Top 4 Centrifuge Electric Suppliers (And How to Choose)

Introduction: Navigating the Global Market for centrifuge electric

In today’s rapidly evolving global market, sourcing reliable electric centrifuges poses significant challenges for international B2B buyers. With diverse applications ranging from medical laboratories to industrial processes, the demand for efficient and cost-effective centrifuge solutions is paramount. This guide is designed to empower businesses, particularly those in Africa, South America, the Middle East, and Europe, by providing an in-depth exploration of the electric centrifuge landscape.

We will cover various types of electric centrifuges, their specific applications, and the latest technological advancements that enhance performance and reliability. Additionally, we’ll delve into crucial aspects of supplier vetting, ensuring that buyers can identify trustworthy partners who meet their quality and service expectations. Understanding cost structures and market trends will further equip buyers to make informed purchasing decisions, optimizing their investments in centrifuge technology.

By navigating the complexities of the electric centrifuge market with this comprehensive guide, businesses can confidently select the right equipment to meet their operational needs. Whether you are in Saudi Arabia, Brazil, or beyond, the insights provided herein will help streamline your sourcing process and enhance your competitive edge in the global marketplace.

Understanding centrifuge electric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop Centrifuge | Compact design, variable speed settings, versatile | Laboratories, medical facilities | Pros: Space-saving, user-friendly. Cons: Limited capacity compared to larger models. |

| Refrigerated Centrifuge | Temperature control, ideal for heat-sensitive samples | Biotech, pharmaceuticals, clinical research | Pros: Protects samples from heat damage. Cons: Higher cost and maintenance. |

| High-Speed Centrifuge | Extremely high RPM capabilities, specialized rotors | Research institutions, blood banks | Pros: Fast separation of components. Cons: Increased operational costs. |

| Microcentrifuge | Small capacity, high-speed operation | Molecular biology, genetics labs | Pros: Efficient for small sample sizes. Cons: Limited to low-volume applications. |

| Ultracentrifuge | Very high speeds, separation of macromolecules | Advanced research, protein purification | Pros: Exceptional separation efficiency. Cons: Requires specialized training and is costly. |

What Are the Key Characteristics of Benchtop Centrifuges?

Benchtop centrifuges are compact and versatile, making them ideal for laboratories with limited space. They typically feature variable speed settings, allowing for a range of applications from basic cell separations to more complex procedures. Their user-friendly design enables quick setup and operation, making them suitable for both experienced technicians and new users. When purchasing, consider the capacity and the types of rotors available, as these can impact the centrifuge’s versatility in handling different sample sizes.

How Do Refrigerated Centrifuges Differ from Standard Models?

Refrigerated centrifuges are designed to maintain a specific temperature during operation, which is crucial for handling heat-sensitive biological samples. This feature is particularly important in sectors such as biotechnology and pharmaceuticals, where sample integrity is paramount. Buyers should evaluate the temperature range and control options, as well as the overall capacity, to ensure it meets their specific needs. While they provide superior sample protection, they also come with higher costs and require regular maintenance.

Why Choose High-Speed Centrifuges for Your Laboratory?

High-speed centrifuges operate at extremely high RPMs, allowing for rapid separation of components in various samples. They are commonly used in research institutions and blood banks where time efficiency and separation quality are critical. When considering a purchase, buyers should assess the model’s speed capabilities and rotor compatibility, as these factors directly affect performance. However, the operational costs can be higher due to energy consumption and maintenance requirements.

What Advantages Do Microcentrifuges Offer for Small Sample Handling?

Microcentrifuges are tailored for small volumes, making them ideal for applications in molecular biology and genetics labs. They operate at high speeds to efficiently separate components in micro-tubes, which is essential for experiments that involve DNA, RNA, or proteins. Buyers should look for models with adjustable speed settings and rotor options to maximize their functionality. While they excel in small-scale applications, their limited capacity may not be suitable for larger sample sizes.

What Makes Ultracentrifuges Essential for Advanced Research?

Ultracentrifuges are specialized for high-speed applications that require the separation of macromolecules, such as proteins and nucleic acids. They are essential in advanced research settings where precision and efficiency in separation are crucial. When considering an ultracentrifuge, buyers should focus on the maximum speed, rotor types, and the training required for safe operation. Despite their exceptional capabilities, they come with a significant price tag and necessitate specialized training for effective use.

Key Industrial Applications of centrifuge electric

| Industry/Sector | Specific Application of centrifuge electric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Blood Separation in Laboratories | Enhances diagnostic accuracy and speeds up analysis | Compliance with health regulations and reliability of performance |

| Pharmaceutical | Drug Formulation and Quality Control | Ensures consistency in drug production | Need for high precision and scalability in manufacturing |

| Environmental Science | Wastewater Treatment | Improves separation of contaminants for cleaner water | Durability and efficiency in harsh conditions |

| Food and Beverage | Juice and Dairy Processing | Maximizes yield and quality of products | Food safety certifications and energy efficiency |

| Research and Development | Cellular and Molecular Research | Facilitates advanced research by isolating components | Customization for specific laboratory needs and space constraints |

How is Electric Centrifuge Used in Healthcare for Blood Separation?

In healthcare, electric centrifuges are critical for blood separation, allowing laboratories to isolate plasma, serum, and other blood components efficiently. This process enhances diagnostic accuracy, as separating blood components helps in conducting various tests more effectively. For international buyers, particularly in regions like Africa and the Middle East, sourcing centrifuges that comply with local health regulations is vital. Reliability and performance are paramount, given the high stakes involved in medical diagnostics.

What Role Does Electric Centrifuge Play in Pharmaceutical Drug Formulation?

In the pharmaceutical sector, electric centrifuges are utilized in drug formulation and quality control processes. They ensure that formulations are homogeneous and free from impurities, which is crucial for maintaining product consistency. For B2B buyers in South America and Europe, it’s essential to select centrifuges that offer high precision and scalability to meet production demands. Moreover, understanding the regulatory landscape for pharmaceutical equipment is critical to ensuring compliance and operational efficiency.

How is Electric Centrifuge Applied in Environmental Science for Wastewater Treatment?

Electric centrifuges are employed in environmental science, particularly for wastewater treatment, where they help separate contaminants from water. This application is vital for improving water quality and meeting environmental regulations. For businesses in Africa and other regions, sourcing centrifuges that can withstand harsh conditions and operate efficiently is crucial. Additionally, energy efficiency is a key consideration, as it directly impacts operational costs and sustainability goals.

In What Ways Does Electric Centrifuge Improve Food and Beverage Processing?

In the food and beverage industry, electric centrifuges are used extensively for juice extraction and dairy processing. They maximize yield and improve the quality of products by efficiently separating solids from liquids. For international buyers, ensuring that the centrifuges meet food safety certifications is essential. Furthermore, energy efficiency is a significant consideration, as it contributes to cost savings and environmental sustainability in production operations.

How is Electric Centrifuge Important for Research and Development?

Electric centrifuges play a crucial role in research and development, particularly in cellular and molecular research. They facilitate the isolation of specific components, enabling scientists to conduct advanced experiments and analyses. For B2B buyers, especially in Europe and the Middle East, customization options are important to meet specific laboratory needs and spatial constraints. Additionally, ensuring that the centrifuge offers reliable performance over time is vital for maintaining research integrity.

3 Common User Pain Points for ‘centrifuge electric’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Centrifuge for Specific Applications

The Problem: B2B buyers often struggle with choosing the right electric centrifuge that meets their unique operational requirements. Factors such as maximum RPM, capacity, and the specific application—whether for clinical diagnostics, research, or industrial processes—can significantly impact the effectiveness of the centrifuge. For instance, a laboratory in Brazil may require a centrifuge that efficiently separates blood components, while a facility in Saudi Arabia may need one for isolating cellular components in biopharmaceuticals. The variety of options available can lead to confusion and potential misalignment with project needs.

The Solution: To effectively source the right centrifuge, buyers should start by conducting a thorough needs assessment. This involves understanding the specific parameters of their intended applications, including the types of samples being processed and the required separation speeds. Engaging with manufacturers or suppliers who offer consultation services can also provide valuable insights into the most suitable models. Additionally, buyers should prioritize centrifuges with flexible operational settings, allowing for adjustments based on varying requirements. Seeking demo units or trial periods can also facilitate informed decision-making before a full investment is made.

Scenario 2: Challenges in Maintenance and Downtime

The Problem: Frequent maintenance and unexpected downtime can significantly disrupt operations for B2B buyers utilizing electric centrifuges. For companies in regions like South America, where access to qualified service technicians may be limited, this can lead to extended periods of inactivity, affecting productivity and profitability. Moreover, the costs associated with repairs and the loss of time can strain budgets and project timelines.

The Solution: To mitigate maintenance issues, B2B buyers should implement a proactive maintenance schedule based on the manufacturer’s guidelines. This includes regular inspections, cleaning, and timely replacement of wear parts. Establishing a relationship with local service providers or manufacturers who offer training can empower staff to conduct basic maintenance and troubleshoot common issues. Investing in a centrifuge with a robust warranty and readily available replacement parts can also minimize downtime, ensuring that operations continue smoothly even when issues arise.

Scenario 3: Compliance with Regulatory Standards

The Problem: In industries such as healthcare and pharmaceuticals, compliance with local and international regulations is paramount. B2B buyers often face challenges in ensuring that their electric centrifuges meet these stringent standards, which can vary significantly across different regions like Europe and the Middle East. Non-compliance can result in costly fines, project delays, or even the inability to operate legally.

The Solution: Buyers should prioritize sourcing centrifuges that are certified and compliant with relevant industry standards, such as ISO or CE markings. It’s advisable to work closely with suppliers who can provide documentation and proof of compliance for their equipment. Additionally, investing in training for staff on compliance protocols and safety standards can foster a culture of adherence and vigilance. Regular audits and assessments of operational procedures related to centrifuge use can help identify and rectify compliance gaps before they become significant issues.

Strategic Material Selection Guide for centrifuge electric

What Are the Key Materials for Electric Centrifuges?

When selecting materials for electric centrifuges, it is crucial to consider various properties that directly impact performance, durability, and application suitability. Below, we analyze four common materials used in the construction of electric centrifuges, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Aluminum Benefit Electric Centrifuge Construction?

Aluminum is a lightweight and corrosion-resistant material commonly used in electric centrifuge rotors and casings. Its excellent thermal conductivity allows for efficient heat dissipation, which is essential during high-speed operations. Aluminum can typically withstand temperatures up to 150°C, making it suitable for various laboratory applications.

Pros: Aluminum is durable yet lightweight, which enhances the efficiency of centrifuge operation. Additionally, it is relatively cost-effective compared to other metals.

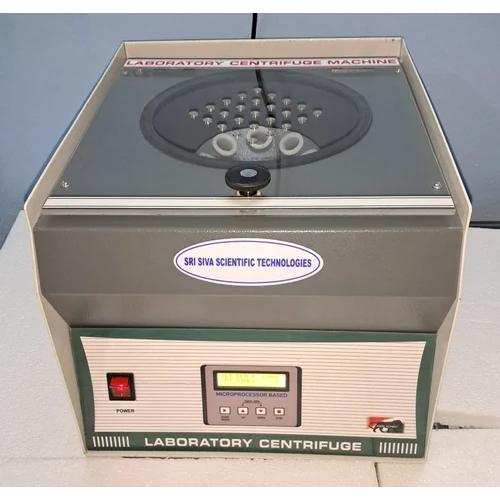

Illustrative image related to centrifuge electric

Cons: While aluminum has good corrosion resistance, it may not perform well in highly acidic or alkaline environments. Its manufacturing complexity can also increase costs if intricate designs are required.

Impact on Application: Aluminum is compatible with a wide range of biological and chemical samples, making it a versatile choice for laboratories.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM and ISO, as aluminum quality can vary significantly.

What Role Does Stainless Steel Play in Centrifuge Design?

Stainless steel is another popular material for electric centrifuges, known for its exceptional strength and corrosion resistance. It can withstand high temperatures (up to 300°C) and pressures, making it ideal for demanding applications.

Pros: Its durability and resistance to rust and corrosion make stainless steel a long-lasting option. It is also easy to clean and sterilize, which is crucial in laboratory settings.

Cons: The higher cost of stainless steel compared to aluminum may deter some buyers. Additionally, its weight can lead to increased energy consumption during operation.

Impact on Application: Stainless steel is particularly suitable for centrifuging samples that are corrosive or require high-speed processing.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of the specific grades of stainless steel (e.g., 304, 316) that comply with regional standards, as these can affect performance and longevity.

Why Is Polypropylene a Good Choice for Centrifuge Components?

Polypropylene is a thermoplastic polymer that is increasingly used for centrifuge tubes and other components. It offers a balance of chemical resistance and lightweight properties, making it suitable for various laboratory applications.

Pros: Polypropylene is cost-effective and provides excellent resistance to many chemicals, including acids and bases. It is also lightweight, which reduces overall energy consumption during centrifugation.

Cons: While polypropylene can handle moderate temperatures (up to 120°C), it is not suitable for high-temperature applications. Its mechanical strength is also lower than that of metals.

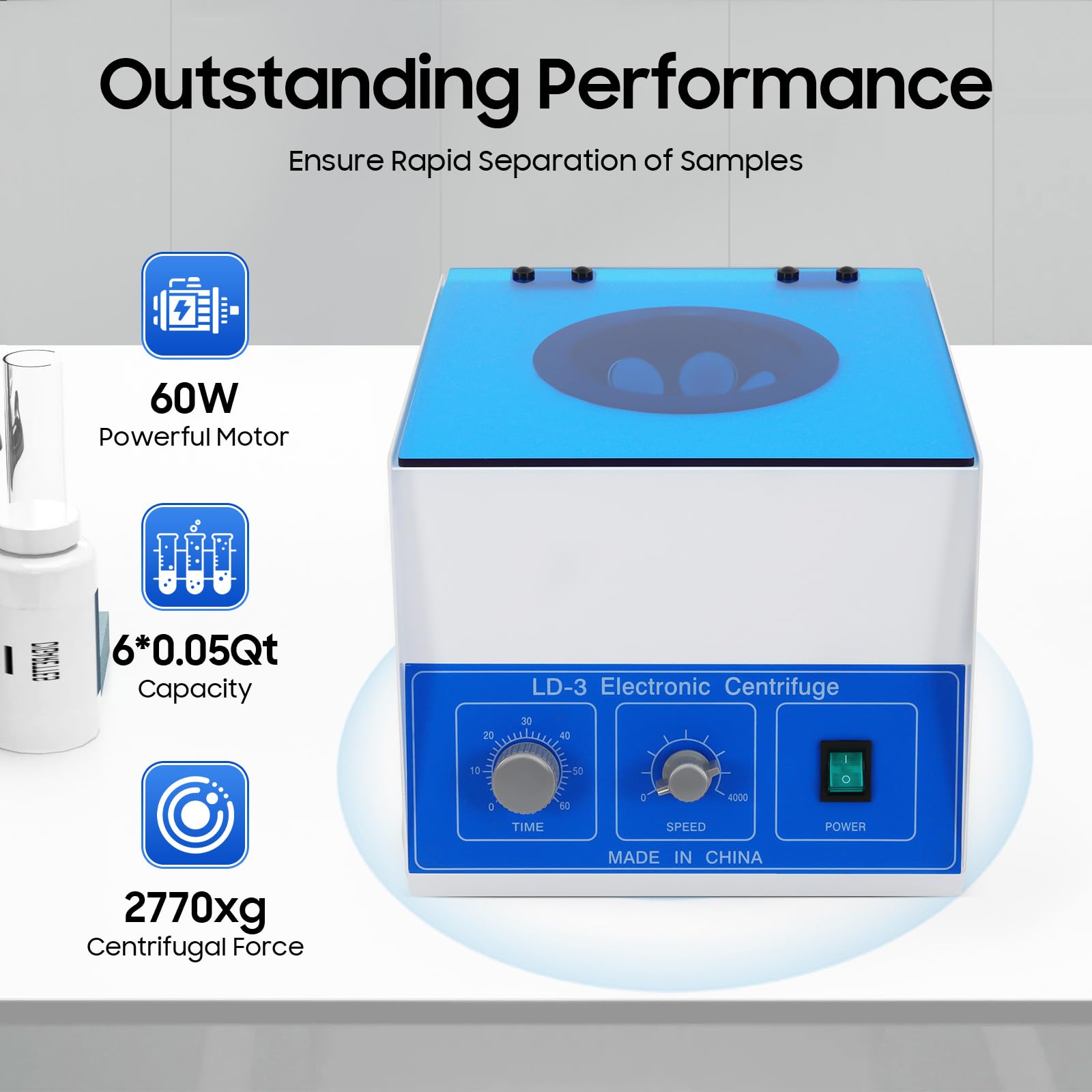

Illustrative image related to centrifuge electric

Impact on Application: This material is ideal for biological samples and routine laboratory use, but caution should be exercised with samples requiring high-speed processing.

Considerations for International Buyers: Buyers should verify that polypropylene components meet international standards for laboratory use, especially in regions with strict regulatory environments.

How Does Carbon Fiber Enhance Electric Centrifuge Performance?

Carbon fiber is a high-performance material known for its lightweight and high-strength properties. It is increasingly being used in high-end centrifuge designs to improve performance and efficiency.

Pros: Carbon fiber offers excellent strength-to-weight ratios, allowing for higher speeds and reduced energy consumption. Its resistance to thermal expansion ensures consistent performance.

Cons: The primary drawback is its high cost and complexity in manufacturing, which can limit its use to specialized applications.

Impact on Application: Carbon fiber is particularly beneficial in applications requiring ultra-high-speed centrifugation, such as in research and advanced medical laboratories.

Considerations for International Buyers: Buyers should consider the availability of carbon fiber components and ensure they meet relevant international standards, as this material may not be as widely available in certain regions.

Summary Table of Material Selection for Electric Centrifuges

| Material | Typical Use Case for centrifuge electric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Rotor and casing in standard centrifuges | Lightweight and cost-effective | Limited performance in extreme pH | Low |

| Stainless Steel | High-speed and corrosive applications | Excellent durability and corrosion resistance | Higher cost and weight | High |

| Polypropylene | Tubes and components for routine use | Chemical resistance and lightweight | Limited temperature tolerance | Low |

| Carbon Fiber | High-performance centrifuges | High strength-to-weight ratio | High cost and manufacturing complexity | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for electric centrifuges, considering performance, application suitability, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for centrifuge electric

What Are the Key Stages in the Manufacturing Process of Electric Centrifuges?

The manufacturing of electric centrifuges involves a structured process that ensures the equipment meets performance standards and client specifications. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

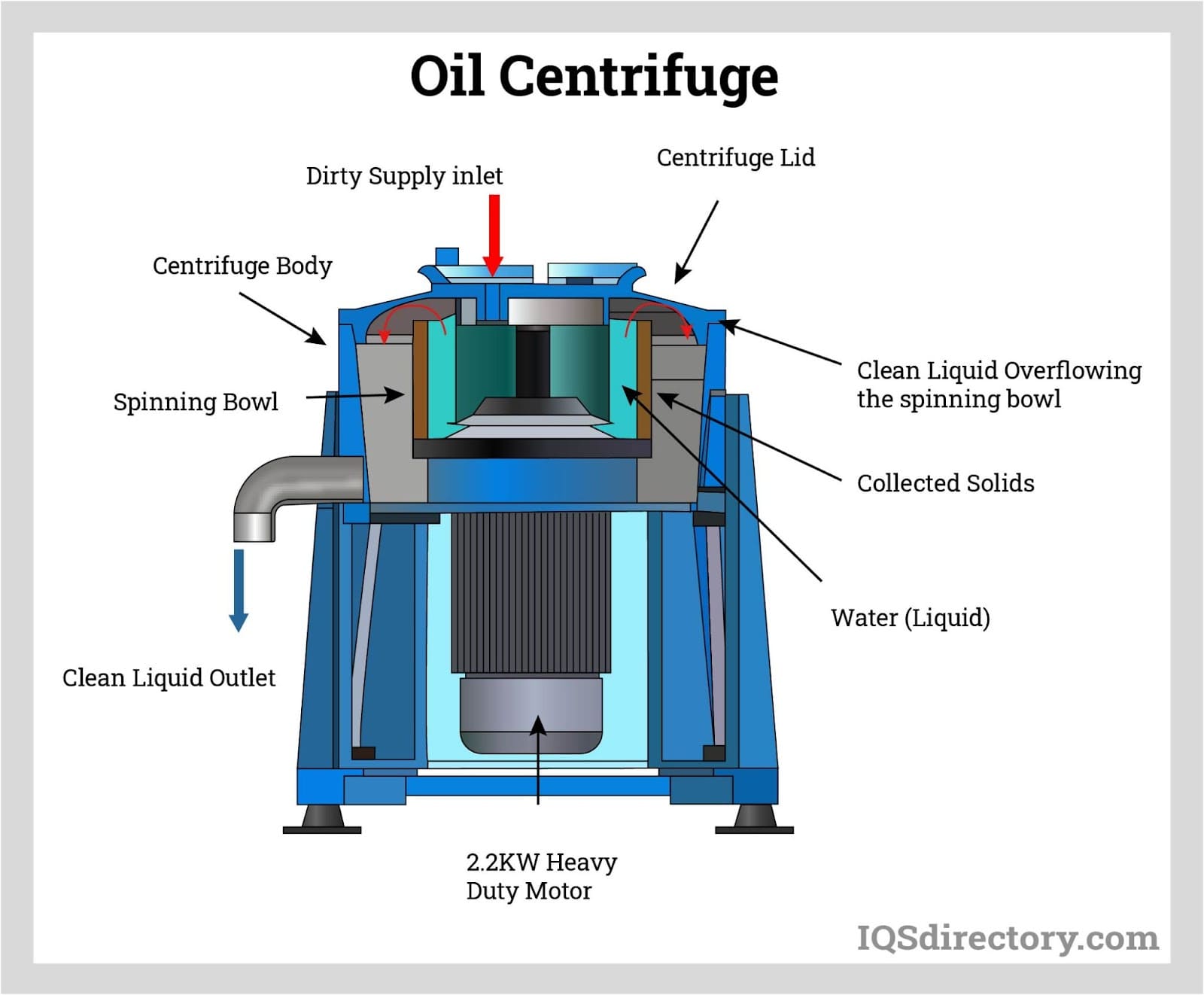

Illustrative image related to centrifuge electric

-

Material Preparation: The first step involves selecting high-quality materials that comply with international standards. This often includes metals such as stainless steel for durability and resistance to corrosion, as well as plastics that are suitable for laboratory environments. Suppliers must ensure that materials are sourced from certified vendors to maintain integrity.

-

Forming: This stage involves transforming raw materials into components through techniques such as machining, stamping, or casting. For electric centrifuges, precision is crucial, as even minor deviations can affect performance. CNC (Computer Numerical Control) machines are frequently employed to ensure that components like rotors and housings are manufactured with high accuracy.

-

Assembly: Once components are formed, they are assembled into the final product. This stage requires skilled labor to ensure that parts fit together correctly and function as intended. Automated assembly lines may be used, particularly for high-volume production, to enhance efficiency while maintaining quality.

-

Finishing: The final stage involves applying surface treatments to enhance durability and aesthetics. This could include polishing, anodizing, or coating to prevent wear and corrosion. Additionally, this stage may also involve the installation of electronic components and wiring, ensuring that the centrifuge operates efficiently and safely.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for electric centrifuges. It ensures that the final product meets industry standards and customer expectations. Key components of QA include adherence to international standards, established QC checkpoints, and common testing methods.

-

International Standards and Certifications: Compliance with international standards such as ISO 9001 is essential for manufacturers of electric centrifuges. This standard outlines the requirements for a quality management system, ensuring consistent quality in products and services. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for certain applications are also crucial.

-

Quality Control Checkpoints: The manufacturing process typically includes several QC checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before they enter the production process.

– In-Process Quality Control (IPQC): Quality checks during the manufacturing process help identify issues early. This can involve monitoring dimensions and tolerances during forming and assembly.

– Final Quality Control (FQC): The finished product undergoes rigorous testing to verify that it meets all performance specifications and safety standards before shipping. -

Common Testing Methods: Various testing methods are employed to ensure quality, including:

– Functional Testing: Ensures that the centrifuge operates correctly under specified conditions.

– Safety Testing: Checks for electrical safety, mechanical integrity, and compliance with safety standards.

– Performance Testing: Measures parameters such as speed, capacity, and efficiency to confirm that the centrifuge performs as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are several methods to ensure quality:

-

Audits: Conducting supplier audits allows buyers to assess the manufacturing processes and quality assurance measures in place. This can be done through on-site visits or third-party audits, providing insights into the supplier’s capabilities and compliance with standards.

-

Quality Reports: Requesting detailed quality control reports from suppliers can provide transparency regarding their processes and results. These reports should outline the QC checkpoints, testing results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased verification of a supplier’s quality control practices. These agencies can conduct inspections at various stages of the manufacturing process and provide certifications that confirm compliance with relevant standards.

-

Certifications and Compliance: Buyers should verify that the supplier holds relevant certifications such as ISO 9001, CE, and others specific to the centrifuge industry. This not only indicates adherence to quality standards but also reassures buyers of the supplier’s commitment to continuous improvement.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when dealing with quality control in manufacturing. Understanding these nuances can help mitigate risks:

-

Regulatory Differences: Different regions have varying regulatory requirements for manufacturing equipment. Buyers must be aware of local regulations in their markets and ensure that suppliers comply with these standards.

-

Cultural and Language Barriers: Communication challenges can lead to misunderstandings regarding quality expectations. Establishing clear lines of communication and possibly utilizing bilingual staff can help bridge these gaps.

-

Logistics and Supply Chain Factors: Transportation and storage conditions can impact the quality of centrifuges. Buyers should consider logistics factors when planning shipments, including temperature control and handling procedures.

-

Post-Purchase Support and Warranty: Understanding the warranty terms and the support available from suppliers post-purchase is critical. Buyers should ensure that the supplier offers adequate support for maintenance and troubleshooting, which is vital for the longevity of the equipment.

In conclusion, the manufacturing processes and quality assurance for electric centrifuges are complex and multifaceted. B2B buyers must be diligent in their assessment of suppliers, ensuring that all stages of production adhere to the highest standards of quality and reliability. By understanding these processes and implementing robust verification methods, buyers can secure the best equipment for their needs, fostering successful business relationships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘centrifuge electric’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring electric centrifuges, providing a systematic approach to ensure that you make informed and effective purchasing decisions. Given the diverse applications of electric centrifuges across various industries such as healthcare, research, and manufacturing, following this checklist will help you identify the right equipment tailored to your specific needs.

1. Define Your Technical Specifications

Clearly outline the technical requirements for the centrifuge you need, including speed, capacity, and type of centrifugation (e.g., fixed-angle, swing-out). Understanding these specifications is crucial as they directly impact the centrifuge’s performance in your application. Ensure you consider factors like sample size and the nature of materials being processed.

2. Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers and distributors with a strong reputation in the industry, especially those with experience in your geographic region. This step is important because reliable suppliers can provide not only high-quality products but also support and services that are essential for maintenance and troubleshooting.

3. Evaluate Potential Suppliers

Before making a commitment, it’s vital to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their track record in delivering equipment on time and their responsiveness to customer inquiries, as these factors can greatly affect your operations.

4. Verify Certifications and Compliance

Ensure that the centrifuges you are considering comply with relevant industry standards and certifications. This includes ISO certifications or compliance with local and international safety regulations. Compliance not only assures product quality but also reduces the risk of legal issues and enhances operational safety.

5. Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotations that outline pricing, delivery timelines, and warranty options. Comparing these quotes allows you to assess the best value for your investment. Look beyond just the initial cost; consider the total cost of ownership, including maintenance and potential downtime.

Illustrative image related to centrifuge electric

6. Assess After-Sales Support and Warranty Options

Evaluate the after-sales support offered by suppliers, including installation, training, and ongoing technical assistance. A strong support system can mitigate operational risks and enhance the longevity of your equipment. Additionally, consider warranty options that can protect your investment in case of defects or malfunctions.

7. Finalize the Purchase Agreement

After thorough evaluation and comparison, finalize the purchase agreement with the selected supplier. Ensure that the contract includes all agreed-upon terms, such as payment schedules, delivery dates, and service commitments. This step is essential to safeguard your interests and ensure clarity in the transaction.

Following this checklist will empower you to make informed decisions when sourcing electric centrifuges, ensuring that you select equipment that meets your operational requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for centrifuge electric Sourcing

What Are the Key Cost Components for Electric Centrifuge Sourcing?

When sourcing electric centrifuges, understanding the cost structure is paramount for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality components such as stainless steel, advanced plastics, and electronics can elevate prices but enhance durability and performance.

-

Labor: Labor costs vary by region and manufacturing practices. Skilled labor is essential for assembly and quality assurance, especially when dealing with precision equipment like centrifuges.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and other indirect costs. A well-managed facility can optimize production efficiency, potentially lowering costs.

-

Tooling: Initial setup costs for molds and specialized equipment can be substantial. However, these costs can be amortized over high-volume production runs, making them less impactful per unit as order quantities increase.

-

Quality Control (QC): Rigorous QC processes are crucial in maintaining product integrity, especially for laboratory equipment. The investment in QC can be significant but is essential for ensuring compliance with industry standards.

-

Logistics: Shipping costs, including packaging, freight, and customs duties, can vary widely based on the destination. Understanding Incoterms is essential for anticipating these costs in international transactions.

-

Margin: Supplier margins can fluctuate based on market conditions and competitive landscape, influencing final pricing.

How Do Price Influencers Affect Electric Centrifuge Costs?

Several factors influence the pricing of electric centrifuges, making it essential for buyers to navigate these nuances effectively.

-

Volume/MOQ: Suppliers often offer tiered pricing based on order volume. Larger orders typically benefit from discounts, making it advantageous for businesses to assess their needs and negotiate accordingly.

-

Specifications/Customization: Customized features can lead to higher costs. Buyers should weigh the necessity of specific features against budget constraints and project requirements.

-

Materials and Quality Certifications: Equipment that meets certain quality standards (e.g., ISO certifications) may command higher prices. Buyers should ensure that the quality aligns with their operational needs to justify the investment.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) influence who bears the shipping costs and risks.

What Tips Can Help Buyers Negotiate Better Prices for Electric Centrifuges?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential.

-

Conduct Comprehensive Research: Understanding the market landscape, including competitor pricing and supplier capabilities, can provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider the long-term costs associated with the centrifuge, including maintenance, energy consumption, and potential downtime. A lower upfront cost may not always equate to savings in the long run.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and favorable terms. Engage in open communication to express needs and expectations.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and import duties that can affect overall costs.

-

Negotiate Payment Terms: Flexible payment terms can enhance cash flow and reduce financial strain. Consider negotiating for installment payments or longer payment periods.

Disclaimer on Indicative Prices

Prices for electric centrifuges can vary widely based on specifications, supplier, and market conditions. The examples provided in this analysis are indicative and should be used for informational purposes only. Buyers are encouraged to request formal quotes from suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing centrifuge electric With Other Solutions

Introduction: Understanding Alternative Solutions to Centrifuge Electric

In the rapidly evolving landscape of laboratory equipment, businesses must evaluate various solutions to optimize their operations. Centrifuge electric devices are popular for their efficiency in separating substances based on density. However, there are alternative technologies and methods available that can achieve similar results. This analysis will compare centrifuge electric with two viable alternatives: Ultracentrifuges and Membrane Filtration Systems. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions that align with their specific project needs.

Comparison Table

| Comparison Aspect | Centrifuge Electric | Ultracentrifuge | Membrane Filtration System |

|---|---|---|---|

| Performance | High-speed separation (up to 20,000 RPM) | Ultra-high speeds (up to 100,000 RPM) | Varies based on membrane type |

| Cost | Moderate initial investment | High initial investment and maintenance | Moderate to low initial investment |

| Ease of Implementation | Simple setup and operation | Complex setup requiring expertise | User-friendly with straightforward setup |

| Maintenance | Low maintenance requirements | High maintenance and operational costs | Low maintenance, but membrane replacement needed |

| Best Use Case | Routine laboratory separations | Specialized research (e.g., biophysics) | Continuous separation of fluids and particles |

Detailed Breakdown of Alternatives

Ultracentrifuges: Pros and Cons

Ultracentrifuges are advanced centrifuges capable of achieving extremely high rotational speeds, allowing for the separation of sub-cellular components and macromolecules. The primary advantage of ultracentrifuges is their unparalleled performance in research settings, particularly in molecular biology and biochemistry, where precision is critical. However, these machines come with a high initial cost and require specialized knowledge for operation and maintenance. Additionally, their operational complexity can lead to longer setup times, making them less suitable for routine tasks.

Illustrative image related to centrifuge electric

Membrane Filtration Systems: Pros and Cons

Membrane filtration systems utilize selective barriers to separate particles from liquids based on size or charge. They are versatile and can be tailored to different applications, such as wastewater treatment or food and beverage processing. One of their key advantages is the cost-effectiveness of operation, as they generally require less energy than centrifuges and have a lower maintenance burden. However, the performance can be influenced by factors such as membrane fouling, which may necessitate regular cleaning or replacement. Membrane systems are best suited for continuous processes rather than batch separation tasks.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate technology for your separation needs requires a thorough analysis of your specific operational requirements, budget constraints, and desired performance outcomes. Centrifuge electric devices excel in routine laboratory applications with moderate costs and low maintenance. In contrast, ultracentrifuges are better suited for specialized research requiring high precision, albeit at a higher cost. Membrane filtration systems offer a flexible, cost-effective alternative for continuous processes but may not provide the same level of specificity as centrifugation. By evaluating these alternatives against your project goals, you can make an informed decision that maximizes efficiency and effectiveness in your operations.

Essential Technical Properties and Trade Terminology for centrifuge electric

What Are the Key Technical Properties of Electric Centrifuges?

When investing in electric centrifuges, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Maximum Speed (RPM)

The maximum speed, measured in revolutions per minute (RPM), indicates how fast the centrifuge can spin. Higher RPMs translate to greater centrifugal force, which is critical for separating components in mixtures effectively. For instance, laboratory centrifuges typically operate between 3,000 to 20,000 RPM, depending on the application. Buyers must assess their specific needs, as different applications (e.g., biological vs. chemical) require varying speeds for optimal results.

2. Centrifugal Force (xg)

Centrifugal force, expressed in multiples of gravitational acceleration (xg), is a vital measure of a centrifuge’s efficiency in separating particles. For example, a centrifuge generating 4,000 xg is effective for isolating cells from biological samples. Understanding this specification helps businesses choose the right centrifuge for their operational requirements, ensuring efficient separation processes.

Illustrative image related to centrifuge electric

3. Capacity

The capacity of a centrifuge refers to the volume of samples it can process at one time, typically measured in milliliters (mL). Common configurations range from small units handling 6 x 20 mL tubes to larger models accommodating up to 50 x 50 mL tubes. B2B buyers should evaluate their sample volume needs to select a centrifuge that maximizes productivity without compromising on quality.

4. Temperature Control

Temperature control is essential for applications that require specific thermal conditions, such as cell cultures or delicate biochemical processes. Some centrifuges come with built-in refrigeration systems to maintain low temperatures during operation, while others may simply provide ambient conditions. Selecting a centrifuge with appropriate temperature control can significantly affect the quality and viability of the samples processed.

5. Noise Level

Noise level, usually measured in decibels (dB), is an important consideration, especially for laboratory environments where quiet operation is preferred. Lower noise levels enhance user comfort and minimize distractions during critical procedures. B2B buyers should inquire about noise specifications to ensure compliance with workplace standards and user preferences.

What Are Common Trade Terms in the Electric Centrifuge Industry?

Navigating the electric centrifuge market requires familiarity with industry terminology. Here are some common trade terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed and sold by another brand. In the context of centrifuges, it is crucial to know if the manufacturer you are dealing with is an OEM, as this can affect quality assurance and warranty conditions. This term is particularly relevant when sourcing components for replacement or upgrades.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of units that a supplier is willing to sell in a single order. Understanding the MOQ is essential for budgeting and inventory management, especially for B2B buyers looking to stock up on centrifuge equipment or parts. It helps in planning purchases to avoid excess inventory or insufficient stock.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to obtain pricing for specific products or services. This is particularly useful for B2B transactions involving custom specifications or bulk orders. A well-prepared RFQ can help buyers receive competitive pricing and identify the best suppliers in the market.

4. Incoterms

Incoterms (International Commercial Terms) are standardized terms used in international trade to define responsibilities of buyers and sellers regarding shipment, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers involved in cross-border purchases of electric centrifuges, as they clarify who bears the risks and costs at each stage of shipping.

5. Calibration

Calibration refers to the process of adjusting the centrifuge’s operational parameters to ensure accuracy and reliability. Regular calibration is essential for maintaining performance standards, particularly in regulated industries like pharmaceuticals and biotechnology. Buyers should consider the calibration requirements and support services when evaluating potential centrifuge suppliers.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions and enhance their operational efficiency when investing in electric centrifuges.

Navigating Market Dynamics and Sourcing Trends in the centrifuge electric Sector

What Are the Current Market Dynamics and Key Trends in the Centrifuge Electric Sector?

The centrifuge electric sector is experiencing significant growth driven by advancements in technology, increasing demand for laboratory automation, and a rising focus on efficiency and precision in various industries such as pharmaceuticals, biotechnology, and medical laboratories. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note the following key trends influencing market dynamics:

-

Technological Advancements: The integration of digital technology into centrifuge systems is leading to enhanced automation and improved operational efficiency. Features such as smart controls, real-time monitoring, and data analytics are becoming standard, allowing for better performance and reduced operational costs.

-

Emerging Markets: Countries in Africa and South America are investing in their healthcare and research infrastructures, leading to increased demand for laboratory equipment, including electric centrifuges. This presents a lucrative opportunity for suppliers to engage with buyers in these regions who are seeking reliable and advanced laboratory solutions.

-

Customization and Flexibility: B2B buyers are increasingly looking for customizable solutions that meet their specific operational needs. Suppliers that can offer tailored centrifuge models, adjustable speed settings, and diverse capacity options are likely to gain a competitive edge.

-

Supply Chain Resilience: The COVID-19 pandemic highlighted the importance of resilient supply chains. Buyers are now prioritizing suppliers who can ensure consistent product availability and timely delivery, alongside quality assurance and support services.

-

Market Consolidation: The centrifuge electric sector is witnessing mergers and acquisitions, as companies aim to enhance their product offerings and expand their market reach. Buyers should consider the stability and reputation of suppliers during their sourcing processes.

How Are Sustainability and Ethical Sourcing Influencing B2B Practices in the Centrifuge Electric Sector?

As global awareness of environmental issues grows, sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the centrifuge electric sector. The environmental impact of manufacturing and disposing of laboratory equipment is significant, prompting many companies to seek out sustainable practices.

-

Sustainable Manufacturing: Suppliers that adopt eco-friendly manufacturing processes—such as reducing waste, minimizing energy consumption, and using recyclable materials—are increasingly favored by buyers. This shift not only addresses environmental concerns but also enhances brand reputation and compliance with regulatory requirements.

-

Ethical Supply Chains: B2B buyers are scrutinizing their supply chains to ensure ethical practices are in place. This includes fair labor practices, transparency, and compliance with international labor standards. Buyers can enhance their corporate social responsibility (CSR) by partnering with suppliers that prioritize ethical sourcing.

-

Green Certifications: Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are gaining traction among buyers looking for sustainable options. Suppliers with such certifications demonstrate their commitment to reducing environmental impact, providing buyers with confidence in their sourcing decisions.

-

Long-term Cost Benefits: Investing in sustainable and ethically sourced centrifuge electric products can lead to long-term cost savings. By reducing energy consumption and waste, companies can lower operational costs while also meeting the growing demand for sustainable practices from customers and stakeholders.

What Is the Evolution of the Centrifuge Electric Sector and Its Importance for B2B Buyers?

The evolution of the centrifuge electric sector has been marked by significant technological advancements and increasing specialization. Initially developed in the late 19th century for basic laboratory separation tasks, centrifuges have transformed into sophisticated machines capable of handling a wide range of applications—from medical diagnostics to complex biological research.

The shift towards automation and digitalization in the 21st century has further enhanced the capabilities of electric centrifuges. These advancements have led to improved precision, efficiency, and user-friendliness, making them indispensable tools in modern laboratories.

For B2B buyers, understanding the historical context of centrifuge technology can provide valuable insights into the ongoing innovations and future trends. As the market continues to evolve, those who remain informed about advancements and market dynamics will be better positioned to make strategic sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of centrifuge electric

-

How do I choose the right electric centrifuge for my laboratory?

Selecting the right electric centrifuge requires an understanding of your specific application needs. Consider factors such as maximum speed (RPM), capacity (number of tubes and volume), and the type of samples you will process. Evaluate whether you need a low-speed centrifuge for biological samples or a high-speed model for more complex applications. Additionally, assess the centrifuge’s footprint, ease of use, and maintenance requirements to ensure it fits well within your laboratory environment. -

What are the key specifications to look for in an electric centrifuge?

Key specifications include maximum speed (measured in RPM), centrifugal force (g-force), and capacity. Look for features such as programmable settings for time and speed, rotor compatibility, and safety features like lid locks. Consider noise levels and the centrifuge’s energy efficiency, which can impact operational costs. Assess whether the centrifuge meets international safety and quality standards relevant to your region, ensuring compliance for your laboratory applications. -

What customization options are available for electric centrifuges?

Many manufacturers offer customization options tailored to specific applications, such as specialized rotors, different tube sizes, or enhanced software for advanced programming. You can also request features like additional safety mechanisms or specific materials that resist corrosion or chemical reactions. Collaborating closely with suppliers can help you determine the best configuration for your laboratory needs, ensuring maximum efficiency and effectiveness. -

What is the minimum order quantity (MOQ) for electric centrifuges?

Minimum order quantities for electric centrifuges can vary significantly between suppliers, ranging from single units for smaller manufacturers to bulk quantities for larger companies. It’s essential to discuss your requirements upfront with potential suppliers to negotiate the best terms. If you’re unsure about committing to a large order, inquire about trial units or demo models, which can help you assess the product before making a larger investment. -

How can I vet suppliers for electric centrifuges in international markets?

To vet suppliers, start by researching their reputation through online reviews, industry forums, and certifications. Request references from other businesses that have purchased from them. Verify compliance with international standards and ensure they have a robust quality assurance process. Engaging in direct communication to discuss their capabilities, lead times, and customer service approach can also provide valuable insights into their reliability. -

What are the common payment terms for international purchases of electric centrifuges?

Payment terms can vary widely, but common practices include advance payment, letter of credit, or payment upon delivery. Some suppliers may offer favorable terms such as net 30 or net 60 days after receipt of goods. It’s crucial to clarify payment expectations during negotiations and to use secure payment methods to mitigate risks associated with international transactions. Always ensure that you have a clear contract outlining all terms and conditions. -

What quality assurance processes should I expect from electric centrifuge manufacturers?

Reputable manufacturers typically have stringent quality assurance processes that include material inspections, performance testing, and adherence to international standards such as ISO certifications. They should provide documentation verifying compliance with safety and quality benchmarks. Requesting detailed information about their QA procedures and post-manufacturing testing can help assure you of the product’s reliability and performance. -

What logistics considerations should I keep in mind when sourcing electric centrifuges internationally?

When sourcing internationally, consider shipping times, customs regulations, and potential tariffs that may affect your overall costs. Collaborate with your supplier to understand their shipping options and the associated lead times. It’s also essential to account for the handling of fragile equipment like centrifuges to avoid damage during transit. Establishing a clear logistics plan, including tracking and insurance, will help ensure a smooth delivery process.

Top 4 Centrifuge Electric Manufacturers & Suppliers List

1. HFS USA – High-Performance Centrifuge Products

Domain: hfsusa.com

Registered: 2017 (8 years)

Introduction: Centrifuge products from HFS USA are designed for high-performance separation processes. They feature durable construction, advanced technology, and user-friendly interfaces. The centrifuges are suitable for various applications, including laboratory research and industrial use. Key specifications include adjustable speed settings, multiple rotor options, and safety features such as lid locks and …

2. Zeny – Centrifuge 800-1

Domain: zeny.us

Registered: 2015 (10 years)

Introduction: {“Model number”:”800-1″,”Power supply”:”AC 110V 60HZ”,”Centrifugal capacity”:”20 ml x 6″,”Motor power”:”25 W”,”Speed range”:”400-4000 r/min”,”Relative centrifugal force”:”1790 xg”,”Timer range”:”1-60 min or always on”,”Specifications”:{“Power”:”25W”,”Voltage”:”110V/60Hz”,”Capacity”:”20ml*6″,”Speed”:”0-4000 rpm”,”Timer range”:”0-60 minutes or always on”,”Separation coefficient”:”1.960″,”Relative ce…

3. CNWTC – Medical Laboratory Low-speed Centrifuge Machine

Domain: cnwtc.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “Medical Laboratory 80-1 Electric Desktop Low-speed Centrifugal Centrifuge Machine”, “Voltage”: “AC 220V/110V 50Hz/60Hz”, “Maximum Speed”: “4000 r/min”, “Maximum Relative Centrifugal Force”: “1790 x g”, “Capacity”: “20ml*6 or 10ml*8”, “Timer Range”: “0-120 min”, “Dimension”: “245×250×220 mm”, “Net Weight”: “6 kg”, “Package Size”: “30*30*27 CM”, “Features”: [“Separating liquid from…

4. Generic – LD-5 Electronic Centrifuge

Domain: americanlaboratorytrading.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “Generic LD-5 Electronic Centrifuge”, “Category”: “Centrifuges”, “Subcategory”: “Mini Centrifuge”, “Manufacturer”: “Generic”, “Item Number”: “32292”, “Price”: “$0.00”, “Warranty”: “Free 90 Day Warranty, One Year Upgrade Available”, “Condition”: “Tested & Refurbished Prior to Shipping”, “Availability”: “Out of Stock”, “Description”: “The Generic LD-5 Electronic Centrifuge is a safe…

Strategic Sourcing Conclusion and Outlook for centrifuge electric

In the competitive landscape of electric centrifuges, strategic sourcing is pivotal for B2B buyers seeking to optimize their procurement processes. By aligning project goals with reliable suppliers, businesses can ensure they acquire high-quality centrifuge solutions tailored to their specific needs. The emphasis on efficiency and cost-effectiveness not only enhances operational productivity but also contributes to long-term sustainability in various sectors, including medical, scientific, and industrial applications.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is essential to leverage local partnerships and global networks. This approach facilitates access to innovative technologies and best practices that can elevate their operations. Furthermore, staying informed about market trends and supplier capabilities will empower businesses to make data-driven decisions that drive growth and enhance competitive advantage.

Looking ahead, the demand for electric centrifuges is projected to grow, driven by advancements in technology and an increasing focus on efficiency. B2B buyers are encouraged to explore emerging opportunities and foster collaborative relationships with trusted suppliers. This proactive stance will not only meet current needs but also position businesses for future success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to centrifuge electric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.