A B2B Buyer’s Guide to Aluminium Coloring: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for aluminium coloring

In the ever-evolving landscape of global trade, sourcing high-quality aluminum coloring solutions presents a significant challenge for international B2B buyers. With diverse methods such as dyeing, electrolytic coloring, integral coloring, and interference coloring available, understanding the nuances of these processes is crucial. This guide aims to demystify the complexities of aluminum coloring, providing insights into the various types, applications, and the criteria for selecting reliable suppliers. By addressing key considerations such as cost, quality control, and technological advancements, we empower buyers from Africa, South America, the Middle East, and Europe—including markets like Nigeria and Vietnam—to make informed purchasing decisions.

As businesses increasingly seek to enhance their product aesthetics while ensuring durability and corrosion resistance, understanding the intricacies of aluminum coloring becomes imperative. This comprehensive resource will explore not only the different coloring techniques but also their practical applications across various industries, from automotive to architectural design. By equipping B2B buyers with essential knowledge and actionable insights, this guide serves as a strategic tool for navigating the global market, ultimately leading to more effective sourcing and improved supplier partnerships. Whether you’re a seasoned procurement professional or new to the industry, understanding aluminum coloring will enhance your competitive edge in today’s dynamic marketplace.

Understanding aluminium coloring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dye Coloring | Involves immersion in dye solution; color depth varies with time and concentration. | Consumer products, architectural components | Pros: Wide color range, good aesthetic appeal. Cons: May fade over time if not sealed properly. |

| Electrolytic Coloring | Two-step process using inorganic metal salts; offers varied color options based on metal type. | Aerospace, automotive, electronics | Pros: Durable, corrosion-resistant colors. Cons: More complex process may lead to higher costs. |

| Integral Coloring | Combines anodizing and coloring in one step; produces robust bronze and black shades. | Heavy-duty industrial applications | Pros: Superior abrasion resistance, strong color integration. Cons: Limited color options. |

| Interference Coloring | Creates colors through optical effects; modifies pore structure for vibrant hues. | High-end design, artistic applications | Pros: Unique color effects, highly aesthetic. Cons: Process complexity may increase production time. |

| Dip Coloring | Similar to dye coloring but less UV-resistant; involves boiling post-dyeing. | Decorative items, consumer goods | Pros: Quick process, varied color options. Cons: Shorter lifespan compared to anodizing methods. |

What Are the Characteristics of Dye Coloring in Aluminium?

Dye coloring is a popular method that involves immersing anodized aluminum in a dye solution, allowing the porous anodic coating to absorb the dye. The color intensity can vary based on several factors, including immersion time, dye concentration, and the thickness of the anodic film. This method is particularly suitable for consumer products and architectural components where aesthetic appeal is paramount. However, buyers should consider the potential for color fading over time if the dye is not properly sealed.

How Does Electrolytic Coloring Enhance Aluminium Durability?

Electrolytic coloring, also known as the two-step process, uses an electric current to deposit inorganic metal salts into the pores of anodized aluminum. This method allows for a broader range of colors and is particularly effective in industries such as aerospace, automotive, and electronics, where durability and corrosion resistance are critical. While this method yields vibrant and long-lasting colors, buyers should be aware that the complexity of the process may lead to higher production costs.

What Are the Benefits of Integral Coloring for Industrial Applications?

Integral coloring combines the anodizing and coloring processes into one step, producing robust shades of bronze and black. This method is ideal for heavy-duty industrial applications, offering superior abrasion resistance and a strong color integration that does not peel or fade. However, the color options are somewhat limited compared to other methods, which may affect design choices for buyers looking for a wider palette.

What Makes Interference Coloring Unique in Design Applications?

Interference coloring creates vibrant hues through optical effects by modifying the pore structure of the anodic layer. This innovative approach is particularly suited for high-end design and artistic applications, where unique color effects can enhance visual appeal. While the aesthetic benefits are significant, buyers should consider the complexity of the process, which may result in longer production times and potentially higher costs.

How Does Dip Coloring Compare to Other Aluminium Coloring Methods?

Dip coloring involves submerging anodized aluminum in a dye tank, similar to dye coloring, but typically requires boiling the metal afterward to lock in the color. This method is often used for decorative items and consumer goods due to its quick processing time and varied color options. However, it may not provide the same level of UV resistance as anodizing methods, which could lead to a shorter lifespan for the finished products. Buyers should weigh the aesthetic benefits against longevity when considering this option.

Key Industrial Applications of aluminium coloring

| Industry/Sector | Specific Application of Aluminium Coloring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components and structures | Enhanced durability and corrosion resistance, aesthetic appeal | Compliance with aviation standards, weight considerations |

| Automotive | Vehicle exteriors and interior components | Improved aesthetics, resistance to environmental factors, and increased resale value | Quality assurance, color consistency, and compatibility with manufacturing processes |

| Construction | Architectural facades and structural elements | Aesthetic versatility, durability, and reduced maintenance costs | Local regulations, environmental impact, and supplier reliability |

| Consumer Electronics | Casings for devices like laptops and smartphones | Enhanced visual appeal, scratch resistance, and lightweight design | Material compatibility, color options, and supply chain logistics |

| Furniture and Home Goods | Decorative furniture and fixtures | Customization options, resistance to wear, and a modern aesthetic | Design flexibility, lead times, and cost-effectiveness |

How is Aluminium Coloring Utilized in Aerospace Applications?

In the aerospace sector, aluminium coloring is primarily employed for aircraft components and structures, where both aesthetics and performance are critical. The anodizing process not only provides a variety of colors but also enhances the material’s durability and corrosion resistance, essential for components exposed to harsh environmental conditions. Buyers in this sector must ensure compliance with stringent aviation standards and consider weight implications, as these factors significantly influence the overall performance and safety of aircraft.

What Role Does Aluminium Coloring Play in the Automotive Industry?

Within the automotive industry, aluminium coloring is utilized for both exterior and interior components, such as wheels, trim, and dashboard elements. The ability to achieve vibrant colors while enhancing resistance to environmental factors contributes to the vehicle’s aesthetic appeal and longevity, ultimately increasing resale value. International buyers should focus on quality assurance and color consistency to meet manufacturing standards, as well as compatibility with existing processes to ensure seamless integration into production lines.

Why is Aluminium Coloring Important in Construction?

Aluminium coloring finds extensive application in construction, particularly for architectural facades and structural elements. The aesthetic versatility allows for unique design options that can enhance the visual appeal of buildings while providing durability and reduced maintenance costs. Buyers must consider local regulations regarding building materials and environmental impact, as well as the reliability of suppliers to ensure the timely delivery of high-quality products.

How Does Aluminium Coloring Enhance Consumer Electronics?

In the consumer electronics sector, aluminium coloring is crucial for creating visually appealing casings for devices such as laptops and smartphones. This process not only provides an attractive finish but also enhances scratch resistance and maintains a lightweight design, which is vital for portable electronics. Buyers should pay attention to material compatibility and color options to align with branding requirements, alongside efficient supply chain logistics to meet market demands.

What Benefits Does Aluminium Coloring Offer for Furniture and Home Goods?

Aluminium coloring is increasingly used in the furniture and home goods industry for decorative elements and fixtures. This application allows for extensive customization options while ensuring resistance to wear, which is essential for high-traffic items. Buyers should prioritize design flexibility and cost-effectiveness, alongside understanding lead times to effectively manage inventory and meet customer expectations in a competitive market.

3 Common User Pain Points for ‘aluminium coloring’ & Their Solutions

Scenario 1: Inconsistent Color Matching for Product Lines

The Problem: B2B buyers often struggle with achieving consistent color matching across different batches of anodized aluminum products. Variability in dye concentration, anodizing conditions, and even the specific aluminum alloy used can lead to noticeable differences in color. This inconsistency can affect brand integrity and customer satisfaction, particularly for businesses that rely on uniformity for aesthetic and functional purposes.

The Solution: To ensure consistent color matching, buyers should establish clear specifications and communicate these with their anodizing supplier. Requesting color range samples before placing large orders can provide a reference point for expected outcomes. Additionally, implementing a standardized process for color approval can help maintain uniformity across batches. Engaging in regular consultations with suppliers about their processes and materials can also help mitigate discrepancies. Consider investing in quality control measures, such as spectrophotometry, to objectively measure color consistency across products.

Scenario 2: Limited Color Options Leading to Design Constraints

The Problem: Many B2B buyers find themselves limited by the color options available for anodized aluminum, which can restrict their design capabilities. While anodizing allows for a wide range of colors, not all suppliers can provide the full spectrum. This can be particularly challenging for companies in industries like automotive or consumer electronics, where color differentiation is crucial for market competitiveness.

The Solution: To overcome this limitation, buyers should research and partner with suppliers who specialize in advanced anodizing techniques that offer a broader color palette. Exploring innovative coloring methods, such as interference coloring or electrolytic coloring, can also unlock new design possibilities. Furthermore, collaborating with suppliers to develop custom color formulations can enable businesses to achieve unique shades that align with their branding. Establishing a close working relationship with a supplier can facilitate this process, allowing for tailored solutions that meet specific aesthetic needs.

Scenario 3: Durability Concerns with Anodized Colors

The Problem: A common pain point for B2B buyers is the concern over the durability of anodized colors, especially in harsh environments. Factors such as UV exposure, chemical exposure, and mechanical wear can lead to fading or degradation of the anodized finish, which can undermine the product’s lifespan and performance. This is especially relevant for industries operating in extreme conditions, such as construction or marine applications.

The Solution: To address durability concerns, it is crucial for buyers to choose the appropriate anodizing process and finishing treatment. Opting for thicker anodic coatings through methods like Type III hard coat anodizing can enhance color retention and resistance to wear. Additionally, buyers should inquire about sealing processes that lock in color and prevent fading. Implementing thorough testing protocols, including accelerated aging tests, can help assess the longevity of anodized colors under expected operational conditions. Collaborating with suppliers to understand the best practices for maintaining and caring for anodized finishes can also contribute to prolonged durability.

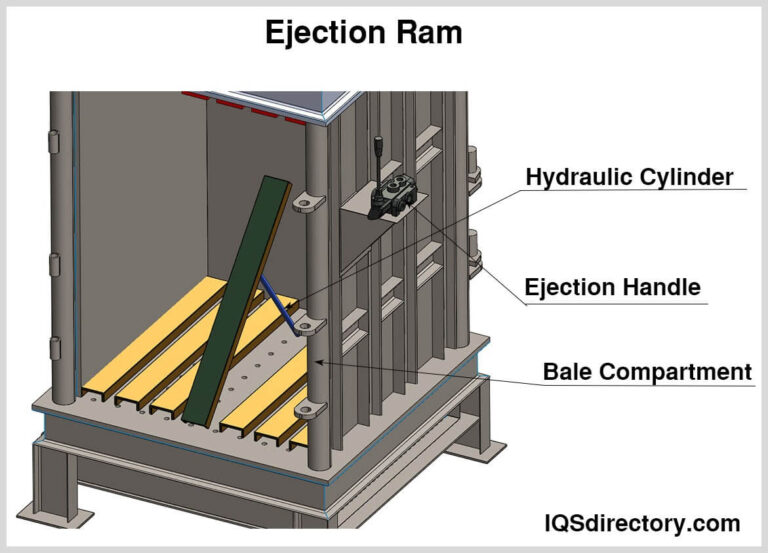

Illustrative image related to aluminium coloring

Strategic Material Selection Guide for aluminium coloring

What Are the Key Materials Used in Aluminium Coloring?

When selecting materials for aluminium coloring, it is essential to understand the properties, advantages, and limitations of the various coloring methods available. Here, we analyze four common materials used in the anodizing and coloring processes for aluminium, focusing on their performance characteristics and suitability for international B2B applications.

How Does Dye Affect Aluminium Coloring?

Key Properties: Dyes used in anodizing are typically organic compounds that penetrate the porous anodic layer of aluminium. The intensity of the color is influenced by factors such as dye concentration, immersion time, and anodic film thickness.

Pros & Cons: Dyes offer a broad spectrum of colors and can produce vibrant finishes. However, they may have lower UV resistance compared to other methods, leading to potential fading over time. The manufacturing complexity is moderate, as dyeing requires careful control of conditions to achieve consistent results.

Impact on Application: Dyes are suitable for applications where aesthetic appeal is critical, such as consumer products and architectural elements. However, they may not be ideal for environments with high UV exposure.

Considerations for International Buyers: Buyers should ensure that the dyes comply with local regulations regarding environmental safety, especially in regions like Europe where stringent chemical regulations exist.

What Are the Benefits of Electrolytic Coloring for Aluminium?

Key Properties: Electrolytic coloring involves immersing anodized aluminium in a bath containing inorganic metal salts, followed by the application of an electric current. This process creates a durable color finish that is integrated into the oxide layer.

Pros & Cons: The method provides excellent durability and corrosion resistance, making it suitable for industrial applications. However, it is more complex and costly than dyeing, requiring specialized equipment and expertise.

Impact on Application: Electrolytic coloring is ideal for products exposed to harsh environments, such as automotive and aerospace components. It offers a wide range of color options and can enhance the performance of the aluminium.

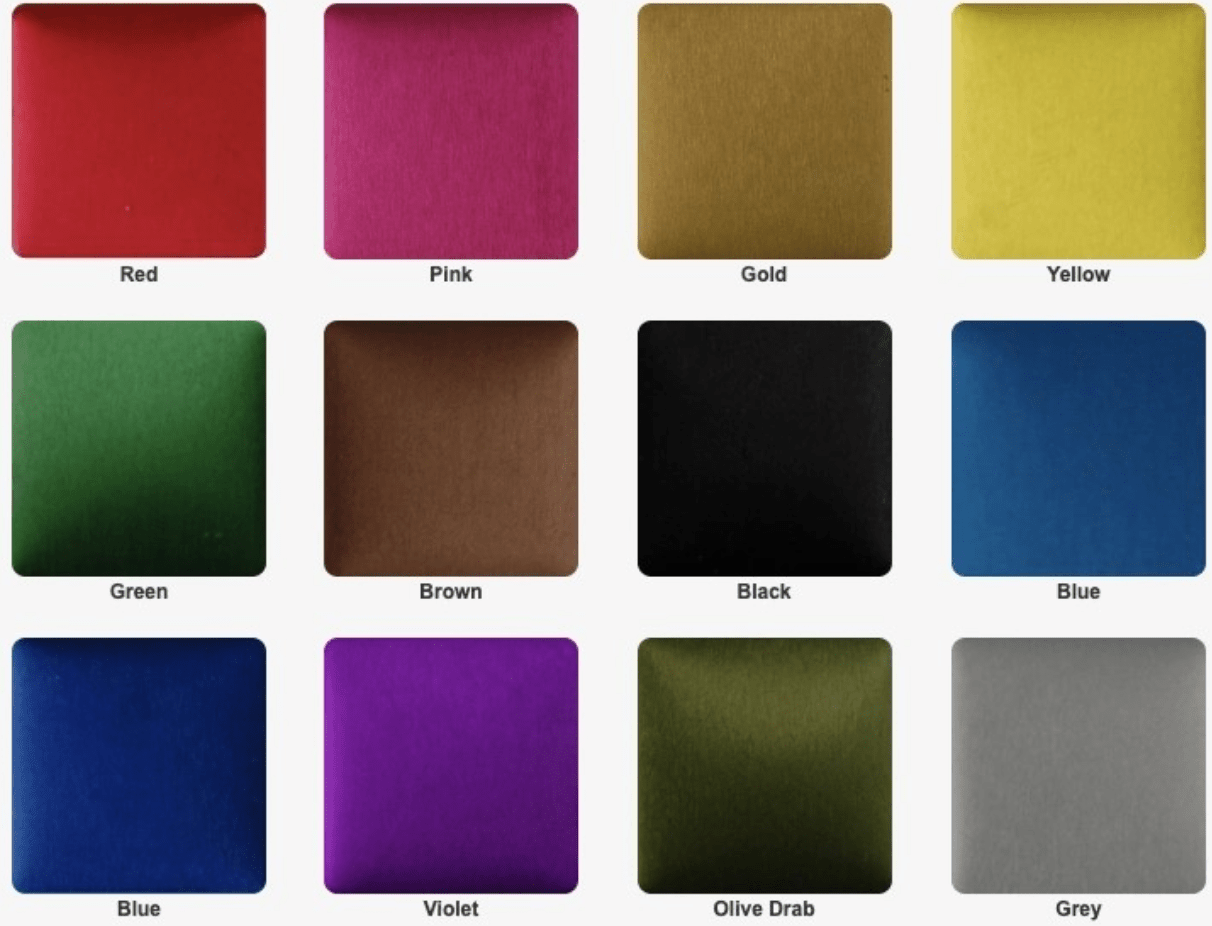

Illustrative image related to aluminium coloring

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial, especially for buyers in Europe and the Middle East, where quality and safety standards are strictly enforced.

How Does Integral Coloring Compare in Aluminium Applications?

Key Properties: Integral coloring combines the anodizing and coloring processes into a single step, resulting in a robust oxide layer with colors typically in bronze and black shades.

Pros & Cons: This method is highly durable and resistant to wear and corrosion, making it suitable for demanding applications. However, the color palette is limited compared to other methods, which may restrict design flexibility.

Impact on Application: Integral coloring is particularly effective for architectural applications and industrial components where durability is paramount. The one-step process also reduces manufacturing time.

Considerations for International Buyers: Buyers should evaluate the specific alloy used, as different alloys can yield varying results in terms of color and finish. Understanding local preferences for color and finish is also essential.

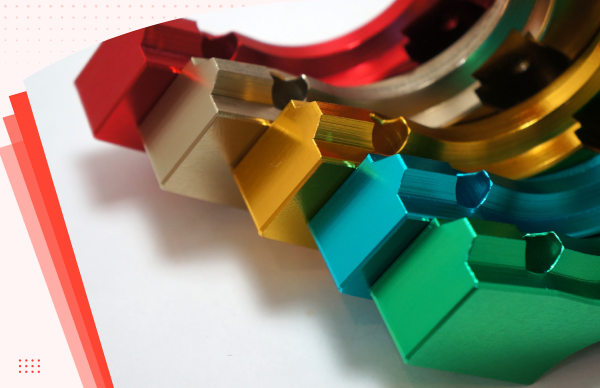

Illustrative image related to aluminium coloring

What Is the Role of Interference Coloring in Aluminium Finishes?

Key Properties: Interference coloring modifies the pore structure of anodized aluminium to create colors through optical interference effects, rather than traditional dyeing.

Pros & Cons: This innovative approach can produce vibrant and unique colors, offering aesthetic advantages. However, it can be more challenging to control, leading to variability in color consistency. The manufacturing complexity is high, requiring specialized techniques.

Impact on Application: Interference coloring is suitable for high-end consumer products and decorative applications where visual impact is crucial. Its unique color effects can differentiate products in competitive markets.

Considerations for International Buyers: Buyers should be aware of the potential for variability in color and finish, which may necessitate additional testing and validation to meet customer expectations.

Summary Table of Material Selection for Aluminium Coloring

| Material | Typical Use Case for aluminium coloring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Dye | Consumer products, architectural elements | Broad spectrum of colors | Lower UV resistance, potential fading | Medium |

| Electrolytic Coloring | Automotive, aerospace components | Excellent durability and corrosion resistance | Higher complexity and cost | High |

| Integral Coloring | Architectural applications, industrial components | Highly durable, reduces manufacturing time | Limited color palette | Medium |

| Interference Coloring | High-end consumer products, decorative applications | Unique and vibrant color effects | Variability in color consistency | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, enabling informed decisions that align with their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminium coloring

What Are the Key Stages in the Manufacturing Process for Aluminum Coloring?

The manufacturing process for aluminum coloring involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is vital for B2B buyers who seek quality and durability in aluminum products.

1. Material Preparation

The initial stage involves sourcing high-quality aluminum alloys that are suitable for anodizing and coloring. This includes assessing the alloy’s composition, which can affect the anodizing results. The aluminum is then cleaned to remove any contaminants, such as oils or oxidation, which could interfere with the anodizing process. Common cleaning methods include alkaline cleaning or acidic pickling.

2. Anodizing

Anodizing is an electrochemical process that enhances the aluminum’s surface properties by creating a thick oxide layer. This layer provides corrosion resistance and improves adhesion for coloring. There are various anodizing methods, including sulfuric acid anodizing and hard coat anodizing, each offering different thicknesses and characteristics.

3. Coloring Techniques

Once anodized, aluminum can undergo several coloring techniques:

-

Dyeing: The anodized aluminum is submerged in a dye solution, allowing the porous oxide layer to absorb the dye. The depth of color is influenced by dye concentration, immersion time, and temperature.

-

Electrolytic Coloring: This two-step process involves immersing the anodized aluminum in a bath of inorganic metal salts and applying an electric current. This method can produce a broader range of colors, depending on the metals used and the application conditions.

-

Integral Coloring: This method combines anodizing and coloring in one step, producing durable colors typically in bronze or black shades.

-

Interference Coloring: This innovative process modifies the pore structure of the anodized layer, creating colors through optical interference rather than dyeing. This method produces vibrant hues such as blue, green, and red.

4. Sealing

The final step in the coloring process is sealing, which locks the dye within the anodized layer. This is usually done by boiling the anodized aluminum in deionized water or applying a chemical sealant. Sealing is crucial as it enhances corrosion resistance and prevents color fading.

How Is Quality Assurance Implemented in Aluminum Coloring?

Quality assurance (QA) is paramount in the aluminum coloring process to ensure that products meet industry standards and customer expectations. B2B buyers should be familiar with international standards and specific quality checkpoints to verify the quality of their suppliers.

Relevant International Standards

B2B buyers should ensure that their suppliers comply with international quality standards such as ISO 9001, which focuses on consistent quality management systems. Additionally, industry-specific certifications, such as CE marking for products sold in Europe or API standards for products used in the petroleum industry, may be relevant depending on the application of the aluminum products.

Key Quality Control Checkpoints

Quality control in aluminum coloring typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Before production begins, incoming materials (aluminum alloys and chemicals) are inspected for quality and compliance with specifications.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, dye concentration, and anodizing time are monitored to ensure consistency. Regular sampling and testing are conducted to detect any deviations early.

-

Final Quality Control (FQC): After the coloring process, finished products undergo final inspections, which may include visual inspections for color uniformity, dimensional checks, and performance tests for corrosion resistance.

What Common Testing Methods Are Used in Aluminum Coloring?

To ensure the quality of colored aluminum products, various testing methods are employed:

-

Visual Inspection: This is the most basic form of quality control, where products are checked for color consistency, surface defects, and overall appearance.

-

Color Matching: Using spectrophotometers, suppliers can measure the color of anodized parts to ensure they meet specified standards.

-

Adhesion Testing: This method assesses how well the colored layer adheres to the aluminum substrate, crucial for preventing peeling or chipping.

-

Corrosion Resistance Testing: Salt spray tests (ASTM B117) are commonly used to evaluate how well the anodized layer protects the aluminum from corrosion.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for mitigating risks.

Conducting Audits

Buyers should consider conducting regular audits of their suppliers’ facilities. This not only assesses compliance with international standards but also evaluates the efficacy of their quality control processes. Audits can be performed by the buyer’s team or by hiring third-party inspection services.

Reviewing Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their QA processes and results. These reports should include data from IQC, IPQC, and FQC stages, highlighting any issues encountered and corrective actions taken.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can further ensure that products meet specified standards. These independent inspectors can perform tests and provide unbiased evaluations of the products before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers should be aware of several nuances when it comes to quality control and certification:

-

Cultural Differences: Understanding local practices and regulations can help buyers navigate quality expectations effectively. For example, certification processes may vary significantly across countries.

-

Documentation Requirements: Ensure that suppliers provide all necessary documentation, including certificates of conformity, test results, and compliance with international standards. This documentation is crucial for customs clearance and quality assurance.

-

Local Regulations: Different regions may have specific regulations governing aluminum products. Buyers should familiarize themselves with these to ensure compliance and avoid potential legal issues.

By being informed about these manufacturing processes and quality assurance practices, B2B buyers can make educated decisions when sourcing aluminum coloring services, ensuring they receive high-quality, durable products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminium coloring’

To assist B2B buyers in procuring aluminum coloring services effectively, this guide outlines essential steps for sourcing high-quality coloring processes. By following this checklist, you can ensure that your aluminum products meet aesthetic and functional requirements while aligning with industry standards.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the aluminum coloring process you need. This includes determining the desired color, finish, and the specific application of the colored aluminum. Understanding these details will help streamline the selection of suppliers who can meet your precise requirements.

- Color Requirements: Specify if you need solid colors, gradients, or specific shades.

- Finish Type: Decide between matte, glossy, or textured finishes based on your application.

Step 2: Research Available Coloring Methods

Familiarize yourself with the various aluminum coloring methods available, such as dyeing, electrolytic coloring, integral coloring, and interference coloring. Each method offers distinct advantages, and understanding these will help you choose the right one for your project.

- Dyeing Process: Often used for vibrant colors but may have limitations in UV resistance.

- Electrolytic Coloring: Provides durable finishes with a wide color range; suitable for high-end applications.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can deliver the quality and service you require. Look for companies that provide detailed information about their processes and capabilities.

- Supplier Profiles: Request company profiles, including their experience and technology used.

- References: Ask for testimonials from previous clients, especially those in similar industries or regions.

Step 4: Request Samples of Finished Products

Before finalizing any agreements, request samples of previously colored aluminum products. This allows you to evaluate the quality, color accuracy, and finish of the samples in real-world conditions.

- Color Consistency: Check for uniformity in color across multiple samples.

- Durability Tests: Inquire about any testing done to ensure the longevity of the color.

Step 5: Verify Compliance with Industry Standards

Ensure that the suppliers adhere to relevant industry standards and certifications. This is crucial for maintaining quality control and ensuring that the coloring process meets environmental and safety regulations.

Illustrative image related to aluminium coloring

- Certifications to Look For: ISO certifications, RoHS compliance, and specific industry-related standards.

- Quality Control Processes: Inquire about their quality assurance practices and testing methods.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate clear terms and conditions regarding pricing, lead times, and payment terms. Ensure that both parties understand the expectations to avoid potential disputes later.

- Detailed Contracts: Include specifics about the coloring process, delivery timelines, and penalties for non-compliance.

- Flexible Terms: Consider including clauses for adjustments based on market fluctuations or changes in order volume.

Step 7: Establish a Communication Plan

Effective communication is key to successful procurement. Set up a plan for regular updates and check-ins throughout the project lifecycle to ensure alignment and address any issues promptly.

- Regular Updates: Schedule weekly or bi-weekly meetings to discuss project progress.

- Point of Contact: Designate a primary contact person from both sides to streamline communication.

By following this checklist, B2B buyers can navigate the complexities of sourcing aluminum coloring services with confidence, ensuring their products meet both aesthetic and functional standards while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for aluminium coloring Sourcing

What Are the Key Cost Components in Aluminium Coloring?

When sourcing aluminum coloring services, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of dyes, electrolytes, and other chemicals significantly influences costs. High-quality dyes and metal salts can be more expensive but provide better color retention and durability.

-

Labor: Skilled labor is required for both the anodizing process and the coloring techniques. Labor costs can vary by region; for instance, skilled labor may be more expensive in Europe compared to Africa or South America.

-

Manufacturing Overhead: This includes costs related to the operation of machinery, utilities, and facility maintenance. The complexity of the coloring process, such as the use of advanced techniques like interference coloring, can increase overhead.

-

Tooling: Initial setup costs for specialized equipment, especially for custom orders, can be significant. Buyers should inquire about any tooling fees that may apply to their specific requirements.

-

Quality Control (QC): Implementing stringent QC processes ensures that the final product meets specified standards. This can add to the overall cost but is crucial for maintaining quality, especially in regulated industries.

-

Logistics: Shipping costs can vary based on the geographic location of the supplier and the buyer. Incoterms will also affect logistics costs and responsibilities, influencing the overall pricing structure.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the standard margins in the aluminum coloring industry can aid in negotiating better deals.

How Do Price Influencers Impact Aluminium Coloring Costs?

Several factors can influence the pricing of aluminum coloring services:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and consider consolidating orders to meet MOQs.

-

Specifications and Customization: Custom colors or specific finishes can increase costs. Communicating clear specifications upfront can help avoid unexpected charges later in the process.

-

Materials: The choice of base aluminum alloy and coloring methods (e.g., dye vs. electrolytic) can impact pricing. Higher-quality materials and advanced coloring techniques tend to be more expensive but offer superior results.

-

Quality and Certifications: Certain industries may require specific certifications (e.g., ISO), which can lead to higher prices. Buyers should evaluate the necessity of certifications based on their end-use applications.

-

Supplier Factors: The supplier’s reputation, experience, and location can affect pricing. Established suppliers may charge more for their expertise and reliability, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms applied to your order is crucial, as they determine the responsibilities of buyers and sellers in terms of shipping and insurance, which can affect overall costs.

What Tips Can Help Buyers Negotiate Better Aluminium Coloring Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Volume Discounts: Engage suppliers in discussions about potential discounts for larger orders. Many suppliers are willing to offer reduced rates for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, durability, and potential rework. A lower upfront cost may lead to higher long-term expenses.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations can impact pricing. Buyers should consider locking in prices or negotiating terms that account for potential currency risks.

-

Request Samples: Before committing to large orders, request samples to evaluate color quality and finish. This can prevent costly mistakes and ensure the final product meets expectations.

-

Be Transparent About Requirements: Clear communication regarding specifications and expectations can prevent misunderstandings and additional costs during production.

While pricing can vary widely based on the aforementioned factors, buyers should approach negotiations with a well-informed perspective to secure favorable terms. Always remember that indicative prices can fluctuate based on market conditions, so it’s advisable to regularly reassess supplier quotes and industry trends.

Illustrative image related to aluminium coloring

Alternatives Analysis: Comparing aluminium coloring With Other Solutions

When considering the most effective ways to enhance the aesthetic appeal and functional properties of aluminum products, various coloring methods come into play. This section provides a comparative analysis of aluminum coloring techniques against alternative solutions, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Aluminium Coloring | Powder Coating | Liquid Coating |

|---|---|---|---|

| Performance | High durability, corrosion resistance | Excellent wear and corrosion resistance | Moderate durability, less resistant to chemicals |

| Cost | Moderate to high, depending on method | Generally lower than anodizing | Usually the lowest cost option |

| Ease of Implementation | Requires specialized equipment | Relatively easy, requires curing | Simple application with minimal setup |

| Maintenance | Low maintenance; resistant to fading | Requires periodic touch-ups | Higher maintenance due to wear |

| Best Use Case | Aerospace, automotive, decorative parts | Industrial applications, furniture | Consumer goods, appliances |

What Are the Advantages and Disadvantages of Powder Coating?

Powder coating is a popular alternative to aluminum coloring, particularly for industrial applications. It involves applying a dry powder to the metal surface, which is then cured under heat to form a hard finish. One of the primary advantages of powder coating is its cost-effectiveness; it generally requires less investment than anodizing and can cover large areas quickly. However, it may not provide the same level of corrosion resistance or aesthetic appeal as anodized aluminum, especially in harsh environments.

How Does Liquid Coating Compare to Aluminium Coloring?

Liquid coating, which involves applying a liquid paint or varnish, is often the simplest and most cost-effective method of coloring aluminum. This technique allows for a wide range of colors and finishes, making it suitable for consumer goods and appliances. However, the durability and chemical resistance of liquid coatings are typically lower than that of anodized aluminum. Maintenance can also be more demanding, as liquid coatings may require more frequent touch-ups and are prone to chipping and fading over time.

Conclusion: How Should B2B Buyers Choose the Right Coloring Solution?

When selecting a coloring solution for aluminum products, B2B buyers should carefully assess their specific needs, including the intended application, environmental conditions, and budget constraints. Aluminum coloring offers superior durability and aesthetic flexibility, making it ideal for high-performance applications in industries like aerospace and automotive. In contrast, powder and liquid coatings provide more cost-effective options for less demanding environments. Ultimately, the choice should align with the desired balance between performance, cost, and maintenance, ensuring that the selected solution meets both operational and aesthetic requirements.

Essential Technical Properties and Trade Terminology for aluminium coloring

What Are the Essential Technical Properties of Aluminium Coloring?

When engaging in the procurement of colored anodized aluminum, understanding the technical properties is crucial for ensuring product quality and meeting application requirements. Here are some key specifications to consider:

1. Material Grade

Material grade indicates the specific composition and properties of the aluminum alloy used. Common grades for anodizing include 6061 and 6063, known for their excellent corrosion resistance and mechanical properties. Selecting the appropriate grade ensures the end product meets the strength and durability needed for its intended application, which is vital for industries ranging from automotive to construction.

2. Anodic Film Thickness

The thickness of the anodic layer affects both the color and protective properties of the aluminum. Typically measured in microns, a thicker anodic film offers better abrasion resistance and color retention. For B2B buyers, specifying the desired film thickness is essential to achieve the required durability and aesthetic appearance, especially in high-wear applications.

3. Color Fastness

Color fastness refers to the resistance of the anodized surface to fading or discoloration when exposed to environmental factors such as UV light and humidity. It is typically tested according to industry standards. For buyers, ensuring high color fastness is critical, particularly for products that will be used outdoors or in harsh conditions, as it directly impacts customer satisfaction and product lifespan.

4. Dye Concentration

Dye concentration affects the vibrancy and depth of the color achieved during anodizing. Higher concentrations can result in more intense colors but may also influence the sealing process and durability. B2B buyers should communicate their color requirements clearly during the RFQ (Request for Quotation) process to ensure the final product meets their visual and performance standards.

5. Sealing Process

The sealing process involves hydrating the anodized layer to lock in dyes and enhance corrosion resistance. This step is essential for ensuring the longevity of the color and the overall durability of the aluminum. Buyers must confirm that the sealing process is included in the manufacturing specifications, as it significantly impacts the end product’s quality.

Which Trade Terminology Should B2B Buyers Understand in Aluminium Coloring?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions in the aluminum coloring sector. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another brand’s name. In the aluminum coloring market, understanding OEM relationships can help buyers identify reliable suppliers who can meet specific design and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to manage inventory costs. Understanding the MOQ helps in planning purchases and budgeting, especially for larger manufacturing operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific quantities and specifications of products. It is a critical step in the procurement process, allowing buyers to compare prices and terms before making purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Knowing the applicable Incoterms is essential for B2B transactions, as they outline who bears the risk and cost at various points in the shipping process.

5. Color Match Expectations

This term refers to the anticipated alignment of colors across batches of anodized aluminum. Due to variations in dye batches and anodizing processes, it’s crucial for buyers to specify their color match expectations during the initial discussions to avoid discrepancies in future orders.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing colored anodized aluminum, ensuring they receive products that meet their specific requirements and expectations.

Navigating Market Dynamics and Sourcing Trends in the aluminium coloring Sector

What Are the Key Market Drivers and Trends in the Aluminium Coloring Sector?

The aluminium coloring sector is witnessing substantial growth, driven by an increasing demand for durable, aesthetically pleasing materials in various industries, including automotive, aerospace, and construction. Key market dynamics include the rising preference for lightweight materials that enhance energy efficiency and the growing emphasis on custom colors and finishes tailored to specific applications. Notably, the global shift towards sustainable manufacturing processes is reshaping sourcing strategies, with buyers increasingly seeking suppliers that utilize eco-friendly practices.

Emerging technologies, such as digital dyeing and automated anodizing processes, are transforming how aluminium is colored. These advancements not only improve efficiency but also enhance color consistency and reduce lead times, making them attractive to B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. For instance, companies in Nigeria and Vietnam are leveraging these innovations to meet local market demands while optimizing their supply chains.

Moreover, as international trade dynamics evolve, companies are focusing on developing robust sourcing networks that enable them to procure high-quality aluminium coloring solutions. This includes establishing partnerships with manufacturers that offer a diverse range of coloring techniques—such as dye, electrolytic, integral, and interference coloring—allowing for greater customization and flexibility in product offerings.

How Do Sustainability and Ethical Sourcing Impact the Aluminium Coloring Sector?

Sustainability is becoming increasingly central to purchasing decisions in the aluminium coloring sector. B2B buyers are not only concerned about the aesthetic and functional qualities of the products but also about the environmental impact of their sourcing practices. The aluminium industry has a significant carbon footprint, and companies are prioritizing suppliers that demonstrate a commitment to reducing emissions through energy-efficient anodizing processes and recycling initiatives.

Ethical sourcing plays a crucial role in this context. Buyers are more inclined to partner with manufacturers that maintain transparent supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) serve as benchmarks for responsible sourcing and environmental stewardship. Additionally, the use of green materials and processes—such as non-toxic dyes and water-based sealants—aligns with the growing demand for environmentally friendly products.

As the global market becomes more interconnected, B2B buyers in regions like South America and the Middle East are increasingly looking for suppliers who can provide verified sustainability credentials, thereby ensuring compliance with local regulations and international standards. This trend not only fosters brand loyalty but also enhances corporate reputation in an eco-conscious marketplace.

What Is the Evolution of Aluminium Coloring in a B2B Context?

The evolution of aluminium coloring has been marked by significant technological advancements and shifts in market demands. Initially, aluminum coloring was limited to basic paint and powder coatings, which offered limited durability and aesthetic appeal. However, with the advent of anodizing in the mid-20th century, the industry witnessed a transformation. Anodizing provided a robust protective layer that not only enhanced corrosion resistance but also allowed for a wider range of colors and finishes.

In recent years, the introduction of sophisticated coloring techniques such as electrolytic coloring and integral coloring has further expanded the capabilities of aluminium products. These innovations have enabled manufacturers to achieve vibrant, long-lasting colors while also improving the material’s mechanical properties. As a result, B2B buyers now have access to a broader array of choices that meet both functional and aesthetic requirements.

Today, the aluminium coloring sector continues to evolve, driven by technological advancements and a growing focus on sustainability. This ongoing transformation presents significant opportunities for B2B buyers to leverage innovative solutions that align with their business objectives and market demands.

Illustrative image related to aluminium coloring

Frequently Asked Questions (FAQs) for B2B Buyers of aluminium coloring

-

How do I choose the right coloring method for anodized aluminum?

Choosing the right coloring method depends on your specific application and aesthetic requirements. The four primary methods—dyeing, electrolytic coloring, integral coloring, and interference coloring—each offer unique advantages. Dyeing allows for a wide range of colors but may not be as durable. Electrolytic coloring provides vibrant hues with enhanced durability. Integral coloring creates strong, abrasion-resistant finishes in darker tones. Assess your project’s functional needs, desired colorfastness, and budget to determine the best method. -

What are the minimum order quantities (MOQs) for aluminum coloring services?

MOQs for aluminum coloring services can vary significantly between suppliers and processes. Typically, MOQs may range from 100 to 1,000 pieces, depending on the complexity of the coloring process and the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your project size while considering cost-effectiveness and production efficiency. -

What should I consider when vetting suppliers for aluminum coloring?

When vetting suppliers, consider their experience in anodizing and coloring aluminum, production capacity, quality certifications, and past client testimonials. Evaluate their compliance with international standards, especially if sourcing from regions like Africa or South America. Request samples of their work to assess color accuracy and finish quality. Moreover, inquire about their lead times and ability to handle custom orders to ensure they can meet your specific requirements. -

How can I ensure color consistency in my aluminum products?

To ensure color consistency, communicate your exact color specifications during the quoting phase. Request color samples before production to verify that the dyeing or coloring process meets your expectations. Establish a clear quality assurance protocol with the supplier, including regular inspections and batch testing. Additionally, consider specifying the anodizing film thickness, as this can impact color absorption and consistency across different batches. -

What are the payment terms typically offered by aluminum coloring suppliers?

Payment terms can vary widely among suppliers, but common arrangements include upfront deposits (often 30-50% of the total order value) followed by balance payments upon completion. Some suppliers may offer net terms (e.g., 30 or 60 days) based on your creditworthiness. Always clarify payment methods accepted, such as wire transfers, letters of credit, or online payment platforms, and ensure that all terms are documented in the contract to avoid disputes. -

How does the logistics of shipping colored aluminum products work?

Shipping logistics for colored aluminum products involve careful packaging to prevent damage during transport. Discuss shipping options with your supplier, including freight forwarding and insurance. Consider customs regulations and import duties specific to your region, as these can impact delivery timelines and costs. If sourcing from international suppliers, ensure that they are familiar with your country’s import requirements to streamline the process. -

What quality assurance measures should I look for in aluminum coloring services?

Look for suppliers who implement stringent quality assurance measures, such as ISO certifications and adherence to industry standards. Inquire about their testing procedures for color accuracy, adhesion, and durability of the anodized finish. Regular quality audits and third-party inspections can also provide added assurance. Establishing a clear QA protocol with your supplier will help maintain product quality and consistency throughout your order. -

Can I customize colors and finishes for my aluminum products?

Yes, many suppliers offer customization options for colors and finishes in aluminum coloring. You can often specify exact color codes (e.g., RAL or Pantone) and finishes (e.g., matte, glossy) to achieve your desired aesthetic. Discuss your requirements during the initial consultation to ensure the supplier can accommodate your customization needs. Keep in mind that more complex customizations may involve additional costs and longer lead times.

Top 7 Aluminium Coloring Manufacturers & Suppliers List

1. SAF – Anodized Aluminum Coloring Solutions

Domain: saf.com

Registered: 1992 (33 years)

Introduction: There are four ways to color anodized aluminum: 1. Dye: Immersion in a liquid solution with dissolved dye; color intensity depends on anodic film thickness, dye concentration, immersion time, and temperature. 2. Electrolytic Coloring (two-step): After anodizing, the metal is immersed in a bath with inorganic metal salt and current is applied, depositing the metal salt in the pores; colors depend o…

2. AluConsult – Anodized Aluminum Coloring Processes

Domain: aluconsult.com

Registered: 2004 (21 years)

Introduction: This company, AluConsult – Anodized Aluminum Coloring Processes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Xometry – Anodizing Services for Aluminum

Domain: xometry.com

Registered: 2015 (10 years)

Introduction: Xometry provides anodizing services for aluminum, including Type II, Type III (hard coat), and Type III (with PTFE). The anodizing process enhances the aluminum’s strength, durability, and corrosion resistance. Anodized aluminum can be dyed in a wide range of colors, including basic colors like black, blue, red, yellow, and white, as well as vibrant options like purple, orange, pink, and gold. The…

4. Caswell Plating – Anodizing Dyes

5. Finishing and Coating – Electrolytic Coloring of Anodized Aluminum

Domain: finishingandcoating.com

Registered: 2020 (5 years)

Introduction: Electrolytic coloring of anodized aluminum is a 2-step process widely practiced in North America since the late 1970s, originating from Japan. It is an energy-efficient method that provides aluminum finishes with excellent light fastness, heat fastness, weather fastness, and chemical resilience, making it popular in architectural and special fields markets. The process involves anodizing aluminum,…

6. TFG USA – Key Product Insights

Domain: tfgusa.com

Registered: 2008 (17 years)

Introduction: Key Takeaways: Enhanced Durability, Aesthetic Flexibility, DIY Potential, Process Variations, Industrial Versatility, Alternative Comparison. Benefits: Durability and Corrosion Resistance, Appearance, Eco-friendly, Easy Maintenance. Potential Disadvantages: Limited Color Range, Thermal Stress Cracking, Initial High Cost for DIY Setups, Environmental Concerns. Types of Anodizing: Type I- Chromic Ac…

7. Kingscote Chemicals – Aluminum Dyes

Domain: kingscotechemicals.com

Registered: 1999 (26 years)

Introduction: Aluminum Dye & Aluminum Dye Kits from Kingscote Chemicals offer over 40 color options for anodizing applications. The dyes are categorized by color hue, metal content, lightfastness, and NSF certification. Common acids used for anodizing include sulfuric and chromic. The product line includes various aluminum dye colors such as Black, Blue, Bordeaux Red, Gold, Orange, Purple, Turquoise, Yellow, Br…

Strategic Sourcing Conclusion and Outlook for aluminium coloring

What Are the Key Insights for Strategic Sourcing in Aluminium Coloring?

In summary, strategic sourcing in aluminium coloring presents significant opportunities for international B2B buyers. Understanding the various coloring methods—such as dyeing, electrolytic coloring, integral coloring, and interference coloring—enables businesses to select the most suitable techniques that align with their aesthetic and functional requirements. The durability and corrosion resistance of anodized aluminum not only enhance product life cycles but also contribute to sustainability goals, appealing to environmentally conscious consumers.

How Can International Buyers Benefit from Aluminium Coloring Solutions?

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for customized, high-quality aluminium products is on the rise. By leveraging strategic sourcing partnerships with reputable suppliers, buyers can ensure consistent quality and innovation in their aluminum coloring processes.

What’s Next for Your B2B Aluminium Coloring Strategy?

Looking ahead, the integration of advanced technologies and sustainable practices in aluminium coloring will be key to staying competitive. Buyers should actively seek out suppliers who offer not only a diverse color palette but also eco-friendly processes. By taking proactive steps now, you can position your business for success in an increasingly competitive landscape. Engage with suppliers today to explore how strategic sourcing can transform your aluminium product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.