Is Your Types Of Bolts With Pictures Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for types of bolts with pictures

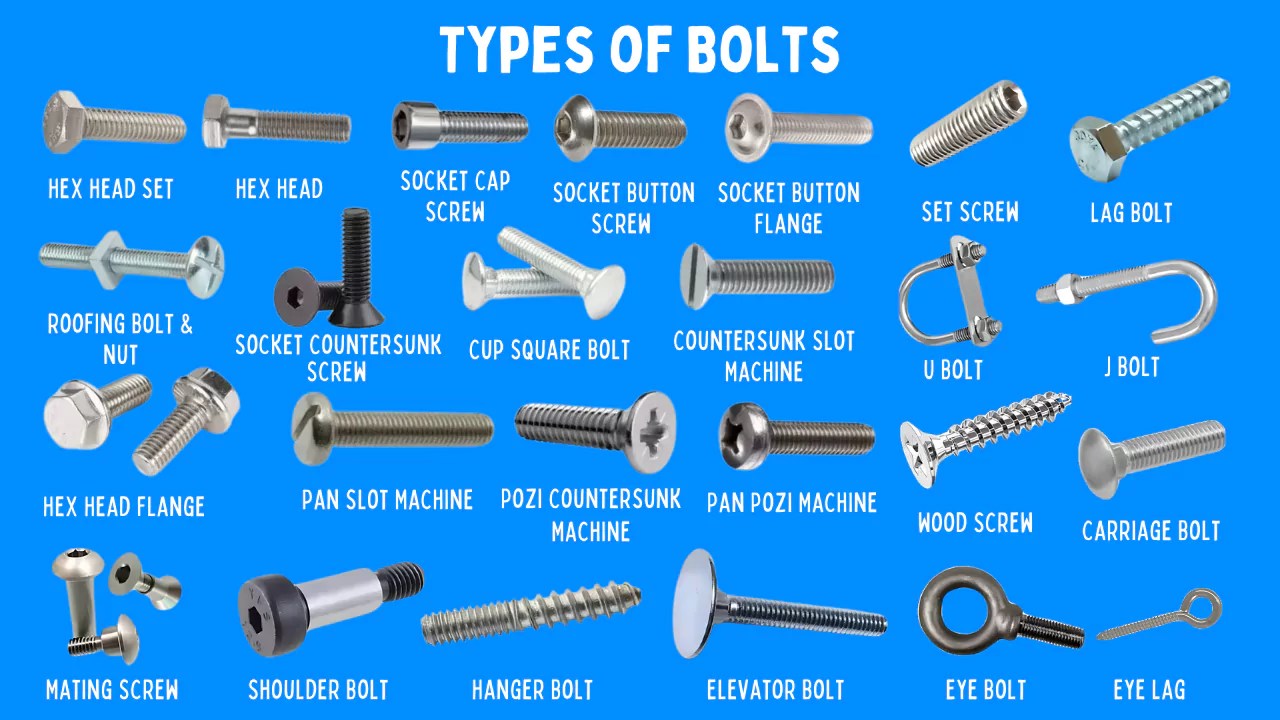

In today’s fast-paced global market, sourcing the right types of bolts can be a daunting challenge for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With an array of options available, selecting the appropriate bolt type for specific applications requires a thorough understanding of their characteristics, uses, and availability. This comprehensive guide on types of bolts, complete with detailed pictures, serves as a vital resource for businesses looking to make informed purchasing decisions.

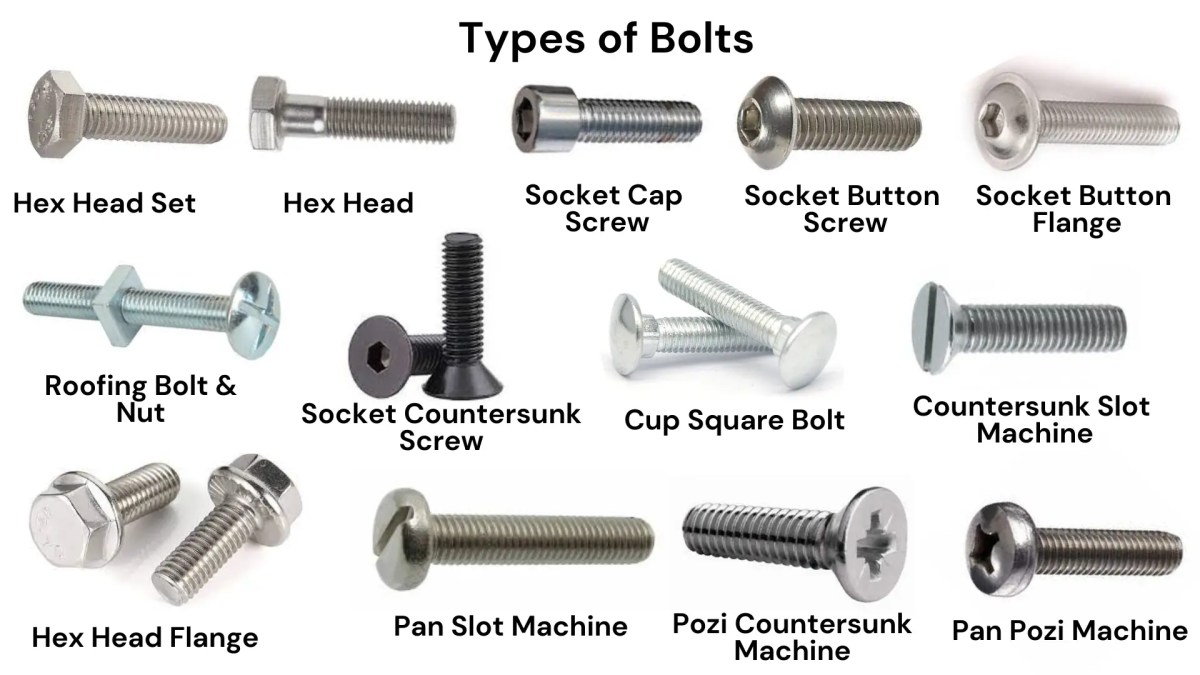

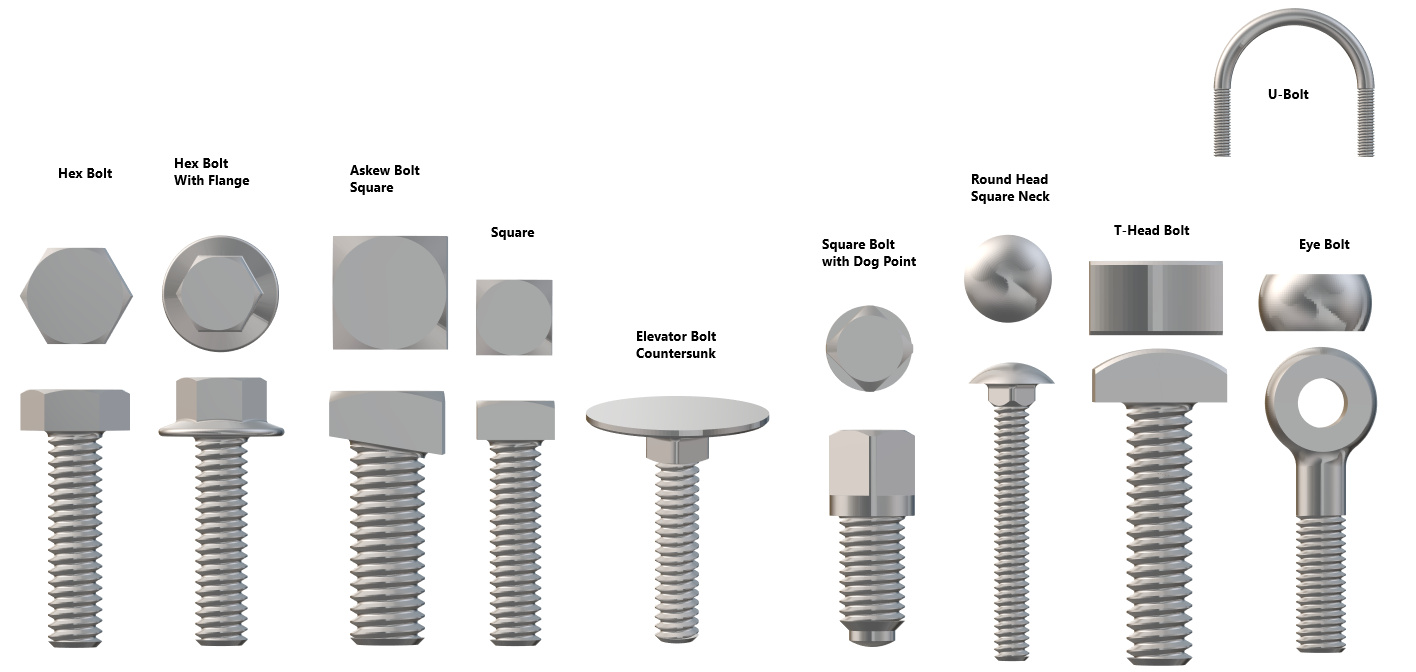

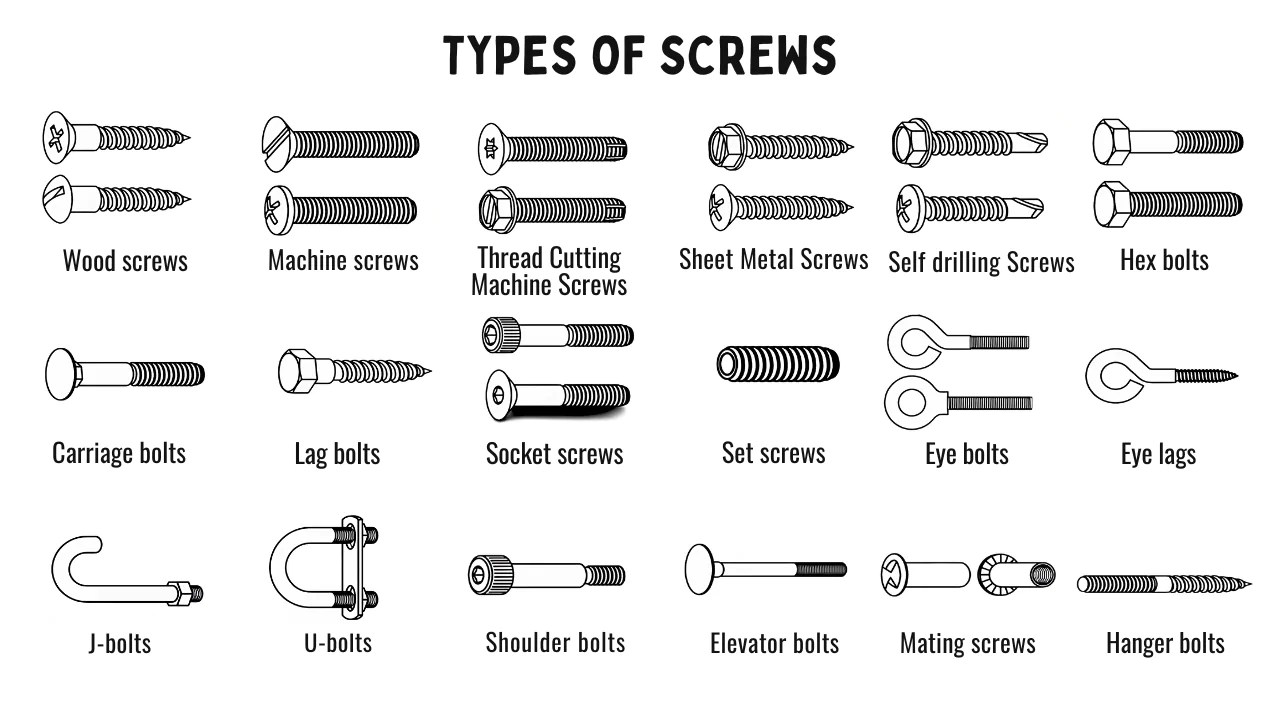

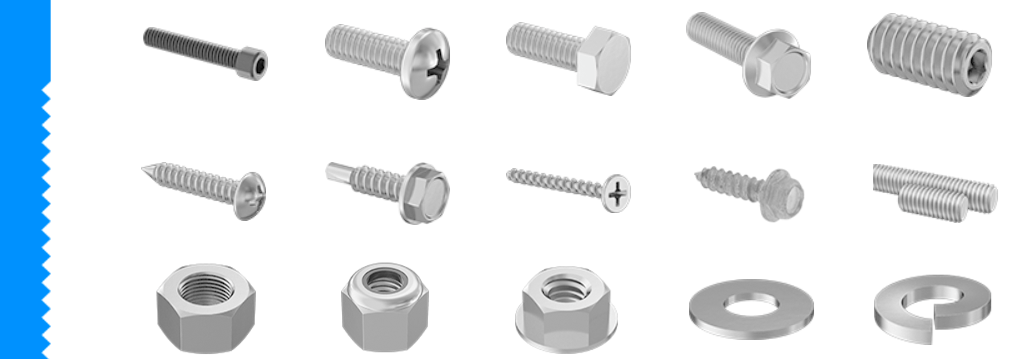

This guide meticulously explores various bolt types, including hex bolts, carriage bolts, and flange bolts, while also delving into their unique applications across different industries. Buyers will gain insights into essential factors such as material specifications, load capacities, and compatibility with nuts and washers. Furthermore, we provide actionable advice on supplier vetting, ensuring that buyers can confidently identify reliable sources that meet their quality and service expectations.

By addressing common pitfalls and providing clear visual references, this guide empowers B2B buyers to navigate the complexities of bolt sourcing effectively. With the knowledge gained here, international buyers can optimize their procurement processes, ensuring they select the best fasteners for their operational needs while also managing costs and enhancing supply chain efficiency.

Understanding types of bolts with pictures Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Bolts | Hexagonal head, available in various grades | Machinery, structural applications | Pros: Versatile, high strength. Cons: Requires a wrench for installation. |

| Carriage Bolts | Rounded head, square neck under the head | Wood construction, furniture assembly | Pros: Smooth finish, easy to install. Cons: Limited to applications needing a rounded head. |

| Flange Bolts | Integrated flange for load distribution | Automotive, heavy machinery | Pros: Reduces the need for washers, strong hold. Cons: Bulkier design may not fit all applications. |

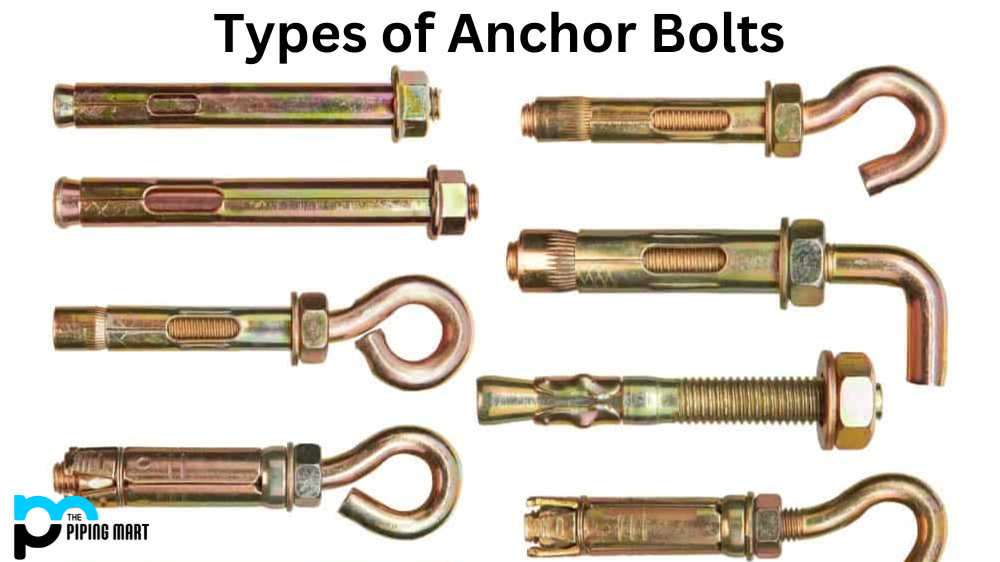

| Eye Bolts | Circular ring at the head for lifting or securing | Lifting applications, rigging | Pros: Easy attachment for ropes/chains. Cons: Limited to specific uses. |

| U-Bolts | U-shaped design, typically used for securing pipes | Plumbing, electrical applications | Pros: Effective for round objects. Cons: May require specific sizing for proper fit. |

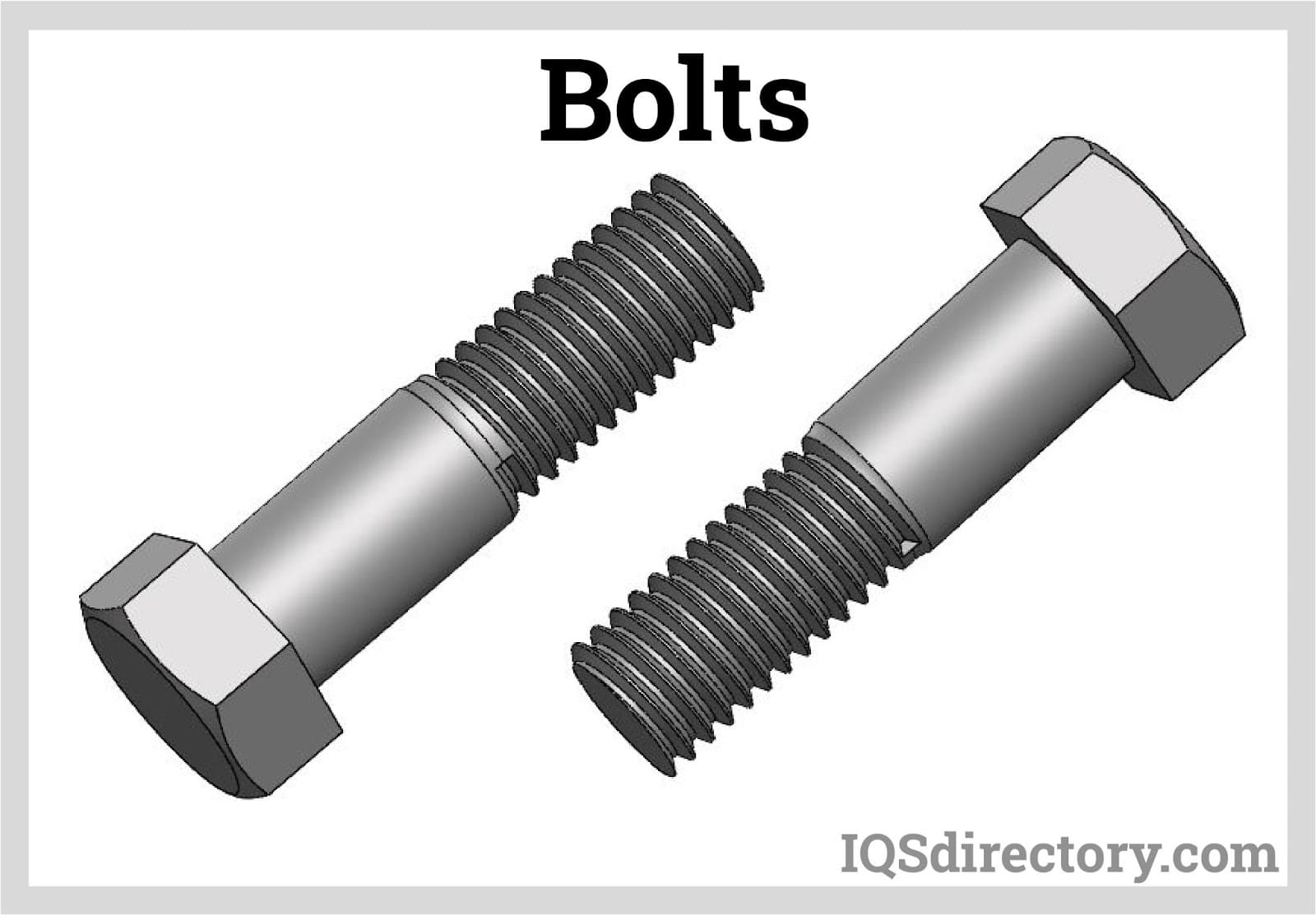

What Are Hex Bolts and Their Key Characteristics?

Hex bolts are characterized by their hexagonal heads, which allow for easy tightening with a wrench. They are available in various grades, making them suitable for a wide range of applications, from machinery to structural components. When purchasing hex bolts, buyers should consider the grade and strength required for their specific application, as well as the environment in which they will be used to ensure longevity and performance.

How Do Carriage Bolts Stand Out in Construction?

Carriage bolts feature a smooth, rounded head and a square neck that prevents rotation when tightened. This design makes them ideal for wood construction and furniture assembly, where a clean finish is essential. Buyers should evaluate the material and coating of carriage bolts to ensure they meet the aesthetic and durability requirements of their projects, especially in outdoor applications where corrosion resistance is critical.

Why Choose Flange Bolts for Heavy Machinery?

Flange bolts are designed with an integrated flange that acts as a washer, distributing the load over a larger area. This feature makes them particularly useful in automotive and heavy machinery applications, where maintaining a secure connection is vital. Buyers should assess the flange size and bolt grade to match the specific load requirements of their applications, as improper sizing can lead to failure.

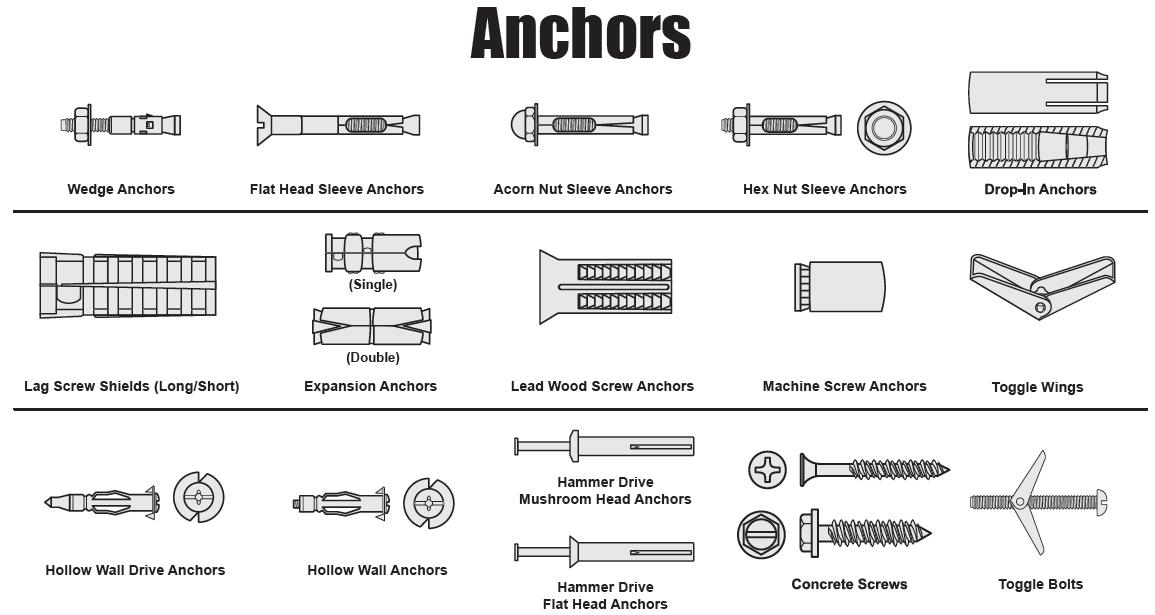

Illustrative image related to types of bolts with pictures

What Are the Advantages of Using Eye Bolts?

Eye bolts are easily identifiable by their circular ring at the head, which allows for the attachment of ropes or chains. They are commonly used in lifting and rigging applications. When purchasing eye bolts, buyers need to consider the load capacity and material to ensure safety and effectiveness in their intended use. Additionally, eye bolts should be inspected regularly for signs of wear or damage.

How Do U-Bolts Function in Plumbing and Electrical Work?

U-bolts are uniquely shaped to secure pipes and other round objects, making them essential in plumbing and electrical applications. Their design allows for a tight fit around cylindrical items, ensuring stability. Buyers should pay attention to the sizing and material of U-bolts, as they must match the specific diameter of the pipes or conduits they are intended to secure, preventing leaks or electrical hazards.

Key Industrial Applications of types of bolts with pictures

| Industry/Sector | Specific Application of types of bolts with pictures | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural steel assembly using hex bolts | Ensures structural integrity and safety in buildings | Certification standards, corrosion resistance, and load ratings |

| Automotive | Engine assembly with shoulder bolts | Enhances reliability and performance of vehicles | Material specifications, heat treatment processes |

| Oil & Gas | Flange connections using flange bolts | Prevents leaks and ensures safety in pipelines | Compliance with industry standards, pressure ratings |

| Manufacturing | Conveyor systems utilizing elevator bolts | Facilitates efficient material handling | Durability under heavy loads, compatibility with existing systems |

| Marine | Boat rigging with eye bolts | Provides secure anchoring and safety in marine applications | Corrosion resistance, material certifications |

How Are Types of Bolts Used in the Construction Industry?

In the construction sector, hex bolts are commonly used for structural steel assembly. They play a crucial role in ensuring the structural integrity and safety of buildings and infrastructure. These bolts must meet specific certification standards to withstand various loads and environmental conditions, especially in regions prone to extreme weather. International buyers should consider factors such as corrosion resistance and load ratings when sourcing these fasteners to ensure they meet local building codes and safety regulations.

What Role Do Bolts Play in Automotive Applications?

Shoulder bolts are critical in automotive engine assembly, where precision and reliability are paramount. They help secure components in place, contributing to the overall performance and longevity of vehicles. Buyers in this sector must focus on material specifications and heat treatment processes to ensure that the bolts can withstand high temperatures and mechanical stress. This is particularly important for international buyers from regions with varying automotive standards, such as Brazil and Saudi Arabia.

Illustrative image related to types of bolts with pictures

Why Are Flange Bolts Important in Oil & Gas?

Flange bolts are essential for making secure connections in oil and gas pipelines, where preventing leaks is vital for safety and environmental protection. These bolts must comply with stringent industry standards to ensure they can handle high pressures and harsh conditions. Buyers should prioritize sourcing from suppliers who can provide documentation of compliance with these standards, as well as information on the pressure ratings of the bolts to ensure safe operation in their specific applications.

How Do Elevator Bolts Enhance Manufacturing Processes?

In manufacturing, elevator bolts are extensively used in conveyor systems to facilitate efficient material handling. Their design allows for a secure connection that can support heavy loads, making them ideal for various applications in production lines. When sourcing elevator bolts, businesses should consider durability under heavy loads and compatibility with existing systems to avoid costly modifications. This is particularly relevant for international buyers looking to integrate new systems with legacy equipment.

What Are the Benefits of Eye Bolts in Marine Applications?

Eye bolts are crucial in marine applications for secure rigging and anchoring of boats. They provide a reliable point for attaching ropes and chains, ensuring safety during navigation. For international buyers in the marine sector, it is vital to source eye bolts made from corrosion-resistant materials to withstand harsh marine environments. Certifications regarding material quality and performance standards should be verified to ensure safety and reliability in marine operations.

3 Common User Pain Points for ‘types of bolts with pictures’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Bolt Type for Specific Applications

The Problem: B2B buyers often face challenges in selecting the appropriate bolt type for their specific applications. With numerous bolt types available—such as hex bolts, carriage bolts, and lag bolts—making the right choice can be overwhelming. Misidentification can lead to product failures, increased costs, and project delays, especially in industries like construction and manufacturing, where precision is paramount. Buyers may find themselves relying on limited or outdated product information, which further complicates the decision-making process.

The Solution: To mitigate this issue, B2B buyers should utilize comprehensive catalogs or databases that feature detailed images and descriptions of various bolt types. Suppliers should provide clear, high-resolution pictures alongside technical specifications, including dimensions, material types, and recommended applications. Buyers are encouraged to create a checklist of requirements based on their specific needs—such as load capacity, environmental conditions, and compatibility with other fasteners. Additionally, engaging with knowledgeable sales representatives who can provide tailored recommendations based on industry standards can be invaluable. Using a systematic approach to bolt selection can significantly reduce errors and enhance project efficiency.

Illustrative image related to types of bolts with pictures

Scenario 2: Sourcing Quality Bolts from Reliable Suppliers

The Problem: Another common pain point for international B2B buyers is the challenge of sourcing high-quality bolts from reliable suppliers. In regions such as Africa and South America, where supply chain issues may arise, buyers often encounter counterfeit or substandard products that do not meet safety or performance standards. This not only jeopardizes the integrity of the final product but can also lead to costly recalls and reputational damage.

The Solution: To ensure quality, buyers should prioritize sourcing from suppliers who provide certifications and quality assurance documentation. Establishing partnerships with reputable manufacturers who adhere to international standards—such as ISO or ASTM—can help mitigate risks. Buyers should also consider implementing a vetting process that includes requesting samples for testing and verification before placing bulk orders. Additionally, utilizing platforms that aggregate supplier reviews and ratings can assist in identifying trustworthy partners. Regular audits and maintaining open communication with suppliers can further enhance the reliability of the supply chain.

Scenario 3: Understanding the Impact of Bolt Specifications on Performance

The Problem: B2B buyers frequently struggle to comprehend how different bolt specifications—such as thread pitch, coating types, and tensile strength—affect overall performance in their applications. This lack of understanding can result in selecting bolts that are either over-engineered or under-specified, leading to unnecessary costs or, worse, product failures that could have catastrophic consequences, especially in high-stakes environments like construction or aerospace.

The Solution: To address this knowledge gap, suppliers should offer educational resources, such as webinars or detailed guides, that explain the implications of various bolt specifications. B2B buyers should take advantage of these resources to gain a deeper understanding of how to assess the requirements of their applications. Conducting thorough research and consulting with engineers or technical experts can also provide insights into how specific bolt characteristics impact performance. Furthermore, utilizing simulation software can help visualize the effects of different bolt choices on assembly integrity, ensuring that the selected fasteners align perfectly with the operational demands of their projects. This proactive approach can lead to better-informed decisions and ultimately enhance the reliability and safety of the final products.

Strategic Material Selection Guide for types of bolts with pictures

What Are the Key Properties of Common Bolt Materials?

When selecting bolts for various applications, the material choice significantly influences performance, durability, and cost. Below, we analyze four common materials used in bolt manufacturing: carbon steel, stainless steel, alloy steel, and brass. Each material has unique properties that cater to different operational needs and environmental conditions.

How Does Carbon Steel Perform in Bolt Applications?

Carbon steel is widely used in bolt manufacturing due to its excellent strength and hardness. It typically has a tensile strength rating of around 400-800 MPa, making it suitable for applications that require high load-bearing capacity. However, carbon steel is prone to corrosion if not properly treated, which can limit its use in humid or corrosive environments.

Pros: Carbon steel bolts are relatively inexpensive and easy to manufacture, making them a cost-effective choice for many applications. They are highly durable and can withstand significant mechanical stress.

Cons: The primary drawback is their susceptibility to rust and corrosion, necessitating protective coatings (like zinc plating) for outdoor or marine applications.

Illustrative image related to types of bolts with pictures

Impact on Application: Carbon steel bolts are ideal for structural applications, automotive parts, and machinery where strength is paramount. However, they may not be suitable for environments with high humidity or exposure to chemicals.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN. In markets like Europe and the Middle East, where corrosion resistance is crucial, buyers might prefer coated options or alternative materials.

What Are the Advantages of Stainless Steel Bolts?

Stainless steel is renowned for its corrosion resistance, making it an excellent choice for applications exposed to moisture or chemicals. It typically has a tensile strength ranging from 500 to 1000 MPa, depending on the grade.

Pros: The primary advantage of stainless steel bolts is their durability and resistance to rust, which extends their lifespan in harsh environments. They also have good aesthetic appeal due to their shiny finish.

Cons: The main disadvantage is the higher cost compared to carbon steel. Manufacturing stainless steel bolts can also be more complex, which may lead to longer lead times.

Impact on Application: Stainless steel bolts are commonly used in marine, food processing, and chemical industries where corrosion is a concern. Their compatibility with various media makes them versatile for different applications.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM A193 or A320. In regions like the Middle East, where high temperatures and humidity are prevalent, stainless steel bolts are often preferred.

Illustrative image related to types of bolts with pictures

How Do Alloy Steel Bolts Compare?

Alloy steel bolts are made by adding elements like chromium, molybdenum, or vanadium to carbon steel, enhancing their mechanical properties. They can achieve tensile strengths exceeding 1000 MPa, making them suitable for heavy-duty applications.

Pros: The key advantage of alloy steel bolts is their superior strength and toughness, which makes them ideal for high-stress environments. They also offer better wear resistance than standard carbon steel.

Cons: The manufacturing process for alloy steel can be more complex and costly, which may drive up the price. Additionally, they may require specific heat treatments to achieve desired properties.

Impact on Application: Alloy steel bolts are often used in aerospace, automotive, and heavy machinery applications where high strength and fatigue resistance are crucial.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A325 or A490. In regions like Europe, where stringent quality controls are in place, alloy steel bolts must meet specific performance criteria.

What Role Does Brass Play in Bolt Manufacturing?

Brass bolts, composed primarily of copper and zinc, are known for their excellent corrosion resistance and electrical conductivity. They typically have lower tensile strength compared to steel but are suitable for specific applications.

Pros: Brass bolts are resistant to corrosion and tarnishing, making them ideal for decorative applications and environments where aesthetics are important. They are also non-magnetic.

Cons: The main limitation is their lower strength compared to steel, which may not be suitable for high-load applications. Brass is also more expensive than carbon steel.

Illustrative image related to types of bolts with pictures

Impact on Application: Brass bolts are often used in plumbing, electrical fittings, and decorative hardware where corrosion resistance and appearance are prioritized over load-bearing capacity.

Considerations for International Buyers: Buyers should check for compliance with relevant standards like ASTM B16. In regions like South America, where humidity can be high, brass bolts may be favored for their corrosion resistance.

Summary Table of Bolt Materials

| Material | Typical Use Case for types of bolts with pictures | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications, automotive parts | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Marine, food processing, chemical industries | Excellent corrosion resistance | Higher cost and complex mfg | High |

| Alloy Steel | Aerospace, automotive, heavy machinery | Superior strength and toughness | More expensive and complex mfg | Med |

| Brass | Plumbing, electrical fittings, decorative hardware | Corrosion resistant and aesthetic | Lower strength than steel | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for types of bolts with pictures

What Are the Main Stages in Bolt Manufacturing Processes?

The manufacturing of bolts is a complex process that ensures the delivery of high-quality fasteners. The main stages include material preparation, forming, assembly, and finishing, each critical to producing robust and reliable bolts.

How Is Material Prepared for Bolt Production?

The first step in the manufacturing process involves selecting the appropriate raw materials. Common materials include carbon steel, stainless steel, and alloy steel, chosen based on the bolt’s intended application. The raw materials are then cut into lengths suitable for the size of the bolts being produced. This can involve processes like shearing or sawing.

Illustrative image related to types of bolts with pictures

Once the materials are prepared, they undergo heat treatment to improve their mechanical properties. Heat treatment processes like quenching and tempering enhance strength and hardness, which are essential for performance under load.

What Forming Techniques Are Used in Bolt Manufacturing?

The forming stage is where the raw material is transformed into a bolt shape. Various techniques are employed, including:

-

Cold Heading: This method involves deforming metal at room temperature using dies, which allows for precise shaping without compromising the material’s integrity. Cold heading is widely used for producing hex bolts and socket screws.

-

Hot Forging: In instances where larger sizes or specific shapes are required, hot forging is applied. This involves heating the metal to a temperature that makes it malleable, allowing for complex geometries to be formed.

-

Thread Rolling: After forming the bolt shape, threads are rolled onto the bolt using cylindrical dies. This method enhances the strength of the threads compared to cutting threads, which can weaken the bolt.

What Are the Assembly and Finishing Processes for Bolts?

Following the forming process, bolts may undergo an assembly phase, especially for specialized types such as shoulder bolts or sex bolts, where additional components are incorporated.

How Is Finishing Done to Ensure Quality?

Finishing processes are crucial in ensuring that bolts meet the required specifications. These processes include:

-

Surface Treatment: Techniques like plating (zinc or nickel), coating (powder coating), or passivation are applied to enhance corrosion resistance and aesthetic appeal.

-

Inspection and Testing: Each batch of bolts is subjected to rigorous inspection. This includes visual checks, dimensional inspections, and non-destructive testing methods to identify any defects.

What Quality Assurance Practices Are Essential for Bolt Manufacturers?

Quality assurance is paramount in bolt manufacturing to ensure compliance with international standards. Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system.

Illustrative image related to types of bolts with pictures

What Are the Relevant International Standards for Bolt Quality?

In addition to ISO 9001, various industry-specific certifications may apply, such as:

-

CE Marking: Indicates compliance with European Union safety, health, and environmental protection standards.

-

API Spec Q1: Relevant for bolts used in the oil and gas industry, focusing on quality management systems.

These certifications not only assure buyers of quality but also facilitate smoother international trade.

How Are Quality Control Checkpoints Established?

Quality control (QC) is integrated into the manufacturing process through various checkpoints:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor critical parameters such as dimensions, material properties, and process conditions.

-

Final Quality Control (FQC): After production, a comprehensive inspection is conducted, including destructive and non-destructive testing methods like tensile testing, hardness testing, and magnetic particle inspection.

What Common Testing Methods Are Used to Ensure Bolt Integrity?

Testing methods play a vital role in confirming the quality and integrity of bolts. Common methods include:

-

Tensile Testing: Measures the strength of the bolt by applying a pulling force until failure occurs, providing insights into its load-bearing capacity.

-

Hardness Testing: Determines the hardness of the bolt material, which correlates with its wear resistance and strength.

-

Dimensional Inspection: Ensures that the bolts conform to specified sizes and tolerances, which is critical for proper fit in applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some methods to ensure quality assurance:

Illustrative image related to types of bolts with pictures

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices.

-

Requesting Quality Reports: Buyers should request detailed quality assurance documentation, including inspection reports and certifications, to assess compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality processes and product integrity.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. Differences in local standards, regulations, and practices can impact quality assurance:

-

Regulatory Compliance: Buyers should familiarize themselves with local regulations and standards that may differ from international norms, ensuring that products are compliant for their specific markets.

-

Cultural Differences: Different regions may have varying approaches to quality management and customer service, which can affect supplier relationships.

By being informed about these factors, international buyers can make more educated decisions and build long-lasting partnerships with reliable bolt manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of bolts with pictures’

Introduction

This practical sourcing guide aims to assist B2B buyers in efficiently procuring various types of bolts, complete with visual references. Understanding the characteristics and applications of different bolts is essential for making informed purchasing decisions that meet your project requirements. By following this checklist, you can ensure that you select the right bolts for your needs while minimizing risks associated with procurement.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the bolts you need. This includes understanding the size, material, thread type, and load capacity necessary for your application. Precise specifications help avoid compatibility issues and ensure that the bolts perform effectively in their intended environment.

Illustrative image related to types of bolts with pictures

- Consider the application: Different projects may require different types of bolts, such as hex bolts for heavy machinery or lag bolts for wood applications.

- Material selection: Decide between options like stainless steel for corrosion resistance or carbon steel for strength.

Step 2: Research Different Bolt Types

Familiarize yourself with various bolt types and their uses. This knowledge is vital for selecting the most appropriate bolts for your specific applications.

- Common types: Review options such as carriage bolts for wood fastening, eye bolts for lifting applications, or U-bolts for securing pipes.

- Visual references: Utilize resources with pictures to visually distinguish between bolt types and enhance understanding.

Step 3: Evaluate Potential Suppliers

Before finalizing your order, vet potential suppliers to ensure they meet your standards. A thorough evaluation helps mitigate risks associated with quality and reliability.

- Request documentation: Ask for certifications, quality assurance processes, and previous case studies to verify their credibility.

- Seek references: Contact other customers in your industry to learn about their experiences with the supplier.

Step 4: Verify Compliance with International Standards

Ensure that the bolts you are sourcing comply with relevant international standards and regulations. This step is crucial for maintaining safety and quality in your projects.

- Look for certifications: Check for compliance with standards such as ISO, ASTM, or ANSI, which indicate the bolts meet stringent quality benchmarks.

- Local regulations: Be aware of any regional standards that may apply, especially if you are sourcing from or selling in different countries.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the bolts to conduct testing. This practice helps confirm that the bolts meet your specifications and performance expectations.

- Conduct tests: Evaluate the samples under conditions similar to those they will face in your application to assess durability and functionality.

- Gather feedback: Involve your technical team in the evaluation process to ensure that the selected bolts meet all operational requirements.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, negotiate terms and pricing to ensure a mutually beneficial agreement. Effective negotiation can lead to better pricing, favorable payment terms, and improved delivery schedules.

- Consider bulk discounts: Many suppliers offer better rates for larger orders; leverage this to maximize savings.

- Discuss payment terms: Aim for flexible payment options that align with your cash flow requirements.

Step 7: Establish a Continuous Communication Channel

After placing your order, maintain open lines of communication with your supplier. This approach fosters a collaborative relationship that can lead to better service and quicker resolutions to any issues that may arise.

- Regular updates: Request periodic updates on order status and delivery timelines to manage expectations.

- Feedback loop: Provide feedback on the products and service received to help the supplier improve and tailor their offerings to your needs.

By following this checklist, B2B buyers can streamline their sourcing process for bolts, ensuring they make informed, strategic decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for types of bolts with pictures Sourcing

What Are the Key Cost Components for Sourcing Different Types of Bolts?

When analyzing the cost structure for bolts, several components contribute to the final pricing. The primary cost components include:

-

Materials: The type of metal used (e.g., carbon steel, stainless steel, or alloy steel) significantly influences the cost. High-quality materials often command higher prices but provide better durability and resistance to corrosion.

-

Labor: The cost of labor varies by region and the complexity of the manufacturing process. Skilled labor is required for precision manufacturing, which can add to the overall cost.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: The initial investment in tooling can be substantial, especially for custom bolts. Reusable tooling can lower costs over time but requires careful planning.

-

Quality Control (QC): Ensuring that bolts meet industry standards and certifications can add to costs. Regular testing and inspections are necessary to maintain quality.

-

Logistics: Shipping and handling costs can vary based on the distance and mode of transport. Import tariffs and taxes also play a role in the final cost for international buyers.

-

Margin: Suppliers typically add a markup to cover their expenses and profit. Understanding this margin can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Bolts?

Numerous factors can influence the pricing of bolts:

-

Volume/MOQ: Bulk orders often qualify for discounts. Establishing a Minimum Order Quantity (MOQ) can benefit buyers looking to reduce per-unit costs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clarify their needs upfront to avoid unexpected expenses.

-

Materials: The choice of materials not only affects durability but also influences price. Specialty materials may be more expensive but could lead to cost savings in the long term through enhanced performance.

-

Quality and Certifications: Bolts that meet specific industry standards (e.g., ISO, ASTM) may have a higher price due to the costs associated with maintaining these certifications.

-

Supplier Factors: Supplier reputation, reliability, and location can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage costs and responsibilities effectively.

What Are the Best Negotiation Tips for B2B Buyers in Different Regions?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several strategies when negotiating pricing for bolts:

-

Research Market Rates: Familiarizing yourself with local and international market rates can provide leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and potential failure. A higher upfront cost may result in lower TCO.

-

Build Relationships with Suppliers: Establishing a good rapport can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers.

-

Be Open to Alternative Sourcing: If a specific supplier cannot meet your price point, exploring alternative suppliers or regions can yield better options.

-

Timing: Understanding seasonal trends in manufacturing and shipping can help buyers take advantage of lower prices during off-peak periods.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

When sourcing bolts internationally, particularly for buyers in regions like Brazil or Saudi Arabia, several nuances are worth considering:

-

Currency Fluctuations: Exchange rates can significantly impact pricing. Buyers should account for potential fluctuations in their budgeting.

-

Import Tariffs and Taxes: Familiarize yourself with any import duties that may apply to your purchases, as these can add considerable costs.

-

Cultural Considerations: Understanding the local business culture can facilitate smoother negotiations and foster better partnerships.

-

Logistics and Delivery Times: Be mindful of the logistics involved in international shipping, including customs clearance, which can delay delivery and affect project timelines.

By taking these factors into account, international B2B buyers can navigate the complexities of bolt sourcing more effectively, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing types of bolts with pictures With Other Solutions

Introduction to Alternatives in Fastening Solutions

In the realm of industrial fastening, selecting the right solution is crucial for ensuring the integrity and durability of assembled components. While traditional bolts serve as a fundamental choice for many applications, alternative fastening solutions have emerged that may provide enhanced performance, cost-effectiveness, or ease of use. This section explores various alternatives to conventional bolts, allowing B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison of Fastening Solutions

| Comparison Aspect | Types Of Bolts With Pictures | Alternative 1: Rivets | Alternative 2: Adhesives |

|---|---|---|---|

| Performance | High tensile strength; versatile | Excellent shear strength; permanent | Good for non-load bearing; lightweight |

| Cost | Moderate; varies by type | Generally lower than bolts | Variable; can be cheaper for large areas |

| Ease of Implementation | Requires tools for installation | Requires special tools; permanent | Easy application; no tools needed |

| Maintenance | Moderate; requires periodic checks | Low; no maintenance needed | None; permanent bonding |

| Best Use Case | Structural applications; machinery | Aircraft, automotive assembly | Bonding materials like plastics, metals |

Detailed Breakdown of Alternatives

Alternative 1: Rivets

Rivets are permanent fasteners that are ideal for applications where a strong, reliable joint is necessary. They provide excellent shear strength, making them suitable for high-stress environments such as aircraft and automotive assembly. The installation of rivets typically requires specialized tools and techniques, which can add to the initial setup costs. However, once installed, rivets do not require maintenance, making them a low-maintenance option for long-term applications.

Alternative 2: Adhesives

Adhesives offer a unique solution for fastening, particularly in applications where traditional mechanical fasteners may not be feasible. They can bond a variety of materials, including metals, plastics, and composites, and are particularly effective in applications requiring a lightweight solution. While the initial cost of high-performance adhesives can be variable, they can ultimately reduce assembly time and costs by eliminating the need for additional fastening hardware. However, adhesives may not be suitable for load-bearing applications where structural integrity is critical, as they can degrade under stress or extreme environmental conditions.

Illustrative image related to types of bolts with pictures

Conclusion: How to Choose the Right Fastening Solution

When selecting a fastening solution, B2B buyers should consider various factors such as the specific requirements of their application, budget constraints, and the expected longevity of the joint. While traditional bolts offer versatility and strength, alternatives like rivets and adhesives may provide unique advantages in specific scenarios. Buyers should evaluate the performance, cost, ease of implementation, and maintenance needs of each option to determine the best solution for their operational requirements. By doing so, they can enhance their product reliability and overall efficiency in assembly processes.

Essential Technical Properties and Trade Terminology for types of bolts with pictures

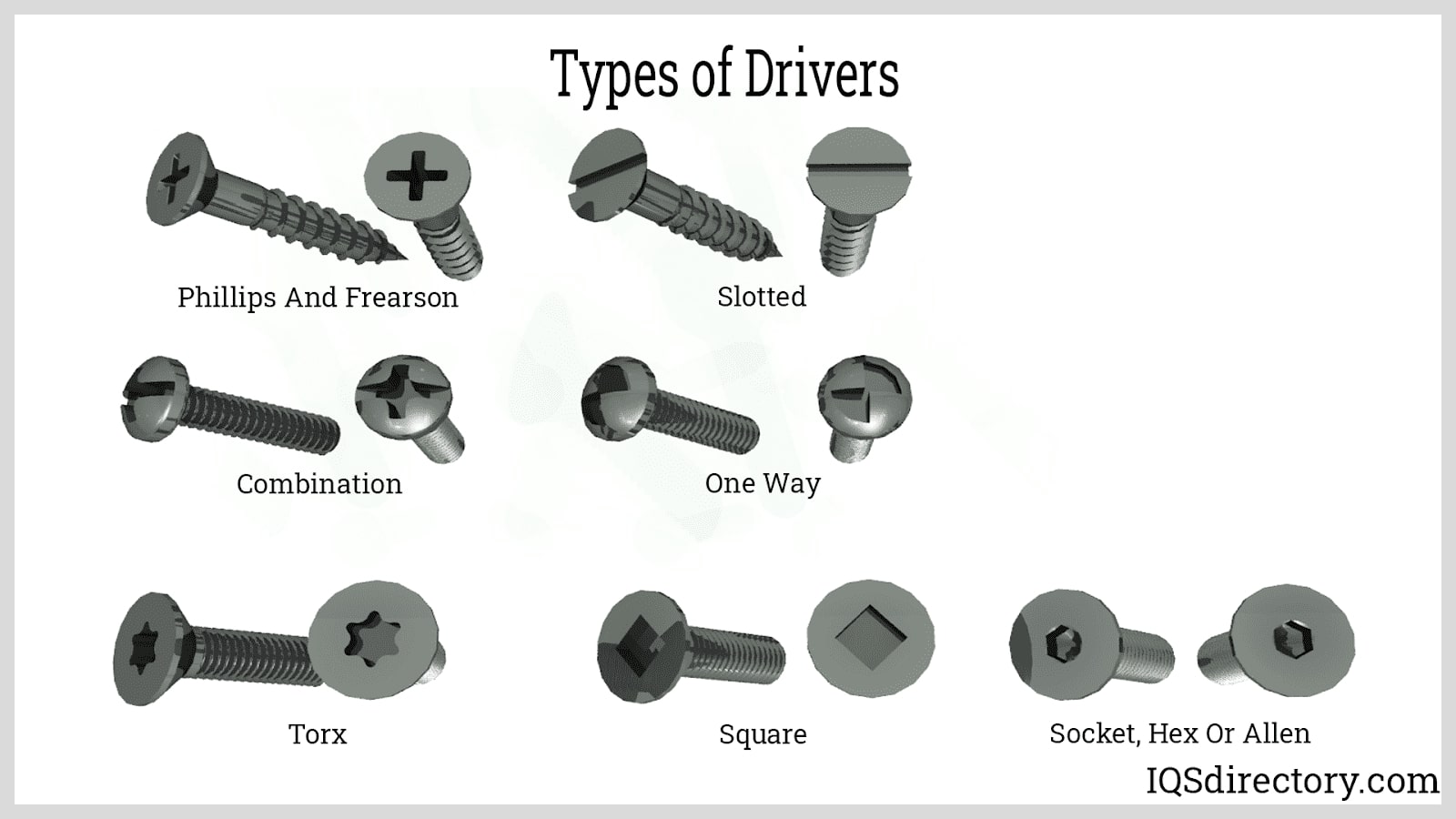

What Are the Key Technical Properties of Different Types of Bolts?

Understanding the technical specifications of bolts is essential for B2B buyers to ensure the right choice for their applications. Here are some critical specifications:

-

Material Grade

– The material grade of a bolt indicates its strength and durability. Common materials include carbon steel, stainless steel, and alloy steel. Each material has a specific tensile strength rating, which affects the bolt’s performance in various environments. For instance, stainless steel is preferred in corrosive environments, while carbon steel is often used in general applications due to its cost-effectiveness. -

Thread Pitch

– Thread pitch refers to the distance between threads, typically measured in millimeters or threads per inch. This specification is crucial when ensuring compatibility with nuts and other fasteners. Mismatched thread pitches can lead to improper fastening and potential failure, making it essential for buyers to verify thread specifications. -

Tolerance

– Tolerance defines the acceptable deviation from specified dimensions, ensuring that bolts fit correctly in their intended applications. High tolerance levels are critical in precision engineering, as they affect assembly and load distribution. Understanding tolerance helps buyers avoid costly rework or assembly issues. -

Coating and Finish

– The coating or finish of a bolt, such as zinc plating or black oxide, affects its corrosion resistance and aesthetic appeal. Buyers should consider the operational environment when selecting a finish; for example, galvanized bolts are ideal for outdoor applications where moisture is prevalent. -

Load Capacity

– Load capacity is a measure of how much weight a bolt can safely support before failure. This is influenced by factors such as diameter, material grade, and thread type. Knowing the load capacity is vital for ensuring safety and performance in structural applications, particularly in industries such as construction and manufacturing. -

Head Style

– The head style of a bolt (e.g., hex, socket, or carriage) determines the type of tool required for installation and the aesthetics of the finished assembly. Different head styles are suited for various applications, with hex heads commonly used for high-torque applications.

What Are Common Trade Terms Related to Bolts in B2B Transactions?

Familiarity with trade terminology is vital for effective communication and negotiation in the B2B environment. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to procure bolts that meet specific performance criteria in assembly applications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and purchasing strategies. Buyers must assess their needs against the MOQ to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is an essential tool for buyers to compare offers and negotiate better deals. Clarity in RFQs can lead to more accurate quotes and efficient procurement processes. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation. -

Lead Time

– Lead time refers to the time it takes from placing an order until it is delivered. This term is crucial for B2B buyers as it impacts project timelines and inventory planning. Understanding lead times can help businesses manage expectations and coordinate supply chain activities effectively. -

Certification Standards

– Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety requirements. Buyers should look for certifications to ensure that the bolts they purchase comply with industry standards, which is essential for maintaining quality in their operations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the types of bolts with pictures Sector

What Are the Current Market Dynamics and Key Trends for B2B Buyers of Bolt Types?

The global fastener market, particularly in the segment of bolts, is experiencing notable growth driven by increasing demand from various sectors such as construction, automotive, and aerospace. Key trends include the adoption of advanced manufacturing technologies like 3D printing and automation, which enhance precision and reduce lead times. Additionally, international buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking suppliers who can offer customized solutions tailored to specific applications. This demand is particularly strong in emerging markets where infrastructure development is a priority.

Sourcing trends are also shifting towards digital platforms that facilitate easier access to a wide range of products. E-commerce and online marketplaces allow B2B buyers to compare prices, specifications, and supplier ratings more effectively. Furthermore, the rise of Industry 4.0 technologies is enabling better inventory management and predictive analytics, ensuring that buyers have timely access to the types of bolts they need, thus minimizing downtime in production processes.

How Are Sustainability and Ethical Sourcing Practices Influencing Bolt Purchasing Decisions?

Sustainability is becoming a critical consideration for B2B buyers in the bolt sector. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is prompting companies to seek suppliers who prioritize sustainable practices. This includes using recycled materials and adopting eco-friendly manufacturing methods.

Ethical sourcing is equally important, with international buyers increasingly demanding transparency in supply chains. Companies that can demonstrate compliance with international labor standards and offer certifications for sustainable materials are more likely to win contracts. Certifications such as ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety are becoming essential for suppliers looking to establish credibility in the market.

Illustrative image related to types of bolts with pictures

Moreover, the trend towards ‘green’ bolts made from sustainable materials, such as biodegradable polymers or recycled metals, is gaining traction. These innovations not only reduce the ecological footprint but also appeal to a growing segment of environmentally-conscious consumers and businesses.

What Is the Evolution of Bolt Types and Their Relevance in Today’s B2B Market?

The history of bolts dates back to ancient times, where rudimentary fasteners were crafted from wood and metal. Over centuries, the evolution of bolts has been closely linked to advancements in metallurgy and manufacturing techniques. The Industrial Revolution marked a significant turning point, leading to the mass production of standardized bolt types, which transformed construction and manufacturing processes.

In contemporary B2B markets, the diversity of bolt types—such as hex bolts, carriage bolts, and lag bolts—reflects the specific needs of various industries. The introduction of high-strength and corrosion-resistant materials has expanded their application in demanding environments, such as marine and aerospace sectors. Today, understanding the nuances of different bolt types, including their specifications and applications, is essential for B2B buyers to ensure optimal performance in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of types of bolts with pictures

-

How do I choose the right type of bolt for my application?

Selecting the appropriate bolt involves understanding the material and load requirements of your application. Consider factors such as tensile strength, corrosion resistance, and environmental conditions. For example, stainless steel bolts are ideal for outdoor applications due to their resistance to rust, while high-strength bolts are suitable for heavy structural connections. Consulting with your supplier about the specific use-case and load capacity will help ensure you make the right choice. -

What is the best bolt type for fastening metal to metal?

For fastening metal to metal, hex bolts or machine screws are typically the best options. Hex bolts provide a strong grip and are suitable for high-tension applications, while machine screws are ideal for precision fastening in lighter assemblies. Additionally, using appropriate nuts and washers can enhance the joint’s integrity and load distribution. Always verify the compatibility of the materials being fastened to ensure a secure connection. -

How can I ensure the quality of bolts when sourcing internationally?

To ensure quality, vet your suppliers by checking their certifications, production processes, and customer reviews. Request samples to evaluate material quality and manufacturing standards. Additionally, consider third-party inspections or audits to verify compliance with international standards such as ISO or ASTM. Establishing clear quality assurance protocols in your purchase agreements can also help mitigate risks associated with international sourcing. -

What are the typical minimum order quantities (MOQs) for bolts?

Minimum order quantities can vary significantly based on the manufacturer and the type of bolts. Generally, MOQs may range from a few hundred pieces for standard bolts to several thousand for custom or specialized fasteners. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are trying to minimize upfront investment or testing new products in your market. -

What payment terms should I expect when purchasing bolts internationally?

Payment terms can vary widely among suppliers but generally include options like advance payment, letter of credit, or payment upon delivery. It’s crucial to discuss and agree on payment methods that protect both parties, such as escrow services or payment milestones tied to production stages. Always clarify the currency used for transactions and any additional fees that may apply, especially in cross-border transactions. -

How can I customize bolts to meet specific requirements?

Customization options may include altering dimensions, material specifications, or adding features like coatings or special threads. Most manufacturers offer design services to help refine your specifications. When considering customization, provide detailed drawings and requirements to the supplier. It’s also beneficial to discuss lead times and costs associated with custom orders to ensure they align with your project timeline. -

What logistics considerations should I keep in mind when importing bolts?

Logistics for importing bolts involve evaluating shipping methods, customs regulations, and potential tariffs. Ensure that your supplier provides accurate documentation for customs clearance, including invoices and certificates of origin. Collaborate with a freight forwarder experienced in your region to streamline the shipping process and minimize delays. Lastly, account for lead times and potential disruptions in the supply chain, particularly in international shipping. -

How do I handle discrepancies in bolt specifications upon delivery?

If discrepancies occur upon delivery, promptly document the issue with photographs and detailed descriptions. Contact your supplier immediately to discuss the problem, referencing your original order specifications. Most reputable suppliers will work with you to resolve issues, whether through replacements, refunds, or adjustments. Establishing a clear return policy and communication protocol in advance can simplify this process and protect your business interests.

Top 6 Types Of Bolts With Pictures Manufacturers & Suppliers List

1. Yijin Solution – Fasteners and Bolts

Domain: yijinsolution.com

Registered: 2019 (6 years)

Introduction: 1. Anchor Bolt: Used to attach structural and non-structural components to concrete slabs, can transfer tensile and shear loads.

2. Arbor Bolt: Required for power tools like miter saws, fastens blades securely, features a washer and reverse threads.

3. Blind Bolt: A structural fastener that excels in strength and flexibility, ideal for restricted access situations.

4. Carriage Bolt: Used for fa…

2. Helix Steel – Fasteners & Hardware Solutions

Domain: helixsteel.ph

Introduction: 40+ Different Types of Bolts and Nuts and Washers: 1. Carriage Bolts: Smooth, large diameter head, square neck for secure fastening in softer materials. 2. Flange Bolts: Round flange under head for load distribution, ideal for metal-to-metal fastening. 3. Plow Bolts: Square neck to prevent rotation, flat head for wear resistance, used in heavy machinery. 4. Hex Head Bolts: Hexagonal heads, machine…

3. Shutterstock – Bolt Heads Stock Collection

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Bolt Heads Stock Collection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Pinterest – Fasteners

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Bolts are a type of fastener used to connect two objects together. They typically have a threaded shaft and a head on one end, and are inserted into pre-drilled holes and tightened with a nut on the other end. Bolts come in a variety of shapes, sizes, and materials, and can be used in a range of applications, including construction, manufacturing, and machinery. Bolts are often preferred over scre…

5. Facebook – Different Types of Bolts

6. Reddit – Product Size Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Product Size Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for types of bolts with pictures

How Can Strategic Sourcing Enhance Your Bolt Procurement?

In summary, understanding the diverse types of bolts and their applications is crucial for international B2B buyers seeking to optimize their procurement strategies. The strategic sourcing of bolts not only ensures quality and reliability but also fosters strong supplier relationships that can lead to cost savings and operational efficiencies. By leveraging comprehensive knowledge of fastener types, such as hex bolts, carriage bolts, and specialty fasteners, businesses can make informed purchasing decisions that align with their specific project requirements.

Illustrative image related to types of bolts with pictures

As you navigate the global marketplace, consider the unique demands of your region—whether it be the robust construction needs in Brazil or the innovative engineering projects in Saudi Arabia. Emphasizing sustainable sourcing practices and maintaining a focus on supplier diversity will further enhance your competitive edge.

Looking ahead, take proactive steps to engage with reliable suppliers, explore emerging fastener technologies, and invest in quality assurance processes. By doing so, you position your business not just to meet current demands but to anticipate future challenges in an ever-evolving market. Act now to refine your sourcing strategy, and empower your operations with the right fastening solutions for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to types of bolts with pictures

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.