Quartz Optics: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for quartz optics

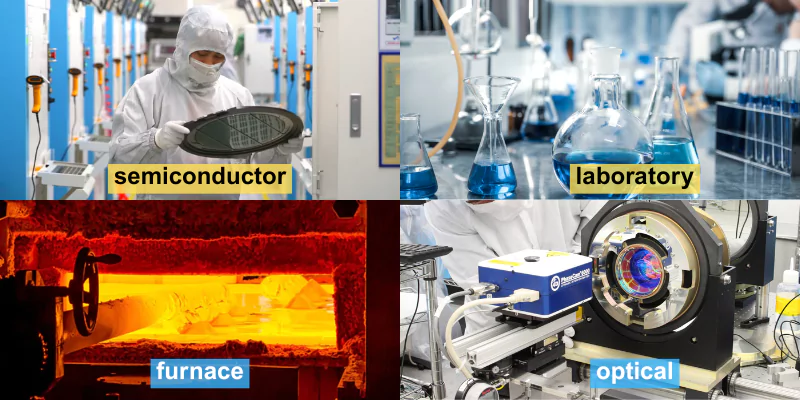

As international B2B buyers navigate the complexities of sourcing quartz optics, the challenge lies in identifying high-quality materials that meet stringent performance criteria. Quartz optics, known for their exceptional purity and thermal stability, play a critical role in various industries, from aerospace to semiconductor manufacturing. This guide serves as an essential resource, offering a comprehensive overview of the different types of quartz optical materials, their applications, and the factors to consider when selecting suppliers.

In this guide, you will explore various quartz optics products, including fused quartz, crystal quartz, and specialized variants like ITO coated quartz. We will delve into their unique properties, such as high UV transparency, low thermal expansion, and robust temperature resistance, which are crucial for applications requiring precision and reliability. Additionally, we will discuss effective strategies for vetting suppliers, understanding pricing structures, and evaluating product specifications to ensure your purchasing decisions align with your operational needs.

By equipping you with actionable insights and expert knowledge, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—to make informed decisions. Whether you are involved in manufacturing, research, or technology development, understanding the global landscape of quartz optics will enhance your procurement strategies and strengthen your competitive edge.

Understanding quartz optics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Quartz | High purity, excellent UV transmission, thermal stability | Laser optics, semiconductor fabrication | Pros: High performance; Cons: Higher cost than standard glass |

| Synthetic Quartz Glass | Manufactured for specific optical properties | Aerospace, medical devices | Pros: Customizable; Cons: Potentially longer lead times |

| Crystal Quartz | Single crystal structure, low fluorescence | Precision optics, scientific instruments | Pros: Superior optical clarity; Cons: Fragility in handling |

| ITO Coated Fused Quartz | Conductive coating for specific applications | Electronics, solar applications | Pros: Enhanced functionality; Cons: More complex manufacturing |

| IR Fused Quartz | Optimized for infrared applications, high thermal resistance | Thermal imaging, spectroscopy | Pros: Excellent IR transmission; Cons: Limited UV transmission |

What are the Characteristics of Fused Quartz and Its Applications?

Fused quartz is known for its high purity and outstanding thermal and chemical stability, making it ideal for applications where UV light transmission is critical. Its ability to withstand high temperatures without deformation makes it suitable for laser optics and semiconductor fabrication. B2B buyers should consider the performance requirements of their applications, as fused quartz tends to be more expensive than conventional glass but offers superior reliability.

How Does Synthetic Quartz Glass Differ in Its Suitability?

Synthetic quartz glass is manufactured to achieve specific optical properties, including exceptional UV transmission and low thermal expansion. This material is commonly utilized in aerospace and medical devices, where precision and reliability are paramount. Buyers should evaluate the customization options available, as these can impact lead times and costs, but the result is often a tailored solution that meets exacting standards.

What Makes Crystal Quartz a Preferred Choice for Precision Optics?

Crystal quartz is characterized by its single crystal structure, which provides low fluorescence and high optical clarity. This material is particularly beneficial in scientific instruments and precision optics. For B2B buyers, the key considerations include the fragility of crystal quartz and the need for careful handling during installation and use. The investment in crystal quartz typically pays off in terms of performance and durability.

What Are the Benefits of ITO Coated Fused Quartz?

ITO (Indium Tin Oxide) coated fused quartz combines the high-performance attributes of fused quartz with a conductive coating, making it suitable for electronic applications and solar technologies. This coating enhances the functionality of devices, enabling better performance in applications such as touch screens and photovoltaic cells. Buyers should weigh the benefits of enhanced functionality against the more complex manufacturing processes and associated costs.

Why Choose IR Fused Quartz for Infrared Applications?

IR fused quartz is specifically designed to optimize transmission in the infrared spectrum while maintaining high thermal resistance. It is extensively used in thermal imaging and spectroscopy applications where infrared light is crucial. For B2B buyers, the advantages include exceptional IR performance, though they should note the limitations in UV transmission, which may affect certain applications. Understanding the specific needs of the application will guide buyers in selecting the appropriate material.

Key Industrial Applications of quartz optics

| Industry/Sector | Specific Application of quartz optics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Optical components for satellite systems | Enhanced reliability and performance in extreme conditions | Need for high-quality, UV-transmissive quartz; compliance with aerospace standards |

| Semiconductor Fabrication | Lenses and windows for photolithography equipment | Precision in microchip manufacturing; improved yield rates | Specifications for purity and thermal stability; tailored dimensions for equipment compatibility |

| Medical Devices | Quartz windows for laser surgical instruments | High durability and optical clarity; improved patient outcomes | Focus on biocompatibility and resistance to sterilization processes |

| Telecommunications | Fiber optic components for communication systems | High-speed data transmission and reduced signal loss | Requirements for low thermal expansion and high UV transmission; sourcing from reliable suppliers |

| Solar Energy | Quartz optics in solar concentrators | Increased energy efficiency and output from solar installations | Specifications for high thermal resistance and optical clarity; availability in bulk for large-scale projects |

How is Quartz Optics Used in Aerospace Applications?

In the aerospace industry, quartz optics are critical for satellite systems and avionics. These optical components must withstand extreme environmental conditions while maintaining high performance. Quartz is favored for its exceptional UV transmission and thermal stability, which are essential for reliable operation in space. Buyers in this sector need to ensure that the quartz optics meet stringent aerospace standards and are sourced from reputable suppliers that can provide documentation of quality and performance.

What Role Does Quartz Optics Play in Semiconductor Fabrication?

Quartz optics are integral to the semiconductor fabrication process, particularly in photolithography equipment. The lenses and windows made from quartz provide the precision needed for microchip manufacturing, enabling high-resolution patterning. The purity and thermal stability of quartz help improve yield rates by minimizing defects during production. International buyers should prioritize sourcing quartz optics that meet specific purity standards and dimensions tailored to their equipment to ensure compatibility.

How Are Quartz Windows Used in Medical Devices?

In the medical field, quartz windows are utilized in laser surgical instruments, where optical clarity and durability are paramount. These components must withstand repeated sterilization while maintaining their integrity and performance. Quartz’s biocompatibility and resistance to thermal shock make it an ideal material for these applications. Buyers in the medical sector should focus on suppliers that can guarantee the biocompatibility and optical quality of their quartz optics, ensuring they meet health regulations.

Why Are Quartz Optics Important in Telecommunications?

Quartz optics are essential in the telecommunications industry, particularly for fiber optic components that facilitate high-speed data transmission. The low thermal expansion and high UV transmission of quartz contribute to reduced signal loss and enhanced performance. Businesses sourcing quartz optics for this application must consider the specific requirements for thermal stability and optical clarity, ensuring that the materials can withstand the rigors of extensive use in communication systems.

How Does Quartz Optics Enhance Solar Energy Solutions?

In the solar energy sector, quartz optics are used in solar concentrators to improve energy efficiency. The high thermal resistance and optical clarity of quartz allow for effective concentration of sunlight, maximizing energy output from solar installations. Buyers in this industry should look for quartz optics that meet specific thermal and optical requirements, and consider sourcing in bulk to accommodate large-scale projects, ensuring consistent performance across installations.

3 Common User Pain Points for ‘quartz optics’ & Their Solutions

Scenario 1: Ensuring High Optical Clarity in High-Temperature Environments

The Problem: B2B buyers often face the challenge of sourcing quartz optics that can maintain high optical clarity and performance under extreme temperatures. Industries such as aerospace, semiconductor fabrication, and laser manufacturing require optical materials that can withstand harsh environments without degrading. Buyers may experience frustration when traditional optical materials fail, leading to increased downtime and compromised product quality.

The Solution: To address this issue, it is crucial to specify quartz optics with high thermal stability and low thermal expansion coefficients. Buyers should prioritize sourcing fused quartz or synthetic quartz glass specifically designed for high-temperature applications. When placing orders, ensure that the supplier provides detailed specifications regarding the temperature resistance and optical transmission properties of the materials. Additionally, conducting pre-purchase testing, such as thermal shock resistance evaluations, can help ensure that the chosen quartz optics will meet performance expectations in demanding settings.

Scenario 2: Navigating Complex Supply Chain Challenges

The Problem: International B2B buyers often encounter complexities in the supply chain when sourcing quartz optics, especially when dealing with suppliers from different regions. Delays in delivery, inconsistent quality, and communication barriers can lead to project setbacks and increased costs. Buyers may feel overwhelmed by the need to balance quality, price, and timely delivery, which can result in lost opportunities in competitive markets.

The Solution: To mitigate supply chain challenges, buyers should establish strong relationships with reliable suppliers who have a proven track record in the quartz optics industry. Engaging with suppliers that offer comprehensive product documentation and quality assurance processes can enhance trust and reliability. Additionally, consider diversifying the supplier base across regions, which can provide alternatives in case of disruptions. Employing a robust vendor management system can also streamline communication and tracking, ensuring that all parties are aligned on delivery timelines and quality standards.

Scenario 3: Customization Needs for Specialized Applications

The Problem: Many B2B buyers require customized quartz optics for specialized applications, such as UV filtering or specific geometrical configurations for lenses and prisms. However, suppliers may not always provide the necessary customization options, leading to dissatisfaction and unmet operational requirements. This limitation can result in compromised performance in critical applications, ultimately affecting the end product’s quality.

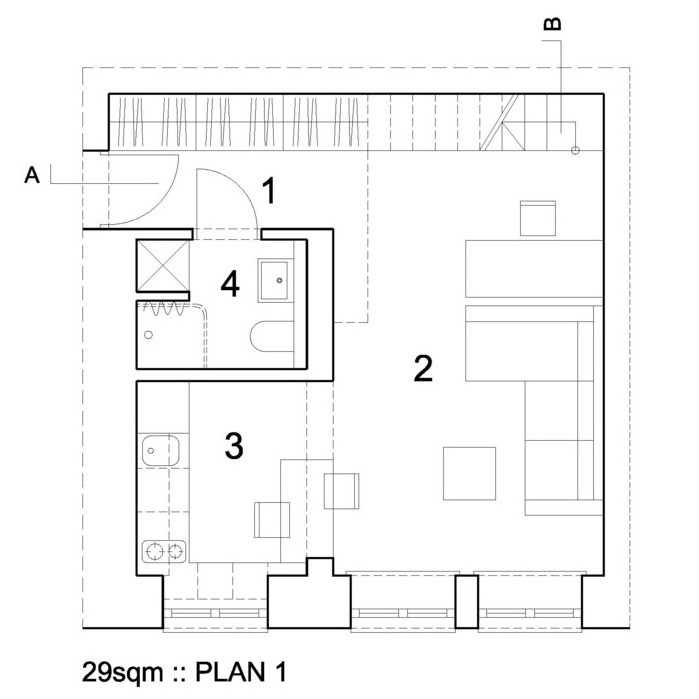

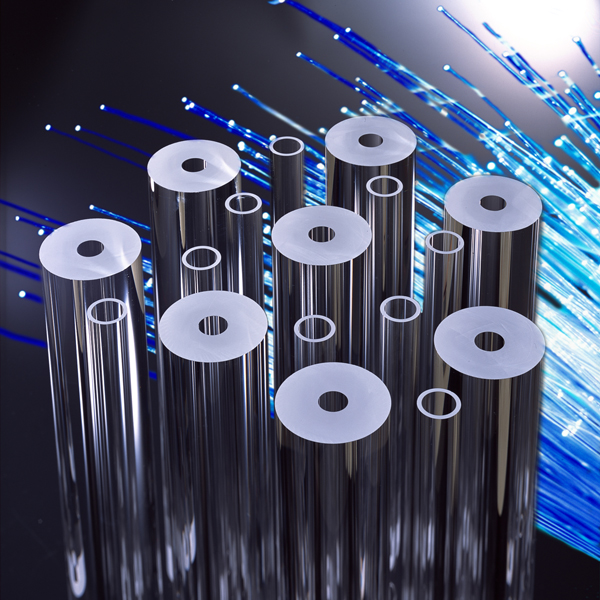

Illustrative image related to quartz optics

The Solution: To overcome customization challenges, buyers should work closely with manufacturers that specialize in bespoke quartz optical solutions. When approaching suppliers, clearly articulate the specific requirements, including dimensions, coatings, and performance characteristics. Requesting prototypes or samples before placing larger orders can help validate that the product meets the desired specifications. Furthermore, consider collaborating with engineering teams to refine designs before final production, ensuring that the custom optics will function optimally in their intended applications. Engaging in early-stage discussions about design requirements can lead to more innovative and effective solutions tailored to unique business needs.

Strategic Material Selection Guide for quartz optics

What Are the Key Properties of Fused Quartz in Optical Applications?

Fused quartz is a synthetic material made from high-purity silica, known for its excellent optical transmission across a wide spectrum, particularly in the ultraviolet range. One of its standout properties is its low coefficient of thermal expansion (CTE), which allows it to maintain dimensional stability under temperature fluctuations. Additionally, fused quartz exhibits remarkable thermal shock resistance, making it suitable for high-temperature applications, such as in semiconductor manufacturing and laser optics.

Pros and Cons: The durability of fused quartz is a significant advantage; it can withstand harsh environments without degrading. However, the manufacturing process can be complex and costly, which may impact the overall pricing for end-users. Fused quartz is best suited for applications requiring high optical clarity and stability, but its cost may be a limiting factor for budget-sensitive projects.

Impact on Application: In applications involving lasers or UV light, the purity and transmission capabilities of fused quartz are critical. Its compatibility with various media makes it a preferred choice in industries such as electronics and aerospace.

How Does IR Fused Quartz Compare in Optical Performance?

IR fused quartz is specifically designed for infrared applications, offering high transmission in the IR spectrum while maintaining the excellent thermal and chemical stability characteristic of standard fused quartz. This material is particularly useful in environments where high temperatures and corrosive conditions are present.

Pros and Cons: The primary advantage of IR fused quartz is its tailored optical properties for IR applications, making it indispensable in thermal imaging and spectroscopy. However, its specialized nature can drive up costs compared to standard quartz options, and it may not be suitable for applications outside its intended spectrum.

Impact on Application: The performance of IR fused quartz is crucial in sectors such as solar energy and environmental monitoring, where precise measurements in the infrared range are necessary. Buyers need to consider compatibility with existing systems and potential regulatory requirements in their regions.

What Advantages Does Heraeus Herasil Offer for Optical Applications?

Heraeus Herasil is a high-quality fused quartz material known for its exceptional purity and low fluorescence. It is often used in demanding optical applications, such as high-energy laser systems and precision optics.

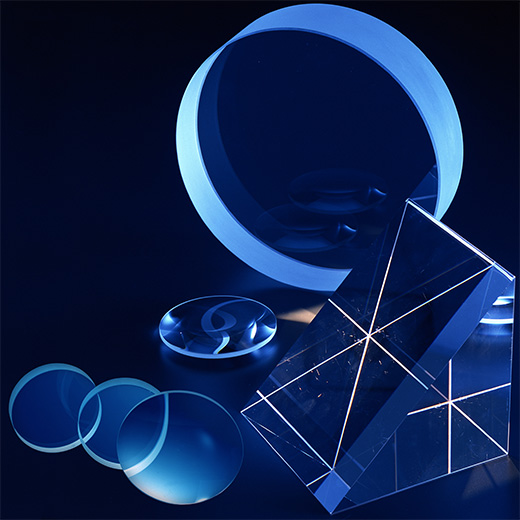

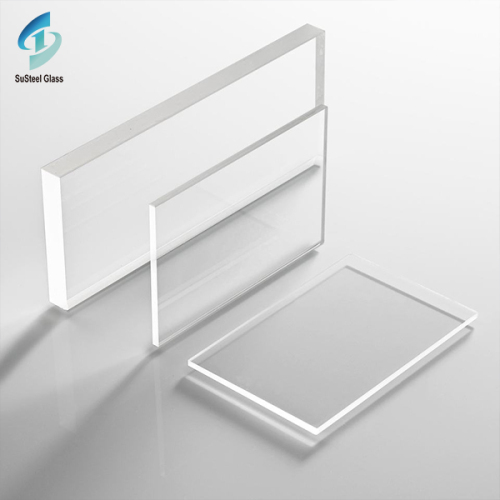

Illustrative image related to quartz optics

Pros and Cons: The key advantage of Heraeus Herasil is its superior optical clarity and minimal impurities, which enhance performance in high-precision applications. However, the cost of Heraeus Herasil can be significantly higher than that of commercial-grade quartz, which may deter some buyers.

Impact on Application: The high purity of Heraeus Herasil makes it an ideal choice for applications requiring minimal light scattering, such as in scientific research and high-tech industries. Compliance with international standards for optical materials is crucial, particularly for buyers in Europe and North America.

What Should International Buyers Consider When Selecting Z-Cut Quartz?

Z-cut quartz is a specific crystallographic orientation that enhances certain optical properties, particularly in applications involving wavefront manipulation and frequency doubling. Its unique properties make it suitable for various optical devices, including filters and waveguides.

Pros and Cons: The advantage of Z-cut quartz lies in its ability to provide specific optical characteristics that are not achievable with other orientations. However, sourcing Z-cut quartz may be more challenging due to its specialized nature, and it may involve longer lead times and higher costs.

Impact on Application: Buyers must consider the specific requirements of their applications, as well as any regional compliance standards that may apply. For instance, in Germany, adherence to DIN standards is essential, while buyers in Africa may need to navigate different regulatory landscapes.

Summary Table of Quartz Optical Materials

| Material | Typical Use Case for quartz optics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Quartz | Semiconductor manufacturing, laser optics | Excellent thermal shock resistance | High manufacturing complexity | High |

| IR Fused Quartz | Thermal imaging, spectroscopy | Tailored for infrared applications | Higher cost due to specialized properties | High |

| Heraeus Herasil | High-energy laser systems, precision optics | Superior purity and low fluorescence | Significantly higher cost than alternatives | High |

| Z-Cut Quartz | Optical filters, waveguides | Enhanced specific optical characteristics | Sourcing challenges and longer lead times | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions tailored to their specific optical application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for quartz optics

What Are the Main Stages of Manufacturing Quartz Optics?

The manufacturing of quartz optics involves several key stages that ensure the production of high-quality optical components. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Quartz Optics Raw Material Processed?

The first step in manufacturing quartz optics is the preparation of raw materials. High-purity silica sand is sourced, which can be either natural or synthetic. For synthetic quartz, a process known as the “fused quartz” method is employed, where silica is melted at high temperatures and then cooled to form a solid glass. This step is crucial as impurities can significantly affect the optical properties of the finished product.

After obtaining the raw material, it undergoes a thorough cleaning process to remove any contaminants. This may involve chemical washes and high-temperature treatments to achieve the desired level of purity. Quality assurance begins at this stage, as the quality of the raw material directly impacts the final optical characteristics.

How Are Quartz Optics Formed?

Once the raw material is prepared, the next phase is forming. This can involve several techniques, including:

- Casting: Molten quartz is poured into molds to create specific shapes, such as lenses or windows.

- Machining: For precise dimensions, quartz pieces are machined using diamond tools. This step is critical for achieving the necessary optical tolerances and surface finishes.

- Grinding and Polishing: After shaping, optical components are ground and polished to achieve the required surface quality and flatness. This process often involves multi-stage grinding and polishing to ensure minimal wavefront distortion, which is vital for optical performance.

What Quality Control Measures Are Necessary in Quartz Optics Manufacturing?

Quality control (QC) in the manufacturing of quartz optics is essential for ensuring that the final products meet international standards and customer specifications. Several key QC measures are typically implemented throughout the manufacturing process.

What International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which outlines quality management principles, and CE marking, which indicates compliance with EU safety and environmental requirements. Other industry-specific standards may include:

Illustrative image related to quartz optics

- API Standards: For optics used in the oil and gas industry.

- ASTM Standards: For testing and material specifications.

These standards ensure that products are consistently manufactured to high-quality levels, providing buyers with the assurance that they are sourcing reliable components.

What Are the Key Quality Control Checkpoints?

Effective QC processes involve several checkpoints throughout the manufacturing stages:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components before they enter the production line. Suppliers should provide certificates of compliance or test reports to verify material quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct routine checks to monitor the quality of the production. This includes dimensional checks, surface quality assessments, and optical performance evaluations.

-

Final Quality Control (FQC): Before shipping, finished products undergo a thorough inspection to ensure they meet all specifications. This includes testing for optical clarity, dimensional accuracy, and surface imperfections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing quartz optics, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some effective strategies:

What Should Buyers Look for in Supplier Audits and Reports?

-

Supplier Audits: Conducting or requesting audits of the manufacturing facility can provide insights into the supplier’s QC processes, equipment, and staff qualifications. Look for ISO certification and any other relevant industry certifications.

-

Test Reports and Certificates: Suppliers should provide detailed reports on material testing and performance evaluations. This documentation should include data on refractive index, transmission rates, and surface quality metrics.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality management system. Independent inspectors can verify compliance with international standards, ensuring that the products meet your specific requirements. This is especially crucial for international buyers from regions like Africa, South America, and the Middle East, where local regulations may vary.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control that can impact their procurement process. Understanding regional standards and requirements is essential to ensure compliance and avoid costly delays.

How Do Regional Regulations Affect Quality Assurance?

For instance, buyers in the European market must comply with CE marking requirements, while those in South America may encounter different local standards. It’s advisable to familiarize yourself with the regulatory landscape in your target market, as non-compliance can lead to significant setbacks.

What Role Does Language and Communication Play?

Language barriers can pose challenges in understanding quality documentation and specifications. Engaging with suppliers who can provide documentation in your preferred language or using translation services can mitigate misunderstandings and ensure clarity in quality expectations.

Conclusion: Ensuring Quality in Quartz Optics Sourcing

In summary, the manufacturing processes and quality assurance measures for quartz optics are critical to delivering high-performance optical components. By understanding the key stages of production, relevant international standards, and effective QC practices, B2B buyers can make informed decisions when sourcing quartz optics. Proactive engagement with suppliers through audits, verification of quality reports, and awareness of regional regulations can further enhance the sourcing experience, ensuring that the final products meet both industry standards and specific application needs.

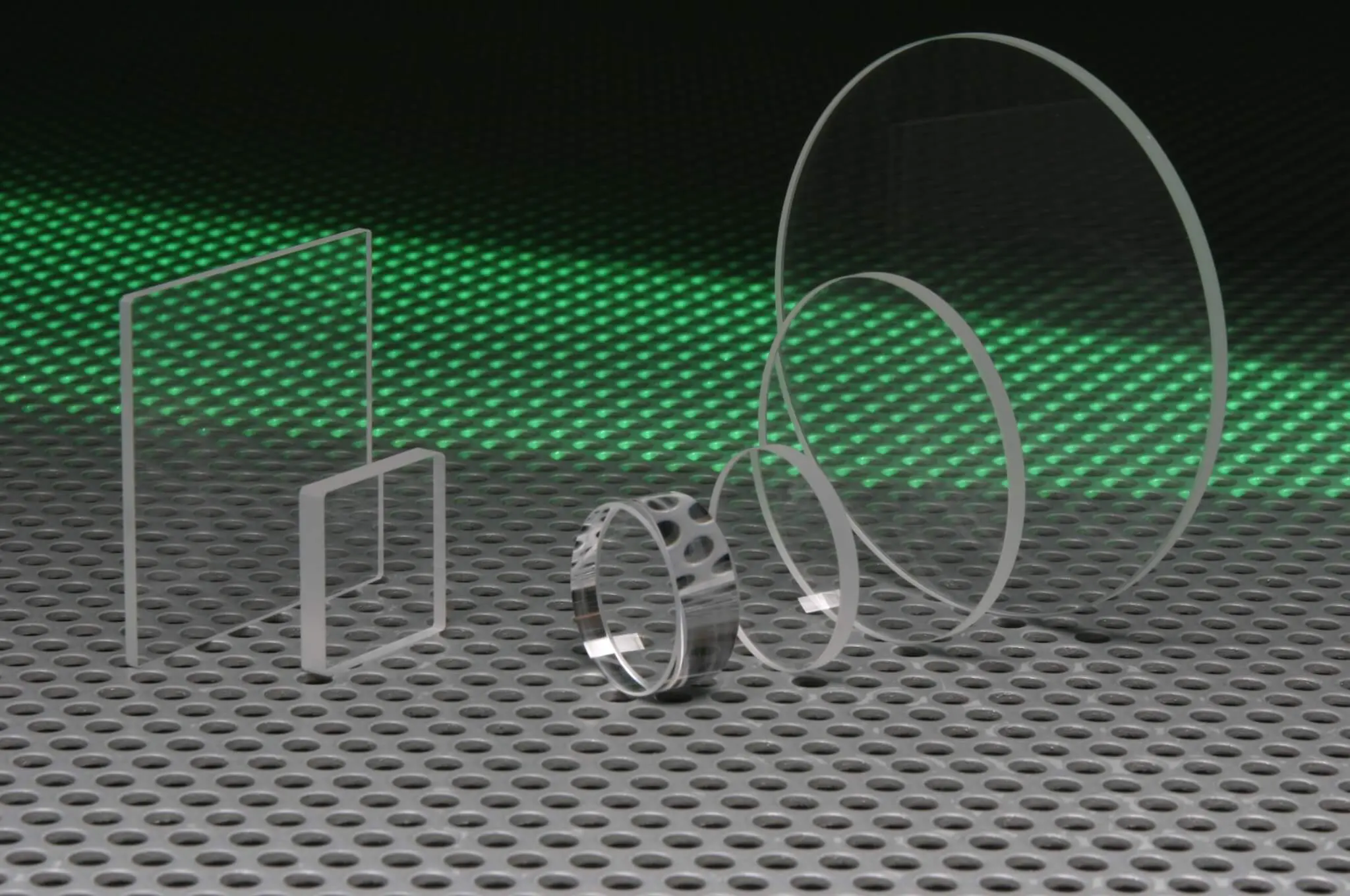

Illustrative image related to quartz optics

Practical Sourcing Guide: A Step-by-Step Checklist for ‘quartz optics’

Introduction

This sourcing guide provides a structured approach for B2B buyers looking to procure quartz optics. Quartz optics are essential in various high-tech applications due to their superior thermal and chemical stability, as well as their excellent transmission properties across a wide spectrum. Following this checklist will ensure that you make informed decisions, minimize risks, and achieve optimal performance for your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes dimensions, optical clarity, transmission wavelength ranges, and thermal resistance. Be specific about the application—whether it’s for lasers, prisms, or windows—as each requires different material properties.

- Considerations:

- Understand the operating environment (temperature, exposure to chemicals).

- Determine if you need natural or synthetic quartz, as their properties differ.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in quartz optics. Look for companies with a proven track record and experience in your specific industry applications.

- Key actions:

- Use industry directories and trade shows to find suppliers.

- Check online reviews and testimonials from other B2B clients.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that ensure quality and compliance with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management.

- What to look for:

- Ask for documentation proving their adherence to quality assurance processes.

- Ensure they have certifications relevant to your industry (e.g., aerospace, electronics).

Step 4: Request Samples and Specifications

Once you’ve narrowed down your list, request samples of the quartz optics you intend to buy. This allows you to assess the quality and suitability of the products for your specific applications.

Illustrative image related to quartz optics

- Sample evaluation:

- Inspect for clarity, surface quality, and any defects.

- Test under your actual operating conditions if possible.

Step 5: Compare Pricing and Terms

Gather pricing information from multiple suppliers and compare it against the quality and specifications offered. Be cautious of prices that seem too low, as they may reflect lower quality.

- Considerations:

- Assess payment terms, delivery timelines, and warranty conditions.

- Understand the total cost of ownership, including potential shipping and customs fees.

Step 6: Negotiate and Confirm Orders

Engage in negotiations with your selected supplier(s) to finalize pricing and terms. Ensure that all your requirements are clearly documented in the contract to avoid misunderstandings.

- Important points:

- Clarify return policies in case the delivered products do not meet specifications.

- Establish a clear timeline for delivery and inspection upon receipt.

Step 7: Establish a Long-Term Relationship

After completing your initial procurement, consider developing a long-term partnership with your chosen supplier. This can lead to better pricing, improved service, and priority support in the future.

- Benefits of a strong relationship:

- Access to innovative products and technologies.

- Streamlined communication and faster response times for future orders.

By following this checklist, B2B buyers can efficiently navigate the procurement process for quartz optics, ensuring that they secure high-quality materials tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for quartz optics Sourcing

What are the Key Cost Components in Quartz Optics Sourcing?

When considering the procurement of quartz optics, understanding the cost structure is essential. The main components influencing pricing include:

-

Materials: The quality and type of quartz (natural vs. synthetic) significantly impact costs. High-purity materials, such as UV-grade quartz, command higher prices due to their specialized applications in sectors like aerospace and electronics.

-

Labor: Skilled labor is required for precise cutting, polishing, and finishing of quartz optics. Labor costs vary by region; for instance, manufacturing in Europe may have higher labor costs compared to South America or Africa, where wage structures differ.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient production processes can help in keeping these costs low, which is crucial for competitive pricing.

-

Tooling: Investment in specialized tooling for custom shapes or sizes can be substantial. Buyers should consider whether standardized products will suffice or if unique specifications will warrant higher tooling costs.

-

Quality Control (QC): Rigorous QC processes ensure that the optics meet required standards, which can add to costs. Products with certifications (like ISO or specific industry-related standards) may be priced higher but offer assurance of quality.

-

Logistics: Transportation costs vary significantly based on distance, shipping methods, and the chosen Incoterms. These costs can add a substantial amount to the total price, especially for international shipments.

-

Margin: Suppliers typically include a margin that reflects their business model, competitive positioning, and market conditions. Understanding market rates can help buyers gauge if the pricing is fair.

How Do Price Influencers Affect Quartz Optics Costs?

Several factors can influence the pricing of quartz optics significantly:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders can lead to bulk discounts, while small quantities may incur higher per-unit costs.

-

Specifications and Customization: Customized products often come with premium pricing. Buyers must balance the need for unique specifications against the potential for cost savings with standard items.

-

Materials and Quality Certifications: Higher quality or specialized materials, such as IR-grade quartz, increase costs. Products with recognized certifications may also carry a premium but can provide value through reliability and compliance.

-

Supplier Factors: Established suppliers with a track record of quality and service may charge higher prices than lesser-known entities. However, the former often provide better reliability and support.

-

Incoterms: The choice of Incoterms can greatly influence the final cost. Terms like FOB (Free on Board) can shift costs and responsibilities, affecting the total landed price.

What Tips Can Help Buyers Negotiate Better Prices for Quartz Optics?

-

Negotiate Volume Discounts: If possible, consolidate orders to meet or exceed MOQs for better pricing. Suppliers are often willing to negotiate on larger volumes.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the purchase, including shipping, duties, and potential future maintenance. A higher upfront cost may lead to lower TCO if the product is more durable or efficient.

-

Understand Pricing Nuances for International Transactions: Factors such as currency fluctuations, import duties, and local taxes can impact final costs. Buyers from regions like Africa and South America should be particularly vigilant about these factors.

-

Establish Long-term Relationships: Building a rapport with suppliers can lead to better pricing, priority service, and insights into upcoming deals or new product offerings.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs. This transparency can reveal areas where you can negotiate or identify unnecessary charges.

Disclaimer

The prices provided in this guide are indicative and can vary based on market conditions, supplier negotiations, and other external factors. Always conduct thorough research and consult multiple suppliers to ensure competitive pricing and quality.

Alternatives Analysis: Comparing quartz optics With Other Solutions

Exploring Alternatives to Quartz Optics: A Comparative Analysis

In the world of optics, quartz has established itself as a leading material due to its unique properties, such as high thermal stability and exceptional optical clarity. However, various alternatives exist that may serve different applications or meet specific buyer requirements. Understanding these options can help B2B buyers make informed decisions tailored to their operational needs.

| Comparison Aspect | Quartz Optics | Alternative 1: Fused Silica | Alternative 2: Optical Glass |

|---|---|---|---|

| Performance | Superior UV transmission; stable thermal properties. | Excellent UV transmission; lower thermal stability compared to quartz. | Good visible light transmission; limited UV and IR capabilities. |

| Cost | Higher cost due to purity and processing. | Generally lower cost than quartz. | Cost-effective; varies based on type and quality. |

| Ease of Implementation | Requires specialized handling and fabrication. | Easier to mold and shape; suitable for mass production. | Widely available and easy to process. |

| Maintenance | Minimal maintenance; high durability. | Low maintenance; less durable than quartz. | Moderate maintenance; can be prone to scratches. |

| Best Use Case | Precision applications like lasers, aerospace, and semiconductor fabrication. | Suitable for general optics and high-volume applications. | Ideal for consumer optics and low-cost applications. |

What Are the Advantages and Disadvantages of Fused Silica?

Fused silica is a synthetic glass made from silica that offers excellent optical properties, particularly in UV light transmission. Its primary advantage is its lower cost compared to quartz, making it an attractive option for high-volume applications. However, it lacks the thermal stability of quartz, which may limit its use in high-temperature environments. Fused silica is easier to mold and shape, allowing for faster production times and reduced costs, making it ideal for industries that prioritize cost-effectiveness over extreme performance.

Illustrative image related to quartz optics

How Does Optical Glass Compare to Quartz Optics?

Optical glass is another alternative that offers a good balance between performance and cost. While it provides decent visible light transmission, it falls short in UV and IR capabilities compared to quartz. Optical glass is typically more affordable, making it suitable for consumer optics and applications where extreme precision is not critical. However, its susceptibility to scratches and other environmental factors can necessitate more frequent maintenance, which may not be ideal for all applications.

How Should B2B Buyers Choose the Right Optical Solution?

When selecting an optical solution, B2B buyers should consider several factors, including the specific application, environmental conditions, budget constraints, and performance requirements. Quartz optics excel in high-stakes applications requiring precision and durability, while alternatives like fused silica and optical glass can be more suitable for cost-sensitive projects or less demanding environments. By aligning these factors with organizational goals and operational needs, buyers can make informed decisions that optimize both performance and cost efficiency.

Essential Technical Properties and Trade Terminology for quartz optics

What Are the Key Technical Properties of Quartz Optics?

When evaluating quartz optics for procurement, understanding specific technical properties is crucial for ensuring that products meet performance expectations. Here are some of the most critical specifications:

1. Material Grade

Material grade indicates the quality and purity of the quartz used. High-grade quartz, such as optical-grade single crystal quartz, offers superior transmission and minimal impurities. This is vital for applications in precision optics, as it directly affects performance in terms of clarity and durability.

2. Tolerance

Tolerance refers to the permissible limits of variation in dimensions and physical properties. In quartz optics, tight tolerances (e.g., ±0.01mm) are essential to ensure proper fit and function in optical systems. For B2B buyers, understanding tolerance levels is crucial when sourcing components that must integrate seamlessly into existing systems.

3. Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion describes how much a material expands or contracts with temperature changes. Quartz boasts a low CTE, making it highly resistant to thermal shock. This property is particularly important in industries such as aerospace and electronics, where components may experience rapid temperature fluctuations.

4. Surface Quality

Surface quality is a measure of the optical finish of quartz components. It is typically expressed in terms of scratch-dig specifications (e.g., 20-10, meaning 20 scratches and 10 digs per specified area). High surface quality is critical for minimizing light scattering and ensuring optimal transmission, making it a key consideration for optics in high-performance applications.

Illustrative image related to quartz optics

5. Flatness

Flatness indicates how much a surface deviates from perfect flatness, usually measured in waves at a specific wavelength (e.g., 1/4 wave). This specification is crucial for applications involving lenses and mirrors, where even minor deviations can lead to significant optical distortion.

6. Transmission Range

Transmission range specifies the wavelengths of light that can pass through quartz without significant absorption. Quartz optics typically have excellent transmission from UV to IR, making them suitable for a wide range of applications, from lasers to sensors.

What Are Common Trade Terms in the Quartz Optics Industry?

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify potential sources for custom quartz optics tailored to specific applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for businesses, particularly for smaller companies or projects that may not require large quantities, as it directly impacts inventory management and cost.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products. It is an important tool for buyers to obtain competitive pricing and evaluate supplier capabilities, ensuring they receive the best possible terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify responsibilities for shipping, insurance, and tariffs. Understanding Incoterms is crucial for international transactions, helping buyers and sellers navigate shipping logistics and costs.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. It is a critical factor for B2B buyers, as longer lead times can impact project timelines and operational efficiency.

6. Custom Fabrication

Custom fabrication refers to the process of producing quartz optics tailored to specific dimensions or properties. This term is significant for buyers seeking specialized components that meet unique application requirements, allowing for enhanced performance in niche markets.

Understanding these properties and terms is essential for B2B buyers in the quartz optics sector, enabling informed decision-making and effective supplier negotiations.

Illustrative image related to quartz optics

Navigating Market Dynamics and Sourcing Trends in the quartz optics Sector

What Are the Key Trends Driving the Quartz Optics Market?

The quartz optics market is currently experiencing dynamic shifts driven by technological advancements and increasing demand across various industries. Key factors include the rise of precision laser applications in sectors such as telecommunications, aerospace, and semiconductor manufacturing. The growing emphasis on miniaturization and high-performance materials has led to a surge in the demand for quartz optics, which offers superior thermal and chemical stability. Notably, regions like Africa and South America are seeing a burgeoning interest in quartz optics as industries modernize and seek reliable components for high-tech applications.

Emerging trends also indicate a growing integration of quartz optics in renewable energy technologies, particularly in solar applications, where high UV transmission is essential. Additionally, advancements in manufacturing processes, such as improved synthetic quartz production, are enhancing the availability and affordability of optical components. International buyers, particularly from Europe and the Middle East, are leveraging these advancements to source high-quality quartz products that meet stringent specifications for their industries.

How Important Is Sustainability and Ethical Sourcing in the Quartz Optics Sector?

Sustainability is increasingly becoming a cornerstone of sourcing strategies in the quartz optics sector. The environmental impact of mining and processing quartz materials necessitates a shift toward more sustainable practices. Ethical sourcing is critical, as companies are now expected to ensure that their supply chains minimize environmental degradation and adhere to social responsibility standards.

To address these concerns, many suppliers are obtaining certifications that signify adherence to sustainable practices. These certifications not only enhance the credibility of suppliers but also align with the growing consumer and regulatory demand for environmentally friendly products. For B2B buyers, prioritizing suppliers who demonstrate commitment to sustainability can foster stronger partnerships and enhance their brand reputation in the marketplace.

What Historical Developments Have Shaped the Quartz Optics Market?

The quartz optics market has evolved significantly over the decades, transitioning from natural quartz sourcing to advanced synthetic manufacturing techniques. Initially, natural quartz was the primary material used in optical applications; however, the need for higher purity and uniformity led to the development of synthetic quartz. This evolution not only increased availability but also improved the performance characteristics of quartz optics, making them indispensable in high-precision applications.

The introduction of laser technology in the late 20th century further propelled the demand for quartz optics, as industries sought materials that could withstand high thermal stress and provide excellent transmission across a wide spectrum. Today, the ongoing advancements in manufacturing processes and the rise of new applications continue to shape the quartz optics landscape, providing B2B buyers with an ever-expanding array of options to meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of quartz optics

-

How do I choose the right quartz optics for my application?

Selecting the right quartz optics requires a clear understanding of your specific application needs. Consider factors such as the wavelength range (UV to IR), thermal stability, and resistance to environmental factors. Assess the optical quality required—such as surface finish and flatness—and whether you need natural or synthetic quartz. Collaborate with suppliers to discuss your application to ensure the selected materials meet performance criteria. Don’t hesitate to request samples to test compatibility before making a large purchase. -

What are the advantages of using quartz optics over other materials?

Quartz optics offer several advantages, including high optical clarity, exceptional thermal and chemical stability, and low fluorescence. They have an outstanding transmission rate across UV, visible, and infrared wavelengths, making them ideal for precision applications in fields like aerospace, electronics, and laser technology. Additionally, quartz’s low coefficient of thermal expansion (CTE) ensures dimensional stability under varying temperatures, enhancing performance in high-temperature environments. -

What is the minimum order quantity (MOQ) for quartz optics?

Minimum order quantities for quartz optics can vary significantly depending on the supplier and the specific product type. Some manufacturers may offer flexible MOQs for standard items, while custom or specialized optics often require larger orders to justify production costs. It’s advisable to communicate your needs with potential suppliers to understand their MOQ policies and explore options for smaller orders if necessary. -

How can I ensure quality assurance when sourcing quartz optics internationally?

To ensure quality assurance, work with suppliers who have established quality control processes, including certifications such as ISO 9001. Request detailed specifications and compliance documentation for the quartz optics you intend to purchase. Additionally, consider conducting factory audits or requesting third-party inspections before shipment. Establishing clear communication with the supplier regarding quality standards and expectations will also help mitigate risks associated with international sourcing. -

What payment terms should I expect when purchasing quartz optics internationally?

Payment terms for international purchases of quartz optics typically include options such as advance payment, letters of credit, or payment upon receipt. Terms may vary based on the supplier’s policies, your relationship with them, and the size of the order. Always clarify payment terms upfront and consider negotiating favorable conditions, such as partial payments for large orders or extended payment periods, to maintain cash flow while ensuring timely delivery. -

How do I handle logistics and shipping for quartz optics?

Logistics for sourcing quartz optics internationally involves careful planning. Choose a reliable freight forwarder familiar with the nuances of shipping fragile optical materials. Discuss shipping methods, insurance coverage, and customs clearance procedures to avoid delays. Ensure that the supplier packages the optics securely to minimize the risk of damage during transit. It’s also wise to stay informed about import regulations in your country to facilitate smooth customs processing. -

Can I customize quartz optics to fit my specific application?

Yes, many suppliers offer customization options for quartz optics, including tailored dimensions, shapes, and coatings. When requesting custom optics, provide detailed specifications and performance requirements to the supplier. Be prepared for potential lead times, as custom orders may take longer to manufacture than standard products. Collaborating closely with the supplier during the design phase can help ensure that the final product meets your needs precisely. -

What industries commonly use quartz optics, and why?

Quartz optics are widely utilized across various industries, including aerospace, electronics, solar energy, and chemical processing. Their unique properties, such as high thermal resistance and excellent UV transmission, make them ideal for applications like high-power lasers, spectrometry, and semiconductor fabrication. Understanding the specific needs of your industry can help you identify the right quartz optical products and leverage their advantages effectively in your operations.

Top 8 Quartz Optics Manufacturers & Suppliers List

1. UQG Optics – Quartz Optical Materials

Domain: uqgoptics.com

Registered: 2001 (24 years)

Introduction: Quartz is a highly valued optical material known for its purity and exceptional thermal and chemical stability. It offers excellent transmission from the ultraviolet to the infrared spectrum, making it essential for high-temperature resistance and optical clarity applications. Quartz is used in the production of lenses, windows, and prisms for precision laser instruments and semiconductor fabricat…

2. Earth Water Fire – Synthetic Quartz for Optical Applications

Domain: earthwaterfire.com

Registered: 1999 (26 years)

Introduction: Quartz in optical applications is a synthetic molten, amorphous quartz glass (SiO2) known for its high optical transmissivity for ultraviolet light and low coefficient of thermal expansion. Key advantages include resistance to high operating temperatures, exceptional UV-light transparency, high temperature shock resistivity, pure material quality, and low fluorescence. Typical applications include…

3. Meller Optics – Crystal Quartz

Domain: melleroptics.com

Registered: 1999 (26 years)

Introduction: This company, Meller Optics – Crystal Quartz, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Esco Optics – Plano-Convex Lenses

Domain: escooptics.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Plano-Convex Lenses, G1 Commercial Grade Fused Quartz”, “Specifications”: {“Focal Length Tolerance”: “+/- 3%”, “Diameter Tolerance”: “+/- 0.125 mm”, “Thickness Tolerance”: “+/- 0.5 mm”, “Design Wavelength”: “546 nm”, “Centration”: “<3′”, “Surface Quality”: “60-40 scratch-dig”, “Edges”: “Fine ground and beveled”}, “Esco PN”: {“12.7 / 25.4”: “$39.60 USD”, “12.7 / 50.8”: “$34.10 USD…

5. MSD Optics – Quartz Glass Solutions

Domain: msd-optics.com

Registered: 2020 (5 years)

Introduction: Quartz glass is categorized into two main types: Fused Quartz (produced from natural quartz sand or quartz crystal through electric fusion) and Fused Silica (synthesized from chemical precursors like SiCl₄ using flame fusion or the soot process). Key properties include high optical purity, thermal stability, excellent chemical resistance, superior laser resistance, and versatility in design. Typic…

6. PGO Online – High-Purity Quartz Glass for Optics

Domain: pgo-online.com

Registered: 2000 (25 years)

Introduction: This company, PGO Online – High-Purity Quartz Glass for Optics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Tydex Optics – Fused Quartz and Fused Silica

Domain: tydexoptics.com

Registered: 2009 (16 years)

Introduction: Fused Quartz and Fused Silica are types of Quartz Glass containing primarily silica in amorphous form. Fused Quartz is made by melting high purity naturally occurring quartz crystals at around 2000°C, resulting in a normally transparent material. Fused Silica is produced using high purity silica sand, typically melted in an electric furnace, leading to a translucent or opaque material due to small…

8. Knight Optical – IR Fused Quartz Windows

Domain: knightoptical.com

Registered: 2007 (18 years)

Introduction: Product: IR Fused Quartz Windows (JGS3)\nMaterial: IR fused quartz (JGS3)\nTransmission Range: 260nm to 3500nm\nWater Content: Less than 5 parts per million (OH)\nFlatness: <λ/2 (over 90% of diameter)\nSurface Quality: <40-20 scratch/dig\nParallelism: <1 arc minute\nCoating Options: Uncoated or AR coating for increased transmission performance\nTypical Processes: Edging, CNC shaping, water jet cut…

Strategic Sourcing Conclusion and Outlook for quartz optics

In the evolving landscape of quartz optics, strategic sourcing emerges as a pivotal factor for international B2B buyers aiming to leverage the material’s unique properties. With its unmatched thermal stability, high UV transmission, and exceptional optical clarity, quartz optics cater to a diverse array of industries, from aerospace to electronics. By aligning sourcing strategies with reliable suppliers, businesses can ensure quality and consistency, ultimately enhancing their operational efficiency and product performance.

Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that offer both natural and synthetic quartz options, tailored to specific applications. This approach not only mitigates supply chain risks but also provides access to cutting-edge innovations in optical technology.

Looking ahead, the demand for quartz optics is set to grow, driven by advancements in technology and an increasing need for high-performance materials. Now is the time for businesses to invest in strategic sourcing initiatives that will position them at the forefront of this dynamic market. Engage with trusted suppliers, explore new product offerings, and ensure your operations are equipped with the best quartz optics solutions available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.