision should align with the intended application and operational priorities. By evaluating these alternatives, buyers can ensure they select the most effective filtration solution for their unique context, leading to enhanced performance and cost efficiency in their operations.

Essential Technical Properties and Trade Terminology for filtration parts

What Are the Key Technical Properties of Filtration Parts?

Understanding the technical specifications of filtration parts is crucial for B2B buyers to ensure optimal performance and compatibility. Here are several critical specifications that should be considered:

1. Material Grade

The material grade refers to the type of material used in the manufacturing of filtration components. Common materials include polypropylene, polyester, and various carbon types. Each material has unique properties, such as chemical resistance, temperature tolerance, and filtration efficiency. Selecting the appropriate material grade is vital for ensuring the longevity and effectiveness of the filtration system, especially in diverse environments like those in Africa and the Middle East.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension. In filtration parts, precise tolerances are essential for ensuring proper fit and function. For example, a tolerance of ±0.01 mm might be necessary for components that must align perfectly to prevent leaks. Inaccurate tolerances can lead to system failures and increased operational costs, making this specification particularly important for buyers focused on quality assurance.

3. Flow Rate

The flow rate indicates the volume of fluid that can pass through the filtration system within a specified time frame, typically measured in liters per minute (L/min). Understanding the required flow rate is crucial for selecting the right filtration parts, as it directly affects the system’s performance. B2B buyers must assess the flow rate to ensure that the filtration system meets operational demands without compromising water quality.

Illustrative image related to filtration parts

4. Pore Size

Pore size determines the filtration capability of a material, affecting its ability to remove particles of different sizes. Commonly measured in microns, pore size is a critical factor in applications ranging from industrial water treatment to residential filtration. Buyers should consider the specific contaminants they aim to filter out when selecting parts based on pore size, as this impacts the overall efficiency of the filtration system.

5. Pressure Rating

The pressure rating indicates the maximum pressure that a filtration part can withstand during operation. This specification is crucial for ensuring safety and preventing failures in high-pressure systems. Buyers need to match the pressure ratings of filtration parts with their operational requirements to avoid catastrophic failures that could lead to costly downtimes.

What Are Common Trade Terms in the Filtration Parts Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are several common trade terms relevant to filtration parts:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of products sold by another company. In the context of filtration parts, an OEM might supply components for a larger filtration system. Understanding the OEM designation helps buyers identify reliable suppliers and assess the quality of parts being sourced.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can influence purchasing decisions and inventory management. Understanding MOQ can help buyers negotiate better terms and plan their procurement strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other pertinent details for specific products or services. In the filtration parts industry, issuing an RFQ helps buyers gather competitive pricing and evaluate suppliers based on their offerings. This process is essential for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is crucial for B2B buyers involved in cross-border procurement of filtration parts. Familiarity with Incoterms can prevent misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is vital for B2B buyers as it impacts project timelines and inventory levels. Understanding lead times allows buyers to plan accordingly, ensuring that their filtration systems remain operational without unexpected delays.

Illustrative image related to filtration parts

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their procurement processes and ensure the efficient operation of their filtration systems.

Navigating Market Dynamics and Sourcing Trends in the filtration parts Sector

What Are the Current Market Dynamics and Key Trends in the Filtration Parts Sector?

The filtration parts sector is experiencing a dynamic evolution driven by increasing global demand for clean water, air quality improvement, and stringent regulatory standards across various industries. Key drivers include urbanization, industrial growth, and heightened awareness of environmental issues, particularly in emerging markets such as Nigeria, Saudi Arabia, and Brazil. As businesses in these regions expand, the need for efficient filtration systems becomes critical for ensuring compliance with health and safety regulations.

Emerging B2B technology trends are reshaping sourcing strategies in the filtration parts market. Digital platforms are enhancing supply chain transparency, enabling buyers to track sourcing processes and verify the quality of filtration components. Additionally, advancements in manufacturing technologies such as injection molding and 3D printing are allowing for rapid prototyping and customization of filtration parts, catering to specific buyer requirements. This flexibility is particularly appealing to international buyers who often seek tailored solutions to meet local challenges.

Another significant trend is the rise of e-commerce platforms, which facilitate easier access to a global marketplace for filtration parts. B2B buyers can now compare prices, quality, and delivery options from multiple suppliers, enhancing competition and driving down costs. This trend is especially beneficial for buyers in regions with limited access to traditional supply chains, as they can leverage online platforms to source high-quality components from reputable manufacturers worldwide.

How Does Sustainability and Ethical Sourcing Affect B2B Filtration Parts Procurement?

Sustainability has become a cornerstone of procurement strategies in the filtration parts sector. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices and materials. The environmental impact of filtration parts, particularly in terms of plastic waste and resource consumption, is prompting companies to seek out solutions that minimize ecological footprints.

Ethical sourcing is also gaining traction as B2B buyers recognize the importance of maintaining responsible supply chains. This includes assessing suppliers for their labor practices, adherence to environmental regulations, and the sustainability of their materials. Green certifications, such as ISO 14001 for environmental management and certifications for recycled materials, are becoming essential criteria in the supplier selection process. Buyers are increasingly inclined to partner with manufacturers who can demonstrate compliance with these standards, not only to meet regulatory requirements but also to enhance their own brand reputation.

Illustrative image related to filtration parts

As a result, companies that invest in sustainable practices and provide verified eco-friendly products are likely to gain a competitive edge in the filtration parts market. This trend is particularly relevant in regions such as Europe, where consumers and businesses are more inclined to support sustainable products, thereby influencing procurement decisions.

What Has Been the Evolution of the Filtration Parts Market?

The filtration parts market has undergone significant evolution over the past few decades, transitioning from simple mechanical filters to advanced systems that incorporate sophisticated technologies. Initially, the industry focused on basic filtration solutions, primarily for water and air purification. However, as industrial applications expanded and environmental regulations tightened, the demand for high-performance filtration components surged.

In recent years, the introduction of advanced materials, such as nanofibers and activated carbon, has revolutionized filtration efficiency and effectiveness. Manufacturers have also embraced automation and digital technologies, streamlining production processes and enhancing customization capabilities. This evolution reflects a broader shift towards innovation and quality in the filtration parts sector, making it essential for B2B buyers to stay informed about the latest advancements to ensure they are sourcing the most effective solutions for their needs.

Overall, understanding these market dynamics, sustainability concerns, and the historical context will empower B2B buyers to make informed decisions that align with their operational goals and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of filtration parts

-

How do I solve supply chain disruptions when sourcing filtration parts?

Supply chain disruptions can significantly impact your procurement process. To mitigate this, establish strong relationships with multiple suppliers to create a diversified supply chain. Regularly assess the financial and operational stability of your partners, especially in regions prone to political or economic instability. Consider employing local suppliers or manufacturers to reduce shipping times and costs. Additionally, maintaining an inventory buffer can provide a safety net during unforeseen disruptions, ensuring you can meet customer demands without delay. -

What is the best filtration part for high-efficiency applications?

For high-efficiency filtration applications, carbon block filters are often the most effective choice. They offer superior adsorption capabilities, allowing for the removal of a wide range of contaminants, including chlorine, VOCs, and PFAS compounds. When selecting a carbon block filter, consider the specific contaminants you aim to remove and the filter’s flow rate, as these factors can significantly impact performance. Collaborating with your supplier to develop custom solutions tailored to your unique requirements can further enhance filtration efficiency. -

How can I ensure the quality of filtration parts from international suppliers?

To ensure quality, conduct thorough supplier vetting before placing orders. Request certifications such as ISO 9001 to verify their quality management systems. Consider visiting manufacturing facilities or using third-party inspection services to evaluate production processes. Additionally, request samples for testing before committing to larger orders. Establish clear quality control parameters in your contracts, including specifications for materials, performance, and testing methods to ensure that the products meet your standards. -

What are common minimum order quantities (MOQs) for filtration parts?

Minimum order quantities (MOQs) for filtration parts can vary widely depending on the manufacturer and the type of product. Generally, MOQs can range from a few hundred units to several thousand. It’s important to discuss MOQs with your supplier upfront to align your purchasing capacity with their requirements. If MOQs are too high for your needs, consider negotiating lower quantities or exploring the possibility of consolidating orders with other buyers to meet the supplier’s requirements. -

What payment terms should I expect when sourcing filtration parts internationally?

Payment terms can vary based on the supplier’s policies and your business relationship. Common terms include advance payment, letters of credit, or payment upon delivery. For new suppliers, consider negotiating partial payments to reduce risk. Always clarify the currency used for transactions and any applicable fees. Establishing a clear agreement on payment terms in your contract can help prevent misunderstandings and ensure smooth transactions throughout the procurement process. -

How do I handle customs and logistics for importing filtration parts?

Handling customs and logistics involves understanding the regulations and tariffs for your specific products. Research the import duties applicable in your country and ensure your supplier provides all necessary documentation, such as invoices and certificates of origin. Partnering with a reliable freight forwarder can streamline the shipping process and help navigate customs clearance. Additionally, consider using a logistics provider with experience in handling filtration parts to mitigate delays and ensure timely delivery to your facility. -

Can I customize filtration parts to meet specific application needs?

Yes, many manufacturers offer customization options for filtration parts. You can collaborate with suppliers to develop tailored solutions based on your specific application requirements, such as dimensions, materials, and filtration efficiency. Be clear about your needs and provide detailed specifications during the initial discussions. Custom parts may involve longer lead times and potentially higher costs, so it’s essential to weigh these factors against the benefits of having a solution that perfectly fits your needs. -

What should I do if I encounter issues with filtration part performance?

If you experience performance issues with filtration parts, first conduct a thorough inspection to identify potential causes, such as installation errors or compatibility problems. Reach out to the supplier for technical support, as they may provide insights or solutions. Document the issues and gather performance data to support your case. If the problem persists, discuss warranty options or seek replacements. Establishing a clear line of communication with your supplier can facilitate quicker resolutions to performance-related challenges.

Top 9 Filtration Parts Manufacturers & Suppliers List

1. Filtration Parts Inc. – Filtration Solutions

Domain: filtrationparts.com

Registered: 2015 (10 years)

Introduction: Filtration Parts Inc. manufactures injection molded parts, melt blown medias, and carbon block tubes for the filtration market. They offer extensive manufacturing capacity for cages, cores, and end caps, and collaborate to develop custom parts. Their product range includes a wide array of polypropylene and polyester medias for pleated separation and clarification filtration. They manufacture 15 st…

2. Filterway – Aquaboon Water Filtration Solutions

Domain: filterway.com

Registered: 2016 (9 years)

Introduction: Aquaboon O-Ring – $7.79

Replacement Cartridge For Aquaboon Spin Down Sediment Water Pre Filter – $9.79

Aquaboon Micron Spin Down Sediment PreFilter, Reusable Whole House Sediment Water Pre Filter, 1″ MNPT + 3/4″ FNPT – $42.99

Aquaboon Nipel Connector – $7.99

Brass Reducer Bushing 1″ х 3/4″ – $11.99

Replacement UV Light Bulb for Aquaboon UV Filtration System – $59.79

Aquaboon Water Softener Salt (4…

3. Filtration Group – Hydraulic Filter Spare Parts

Domain: shopindustrial.filtrationgroup.com

Registered: 1998 (27 years)

Introduction: Spare Parts & Accessories for Hydraulic Filters include various types of filters such as Simplex Filters, Duplex Filters, and Parallel Filters. Specific products listed are:

– Seal kits (e.g., SEAL-KIT PI 2005-2011 NBR VP, SEAL-KIT PI 2110 NBR VP)

– Maintenance Indicators

– Filter housing, bowl, and head components

– Handles

– Air & Desiccant Breathers (e.g., Air breather plastic, Tank air breathe…

4. Total Apex – Water Filtration Parts & Accessories

Domain: totalapex.com

Registered: 2008 (17 years)

Introduction: Water Filtration Parts and Accessories, Water Boosters, Water Filtration Systems, Connectors & Disconnects, Straight Barb, Barb Tee, Barb Elbow, Faucet Socket, BIB Pump Labels, Pump Parts & Accessories, Rack Parts & Accessories.

5. Filtration Systems – Replacement Parts

Domain: filtrationsystems.com

Registered: 1996 (29 years)

Introduction: Replacement Parts for Filtration Systems Over-The-Top® Filter Housings & Systems include: 1. Replacement Lid Hardware – Available in stainless steel or carbon steel, consists of Bar Knob (Castle Nut), Eyebolt (Swing Bolt), Axle Bolt, Axle Nut. 2. Bar Knob Wrench – A tool for quickly torquing or loosening lid closure nuts, made of plated carbon steel. 3. O-Rings – Two required for proper sealing, a…

6. US Water Systems – American Made Reverse Osmosis System

Domain: uswatersystems.com

Registered: 2003 (22 years)

Introduction: American Made Reverse Osmosis System: From $559.95 (originally $1,155.61)\nMatrixx Smart Metered Water Softener: From $1,199.00 (originally $2,158.34)\nMagna Compact Whole House Water Filter: $799.89 (originally $1,465.00)\nFeatures: Certified Components, Prevents Scale, Protects Appliances, Improved Hair and Skin Health, Brighter and Cleaner Clothes, Compact Whole House Filtration, Superior Ameri…

7. Commercial Filtration Supply – Liquid Filtration Parts

Domain: commercialfiltrationsupply.com

Registered: 2016 (9 years)

Introduction: Get Liquid Filtration Replacement Parts for Top Brand Models – Commercial Filtration Supply. Product types include: Strainers (Simplex, Duplex, Y (Wye), Fabricated, Self Cleaning), Bag Filtration (Housing, Filter Bags), Cartridge Filtration (Cartridge Housings, Filter Cartridges), Eaton Hydraulic Filtration (Offline Filtration Systems, Contamination Monitoring, Lubrication Filters), Valves (Ball, …

8. Pentair – Water Softener Parts

Domain: pentair.com

Registered: 1996 (29 years)

Introduction: Water Softener Parts, Replacement Water Filter Parts, Original Equipment Manufacturer Parts, Inlet Connectors, Water Blocks, Port Fittings, Beverage Fittings, O-Rings, Commercial Water Solutions, Total Water Management, Water Testing, Free Water Test Kit.

9. iSpring – Water Filtration System Parts & Accessories

Domain: ispringfilter.com

Registered: 2007 (18 years)

Introduction: iSpring Water Filtration System Parts and Accessories include: Booster Pump, Filter Housings, Fittings, Flood Prevention, Membrane Housing, O-Rings, Plumber’s tape, Sliding Kits, Tanks and Pitchers, TDS Tester, Tubings, Wooden Stand, Wrench.

Strategic Sourcing Conclusion and Outlook for filtration parts

In the evolving landscape of filtration parts, strategic sourcing emerges as a critical driver for operational efficiency and product quality. By prioritizing partnerships with manufacturers that emphasize innovation and responsiveness, B2B buyers can secure high-quality components that meet diverse market needs. Leveraging local suppliers in regions such as Africa, South America, the Middle East, and Europe can not only reduce lead times but also enhance the adaptability of supply chains.

Moreover, the ability to customize filtration solutions—such as injection-molded parts and carbon block tubes—offers significant competitive advantages. As regulatory pressures increase and demand for sustainable practices rises, investing in advanced filtration technologies will be pivotal. Buyers should also consider the importance of ongoing maintenance and timely replacement of parts to ensure optimal system performance.

Looking ahead, the filtration market is poised for growth, fueled by advancements in technology and increasing awareness of water quality issues. International buyers are encouraged to explore new supplier relationships that align with their strategic objectives. Embrace this opportunity to enhance your sourcing strategy and elevate your filtration solutions to meet the demands of a dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.