Space Altitude Chamber Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for space altitude chamber

Navigating the complexities of sourcing a space altitude chamber presents a unique challenge for international B2B buyers. With the increasing demand for altitude simulation in diverse sectors such as military training, sports performance, and scientific research, understanding the intricacies of these chambers is crucial. This guide offers a comprehensive overview of the various types of altitude chambers available on the market, their applications, and essential factors to consider when vetting suppliers.

From modular to conversion chambers, our exploration highlights how these innovative solutions can meet the specific needs of businesses across Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil. We delve into the technical specifications, operational capabilities, and the importance of ongoing support and maintenance, empowering you to make informed purchasing decisions.

In addition, we provide insights into cost considerations and potential ROI, ensuring that you can align your investment with your organizational goals. By equipping B2B buyers with actionable information and expert guidance, this guide serves as an essential resource for navigating the global market for space altitude chambers, ultimately enhancing your operational efficiency and strategic capabilities.

Understanding space altitude chamber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conversion Chamber | Customizable to fit existing spaces; easy entry and exit | Sports training, rehabilitation | Pros: Flexible installation, cost-effective. Cons: May require modifications to space. |

| Modular Chamber | Prefabricated, expandable, and relocatable | Military training, research facilities | Pros: Versatile design, easy relocation. Cons: Initial investment can be high. |

| Environmental Chamber | Simulates various climates with temperature and humidity control | Scientific research, environmental studies | Pros: Comprehensive environmental simulation. Cons: Complexity in setup and operation. |

| Hypobaric Chamber | Operates under negative pressure; specific safety protocols needed | Aviation and aerospace training | Pros: Accurate altitude simulation. Cons: High operational costs, limited accessibility. |

| Normobaric Chamber | Maintains standard pressure while reducing oxygen levels | Athletic training, acclimatization | Pros: Safe, user-friendly, cost-effective. Cons: May not fully replicate true altitude effects. |

What Are the Characteristics of Conversion Chambers?

Conversion chambers are designed to transform existing spaces into altitude simulation environments. They can be installed in various locations, including gyms, hospitals, or research facilities, allowing for seamless integration. The flexibility of these chambers makes them particularly appealing for B2B buyers who may have budget constraints but still require effective altitude training solutions. Key considerations for purchasing include the size of the existing space and the anticipated usage patterns.

How Do Modular Chambers Stand Out in Versatility?

Modular chambers are prefabricated units that offer significant versatility. They can be expanded or relocated based on changing needs, making them ideal for organizations that anticipate growth or require mobility. These chambers are particularly useful for military and research applications where training environments may need to be adjusted frequently. Buyers should consider installation logistics and any required infrastructure, such as power supply, before making a purchase.

Why Choose Environmental Chambers for Comprehensive Studies?

Environmental chambers provide advanced climate simulation capabilities, allowing organizations to replicate specific environmental conditions, including temperature and humidity variations alongside altitude changes. This makes them invaluable for scientific research and environmental studies. When considering a purchase, organizations should evaluate the chamber’s specifications to ensure it meets their research requirements, including the ability to simulate extreme conditions.

What Are the Advantages of Hypobaric Chambers in Aviation Training?

Hypobaric chambers are specialized units that simulate the effects of high altitude through controlled negative pressure. These chambers are crucial for aviation and aerospace training, as they help personnel understand and manage the physiological impacts of rapid altitude changes. However, the operational costs and safety protocols can be significant, so buyers must assess their budget and training needs carefully.

How Do Normobaric Chambers Benefit Athletic Training?

Normobaric chambers maintain standard atmospheric pressure while lowering oxygen levels, allowing athletes to train in hypoxic conditions safely. This type of chamber is user-friendly and cost-effective, making it suitable for various applications, from professional sports to personal training. B2B buyers should consider the chamber’s airflow capabilities and its adaptability to different training regimens when evaluating options.

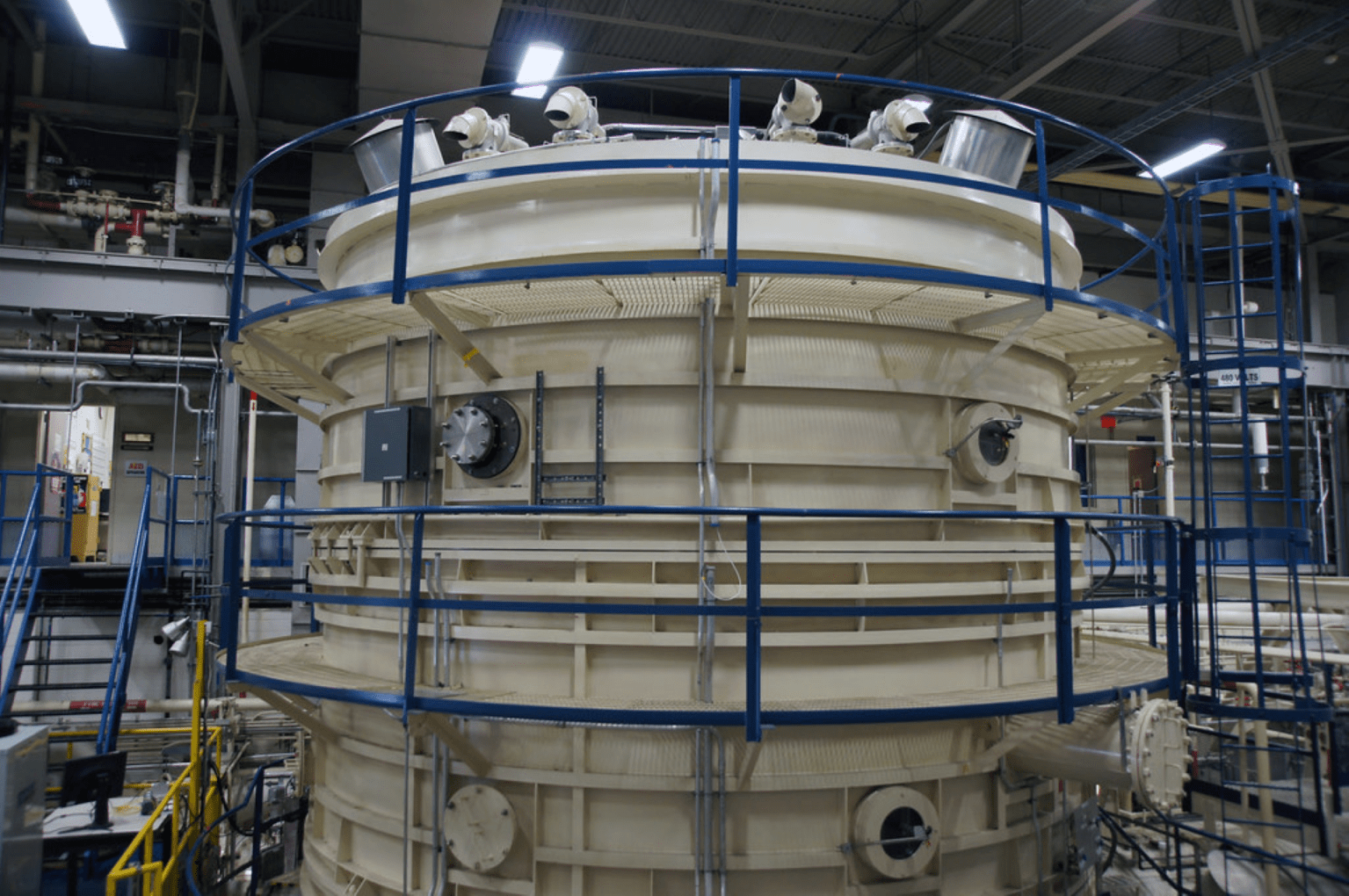

Illustrative image related to space altitude chamber

Key Industrial Applications of space altitude chamber

| Industry/Sector | Specific Application of space altitude chamber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Training for pilots and crew to manage hypoxia | Enhanced safety and preparedness for high-altitude missions | Compliance with military training standards, chamber size, and control features |

| Sports & Fitness | Altitude training for athletes to improve performance | Improved endurance, recovery, and competitive edge | Customization options, chamber capacity, and user experience features |

| Medical & Rehabilitation | Hypoxia therapy for respiratory conditions | Effective treatment for patients with lung diseases | Safety certifications, climate control capabilities, and user-friendly interfaces |

| Research & Development | Scientific studies on human physiology under hypoxic conditions | Valuable data for various applications in health and performance | Integration with existing systems, data collection capabilities, and technical support |

| Environmental Testing | Simulating various climates and altitudes for product testing | Reliable testing conditions for aerospace and outdoor gear | Flexibility in configuration, environmental controls, and ease of operation |

How is a Space Altitude Chamber Used in Aerospace & Defense Training?

In the aerospace and defense sector, space altitude chambers are essential for training pilots and crew members to recognize and manage hypoxia. These chambers simulate high-altitude environments, allowing personnel to experience low-oxygen conditions safely. This training enhances their preparedness for real-life scenarios, ensuring that they can operate effectively under stressful conditions. For international buyers, especially in regions like the Middle East and Europe, sourcing a chamber that meets military standards and offers automated training features is crucial for compliance and efficiency.

What are the Benefits of Space Altitude Chambers for Sports & Fitness?

Athletes utilize space altitude chambers for altitude training, which enhances their endurance and recovery by simulating high-altitude conditions. This training method helps improve oxygen uptake, leading to better performance in competitions. B2B buyers in the sports industry should consider customizable chambers that can accommodate varying numbers of users and offer features like climate control for optimal training conditions. The ability to integrate these chambers into existing training facilities is also a significant consideration for buyers in regions like Africa and South America, where sports performance is increasingly prioritized.

How Do Space Altitude Chambers Aid in Medical & Rehabilitation Settings?

In medical applications, altitude chambers are used for hypoxia therapy, providing a controlled environment for patients with respiratory issues. This therapy can significantly improve patients’ quality of life by mimicking high-altitude conditions that promote better lung function. Buyers in the healthcare sector should focus on sourcing chambers that have the necessary safety certifications and climate control capabilities to ensure patient comfort and safety. The user interface must also be intuitive for medical staff, particularly in emerging markets in Africa and South America.

What Role Do Space Altitude Chambers Play in Research & Development?

Research institutions employ space altitude chambers to conduct studies on human physiology under hypoxic conditions, yielding valuable insights for various applications. These chambers allow researchers to simulate different altitudes and oxygen levels, facilitating extensive data collection on human responses. Buyers in this sector should prioritize chambers that offer integration with existing research systems and have robust data collection capabilities. Technical support is also vital, especially for institutions in Europe, where research standards are high.

How are Space Altitude Chambers Utilized in Environmental Testing?

Space altitude chambers are increasingly used for environmental testing, enabling companies to simulate various climates and altitudes for product validation. This is particularly important for aerospace and outdoor gear manufacturers who need reliable testing conditions. B2B buyers should look for chambers that offer flexibility in configuration and precise environmental controls to ensure accurate testing outcomes. Ease of operation is also critical, especially for businesses in regions like Brazil and the Middle East, where rapid product development cycles are common.

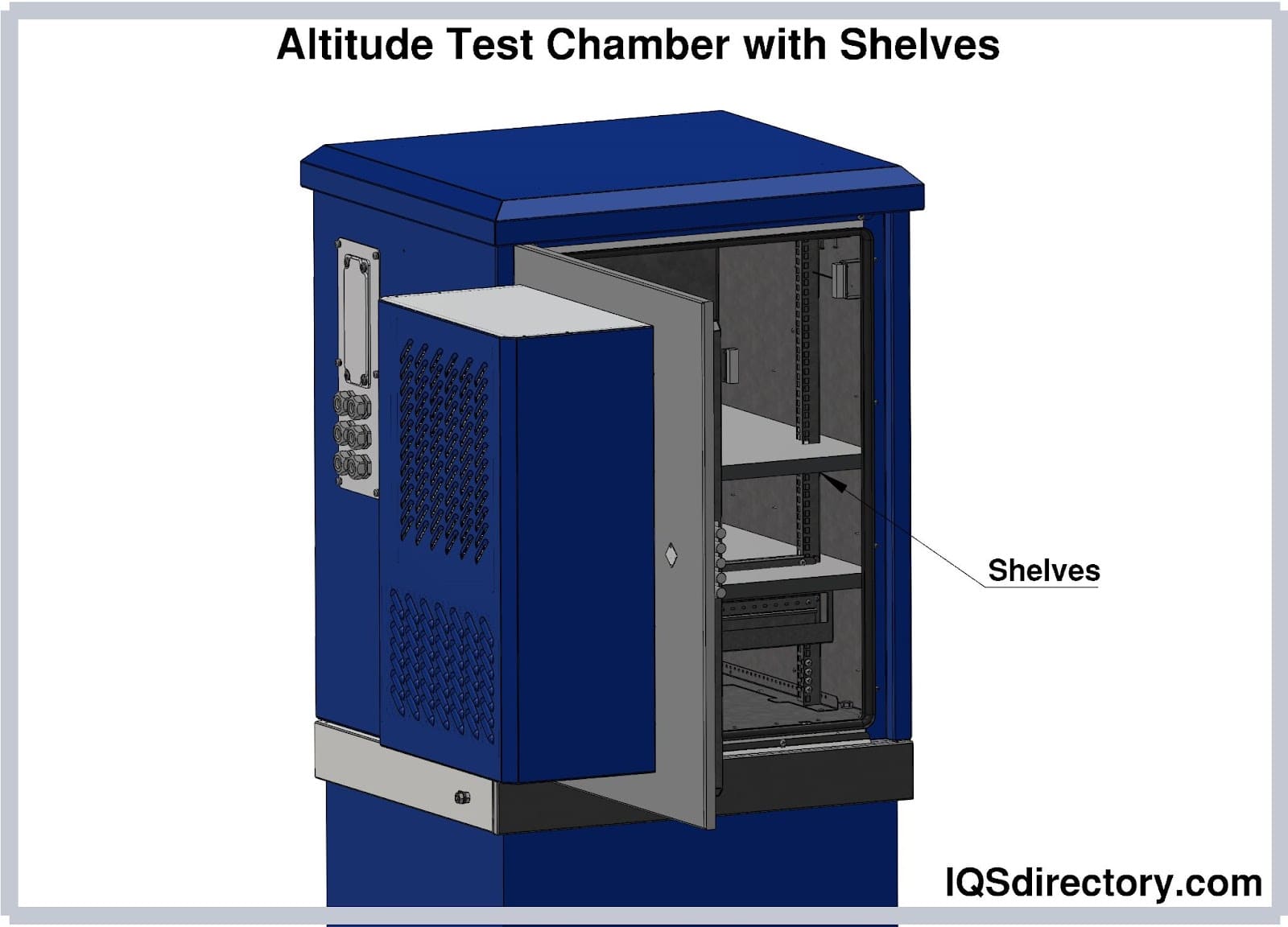

Illustrative image related to space altitude chamber

3 Common User Pain Points for ‘space altitude chamber’ & Their Solutions

Scenario 1: Integration Challenges with Existing Facilities

The Problem: Many B2B buyers, especially those in the aerospace, military, and sports sectors, often face significant hurdles when integrating a space altitude chamber into existing facilities. The complexities can arise from architectural constraints, the need for specialized electrical and HVAC systems, and the potential for disruption to ongoing operations. Buyers may worry about the financial implications of retrofitting spaces or the possibility of prolonged downtime during installation.

The Solution: To address these integration challenges, it is crucial to engage with manufacturers who offer customizable and modular altitude chambers. Start by conducting a thorough assessment of your existing space to determine the most effective layout for the chamber. Collaborate closely with the supplier to design a solution that fits seamlessly into your facility without requiring excessive renovations. For instance, companies like Hypoxico provide modular chambers that can be easily expanded or relocated, minimizing disruption. Additionally, ensure that the selected chamber is compatible with standard building materials and does not necessitate complex construction, which could increase costs and time. Prioritize suppliers that offer comprehensive support during the installation phase, including guidance on necessary infrastructure adjustments.

Scenario 2: Training and User Familiarity

The Problem: Another common pain point for organizations investing in space altitude chambers is ensuring that their staff is adequately trained to operate the equipment effectively. Lack of familiarity with the technology can lead to improper use, which not only reduces the efficacy of the altitude training but also raises safety concerns. This is particularly critical in sectors like aviation and military, where the stakes are high.

The Solution: To mitigate this issue, implement a robust training program in collaboration with the altitude chamber provider. Many manufacturers offer comprehensive training sessions as part of the purchase agreement, which can include both theoretical education and hands-on practice. Ensure that training covers all operational modes of the chamber, including manual, scheduler, and eco modes, to maximize versatility and efficiency. Additionally, consider setting up a mentorship program where experienced users can guide new staff, reinforcing best practices and safety protocols. Regular refresher courses can also be beneficial to keep all users updated on the latest features and safety measures, fostering a culture of continuous learning.

Illustrative image related to space altitude chamber

Scenario 3: Managing Operational Costs and Efficiency

The Problem: B2B buyers often express concerns about the ongoing operational costs associated with maintaining a space altitude chamber. These costs can stem from energy consumption, maintenance needs, and the potential requirement for specialized technicians. Buyers may fear that these expenses could outweigh the benefits, especially in budget-sensitive environments.

The Solution: To effectively manage operational costs, it is essential to choose an altitude chamber that emphasizes energy efficiency and low maintenance requirements. Look for options that incorporate advanced technology, such as eco modes that optimize energy use without compromising performance. For instance, some systems allow for remote access control via smartphones or tablets, enabling users to monitor and adjust settings efficiently, thus reducing unnecessary energy consumption. Additionally, establish a maintenance schedule in conjunction with the manufacturer, ensuring that all components are regularly serviced to prevent costly breakdowns. Investing in a chamber with a good warranty and ongoing support can also provide peace of mind regarding long-term operational costs. By prioritizing energy-efficient models and establishing solid maintenance practices, organizations can significantly reduce their total cost of ownership while maximizing the benefits of altitude training.

Strategic Material Selection Guide for space altitude chamber

What Materials Are Commonly Used in Space Altitude Chambers?

When selecting materials for space altitude chambers, it is crucial to consider factors such as performance under varying environmental conditions, durability, and compliance with international standards. Below is an analysis of four common materials used in the construction of these chambers, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to space altitude chamber

Aluminum: A Lightweight and Versatile Choice

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and good thermal conductivity. It can withstand a range of temperatures and pressures, making it suitable for altitude chambers.

Pros & Cons: Aluminum is lightweight and easy to fabricate, which simplifies the manufacturing process. However, it can be more expensive than steel and may require additional coatings to enhance its corrosion resistance in humid environments.

Impact on Application: Aluminum is compatible with various media and can be used in both hypoxic and hyperoxic environments, making it a versatile choice for different applications.

Illustrative image related to space altitude chamber

Considerations for International Buyers: Compliance with ASTM standards is essential, particularly in regions like Europe and North America. Buyers from Africa and South America should ensure that local suppliers can meet these standards, as well as any specific regional requirements.

Stainless Steel: Durability and Strength

Key Properties: Stainless steel offers high tensile strength, excellent corrosion resistance, and the ability to withstand high pressures and temperatures. It is particularly effective in environments where hygiene is a concern.

Pros & Cons: The durability of stainless steel makes it ideal for long-term applications. However, it is heavier than aluminum and can be more costly, both in terms of raw materials and manufacturing complexity.

Impact on Application: Stainless steel is suitable for applications requiring high structural integrity, such as military and research settings. Its resistance to corrosion ensures longevity in various environmental conditions.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that meet international standards like DIN and JIS, especially in regions with stringent regulations, such as Europe and the Middle East.

Composite Materials: Innovative and Customizable

Key Properties: Composite materials, often a combination of resins and fibers, offer high strength while being lightweight. They can be engineered to provide specific thermal and mechanical properties, making them suitable for custom applications.

Pros & Cons: Composites allow for design flexibility and can be tailored to meet specific performance criteria. However, they can be more expensive to manufacture and may require specialized processing techniques.

Impact on Application: Composites can be designed to withstand extreme conditions, making them ideal for advanced research applications and military training environments.

Considerations for International Buyers: Buyers should ensure that composite materials meet international standards for safety and performance. This is particularly important for regions like Saudi Arabia and Brazil, where regulatory compliance can impact project timelines.

Illustrative image related to space altitude chamber

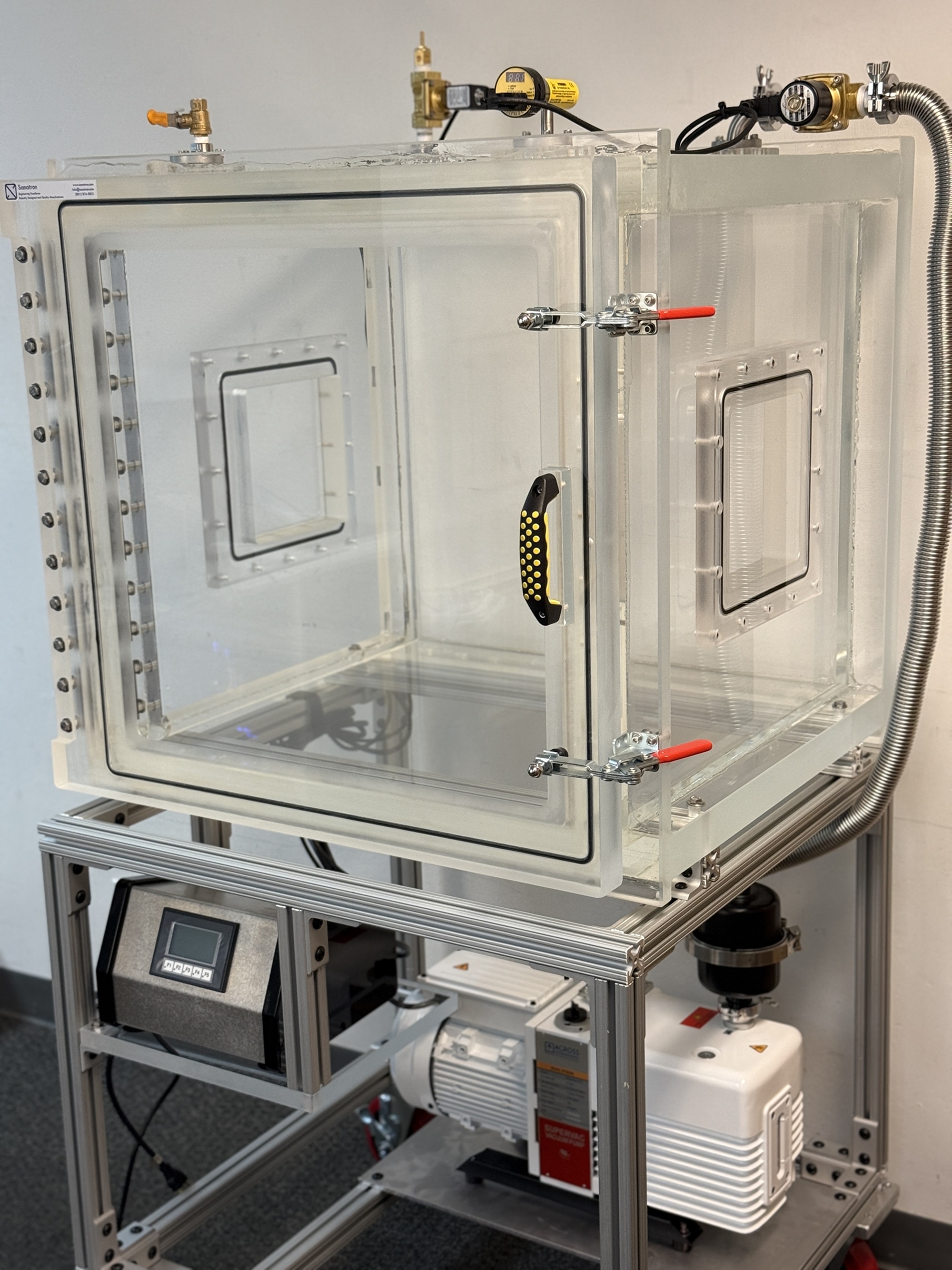

Glass Reinforced Plastic (GRP): Lightweight and Cost-Effective

Key Properties: GRP is a composite material made from a polymer matrix reinforced with glass fibers. It is lightweight, corrosion-resistant, and offers good thermal insulation properties.

Pros & Cons: GRP is generally less expensive than metals and can be molded into complex shapes, which is beneficial for custom designs. However, it may not offer the same level of strength as metals and could be less durable in high-pressure applications.

Impact on Application: GRP is suitable for applications where weight is a critical factor, such as in portable altitude chambers. Its insulating properties can also help maintain stable internal conditions.

Considerations for International Buyers: While GRP can be a cost-effective option, buyers should verify that the material meets the necessary performance standards for their specific applications, especially in regulated markets like Europe.

Summary Table of Material Selection for Space Altitude Chambers

| Material | Typical Use Case for space altitude chamber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight chambers for athletes and research | Excellent strength-to-weight ratio | Higher cost than steel | Medium |

| Stainless Steel | High-integrity chambers for military training | Exceptional durability and corrosion resistance | Heavier and more expensive | High |

| Composite Materials | Custom chambers for advanced research | Design flexibility and tailored performance | Higher manufacturing complexity | High |

| Glass Reinforced Plastic | Portable altitude chambers | Cost-effective and lightweight | Lower strength in high-pressure settings | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions when investing in space altitude chambers. Understanding the properties and implications of each material can lead to better project outcomes and compliance with regional standards.

Illustrative image related to space altitude chamber

In-depth Look: Manufacturing Processes and Quality Assurance for space altitude chamber

What Are the Main Stages of Manufacturing a Space Altitude Chamber?

Manufacturing a space altitude chamber involves several critical stages, each designed to ensure the final product meets stringent safety and operational standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This stage involves sourcing high-quality materials that comply with industry standards. The materials often include specialized metals, polymers, and insulation materials that can withstand the rigors of altitude simulation. Suppliers must provide material certification to ensure compliance with international standards, such as ASTM or ISO.

-

Forming: The forming process transforms raw materials into usable components. Techniques may include CNC machining, welding, and laser cutting. These methods are crucial for creating precise parts that fit together seamlessly, ensuring structural integrity under varying pressure conditions.

-

Assembly: Once components are formed, they undergo assembly. This process requires skilled technicians who adhere to specific protocols to ensure each chamber is constructed accurately. Quality checks are performed throughout this stage, focusing on alignment, sealing, and overall functionality.

-

Finishing: The final stage involves surface treatments and coatings that enhance durability and aesthetic appeal. Finishing processes may include powder coating or anodizing, which not only protect against corrosion but also meet specific industry standards for safety and performance.

Which Key Techniques Are Used in Manufacturing Space Altitude Chambers?

Several advanced techniques are employed in the manufacturing of altitude chambers to ensure efficiency, safety, and precision.

-

Normobaric Hypoxia Simulation Technology: This innovative technique allows chambers to simulate high-altitude conditions without altering air pressure. It reduces oxygen levels while maintaining normal atmospheric pressure, providing a safe environment for users.

-

Automated Control Systems: Modern altitude chambers integrate sophisticated control systems that allow for real-time monitoring and adjustments of oxygen levels, temperature, and humidity. This automation enhances user experience and ensures consistent operational conditions.

-

Modular Design: Many manufacturers offer modular chambers that can be customized based on client needs. This flexibility allows for easy expansion or relocation, making them ideal for various applications from sports training to research.

What International Standards Guide Manufacturing and Quality Assurance for Space Altitude Chambers?

B2B buyers should be aware of relevant international standards and certifications that ensure quality and safety in manufacturing altitude chambers.

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization aiming to enhance customer satisfaction through effective processes. Manufacturers that comply with ISO 9001 demonstrate their commitment to quality.

-

CE Marking: In Europe, CE marking signifies that a product meets health, safety, and environmental protection standards. This is particularly important for altitude chambers intended for medical or research applications.

-

API Standards: For chambers used in military or aerospace contexts, compliance with API (American Petroleum Institute) standards ensures that materials and construction methods are suitable for high-stakes environments.

What Are the Key Quality Control Checkpoints in Manufacturing Space Altitude Chambers?

Quality control (QC) is essential throughout the manufacturing process to ensure that the altitude chambers meet safety and performance standards.

Illustrative image related to space altitude chamber

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon receipt. Suppliers must provide documentation proving compliance with specifications and standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves regular inspections and testing of components. This can include dimensional checks, pressure tests, and functional assessments to catch any defects early.

-

Final Quality Control (FQC): Once assembly is complete, FQC entails a comprehensive evaluation of the finished product. This includes functionality tests, safety checks, and performance evaluations to ensure the chamber operates as intended.

What Common Testing Methods Are Employed for Space Altitude Chambers?

Several testing methods are commonly used to validate the performance and safety of altitude chambers.

-

Pressure Testing: This method ensures that the chamber can withstand the required pressure differentials without leaks. It simulates the stress the chamber would experience during operation.

-

Oxygen Level Monitoring: Continuous monitoring of oxygen levels during testing ensures that the chamber can effectively simulate the desired altitude conditions. This is crucial for user safety and training efficacy.

-

Environmental Testing: Chambers may undergo testing to assess their performance under varying temperature and humidity conditions. This ensures that they can operate effectively in diverse environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps to verify QC processes:

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to evaluate their manufacturing processes, quality management systems, and compliance with relevant standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including test results, failure rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s capabilities and adherence to quality standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider specific nuances when it comes to QC and certification:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that suppliers are compliant with local regulations in their respective markets, such as the GCC standards in the Middle East or ANVISA regulations in Brazil.

-

Documentation and Traceability: Buyers should prioritize suppliers who provide comprehensive documentation for all materials and processes, ensuring traceability and accountability.

-

Local Partnerships: Establishing partnerships with local firms can facilitate smoother compliance with regional standards and enhance understanding of local market needs.

By focusing on these manufacturing and quality assurance aspects, B2B buyers can make informed decisions when sourcing space altitude chambers, ensuring they receive products that meet their operational requirements and safety standards.

Illustrative image related to space altitude chamber

Practical Sourcing Guide: A Step-by-Step Checklist for ‘space altitude chamber’

In the rapidly evolving field of aerospace and high-altitude training, sourcing a space altitude chamber requires careful consideration and strategic planning. This checklist will guide international B2B buyers through the essential steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for identifying the right altitude chamber for your needs. Consider factors such as the altitude range (up to 30,000 feet), chamber size, user capacity, and whether you need features like climate control or remote operation capabilities. This foundational step ensures that your chosen solution aligns with your operational requirements and end goals.

Step 2: Assess Your Budget and Funding Sources

Budgeting is a critical component of the procurement process. Determine the total cost of ownership, including initial purchase, installation, maintenance, and operation costs. Seek out potential funding sources or financial models, especially if you are operating in regions like Africa or South America where funding may be limited. Understanding your financial parameters upfront will help narrow your options effectively.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. Review company profiles, their history in the industry, and case studies that demonstrate their expertise. Request references from other buyers in similar industries or geographic regions to gauge reliability and quality. This diligence helps ensure that you are partnering with a reputable supplier capable of meeting your needs.

Step 4: Verify Compliance with Regulatory Standards

Altitude chambers must adhere to specific safety and operational standards, especially in regulated industries such as military or medical applications. Verify that the supplier’s products comply with local and international regulations, such as those from aviation authorities or health organizations. This step mitigates risks associated with non-compliance, ensuring safe operations for users.

Step 5: Request Customization Options

Different applications may require unique configurations. Engage suppliers about customization options for chamber design, features, and functionality. For instance, inquire about modular designs that allow for future expansion or specific capabilities tailored to your training or research needs. Customization can significantly enhance the chamber’s utility and lifespan.

Step 6: Assess After-Sales Support and Maintenance Services

After-sales support can be a significant factor in the long-term success of your investment. Inquire about warranty terms, technical support availability, and the supplier’s capability to provide maintenance services. A supplier with robust support infrastructure can help minimize downtime and ensure optimal performance of the altitude chamber.

Illustrative image related to space altitude chamber

Step 7: Plan for Installation and Training

Proper installation and user training are essential for maximizing the benefits of your altitude chamber. Discuss with suppliers about their installation process, timeline, and whether they provide training for your staff on the operational aspects of the chamber. This proactive approach helps ensure that your team is well-equipped to utilize the chamber effectively from day one.

By following these steps, B2B buyers can navigate the complexities of procuring a space altitude chamber with confidence, ensuring they select a solution that meets their technical requirements and operational goals.

Comprehensive Cost and Pricing Analysis for space altitude chamber Sourcing

What Are the Key Cost Components for Sourcing Space Altitude Chambers?

When sourcing space altitude chambers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: High-quality materials are essential for durability and performance, particularly in environments simulating extreme altitudes. The choice of materials can significantly impact costs, with specialized components for oxygen regulation and climate control being more expensive.

-

Labor: Skilled labor is required for assembly and installation. This includes engineers and technicians familiar with hypoxic systems, which may lead to higher labor costs, especially if sourcing from regions with a limited skilled workforce.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and general administration. Efficient manufacturing processes can help mitigate these costs, but they can vary widely based on geographic location and the production scale.

-

Tooling: Custom tooling may be necessary for unique designs or specifications, adding to the initial investment. The complexity of the chamber design will influence tooling costs.

-

Quality Control (QC): Rigorous QC processes are critical, especially for chambers used in military or medical applications. The costs associated with testing and certification can vary, impacting the overall price.

-

Logistics: Shipping and handling costs can be significant, particularly for large, complex systems. Buyers should consider the logistics of transporting chambers to their location, including customs duties and insurance.

-

Margin: Suppliers typically include a profit margin based on their operating costs and market positioning. Understanding the supplier’s margin can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of Space Altitude Chambers?

Several factors influence the pricing of altitude chambers, and being aware of these can aid in making informed purchasing decisions.

Illustrative image related to space altitude chamber

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced unit costs. Buyers looking to establish long-term partnerships can negotiate better pricing based on anticipated order volumes.

-

Specifications and Customization: Customized chambers tailored to specific needs (like size, features, or performance capabilities) generally incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: The level of certification (ISO, military standards, etc.) can impact costs. Chambers designed for specialized applications will often require higher-quality materials and rigorous testing, increasing overall expenditure.

-

Supplier Factors: The supplier’s reputation, experience, and location play a role in pricing. Established suppliers with proven track records may command higher prices due to their reliability and quality assurance.

-

Incoterms: Understanding the agreed Incoterms is vital, as they dictate responsibility for shipping costs and risks. This can influence the total cost of ownership significantly, especially for international transactions.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Space Altitude Chambers?

For B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, strategic approaches can yield cost efficiencies.

-

Negotiation: Leverage multiple supplier quotes to negotiate better terms. Establishing relationships with suppliers can lead to favorable pricing and terms over time.

-

Total Cost of Ownership: Consider not just the initial purchase price but also operational costs, maintenance, and potential downtime. Investing in higher-quality chambers may reduce long-term expenses.

-

Understand Pricing Nuances for International Sourcing: Be aware of currency fluctuations, import taxes, and tariffs that can affect the final cost when sourcing from different countries.

-

Long-Term Partnerships: Building long-term relationships with suppliers can facilitate better pricing agreements and access to new technologies or upgrades, enhancing overall value.

-

Stay Informed: Regularly review market trends and technological advancements in altitude chamber design. This knowledge can empower buyers to make more informed purchasing decisions.

Disclaimer on Indicative Prices

Pricing for space altitude chambers can vary widely based on the factors discussed. Therefore, it is advisable for buyers to request detailed quotes tailored to their specific requirements from multiple suppliers to gain a comprehensive understanding of potential costs.

Alternatives Analysis: Comparing space altitude chamber With Other Solutions

Introduction: What Are the Alternatives to Space Altitude Chambers?

When considering solutions for simulating high-altitude conditions, businesses must explore various options beyond traditional space altitude chambers. While altitude chambers provide a controlled environment for training and research, alternative technologies can also achieve similar outcomes. This section compares space altitude chambers with other viable solutions, highlighting their unique advantages and limitations.

Comparison Table

| Comparison Aspect | Space Altitude Chamber | Hypobaric Chamber | Altitude Simulation System |

|---|---|---|---|

| Performance | Simulates up to 30,000 feet; normobaric hypoxia | Simulates true altitude; requires pressure changes | Simulates altitude using environmental controls |

| Cost | High initial investment; customizable features | Very high due to complex construction | Moderate; lower operational costs |

| Ease of Implementation | Freely enter and exit; standard materials used | Requires specialized construction and safety measures | Can be implemented in existing facilities |

| Maintenance | Low maintenance; ongoing support available | High maintenance due to complex systems | Moderate; requires periodic calibration |

| Best Use Case | Athletic training, research, rehabilitation | Military training, aerospace applications | General fitness, environmental research |

Detailed Breakdown of Alternatives

Hypobaric Chamber

Hypobaric chambers simulate high-altitude environments by lowering atmospheric pressure. This method is effective for training military personnel and aerospace professionals who need to prepare for real-world scenarios involving rapid decompression and hypoxia. However, the construction of hypobaric chambers is expensive, requiring specialized materials and safety protocols. Additionally, the complexity of the system necessitates a higher maintenance level and operational training for users. While they are ideal for specific applications, their high cost and operational complexity can be a barrier for many organizations.

Illustrative image related to space altitude chamber

Altitude Simulation System

Altitude simulation systems leverage environmental controls to mimic high-altitude conditions without altering atmospheric pressure. These systems are more affordable and can be integrated into existing facilities, making them accessible for a broader range of applications, such as fitness training and research. They provide a flexible solution that can simulate various environmental factors, including temperature and humidity. However, they may not offer the same degree of physiological training that hypobaric or altitude chambers provide, limiting their use for specialized training purposes.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing the right solution for altitude simulation involves a careful assessment of your specific requirements and operational capabilities. Space altitude chambers offer high performance and flexibility for various applications, making them an excellent choice for organizations focused on athletic training or rehabilitation. In contrast, hypobaric chambers are best suited for military or aerospace training due to their ability to simulate true altitude conditions, albeit at a higher cost. Lastly, altitude simulation systems provide a cost-effective alternative for general fitness and research applications but may lack the depth of training offered by specialized chambers. By evaluating performance, cost, implementation ease, maintenance, and specific use cases, B2B buyers can make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for space altitude chamber

What Are the Key Technical Properties of Space Altitude Chambers?

When considering the acquisition of a space altitude chamber, several critical technical properties must be evaluated to ensure the system meets specific operational needs. Here are the essential specifications that B2B buyers should be aware of:

-

Altitude Simulation Range

This property defines the chamber’s capability to simulate various altitudes, typically ranging from sea level to 30,000 feet or higher. Understanding this range is crucial for buyers as it determines the chamber’s suitability for specific applications, such as aerospace training, scientific research, or athletic performance enhancement. -

Airflow Rate

Measured in liters per minute, the airflow rate refers to the volume of hypoxic air the chamber can deliver. High airflow rates (e.g., up to 16,000 liters per minute) allow for quicker adjustments to altitude and oxygen levels, enhancing user experience and training effectiveness. This property is vital for organizations that require rapid acclimatization or research protocols. -

Control Systems

Advanced altitude chambers often feature integrated control systems that allow for real-time monitoring and adjustments of altitude, temperature, and humidity. A user-friendly interface, such as a touchscreen or remote access via mobile devices, can significantly improve operational efficiency. Buyers should prioritize systems that offer automation capabilities and customizable settings for various training scenarios. -

Material Grade and Construction Standards

The quality of materials used in the chamber’s construction impacts its durability and safety. Chambers built to industrial standards ensure reliability and longevity, essential for organizations that rely on consistent performance. Buyers should inquire about the specific materials used and any relevant certifications that ensure compliance with safety regulations. -

Safety Features

Safety is paramount in altitude chambers, especially for military or medical applications. Features such as emergency oxygen delivery systems, pressure sensors, and automated safety protocols are critical. Understanding these safety measures helps organizations mitigate risks associated with hypoxia and rapid decompression. -

Installation Flexibility

The ability to integrate the chamber into existing facilities or as part of new construction projects adds significant value. Options such as modular designs that can be expanded or relocated are advantageous for organizations with evolving needs.

What Are Common Trade Terms Related to Space Altitude Chambers?

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some common terms relevant to space altitude chambers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be sold under another company’s brand. For altitude chambers, understanding OEM relationships can help buyers ensure they are sourcing high-quality products from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for organizations looking to purchase multiple units or custom configurations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. In the context of altitude chambers, submitting an RFQ helps buyers obtain detailed quotes that include specifications, lead times, and payment terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for organizations operating in multiple countries, as they can significantly impact total costs. -

Lead Time

This term refers to the amount of time it takes from placing an order to the delivery of the product. For altitude chambers, lead time can vary based on customization and production schedules. Buyers should consider lead time in their planning to ensure timely implementation of training or research programs. -

Calibration

Calibration involves adjusting the equipment to ensure accurate readings and performance. For altitude chambers, regular calibration is vital to maintain the integrity of altitude simulation and ensure user safety. Buyers should inquire about the calibration process and the frequency required for optimal operation.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting space altitude chambers that align with their operational objectives and safety standards.

Navigating Market Dynamics and Sourcing Trends in the space altitude chamber Sector

What Are the Current Market Dynamics and Key Trends in the Space Altitude Chamber Sector?

The global market for space altitude chambers is experiencing robust growth driven by several factors, including increased demand for high-altitude training among military and civilian sectors, advancements in hypoxia research, and the expanding commercial space industry. In particular, regions such as Africa, South America, the Middle East, and Europe are witnessing heightened interest from B2B buyers seeking innovative solutions for altitude simulation. Countries like Saudi Arabia and Brazil are investing in research and development, emphasizing the need for advanced training facilities that can safely replicate high-altitude conditions.

Emerging technologies are reshaping sourcing trends within the sector. For instance, modular and customizable altitude chambers are becoming popular due to their flexibility and ease of integration into existing facilities. Furthermore, features like remote monitoring and climate control are increasingly sought after, allowing for enhanced user experience and operational efficiency. As international buyers look for reliable suppliers, the emphasis on quality, innovation, and after-sales support has never been more critical.

Additionally, the rise of telemedicine and remote training solutions is influencing purchasing decisions. Companies are looking for altitude chambers that can be operated remotely, thereby reducing the need for on-site personnel. This trend is particularly relevant in regions where skilled labor is scarce or where training sessions need to be optimized for efficiency.

How Is Sustainability and Ethical Sourcing Addressed in the Altitude Chamber Industry?

Sustainability is becoming an integral part of the B2B landscape in the altitude chamber sector. As environmental concerns gain traction globally, buyers are increasingly prioritizing products that are manufactured using sustainable practices. This includes the use of eco-friendly materials and processes that minimize environmental impact during production and operation.

Ethical sourcing is also critical in ensuring that suppliers adhere to fair labor practices and responsible material procurement. Companies that can demonstrate compliance with environmental regulations and ethical standards are likely to gain a competitive edge. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming important markers for B2B buyers seeking sustainable solutions.

Moreover, advancements in technology allow for the development of altitude chambers that consume less energy while maintaining optimal performance. Suppliers that invest in energy-efficient systems and renewable energy sources are appealing to international buyers looking to mitigate their carbon footprint. By choosing partners committed to sustainability, companies can enhance their brand reputation and align with global sustainability goals.

Illustrative image related to space altitude chamber

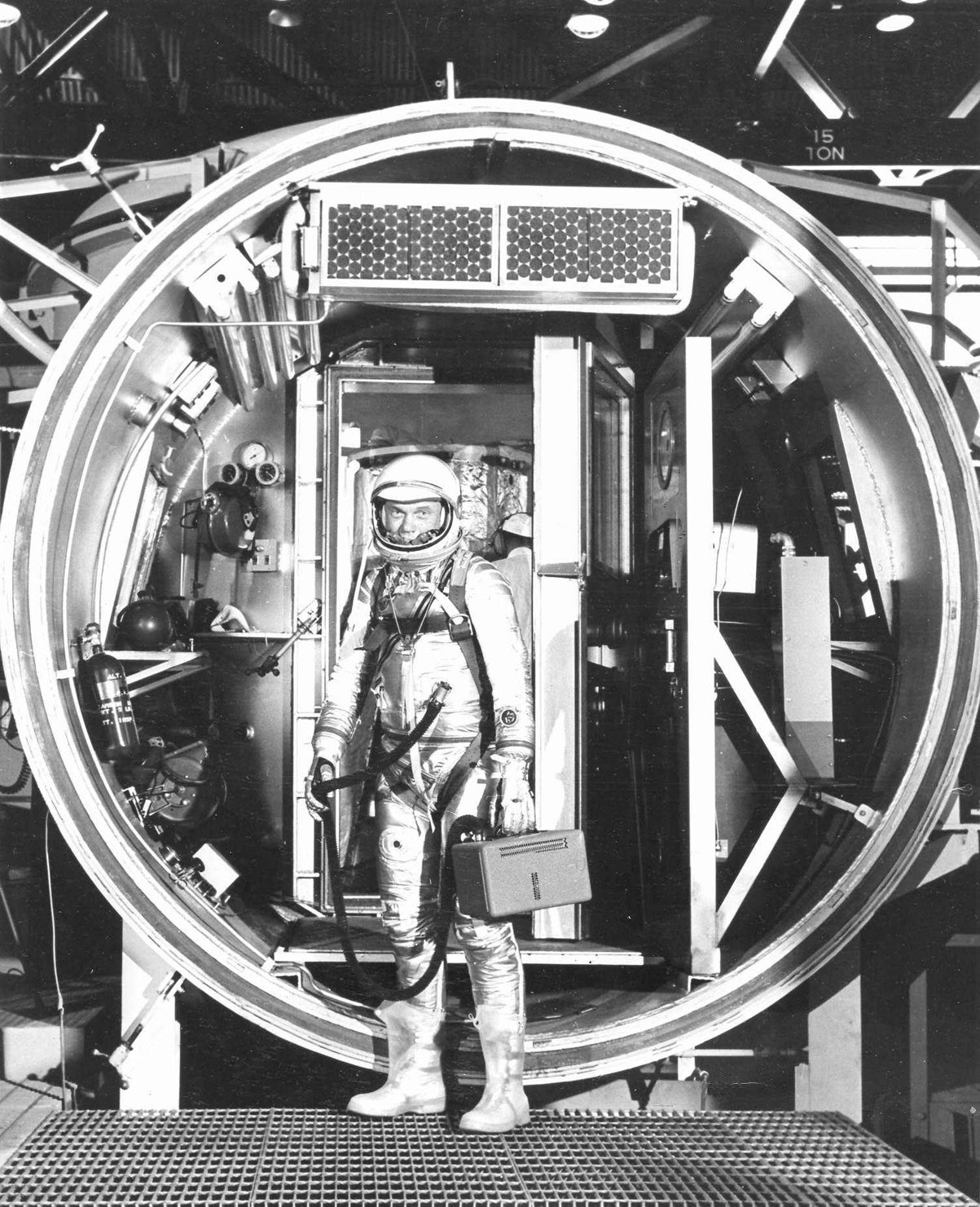

What Is the Brief Evolution of Space Altitude Chambers for B2B Buyers?

The evolution of altitude chambers has been marked by significant technological advancements since their inception. Initially, hypobaric chambers were the standard for altitude simulation, relying on negative pressure systems to replicate high-altitude conditions. These traditional systems, while effective, were often cumbersome and required specialized construction materials, limiting their accessibility and application.

The introduction of normobaric hypoxia technology revolutionized the market. By maintaining standard atmospheric pressure while reducing oxygen levels, modern altitude chambers have become more versatile and user-friendly. This innovation has allowed for the integration of altitude training into various sectors, including sports, military training, and medical research.

Today, altitude chambers are not only used for acclimatization but also serve diverse applications such as rehabilitation, therapy, and scientific research. The focus on customization and modular designs reflects the needs of a global market that demands flexibility and efficiency. As the sector continues to evolve, B2B buyers can expect ongoing innovations that enhance training methodologies and expand the applications of altitude simulation technology.

Frequently Asked Questions (FAQs) for B2B Buyers of space altitude chamber

-

How do I select the right altitude chamber for my needs?

Choosing the right altitude chamber depends on various factors such as the intended application (e.g., training, research, rehabilitation), space availability, and the number of users. Consider whether you need a modular or conversion chamber based on your existing infrastructure. Additionally, assess the altitude range you require and any specific climate controls necessary for your operations. Consulting with manufacturers can provide insights into customization options that align with your unique requirements. -

What are the key features to look for in a space altitude chamber?

When sourcing a space altitude chamber, prioritize features such as safety protocols, ease of operation, and climate control capabilities. Look for chambers that offer normobaric hypoxia simulation, which allows for safe and flexible use. Other essential features include remote access for control, user-friendly interfaces, and high airflow rates for efficient performance. Ensure the chamber meets international safety standards and includes comprehensive customer support for ongoing maintenance. -

What are the typical lead times for ordering an altitude chamber?

Lead times for altitude chambers can vary significantly based on customization and manufacturing processes. Generally, expect a timeline of 12 to 16 weeks from order confirmation to delivery, particularly for custom-built chambers. Factors influencing lead time include design complexity, materials required, and production capacity. It’s advisable to discuss specific timelines with suppliers during the procurement process to align with your project deadlines. -

What is the minimum order quantity (MOQ) for altitude chambers?

Minimum order quantities for altitude chambers can differ by manufacturer and depend on the complexity and scale of the order. Some suppliers may have a MOQ of one unit for standard models, while others might require larger orders for customized solutions. Always inquire with potential suppliers about their MOQ policies to ensure they align with your purchasing strategy and budget. -

What payment terms should I expect when purchasing an altitude chamber?

Payment terms for altitude chambers typically involve a deposit upon order confirmation, with the balance due prior to delivery. Some manufacturers may offer flexible payment options, including installment plans or financing for larger orders. Always clarify payment terms during negotiations to avoid misunderstandings and ensure that they fit your financial planning. -

How can I ensure quality assurance in the altitude chamber procurement process?

To ensure quality assurance, request documentation regarding the manufacturing processes, safety certifications, and compliance with international standards from potential suppliers. It’s beneficial to conduct factory audits or request product samples before finalizing the order. Additionally, seek references from previous clients to gauge the supplier’s reliability and the performance of their altitude chambers in real-world applications. -

What logistics considerations should I keep in mind for international shipping of altitude chambers?

When shipping altitude chambers internationally, consider customs regulations, shipping costs, and delivery timelines. Work with suppliers who have experience in international logistics and can provide guidance on necessary documentation, tariffs, and duties. It’s also essential to assess the handling requirements of the chambers during transit to prevent damage and ensure they arrive in optimal condition. -

Can altitude chambers be customized for specific training or research needs?

Yes, altitude chambers can be fully customized to meet specific training or research requirements. Manufacturers often offer options for altitude range, chamber size, and integrated features such as climate control and oxygen enrichment. Collaborating closely with the manufacturer during the design phase will help ensure that the final product aligns with your operational goals and facilitates the intended applications effectively.

Top 5 Space Altitude Chamber Manufacturers & Suppliers List

1. Hypoxico – Customizable Altitude Chambers

Domain: hypoxico.com

Registered: 1999 (26 years)

Introduction: Altitude Chambers are fully customizable, allowing for tailored size, design, installation, and operation. They simulate altitude from sea level up to 30,000 feet and operate 24/7 with remote access via smartphone, tablet, or computer. Features include full climate control (temperature and humidity settings), hyperoxic capabilities, and various operational modes (Manual, Scheduler, EcoMode). Chamb…

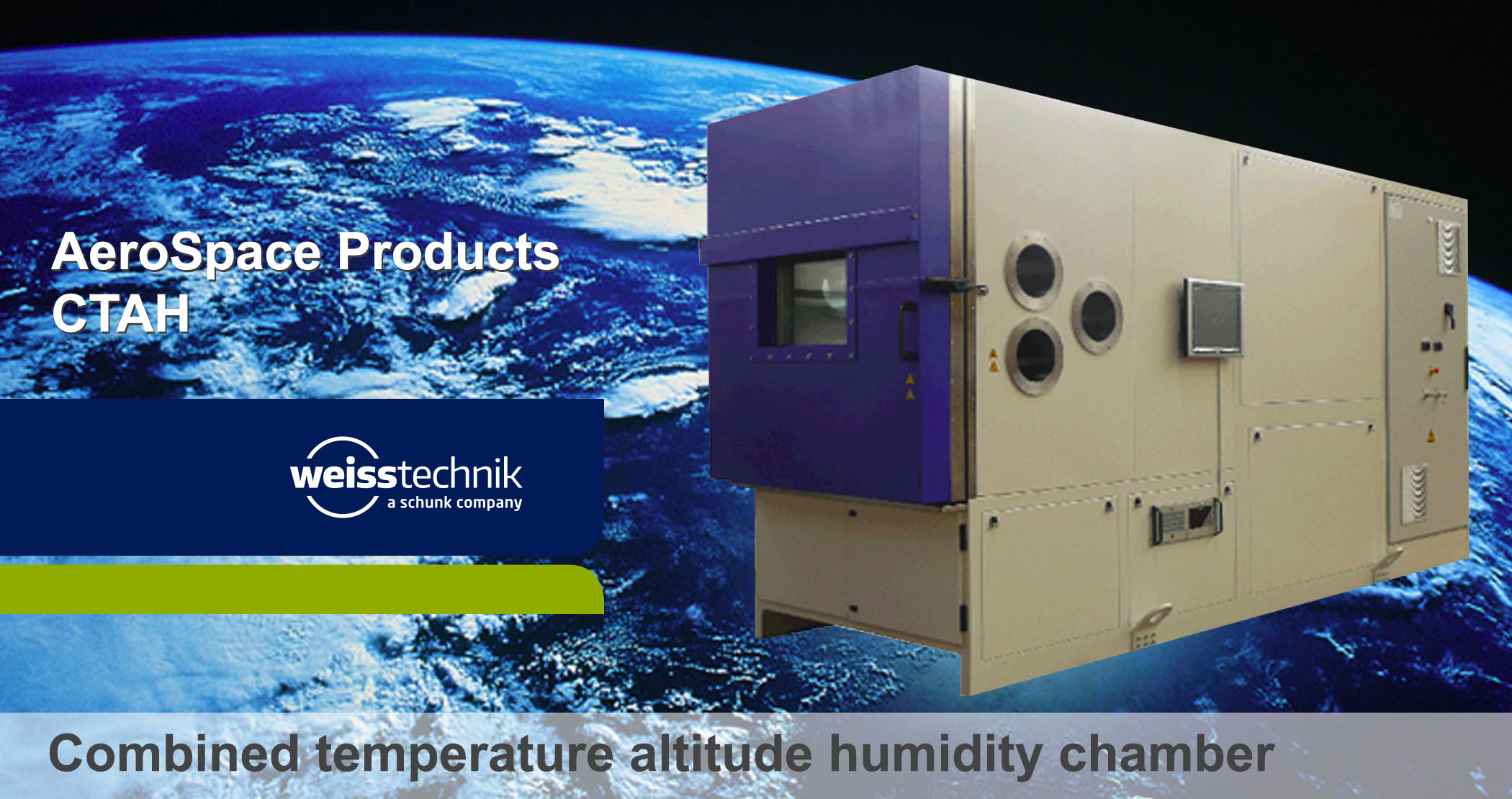

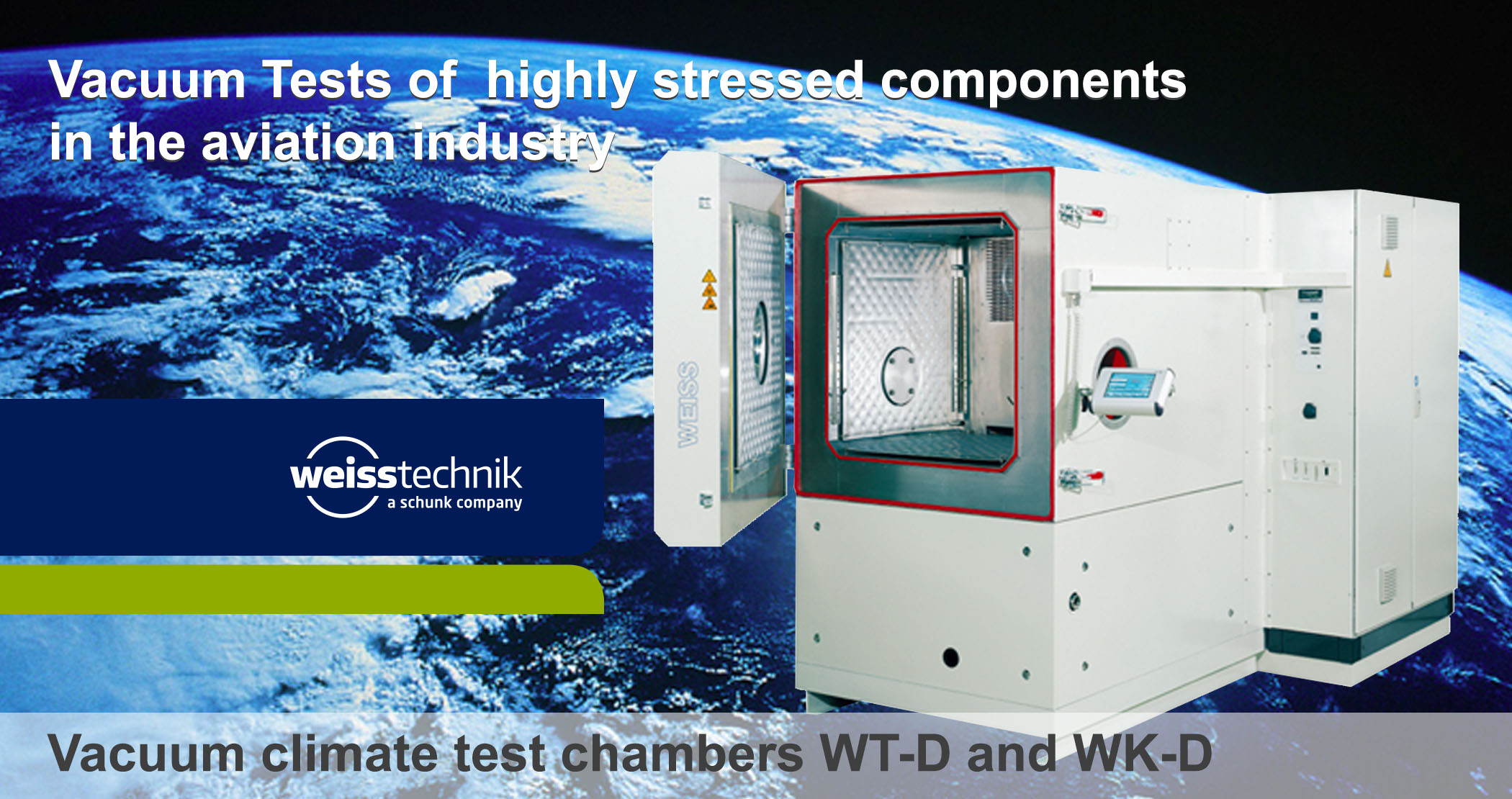

2. Weiss Technik – Altitude and Space Simulation Test Chambers

Domain: weiss-na.com

Registered: 2013 (12 years)

Introduction: Weiss Technik offers altitude and space simulation test chambers designed for testing applications with satellites, rockets, airplanes, or helicopters. These chambers are engineered to withstand extreme conditions such as vacuum, extended mbar, low temperature, and ultra-low temperatures. Key features include:

– Pre-engineered and custom options available

– Capable of ultra-low cooling and exten…

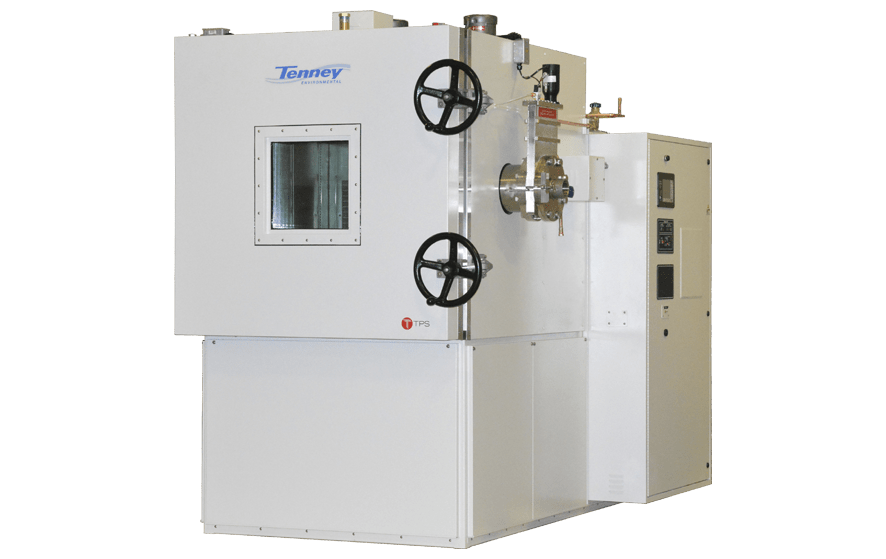

3. ETC – FALCON Hypobaric Chamber

Domain: etcaircrewtraining.com

Registered: 2002 (23 years)

Introduction: ETC’s altitude chamber provides a safe, controlled, and medically monitored environment for military hypoxia training and research. Key features include:

– FALCON Hypobaric Chamber for training and research applications involving rapid pressure, oxygen concentration, temperature, and humidity changes.

– Built to high industrial standards for safe and reliable operation.

– Automated and repeatab…

4. AF Research Lab – Research Altitude Chambers

Domain: afresearchlab.com

Registered: 2017 (8 years)

Introduction: Research Altitude Chambers (RAC) are a family of four computer-controlled altitude chambers managed by the Air Force Research Laboratory’s 711th Human Performance Wing. They are designed for studies on the durability of flight equipment and the effects of altitude on the human body, as well as providing training for air crews.

– Chamber 1: Studies hypoxia, decompression sickness, fatigue, and pe…

5. Elson Space – Large Altitude Hypobaric Chamber

Domain: elsonspace.com

Registered: 2010 (15 years)

Introduction: Large Altitude Hypobaric Chamber designed for high-altitude simulation, suitable for research and training purposes. It features advanced technology for controlled atmospheric conditions, ensuring safety and reliability. The chamber accommodates multiple users and is equipped with monitoring systems for physiological data. Ideal for aerospace, military, and medical applications.

Strategic Sourcing Conclusion and Outlook for space altitude chamber

As the demand for space altitude chambers grows across various sectors, international B2B buyers must prioritize strategic sourcing to maximize value and ensure optimal performance. The key takeaways from this guide emphasize the importance of customization, safety, and advanced technology in selecting the right altitude chamber. Buyers should consider factors such as chamber design, operational capabilities, and ongoing support when making purchasing decisions.

Strategic sourcing enables organizations to align their requirements with the best available technologies, ensuring that they can effectively simulate hypoxic conditions for training, research, or rehabilitation. Additionally, understanding the unique applications of altitude chambers across different industries—from military training to sports performance—can facilitate informed decisions that enhance operational efficiency.

Illustrative image related to space altitude chamber

Looking ahead, the future of altitude chamber technology is promising, with innovations driving accessibility and versatility. International buyers from regions like Africa, South America, the Middle East, and Europe should seize this opportunity to engage with leading manufacturers and explore customized solutions that meet their specific needs. By investing in state-of-the-art altitude chambers, organizations can stay ahead in a competitive landscape, enhancing their capabilities and fostering growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.