Set Screw Bearing: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for set screw bearing

In today’s competitive global landscape, sourcing reliable set screw bearings can present significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for high-quality bearings that ensure efficient machinery performance and durability is paramount. This guide aims to navigate these complexities by providing a comprehensive overview of set screw bearings, covering various types, applications, and the critical factors influencing supplier selection and cost.

With detailed insights into specifications and industry standards, buyers can make informed decisions that align with their operational needs and budget constraints. We delve into the nuances of bearing performance metrics, including load ratings and lubrication requirements, ensuring that you understand what to look for when evaluating potential suppliers.

Furthermore, this guide offers strategic tips for vetting suppliers, emphasizing the importance of quality assurance and compliance with international standards. By equipping B2B buyers with actionable insights and expert recommendations, we empower you to confidently navigate the procurement process for set screw bearings, ultimately driving productivity and reliability in your operations. Whether you are sourcing for manufacturing, automotive, or any other sector, this resource is designed to support your purchasing decisions and enhance your supply chain efficiency.

Understanding set screw bearing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Set Screw Bearings | Basic design with a set screw for axial retention | General machinery, conveyors | Pros: Cost-effective, easy installation. Cons: Limited load capacity. |

| Insert Bearings | Comes with an insert that fits into a housing | Agricultural equipment, automotive | Pros: Versatile, can be replaced easily. Cons: Requires precise housing dimensions. |

| Heavy-Duty Set Screw Bearings | Designed for high load and stress applications | Mining, construction equipment | Pros: High load capacity, durable. Cons: Higher cost, heavier. |

| Flanged Set Screw Bearings | Features a flange for added stability and mounting options | HVAC systems, industrial machinery | Pros: Enhanced stability, easier mounting. Cons: Increased space requirements. |

| Stainless Steel Set Screw Bearings | Corrosion-resistant materials for harsh environments | Food processing, marine applications | Pros: Excellent durability, resistant to corrosion. Cons: Higher initial cost. |

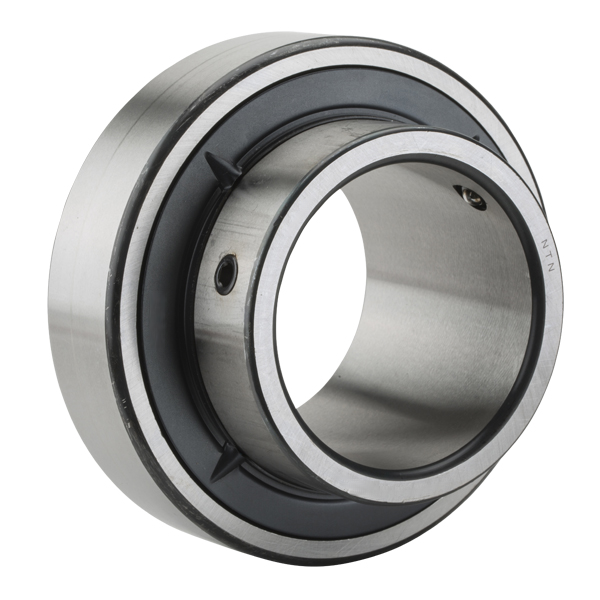

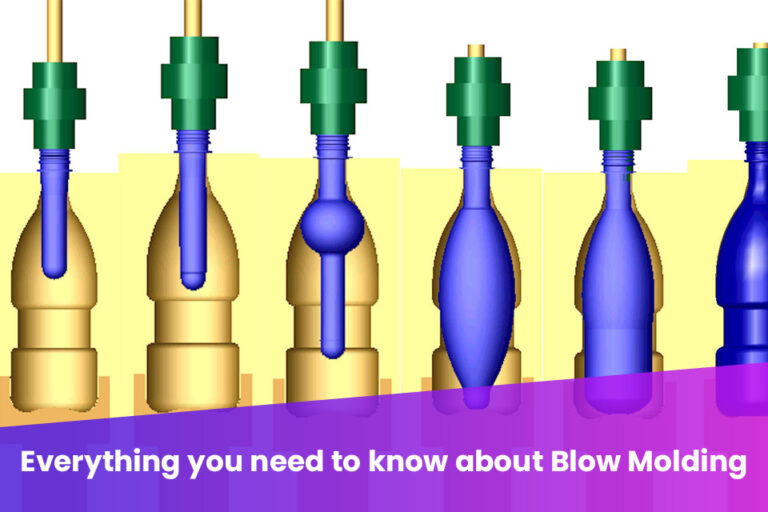

What are Standard Set Screw Bearings and Their Applications?

Standard set screw bearings are characterized by their straightforward design, featuring a set screw that holds the inner ring in place on the shaft. This type is commonly used in general machinery and conveyor systems due to its cost-effectiveness and ease of installation. Buyers should consider the limited load capacity of these bearings, which may not be suitable for high-stress applications.

Illustrative image related to set screw bearing

How Do Insert Bearings Differ from Other Types?

Insert bearings come with a removable insert that fits into a housing, offering flexibility and ease of replacement. They are ideal for applications in agricultural equipment and automotive industries where maintenance and replacement are frequent. When purchasing, buyers must ensure precise housing dimensions to guarantee compatibility, as incorrect sizing can lead to performance issues.

What Makes Heavy-Duty Set Screw Bearings Essential?

Heavy-duty set screw bearings are designed to withstand high loads and stresses, making them suitable for demanding applications such as mining and construction equipment. These bearings offer superior durability and load capacity, but buyers should be prepared for a higher upfront investment and increased weight compared to standard options.

Why Choose Flanged Set Screw Bearings?

Flanged set screw bearings include a flange that enhances stability and simplifies mounting, making them a popular choice in HVAC systems and industrial machinery. The added stability can reduce the risk of misalignment during operation. However, buyers should note that these bearings require more space, which may not be ideal for compact setups.

What Are the Benefits of Stainless Steel Set Screw Bearings?

Stainless steel set screw bearings are specifically designed for environments that require corrosion resistance, such as food processing and marine applications. Their durability and resistance to harsh conditions make them a valuable choice for industries that prioritize hygiene and longevity. Buyers should consider the higher initial cost against the long-term benefits of reduced maintenance and replacement needs.

Key Industrial Applications of set screw bearing

| Industry/Sector | Specific Application of set screw bearing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced efficiency and reduced downtime | Load capacity, material compatibility, lubrication type |

| Agriculture | Agricultural Machinery | Increased reliability in harsh environments | Corrosion resistance, size specifications, and seal options |

| Mining and Minerals | Heavy Equipment | Improved durability under extreme conditions | Static and dynamic load ratings, sourcing from local suppliers |

| Automotive | Engine Components | Precision performance and reduced vibration | Compatibility with existing components, thermal stability |

| Food Processing | Processing Equipment | Compliance with hygiene standards and operational efficiency | FDA compliance, ease of cleaning, and material specifications |

How Are Set Screw Bearings Used in Manufacturing Conveyor Systems?

Set screw bearings play a crucial role in manufacturing conveyor systems by providing reliable support for rotating shafts. They help reduce friction and wear, ensuring smooth operation. In environments where continuous operation is essential, such as automotive or electronic assembly lines, these bearings minimize downtime caused by maintenance. Buyers should consider load capacity and the material of the bearing, as these factors directly impact the system’s overall efficiency.

What Role Do Set Screw Bearings Play in Agricultural Machinery?

In agricultural machinery, set screw bearings are vital for ensuring the smooth operation of components such as tillers, harvesters, and irrigation systems. These bearings help maintain performance in harsh conditions, including exposure to dirt and moisture. Buyers from regions like Africa and South America should prioritize corrosion-resistant materials to enhance durability and reduce maintenance costs, ultimately leading to improved productivity on farms.

How Are Set Screw Bearings Essential for Mining and Heavy Equipment?

Set screw bearings are indispensable in the mining and minerals sector, where heavy equipment operates under extreme conditions. These bearings provide robust support for heavy loads and withstand the harsh environments typical of mining operations. When sourcing for this application, businesses should focus on the static and dynamic load ratings to ensure reliability and longevity, particularly in regions with challenging terrain.

Why Are Set Screw Bearings Important for Automotive Engine Components?

In the automotive industry, set screw bearings are used in engine components to ensure precision performance and minimize vibrations. These bearings contribute to the overall efficiency of engines, enhancing fuel economy and reducing emissions. Buyers must consider compatibility with existing components and thermal stability, especially when sourcing from international suppliers in Europe and the Middle East, where stringent regulations may apply.

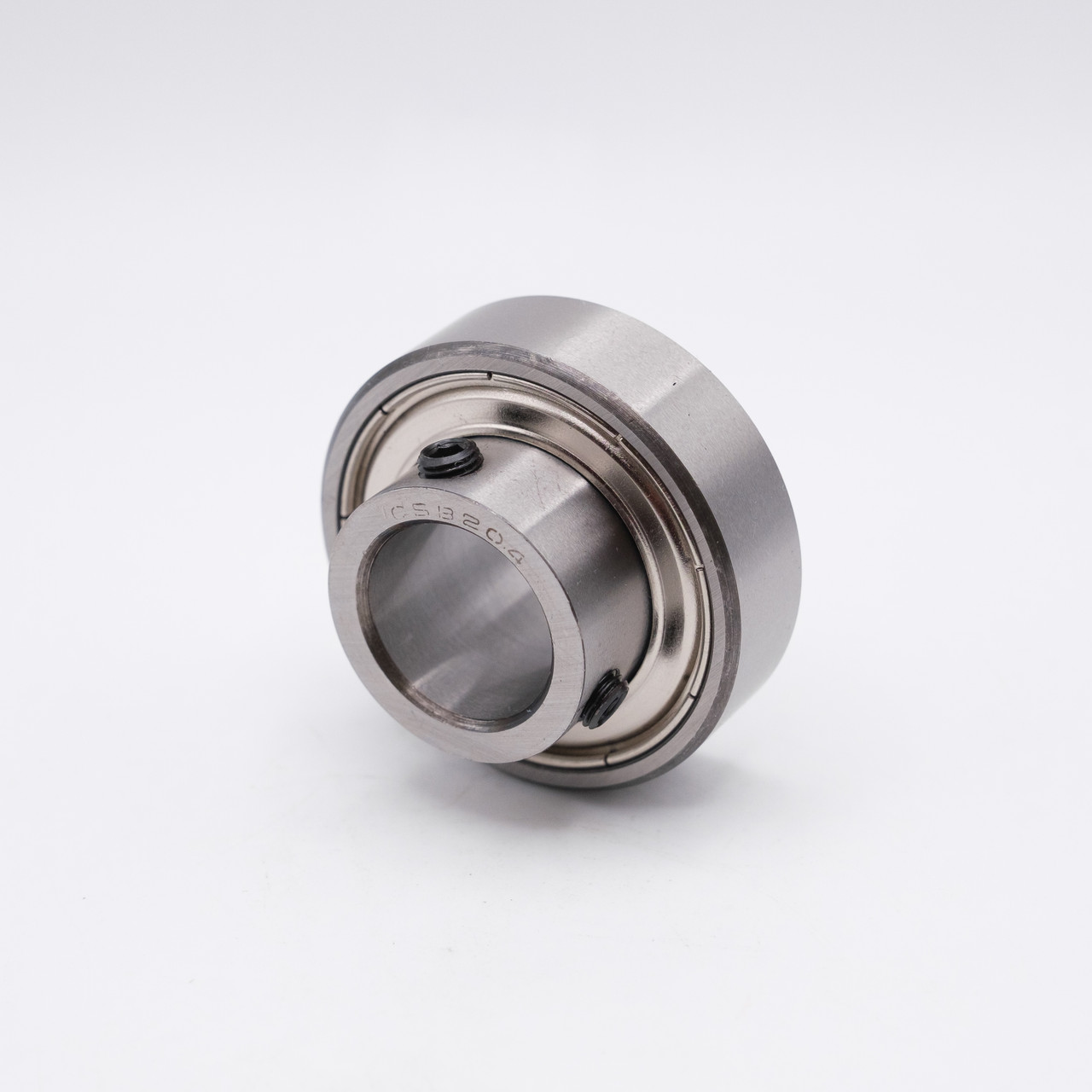

Illustrative image related to set screw bearing

How Do Set Screw Bearings Enhance Food Processing Equipment?

In the food processing industry, set screw bearings are critical for maintaining hygiene and operational efficiency in processing equipment. These bearings must comply with strict food safety regulations while providing reliable performance. Buyers should focus on FDA-compliant materials and ease of cleaning when sourcing bearings for this application, ensuring that they meet industry standards while maximizing productivity in food processing operations.

3 Common User Pain Points for ‘set screw bearing’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Set Screw Bearing for Specific Applications

The Problem: B2B buyers often face challenges in selecting the appropriate set screw bearing for their specific applications. With a myriad of options available, from different sizes to various load ratings and materials, it can be overwhelming. Missteps in this process can lead to equipment failure, increased downtime, and costly repairs, particularly in industries such as manufacturing and automotive, where precision and reliability are paramount.

The Solution: To overcome this challenge, buyers should start by conducting a thorough needs assessment. This includes analyzing the operational environment, load requirements, and speed of operation. Utilizing a customizable bearing finder tool can significantly streamline this process. Such tools allow buyers to filter options based on specific dimensions, load ratings, and housing configurations. Additionally, consulting with suppliers who offer technical support can provide insights into the best choices for unique application scenarios. Documenting performance requirements will also aid in making informed decisions, ensuring that the selected set screw bearing meets both current and future needs.

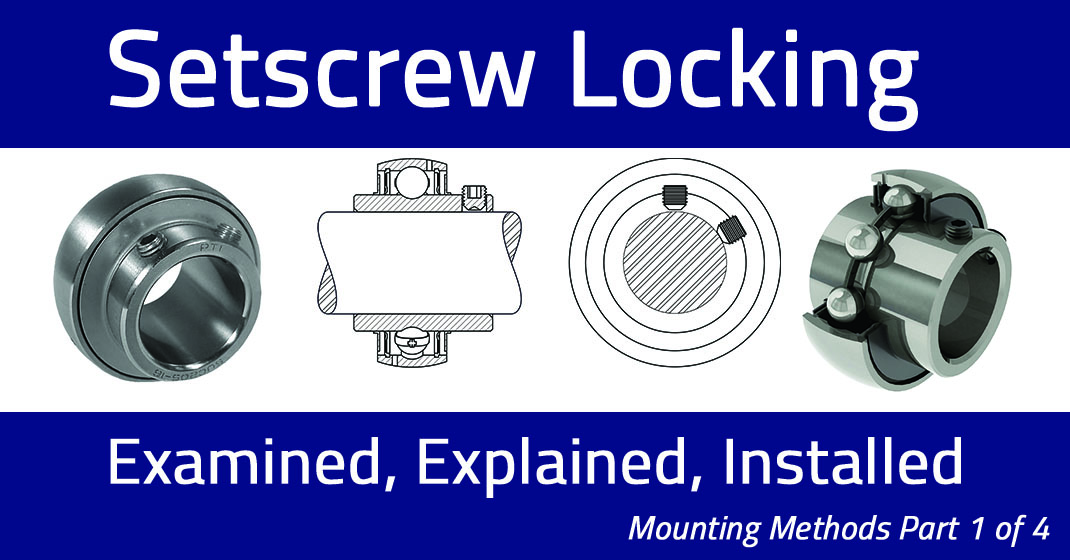

Scenario 2: Frequent Bearing Failures Due to Improper Installation

The Problem: Another common issue faced by buyers is frequent bearing failures stemming from improper installation practices. Set screw bearings are designed for easy installation; however, incorrect mounting techniques can lead to misalignment, excessive vibration, and premature wear. This is particularly frustrating for maintenance teams who may find themselves troubleshooting the same issue repeatedly, leading to increased labor costs and operational delays.

The Solution: To mitigate installation errors, it is crucial to provide comprehensive training for personnel involved in the installation process. This training should include best practices for aligning and securing set screw bearings correctly. Buyers can also benefit from detailed installation manuals and video tutorials offered by manufacturers. Additionally, employing tools such as torque wrenches during installation can ensure that set screws are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening. Regular inspection and maintenance schedules can further reduce the likelihood of failure and extend the lifespan of the bearings.

Scenario 3: Inconsistent Lubrication Leading to Performance Issues

The Problem: Inconsistent lubrication is a significant pain point for B2B buyers using set screw bearings. Many users overlook the importance of proper lubrication, which can lead to overheating, increased friction, and ultimately bearing failure. This issue is exacerbated in environments with high dust and debris, where contaminants can compromise lubrication effectiveness.

The Solution: To address lubrication concerns, buyers should implement a structured lubrication program tailored to the operational conditions of their equipment. This includes selecting the right type of lubricant—considering factors such as temperature and load conditions. Automated lubrication systems can also be employed to ensure consistent application and reduce the risk of human error. Additionally, regular audits of lubrication practices should be conducted to identify any gaps and ensure that all bearings receive adequate maintenance. Educating staff on the importance of lubrication in bearing performance can foster a culture of proactive maintenance, ultimately leading to enhanced reliability and efficiency in operations.

Strategic Material Selection Guide for set screw bearing

What Are the Key Properties of Common Materials Used in Set Screw Bearings?

Set screw bearings are critical components in various machinery and equipment, and the choice of material significantly influences their performance and longevity. Here, we analyze four common materials used in manufacturing set screw bearings: stainless steel, carbon steel, bronze, and thermoplastics. Each material has unique properties, advantages, and limitations that can affect application suitability, particularly for international buyers.

How Does Stainless Steel Benefit Set Screw Bearings?

Stainless steel is renowned for its excellent corrosion resistance, making it ideal for applications in humid or chemically aggressive environments. It typically withstands temperatures up to 500°F (260°C) and exhibits good mechanical strength, which is crucial for load-bearing applications.

Pros: Its durability and resistance to rust and oxidation make stainless steel a preferred choice for industries such as food processing and pharmaceuticals.

Cons: However, stainless steel can be more expensive than other materials and may require specialized machining processes, increasing manufacturing complexity.

Impact on Application: In regions like Europe and the Middle East, where stringent hygiene standards are enforced, stainless steel bearings are often required to comply with regulations such as those set by ASTM or DIN.

What Advantages Does Carbon Steel Offer for Set Screw Bearings?

Carbon steel is widely used due to its high strength and affordability. It can handle significant loads and is suitable for applications where corrosion resistance is less critical.

Pros: The cost-effectiveness of carbon steel makes it an attractive option for manufacturers looking to minimize expenses without sacrificing performance.

Cons: Its susceptibility to rust and corrosion limits its use in wet or corrosive environments, necessitating protective coatings or regular maintenance.

Impact on Application: In regions like South America, where cost considerations are paramount, carbon steel bearings are often favored in non-corrosive applications. However, buyers should ensure compliance with local standards for material quality.

How Does Bronze Enhance the Performance of Set Screw Bearings?

Bronze, an alloy primarily composed of copper and tin, is known for its excellent wear resistance and low friction properties. It performs well under high load and temperature conditions, making it suitable for heavy-duty applications.

Pros: The self-lubricating properties of bronze reduce the need for additional lubrication, which can be beneficial in maintenance-heavy industries.

Illustrative image related to set screw bearing

Cons: The higher cost of bronze compared to steel can be a drawback, especially for bulk purchases.

Impact on Application: In regions like Africa, where mining and heavy machinery are prevalent, bronze bearings are often used for their durability and performance under extreme conditions. Buyers should consider the specific alloy used, as variations can impact performance.

What Role Do Thermoplastics Play in Set Screw Bearing Applications?

Thermoplastics, such as nylon or acetal, are increasingly being used in set screw bearings due to their lightweight and corrosion-resistant properties. They can operate effectively in temperatures up to 200°F (93°C) and are suitable for non-metallic applications.

Pros: Thermoplastics are cost-effective and can be produced with complex geometries, reducing manufacturing costs.

Cons: Their lower mechanical strength compared to metals limits their use in high-load applications.

Impact on Application: In Europe, where there is a growing trend towards lightweight materials in automotive and aerospace industries, thermoplastic bearings are gaining popularity. Compliance with environmental regulations regarding plastic use is an important consideration for buyers.

Summary of Material Properties for Set Screw Bearings

| Material | Typical Use Case for Set Screw Bearing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | General machinery, automotive | High strength and cost-effective | Susceptible to corrosion | Low |

| Bronze | Heavy-duty machinery, mining | Excellent wear resistance | Higher cost compared to steel | Med |

| Thermoplastics | Lightweight applications, automotive | Lightweight and corrosion-resistant | Lower mechanical strength | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in set screw bearings, aiding in informed decision-making tailored to their specific regional and industry needs.

Illustrative image related to set screw bearing

In-depth Look: Manufacturing Processes and Quality Assurance for set screw bearing

What Are the Key Stages in the Manufacturing Process of Set Screw Bearings?

The manufacturing of set screw bearings involves several critical stages to ensure precision and performance. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing process is material preparation. Set screw bearings are typically made from high-quality steel alloys, such as carbon steel or stainless steel, which provide the necessary strength and corrosion resistance. The selection of material is crucial, as it directly affects the bearing’s performance and longevity. Suppliers should provide certifications for the materials used, ensuring compliance with international standards.

How Are Set Screw Bearings Formed?

Once materials are prepared, the next step is forming. This process can include forging, machining, or casting, depending on the design specifications. Forging is often preferred for its ability to enhance the mechanical properties of the material through work hardening. Machining follows, where precision tools shape the bearing components to exact specifications. This stage is critical for achieving tight tolerances, which are essential for proper functioning.

Illustrative image related to set screw bearing

What Is Involved in the Assembly Process?

The assembly of set screw bearings involves fitting various components together, such as the inner and outer rings, rolling elements, and seals. During this phase, attention to detail is paramount. The assembly is often performed in a clean environment to avoid contamination, which can lead to premature failure. It’s also common for manufacturers to implement automated systems to enhance efficiency and consistency.

What Finishing Techniques Are Used for Quality Control?

After assembly, finishing processes are applied to improve the surface quality and enhance the bearing’s performance. This can include processes like grinding, polishing, and coating. Coatings may be applied for additional protection against wear and corrosion. The finishing stage is vital, as it directly influences the bearing’s durability and functionality under various operational conditions.

How Is Quality Assurance Implemented in the Manufacturing of Set Screw Bearings?

Quality assurance (QA) is integral to the manufacturing of set screw bearings, ensuring that each product meets stringent standards. B2B buyers should be familiar with the QA processes and how they affect product reliability.

Illustrative image related to set screw bearing

What International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer has established processes to consistently deliver quality products. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for oil and gas applications, provide further assurance of product quality.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, IPQC monitors the processes to ensure they remain within specified tolerances. This may include periodic inspections and testing.

- Final Quality Control (FQC): The final inspection ensures that the completed bearings meet all specifications and performance criteria before they are shipped to customers.

These checkpoints help identify and rectify issues early, minimizing the risk of defective products reaching the market.

Which Testing Methods Are Commonly Used?

Common testing methods for set screw bearings include:

- Dimensional Inspection: Measuring critical dimensions to ensure they meet specifications.

- Load Testing: Assessing the bearing’s performance under various load conditions to verify its strength and durability.

- Vibration Analysis: Identifying potential issues related to balance and alignment.

- Material Testing: Evaluating the material properties, such as hardness and tensile strength.

These tests are essential for confirming that the bearings will perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several strategies:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Audits should evaluate the manufacturer’s adherence to quality standards, production processes, and testing protocols. Buyers can request audit reports and certifications to gain insight into the supplier’s quality management system.

Illustrative image related to set screw bearing

How Important Are Quality Assurance Reports?

Quality assurance reports provide detailed information about the testing and inspection results for each batch of products. Buyers should request these reports to verify that the bearings have undergone rigorous testing and meet specified standards. Understanding the frequency and scope of testing conducted by the supplier can also provide confidence in their quality control practices.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing processes, conduct tests, and validate compliance with international standards. This external verification can be particularly beneficial for buyers in emerging markets, where local suppliers may have varying levels of quality assurance.

What Nuances Should International Buyers Be Aware Of?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of specific nuances in quality assurance.

Illustrative image related to set screw bearing

Are There Regional Standards to Consider?

Different regions may have specific standards and regulations that suppliers must comply with. For instance, buyers in Europe need to ensure that products meet CE marking requirements, while those in other regions may focus on local compliance standards. Understanding these regulations is essential for successful international transactions.

How Can Cultural Differences Affect Quality Perceptions?

Cultural differences can influence perceptions of quality and reliability. Buyers should engage in open communication with suppliers to clarify expectations regarding quality standards and delivery timelines. Establishing strong relationships can help navigate these differences and ensure both parties are aligned in their quality expectations.

Conclusion: Why Quality Assurance Is Essential for B2B Buyers

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for set screw bearings is essential for B2B buyers. By focusing on quality at every stage—from material preparation to final inspection—buyers can ensure they are sourcing reliable products that meet their operational needs. Engaging with suppliers who prioritize quality and adhere to international standards will ultimately lead to better performance and reduced operational risks.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘set screw bearing’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure set screw bearings. The process of sourcing these components requires careful consideration of technical specifications, supplier reliability, and compliance with industry standards. By following this checklist, buyers can ensure they make informed decisions that meet their operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is critical to have a clear understanding of your technical requirements for set screw bearings. This includes parameters such as load ratings, dimensions, materials, and operational environment.

- Load Ratings: Specify both static and dynamic load ratings to ensure the bearings can withstand the required operational stresses.

- Dimensions: Clearly define the inner diameter, outer diameter, and width to match your machinery specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in set screw bearings. This step is vital to ensure you are partnering with reputable manufacturers or distributors who can meet your needs.

- Supplier Background: Look for suppliers with a proven track record in your industry, especially those with experience serving international markets.

- Product Range: Evaluate the breadth of their product offerings to ensure they can provide the specific bearings you need.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or other industry-specific accreditations. These certifications indicate that the supplier adheres to quality management standards, which is crucial for ensuring product reliability.

- Quality Assurance: Suppliers with certifications often have robust quality control processes in place.

- Compliance: Ensure the supplier complies with international standards relevant to your region, particularly if you are sourcing from countries with varying regulations.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the set screw bearings you intend to buy. This allows you to assess the quality and suitability of the product for your specific application.

- Testing: Conduct performance tests on the samples to verify they meet your technical specifications.

- Fit and Compatibility: Ensure the samples fit correctly in your machinery and perform under expected operational conditions.

Step 5: Review Pricing and Payment Terms

Obtain detailed quotations from multiple suppliers to compare pricing and payment terms. Understanding the total cost of ownership, including shipping and import duties, is essential for budget management.

- Negotiation: Use the information from multiple quotes to negotiate better terms or discounts.

- Payment Flexibility: Look for suppliers that offer flexible payment options to ease cash flow management.

Step 6: Check References and Reviews

Before finalizing your supplier choice, check references and reviews from other businesses that have sourced from them. This step provides insights into the supplier’s reliability, customer service, and product quality.

- Client Testimonials: Reach out to references provided by the supplier and ask about their experience with product performance and support.

- Online Reviews: Look for independent reviews or case studies that highlight the supplier’s performance in real-world applications.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This should include delivery schedules, warranty information, and after-sales support.

- Legal Considerations: Consult with legal experts if necessary to ensure that the agreement protects your interests.

- Follow-Up: Establish a communication plan for follow-up and support after the purchase to address any potential issues promptly.

By following this checklist, B2B buyers can confidently navigate the sourcing process for set screw bearings, ensuring they select the right products and suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for set screw bearing Sourcing

What Are the Key Cost Components in Set Screw Bearing Sourcing?

When sourcing set screw bearings, buyers must consider several cost components that contribute to the overall price. These include:

Illustrative image related to set screw bearing

-

Materials: The quality and type of materials used in manufacturing set screw bearings, such as steel or composite materials, significantly affect cost. High-grade materials enhance durability but may increase the price.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Automated processes may reduce labor costs, while skilled labor is often needed for quality assurance and intricate manufacturing tasks.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower overhead costs.

-

Tooling: The cost of specialized tools and dies required for production is a significant factor. Custom tooling can lead to higher initial costs but may reduce per-unit costs over larger production runs.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that the bearings meet industry standards and specifications. While this adds to the cost, it can prevent costly defects and enhance customer satisfaction.

-

Logistics: Transportation and warehousing costs are crucial, especially for international shipping. Factors such as shipping method, distance, and customs duties can impact the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary widely based on market conditions, competition, and supplier reputation.

How Do Price Influencers Affect Set Screw Bearing Costs?

Several factors can influence the pricing of set screw bearings, impacting the final cost for buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to volume discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom specifications or unique designs can lead to increased costs due to additional tooling and manufacturing processes. Buyers should clearly define requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Bearings made from high-quality materials or those that meet specific industry certifications (e.g., ISO standards) typically command higher prices. Buyers should weigh the benefits of quality against their budget.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can influence pricing. Local suppliers may offer lower shipping costs, while established manufacturers with a reputation for quality may charge a premium.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect the total cost. Buyers should understand responsibilities regarding shipping, insurance, and customs clearance to avoid additional expenses.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

To ensure cost-effective sourcing of set screw bearings, buyers should consider the following strategies:

-

Conduct Market Research: Understanding market prices and supplier capabilities can provide leverage during negotiations. Buyers should gather multiple quotes to compare offerings.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and improved terms in future transactions.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes maintenance, durability, and potential failure costs. Investing in high-quality bearings may reduce long-term expenses.

-

Be Clear About Requirements: Clearly communicate specifications, expected delivery times, and quality standards to avoid misunderstandings that can lead to increased costs.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Brazil, Germany) should be aware of currency fluctuations, tariffs, and local regulations that can impact pricing.

Disclaimer on Pricing

Prices for set screw bearings can vary widely based on the factors discussed above. Buyers are encouraged to request detailed quotes and conduct thorough due diligence when evaluating suppliers to ensure they are receiving competitive pricing aligned with their specific needs.

Illustrative image related to set screw bearing

Alternatives Analysis: Comparing set screw bearing With Other Solutions

Exploring Alternative Solutions to Set Screw Bearings

When considering mechanical components for applications requiring rotational motion and load support, set screw bearings are often a go-to choice. However, there are several alternative solutions available that may better fit specific operational needs or budget constraints. This section provides a comparative analysis of set screw bearings against two viable alternatives: Pillow Block Bearings and Flanged Bearings.

Comparison Table

| Comparison Aspect | Set Screw Bearing | Pillow Block Bearing | Flanged Bearing |

|---|---|---|---|

| Performance | Good load capacity, moderate speed | High load capacity, stable operation | Moderate load capacity, compact design |

| Cost | Moderate cost | Higher cost due to mounting | Lower cost |

| Ease of Implementation | Requires precise installation | Generally easy to install | Very easy to install |

| Maintenance | Requires regular checking of set screws | Low maintenance needs | Low maintenance needs |

| Best Use Case | General applications in machinery | Heavy-duty applications | Space-constrained environments |

Detailed Breakdown of Alternatives

Pillow Block Bearings

Pillow block bearings are designed to support rotating shafts and are mounted on a base. They offer superior load handling capabilities compared to set screw bearings, making them ideal for heavy-duty applications such as conveyor systems and large machinery. The main advantage of pillow block bearings is their ability to absorb misalignment and their robust construction, which often leads to longer service life. However, they come at a higher price point and can require more space for installation.

Flanged Bearings

Flanged bearings provide a compact solution for applications where space is limited. They have a flange that allows for easy mounting, which simplifies installation and can be beneficial in applications where space is at a premium. While their load capacity is generally lower than that of set screw and pillow block bearings, they are often more cost-effective. Flanged bearings are ideal for light-duty applications or in situations where weight and size constraints are critical. The downside is that they may not perform well under heavy loads or high-speed conditions.

Conclusion: Choosing the Right Bearing Solution for Your Needs

Selecting the right bearing solution involves evaluating your specific application requirements, including load capacity, space limitations, and budget. While set screw bearings offer a good balance of performance and cost, alternatives like pillow block and flanged bearings may provide advantages in certain scenarios. Pillow block bearings excel in heavy-duty applications, while flanged bearings are ideal for compact installations. By carefully assessing these factors, B2B buyers can make informed decisions that align with their operational needs and ensure optimal performance in their machinery.

Essential Technical Properties and Trade Terminology for set screw bearing

What Are the Key Technical Properties of Set Screw Bearings?

When selecting set screw bearings, understanding their technical specifications is crucial for ensuring compatibility and performance in your applications. Here are some essential properties to consider:

-

Material Grade

The material used for set screw bearings typically includes steel, stainless steel, or thermoplastic. The grade of the material affects the bearing’s strength, corrosion resistance, and durability. For example, stainless steel is preferable for environments exposed to moisture or chemicals, while carbon steel is often used for general applications. Choosing the right material can significantly impact the longevity and reliability of your machinery. -

Load Ratings

Load ratings are critical specifications that indicate the maximum load a bearing can support. They are categorized as static load rating (the maximum load the bearing can handle when stationary) and dynamic load rating (the maximum load during operation). Understanding these ratings helps in selecting the appropriate bearing for your specific application, ensuring that it can withstand operational demands without premature failure. -

Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the bearing. High precision tolerances are essential for applications requiring exact fit and function, such as in automotive or aerospace industries. Selecting bearings with appropriate tolerances helps reduce wear and increases the efficiency of the assembly. -

Inner and Outer Diameter (ID and OD)

The inner diameter (ID) and outer diameter (OD) are fundamental dimensions that dictate how the bearing fits within your application. Accurate measurement of these dimensions ensures proper installation and functionality. Misalignment due to incorrect ID or OD can lead to premature wear and failure. -

Housing Width

The housing width is the dimension of the bearing’s outer casing that affects its overall stability and fit within the assembly. Choosing the correct housing width is essential for ensuring that the bearing can adequately handle the loads and stresses of its operational environment. -

Lubrication Type

Bearings can be lubricated with grease or oil, which affects their performance and longevity. The choice of lubrication is influenced by the operating environment, speed, and load conditions. Proper lubrication reduces friction, dissipates heat, and prevents wear, making it a vital consideration during selection.

What Are Common Trade Terms Associated with Set Screw Bearings?

Familiarizing yourself with industry terminology can facilitate better communication and decision-making in the procurement process. Here are some common trade terms related to set screw bearings:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring compatibility with existing machinery, especially in industries such as automotive and manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of an item that a supplier is willing to sell. This term is significant for buyers to know as it impacts inventory management and procurement costs. Suppliers may set MOQs to ensure profitability on production runs. -

RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests price quotes from suppliers for specific quantities of goods or services. This document is essential for comparing prices and terms from multiple suppliers, helping businesses make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international shipping contracts. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which is vital for international transactions involving bearings. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for project planning and inventory management, especially in industries where downtime can be costly. -

Bearing Type

This term distinguishes between various bearing designs, such as ball bearings, roller bearings, and set screw bearings. Knowing the specific type required for an application helps buyers ensure they are selecting a product that meets their operational needs effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of selecting and procuring set screw bearings with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the set screw bearing Sector

What Are the Current Market Dynamics and Key Trends in the Set Screw Bearing Sector?

The global set screw bearing market is currently driven by a confluence of technological advancements, increasing demand for automation, and the growing emphasis on energy efficiency. As industries such as manufacturing, automotive, and agriculture continue to evolve, the demand for high-performance bearings that can withstand harsh environments is surging. Notably, regions like Africa and South America are experiencing increased industrialization, which is propelling the need for reliable components like set screw bearings. Furthermore, European markets, particularly Germany, are leading in innovation, emphasizing precision engineering and advanced materials.

Emerging B2B tech trends are notably shaping sourcing strategies. The integration of Industry 4.0 technologies, including IoT and predictive analytics, is enabling manufacturers to optimize their supply chains and enhance product performance. Digital platforms are becoming essential tools for international buyers, facilitating real-time data access, part interchanges, and CAD modeling, which streamline the selection and procurement processes. Additionally, there is a shift towards localized sourcing, driven by the need for reduced lead times and increased supply chain resilience.

How Important Is Sustainability and Ethical Sourcing for Set Screw Bearings?

Sustainability is rapidly becoming a critical factor in the procurement of set screw bearings. The environmental impact of manufacturing processes and materials used in bearings is under scrutiny, leading to a growing demand for eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainability through certifications such as ISO 14001 or by using recycled materials in their products.

Ethical supply chains are also gaining traction, with companies focusing on transparency and accountability. Buyers are now more inclined to partner with manufacturers who adhere to ethical labor practices and demonstrate a commitment to reducing their carbon footprint. This trend not only meets regulatory requirements but also enhances brand reputation and consumer trust. As companies strive to align with global sustainability goals, sourcing from suppliers with recognized ‘green’ certifications is becoming a strategic priority.

What is the Brief Evolution of Set Screw Bearings?

Set screw bearings have evolved significantly since their inception in the early 20th century. Initially designed for simple applications, advancements in material science and engineering have transformed these components into high-performance solutions capable of supporting complex machinery. The introduction of innovative materials, such as composite plastics and advanced steel alloys, has enhanced durability and load-bearing capabilities.

In recent years, the focus has shifted towards customization and precision manufacturing, allowing for tailored solutions that meet specific operational needs. This evolution reflects broader trends in the industrial sector, where efficiency and performance are paramount. As industries continue to innovate, the role of set screw bearings will likely expand, further solidifying their importance in modern machinery.

Frequently Asked Questions (FAQs) for B2B Buyers of set screw bearing

-

How do I choose the right set screw bearing for my application?

Selecting the right set screw bearing involves considering several key factors. First, assess the load requirements, including both static and dynamic load ratings, to ensure the bearing can handle the stresses of your application. Additionally, evaluate the size and type of housing to ensure compatibility. Material selection is also crucial; for instance, stainless steel bearings may be preferable in corrosive environments. Finally, consider the speed and operating conditions, including temperature and lubrication needs, to ensure optimal performance and longevity. -

What are the advantages of using set screw bearings over other types?

Set screw bearings offer several advantages, including ease of installation and maintenance. They typically allow for precise positioning on shafts, which can reduce the risk of misalignment. Their design also accommodates a variety of load conditions, making them versatile for different applications. Additionally, many set screw bearings are designed for durability, providing longer service life and reduced downtime compared to other bearing types, which can lead to significant cost savings in industrial settings. -

What is the typical lead time for ordering set screw bearings internationally?

Lead times for international orders of set screw bearings can vary based on several factors, including supplier location, order volume, and shipping method. Typically, you can expect lead times ranging from 2 to 6 weeks. For urgent needs, express shipping options may be available, although they can incur additional costs. It’s advisable to confirm lead times with your supplier prior to placing an order, especially if you require the bearings for a specific project deadline. -

What are the minimum order quantities (MOQs) for set screw bearings?

Minimum order quantities for set screw bearings can differ significantly among suppliers. Some manufacturers may have MOQs as low as 10 units, while others, especially for custom orders, may require hundreds or more. It’s essential to discuss your specific needs with potential suppliers to understand their MOQ policies. If your order volume is lower than their MOQ, consider consolidating orders with other products or negotiating with the supplier for a special arrangement. -

How can I vet suppliers of set screw bearings for reliability?

Vetting suppliers is crucial to ensure you receive high-quality set screw bearings. Start by researching their reputation in the industry through online reviews and testimonials. Look for certifications such as ISO 9001, which indicate adherence to quality standards. Request references from previous clients to gauge their experiences. Additionally, assessing their manufacturing capabilities and quality control processes can provide insight into their reliability. Establishing a good line of communication during the inquiry process can also help gauge their professionalism. -

What payment terms should I expect when sourcing set screw bearings internationally?

Payment terms can vary widely based on the supplier and the nature of your business relationship. Common terms include payment in advance, letter of credit, or payment upon delivery. Some suppliers may offer net 30 or net 60 terms for established customers. Always clarify payment methods accepted (e.g., bank transfers, credit cards) and any additional fees involved in international transactions. It’s advisable to negotiate terms that suit your cash flow while ensuring the supplier feels secure in the transaction. -

What quality assurance measures should I look for when purchasing set screw bearings?

When sourcing set screw bearings, inquire about the supplier’s quality assurance measures. Look for suppliers who implement rigorous testing protocols, including dimensional checks, load testing, and material analysis. Certifications like ISO 9001 or similar industry standards can indicate a commitment to quality. Request information on their warranty policies and how they handle defective products. A supplier’s willingness to provide detailed quality documentation can also be a positive sign of their reliability. -

What logistics considerations should I keep in mind for international shipping of set screw bearings?

Logistics play a vital role in the timely delivery of set screw bearings. Consider the shipping method best suited for your timeframe and budget—air freight is faster but more expensive than sea freight. Be aware of customs regulations and any duties or taxes applicable in your country. Collaborating with a logistics partner experienced in international shipping can help navigate these complexities and ensure compliance with all regulatory requirements. Additionally, track shipments to mitigate delays and stay informed about delivery status.

Top 7 Set Screw Bearing Manufacturers & Suppliers List

1. McMaster – Set Screw Bearings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Set Screw Bearings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

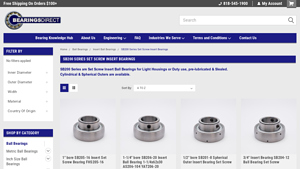

2. Bearings Direct – SB200 Series Insert Bearing

Domain: bearingsdirect.com

Registered: 1999 (26 years)

Introduction: SB200 Series Insert Bearing, Free Shipping On Orders $100+, In Stock in Glendale CA, Contact: 818-545-1900

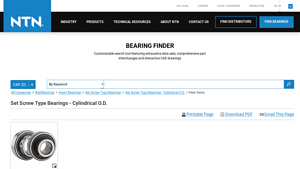

3. NTN – Set Screw Type Bearings

Domain: bearingfinder.ntnamericas.com

Registered: 2012 (13 years)

Introduction: Set Screw Type Bearings – Cylindrical O.D.\nAvailable Sizes: \n- d (in): 0.472 to 5.5118\n- d (mm): 12 to 140\n- D (in): 1.5748 to 11.811\n- D (mm): 40 to 300\n- C (in): 0.4724 to 2.7953\n- C (mm): 12 to 71\n- B (in): 0.5512 to 5.7087\n- B (mm): 14 to 145\n- r (in): 0.0236 to 0.1575\n- r (mm): 0.6 to 4\nStatic Load Rating: \n- (lbf): 1030 to 55500\n- (N): 4600 to 246000\n- (kN): 4.6 to 246\nDynami…

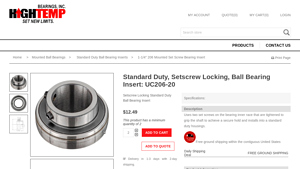

4. High Temp Bearings – 1-1/4 206 Mounted Set Screw Bearing Insert

Domain: hightempbearings.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “1-1/4″ 206 Mounted Set Screw Bearing Insert”, “Price”: “$12.49”, “Minimum Quantity”: “2”, “Delivery”: “1-3 days with 2-day shipping”, “Shipping”: “Free ground shipping within the contiguous United States”, “Specifications”: {“Description”: “Uses two set screws on the bearing inner race that are tightened to grip the shaft to achieve a secure hold and installs into a standard duty…

5. Buyers Products – Set Screw Style Pillow Block Bearings

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: Set Screw Style Pillow Block Bearings are designed to support shafts and reduce friction in various applications. They feature a durable construction for long-lasting performance and are available in multiple sizes to accommodate different shaft diameters. The set screw design ensures a secure fit, preventing slippage during operation. Ideal for use in machinery, conveyors, and other equipment req…

6. LDK Bearings – Set Screw Bearings

Domain: ldk-bearings.com

Registered: 1999 (26 years)

Introduction: This company, LDK Bearings – Set Screw Bearings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

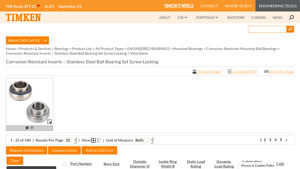

7. Timken – Corrosion-Resistant Stainless Steel Ball Bearing Inserts

Domain: cad.timken.com

Registered: 1994 (31 years)

Introduction: Corrosion-Resistant Inserts – Stainless Steel Ball Bearing Set Screw Locking. Key specifications include:

– Bore Sizes: 12 mm, 15 mm, 1/2 in, 5/8 in, 3/4 in, 17 mm, 20 mm

– Outside Diameter: 1.85 in (47 mm)

– Inside Ring Width: 1.22 in (31 mm)

– Static Load Rating: 1203 lbf (5350 N)

– Dynamic Load Rating: 2451 lbf (10900 N)

– Lubrication Types: Standard Food Safe Grease, Food Grade Solid Lub…

Strategic Sourcing Conclusion and Outlook for set screw bearing

What Are the Key Takeaways for Sourcing Set Screw Bearings?

As the demand for set screw bearings continues to rise across various industries, international B2B buyers must prioritize strategic sourcing to optimize their supply chains. Key considerations include evaluating supplier reliability, understanding load ratings, and selecting the appropriate materials for specific applications. This ensures not only the longevity of the bearings but also enhances operational efficiency.

How Can Strategic Sourcing Impact Your Business?

Strategic sourcing enables businesses to mitigate risks associated with supply chain disruptions, particularly in the diverse markets of Africa, South America, the Middle East, and Europe. By fostering strong relationships with manufacturers, buyers can gain access to the latest innovations and competitive pricing, ultimately leading to cost savings and improved product quality.

What’s Next for International Buyers?

Looking ahead, international buyers should actively engage in market research and supplier evaluations to stay ahead of industry trends. As technology evolves, consider integrating digital tools for better procurement processes. Embrace this opportunity to refine your sourcing strategies and position your business for growth in the global marketplace. Your proactive approach in sourcing high-quality set screw bearings will not only enhance your operational capabilities but also strengthen your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.