Dc Motor Magnet Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for dc motor magnet

Navigating the complex landscape of sourcing DC motor magnets poses significant challenges for international B2B buyers, particularly those operating in emerging markets such as Africa, South America, the Middle East, and Europe. The demand for high-performance DC motor magnets—critical components in various applications from electric vehicles to robotics—continues to rise. However, identifying reliable suppliers, understanding the nuances of different magnet types, and evaluating costs can overwhelm even the most seasoned procurement professionals.

This comprehensive guide aims to equip buyers with essential insights into the global market for DC motor magnets. It covers a range of topics, including the various types of magnets available—such as neodymium and ferrite—along with their specific applications and benefits. Additionally, we delve into the intricacies of supplier vetting processes, ensuring you can make informed decisions based on quality, reliability, and pricing. By offering actionable strategies and key considerations, this guide empowers B2B buyers to navigate the sourcing process with confidence, minimizing risks and optimizing supply chain efficiency.

As you explore the contents, you’ll gain a deeper understanding of how to leverage the right DC motor magnets for your business needs, ensuring you remain competitive in an ever-evolving market landscape. Whether you are in Brazil, Nigeria, or beyond, this guide serves as your authoritative resource for making strategic purchasing decisions in the dynamic world of DC motor magnets.

Understanding dc motor magnet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Neodymium Magnets | High magnetic strength, compact size, nickel plated | Robotics, high-torque motors | Pros: Excellent torque density, lightweight. Cons: Higher cost compared to other types. |

| Ferrite Magnets | Lower magnetic strength, cost-effective | Household appliances, low-power motors | Pros: Affordable, good for basic applications. Cons: Bulkier, less efficient in high-performance settings. |

| Samarium-Cobalt Magnets | High-temperature resistance, corrosion-resistant | Aerospace, military applications | Pros: Stable performance in extreme conditions. Cons: More expensive and brittle. |

| Arc Magnets | Curved shape for optimized magnetic field | Electric vehicles, servo motors | Pros: Efficient torque generation. Cons: Limited availability and higher manufacturing costs. |

| Block Magnets | Rectangular shape, versatile in application | Industrial machinery, automation | Pros: Easy to install, adaptable. Cons: May require additional components for optimal performance. |

What Are the Characteristics of Neodymium Magnets for DC Motors?

Neodymium magnets, known for their exceptional magnetic strength, are often used in high-performance applications such as robotics and high-torque motors. Their compact size allows for efficient designs, making them ideal for applications where space is limited. B2B buyers should consider the higher cost of these magnets against their performance benefits, especially in applications requiring lightweight and high-efficiency motors.

How Do Ferrite Magnets Compare in Cost and Performance?

Ferrite magnets are a budget-friendly option, providing decent performance for low-power motors and household appliances. While their magnetic strength is lower than that of neodymium magnets, they are suitable for applications where high performance is not critical. Buyers should weigh the cost savings against potential inefficiencies in high-demand scenarios, particularly in industrial applications.

Why Choose Samarium-Cobalt Magnets for Specialized Applications?

Samarium-cobalt magnets excel in high-temperature environments, making them suitable for aerospace and military applications where reliability is crucial. Their corrosion resistance adds to their durability, but this comes at a higher price point. B2B buyers in specialized industries should assess the long-term benefits of investing in these magnets against their initial costs, especially in demanding conditions.

What Are the Advantages of Using Arc Magnets in Electric Motors?

Arc magnets are specifically designed to optimize the magnetic field in electric motors, particularly in applications like electric vehicles and servo motors. Their shape allows for efficient torque generation, which is essential for high-performance motors. However, they may be less readily available and can come with higher manufacturing costs, making them a consideration for B2B buyers focused on innovation.

How Versatile Are Block Magnets in Industrial Applications?

Block magnets offer versatility in various applications, from industrial machinery to automation. Their rectangular shape makes them easy to install and adaptable to different configurations. While they can enhance performance, buyers should consider that some setups may require additional components to achieve optimal results. This adaptability can be a significant advantage for businesses looking to customize their motor solutions.

Key Industrial Applications of dc motor magnet

| Industry/Sector | Specific Application of dc motor magnet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Power Steering Systems | Enhances vehicle maneuverability and driver comfort | High torque density, compact design, compliance with safety standards |

| Renewable Energy | Wind Turbine Generators | Efficient energy conversion and reliability | Durability in harsh environments, specialized coatings, and high-temperature resistance |

| Robotics | Robotic Arms and Automation Systems | Precision control and increased productivity | Custom magnet designs, rapid prototyping capabilities, and scalability |

| Consumer Electronics | Electric Bicycles and Scooters | Improved efficiency and longer battery life | Lightweight materials, high magnetic strength, and cost-effectiveness |

| Industrial Machinery | Conveyor Systems and Automated Production Lines | Increased operational efficiency and reduced downtime | Standardized sizes, availability of bulk orders, and compatibility with existing systems |

How Are dc Motor Magnets Utilized in Automotive Applications?

In the automotive sector, dc motor magnets are integral to electric power steering systems, which enhance vehicle maneuverability. These systems rely on high-torque, compact dc motors to provide precise steering assistance, improving driver comfort and safety. International B2B buyers should consider sourcing high-density neodymium magnets that meet automotive safety standards. Additionally, understanding the local market for automotive components is crucial, especially in emerging markets like Nigeria and Brazil, where demand for electric vehicles is growing.

What Role Do dc Motor Magnets Play in Renewable Energy?

In renewable energy applications, particularly in wind turbine generators, dc motor magnets facilitate efficient energy conversion. These magnets enable the rotor to spin effectively, converting wind energy into electrical energy. For international buyers in regions with developing energy infrastructures, such as parts of Africa and South America, it is essential to source magnets that can withstand harsh environmental conditions and offer high-temperature resistance. Custom coatings may also be necessary to enhance durability and performance.

How Are dc Motor Magnets Transforming Robotics?

In robotics, dc motor magnets are crucial for the operation of robotic arms and automation systems, providing the precision required for intricate tasks. The use of high-torque neodymium magnets enables these systems to perform with greater efficiency, leading to increased productivity in manufacturing and assembly lines. Buyers in this sector should prioritize suppliers that offer custom magnet designs and rapid prototyping capabilities, especially in competitive markets in Europe and the Middle East, where innovation is key.

What Benefits Do dc Motor Magnets Offer in Consumer Electronics?

For electric bicycles and scooters, dc motor magnets enhance energy efficiency and extend battery life. These applications require lightweight and compact magnets that can deliver high performance without adding significant weight. Buyers in the consumer electronics sector should look for cost-effective solutions that do not compromise on quality. Understanding regional trends in electric mobility can also help buyers from South America and Africa make informed sourcing decisions.

How Are dc Motor Magnets Used in Industrial Machinery?

In industrial machinery, dc motor magnets are vital for the operation of conveyor systems and automated production lines. They help increase operational efficiency and minimize downtime by ensuring reliable motor performance. B2B buyers should focus on sourcing standardized sizes that can easily integrate with existing machinery, while also considering bulk order availability to meet production needs. Additionally, compatibility with various industrial standards is critical for seamless integration in diverse manufacturing environments.

3 Common User Pain Points for ‘dc motor magnet’ & Their Solutions

Scenario 1: Sourcing Quality Magnets for High-Performance Motors

The Problem: B2B buyers often face challenges in sourcing high-quality neodymium magnets for their DC motors. This issue is particularly prevalent in regions with limited access to reliable suppliers. Buyers may encounter products that do not meet specifications, leading to inefficiencies in motor performance, increased failure rates, and ultimately, higher costs. Additionally, inconsistent quality can disrupt production timelines, which is especially problematic for manufacturers in fast-paced industries.

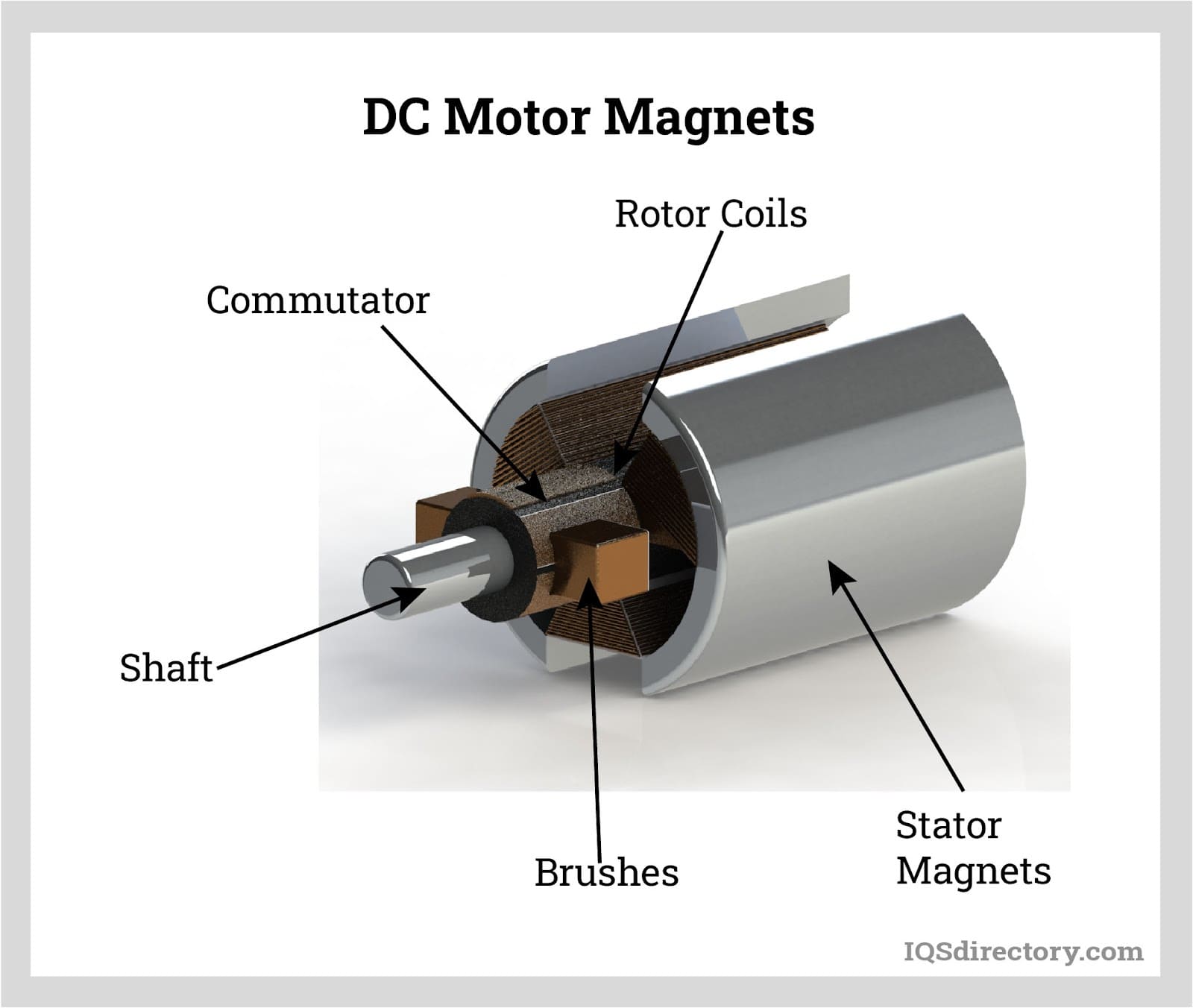

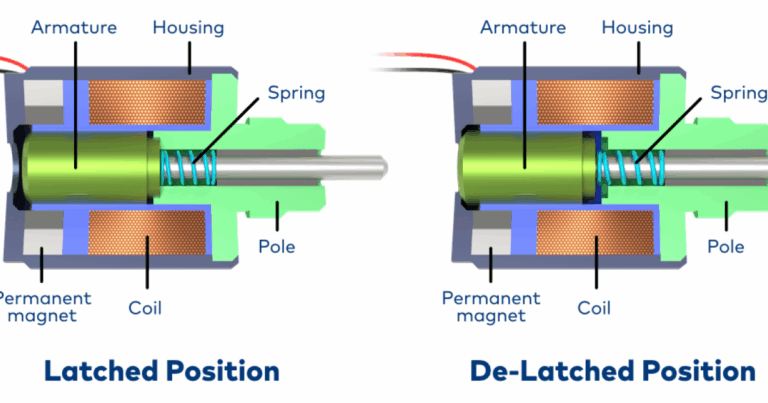

Illustrative image related to dc motor magnet

The Solution: To ensure the procurement of quality DC motor magnets, buyers should engage with reputable suppliers who provide comprehensive product specifications and certifications. It’s crucial to verify that the magnets meet industry standards, such as those set by the International Electrotechnical Commission (IEC). Conducting due diligence through supplier audits and requesting samples for testing can also help assess quality before placing bulk orders. Furthermore, leveraging local or regional suppliers can mitigate shipping delays and customs issues, enhancing supply chain reliability.

Scenario 2: Overcoming Compatibility Issues with Existing Motor Designs

The Problem: Many B2B buyers struggle with compatibility issues when integrating new DC motor magnets into existing designs. This often occurs when businesses attempt to upgrade their systems without fully understanding the specifications of their current motor setups. As a result, they may experience reduced efficiency, increased noise, or even mechanical failures, leading to costly downtime.

The Solution: To address compatibility challenges, buyers should perform a thorough analysis of their current motor designs before selecting new magnets. This involves understanding the magnetic requirements, dimensions, and performance characteristics of the existing components. Collaborating with engineering teams to create detailed specifications and using simulation software can facilitate this process. Additionally, buyers can work with suppliers who offer custom solutions, allowing for tailored magnet designs that seamlessly integrate with existing systems, thus avoiding compatibility pitfalls.

Scenario 3: Navigating the Challenges of Magnet Coating and Durability

The Problem: Buyers frequently encounter issues related to the durability and performance of DC motor magnets, particularly regarding their coatings. Poorly coated magnets can lead to corrosion, loss of magnetic strength, and a significant reduction in lifespan, which is a critical concern in industries such as automotive and aerospace where reliability is paramount.

The Solution: To mitigate durability issues, buyers should prioritize sourcing magnets with high-quality coatings suited for their specific applications. For instance, nickel plating is commonly used for its corrosion resistance, but in environments with extreme conditions, alternative coatings such as epoxy or Parylene may be more appropriate. Engaging in discussions with suppliers about the expected operational environment and potential challenges can help identify the best coating options. Additionally, implementing routine maintenance checks can further prolong the life of the magnets and ensure optimal performance over time. By focusing on the right coating and maintenance strategies, buyers can enhance the reliability of their DC motor applications.

Strategic Material Selection Guide for dc motor magnet

What Are the Key Materials for DC Motor Magnets?

When selecting materials for DC motor magnets, it is essential to consider various properties that influence performance, durability, and cost. Below are analyses of four common materials used in DC motor magnets: Neodymium, Ferrite, Samarium-Cobalt, and Alnico.

How Does Neodymium Perform in DC Motor Applications?

Neodymium magnets, known for their exceptional magnetic strength, are the most widely used in DC motors. They exhibit a high temperature rating (up to 80°C for standard grades and higher for specialized grades) and excellent corrosion resistance when nickel-plated.

Pros: Neodymium magnets provide superior torque density, making them ideal for compact and high-efficiency motors. Their small size allows for significant space savings in design.

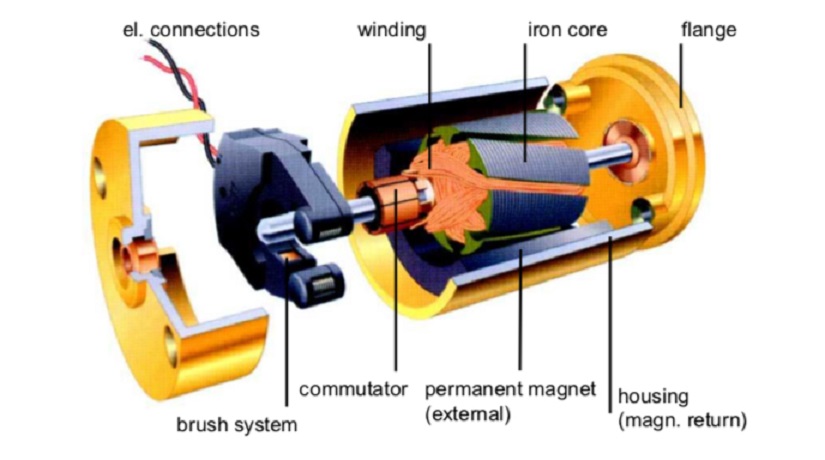

Illustrative image related to dc motor magnet

Cons: The primary drawback is their cost, which is higher than other materials. They are also susceptible to demagnetization under extreme temperatures unless specifically designed for high-temperature applications.

Impact on Application: Neodymium magnets are particularly suitable for applications requiring high performance in limited space, such as robotics and electric vehicles. However, buyers must ensure compliance with international standards like ASTM and JIS, especially regarding sourcing and environmental impact.

What About Ferrite Magnets in DC Motors?

Ferrite magnets are a cost-effective alternative to neodymium magnets. They are characterized by lower magnetic strength but offer excellent temperature stability (up to 250°C) and corrosion resistance.

Pros: Ferrite magnets are significantly cheaper to produce, making them attractive for high-volume applications. They are also less prone to demagnetization.

Cons: The lower magnetic strength means that larger sizes are required to achieve the same performance as neodymium magnets, which can negate some of the cost benefits in space-constrained designs.

Impact on Application: Ferrite magnets are suitable for applications where cost is a primary concern, such as household appliances. Buyers should be aware of regional preferences for materials and local manufacturing capabilities.

How Do Samarium-Cobalt Magnets Compare?

Samarium-Cobalt (SmCo) magnets are known for their high performance and stability in extreme environments, including high temperatures (up to 300°C) and corrosive conditions.

Pros: They offer excellent magnetic strength and resistance to demagnetization, making them suitable for high-performance applications where reliability is critical.

Cons: The cost of SmCo magnets is typically high, and their manufacturing process is more complex than that of ferrite or neodymium magnets.

Impact on Application: These magnets are ideal for aerospace and military applications where performance cannot be compromised. International buyers should consider the availability of SmCo and potential supply chain issues due to their specialized nature.

What Role Does Alnico Play in DC Motor Magnets?

Alnico magnets, made from aluminum, nickel, and cobalt, are known for their high-temperature resistance (up to 550°C) and good corrosion resistance.

Pros: They maintain their magnetic properties well over time and are less susceptible to demagnetization than other materials.

Cons: Alnico magnets have lower magnetic strength compared to neodymium and SmCo, which can limit their use in high-performance applications.

Impact on Application: Alnico is often used in applications where high temperatures are a concern, such as in electric motors for industrial applications. Buyers should ensure compliance with relevant standards and consider the specific needs of their applications.

Summary Table of Materials for DC Motor Magnets

| Material | Typical Use Case for dc motor magnet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neodymium | Robotics, electric vehicles | Superior torque density | High cost, temperature sensitive | High |

| Ferrite | Household appliances | Cost-effective, temperature stable | Lower magnetic strength | Low |

| Samarium-Cobalt | Aerospace, military applications | High performance in extreme conditions | High cost, complex manufacturing | High |

| Alnico | Industrial motors | High-temperature resistance | Lower magnetic strength | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing DC motor magnets tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dc motor magnet

What Are the Main Stages in the Manufacturing Process of DC Motor Magnets?

The manufacturing process of DC motor magnets, particularly neodymium (NdFeB) magnets, involves several critical stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials used for DC motor magnets are rare earth elements, specifically neodymium, iron, and boron. The first step is to source these raw materials from reliable suppliers. After procurement, the materials are processed to remove impurities, which may involve chemical treatments and refinement to achieve the desired chemical composition.

-

Forming: Once the materials are prepared, they undergo a forming process. This often involves powder metallurgy, where the raw materials are mixed, compacted, and then sintered at high temperatures to create a solid magnet. Advanced techniques like hot pressing or injection molding may also be employed, depending on the specific requirements of the magnet’s application.

-

Assembly: After forming, the magnets are often assembled into specific configurations. This could involve combining magnets into larger assemblies or integrating them with other components like rotors and stators in DC motors. Precision is key during this stage to ensure the correct alignment and orientation of the magnetic fields.

-

Finishing: The final stage includes surface finishing and coating to enhance durability and corrosion resistance. Common coatings include nickel plating or epoxy coating, which are essential for magnets used in harsh environments. This stage may also involve grinding or machining to achieve precise dimensions and tolerances.

What Quality Assurance Practices Are Essential in DC Motor Magnet Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of DC motor magnets to ensure they meet the required specifications and standards. Here are several key practices and relevant international standards:

-

International Standards: Compliance with international standards such as ISO 9001 ensures a robust quality management system. This certification indicates that the manufacturer consistently meets customer and regulatory requirements. Other relevant certifications may include CE for European markets and API for specific industrial applications.

-

Quality Control Checkpoints: Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are performed to monitor parameters such as temperature, pressure, and dimensions.

– Final Quality Control (FQC): After manufacturing, the finished magnets undergo rigorous testing to verify performance against specifications. -

Common Testing Methods: Various testing methods are employed to assess the magnetic properties, mechanical strength, and durability of the magnets. These may include:

– Magnetic Testing: To measure magnetic strength and coercivity.

– Thermal Testing: To evaluate performance at high temperatures.

– Mechanical Testing: To assess tensile strength and brittleness.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of potential suppliers is crucial. Here are several strategies to ensure that your supplier meets quality standards:

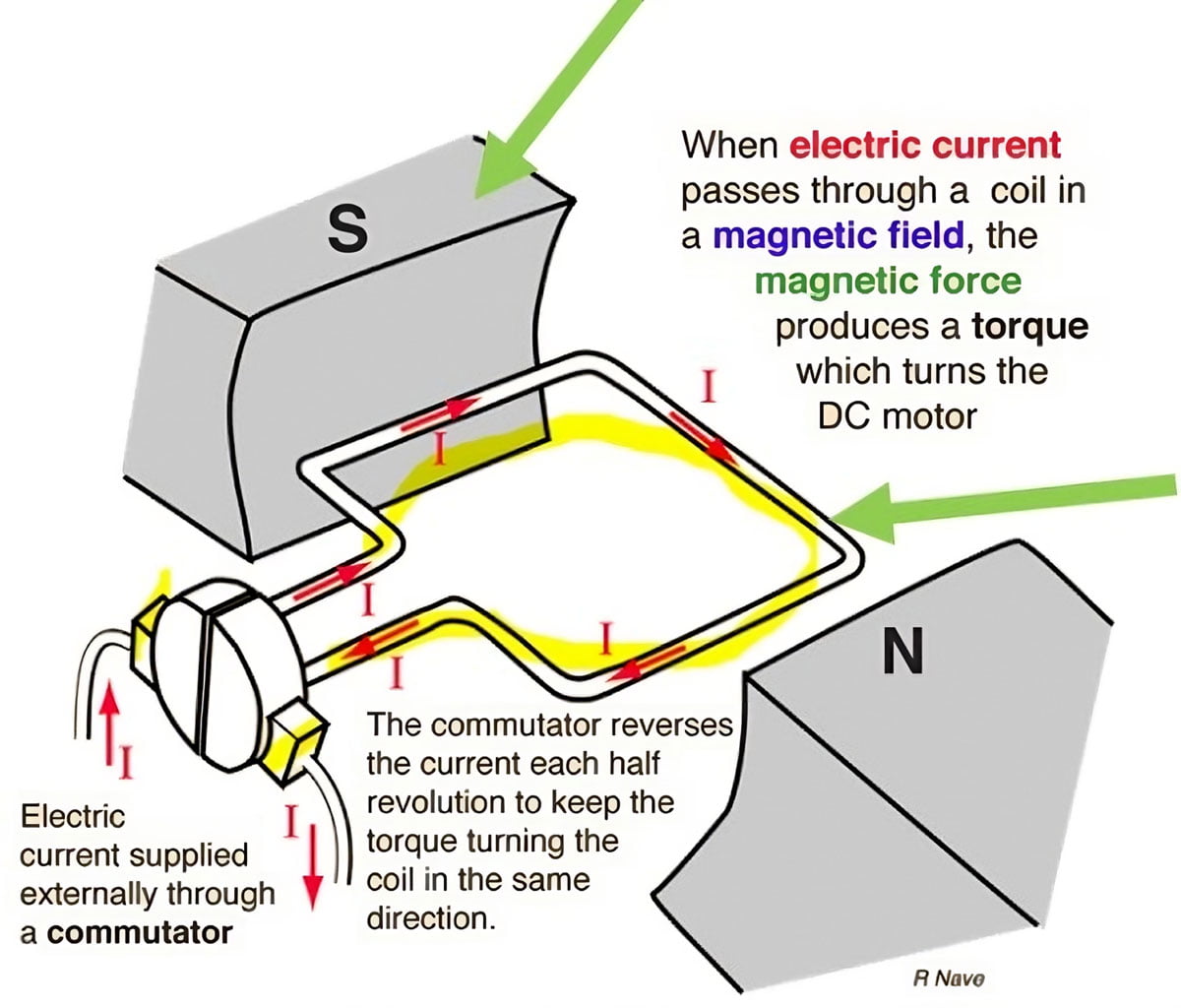

Illustrative image related to dc motor magnet

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes, quality control systems, and adherence to international standards. This not only helps in assessing their capabilities but also fosters stronger business relationships.

-

Quality Reports and Certifications: Requesting quality reports and certifications from suppliers can validate their compliance with international standards. This documentation should detail their quality management processes, testing results, and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality assurance processes. These services can perform on-site inspections and testing, ensuring that the products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, particularly in diverse regions, B2B buyers should be aware of several nuances that can affect quality control:

-

Cultural Differences: Understanding cultural approaches to manufacturing and quality assurance can be crucial. Different regions may have varying standards of quality, and being aware of these differences can help in setting realistic expectations.

-

Regulatory Compliance: Each country may have specific regulations regarding manufacturing and product quality. Buyers should ensure that suppliers are compliant with local and international regulations, which may include environmental considerations and safety standards.

-

Communication and Transparency: Effective communication is vital in maintaining quality standards. Establishing clear channels of communication and expectations regarding quality can help mitigate misunderstandings and ensure that all parties are aligned.

-

Flexibility in Specifications: International buyers should be open to discussing and adapting specifications based on the supplier’s capabilities. This flexibility can lead to better quality outcomes and foster innovation in the manufacturing process.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing DC motor magnets, ensuring they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc motor magnet’

To assist international B2B buyers in procuring DC motor magnets effectively, this practical sourcing guide outlines essential steps to ensure a successful procurement process. By following this checklist, you can make informed decisions that align with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for the DC motor magnets you require. This includes parameters such as size, material (e.g., neodymium, ferrite), grade (N35, N52, etc.), and magnetization direction. Having precise specifications helps suppliers provide accurate quotes and reduces the likelihood of errors during production.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in DC motor magnets. Look for companies with a proven track record in your region or industry. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors.

- Tip: Check supplier reviews and testimonials to gauge reliability and product quality.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you consider possess relevant certifications that affirm their compliance with industry standards. Certifications like ISO 9001 indicate a commitment to quality management, which is crucial for maintaining product consistency and reliability.

- Action Point: Request copies of certifications and verify their validity through the issuing organizations.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the DC motor magnets. Testing samples allows you to evaluate their performance and ensure they meet your specifications. Pay attention to factors such as magnetic strength, size accuracy, and surface finish.

- Important: Consider conducting a small-scale trial run to assess compatibility with your applications.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with selected suppliers to obtain the best pricing and payment terms. Be transparent about your budget and volume requirements, as this can lead to better deals. Additionally, clarify shipping costs, lead times, and minimum order quantities (MOQs).

- Note: Don’t hesitate to ask for discounts on bulk orders or long-term contracts.

Step 6: Assess After-Sales Support

A reliable supplier should provide robust after-sales support, including guidance on installation, maintenance, and troubleshooting. Evaluate the availability of technical support and whether they offer warranty services for their products.

- Key Consideration: Ask about the process for handling defective products or returns to ensure smooth operations.

Step 7: Finalize the Agreement

Once all details are settled, formalize the agreement with the chosen supplier. Ensure that the contract includes all specifications, pricing, delivery timelines, and support services. This legal documentation protects both parties and provides clarity on expectations.

By following this checklist, B2B buyers can navigate the complexities of sourcing DC motor magnets more effectively, ensuring they secure the right products for their operational needs.

Comprehensive Cost and Pricing Analysis for dc motor magnet Sourcing

What Are the Key Cost Components in DC Motor Magnet Sourcing?

When sourcing DC motor magnets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. Neodymium magnets, known for their strength, are generally more expensive than ferrite magnets. The price can vary based on global supply and demand, especially for rare earth materials, which are subject to market fluctuations.

-

Labor: Labor costs can vary by region. For example, manufacturers in Africa or South America may have lower labor costs compared to Europe. However, labor quality and skill level can affect production efficiency and, ultimately, the cost of magnets.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can lower these costs, enabling suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs for custom magnet shapes or sizes can be significant. Buyers should factor these costs into their total sourcing budget, particularly for specialized applications.

-

Quality Control: Ensuring that the magnets meet specified performance standards requires investment in quality assurance processes. Certifications (e.g., ISO) may also increase costs but are essential for ensuring reliability and performance.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and volume. International buyers should consider Incoterms, which define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

-

Margin: Suppliers will include a margin on top of their total costs to ensure profitability. This can vary based on market competition and the supplier’s position in the industry.

How Do Price Influencers Affect DC Motor Magnet Costs?

Several factors influence the pricing of DC motor magnets, which buyers should consider when negotiating:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact unit pricing. Larger orders typically lead to lower prices per unit, so buyers should assess their needs carefully to optimize costs.

-

Specifications and Customization: Custom magnets designed for specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality: Higher quality materials, such as N52 neodymium magnets, command higher prices. Buyers must balance quality with cost to meet application requirements without overspending.

-

Supplier Factors: Relationships with suppliers, their reputation, and their production capabilities can influence pricing. Established suppliers may offer better terms based on reliability and product quality.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine who bears the costs and risks associated with shipping, which can significantly affect the total cost.

What Are the Best Negotiation Strategies for B2B Buyers?

To achieve cost-efficiency in sourcing DC motor magnets, B2B buyers can employ several strategies:

-

Leverage Volume Discounts: Consolidating orders or forming purchasing alliances with other companies can help negotiate better prices based on higher volumes.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential failures, and replacement costs. A higher initial price may lead to lower TCO if the quality is superior.

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and warranties. Flexible terms can lead to better cash flow management and reduced risk.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers. Compare prices, quality, and service levels to ensure you are getting the best deal.

-

Understand Local Market Dynamics: For buyers in regions like Africa or South America, being aware of local market conditions can provide leverage in negotiations. Supply chain disruptions or economic factors may affect pricing.

Conclusion

Sourcing DC motor magnets requires a strategic approach to understand the cost components and price influencers. By leveraging negotiation strategies and considering total cost implications, international B2B buyers can make informed purchasing decisions that align with their operational needs. Always remember that indicative prices can fluctuate based on market conditions and should be verified with suppliers for accuracy.

Alternatives Analysis: Comparing dc motor magnet With Other Solutions

In the competitive landscape of industrial motors, B2B buyers often seek alternatives to DC motor magnets. Understanding these alternatives can lead to more informed purchasing decisions, tailored to specific applications and operational needs. Below, we will explore several alternatives to DC motor magnets, highlighting their strengths and weaknesses to help you make the best choice for your business.

| Comparison Aspect | Dc Motor Magnet | Ferrite Magnet | Brushless DC Motor |

|---|---|---|---|

| Performance | High torque density, compact size | Lower torque, larger size | High efficiency, better control |

| Cost | Generally higher due to material | Lower cost, more affordable | Moderate cost, requires controller |

| Ease of Implementation | Simple integration in standard designs | Easy to source, widely available | More complex due to controller needs |

| Maintenance | Low maintenance, reliable | Low maintenance, durable | Low maintenance, but controller may require attention |

| Best Use Case | Robotics, high-performance applications | Household appliances, lower-end motors | Electric vehicles, drones, precision applications |

What Are the Pros and Cons of Ferrite Magnets as an Alternative?

Ferrite magnets, made from a combination of iron oxide and other metals, present a cost-effective alternative to DC motor magnets. They are widely used in applications where high magnetic strength is not critical, making them suitable for household appliances and other lower-end motors. The primary advantages include their affordability and durability. However, their performance is limited by lower torque and larger physical dimensions compared to neodymium magnets, which may not meet the demands of high-performance applications.

How Do Brushless DC Motors Compare to DC Motor Magnets?

Brushless DC motors (BLDC) represent a more advanced technology that eliminates the need for traditional brushes and commutators. This results in higher efficiency and enhanced control over speed and torque. BLDC motors are often favored in applications such as electric vehicles and drones, where performance and reliability are paramount. However, they require a more complex implementation due to the need for electronic controllers, which can increase the overall system cost. While they offer significant advantages in efficiency and performance, the initial investment and complexity may deter some buyers.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a motor solution, B2B buyers must consider their specific operational requirements, including performance, cost constraints, and ease of integration. For high-performance applications where space and efficiency are critical, DC motor magnets or brushless DC motors might be the best fit. In contrast, for more budget-conscious projects or those with less demanding performance criteria, ferrite magnets could be the optimal choice. By carefully evaluating these alternatives, buyers can align their motor solutions with their strategic objectives, ensuring both performance and cost-effectiveness in their operations.

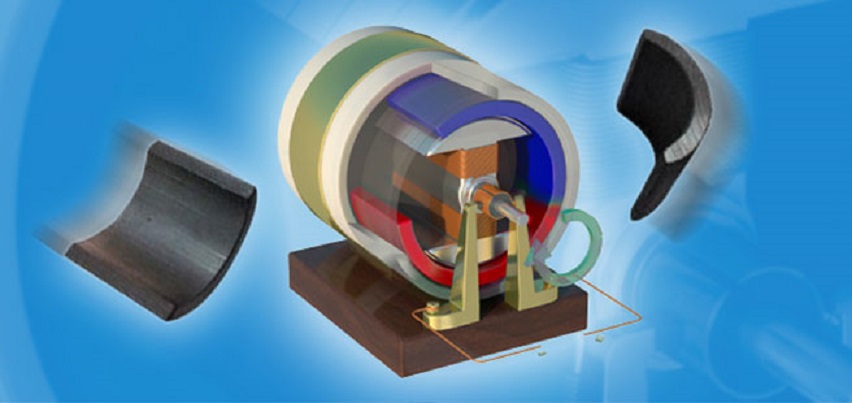

Illustrative image related to dc motor magnet

Essential Technical Properties and Trade Terminology for dc motor magnet

What Are the Key Technical Properties of DC Motor Magnets?

When sourcing DC motor magnets, understanding their technical specifications is crucial for ensuring optimal performance and compatibility with your applications. Here are some essential properties that B2B buyers should consider:

-

Material Grade

The most common materials used for DC motor magnets are neodymium (NdFeB), ferrite, and samarium-cobalt (SmCo). Neodymium magnets, particularly those rated N35 to N52, offer the highest magnetic strength and are ideal for compact, high-efficiency motors. Ferrite magnets are a cost-effective alternative but provide lower magnetic strength. The choice of material impacts not only performance but also cost and application suitability. -

Magnetization Direction

The orientation in which the magnets are magnetized (e.g., axial or radial) significantly affects the motor’s performance. Axial magnetization is commonly used in applications requiring high torque, while radial magnetization is often seen in smaller motors. Understanding magnetization is essential for aligning the magnets correctly within the motor assembly. -

Tolerance and Dimensional Specifications

Precision in dimensions is vital for ensuring that the magnets fit properly in the motor assembly. Tolerances typically range from ±0.1 mm to ±0.5 mm, depending on the application. Tight tolerances are crucial in high-performance applications where even minor discrepancies can lead to inefficiencies or mechanical failures. -

Coating and Surface Treatment

Most DC motor magnets are coated (often with nickel or epoxy) to enhance durability and resistance to corrosion. The type of coating affects the magnet’s lifespan, especially in harsh environments. Buyers should specify the required coating based on their operational conditions to ensure longevity. -

Temperature Rating

The maximum operating temperature of a magnet is critical for applications exposed to high heat. Neodymium magnets generally perform well up to 80°C, while SmCo magnets can withstand higher temperatures. Selecting a magnet with an appropriate temperature rating prevents demagnetization and ensures reliable operation. -

Magnetic Strength (Gauss or Tesla Rating)

The strength of the magnetic field is often measured in Gauss or Tesla. A higher rating indicates a stronger magnet, which is essential for applications requiring significant force or torque. Understanding magnetic strength helps in selecting the right magnet for the intended application, ensuring efficiency and effectiveness.

What Are Common Trade Terms Used in the DC Motor Magnet Industry?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s end product. Understanding OEM specifications is vital for ensuring that the magnets meet the necessary standards for your motors. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their budgets and inventory effectively, especially when sourcing specialized magnets. -

RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. Using an RFQ ensures that buyers receive competitive pricing and helps streamline procurement. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risks, and responsibilities. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time helps buyers manage project timelines and ensures that they have the necessary components when needed. -

Customization Options

Many suppliers offer customization for magnet dimensions, coatings, and magnetization. Understanding customization options allows buyers to tailor products to their specific needs, enhancing performance and compatibility with their applications.

By grasping these properties and terms, B2B buyers can make informed decisions when sourcing DC motor magnets, ensuring they meet their specific operational requirements while optimizing costs and performance.

Illustrative image related to dc motor magnet

Navigating Market Dynamics and Sourcing Trends in the dc motor magnet Sector

What Are the Key Trends Influencing the DC Motor Magnet Market?

The global market for DC motor magnets is being driven by several key factors, including the rapid expansion of electric vehicles (EVs), renewable energy technologies, and advancements in automation. As industries seek efficient energy solutions, the demand for high-performance neodymium magnets—known for their superior strength and lightweight properties—has surged. Notably, regions like Africa, South America, the Middle East, and Europe are experiencing an uptick in manufacturing capabilities, leading to increased local sourcing of DC motor magnets. This trend is particularly evident in Brazil and Nigeria, where investments in infrastructure and manufacturing are creating new opportunities for suppliers.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are also reshaping sourcing strategies. B2B buyers are increasingly looking for suppliers who can provide not only high-quality products but also integrated solutions that enhance operational efficiencies. Additionally, the rise of e-commerce platforms is facilitating quicker access to suppliers, enabling international buyers to compare prices and specifications effectively. The push for customization in magnet designs to meet specific motor configurations is another trend gaining traction, prompting suppliers to offer tailored solutions.

How Is Sustainability Reshaping the DC Motor Magnet Supply Chain?

Sustainability has become a paramount concern in the sourcing of DC motor magnets. The environmental impact of magnet production, particularly in terms of mining and processing rare earth elements, has raised questions about the ethical implications of sourcing practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through responsible sourcing and production methods. This includes utilizing recycled materials and adopting energy-efficient manufacturing processes.

Moreover, certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers aiming to compete in the international marketplace. Buyers are also looking for ‘green’ materials, which include magnets that are produced with lower environmental footprints, such as those utilizing ferrite or alternative materials that do not rely on rare earth elements. As awareness of climate change grows, companies that can prove their sustainability credentials will not only attract conscientious buyers but also enhance their brand reputation in a competitive landscape.

What Is the Historical Context of DC Motor Magnets?

The evolution of DC motor magnets dates back to the early 19th century when the first DC motors were introduced. Initially, these motors faced challenges due to the limitations of battery technology, which were both expensive and inefficient. However, advancements in magnet technology, particularly the development of permanent magnets made from neodymium-iron-boron in the 1980s, revolutionized the sector. These high-performance magnets enabled more compact and efficient motor designs, paving the way for their widespread application in various industries, including automotive and consumer electronics.

As the demand for energy-efficient solutions continues to rise, understanding the historical context of DC motor magnets is vital for B2B buyers. It illustrates the technological advancements that have shaped current offerings and highlights the ongoing innovations that will drive future trends. By staying informed about this evolution, international buyers can make strategic sourcing decisions that align with market demands and technological capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of dc motor magnet

-

How do I choose the right dc motor magnet for my application?

Choosing the right dc motor magnet depends on several factors, including the motor’s design, required torque, and operational environment. Neodymium magnets are favored for their high strength-to-size ratio, making them ideal for compact motors. Consider the temperature range, corrosion resistance, and magnetization direction required for your specific application. Collaborating with a supplier that offers customization options can help ensure you select the best magnet to optimize performance and efficiency. -

What are the advantages of using neodymium magnets in dc motors?

Neodymium magnets provide superior magnetic strength, which enhances the efficiency and torque of dc motors. Their compact size allows for lighter and smaller motor designs, which is beneficial in applications where space is a constraint. Additionally, neodymium magnets exhibit excellent temperature stability and durability, making them suitable for various environments. Their reliability in high-performance applications, such as robotics and electric vehicles, further solidifies their preference in the industry. -

What is the minimum order quantity (MOQ) for dc motor magnets?

Minimum order quantities for dc motor magnets typically range from 10 to 65 pieces, depending on the supplier and specific product type. It’s essential to confirm the MOQ before placing an order, as it can vary based on the magnet’s size, grade, and customization options. For international buyers, understanding MOQ can help in planning inventory and managing costs effectively, ensuring that you meet production needs without excess stock. -

What payment terms should I expect when sourcing dc motor magnets internationally?

Payment terms can vary significantly among suppliers, but common practices include upfront payments, partial deposits, or net 30/60 terms. For international transactions, it’s crucial to discuss currency preferences, payment methods (such as wire transfer, credit card, or PayPal), and any associated fees. Establishing clear payment terms in advance can help mitigate risks and build trust between buyers and suppliers, ensuring a smoother procurement process. -

How can I ensure the quality of dc motor magnets from suppliers?

To ensure quality, request detailed specifications, certifications, and test reports from potential suppliers. Look for compliance with international standards such as ISO 9001 for quality management systems. Additionally, consider conducting factory audits or third-party inspections to verify manufacturing processes. Establishing a strong relationship with suppliers and maintaining open communication can further enhance quality assurance throughout the sourcing process. -

What logistics considerations should I keep in mind when importing dc motor magnets?

Logistics plays a crucial role in the timely delivery of dc motor magnets. Consider factors such as shipping methods (air freight vs. sea freight), customs duties, and import regulations specific to your country. Work closely with your supplier to understand packaging requirements and ensure compliance with international shipping standards. Establishing a reliable logistics partner can help streamline the import process, reducing delays and potential costs. -

Can I customize the size and coating of dc motor magnets?

Yes, many suppliers offer customization options for both size and coating of dc motor magnets. Customization can enhance performance based on specific application needs, such as temperature resistance or environmental exposure. When requesting custom magnets, provide detailed specifications and discuss any unique requirements with your supplier. This collaborative approach can lead to better solutions that meet your operational demands. -

What are the common applications for dc motor magnets in various industries?

Dc motor magnets are widely used across multiple industries, including automotive, consumer electronics, robotics, and renewable energy. Applications range from electric vehicles, where they enhance motor efficiency, to household appliances that require compact and powerful motors. Understanding the specific needs of your industry can help you choose the right magnet type and grade, optimizing your product’s performance and reliability.

Top 5 Dc Motor Magnet Manufacturers & Suppliers List

1. Super Magnet Man – Neodymium Motor Magnets

Domain: supermagnetman.com

Registered: 2003 (22 years)

Introduction: Neodymium motor magnets engineered for brushless DC motors, robotics, and high-performance motion systems. Strongest commercially available magnet material (NdFeB) for compact designs. Includes square, rectangular blocks, and arc magnets for various motor configurations. Common uses: brushless DC motors, high-torque servo motors, precision robotics drives, compact gearless drive systems, prototypi…

2. Electric Motors – Permanent Magnet DC Motors

Domain: electricmotors.com

Registered: 1996 (29 years)

Introduction: Permanent Magnet DC Motors are designed for use with SCR controllers, providing constant torque and adjustable speeds. They are available in voltages of 12, 24, 90, and 180 volts. Key features include: totally enclosed fan cooled or non-ventilated design for longer life, heavy-duty gauge steel construction, NEMA 56 C flange mount with removable bases, Class F insulation, and heavy-duty permanently…

3. Magnetic Innovations – Brushless Torque Motors & Actuators

Domain: magneticinnovations.com

Registered: 2007 (18 years)

Introduction: Brushless Inrunner Torque Motors: IR-F 52 mm, IR-F 85 mm, IR-F 170 mm; Torque Motors (Outrunner): MI-F 40, MI-F 40 Combined, MI-F 110, MI-F 110 Combined, MI-F 250, MI-F 250 Combined, MI-F 485; High Speed Linear Actuator; Moving Magnet Actuators: 1525, 1555, 3070, 5536, 9054, 240-380; Electric Linear Actuators: MMB 1525, MMB 1555, MMB 3070, MMB 4090, MMB 5536, MMB 9054; Motor Controller; Vacuum Act…

4. HSMAG – DC Motor Magnets

Domain: hsmagnets.com

Registered: 2010 (15 years)

Introduction: DC Motor Magnets Supplier – HSMAG offers a variety of DC motor magnets including: 1. NdFeB N56M Magnet – Huge Disc Round Ø120 x 60mm, Super Strong Sintered Cylindrical Round Neodymium Magnet. 2. N54 Magnet – Huge Disc Round Nickel Ø100 x 50mm, Super Strong Sintered Cylindrical Round Neodymium Magnet. 3. N56 NdFeB Magnet – Giant Round Disc Ø100 x 50mm, Super Strong Sintered Cylindrical Round Neodym…

5. Bodine – Permanent Magnet DC Motors

Domain: bodine-electric.com

Registered: 1997 (28 years)

Introduction: Bodine permanent magnet DC (PMDC) motors include 24A, 33A, and 42A frame motors designed for high efficiency, high starting torque, and linear speed/torque performance. They are suitable for adjustable speed applications and come in low-voltage (12 or 24 VDC), SCR rated (90 VDC or 180 VDC), and standard (130 VDC) windings. Applications include agricultural equipment, warehouse automation robots, p…

Strategic Sourcing Conclusion and Outlook for dc motor magnet

In the realm of DC motor magnets, strategic sourcing is pivotal for businesses looking to enhance their operational efficiency and product quality. Understanding the diverse types of magnets, such as neodymium and ferrite, is crucial for making informed decisions that align with specific application needs. With the increasing demand for compact and high-performance motors, the selection of the right magnet can significantly impact the overall performance and reliability of the end product.

B2B buyers from regions like Africa, South America, the Middle East, and Europe must prioritize sourcing partnerships that offer not only competitive pricing but also customizable solutions tailored to their unique requirements. Engaging with suppliers who provide technical support and rapid prototyping capabilities can help streamline the development process and reduce time to market.

As the global market for DC motors continues to evolve, it is essential for international buyers to stay abreast of trends and innovations. Investing in strategic sourcing today will not only enhance product offerings but also position businesses for future growth. Take the proactive step to evaluate your sourcing strategies and partner with suppliers that can deliver quality, reliability, and innovation in your DC motor magnet needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.