Is Your Rippa Mini Excavator Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for rippa mini excavator

In an increasingly competitive landscape, sourcing the right Rippa mini excavator can pose significant challenges for international B2B buyers. As construction and agricultural projects expand across Africa, South America, the Middle East, and Europe, the demand for compact, efficient, and reliable machinery has never been higher. This comprehensive guide aims to equip decision-makers with essential insights into the diverse range of Rippa mini excavators available, their applications, and the critical factors to consider when selecting a supplier.

From understanding the specifications of models like the R10 and R32 to exploring the nuances of cost structures and after-sales support, this guide addresses the full spectrum of considerations necessary for making informed purchasing decisions. Additionally, we delve into the importance of supplier vetting, highlighting how to assess quality, reliability, and service capabilities.

With actionable insights tailored specifically for markets in Nigeria, Vietnam, and beyond, this guide empowers B2B buyers to navigate the complexities of the global market confidently. By providing a clear framework for evaluating options, we ensure that buyers can secure the best equipment to meet their operational needs while maximizing return on investment.

Understanding rippa mini excavator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rippa R10 | Compact, lightweight (1000kg), 8.2 kW power | Small landscaping, tight spaces | Pros: Affordable, easy to maneuver; Cons: Limited power for heavy tasks. |

| Rippa R15 | Mid-weight (1500kg), powerful Kubota D722 engine | General construction, utility work | Pros: Good balance of power and weight; Cons: May not excel in extreme conditions. |

| Rippa R22 | Larger capacity (2371kg), 18 kW power | Heavy-duty excavation, larger projects | Pros: High digging depth and capacity; Cons: Requires more space for operation. |

| Rippa R32 | Robust (3171kg), advanced hydraulic system | Infrastructure development, mining | Pros: Excellent for extensive digging; Cons: Higher investment cost. |

| R57 Mini Excavator | Heavy-duty (5700kg), 51 kW power | Large-scale construction, demolition | Pros: Exceptional power and depth; Cons: Less suitable for small projects. |

What are the Key Characteristics of Rippa R10 Mini Excavator?

The Rippa R10 is ideal for small-scale projects requiring agility and precision. With an operating weight of just 1000kg and a maximum power output of 8.2 kW, it is designed for tight spaces and landscaping tasks. This model is particularly suited for businesses focused on small construction or maintenance jobs, where maneuverability is crucial. Buyers should consider the R10’s cost-effectiveness and ease of transport, but be aware that its limited power may restrict its application in more demanding environments.

How Does the Rippa R15 Fit into General Construction Needs?

The Rippa R15 mini excavator strikes a balance between weight and power, making it a versatile choice for general construction and utility work. Weighing 1500kg and equipped with a Kubota D722 engine, it offers sufficient power for various tasks without being overly cumbersome. This model is suitable for contractors looking to perform moderate excavation and landscaping tasks efficiently. While it provides a good range of capabilities, buyers should consider that it may not perform optimally in extreme conditions or heavy-duty applications.

What Advantages Does the Rippa R22 Offer for Heavy-Duty Excavation?

With an operating weight of 2371kg and 18 kW of power, the Rippa R22 is designed for more substantial excavation projects. Its high digging depth and capacity make it suitable for heavy-duty applications in construction and infrastructure development. This model is ideal for companies involved in larger projects that require robust machinery. However, buyers should keep in mind that its size requires more operational space, and the investment cost is higher compared to smaller models.

Illustrative image related to rippa mini excavator

Why Choose the Rippa R32 for Infrastructure Development?

The Rippa R32 mini excavator is a robust option for businesses engaged in infrastructure development and mining. Its weight of 3171kg and advanced hydraulic system provide excellent digging capabilities, making it suitable for extensive excavation tasks. Companies looking to invest in reliable and powerful machinery will find the R32 advantageous. However, potential buyers should evaluate the higher upfront costs associated with this model, as well as the need for adequate space for operation.

What Makes the R57 Mini Excavator Suitable for Large-Scale Projects?

The R57 mini excavator stands out in the Rippa lineup as a heavy-duty option, weighing 5700kg and delivering 51 kW of power. It is specifically designed for large-scale construction and demolition tasks, providing exceptional digging depth and capacity. This model is ideal for companies that frequently undertake significant excavation projects. While its power and capabilities are unmatched, the R57 may not be the best fit for smaller jobs due to its size and cost. Buyers should weigh these factors against their project needs.

Key Industrial Applications of rippa mini excavator

| Industry/Sector | Specific Application of rippa mini excavator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site preparation and foundation digging | Enhances productivity by enabling quick and efficient site preparation. | Ensure compliance with local regulations and certifications. |

| Agriculture | Land clearing and drainage work | Improves land usability and crop yield by clearing land and managing water flow. | Consider attachment options for various agricultural tasks. |

| Landscaping and Gardening | Tree stump removal and landscaping enhancements | Facilitates aesthetic improvements and land utilization in residential and commercial areas. | Look for compact models to navigate tight spaces effectively. |

| Mining and Quarrying | Material handling and trenching | Increases operational efficiency by facilitating easy movement of materials. | Evaluate durability and power for heavy-duty tasks. |

| Utility and Infrastructure | Cable and pipeline installation | Streamlines the installation process, reducing downtime and labor costs. | Assess hydraulic capabilities for diverse utility tasks. |

How is the Rippa Mini Excavator Used in Construction Projects?

In the construction sector, Rippa mini excavators are essential for site preparation and foundation digging. Their compact size allows them to maneuver in tight spaces, making them ideal for urban construction sites. By utilizing these excavators, businesses can significantly enhance their productivity, as they facilitate quick excavation and grading operations. Buyers in regions like Africa and South America should ensure that the excavators meet local regulatory standards for emissions and safety to avoid any operational hurdles.

What Role Does the Rippa Mini Excavator Play in Agriculture?

Rippa mini excavators are increasingly used in agriculture for land clearing and drainage work. They help farmers prepare their fields by removing debris and improving water management, which can lead to increased crop yields. For international buyers, especially in regions with diverse agricultural practices, it’s important to consider various attachment options that can enhance the excavator’s utility for tasks such as furrowing or soil aeration. Ensuring that the equipment is adaptable to local farming techniques is crucial for maximizing investment.

How Can Rippa Mini Excavators Enhance Landscaping Projects?

In landscaping and gardening, Rippa mini excavators are utilized for tree stump removal and enhancing outdoor aesthetics. Their agility allows landscapers to work in confined areas without damaging existing plants or structures. This capability not only saves time but also improves the overall quality of landscaping projects. Buyers should evaluate the machine’s size and attachment compatibility to ensure they can handle the specific requirements of their landscaping tasks, particularly in urban environments where space is limited.

Illustrative image related to rippa mini excavator

How Do Rippa Mini Excavators Assist in Mining and Quarrying?

In the mining and quarrying industries, Rippa mini excavators are valuable for material handling and trenching operations. Their robust design and powerful hydraulics enable them to efficiently move materials, thereby increasing operational efficiency. For businesses in these sectors, it’s essential to assess the excavator’s durability and power to ensure it can withstand the rigors of heavy-duty tasks. Additionally, buyers should consider the availability of parts and service support in their region to minimize downtime.

What Benefits Do Rippa Mini Excavators Offer for Utility and Infrastructure Work?

Rippa mini excavators are particularly beneficial in utility and infrastructure projects, such as cable and pipeline installation. Their compactness allows for efficient trenching and material handling, which can significantly reduce installation time and labor costs. International buyers should focus on the hydraulic capabilities of the excavators, ensuring they can handle the diverse tasks associated with utility work. Understanding local utility regulations and compliance requirements is also critical to streamline operations and avoid legal complications.

3 Common User Pain Points for ‘rippa mini excavator’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Parts and Service for Rippa Mini Excavators

The Problem: B2B buyers often encounter challenges in sourcing reliable replacement parts and after-sales service for Rippa mini excavators. In regions like Africa or South America, where infrastructure may not be robust, obtaining timely service and parts can result in prolonged downtimes and increased operational costs. Buyers may also struggle with navigating the complexities of international shipping and customs, leading to delays in getting their machinery back in operation.

The Solution: To mitigate these issues, buyers should establish a strong relationship with their Rippa dealer or manufacturer. This involves asking for a comprehensive parts catalog and ensuring that they have a reliable supply chain for critical components. Buyers can also negotiate service level agreements (SLAs) that specify response times for repairs and parts delivery. Investing in training for local technicians on Rippa machinery can further reduce downtime by empowering them to handle minor repairs and routine maintenance. Additionally, utilizing online platforms or forums to connect with other Rippa owners can provide insights into sourcing parts and best practices for maintenance.

Scenario 2: Maximizing Productivity with Rippa Mini Excavators on Diverse Job Sites

The Problem: B2B buyers often face productivity challenges when using Rippa mini excavators across varied job sites with different soil conditions and project requirements. The compact size and versatility of Rippa machines are their main selling points, yet users may find that they struggle to adapt the excavators for specific tasks such as trenching, grading, or heavy lifting, especially when working in challenging terrains.

Illustrative image related to rippa mini excavator

The Solution: To enhance productivity, buyers should invest time in understanding the specific features of their Rippa mini excavators, such as adjustable hydraulic settings and different attachment options (e.g., buckets, thumbs, and augers). Each model comes with unique capabilities tailored for specific tasks. Buyers should also consider utilizing attachments that are specifically designed for the type of work they will be doing. For instance, using a trenching bucket for digging trenches can significantly improve efficiency. Conducting on-site training sessions for operators to familiarize them with the excavator’s capabilities will maximize their productivity and ensure that they are using the equipment to its full potential.

Scenario 3: Navigating Regulatory Compliance and Certification Challenges

The Problem: Many B2B buyers in regions such as Europe and the Middle East face stringent regulatory compliance challenges when operating mini excavators like those from Rippa. These regulations often include safety standards, emissions controls, and certifications that can vary significantly from one country to another. Failure to comply can result in hefty fines, project delays, and even damage to reputation.

The Solution: Buyers should proactively engage with local regulatory bodies to understand the specific compliance requirements for operating Rippa mini excavators in their respective regions. This includes ensuring that the equipment meets CE, EPA, or Euro V certification standards, which Rippa models typically uphold. Buyers should also keep abreast of any changes in regulations by subscribing to industry newsletters or joining local construction associations. Additionally, documenting all compliance-related activities, such as maintenance records and safety inspections, can help buyers demonstrate adherence to regulations and avoid potential fines. Leveraging the manufacturer’s resources for compliance guidance can also streamline this process and ensure a smoother operation.

Illustrative image related to rippa mini excavator

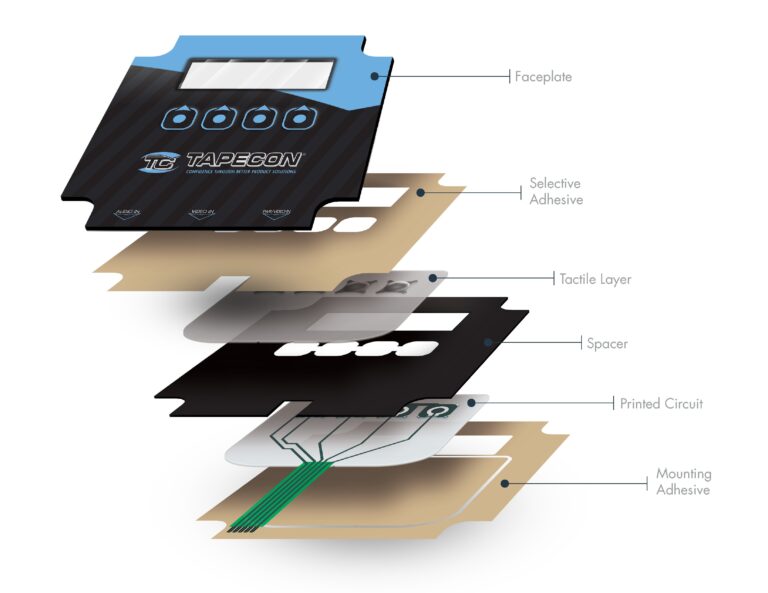

Strategic Material Selection Guide for rippa mini excavator

What Are the Key Materials Used in Rippa Mini Excavators?

When it comes to the construction and performance of Rippa mini excavators, the choice of materials is crucial. The materials selected not only influence the durability and efficiency of the machines but also affect their cost and compliance with international standards. Here, we analyze four common materials used in Rippa mini excavators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel: The Backbone of Structural Integrity

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for structural components of mini excavators. It typically withstands temperatures up to 600°C and exhibits good corrosion resistance when treated.

Pros & Cons: Steel is highly durable and can handle significant stress, making it suitable for heavy-duty applications. However, it can be heavier than alternative materials, which may affect the overall weight of the excavator. Additionally, the cost of high-quality steel can be relatively high, and manufacturing processes, such as welding and machining, can add complexity.

Impact on Application: Steel components are essential for the frame and arm of the excavator, providing the necessary strength for digging and lifting operations.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used complies with local standards, such as ASTM A36 or DIN 17100, to ensure quality and safety.

Illustrative image related to rippa mini excavator

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with excellent corrosion resistance and thermal conductivity. It can withstand temperatures up to 200°C, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its weight, which can enhance maneuverability and reduce fuel consumption. However, it is less strong than steel, making it less suitable for high-stress components. The manufacturing process for aluminum can also be more complex and costly.

Impact on Application: Aluminum is often used in non-structural components, such as housing for electrical systems and lighter attachments, where weight savings are critical.

Illustrative image related to rippa mini excavator

Considerations for International Buyers: Compliance with international standards such as JIS H 4000 is essential for aluminum components. Buyers should also consider local availability and costs, as aluminum can be more expensive in some regions.

Composite Materials: Versatile and Innovative

Key Properties: Composites, often made from a combination of materials like fiberglass and resin, are known for their high strength-to-weight ratio and excellent resistance to corrosion and environmental factors.

Pros & Cons: Composites are highly versatile and can be tailored for specific applications, providing significant weight savings. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composites are suitable for components that require both strength and lightweight characteristics, such as certain body panels and covers.

Considerations for International Buyers: Buyers should be aware of the specific standards for composite materials in their region, as these can vary significantly. Ensuring compliance with local regulations is crucial.

Illustrative image related to rippa mini excavator

Rubber: Essential for Mobility and Stability

Key Properties: Rubber is flexible and resilient, providing excellent shock absorption and traction. It performs well in a wide range of temperatures, typically from -40°C to 120°C.

Pros & Cons: The main advantage of rubber is its ability to provide stability and reduce vibrations, which enhances operator comfort. However, rubber can wear out more quickly than metals, requiring regular maintenance and replacement.

Impact on Application: Rubber is primarily used in tracks and tires, which are critical for the mobility of mini excavators on various terrains.

Illustrative image related to rippa mini excavator

Considerations for International Buyers: Buyers should ensure that the rubber used meets local standards for durability and performance, especially in regions with extreme weather conditions.

Summary Table of Material Selection

| Material | Typical Use Case for rippa mini excavator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components (frame, arm) | High tensile strength and durability | Heavier than alternatives; higher cost | High |

| Aluminum | Non-structural components (housing) | Lightweight, enhances maneuverability | Less strong; complex manufacturing | Medium |

| Composite | Body panels and covers | High strength-to-weight ratio | Expensive; specialized manufacturing | High |

| Rubber | Tracks and tires | Excellent shock absorption and traction | Shorter lifespan; requires maintenance | Medium |

This guide provides a comprehensive overview of the materials used in Rippa mini excavators, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rippa mini excavator

The manufacturing processes and quality assurance protocols for Rippa mini excavators are crucial aspects that international B2B buyers should understand to make informed purchasing decisions. This section provides a detailed overview of the manufacturing stages, key techniques, quality assurance standards, and how buyers can ensure the reliability and compliance of their suppliers.

What Are the Main Stages of Manufacturing Rippa Mini Excavators?

The manufacturing of Rippa mini excavators involves several key stages that ensure the final product meets high-quality standards and performance expectations.

Illustrative image related to rippa mini excavator

-

Material Preparation: This initial phase involves sourcing high-quality raw materials, including steel and other metals, which are essential for the structural integrity of the excavators. Rippa focuses on using durable, high-grade materials that can withstand rigorous operational conditions. Suppliers are often evaluated based on their material quality and compliance with international standards.

-

Forming: The next step involves shaping the prepared materials into components. Advanced techniques such as laser cutting and CNC machining are utilized to create precise and intricate parts of the excavator. These methods enhance accuracy and reduce waste, which is important for cost-effectiveness and environmental sustainability.

-

Assembly: After forming, the components are assembled into the complete mini excavator. This stage includes integrating the engine, hydraulic systems, and control mechanisms. Rippa employs skilled labor and automated systems to ensure that the assembly process is efficient and consistent, minimizing the risk of defects.

-

Finishing: The finishing stage involves painting and coating the excavators to protect against corrosion and enhance aesthetics. Rippa utilizes advanced painting technologies that ensure a durable finish, which is essential for longevity, especially in harsh environments typical of many international markets.

How Does Rippa Ensure Quality Assurance Throughout Manufacturing?

Quality assurance is an integral part of Rippa’s manufacturing process, designed to comply with international standards and meet customer expectations.

-

Compliance with International Standards: Rippa adheres to ISO 9001 standards, which provide a framework for quality management systems. This certification ensures that processes are consistent and that products meet customer and regulatory requirements. Additionally, Rippa’s products are CE and EPA certified, affirming compliance with European and American environmental and safety standards.

-

Quality Control Checkpoints: The quality control process is comprehensive and includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to catch defects early in the process. This includes monitoring machinery and checking tolerances on critical components.

– Final Quality Control (FQC): After assembly, each mini excavator undergoes rigorous testing and inspection to ensure it meets performance standards before being shipped to customers. -

Common Testing Methods: Rippa employs various testing methods, including:

– Functional Testing: Each excavator is operated to ensure all systems, including hydraulics and controls, function correctly.

– Load Testing: The structural integrity of the excavator is assessed under load to ensure it can perform as expected in real-world conditions.

– Durability Testing: Long-term performance is simulated to identify potential issues that could arise during extensive use.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure reliability and compliance.

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the production processes, material quality, and adherence to quality management systems. Buyers should request audit reports and certifications to assess the supplier’s commitment to quality.

-

Quality Control Reports: Requesting detailed quality control reports from the supplier can provide transparency on the testing processes and results. These reports should include data from IQC, IPQC, and FQC stages, demonstrating the effectiveness of their quality assurance measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing practices and product quality. This can be particularly important for buyers who may not have the capacity to perform audits themselves.

What Are the Quality Control Nuances for International Buyers?

Understanding the nuances of quality control is particularly important for B2B buyers in diverse markets. Here are some considerations:

-

Regulatory Compliance: Buyers must be aware of the specific regulations in their respective countries regarding construction equipment. Ensuring that Rippa mini excavators meet these requirements can prevent legal and operational issues.

-

Cultural Differences in Quality Standards: Quality expectations may vary by region, so buyers should communicate their specific needs and standards clearly to suppliers. This includes understanding local preferences for durability, performance, and environmental impact.

-

After-Sales Support: Quality assurance doesn’t end at the point of sale. Understanding the supplier’s after-sales support, warranty policies, and availability of replacement parts is essential for maintaining equipment performance over time.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices at Rippa is vital for B2B buyers looking to invest in mini excavators. By leveraging this information, buyers can make informed decisions that align with their operational needs and compliance requirements, ensuring they receive high-quality equipment that will perform reliably in their specific market conditions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rippa mini excavator’

The following guide provides a comprehensive step-by-step checklist for B2B buyers looking to procure a Rippa mini excavator. This checklist aims to streamline the sourcing process, ensuring that buyers make informed decisions that align with their operational needs and budget constraints.

Illustrative image related to rippa mini excavator

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s vital to outline your technical requirements. Determine the operating weight, engine power, and digging depth necessary for your specific projects. Understanding these specifications helps narrow down your options and ensures the selected model meets your operational demands.

- Consider the range of models: Rippa offers various models, such as the R10, R15, and R32, each suited for different tasks.

- Evaluate the applications: Identify whether you need the excavator for landscaping, construction, or demolition to select the most suitable model.

Step 2: Research Supplier Credentials

It’s essential to verify the credibility of potential suppliers. Look for certifications such as CE, EPA, and Euro V compliance, which indicate adherence to safety and environmental standards.

- Check for experience: Suppliers with a proven track record in the mini excavator market are more likely to provide reliable products and services.

- Request documentation: Ask for certifications and compliance documents to ensure the equipment meets international standards.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability.

- Assess customer service: Look for suppliers known for responsive customer support and after-sales service.

- Compare multiple offers: Don’t settle for the first quote; obtain multiple proposals to understand the market price and service levels.

Step 4: Understand Pricing Structures

Analyze the pricing structures of different suppliers to ensure transparency. This includes not only the initial cost but also financing options, warranties, and potential hidden fees.

Illustrative image related to rippa mini excavator

- Consider total cost of ownership: Evaluate ongoing maintenance costs and spare parts availability to budget effectively.

- Negotiate terms: Discuss payment terms and possible discounts for bulk purchases or long-term contracts.

Step 5: Inquire About After-Sales Support

After-sales support is crucial for maintaining operational efficiency. Ask potential suppliers about their warranty policies, maintenance services, and availability of spare parts.

- Look for comprehensive service packages: Ensure that the supplier offers technical support and training for your team.

- Check response times: Assess how quickly they can provide service or parts in case of equipment failure.

Step 6: Finalize Logistics and Delivery Terms

Once you have selected a supplier, finalize logistics and delivery terms. This includes shipping methods, estimated delivery times, and installation services if required.

- Clarify responsibilities: Ensure that both parties understand who is responsible for shipping and handling.

- Plan for customs and import regulations: For international purchases, be aware of any customs duties or import regulations that may apply.

Step 7: Conduct a Pre-Delivery Inspection

Before taking possession of the Rippa mini excavator, conduct a thorough inspection. This ensures that the equipment meets your specifications and is free from defects.

- Check operational readiness: Confirm that all components are functioning correctly.

- Document findings: Keep a record of the inspection for future reference and warranty claims.

By following this checklist, B2B buyers can confidently navigate the procurement process for Rippa mini excavators, ensuring they select the right equipment for their needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for rippa mini excavator Sourcing

What Are the Key Cost Components for Rippa Mini Excavator Sourcing?

When sourcing Rippa mini excavators, understanding the cost structure is essential. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing mini excavators significantly affect pricing. Rippa uses high-grade steel and components, including renowned engines from Kubota, which contribute to the overall cost.

-

Labor: Labor costs encompass wages for skilled workers involved in assembly and quality control. In regions like China, where Rippa is based, labor costs may be lower compared to Western countries, providing a competitive edge in pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production processes can help minimize these overheads, ultimately reflecting in the final price.

-

Tooling: The initial investment in tooling and machinery required for the production of mini excavators is substantial. This cost is typically amortized over the production volume, influencing the pricing strategy.

-

Quality Control (QC): Ensuring that Rippa excavators meet international standards (such as CE, EPA, and Euro V certifications) involves rigorous testing and quality assurance processes, adding to the overall cost.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and any tariffs or customs duties applicable. For international buyers, understanding these logistics costs is critical to budget accurately.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can fluctuate based on market conditions and demand.

What Influences Pricing for Rippa Mini Excavators?

Several factors can influence the pricing of Rippa mini excavators, particularly for international buyers:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Negotiating a minimum order quantity (MOQ) can yield significant savings.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should balance their needs against budget constraints, understanding that higher customization often leads to higher prices.

-

Materials and Quality/Certifications: Higher quality materials and certifications can increase the cost but ensure better durability and compliance with international standards.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: The agreed terms of shipment and delivery (like FOB, CIF, etc.) impact the total cost. Understanding these terms helps buyers manage costs effectively.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Terms: Always negotiate payment terms and delivery schedules. A favorable payment structure can ease cash flow.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential resale value. This holistic view can guide better purchasing decisions.

-

Research Market Prices: Familiarize yourself with the market prices for Rippa mini excavators to strengthen your negotiation position. Use multiple sources to gather data on pricing trends.

-

Be Aware of Pricing Nuances: Different regions may experience fluctuations in pricing due to local demand, currency exchange rates, and shipping costs. Understanding these nuances can provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for Rippa mini excavators can vary based on specifications, configurations, and market conditions. The prices mentioned in various sources, such as $4,558 for the R10 ECO and $29,030 for the R32 PRO, are indicative and may change. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your specific requirements.

Alternatives Analysis: Comparing rippa mini excavator With Other Solutions

When considering the acquisition of a mini excavator, it is essential for B2B buyers to evaluate various options available in the market. This analysis will compare the Rippa Mini Excavator with alternative solutions, including traditional backhoe loaders and compact skid steer loaders, providing insights into their respective strengths and weaknesses.

Illustrative image related to rippa mini excavator

| Comparison Aspect | Rippa Mini Excavator | Traditional Backhoe Loader | Compact Skid Steer Loader |

|---|---|---|---|

| Performance | Excellent for digging, trenching; versatile with attachments | Good for digging and loading; less maneuverable | Very agile; excels in tight spaces and grading |

| Cost | Competitive pricing (starting from approx. $4,558) | Higher upfront costs (approx. $30,000+) | Moderate pricing (approx. $20,000+) |

| Ease of Implementation | Simple operation; minimal training required | Moderate complexity; operator training needed | User-friendly; quick learning curve |

| Maintenance | Low maintenance; parts readily available | Higher maintenance due to complexity | Moderate maintenance; robust design |

| Best Use Case | Urban construction, landscaping, small to medium projects | Larger construction sites, utility work | Landscaping, material handling, small job sites |

What Are the Advantages and Disadvantages of the Traditional Backhoe Loader?

Traditional backhoe loaders are known for their robust capabilities in excavation and loading tasks. They offer a strong digging arm and a loader bucket, making them suitable for larger projects. However, they tend to be more expensive and less maneuverable than mini excavators, particularly in tight spaces. While they are effective for extensive job sites, their size can be a drawback in urban or confined environments.

How Does the Compact Skid Steer Loader Compare?

Compact skid steer loaders are highly versatile and agile, making them ideal for landscaping and material handling tasks. They are user-friendly and require minimal training, allowing for quick operation. However, they may not have the same digging depth or power as a mini excavator, limiting their effectiveness for more intensive excavation tasks. Additionally, while they are moderately priced, they can still be a significant investment for smaller businesses.

How Can B2B Buyers Choose the Right Solution?

When selecting the right equipment, B2B buyers should consider their specific operational needs, including project scale, work environment, and budget constraints. The Rippa Mini Excavator offers a compelling option for those needing a cost-effective, versatile solution for urban construction and landscaping tasks. In contrast, traditional backhoe loaders might be better suited for larger, more demanding projects, while compact skid steer loaders provide agility for smaller jobs but may lack the power needed for heavy excavation. Ultimately, understanding the unique requirements of each project will guide buyers in making an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for rippa mini excavator

What Are the Key Technical Properties of Rippa Mini Excavators?

When evaluating Rippa mini excavators, understanding their critical specifications is essential for making informed purchasing decisions. Below are some of the vital technical properties to consider:

1. Operating Weight

The operating weight of Rippa mini excavators ranges from 0.8 to 5.7 tons, depending on the model. This specification is crucial as it affects the machine’s stability and its ability to work in various terrains. Heavier machines generally offer better stability and digging power, making them suitable for larger projects.

Illustrative image related to rippa mini excavator

2. Maximum Power Output

The power output of Rippa excavators varies from 8.2 kW to 51 kW across different models. This specification is significant because it determines the machine’s ability to perform demanding tasks. Higher power output often translates to increased efficiency and faster completion of projects, which is vital for contractors aiming to meet tight deadlines.

3. Maximum Digging Depth

The maximum digging depth ranges from approximately 1,800 mm to 3,890 mm, depending on the model. This property is crucial for buyers who need to perform specific tasks, such as trenching or foundation work. Understanding the digging depth ensures that the excavator can meet the requirements of various applications, from landscaping to construction.

4. Engine Type

Rippa mini excavators are typically equipped with reliable engines, such as Kubota or Yanmar. The engine type is essential for B2B buyers as it influences fuel efficiency, maintenance costs, and overall performance. Reliable engines reduce downtime and enhance productivity, making them a critical consideration for businesses.

5. Hydraulic System

The hydraulic system plays a crucial role in the excavator’s performance. Rippa machines utilize advanced hydraulic systems that enable precise control over attachments and digging operations. Understanding the hydraulic capabilities is vital for buyers looking to use various attachments, such as buckets or hydraulic thumbs, enhancing the machine’s versatility.

What Are Common Trade Terminologies Related to Rippa Mini Excavators?

Familiarity with industry-specific jargon can streamline communication and facilitate smoother transactions. Here are some common terms relevant to Rippa mini excavators:

Illustrative image related to rippa mini excavator

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding the OEM is crucial for buyers who seek high-quality parts and service, ensuring the longevity and reliability of their machinery.

2. MOQ (Minimum Order Quantity)

MOQ signifies the minimum quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning, particularly for companies looking to stock equipment for multiple projects.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. It is vital for B2B transactions as it helps buyers gauge market prices and compare different suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is crucial for international buyers, as they clarify shipping responsibilities, insurance, and risk transfer, ultimately aiding in smoother cross-border transactions.

5. Warranty and After-Sales Service

Warranty refers to the guarantee provided by the manufacturer regarding the product’s performance and quality. For B2B buyers, understanding warranty terms and after-sales service options is vital, as they ensure peace of mind and support for maintenance needs post-purchase.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions, ensuring they select the right Rippa mini excavator for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the rippa mini excavator Sector

What Are the Key Market Dynamics and Trends Impacting Rippa Mini Excavators?

The global market for mini excavators, particularly Rippa models, is experiencing robust growth driven by increasing urbanization and infrastructure development across emerging economies. In regions such as Africa and South America, the demand for versatile and compact machinery is surging, largely due to ongoing construction projects and the need for efficient land management. Moreover, advancements in technology are fostering innovation in mini excavators, making them more efficient and user-friendly. Features such as enhanced hydraulic systems and eco-friendly engines are becoming standard, catering to the evolving needs of contractors who prioritize both performance and sustainability.

International B2B buyers are also witnessing a shift towards digital sourcing platforms, which streamline the procurement process. Online marketplaces facilitate easier access to Rippa mini excavators, allowing buyers to compare prices, specifications, and supplier reputations. Additionally, the integration of AI and data analytics in sourcing strategies is enabling companies to make informed decisions, optimizing their purchasing processes and reducing costs.

How Is Sustainability Influencing the Sourcing of Rippa Mini Excavators?

Sustainability is a pivotal concern for today’s B2B buyers, particularly in the construction equipment sector. The environmental impact of machinery production and operation is under scrutiny, leading to a demand for more sustainable practices. Rippa mini excavators are designed with eco-friendly technologies, including engines that meet stringent Euro V emissions standards. This not only minimizes their carbon footprint but also aligns with the growing regulatory pressures and consumer expectations for greener products.

Ethical sourcing has become equally important, with buyers increasingly favoring suppliers that maintain transparent supply chains and sustainable material sourcing. Certifications such as CE and EPA are critical indicators of compliance with environmental standards, offering assurance to international buyers regarding the quality and sustainability of Rippa products. By prioritizing suppliers who adhere to ethical practices, businesses can enhance their brand reputation while contributing positively to the environment.

What Is the Evolution of Rippa Mini Excavators in the B2B Market?

Rippa has established itself as a leading manufacturer of mini excavators, particularly recognized for its commitment to quality and innovation. Originating in China, Rippa has expanded its product offerings to cater to a global audience, with models ranging from lightweight machines for small projects to more robust options for heavy-duty applications. Over the years, the company has focused on improving performance, durability, and operator comfort, responding to the feedback of international buyers.

The evolution of Rippa mini excavators reflects broader trends in the construction industry, where the demand for compact, versatile, and energy-efficient machinery is on the rise. As the company continues to innovate and adapt to market needs, it remains well-positioned to serve the growing demands of B2B buyers in various regions, including Africa, South America, and Europe. The emphasis on technology and sustainability will likely shape the future of Rippa mini excavators, ensuring they meet the challenges of modern construction.

Illustrative image related to rippa mini excavator

Frequently Asked Questions (FAQs) for B2B Buyers of rippa mini excavator

-

How do I choose the right Rippa mini excavator for my project?

Selecting the appropriate Rippa mini excavator depends on various factors such as the project scale, type of work, and terrain. For lighter tasks, models like the R10 or R13, weighing around 1 to 1.3 tons, are suitable for tight spaces and smaller jobs. Conversely, for more extensive projects requiring deeper digging, consider the R32 or R57 models with greater power and digging depth capabilities. Assess your specific requirements against the specifications provided in the product catalog to ensure optimal performance. -

What are the payment options available when purchasing Rippa mini excavators?

Payment options for Rippa mini excavators typically include bank transfers, letters of credit, and payment through trusted third-party platforms. Many suppliers may require a deposit upfront, with the balance due upon delivery or after installation. It’s crucial to discuss and agree upon payment terms before finalizing any purchase to avoid misunderstandings and ensure smooth transactions. -

What is the minimum order quantity (MOQ) for Rippa mini excavators?

The MOQ for Rippa mini excavators can vary based on the supplier and the specific model. Generally, suppliers may have an MOQ of one unit for direct purchases, but discounts may apply for bulk orders. It is advisable to communicate directly with the supplier to clarify their MOQ and any potential pricing incentives for larger orders, especially if you are considering reselling the equipment. -

How can I ensure the quality of Rippa mini excavators before purchasing?

To ensure quality, request certifications such as CE, EPA, and Euro V compliance, which indicate adherence to international safety and environmental standards. Additionally, consider visiting the manufacturer’s facility or arranging a product demonstration. Reading reviews and testimonials from other buyers can also provide insights into the reliability and performance of the excavators. -

What customization options are available for Rippa mini excavators?

Rippa offers various customization options, including attachments like hydraulic thumbs, buckets of different sizes, and specialized tracks. Buyers can also request specific features tailored to unique job requirements. Discuss your needs with the supplier to explore available customization options and ensure the excavator meets your operational demands. -

How do I handle logistics and shipping for international purchases of Rippa mini excavators?

When purchasing Rippa mini excavators internationally, it’s important to work closely with your supplier to determine the best shipping method, whether by sea or air. Consideration should be given to customs regulations, import duties, and shipping insurance. Engaging a reliable freight forwarder can streamline the logistics process, ensuring timely and safe delivery to your location. -

What after-sales support can I expect for Rippa mini excavators?

Most suppliers provide robust after-sales support, including warranty coverage, maintenance services, and access to spare parts. It is advisable to inquire about the specifics of after-sales support, such as response times for service requests and the availability of training for operators. A good after-sales service is crucial for minimizing downtime and ensuring the longevity of your equipment. -

How do I vet suppliers when sourcing Rippa mini excavators?

To vet suppliers, start by checking their business credentials, including registration and certifications. Look for reviews from previous customers and ask for references. Additionally, evaluate their experience in the industry and their capacity to deliver on your specific needs. Engaging in direct communication and possibly visiting their operations can provide further assurance of their reliability.

Top 8 Rippa Mini Excavator Manufacturers & Suppliers List

1. Rippa – Texas R10 Side Control Excavator

Domain: thekhazana.net

Registered: 2006 (19 years)

Introduction: [{‘name’: ‘Rippa Texas R10 Side Control’, ‘type’: ‘Excavator’, ‘features’: ‘Hydraulic Thumb/Bucket/Telescopic Track/Swing Boom’, ‘engine’: ‘Briggs & Stratton’, ‘price’: {‘msrp’: 8500, ‘sale’: 7500}, ‘accessories’: [’14” Bucket’, ‘Hydraulic Thumb Clip’, ‘Swing Boom’, ‘Telescopic Track’, ‘Side Control’, ‘Quick Attach’]}, {‘name’: ‘Rippa Texas R10 Front Control’, ‘type’: ‘Excavator’, ‘features’: ‘Hyd…

2. Rippa – Mini Excavators

Domain: rippa.com

Registered: 2001 (24 years)

Introduction: Rippa Mini Excavators: R10 (1000kg, 8.2 kW, 1833mm, Kubota Z482), R13 (1300kg, 10.2 kW, 1843mm, Kubota D722), R15 (1500kg, 10.2 kW, 1807mm, Kubota D722), R18 (1818kg, 11.8 kW, 2420mm, Kubota D902), R22 (2371kg, 18 kW, 2293mm, Kubota D1105), R32 (3171kg, 18.5 kW, 2827mm, Kubota V1505), R57 (5700kg, 51 kW, 3890mm, Kubota V2607), R82 (8200kg, 0.27-0.33m³ bucket capacity, Yanmar/Changchai, 45/2100KW/r…

3. Rippa – R10 Mini Excavator

Domain: rippaequipment.com

Registered: 2024 (1 years)

Introduction: Rippa R10 Mini Excavator: Kubota Diesel engine, Hydraulic Thumb/Bucket, Telescopic Track, Swing Boom, Price: $12,000.00 USD. Rhinoceros Compact Mini Skid Steer: Kubota D1703, Price: $22,000.00 USD. Rhinoceros XN228L Pro Wheeled Backhoe Loader, Price: $30,000.00 USD.

4. Facebook – Chinese Excavators

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Chinese Excavators, Mini Skids, Rippa mini

5. Rippa – R32 Pro Mini Excavator

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Rippa R32 Pro Mini Excavator”,”Engine”: “Kubota V1505″,”Condition”: “New”,”Price”: “$28,999.00 or Best Offer”,”Quantity Available”: 3,”Model Year”: 2024,”Net Horsepower (HP)”: “21 – 30″,”Seller Feedback”: “100% positive feedback”,”Support”: “24/7 Support”,”Warranty”: “Included”}

6. Rippa – Mini Excavators for Sale

Domain: machineryline.com

Registered: 2005 (20 years)

Introduction: Rippa mini excavators for sale, including models such as R10 ECO, R13 PRO, R15 ECO, R18 PRO, R22 PRO, and R32 PRO. Key specifications include:

– Power: R10 ECO (8.23 kW / 11.2 HP), R13 PRO (12.72 kW / 17.3 HP), R15 ECO (10.2 kW / 13.88 HP), R18 PRO (11.83 kW / 16.1 HP), R22 PRO (18.16 kW / 24.7 HP), R32 PRO (18.38 kW / 25 HP)

– Fuel: Diesel

– Euro standard: Euro 5

– Digging depth: R10 ECO (5.97 ft…

7. Rippa Machinery – Mini and Large Excavators

Domain: rippamachinery.com

Registered: 2022 (3 years)

Introduction: Professional mini excavators, large excavators, skid steer loaders, and electric forklifts. Mini Excavators available in various sizes: 1 Ton, 1.2 Ton, 1.5 Ton, 1.8 Ton, 2 Ton, 2.2 Ton, 2.5 Ton, 3 Ton, 3.5 Ton, 4 Ton, 5 Ton, 6 Ton, 8 Ton, 9 Ton, 10 Ton, and Micro Excavator (0.8 Ton). Large Excavators: 15 Ton, 20 Ton, 23 Ton, 30 Ton, 50 Ton, and 60 Ton. Skid Steer Loaders: Mini Skid Steer, RS06, RS…

8. Rippa – NDI322 Mini Excavator

Domain: bisonequipmentandexcavators.com

Registered: 2024 (1 years)

Introduction: {“name”:”Rippa NDI322 Mini Excavator”,”engine”:”Kubota D722 Diesel”,”price”:”$10,990.00″,”machine_configuration”:”Base Machine (Hydraulic Thumb Included) with Swing Boom and Retractable Track”,”attachment_packages”:[{“name”:”Ease-of-Use Package”,”details”:”3-way Auxiliary Valve, Manual Quick Hitch Coupler”,”price”:”+$299.00″},{“name”:”Basic Attachments Package”,”details”:”30\” Rake, 8\” Trencher B…

Strategic Sourcing Conclusion and Outlook for rippa mini excavator

In conclusion, strategic sourcing of Rippa mini excavators presents a compelling opportunity for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Rippa’s robust range of models, certified for quality and environmental standards, ensures that businesses can find the right equipment tailored to their specific needs, from compact urban projects to larger construction sites.

Investing in Rippa mini excavators not only guarantees access to reliable machinery but also fosters long-term relationships with a manufacturer recognized for its commitment to quality and customer service. By leveraging Rippa’s extensive dealer network and after-sales support, buyers can enhance operational efficiency and minimize downtime, making these excavators a strategic asset for any construction or landscaping project.

As the global demand for efficient and environmentally friendly construction equipment continues to rise, now is the time to engage with Rippa. Explore partnership opportunities, evaluate the diverse product offerings, and position your business at the forefront of innovation in the heavy machinery sector. Make a strategic move today to secure your competitive advantage with Rippa mini excavators.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to rippa mini excavator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.