Unlocking Value: A Strategic Analysis of the Four Wheel Barrel Market

Introduction: Navigating the Global Market for four wheel barrel

In the dynamic landscape of global trade, sourcing the right four-wheel barrow can pose significant challenges for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. With a multitude of options available, from traditional steel designs to innovative electric models, making an informed decision requires thorough understanding. This comprehensive guide addresses critical aspects of the four-wheel barrow market, including various types, their applications in sectors such as agriculture, landscaping, and construction, and essential supplier vetting strategies.

B2B buyers will benefit from insights into cost considerations, operational efficiencies, and durability factors that influence long-term value. By exploring key features such as load capacities, maneuverability, and material resilience, this guide empowers international buyers to navigate their purchasing decisions confidently. Whether you’re based in Saudi Arabia or Vietnam, the detailed information provided will help you assess product specifications, supplier reliability, and market trends effectively.

With this resource, you’ll not only streamline your procurement process but also enhance your operational productivity by selecting the most suitable four-wheel barrow for your specific business needs. Join us as we delve into the intricacies of the four-wheel barrow market, ensuring you are well-equipped to make strategic purchasing decisions that drive success in your operations.

Understanding four wheel barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Four-Wheel Wheelbarrow | Traditional design with four wheels for stability; manual push | Landscaping, construction, gardening | Pros: Stable, easy to use; Cons: Labor-intensive, limited load capacity. |

| Heavy-Duty Steel Wheelbarrow | Reinforced steel construction; high load capacity (up to 700 lbs) | Construction, heavy-duty landscaping | Pros: Durable, high capacity; Cons: Heavier, may require more effort to maneuver. |

| Electric Power Drive Wheelbarrow | Motorized for easy transport; features like power dump and speed control | Large-scale agriculture, nurseries, parks | Pros: Reduces physical strain, efficient; Cons: Higher upfront cost, requires charging. |

| Articulating Chassis Wheelbarrow | Flexible design for tight spaces; enhanced maneuverability | Landscaping, gardening, construction | Pros: Greater agility, suitable for varied terrains; Cons: May have lower load capacity. |

| Dumping Wheelbarrow | Quick dump feature for easy unloading; often motorized | Construction, waste management, gardening | Pros: Saves time on unloading; Cons: More complex mechanics, potentially higher maintenance. |

What Are the Characteristics of Standard Four-Wheel Wheelbarrows?

Standard four-wheel wheelbarrows are designed for stability and ease of use. They typically feature a simple, manual push mechanism and a large tray for carrying materials. This type is particularly suitable for landscaping, gardening, and construction tasks where maneuverability is essential. B2B buyers should consider the load capacity and wheel quality, as these factors influence performance on various terrains. While they are user-friendly, the labor-intensive nature of manual operation may be a drawback for larger jobs.

How Do Heavy-Duty Steel Wheelbarrows Stand Out?

Heavy-duty steel wheelbarrows are built to withstand rigorous use, featuring a robust construction that supports heavy loads, often up to 700 lbs. These wheelbarrows are ideal for construction sites and heavy-duty landscaping tasks where durability is paramount. Buyers should evaluate the weight and ease of maneuverability, as these wheelbarrows can be cumbersome. While they offer superior strength and longevity, they may require more physical effort to operate, which can be a consideration for teams with limited manpower.

What Benefits Do Electric Power Drive Wheelbarrows Offer?

Electric power drive wheelbarrows revolutionize material transport by providing motorized assistance. These models come with features like power dumping and speed control, making them suitable for large-scale agricultural operations and nurseries. B2B buyers must assess the battery life, charging infrastructure, and potential maintenance needs. Although the initial investment is higher, the reduction in physical strain and increased efficiency can lead to significant time savings and productivity gains in the long run.

Illustrative image related to four wheel barrel

Why Choose Articulating Chassis Wheelbarrows?

Articulating chassis wheelbarrows are designed for enhanced maneuverability, allowing for easy navigation in tight spaces. This feature makes them particularly effective in landscaping and construction projects where space is constrained. When considering a purchase, B2B buyers should look for models that maintain a balance between load capacity and flexibility. While they excel in agility, potential buyers should be aware that these wheelbarrows might not support as heavy a load as their heavy-duty counterparts.

What Are the Advantages of Dumping Wheelbarrows?

Dumping wheelbarrows facilitate quick unloading, often featuring a motorized or manual dump mechanism. They are widely used in construction, waste management, and gardening, where efficiency in material handling is crucial. Buyers should pay attention to the mechanism’s reliability and the wheelbarrow’s overall weight. While they can significantly reduce the time spent on unloading materials, the complexity of the dumping mechanism may lead to higher maintenance demands, which should be factored into the purchasing decision.

Key Industrial Applications of four wheel barrel

| Industry/Sector | Specific Application of Four Wheel Barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Material transport on construction sites | Enhances efficiency in moving heavy materials | Durability, weight capacity, and terrain adaptability |

| Agriculture | Handling soil, fertilizers, and crops | Streamlines farm operations and reduces labor costs | Corrosion resistance, load capacity, and ease of maneuverability |

| Landscaping | Transporting plants, soil, and landscaping materials | Improves project turnaround times and reduces fatigue | Stability, tire type for terrain, and ergonomic design |

| Waste Management | Collecting and transporting waste materials | Increases productivity and safety in waste handling | Weight capacity, ease of dumping, and maneuverability |

| Municipal Services | Park maintenance and public space landscaping | Enhances community aesthetics and operational efficiency | Versatility, ease of use, and maintenance requirements |

How is Four Wheel Barrel Used in the Construction Industry?

In the construction sector, four wheel barrows are essential for transporting heavy materials such as concrete, bricks, and tools across job sites. Their design allows for a higher load capacity, which minimizes the number of trips required, thereby enhancing overall efficiency. For international buyers, sourcing durable models that can withstand harsh conditions is crucial, particularly in regions with extreme weather or rough terrains. Key considerations include the wheelbarrow’s weight capacity, material composition (such as steel or poly), and maneuverability in tight spaces.

What Role Does a Four Wheel Barrel Play in Agriculture?

Agricultural operations benefit significantly from four wheel barrows, which are utilized for moving soil, fertilizers, and harvested crops. These wheelbarrows reduce the physical strain on workers, allowing for quicker transport of materials across fields. Buyers from regions like Africa and South America should prioritize models that are corrosion-resistant to withstand exposure to fertilizers and moisture. Additionally, ease of use and maintenance are vital, as farmers often operate in remote areas with limited access to repair services.

How Do Landscaping Professionals Utilize Four Wheel Barrels?

In landscaping, four wheel barrows are indispensable for transporting soil, plants, and decorative stones. Their stability allows landscapers to navigate uneven ground without tipping over, thus improving safety and efficiency. For buyers in Europe and the Middle East, sourcing models with ergonomic designs can help reduce worker fatigue during long hours of labor. Furthermore, considering the type of tires is essential to ensure optimal performance on various terrains, including gravel and grass.

Why Are Four Wheel Barrels Important in Waste Management?

In waste management, four wheel barrows facilitate the collection and transport of waste materials, enhancing the efficiency of cleanup operations. Their larger capacity allows workers to gather more waste in fewer trips, thus speeding up the process. Businesses in this sector should look for models that are easy to dump and clean, as well as those that can handle heavy loads. Additionally, sourcing durable materials is crucial to ensure longevity, particularly in environments that are exposed to harsh waste conditions.

Illustrative image related to four wheel barrel

How Do Municipal Services Benefit from Four Wheel Barrels?

Municipal services utilize four wheel barrows for park maintenance and public landscaping efforts. These barrows help transport tools, plants, and other materials necessary for maintaining public spaces, ultimately contributing to community aesthetics. Buyers should consider the versatility of the wheelbarrow, as models that can adapt to various tasks will provide greater value. Additionally, ease of maneuverability and low maintenance requirements are essential factors, particularly for municipal staff who often work in diverse environments.

3 Common User Pain Points for ‘four wheel barrel’ & Their Solutions

Scenario 1: Overcoming Heavy Load Transportation Challenges

The Problem: B2B buyers in industries like construction and landscaping often face the challenge of transporting heavy materials efficiently. Traditional wheelbarrows may not be sufficient for heavy loads, leading to worker fatigue, safety risks, and decreased productivity. For instance, a landscaping company might struggle with moving soil, rocks, or plants, which can result in delays and increased labor costs.

The Solution: To effectively address this issue, buyers should consider sourcing a four-wheel barrow with a high load capacity, such as those with a 10-cubic foot volume and a weight limit of 700 lbs. When selecting a wheelbarrow, prioritize features such as durable materials, ergonomic design, and stability. Steel construction can provide the necessary strength, while a four-wheel design enhances balance and maneuverability, reducing strain on workers. Additionally, incorporating electric options, like power drive and dump features, can significantly streamline operations by allowing for easier loading and unloading. Investing in a quality four-wheel barrow not only enhances efficiency but also improves workplace safety.

Scenario 2: Navigating Uneven Terrain and Tight Spaces

The Problem: Many B2B buyers, particularly those in agriculture or urban landscaping, encounter the problem of navigating uneven terrain or confined spaces. Standard two-wheel wheelbarrows can be cumbersome, making it difficult to transport materials without spilling or tipping over. This issue is especially pronounced in areas with tight pathways or varying ground levels, leading to frustration and potential damage to goods.

The Solution: To mitigate these challenges, buyers should opt for a four-wheel barrow designed for stability and maneuverability. Look for models featuring articulating chassis or swivel casters that allow for smooth navigation around corners and obstacles. Additionally, large, flat-free tires can provide traction and stability on uneven surfaces. When sourcing these products, consider suppliers that offer customizable options to match specific operational needs, such as varying wheel sizes or weight capacities. Training staff on how to properly maneuver these wheelbarrows in tight spaces can also enhance efficiency and reduce accidents.

Scenario 3: Ensuring Longevity and Low Maintenance Costs

The Problem: Many B2B buyers are concerned about the longevity and maintenance of their equipment. Wheelbarrows are often subjected to harsh working conditions, leading to rust, wear, and frequent repairs. This can result in increased costs over time, impacting overall operational budgets. Companies may find themselves frequently replacing wheelbarrows, which disrupts workflows and can lead to project delays.

The Solution: To ensure longevity and reduce maintenance costs, buyers should focus on sourcing four-wheel barrows made from corrosion-resistant materials, such as high-density polyethylene or powder-coated steel. These materials are less likely to rust and can withstand various environmental conditions. Moreover, selecting models with sealed bearings and low-maintenance features can minimize the need for regular upkeep. Buyers should also implement a routine inspection and maintenance schedule, allowing them to identify wear and tear early on. This proactive approach, combined with investing in durable wheelbarrows, will ultimately lead to lower long-term costs and uninterrupted operations.

Strategic Material Selection Guide for four wheel barrel

What Materials Are Commonly Used in Four Wheel Barrels?

When selecting materials for four wheel barrels, several options are prevalent in the market, each offering unique properties and advantages. Understanding these materials can help international B2B buyers make informed decisions based on performance, cost, and application suitability.

Illustrative image related to four wheel barrel

How Does Steel Perform in Four Wheel Barrels?

Steel is a widely used material for four wheel barrels due to its high strength and durability. It typically exhibits excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel’s corrosion resistance can be enhanced through galvanization or powder coating, which is essential for outdoor use in varying climates.

Pros: Steel wheelbarrows are robust and can handle heavy loads, often rated for capacities up to 700 lbs. They are relatively easy to manufacture and can be produced at a lower cost compared to other materials.

Cons: However, steel is prone to rust if not properly treated, which can limit its lifespan. Additionally, the weight of steel can make handling more cumbersome, especially in regions with rough terrain.

Impact on Application: Steel wheelbarrows are ideal for construction sites or agricultural settings where heavy materials like soil, gravel, or concrete are transported.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for corrosion resistance, particularly in humid or coastal environments.

What Are the Benefits of Using Polypropylene in Four Wheel Barrels?

Polypropylene is a lightweight, corrosion-resistant plastic that has gained popularity in the production of four wheel barrels. It offers good impact resistance and can withstand a wide range of temperatures, making it suitable for various applications.

Pros: The lightweight nature of polypropylene makes these wheelbarrows easy to maneuver, which is beneficial for users who need to transport lighter loads. They are also resistant to chemicals, making them suitable for transporting fertilizers or other agricultural products.

Cons: While polypropylene is durable, it may not withstand heavy loads as effectively as steel. Additionally, the manufacturing process can be more complex, potentially leading to higher costs.

Impact on Application: Polypropylene wheelbarrows are well-suited for gardening, landscaping, and light agricultural tasks where weight and ease of use are priorities.

Illustrative image related to four wheel barrel

Considerations for International Buyers: Buyers should verify that the polypropylene used meets international safety and quality standards, such as ASTM or DIN, particularly in regions like Europe and South America.

How Does Aluminum Compare as a Material for Four Wheel Barrels?

Aluminum is another material option for four wheel barrels, known for its lightweight and corrosion-resistant properties. It is often used in applications where weight reduction is essential, such as in landscaping or gardening.

Pros: Aluminum wheelbarrows are easy to handle and transport, making them ideal for users who need to move materials frequently. They also resist corrosion naturally, which is advantageous in wet or humid climates.

Cons: However, aluminum may not support as heavy a load as steel, often limited to around 300-400 lbs. The cost of aluminum can also be higher than that of steel or polypropylene, which may affect budget considerations.

Impact on Application: Aluminum wheelbarrows are best for lighter tasks, such as transporting plants or mulch, where ease of handling is more critical than load capacity.

Considerations for International Buyers: Buyers should consider the environmental impact of aluminum production and ensure compliance with local regulations regarding material sourcing and recycling, especially in Europe.

What Role Does Composite Material Play in Four Wheel Barrels?

Composite materials, which combine various materials for enhanced performance, are increasingly used in four wheel barrels. These can include mixtures of plastics and metals designed to offer the best of both worlds.

Pros: Composite wheelbarrows can offer excellent strength-to-weight ratios, making them both durable and easy to handle. They are also resistant to rust and corrosion, suitable for outdoor use.

Cons: The manufacturing process can be complex and costly, which may lead to higher prices in the market. Additionally, the long-term durability of composites can vary based on the specific materials used.

Impact on Application: Composite wheelbarrows are versatile and can be used in various applications, from construction to gardening, depending on their specific formulation.

Considerations for International Buyers: Buyers should ensure that composite materials comply with relevant international standards, particularly in terms of safety and environmental impact.

Summary Table of Material Selection for Four Wheel Barrels

| Material | Typical Use Case for four wheel barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction and heavy-duty tasks | High strength and load capacity | Prone to rust without treatment | Medium |

| Polypropylene | Gardening and light agricultural tasks | Lightweight and corrosion-resistant | Limited load capacity | Medium |

| Aluminum | Landscaping and lighter tasks | Lightweight and corrosion-resistant | Higher cost and lower load capacity | High |

| Composite | Versatile applications across industries | Excellent strength-to-weight ratio | Complex manufacturing process | High |

This guide serves as a strategic resource for B2B buyers to navigate the material selection process for four wheel barrels, ensuring that they choose the best option for their specific needs and regional requirements.

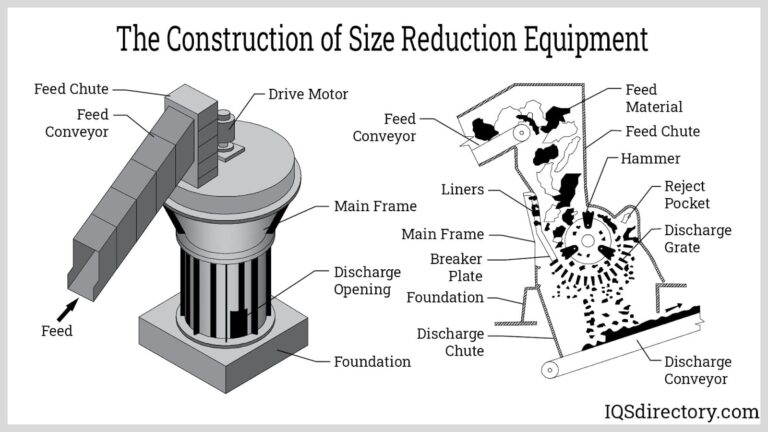

In-depth Look: Manufacturing Processes and Quality Assurance for four wheel barrel

What Are the Main Stages of Manufacturing a Four Wheel Barrow?

The manufacturing of a four wheel barrow involves several critical stages, each contributing to the final product’s quality and durability. Understanding these stages can help B2B buyers assess the capabilities and reliability of potential suppliers.

1. Material Preparation

The first step in the manufacturing process is material preparation. Manufacturers typically use high-grade steel or durable polymer for the frame and tray, selected for their strength and resistance to corrosion. The materials undergo thorough inspection to ensure they meet specified standards for thickness and tensile strength. Suppliers may utilize advanced software for material optimization, reducing waste and ensuring cost-effectiveness.

2. Forming

Once the materials are prepared, they move to the forming stage. Techniques such as stamping, bending, and welding are employed to shape the steel into the desired frame and tray designs. For polymer models, injection molding is commonly used. This stage requires precision machinery to ensure that all components fit together seamlessly, as misalignment can lead to structural weaknesses in the finished product.

3. Assembly

The assembly process involves integrating various components, such as wheels, handles, and trays. Manufacturers often utilize automated assembly lines for efficiency, although skilled labor is crucial for quality assurance during this phase. Each component is carefully inspected for defects, and assembly tolerances are strictly adhered to, as they significantly impact the barrow’s performance and durability.

4. Finishing

The final stage is finishing, which includes painting, coating, and additional treatments to enhance durability and aesthetics. Powder coating is a popular method for steel wheelbarrows, providing a robust finish that resists scratches and rust. For polymer models, UV-resistant coatings may be applied to prevent fading and degradation. This stage also involves final inspections to ensure the product meets visual and functional quality standards.

Illustrative image related to four wheel barrel

What International Standards Should B2B Buyers Consider in Quality Assurance?

Quality assurance is paramount in manufacturing four wheel barrows, especially for international markets. Buyers should ensure that their suppliers adhere to relevant quality standards.

ISO 9001 Certification

ISO 9001 is a globally recognized standard for quality management systems. Suppliers with this certification demonstrate their commitment to consistent quality and continuous improvement. B2B buyers should request documentation of a supplier’s ISO 9001 certification to ensure they maintain high-quality production standards.

CE Marking

For suppliers in Europe, CE marking is essential. This mark indicates that a product meets European safety, health, and environmental protection standards. B2B buyers should verify that their suppliers have the necessary documentation to support CE compliance, as this can affect marketability in the EU.

Illustrative image related to four wheel barrel

API Standards

For specialized applications, especially in heavy-duty or industrial environments, API (American Petroleum Institute) standards may apply. These standards ensure that products can withstand rigorous conditions, which is crucial for buyers in sectors such as construction and agriculture.

What Are the Key Quality Control Checkpoints in Manufacturing?

Implementing robust quality control (QC) practices is vital for maintaining product integrity. Key checkpoints throughout the manufacturing process include:

Incoming Quality Control (IQC)

IQC involves inspecting raw materials upon delivery to ensure they meet predefined specifications. This initial checkpoint helps prevent defects from entering the production line. Buyers can inquire about IQC processes to gauge supplier diligence in material selection.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC checkpoints are established to monitor ongoing production. This includes inspections after forming and assembly stages to catch any defects early. Advanced manufacturers may use automated systems to monitor production metrics in real time, providing insights into potential issues before they escalate.

Final Quality Control (FQC)

FQC is the last line of defense, ensuring that finished products meet all specifications before shipping. This involves comprehensive testing of functionality, safety, and aesthetics. Buyers should ask suppliers for details on their FQC procedures, including any testing methods employed.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers seeking reliability and performance. Here are several methods to assess supplier quality:

Conducting Supplier Audits

Regular supplier audits allow buyers to evaluate the effectiveness of a supplier’s quality management system. Audits can be conducted by the buyer’s quality team or through third-party services. Key areas to assess include production capabilities, quality documentation, and adherence to international standards.

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports, including results from various testing methods. Buyers should review these reports to understand the consistency of product quality and any corrective actions taken in response to past defects.

Illustrative image related to four wheel barrel

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s operations. These inspectors can conduct random checks during production and provide detailed reports on compliance with quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is crucial.

Regional Compliance Variances

Different regions may have specific regulations and quality standards that suppliers must adhere to. Buyers should familiarize themselves with these requirements to ensure their suppliers are compliant. For instance, products exported to the Middle East may need to meet local safety standards that differ from those in Europe.

Illustrative image related to four wheel barrel

Language and Cultural Barriers

Language and cultural differences can impact communication about quality expectations. Buyers should ensure that all quality documentation is available in relevant languages and that suppliers understand the specific quality standards required for their markets.

Logistics and Supply Chain Considerations

Quality control also extends to logistics. B2B buyers should consider how products are handled during shipping and storage, as this can affect quality upon arrival. Engaging suppliers who demonstrate strong logistics practices can help mitigate risks associated with product damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance protocols for four wheel barrows is critical for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with adherence to international standards and robust QC practices, buyers can ensure they source reliable and high-quality products for their markets.

Illustrative image related to four wheel barrel

Practical Sourcing Guide: A Step-by-Step Checklist for ‘four wheel barrel’

To assist B2B buyers in sourcing four-wheel barrows effectively, this guide offers a structured checklist. This will ensure that your procurement process is streamlined, efficient, and tailored to meet specific operational needs.

Step 1: Define Your Technical Specifications

Understanding the exact requirements for your four-wheel barrow is crucial. Consider factors such as load capacity, volume, material (steel vs. poly), and intended use (landscaping, construction, etc.). Clearly defining these specifications helps in narrowing down your options and ensures the equipment meets your operational demands.

Step 2: Research Market Trends and Pricing

Conduct comprehensive market research to gauge current pricing and trends in the four-wheel barrow sector. This involves reviewing industry reports, competitor offerings, and customer reviews. Establishing a baseline for pricing allows you to identify reasonable costs and negotiate effectively with suppliers.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in four-wheel barrows. Focus on those with a proven track record in your region or industry. Utilize platforms like trade directories, industry expos, and online marketplaces to find reputable vendors who can meet your needs.

Illustrative image related to four wheel barrel

Step 4: Evaluate Supplier Certifications and Compliance

Before engaging with suppliers, check for necessary certifications and compliance with industry standards. Ensure they adhere to safety regulations and quality management systems (such as ISO certifications). This step safeguards against sourcing substandard products that could affect your operations.

Step 5: Request Samples for Assessment

Once you’ve narrowed down your suppliers, request samples of the four-wheel barrows for evaluation. Testing the samples allows you to assess build quality, functionality, and ease of use. Look for features such as ergonomic design, wheel durability, and weight distribution to ensure they align with your operational requirements.

Step 6: Analyze Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by your potential suppliers. A robust warranty indicates the supplier’s confidence in their product and provides peace of mind for your investment. Additionally, ensure that they offer reliable customer service and support for maintenance or repairs.

Step 7: Negotiate Terms and Finalize Purchase

Engage in negotiations to secure the best terms for pricing, delivery schedules, and payment options. Be clear about your expectations regarding lead times and bulk order discounts. Finalizing the purchase with a well-drafted contract protects both parties and sets clear expectations for the transaction.

Illustrative image related to four wheel barrel

By following this checklist, B2B buyers can ensure a systematic approach to sourcing four-wheel barrows, ultimately leading to informed decisions that enhance operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for four wheel barrel Sourcing

What Are the Key Cost Components for Sourcing Four Wheel Barrels?

When considering the sourcing of four wheel barrels, it is essential to understand the various cost components involved in their production. The primary components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials used in four wheel barrels include steel, plastic, and rubber. Steel offers durability but is heavier, while plastic is lighter and resistant to corrosion but may not support heavy loads as effectively.

-

Labor: Labor costs can vary widely based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and productivity of the workforce, which can affect the quality of the final product.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help lower these costs, enabling suppliers to offer more competitive pricing.

-

Tooling: Initial costs for molds and tools can be significant, especially for custom designs. These costs are amortized over the production volume, so higher volumes can reduce the per-unit tooling cost.

-

Quality Control (QC): Implementing robust QC processes adds to the cost but ensures that the products meet required specifications and safety standards. Certifications like ISO can also influence costs but enhance the product’s marketability.

-

Logistics: Shipping costs, including freight and insurance, are critical, particularly for international buyers. Factors such as distance, mode of transport, and weight of the barrels will influence logistics expenses.

-

Margin: Suppliers will typically build a profit margin into their pricing. Understanding the supplier’s pricing strategy can provide insights into potential negotiation points.

How Do Price Influencers Affect Four Wheel Barrel Sourcing?

Several factors influence the pricing of four wheel barrels, impacting the total cost for buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Suppliers often provide discounts for larger orders, so understanding your needs and potential for bulk purchases is crucial.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: The choice of materials not only affects durability but also price. Products with recognized quality certifications may come at a premium but can enhance reliability and customer satisfaction.

-

Supplier Factors: The supplier’s reputation, financial stability, and production capabilities can influence pricing. Established suppliers may charge more due to their reliability and service levels.

-

Incoterms: The international commercial terms agreed upon can greatly affect the final price. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for calculating total landed costs.

What Are the Best Buyer Tips for Cost-Efficient Four Wheel Barrel Sourcing?

To optimize sourcing costs and ensure value for money, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, volume discounts, and potential cost-saving options. Establishing a long-term partnership can also lead to better terms over time.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the four wheel barrels, including maintenance, durability, and operational efficiency. A higher upfront cost may lead to lower TCO if the product lasts longer and requires less maintenance.

-

Understand Pricing Nuances for International B2B Transactions: Different regions may have varying pricing structures due to economic factors, supply chain dynamics, and regulatory costs. Buyers from Africa, South America, the Middle East, and Europe should be aware of these differences and factor them into their sourcing strategies.

-

Disclaimer for Indicative Prices: Keep in mind that prices can fluctuate based on market conditions, currency exchange rates, and supply chain issues. Always request updated quotes before making purchasing decisions.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions when sourcing four wheel barrels, ultimately enhancing their procurement efficiency and cost-effectiveness.

Alternatives Analysis: Comparing four wheel barrel With Other Solutions

When evaluating the best solutions for material handling and transport, the four wheel barrel stands out as a popular choice. However, it is essential for B2B buyers to consider viable alternatives that may better suit their specific operational needs. In this analysis, we will compare the four wheel barrel with two prominent alternatives: electric power drive wheelbarrows and traditional two-wheel wheelbarrows.

Comparison Table

| Comparison Aspect | Four Wheel Barrel | Electric Power Drive Wheelbarrow | Traditional Two-Wheel Wheelbarrow |

|---|---|---|---|

| Performance | High stability; can carry heavy loads (up to 700 lbs) | Excellent for heavy loads; powered movement reduces strain | Good for moderate loads; requires manual effort |

| Cost | Moderate, typically ranges from $150-$300 | Higher initial investment ($800-$1,200) | Low-cost options available ($50-$150) |

| Ease of Implementation | Easy to use; no setup required | Requires charging and occasional maintenance | Very straightforward; no setup or training needed |

| Maintenance | Minimal maintenance needed | Requires battery maintenance and periodic checks | Low maintenance; durable with proper care |

| Best Use Case | Landscaping, construction, and heavy-duty tasks | Large farms, nurseries, and extensive landscaping | Residential gardening and light-duty tasks |

Detailed Breakdown of Alternatives

Electric Power Drive Wheelbarrow

The electric power drive wheelbarrow provides an innovative solution for transporting heavy loads with minimal physical strain. Its powered movement allows users to navigate rough terrain effortlessly, making it an ideal choice for farms, nurseries, and extensive landscaping projects. However, the initial investment can be substantial, and regular battery maintenance is required, which might deter some buyers. Furthermore, while it excels in performance, the reliance on electricity could pose challenges in areas with unstable power supply.

Traditional Two-Wheel Wheelbarrow

The traditional two-wheel wheelbarrow is a cost-effective alternative that offers simplicity and ease of use. It is suitable for light to moderate loads, making it perfect for residential gardening or small-scale projects. The affordability of these wheelbarrows is a significant advantage, with many options available under $150. However, they require manual effort, which can become a drawback for larger tasks or in challenging terrain. Additionally, their stability is not as robust as that of the four wheel barrel, especially when handling heavy loads.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate material handling solution, B2B buyers should assess their specific operational requirements, including load capacity, terrain type, and budget constraints. The four wheel barrel excels in stability and load capacity, making it ideal for heavy-duty tasks. In contrast, the electric power drive wheelbarrow is perfect for those seeking ease of movement over rough terrain but comes with a higher price tag and maintenance needs. The traditional two-wheel wheelbarrow offers an economical choice for lighter tasks but may not perform as well under heavier loads. Ultimately, understanding the unique demands of your projects will guide you in making the most informed decision for your business.

Essential Technical Properties and Trade Terminology for four wheel barrel

What Are the Essential Technical Properties of a Four Wheel Barrow?

When considering the procurement of four wheel barrows, several key technical properties must be evaluated to ensure the product meets operational requirements. Understanding these specifications can significantly impact efficiency, durability, and overall performance.

1. Load Capacity

The load capacity refers to the maximum weight a wheelbarrow can safely transport. This is typically expressed in pounds or kilograms, with common capacities ranging from 700 lbs (317 kg) to over 1,000 lbs (454 kg) for heavy-duty models. For B2B buyers, selecting a wheelbarrow with an appropriate load capacity is critical for productivity, ensuring that it can handle the demands of landscaping, construction, or agricultural tasks without risk of failure.

2. Material Composition

The materials used in the construction of a four wheel barrow significantly affect its durability and maintenance needs. Common materials include steel, which offers strength and longevity, and polyethene, which is lightweight and corrosion-resistant. For international buyers, understanding the material properties helps in assessing resistance to environmental factors, particularly in regions with high humidity or varying temperatures, ensuring the equipment lasts longer.

3. Wheel Configuration and Size

Four wheel barrows generally feature larger wheels than traditional two-wheel versions, providing enhanced stability and maneuverability. The wheel size, often between 10 to 13 inches in diameter, can affect performance on uneven surfaces. Buyers should consider the terrain in which the wheelbarrow will be used, as larger, all-terrain wheels are better suited for rough or muddy conditions, ensuring a smoother operation.

4. Ergonomics and Design Features

Ergonomic handles and designs are essential for reducing strain on the user. Features such as adjustable handles and padded grips can enhance comfort and reduce fatigue during prolonged use. For B2B buyers, investing in ergonomic designs can lead to improved worker efficiency and reduced risk of injury, translating to lower insurance costs and higher productivity.

5. Dump Mechanism

Some four wheel barrows come equipped with a dumping feature, allowing users to easily unload materials without manual lifting. This feature is particularly beneficial in applications such as landscaping or construction where frequent material transport is required. Buyers should evaluate the ease of use of the dump mechanism, as a well-designed feature can enhance operational efficiency.

Illustrative image related to four wheel barrel

What Trade Terminology Should B2B Buyers Understand When Sourcing Four Wheel Barrows?

Familiarity with industry terminology can streamline the procurement process and enhance communication with suppliers. Here are some essential trade terms relevant to four wheel barrow procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed under another company’s brand. For buyers, understanding OEM relationships is crucial for ensuring product quality and consistency, as reputable OEMs often provide better warranties and support.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory planning, particularly if the wheelbarrows will be used in bulk operations or distributed across multiple sites.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a detailed price quote for specific products. This is a vital step in the procurement process, allowing buyers to compare prices and terms from multiple vendors, ensuring they receive the best deal possible.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms can help buyers navigate shipping responsibilities, insurance, and risk management when sourcing wheelbarrows from international suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This metric is crucial for planning and scheduling, particularly in industries where timely deliveries are essential for maintaining operations.

6. Warranty and Support

A warranty is a promise from the manufacturer regarding the condition of the product and their commitment to repair or replace it if necessary. For B2B buyers, understanding warranty terms can provide peace of mind and protect against potential defects, ensuring that investments in wheelbarrows are safeguarded.

By familiarizing themselves with these technical specifications and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the four wheel barrel Sector

What Are the Current Market Dynamics and Key Trends in the Four Wheel Barrel Sector?

The four wheel barrel sector is experiencing significant growth, driven by several global factors. Increasing urbanization and infrastructure development, particularly in emerging markets across Africa and South America, have heightened demand for efficient material handling solutions. As cities expand, the need for versatile and robust wheelbarrows has surged, with applications ranging from landscaping to construction. Furthermore, technological advancements are reshaping the sector. Innovations such as electric-powered wheelbarrows are becoming more prevalent, offering enhanced efficiency and reducing labor costs. These models are especially appealing to businesses focused on sustainability and reducing their carbon footprint.

International B2B buyers must also pay attention to sourcing trends. The shift towards online procurement platforms is transforming how companies source four wheel barrels. Buyers can now access a wider range of products, compare prices, and evaluate suppliers more efficiently. This digital transformation is particularly relevant for regions like the Middle East and Europe, where online purchasing is rapidly gaining traction. Additionally, buyers are increasingly looking for suppliers who offer customization options to cater to specific project needs, such as varying load capacities and ergonomic designs.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Four Wheel Barrel Sector?

Sustainability has become a critical consideration for B2B buyers in the four wheel barrel sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. Ethical sourcing is equally important; buyers are increasingly favoring vendors who adhere to fair labor practices and transparent supply chains. This trend is particularly pronounced among businesses in Europe, where regulatory frameworks emphasize corporate social responsibility.

To align with sustainability goals, buyers should look for products made from recyclable or sustainably sourced materials, such as recycled steel or eco-friendly plastics. Certifications like the Forest Stewardship Council (FSC) for wood components and ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainable practices. Moreover, investing in durable and repairable products can contribute to a circular economy, reducing waste and extending the lifespan of equipment. By prioritizing these factors, B2B buyers can enhance their brand reputation while contributing to environmental preservation.

Illustrative image related to four wheel barrel

What Is the Evolution and Historical Context of the Four Wheel Barrel?

The four wheel barrel, while seemingly a simple tool, has undergone significant evolution since its inception. Historically, wheelbarrows can be traced back to ancient China, where they were utilized for transporting goods across challenging terrains. The design has evolved from basic wooden structures to modern, robust variants made from metal and high-grade plastics.

In the late 20th century, the introduction of pneumatic tires and ergonomic designs revolutionized the four wheel barrel, making them more user-friendly and efficient. Today, advanced features such as electric power drives and enhanced load capacities reflect the ongoing innovation in this sector. Understanding this evolution is vital for B2B buyers, as it underscores the importance of selecting products that not only meet current operational needs but also incorporate the latest technologies for improved performance and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of four wheel barrel

-

How do I choose the right four wheel barrel for my business needs?

Selecting the right four wheel barrel depends on several factors, including load capacity, material, and intended use. For heavy-duty applications, consider models with higher weight capacities, such as those around 700 lbs. Materials like steel offer durability, while poly versions provide corrosion resistance. Additionally, think about features like maneuverability and ease of dumping. It’s also wise to assess the terrain where the wheelbarrow will be used to ensure it meets specific operational requirements. -

What is the best four wheel barrel for landscaping projects?

For landscaping projects, a four wheel barrel with a larger capacity, typically around 10 cubic feet, is ideal. Models that feature pneumatic tires provide better traction on uneven terrain. Electric-powered options are also advantageous for reducing physical strain and increasing efficiency, especially in larger gardens or parks. Look for features like an articulating chassis for enhanced maneuverability, which is crucial in tight spaces often found in landscaping environments. -

What customization options are available for four wheel barrels?

Many manufacturers offer customization options for four wheel barrels, including different sizes, colors, and materials to suit specific business branding or operational needs. You may also request features like reinforced handles, specialized wheels for particular terrains, or additional attachments for dumping or hauling. Discussing your requirements with suppliers can lead to tailored solutions that enhance functionality and productivity in your operations. -

What are the minimum order quantities (MOQ) for four wheel barrels?

Minimum order quantities for four wheel barrels can vary significantly between suppliers. Typically, MOQs range from 10 to 50 units, depending on the manufacturer’s production capabilities and the type of customization required. It’s advisable to negotiate MOQs, especially if you are a new buyer or testing the market with a smaller order. Establishing a good relationship with suppliers can also lead to more favorable terms. -

What payment terms should I expect when sourcing four wheel barrels internationally?

Payment terms for international orders usually involve upfront deposits, often ranging from 30% to 50%, with the remaining balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for larger transactions to mitigate risks. Always clarify payment methods accepted, such as wire transfers or credit terms, and consider discussing options for extended payment plans, especially if you are placing a significant order. -

How do I ensure quality assurance when sourcing four wheel barrels?

To ensure quality assurance, request product samples before placing a bulk order. Establish clear quality standards and specifications with your supplier, including materials, dimensions, and load capacities. Conduct factory inspections or audits if possible, and consider third-party quality control services that can verify product standards and compliance with international regulations. Maintaining open communication with your supplier throughout the production process is crucial for addressing any quality concerns early. -

What logistics considerations should I keep in mind when importing four wheel barrels?

When importing four wheel barrels, consider shipping methods, freight costs, and customs duties. Evaluate whether air or sea freight is more suitable based on your budget and urgency. Additionally, understand the import regulations of your country, including any certifications required for imported goods. Partnering with a reliable logistics provider can streamline the process and help manage any potential delays or complications during transit. -

What are the common uses for four wheel barrels in different industries?

Four wheel barrels are versatile tools used across various industries, including landscaping, construction, agriculture, and waste management. In landscaping, they facilitate the transport of soil and plants. Construction sites utilize them for moving materials like gravel or bricks. In agriculture, they assist in transporting produce or tools. Understanding the specific needs of your industry can help you select the most appropriate model to enhance efficiency and productivity.

Top 4 Four Wheel Barrel Manufacturers & Suppliers List

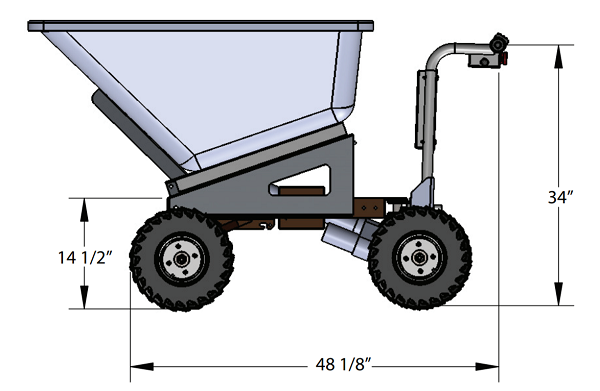

1. Granite – Overland Electric Wheelbarrow

Domain: store.graniteind.com

Registered: 1997 (28 years)

Introduction: {“name”: “Overland Electric Wheelbarrow”, “capacity”: “10 cu. ft.”, “features”: {“4WD”: true, “power_dump”: true, “battery”: “39 Amp-Hr Battery Pack”, “weight_capacity”: “750 lbs”, “dimensions”: {“height”: “1 in”, “width”: “29 in”, “length”: “51 in”}, “safety_features”: [“SmoothStart”, “HillSense”, “AutoLock”, “Emergency Stop”, “Four Wheel Design”, “Overload Fuse”, “Throttle Controlled Braking”, “…

2. Handtrucks2Go – 4-Wheel Power Drive and Dump Wheel Barrow

Domain: handtrucks2go.com

Registered: 2010 (15 years)

Introduction: {‘product_name’: ‘4-Wheel Power Drive and Dump Wheel Barrow’, ‘hopper_capacity’: ’10 cubic foot’, ‘tire_type’: ‘Flat-Free Dual 13″ all terrain tires’, ‘motor_type’: ‘(2) 24 Volt DC Permanent Magnet Motor’, ‘continuous_power’: ‘400 watts (0.536HP) at 24V’, ‘drive_system’: ‘Single Reduction Open Differential Transaxle’, ‘gear_ratio’: ’21:01′, ‘capacity_level_ground’: ‘750 lbs (295 kgs)’, ‘capacity_3…

3. Overland Carts – 400 Series Electric Powered Wheelbarrow

Domain: overlandcarts.com

Registered: 2011 (14 years)

Introduction: 400 Series Electric Powered Wheelbarrow with 4 Wheel Drive

Key Features:

– Capacity: 750 lbs

– Models:

– C34-10F (70255): 10 Cu. Ft. Hopper, 13″ Dual Ag Tires, 4WD

– C34-8F (70236): 8 Cu. Ft. Hopper, 13″ Dual Ag Tires, 4WD

– Articulated chassis for easier maneuverability over uneven terrain

– Dual drive axles for exceptional grip

– Heavy Duty Dumping Hopper made from high density polyethylen…

4. Gorilla Made – 6 cu. ft. Pro Grade Steel Wheelbarrow

Domain: gorillamade.com

Registered: 2018 (7 years)

Introduction: Gorilla Wheelbarrows are designed for heavy-duty use, featuring a unique power pivot design for easier dumping, a true 16-inch pneumatic tire for stability on any terrain, and an extra-wide stance for loading stability. Key products include: 6 cu. ft. Pro Grade Steel Wheelbarrow with XD Structure, 6 cu. Ft. Pro Grade Poly Wheelbarrow with XD Structure, and 8 cu. Ft. Pro Grade Poly Dual Wheel Wheel…

Strategic Sourcing Conclusion and Outlook for four wheel barrel

What Are the Key Insights on Strategic Sourcing for Four Wheel Barrels?

In summary, the strategic sourcing of four-wheel barrels presents significant opportunities for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The versatility and durability of these products make them ideal for various applications, from agriculture to landscaping and construction. By focusing on quality, capacity, and innovative designs—such as electric-powered options—buyers can enhance operational efficiency and reduce labor costs.

Investing in high-quality four-wheel barrels not only ensures longevity but also supports sustainable practices by minimizing environmental impact. It is essential for buyers to consider local suppliers who can provide logistical advantages, particularly in regions with challenging terrain or infrastructure.

Looking ahead, the demand for advanced wheelbarrow solutions is expected to grow, driven by increasing urbanization and the need for efficient material handling. International buyers should take proactive steps to establish relationships with reliable manufacturers, ensuring they stay ahead of market trends and technological advancements. Now is the time to leverage strategic sourcing to enhance your supply chain and capitalize on the benefits of innovative four-wheel barrel solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.