A B2B Buyer’s Guide to Carlton Scale: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for carlton scale

In today’s rapidly evolving global market, sourcing reliable weighing solutions, such as those offered by Carlton Scale, presents a significant challenge for international B2B buyers. With increasing demand for precision and efficiency across various industries, decision-makers must navigate a complex landscape of options that includes everything from analytical balances to advanced industrial automation systems. This comprehensive guide aims to demystify the process of acquiring Carlton Scale products and services, providing insights into the diverse types of weighing instruments, their applications, and best practices for supplier vetting.

By delving into aspects such as cost considerations, calibration services, and integration capabilities, this guide empowers B2B buyers—particularly those in regions like Africa, South America, the Middle East, and Europe (including markets such as Saudi Arabia and Brazil)—to make informed purchasing decisions. Understanding the nuances of Carlton Scale’s offerings can lead to enhanced operational efficiency and improved product quality, essential factors for businesses looking to maintain a competitive edge in their respective markets.

As you explore this guide, expect actionable insights and expert advice that will not only facilitate the selection of the right weighing solutions but also foster long-term partnerships with trusted suppliers. Your journey toward achieving precision and reliability in your operations begins here.

Understanding carlton scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Platform Scales | Flat surface for weighing large items; robust design | Warehousing, shipping, and logistics | Pros: Versatile, easy to use. Cons: Limited precision for small items. |

| Load Cells | Converts mechanical force into electrical signals | Manufacturing, automotive, and aerospace | Pros: High accuracy, customizable. Cons: Requires calibration and maintenance. |

| In-Motion Check Weighers | Weighs products while in motion; integrated systems | Food processing, packaging, and logistics | Pros: Increases efficiency, reduces waste. Cons: Higher initial investment. |

| Analytical Balances | High precision scales for small weights | Laboratories, pharmaceuticals, research | Pros: Extremely accurate, ideal for small samples. Cons: Fragile, requires careful handling. |

| Truck Scales | Designed for weighing trucks and trailers | Transportation, logistics, and freight | Pros: Heavy-duty, essential for compliance. Cons: Space-intensive, requires installation. |

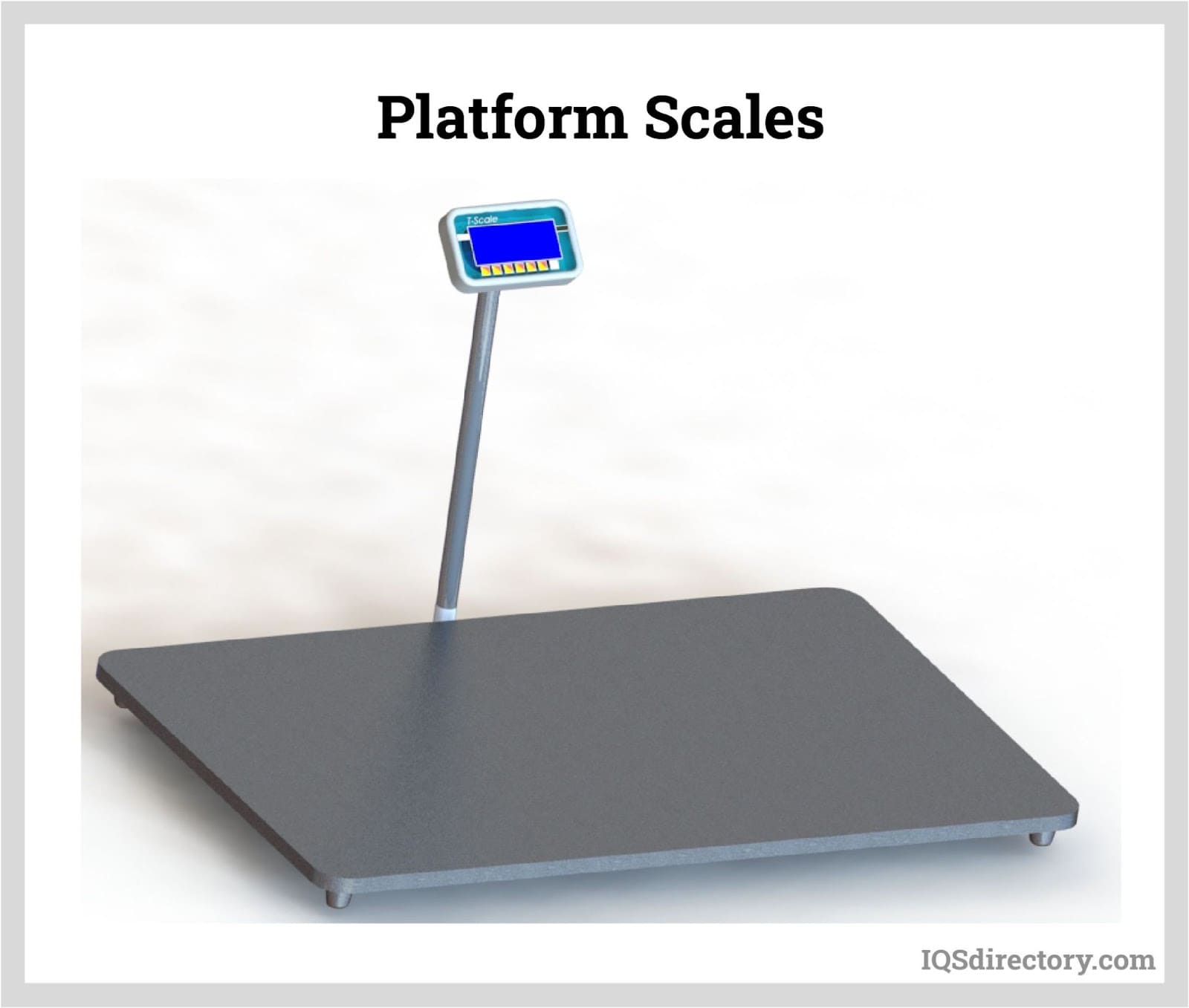

What Are Platform Scales and Their Applications?

Platform scales are essential for weighing large items, featuring a flat surface that supports heavy loads. Their robust design allows for easy loading and unloading, making them ideal for warehousing, shipping, and logistics operations. When considering a platform scale, B2B buyers should evaluate the scale’s capacity, size, and ease of integration into existing workflows. While they offer versatility and user-friendliness, platform scales may lack the precision required for smaller items.

How Do Load Cells Function and Where Are They Used?

Load cells are transducers that convert mechanical energy into electrical signals, making them vital in various industrial applications. They are commonly used in manufacturing, automotive, and aerospace sectors where precise weight measurements are critical. When purchasing load cells, B2B buyers should consider factors such as load capacity, accuracy, and the environment in which they will be used. While load cells offer high accuracy and customization options, they require regular calibration and maintenance to ensure optimal performance.

What Are In-Motion Check Weighers and Their Benefits?

In-motion check weighers are designed to weigh products as they move along a production line, integrating seamlessly into packaging and processing systems. This type of scale is particularly beneficial in food processing and logistics, where efficiency and accuracy are paramount. B2B buyers should assess the speed and accuracy of the check weigher, along with its compatibility with existing machinery. Despite their higher initial investment, in-motion check weighers can significantly enhance operational efficiency and minimize product waste.

Why Choose Analytical Balances for Precision Weighing?

Analytical balances provide high precision for weighing small samples, making them indispensable in laboratories, pharmaceuticals, and research settings. Their design is tailored for accuracy, often featuring draft shields to prevent disturbances from air currents. When considering an analytical balance, buyers should focus on its sensitivity, maximum capacity, and the need for calibration. While they deliver exceptional accuracy, analytical balances are fragile and require careful handling and maintenance to ensure longevity.

What Are Truck Scales and Their Role in Logistics?

Truck scales are specifically designed for weighing trucks and trailers, playing a crucial role in transportation, logistics, and freight operations. They help ensure compliance with weight regulations and optimize load distribution. B2B buyers should consider factors such as scale size, installation requirements, and durability when purchasing truck scales. Although they are heavy-duty and essential for operational compliance, truck scales can be space-intensive and may require significant upfront investment for installation.

Key Industrial Applications of carlton scale

| Industry/Sector | Specific Application of Carlton Scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated Weighing Systems for Ingredients | Ensures precise ingredient measurement, improving product quality and consistency. | Need for compliance with food safety regulations and standards. |

| Pharmaceuticals | Precision Weighing for Drug Formulation | Guarantees accurate dosages, essential for safety and efficacy of medications. | Must meet stringent regulatory standards for pharmaceutical manufacturing. |

| Chemical | Bulk Material Weighing and Monitoring | Enhances process efficiency and reduces waste in chemical production. | Consideration for hazardous materials handling and safety compliance. |

| Utilities and Municipalities | Weighing Solutions for Waste Management | Optimizes waste collection and disposal processes, reducing operational costs. | Need for scalability and integration with existing municipal systems. |

| Engineering and Machinery | Calibration Services for Heavy Equipment | Ensures accuracy in measurements, which is critical for safety and operational efficiency. | Focus on the availability of local service support and quick turnaround times. |

How is Carlton Scale Used in the Food and Beverage Industry?

In the food and beverage sector, Carlton Scale provides automated weighing systems that streamline the measurement of ingredients in production lines. This application is crucial for maintaining product quality and consistency, as even minor deviations can lead to significant variations in taste and safety. Buyers should focus on sourcing equipment that complies with local food safety regulations, particularly in regions like Africa and South America, where regulatory frameworks can vary widely.

What Role Does Carlton Scale Play in Pharmaceuticals?

Carlton Scale’s precision weighing solutions are vital in the pharmaceutical industry, where accurate dosing is paramount. These scales facilitate the formulation of drugs, ensuring that each batch meets required specifications for safety and efficacy. International buyers must consider the need for equipment that adheres to rigorous regulatory standards, such as Good Manufacturing Practices (GMP), particularly in regions like the Middle East and Europe, where compliance is strictly enforced.

How Does Carlton Scale Enhance Chemical Production?

In the chemical industry, Carlton Scale’s bulk material weighing and monitoring systems significantly enhance operational efficiency by minimizing waste and ensuring accurate measurements. This application is particularly beneficial in environments where chemical reactions depend on precise ingredient ratios. Buyers in this sector should prioritize sourcing solutions that are capable of handling hazardous materials safely, which is critical in regions with strict environmental regulations.

What Benefits Does Carlton Scale Provide to Utilities and Municipalities?

Carlton Scale’s weighing solutions for waste management help municipalities optimize their waste collection and disposal processes. By providing accurate weight data, these systems assist in resource allocation and operational cost reduction. When sourcing these solutions, municipalities should consider the scalability of the systems to accommodate future growth and the ability to integrate with existing waste management frameworks.

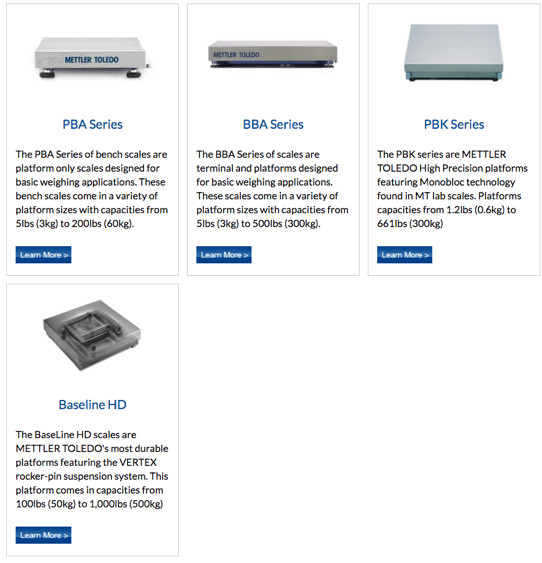

Illustrative image related to carlton scale

How is Calibration Important for Engineering and Machinery?

Calibration services offered by Carlton Scale are essential for ensuring the accuracy of heavy equipment used in engineering and machinery applications. Accurate measurements are critical for safety and operational efficiency, especially in sectors where precision is non-negotiable. Buyers should look for providers that offer local service support to ensure quick turnaround times, which is particularly important in regions with challenging logistics.

3 Common User Pain Points for ‘carlton scale’ & Their Solutions

Scenario 1: Inconsistent Measurement Accuracy in Industrial Applications

The Problem: B2B buyers often face challenges with inconsistent measurement accuracy, especially in industries that require precise weighing, such as pharmaceuticals and food and beverage. This inconsistency can lead to product quality issues, regulatory compliance failures, and ultimately, financial losses. For instance, a company may find that its scales are not calibrated correctly, resulting in discrepancies that could compromise the integrity of its products and lead to customer dissatisfaction.

The Solution: To combat measurement inaccuracies, it is crucial to establish a routine calibration and maintenance schedule with Carlton Scale. Buyers should utilize Carlton Scale’s comprehensive calibration services to ensure all weighing instruments are regularly checked against industry standards. This process not only enhances measurement precision but also helps maintain compliance with regulatory requirements. Implementing a tracking system for calibration dates and results will allow businesses to proactively manage their equipment and reduce the risk of operational disruptions. Additionally, investing in automated calibration systems can streamline this process, ensuring that scales remain accurate with minimal manual intervention.

Scenario 2: Difficulty in Integrating Weighing Systems with Existing Operations

The Problem: Many companies experience integration challenges when introducing new weighing systems into their existing operations. This is particularly true for firms with legacy systems or those operating on a tight budget. Issues may arise from incompatible software or hardware, leading to delays in productivity and increased operational costs. For example, a manufacturing plant might struggle to sync new in-motion check weighers with its current data management systems, causing bottlenecks in production.

The Solution: To effectively integrate Carlton Scale’s weighing solutions, buyers should first conduct a thorough assessment of their current systems and requirements. Collaborating with Carlton Scale’s technical team during the selection process can provide insights into which products will best fit into existing operations. Buyers should consider customized solutions that allow for seamless integration, such as PLCs and data collection systems tailored to their specific environment. Moreover, engaging in training programs offered by Carlton Scale can empower staff to utilize the new systems efficiently, ensuring a smoother transition and minimizing downtime.

Scenario 3: Limited Technical Support and Training for Equipment Usage

The Problem: B2B buyers often report a lack of comprehensive training and ongoing technical support when adopting new weighing technologies. This can lead to underutilization of equipment, operational inefficiencies, and increased frustration among employees. For instance, a company might invest in advanced weighing technology only to find that their staff is not adequately trained to operate it effectively, resulting in mistakes that affect production quality and safety.

The Solution: To address this issue, businesses should prioritize training and support as a critical component of their equipment procurement process. Carlton Scale offers extensive training programs tailored to the specific needs of their clients, covering everything from basic operations to advanced troubleshooting techniques. Buyers should take advantage of these training sessions to ensure their teams are well-equipped to handle the new technology. Additionally, establishing a dedicated support line with Carlton Scale can provide immediate assistance for any technical queries, enabling companies to resolve issues swiftly and maintain operational efficiency. Continuous learning opportunities, such as refresher courses or updates on new features, can further enhance employee competency and confidence in using the equipment.

Strategic Material Selection Guide for carlton scale

What Are the Key Materials Used in Carlton Scale Products?

When selecting materials for industrial weighing solutions, especially in the context of Carlton Scale products, it’s essential to consider the specific properties and applications that align with the operational requirements of various industries. Below is an analysis of four common materials used in Carlton Scale products: stainless steel, aluminum, carbon steel, and plastic composites.

How Does Stainless Steel Benefit Weighing Equipment?

Stainless steel is a popular choice for manufacturing scales and weighing instruments due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for a wide range of applications, including food and beverage, pharmaceuticals, and chemicals.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, ensuring a long lifespan for weighing equipment. It is easy to clean, which is crucial in industries where hygiene is paramount.

Cons: The primary drawback of stainless steel is its higher cost compared to other materials. Additionally, it can be heavier, which may affect portability in certain applications.

Impact on Application: Stainless steel scales are compatible with various media, including liquids and powders, making them versatile across multiple industries.

Considerations for International Buyers: Buyers from regions such as the Middle East and Europe should ensure compliance with local standards (e.g., ASTM, DIN) regarding material specifications, especially in food and pharmaceutical applications.

What Are the Advantages of Aluminum in Weighing Solutions?

Aluminum is another widely used material in the manufacturing of scales, particularly for portable and lightweight applications. Its low density makes it ideal for scales that require mobility without sacrificing strength.

Pros: Aluminum is lightweight, which enhances portability and ease of installation. It is also resistant to corrosion, particularly in environments with limited exposure to harsh chemicals.

Cons: While aluminum is strong, it is not as durable as stainless steel and can be prone to deformation under heavy loads. Its cost is generally lower than stainless steel but can vary based on alloy types.

Impact on Application: Aluminum scales are often used in applications where weight and portability are critical, such as in logistics and shipping.

Considerations for International Buyers: Buyers should be aware of the specific aluminum alloy used, as different alloys have varying strength and corrosion resistance properties. Compliance with international standards is also essential.

Why Choose Carbon Steel for Heavy-Duty Applications?

Carbon steel is frequently used in industrial applications due to its high strength and durability. It is particularly suitable for heavy-duty scales and weighing systems that require robustness.

Pros: Carbon steel offers excellent strength and is typically more cost-effective than stainless steel. It can handle heavy loads without significant deformation.

Cons: The primary drawback is its susceptibility to corrosion, which can limit its use in humid or chemically aggressive environments unless properly coated.

Impact on Application: Carbon steel scales are ideal for heavy materials and industrial applications, such as construction and mining.

Considerations for International Buyers: Buyers in humid regions, such as parts of Africa and South America, should consider protective coatings to enhance corrosion resistance and ensure compliance with local standards.

How Do Plastic Composites Fit into Weighing Equipment?

Plastic composites are increasingly used in weighing applications due to their versatility and lightweight nature. These materials can be engineered to provide specific properties, such as chemical resistance and flexibility.

Pros: Plastic composites are lightweight and can be molded into complex shapes, making them suitable for custom applications. They also offer good resistance to various chemicals.

Cons: While they are resistant to corrosion, plastic composites may not withstand high temperatures or heavy loads as effectively as metals.

Impact on Application: These materials are often used in specialized applications, such as in chemical processing, where corrosion resistance is critical.

Considerations for International Buyers: Buyers should verify the specific type of plastic composite used, as different formulations can affect performance. Compliance with industry standards for chemical resistance is also important.

Summary Table of Material Selection for Carlton Scale Products

| Material | Typical Use Case for carlton scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage scales | Highly durable and corrosion-resistant | Higher cost compared to other materials | High |

| Aluminum | Portable weighing scales | Lightweight and easy to install | Less durable under heavy loads | Medium |

| Carbon Steel | Heavy-duty industrial scales | Excellent strength and cost-effective | Susceptible to corrosion | Low |

| Plastic Composites | Chemical processing applications | Lightweight and customizable | Limited high-temperature resistance | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for carlton scale

What Are the Main Stages of Manufacturing for Carlton Scale Products?

The manufacturing process at Carlton Scale is meticulously designed to ensure the delivery of high-quality industrial weighing solutions. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to carlton scale

-

Material Preparation: This initial stage involves sourcing high-grade raw materials, which are critical for the durability and precision of weighing instruments. Common materials include stainless steel and aluminum, which are selected for their strength and resistance to corrosion. Materials are thoroughly inspected upon arrival to ensure they meet the required specifications.

-

Forming: In this stage, raw materials are shaped into components using techniques such as cutting, bending, and machining. Advanced CNC (Computer Numerical Control) machines are often employed to achieve precise dimensions and tolerances. This automation not only enhances efficiency but also reduces human error, which is crucial in maintaining the accuracy of weighing systems.

-

Assembly: After forming, components are brought together in the assembly process. Skilled technicians utilize standardized procedures to ensure that each weighing instrument is assembled correctly. This stage often includes the integration of electronic components, such as load cells and data acquisition systems, which are essential for the functionality of modern weighing solutions.

-

Finishing: The final manufacturing stage involves surface treatments and coatings that enhance the aesthetics and protect against wear and environmental factors. Techniques such as powder coating and anodizing are commonly used. This stage also includes thorough cleaning processes to remove any contaminants that may affect performance.

How Does Carlton Scale Ensure Quality Control in Manufacturing?

Quality assurance is a cornerstone of Carlton Scale’s manufacturing philosophy. The company adheres to relevant international standards, such as ISO 9001, which ensures a consistent quality management system is in place. This certification demonstrates the company’s commitment to quality in every aspect of its operations.

-

International Standards Compliance: Carlton Scale’s products often need to meet various international certifications, including CE marking for the European market and API standards for certain industrial applications. These certifications require rigorous testing and documentation, ensuring that products are safe and reliable for end-users.

-

Quality Control Checkpoints: Quality control is embedded throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production line, ensuring they meet the required specifications.

– In-Process Quality Control (IPQC): During manufacturing, processes are monitored to identify and rectify any deviations from quality standards in real-time.

– Final Quality Control (FQC): Once the product is assembled, it undergoes a final inspection to verify its performance and compliance with specifications. This may include functional testing and calibration of weighing instruments. -

Common Testing Methods: Various testing methods are employed to ensure product reliability. These may include:

– Load Testing: Assessing the accuracy and performance of scales under different weight loads.

– Environmental Testing: Evaluating the product’s performance under various environmental conditions, such as humidity and temperature fluctuations.

– Calibration: Ensuring that all instruments are calibrated against recognized standards to guarantee precision.

How Can B2B Buyers Verify Carlton Scale’s Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers like Carlton Scale is essential. Here are several approaches:

-

Supplier Audits: Conducting on-site audits allows buyers to directly assess the manufacturing processes and quality control systems in place. This not only provides insights into compliance with standards but also helps establish a relationship with the manufacturer.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can provide buyers with documentation of the testing and inspection processes. These reports often include metrics on defect rates, calibration results, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing and quality control processes. These inspections can help ensure that products meet the required specifications before shipment.

-

Certification Verification: Buyers should verify the validity of certifications such as ISO 9001 or CE. This can often be done through the issuing bodies, ensuring that the supplier maintains compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of certain nuances related to quality control when sourcing from companies like Carlton Scale.

-

Cultural and Regulatory Differences: Different regions may have varying regulations regarding product safety and quality standards. It’s crucial for buyers to understand these differences and how they may impact product specifications and compliance.

-

Documentation Requirements: International shipments often require extensive documentation, including quality certificates and compliance declarations. Buyers should ensure that suppliers are prepared to provide all necessary paperwork to facilitate smooth customs processes.

-

Language Barriers: Communication can sometimes be hindered by language differences. Buyers should ensure that they have a clear line of communication with suppliers to address any quality concerns and to understand the specifications and testing protocols.

-

Logistical Considerations: Quality control does not end at the factory. Buyers must also consider the logistics of shipping and handling, as these can affect product integrity. Ensuring proper packaging and transportation conditions is vital to maintaining quality throughout the supply chain.

By understanding the manufacturing processes and quality assurance measures employed by Carlton Scale, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carlton scale’

In this guide, we provide a practical checklist for B2B buyers seeking to procure Carlton Scale products and services. This checklist will help streamline your sourcing process, ensuring that you select the right solutions for your industrial weighing and automation needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before approaching suppliers. This includes understanding the types of scales you need (e.g., platform scales, analytical balances) and the specific applications they will serve. Consider factors such as load capacity, precision requirements, and environmental conditions.

- Load Capacity: Determine the maximum weight your scales need to measure.

- Precision Needs: Specify the level of accuracy required for your operations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in the products you need. Look for companies with a solid reputation in the industry, such as Carlton Scale, which has been providing reliable services since 1933.

- Experience: Assess the supplier’s years in business and their market presence.

- Product Range: Ensure they offer a comprehensive range of weighing solutions suitable for your industry.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential for ensuring quality and compliance with industry standards. Suppliers like Carlton Scale should possess relevant certifications that demonstrate their commitment to quality management and safety protocols.

Illustrative image related to carlton scale

- ISO Certifications: Look for ISO 9001 or similar quality management certifications.

- Industry-Specific Compliance: Confirm compliance with regulations pertinent to your sector, such as those for pharmaceuticals or food and beverage.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline product specifications, pricing, and terms of service. This will allow you to compare offers effectively and make an informed decision.

- Breakdown of Costs: Ensure the quote includes all potential costs, such as installation and calibration services.

- Warranty and Support: Check the warranty period and the level of after-sales support offered.

Step 5: Assess Customer Reviews and Case Studies

Investigate customer reviews and case studies to gauge the supplier’s reliability and service quality. Look for feedback from businesses similar to yours, as this can provide insights into how well the supplier meets industry-specific needs.

- Customer Feedback: Analyze reviews on platforms like Indeed or industry forums.

- Case Studies: Request case studies that demonstrate successful implementations of their products.

Step 6: Arrange for Demonstrations or Trials

If possible, arrange for product demonstrations or trial periods. This hands-on experience can help you assess whether the scales meet your operational requirements and ease of use.

- Functionality Testing: Evaluate the scales in real-world scenarios to ensure they perform as expected.

- User Training: Inquire about training programs for your staff to ensure they can operate the equipment efficiently.

Step 7: Finalize Contract Terms

Before making a purchase, carefully review and finalize the contract terms. Ensure that all agreements regarding pricing, delivery schedules, and service commitments are documented clearly.

Illustrative image related to carlton scale

- Delivery Schedule: Confirm timelines for delivery and installation.

- Service Level Agreements (SLAs): Include SLAs that outline expected response times for maintenance and support.

By following this checklist, B2B buyers can ensure a thorough and informed procurement process for Carlton Scale products, leading to better operational efficiencies and successful partnerships.

Comprehensive Cost and Pricing Analysis for carlton scale Sourcing

What Are the Key Cost Components in Carlton Scale Sourcing?

When sourcing from Carlton Scale, understanding the cost structure is crucial for effective budgeting and procurement planning. The primary cost components include:

-

Materials: The cost of raw materials, such as metals and electronic components, directly impacts the pricing of weighing systems. Quality materials not only enhance durability but also influence the scale’s precision and reliability.

-

Labor: Labor costs encompass wages for skilled technicians involved in manufacturing, calibration, and installation. High-quality labor is essential for ensuring that the products meet industry standards and customer specifications.

-

Manufacturing Overhead: This includes costs related to utilities, rent, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs, which may be reflected in competitive pricing.

-

Tooling: Investment in specialized tools and machinery for production can affect the initial cost. Custom tools may be required for specific projects, which can increase upfront expenses.

-

Quality Control (QC): Rigorous QC processes are essential to maintain product integrity. The costs associated with testing and certifications can add to the overall price but are vital for ensuring compliance with international standards.

-

Logistics: Shipping and handling costs vary based on the destination, especially for international buyers. Factors such as distance, mode of transportation, and customs duties can significantly influence logistics costs.

-

Margin: Finally, the profit margin that Carlton Scale applies to its products will determine the final pricing. This margin can vary based on market conditions and competitive landscape.

How Do Price Influencers Impact Your Sourcing Decisions?

Several factors can influence the pricing of Carlton Scale products, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower unit prices due to economies of scale. Understanding Carlton Scale’s MOQ can help you negotiate better deals.

-

Specifications and Customization: Custom solutions tailored to specific needs may incur additional costs. Clearly defining your requirements can help in obtaining precise quotes.

-

Material Quality and Certifications: Higher quality materials and necessary certifications can elevate costs. However, investing in quality can result in lower Total Cost of Ownership (TCO) through reduced maintenance and longer lifespan.

-

Supplier Factors: Carlton Scale’s reputation, service level, and responsiveness can also affect pricing. A reliable supplier may charge a premium, but the assurance of quality and support can justify the cost.

-

Incoterms: The choice of Incoterms can significantly impact the total price. Buyers should be aware of their responsibilities concerning shipping, insurance, and customs to accurately assess total costs.

What Negotiation Strategies Can Help Maximize Cost-Efficiency?

To enhance cost-efficiency when sourcing from Carlton Scale, consider the following tips:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs, including maintenance, operational efficiency, and potential downtime.

-

Leverage Market Research: Conduct thorough research on market prices and competitors to strengthen your negotiating position. Knowledge of industry standards can help you argue for better pricing.

-

Build Relationships: Establishing a strong relationship with Carlton Scale representatives can lead to better pricing and terms. Long-term partnerships often yield benefits such as discounts or preferential treatment on orders.

-

Be Flexible with Specifications: If possible, consider alternative materials or designs that may reduce costs without compromising quality. Flexibility can lead to innovative solutions that align with budget constraints.

-

Timing Your Orders: Take advantage of seasonal discounts or promotions. Understanding Carlton Scale’s production cycles can help you time your orders for the best pricing.

What Should International Buyers Consider When Sourcing from Carlton Scale?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, specific nuances are vital:

Illustrative image related to carlton scale

-

Currency Fluctuations: Be aware of the impact of currency exchange rates on pricing. Negotiate prices in your local currency to mitigate risks associated with fluctuations.

-

Import Regulations and Tariffs: Research applicable tariffs and import regulations in your country. These can add unexpected costs to your procurement budget.

-

Cultural Differences: Understanding cultural nuances in business negotiations can foster smoother communication and more fruitful discussions.

-

Logistics Challenges: Consider potential delays in shipping and customs clearance. Planning for these factors can help avoid disruptions to your operations.

-

Local Partnerships: Establishing local partnerships for installation and maintenance can enhance service delivery and reduce operational risks.

In conclusion, comprehensive knowledge of the cost structure, price influencers, and negotiation strategies can significantly enhance your sourcing experience with Carlton Scale. By understanding these elements, B2B buyers can make informed decisions that optimize both cost and quality.

Alternatives Analysis: Comparing carlton scale With Other Solutions

Exploring Alternatives to Carlton Scale for Industrial Weighing Solutions

In today’s competitive industrial landscape, businesses are constantly evaluating the most effective weighing solutions to optimize their operations. While Carlton Scale has established itself as a reputable provider of weighing and measuring services, various alternatives exist that may better suit specific needs and contexts. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational goals.

| Comparison Aspect | Carlton Scale | Load Cell Technology | Weighing Software Solutions |

|---|---|---|---|

| Performance | High accuracy and reliability | Excellent for dynamic applications | Enhanced data analytics capabilities |

| Cost | Moderate initial investment | Variable costs based on application | Subscription-based, potentially lower upfront costs |

| Ease of Implementation | Requires professional installation | Can be integrated with existing systems | User-friendly, minimal setup needed |

| Maintenance | Regular calibration needed | Low maintenance, durable | Software updates required |

| Best Use Case | Heavy industrial applications | Precision measurement in various industries | Data-heavy environments needing analysis |

Load Cell Technology: A Robust Alternative

Load cell technology is a widely used solution for industrial weighing. This method involves transducers that convert mechanical forces into electrical signals, providing accurate weight measurements. The primary advantage of load cells is their versatility; they can be utilized across various applications, from manufacturing to logistics. However, the cost can vary significantly based on the specific use case and installation requirements. While they offer durability and low maintenance, integrating load cells into existing systems may require some technical expertise.

Weighing Software Solutions: A Modern Approach

Weighing software solutions are increasingly popular for businesses that require advanced data analytics and reporting capabilities. These solutions often integrate seamlessly with existing hardware, providing real-time data processing and analysis. A key benefit is the reduced upfront investment compared to traditional hardware solutions, as many software options operate on a subscription basis. However, users must remain vigilant about regular software updates to ensure optimal performance and security. This alternative is particularly beneficial for businesses focused on data-heavy environments, such as those in logistics and supply chain management.

Choosing the Right Solution for Your Needs

When evaluating weighing solutions, B2B buyers should carefully consider their specific operational requirements, budget constraints, and long-term goals. Carlton Scale offers a reliable and comprehensive service, particularly for heavy industrial applications. In contrast, load cell technology provides flexibility for various industries, while weighing software solutions excel in data-driven environments. By assessing the unique needs of their operations and comparing the pros and cons of each alternative, businesses can select the most suitable solution that enhances efficiency, accuracy, and overall performance.

Essential Technical Properties and Trade Terminology for carlton scale

What Are the Key Technical Properties of Carlton Scale Products?

When considering the purchase of weighing solutions from Carlton Scale, understanding the essential technical properties is crucial for ensuring that the equipment meets your operational requirements. Below are some critical specifications that buyers should be aware of:

-

Load Capacity: This refers to the maximum weight that a scale can measure accurately. Load capacities vary significantly across different scales, from small analytical balances to large truck and railroad scales. Selecting the appropriate load capacity is vital for ensuring safety and operational efficiency, as exceeding the maximum capacity can lead to inaccurate readings and equipment damage.

-

Material Grade: The materials used in the construction of weighing equipment influence durability, accuracy, and resistance to environmental factors. Common materials include stainless steel for its corrosion resistance, and aluminum for its lightweight properties. Choosing the right material grade can enhance the longevity of the scales, especially in industries such as food and beverage or pharmaceuticals where hygiene is paramount.

-

Accuracy and Precision: Accuracy refers to how closely a measurement reflects the true value, while precision indicates the repeatability of measurements under unchanged conditions. Scales from Carlton Scale are designed to meet specific accuracy standards, which is essential for compliance in regulated industries. High accuracy and precision are crucial for maintaining product quality and meeting industry standards.

-

Calibration Range: This specification outlines the range within which the scale can be calibrated for optimal performance. Calibration is vital for ensuring that measurements remain consistent over time. A wider calibration range allows for greater flexibility in various applications and is particularly important for businesses that handle diverse products with varying weights.

-

Environmental Resistance: Many scales are designed to withstand specific environmental conditions, such as humidity, temperature fluctuations, and exposure to chemicals. Understanding the environmental resistance of the equipment is essential for operations in sectors like manufacturing or chemical processing, where harsh conditions can affect scale performance.

-

Data Integration Capabilities: Modern weighing solutions often come equipped with advanced data acquisition systems that allow for seamless integration with existing manufacturing systems. This capability enables real-time data collection and analysis, improving overall operational efficiency and decision-making processes.

What Common Trade Terms Should B2B Buyers Know When Purchasing Weighing Solutions?

Familiarity with industry jargon can help streamline negotiations and enhance communication with suppliers. Here are several common trade terms relevant to Carlton Scale products:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end product. For buyers, understanding whether a scale is produced by an OEM can influence the decision-making process, particularly regarding warranty and support options.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for businesses looking to scale operations without incurring excess costs.

-

RFQ (Request for Quotation): An RFQ is a standard business process where a buyer requests pricing information from suppliers for specific products or services. Submitting an RFQ can help businesses compare costs and terms from multiple suppliers, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for determining shipping costs, risk, and responsibilities, particularly when sourcing from international suppliers.

-

Calibration Certification: This is a document provided by the manufacturer or a third-party organization that verifies that a scale has been calibrated to meet specific standards. Having a calibration certificate is often necessary for compliance in regulated industries, making it an important consideration for B2B buyers.

-

Turnkey Solutions: This term refers to a complete service or product that is ready for immediate use upon delivery. For businesses seeking efficiency, turnkey solutions can simplify the procurement process, as they often include installation and support services.

Understanding these technical properties and trade terms can empower B2B buyers to make informed decisions when investing in weighing solutions from Carlton Scale, ensuring that they meet their operational needs while optimizing performance and compliance.

Navigating Market Dynamics and Sourcing Trends in the carlton scale Sector

What Are the Key Drivers Shaping the Carlton Scale Market?

The global market for industrial weighing and measuring solutions, including the Carlton Scale sector, is experiencing significant transformation driven by technological advancements, increasing demand for precision, and the need for operational efficiency. Key trends include the integration of automation and IoT, which facilitate real-time data collection and analysis, enabling businesses to optimize their supply chains and enhance decision-making processes. As industries such as food and beverage, pharmaceuticals, and raw materials become increasingly competitive, there is a heightened focus on acquiring advanced weighing solutions that promise accuracy and reliability.

Illustrative image related to carlton scale

Moreover, emerging markets in Africa, South America, and the Middle East are witnessing a rise in infrastructure projects and industrial activities, creating a robust demand for weighing solutions. In regions like Saudi Arabia and Brazil, government initiatives aimed at diversifying economies and boosting local manufacturing are further propelling the need for efficient industrial solutions. Buyers from these regions should prioritize partnerships with suppliers that not only offer high-quality products but also demonstrate an understanding of local market dynamics and regulatory requirements.

How Is Sustainability Influencing Sourcing Decisions in the Carlton Scale Sector?

Sustainability has become a critical factor in B2B sourcing decisions, particularly for companies involved in the industrial sector. The environmental impact of manufacturing processes and the importance of ethical supply chains are increasingly influencing buyer preferences. For Carlton Scale, this means that international buyers are seeking suppliers that implement sustainable practices, such as using eco-friendly materials and minimizing waste during production.

Moreover, certifications like ISO 14001 (Environmental Management) and compliance with local environmental regulations are becoming essential criteria for sourcing decisions. Buyers are encouraged to assess suppliers based on their sustainability credentials and their commitment to reducing their carbon footprint. This trend not only aligns with global sustainability goals but also enhances brand reputation and customer loyalty, making it a win-win for businesses committed to ethical sourcing.

Illustrative image related to carlton scale

What Is the Historical Context of Carlton Scale and Its Relevance Today?

Carlton Scale has a rich history dating back to 1933, establishing itself as a trusted provider of industrial weighing solutions. Over the decades, the company has expanded its offerings from traditional weighing instruments to advanced automation and data integration systems, adapting to the evolving needs of various industries. Significant acquisitions, such as those of ES, Inc. and Everest Scale, have bolstered Carlton Scale’s capabilities, positioning it as a leader in providing comprehensive solutions tailored to modern industrial challenges.

This historical context is relevant for B2B buyers as it underscores the company’s long-standing commitment to quality and innovation. Buyers can be assured of Carlton Scale’s expertise in navigating the complexities of industrial requirements, providing them with reliable solutions that enhance operational efficiency and safety. As the market continues to evolve, Carlton Scale’s legacy of excellence remains a cornerstone for businesses looking to invest in durable and effective weighing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of carlton scale

-

How do I solve issues with the calibration of my Carlton Scale?

To address calibration issues, first, ensure that your scale is placed on a stable, level surface free from vibrations. Regularly scheduled maintenance is essential, so consult Carlton Scale’s calibration services, which involve comparing your scale against known standards. If discrepancies are found, adjustments can be made to restore accuracy. For ongoing reliability, consider implementing a calibration schedule based on your specific operational needs. Additionally, Carlton Scale offers training for staff to recognize and resolve common calibration problems. -

What is the best type of scale for industrial applications?

The best type of scale for industrial applications depends on your specific needs. For heavy-duty environments, floor scales or platform scales are ideal for weighing large items. Analytical balances are perfect for precision measurements in laboratories. If your operations involve moving products, in-motion check weighers are highly effective. Carlton Scale provides a diverse range of options, and consulting their experts can help determine the best fit based on factors like load capacity, environment, and required accuracy. -

What customization options are available for Carlton Scales?

Carlton Scale offers extensive customization options to meet diverse industrial needs. This includes tailored software integration for data collection, custom weight measurement systems, and specific configurations for unique operational requirements. Buyers can work with Carlton’s engineering team to design solutions that enhance workflow efficiency and data accuracy. Discuss your specific needs during the inquiry phase to ensure that the custom features align with your operational goals. -

What are the minimum order quantities (MOQ) for Carlton Scales?

Minimum order quantities (MOQ) can vary based on the type of equipment and specific agreements. Carlton Scale typically works with businesses to establish MOQs that suit both parties, especially for bulk orders of standard products. For customized solutions, MOQs may differ based on the complexity and materials involved. It’s advisable to engage with a Carlton Scale representative to discuss your requirements and negotiate terms that work for your business. -

What payment terms does Carlton Scale offer for international buyers?

Carlton Scale offers flexible payment terms tailored for international buyers, which may include options such as advance payment, letters of credit, or net terms based on the buyer’s creditworthiness. It’s essential to discuss payment preferences upfront during negotiations to ensure a smooth transaction process. Additionally, understanding currency exchange rates and potential tariffs is crucial for accurate budgeting in international purchases. -

How does Carlton Scale ensure quality assurance for its products?

Quality assurance at Carlton Scale is maintained through rigorous testing and calibration of all products before they reach the customer. They employ standard operating procedures that comply with international quality standards, ensuring that every scale and system meets stringent performance metrics. Regular audits and feedback loops from clients help refine processes. Buyers can request quality certifications and detailed reports to validate the reliability of their purchased equipment. -

What logistics support does Carlton Scale provide for international shipping?

Carlton Scale understands the complexities of international shipping and offers logistics support to facilitate smooth delivery. They can assist with documentation, customs clearance, and selecting reliable shipping partners. It’s advisable to discuss logistics during the order process to align on timelines, costs, and shipping methods that best suit your operational needs. They also provide tracking services to keep you informed throughout the shipping process. -

What training does Carlton Scale offer for using their equipment?

Carlton Scale provides comprehensive training programs to ensure that users can operate their equipment safely and effectively. Training sessions cover proper handling, maintenance, and troubleshooting techniques tailored to specific equipment types. These programs can be conducted on-site or virtually, depending on your location and preferences. Investing in training not only enhances safety but also maximizes the operational efficiency of your weighing systems, leading to improved productivity.

Top 5 Carlton Scale Manufacturers & Suppliers List

1. Carlton Scale – Industrial Weighing Solutions

Domain: carltonscale.com

Registered: 1997 (28 years)

Introduction: Carlton Scale offers a range of industrial weighing and measuring services including batching, check weighing, counting, data communication, filling, formulation, general weighing, hazardous area weighing, in-motion weighing, laboratory quality control, tank/hopper/silo/vessel validation, and vehicle weighing. Their product lineup includes accessories, balances, bench/portable scales, bulk weighin…

2. Carlton Scale – Weighing Instruments

Domain: scalemanufacturers.com

Registered: 2006 (19 years)

Introduction: Carlton Scale sells, services, and calibrates all types of weighing instruments, scales, and controls. Their product line includes analytical balances, railroad track scales, and customized weighing systems. They also offer in-motion check weighers, data collection and transfer, PLCs, and custom software. Key product categories include balance scales, bench scales, digital scales, electronic scale…

3. Carlton Industrial Solutions – Tailored Weighing Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Carlton Industrial Solutions – Tailored Weighing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Carlton Industrial Solutions – Weighing & Automation Solutions

Domain: carltonindustrialsolutions.com

Registered: 2022 (3 years)

Introduction: Industrial Weighing, Automation, Crane & Hoist, Precision Safety, Operator Training

5. Carlton Scale – Tank Weighing Solutions

Domain: mgnewell.com

Registered: 1998 (27 years)

Introduction: Carlton Scale is designed for tank weighing applications, featuring attached pipes that differentiate it from platform scales. The scale deflects downwards under load, affecting sensitivity due to the upward force from the attached pipes. Proper calibration is crucial for accurate metrology, ideally using test weights to simulate normal operation, although this can be challenging and costly. The R…

Strategic Sourcing Conclusion and Outlook for carlton scale

In the evolving landscape of industrial solutions, Carlton Scale stands out as a trusted partner for businesses seeking reliable weighing and measurement services. With a comprehensive portfolio that includes calibration, automation, and tailored training, Carlton Scale addresses the diverse needs of sectors ranging from food and beverage to pharmaceuticals and chemicals. The strategic acquisitions of companies like ES, Inc. and Everest Scale, Inc. further enhance its capabilities, ensuring clients benefit from cutting-edge technology and expert support.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the value of strategic sourcing with Carlton Scale cannot be overstated. By integrating advanced weighing solutions into their operations, businesses can improve efficiency, maintain compliance, and enhance product quality. As global supply chains become increasingly interconnected, partnering with a reliable provider like Carlton Scale will be essential for sustaining competitive advantages.

Looking forward, now is the time for businesses to leverage Carlton Scale’s expertise to drive innovation and operational excellence. Engage with Carlton Scale today to explore how their solutions can transform your weighing and measurement processes, ensuring you stay ahead in a dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to carlton scale