A B2B Buyer’s Guide to Deburring Equipment: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for deburring equipment

In the competitive landscape of global manufacturing, sourcing the right deburring equipment is crucial for businesses aiming to enhance product quality and operational efficiency. Burrs, those unwanted protrusions formed during machining processes, can compromise the functionality and safety of components, leading to costly rework and diminished customer satisfaction. This guide serves as a comprehensive resource for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Nigeria, who are navigating the complexities of deburring equipment procurement.

Throughout this guide, we delve into various types of deburring machinery, including vibratory, tumbling, and electrochemical systems, and explore their specific applications across diverse industries. Buyers will gain insights into how to effectively vet suppliers, ensuring they partner with reputable manufacturers that meet their quality standards and budgetary constraints. Additionally, we provide a detailed analysis of cost considerations, enabling informed purchasing decisions that align with both operational needs and financial goals.

By addressing key challenges and equipping buyers with actionable knowledge, this guide empowers manufacturers to make strategic investments in deburring technology. In doing so, businesses can optimize production processes, enhance product reliability, and ultimately achieve a competitive edge in their respective markets.

Understanding deburring equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vibratory Deburring Machines | Uses abrasive media in a vibrating bowl for batch processing. | Small, complex parts in mass finishing. | Pros: Efficient for small parts; good surface finish. Cons: Longer cycle times for larger components. |

| Tumbling Barrels | Rotates parts with abrasive media for deburring larger components. | Automotive and aerospace industries. | Pros: Handles larger parts; effective for heavy burrs. Cons: Requires more space and maintenance. |

| Brush Deburring Machines | Employs rotating brushes for flat surfaces and edges. | Sheet metal and stamped parts processing. | Pros: High-speed operation; effective on flat surfaces. Cons: Limited to specific geometries. |

| Thermal Deburring Machines | Uses controlled combustion to remove burrs from intricate parts. | Aerospace and automotive components. | Pros: Reaches hard-to-access areas; effective for complex geometries. Cons: Higher operational costs. |

| Electrochemical Deburring | Utilizes electric current and electrolyte to dissolve burrs. | Medical devices and precision components. | Pros: Precision deburring for delicate parts; minimal material loss. Cons: Requires specialized setup and expertise. |

What Are Vibratory Deburring Machines and Their Applications?

Vibratory deburring machines utilize a vibrating bowl filled with abrasive media to gently smooth out burrs on small, complex parts. Ideal for batch processing, these machines are widely employed in industries that require consistent finishing, such as electronics and small component manufacturing. When considering a purchase, B2B buyers should evaluate the machine’s capacity and the type of media required, as these factors significantly influence the deburring efficiency and surface finish quality.

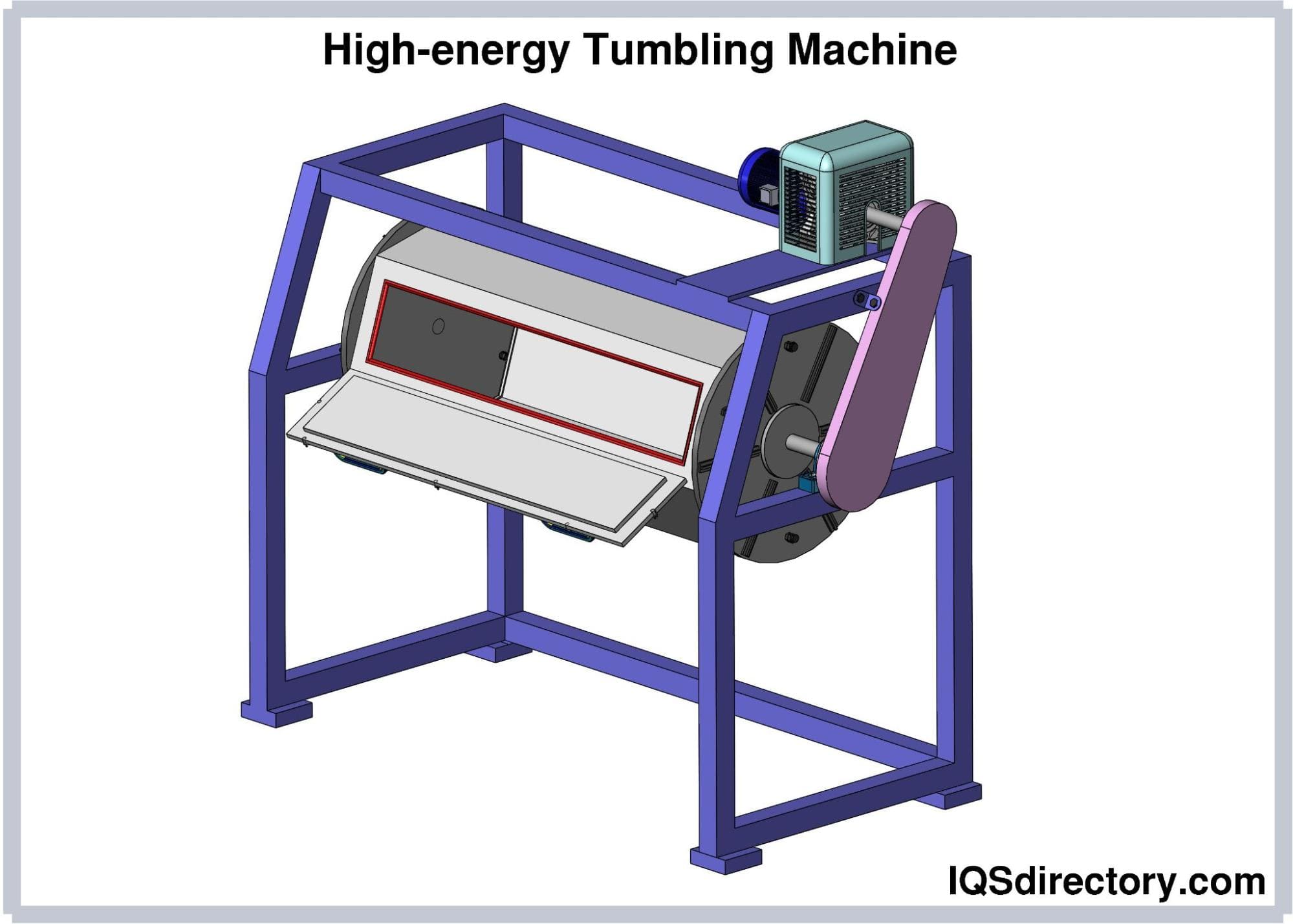

How Do Tumbling Barrels Work in Deburring?

Tumbling barrels operate by rotating components along with abrasive media, effectively removing burrs from larger and heavier parts. Commonly used in automotive and aerospace sectors, they are suitable for mass production environments where efficiency and durability are paramount. Buyers should assess the machine’s size, the volume of parts processed, and the abrasiveness of the media to ensure optimal performance for their specific applications.

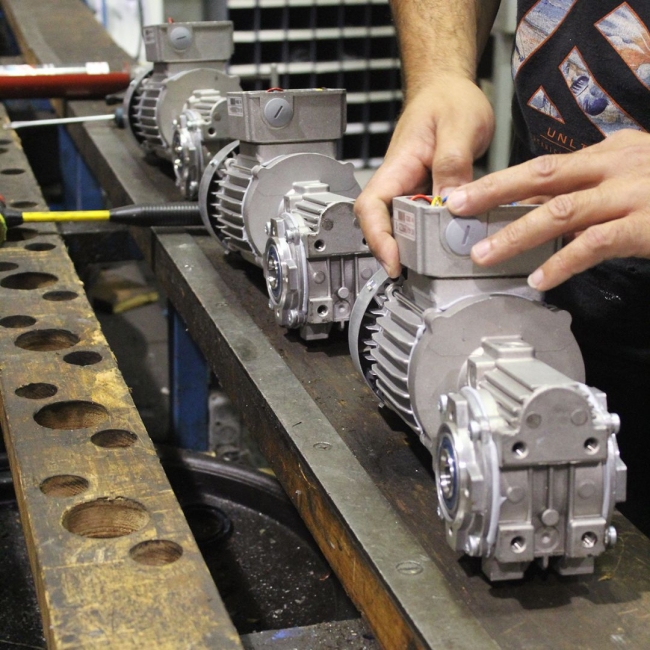

Illustrative image related to deburring equipment

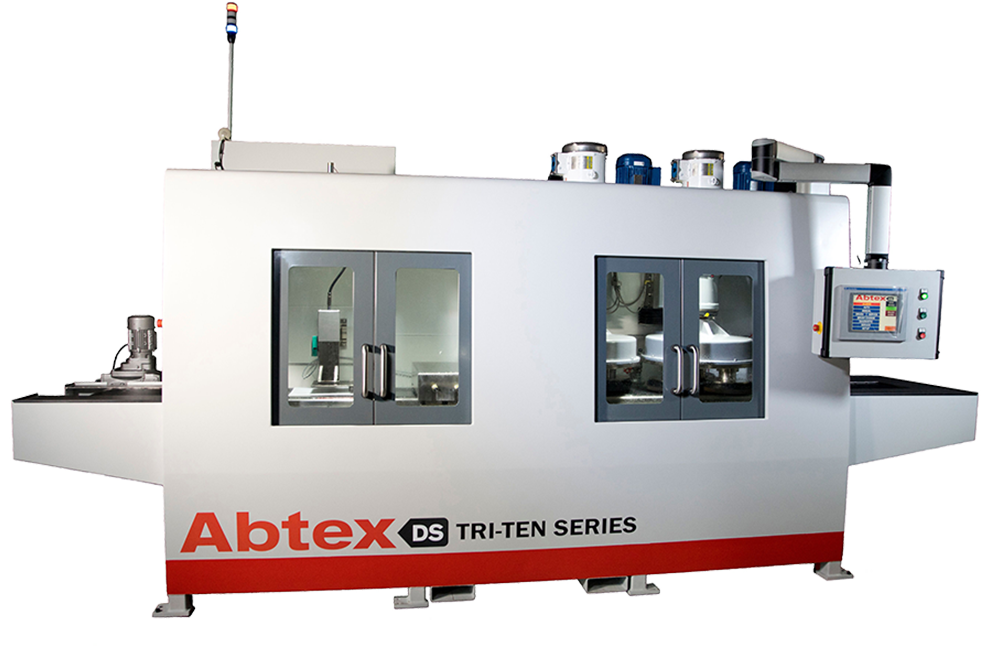

What Are the Benefits of Brush Deburring Machines?

Brush deburring machines feature rotating brushes that apply abrasive bristles to flat surfaces and edges, making them an excellent choice for sheet metal and stamped parts. These machines are favored for their speed and efficiency in high-volume production lines. B2B purchasers should consider the types of parts they will be processing, as these machines are best suited for specific geometries and may not handle intricate shapes as effectively.

Why Choose Thermal Deburring Machines for Complex Parts?

Thermal deburring machines employ a controlled combustion process to eliminate burrs from intricate components, making them particularly useful in industries like aerospace and automotive. Their ability to reach hard-to-access areas ensures a thorough deburring process. Buyers must weigh the operational costs and the need for specialized training to operate these machines effectively, as they can be more expensive compared to traditional methods.

What Is Electrochemical Deburring and Its Advantages?

Electrochemical deburring utilizes an electrolyte solution and electric current to dissolve burrs, offering a precise solution for delicate or high-value components, such as those found in the medical device industry. This method minimizes material loss and is ideal for intricate geometries. B2B buyers should consider the initial setup requirements and the expertise needed to operate such specialized equipment, as these factors can impact overall cost and efficiency.

Illustrative image related to deburring equipment

Key Industrial Applications of deburring equipment

| Industry/Sector | Specific Application of deburring equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Removing burrs from machined engine components | Enhances safety, assembly accuracy, and product durability | Equipment must handle high-volume production and various metal types. |

| Aerospace | Deburring intricate parts for fuel systems and turbines | Ensures precision, compliance with safety standards, and reduces failure rates | Precision and reliability are critical; consider equipment capable of handling complex geometries. |

| Electronics | Smoothing edges of circuit boards and connectors | Improves functionality and aesthetic appeal, reducing assembly issues | Look for machines that can handle delicate materials without damage. |

| Medical Devices | Deburring surgical instruments and implants | Ensures patient safety and compliance with stringent regulations | Equipment should allow for precision deburring of high-value components. |

| Construction | Deburring steel and aluminum components for structural applications | Enhances safety and improves assembly quality in construction projects | Equipment should be robust to handle large parts and ensure consistent results. |

How Is Deburring Equipment Used in the Automotive Industry?

In the automotive sector, deburring equipment is essential for refining machined engine components, such as cylinder heads and crankshafts. The presence of burrs can compromise the functionality and safety of these parts, leading to assembly difficulties and potential failures. Automated deburring solutions, including brush and vibratory machines, are preferred for their efficiency in processing large volumes of parts. Buyers should consider equipment that can accommodate various metals and withstand high production rates, ensuring consistent quality across multiple batches.

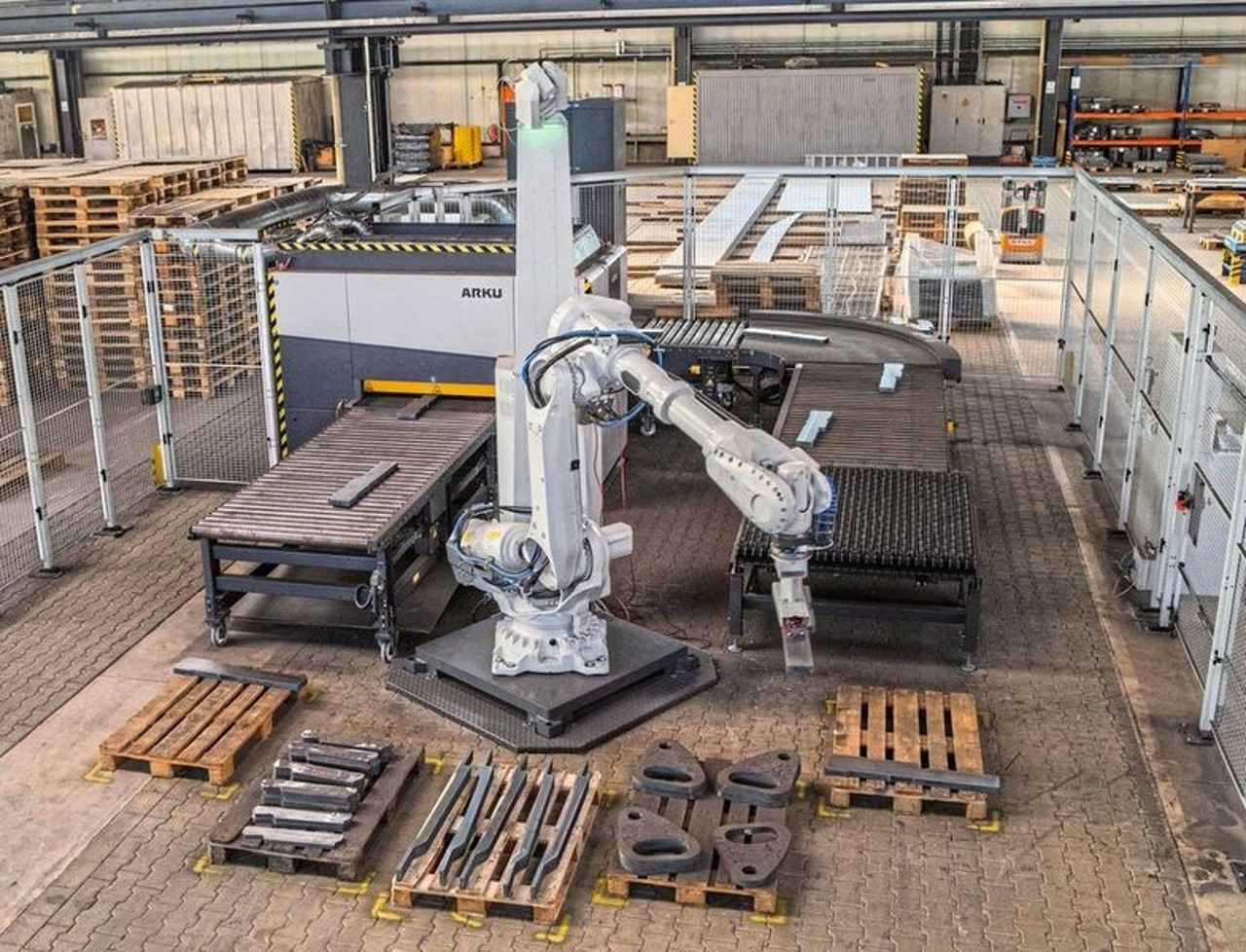

What Role Does Deburring Equipment Play in Aerospace Manufacturing?

Aerospace manufacturing demands the highest precision due to safety regulations and the critical nature of its components. Deburring equipment is used to treat intricate parts, such as those found in fuel systems and turbines, where even minor imperfections can lead to catastrophic failures. The use of thermal and electrochemical deburring methods is common in this industry to ensure that complex geometries are maintained without compromising structural integrity. International buyers must prioritize sourcing equipment that meets rigorous aerospace standards while providing reliability and precision.

How Is Deburring Equipment Utilized in the Electronics Sector?

In the electronics industry, deburring equipment plays a vital role in smoothing edges of circuit boards and connectors. Burrs can interfere with electrical connections, leading to malfunctioning devices. Automated deburring machines equipped with specialized brushes or vibratory systems are favored for their ability to handle delicate materials without causing damage. Buyers from regions with growing electronics markets, such as Africa and South America, should seek machines that can adapt to various material types and provide a high-quality finish to ensure product reliability.

Why Is Deburring Equipment Critical for Medical Device Manufacturing?

The medical device industry requires stringent adherence to safety and quality standards, making deburring equipment indispensable for processing surgical instruments and implants. Burrs can pose significant risks, including infection or device failure, making precision in deburring essential. Solutions such as electrochemical deburring are often employed for their ability to delicately remove imperfections from high-value components. Buyers should focus on sourcing equipment that ensures compliance with medical regulations and can handle the unique demands of intricate medical designs.

How Does Deburring Equipment Enhance Construction Projects?

In the construction industry, deburring equipment is used to process steel and aluminum components essential for structural integrity. Burrs left on materials can lead to safety hazards during assembly and may compromise the overall quality of construction projects. Tumbling barrels and vibratory deburring machines are commonly used to ensure smooth edges and surfaces. Buyers should consider robust equipment that can handle larger parts and maintain consistent results, particularly in regions with expanding construction demands, such as the Middle East and Africa.

Illustrative image related to deburring equipment

3 Common User Pain Points for ‘deburring equipment’ & Their Solutions

Scenario 1: Inconsistent Quality of Finished Parts

The Problem: Many B2B buyers face the challenge of inconsistent quality in the finished parts due to improper deburring processes. Burrs left on machined components can lead to defects that not only affect the aesthetics of the product but can also compromise functionality and safety. This inconsistency is particularly troubling for manufacturers supplying critical components in industries such as automotive or aerospace, where precision is paramount. If parts are not deburred adequately, they can lead to assembly issues, product recalls, or, worse, safety hazards.

The Solution: To ensure consistent quality, buyers should invest in automated deburring equipment tailored to their specific production needs. This includes evaluating the type of burrs typically formed during machining and selecting the appropriate deburring method, such as vibratory or brush deburring machines. Implementing a quality control system that includes routine checks after the deburring process can also help maintain standards. Regular training for operators on the correct usage of deburring machines can further enhance the consistency of the results. By adopting a systematic approach to deburring, manufacturers can significantly reduce the risk of defects in their products.

Scenario 2: High Operational Costs Due to Inefficient Processes

The Problem: B2B buyers often encounter high operational costs stemming from inefficient deburring processes. Manual deburring methods can be labor-intensive and time-consuming, leading to increased labor costs and production delays. Additionally, the potential for human error in manual processes can result in further financial losses due to rework and scrap. Buyers in competitive markets, such as electronics or consumer goods, may find that these inefficiencies undermine their profitability and market position.

The Solution: To combat high operational costs, manufacturers should consider transitioning to automated deburring systems that enhance productivity and reduce labor requirements. Investing in advanced machinery, such as centrifugal disc finishing machines or thermal deburring systems, can lead to significant time savings and consistent results. Furthermore, integrating deburring equipment into the existing production line can streamline workflows, thereby minimizing downtime. Conducting a cost-benefit analysis can help buyers understand the return on investment associated with upgrading their deburring capabilities, ultimately leading to lower operational costs and improved competitiveness.

Scenario 3: Difficulty in Selecting the Right Deburring Equipment

The Problem: Many B2B buyers struggle with selecting the right deburring equipment for their specific needs. With a variety of options available, including different technologies and methods, it can be overwhelming to determine which solution will yield the best results for their unique production requirements. This confusion can lead to misinvestments in equipment that does not meet their operational needs, resulting in wasted resources and inadequate deburring outcomes.

The Solution: To effectively navigate the selection process, buyers should start by conducting a thorough analysis of their production environment and the types of materials they work with. Engaging with deburring equipment suppliers to discuss specific challenges can provide valuable insights into the most suitable technologies. Buyers should also consider equipment scalability to accommodate future production increases. Additionally, leveraging industry case studies or testimonials can help buyers understand how different equipment has performed in similar applications. Finally, requesting demonstrations or trials of deburring equipment can allow manufacturers to evaluate performance before making a significant investment, ensuring they choose the right solution for their operational needs.

Strategic Material Selection Guide for deburring equipment

What Are the Key Properties of Ferrous Metals in Deburring Applications?

Ferrous metals, such as steel and stainless steel, are widely used in various industries due to their strength and durability. These materials typically exhibit high temperature and pressure ratings, making them suitable for heavy-duty applications. Corrosion resistance is a significant property, especially in stainless steel, which is vital for industries like food processing and pharmaceuticals. However, ferrous metals can develop sharp burrs during machining processes, necessitating robust deburring solutions to ensure safety and functionality.

Illustrative image related to deburring equipment

Pros and Cons of Using Ferrous Metals

The advantages of ferrous metals include their high tensile strength and cost-effectiveness, making them a preferred choice for many manufacturers. However, they can be prone to rust and corrosion, particularly in humid environments, which may require additional protective coatings. The manufacturing complexity can also increase when working with harder grades of steel, necessitating specialized deburring equipment that can handle these tougher materials.

Impact on Application and Considerations for International Buyers

For international B2B buyers, particularly in regions like Africa and the Middle East, understanding local standards such as ASTM or DIN is crucial. Compliance with these standards ensures that the deburring equipment meets safety and quality requirements. Additionally, buyers should consider the availability of ferrous metals in their local markets and the associated costs.

How Do Non-Ferrous Metals Affect Deburring Equipment Selection?

Non-ferrous metals, including aluminum, brass, and titanium, present unique challenges in deburring due to their varying hardness and ductility. Aluminum, for instance, is softer and easier to deburr, while titanium is much harder and requires more aggressive methods. The temperature and pressure ratings of these materials can vary significantly, influencing the choice of deburring equipment.

Illustrative image related to deburring equipment

Pros and Cons of Non-Ferrous Metals

The primary advantage of non-ferrous metals is their lightweight nature and resistance to corrosion, particularly in applications like aerospace and automotive. However, they can be more expensive than ferrous metals, and their machining processes may produce different types of burrs that require specialized deburring techniques. For example, aluminum burrs are often softer and can be removed using gentler methods, while titanium burrs may necessitate more robust solutions.

Impact on Application and Considerations for International Buyers

International buyers should be aware of the specific standards applicable to non-ferrous metals in their regions, such as JIS in Japan or EN standards in Europe. Understanding these regulations can help ensure compliance and quality assurance in the deburring process.

What Are the Key Properties of Sheet Metal in Deburring Processes?

Sheet metal, particularly steel sheet metal, is commonly used in construction and automotive industries. It typically exhibits good strength and formability, with varying thicknesses that can influence the deburring process. The primary concern with sheet metal is the formation of burrs during shearing or laser cutting, which can affect the final product’s fit and finish.

Pros and Cons of Using Sheet Metal

The advantages of sheet metal include its versatility and cost-effectiveness, especially for high-volume production runs. However, the manufacturing complexity can increase with thicker materials, necessitating more powerful deburring equipment. Additionally, burrs can lead to safety hazards and functional issues in the final product, emphasizing the need for effective deburring solutions.

Impact on Application and Considerations for International Buyers

For buyers in regions like South America and Europe, understanding the local manufacturing standards is essential to ensure the quality of sheet metal products. Compliance with standards such as ASTM A1008 for cold-rolled steel can enhance product reliability and safety.

Illustrative image related to deburring equipment

How Do Plastics Influence Deburring Equipment Choices?

Plastics, including those used in consumer goods and electronics, often require deburring to achieve a smooth finish. Commonly used plastics include ABS, polycarbonate, and nylon, each with unique properties affecting the deburring process. Plastics generally have lower temperature and pressure ratings compared to metals, which can influence the choice of deburring techniques.

Pros and Cons of Using Plastics

The primary advantage of plastics is their lightweight nature and resistance to corrosion, making them ideal for various applications. However, they can be more susceptible to damage during the deburring process, requiring careful handling and specialized equipment. The cost of plastics can vary, but they often present a more economical option for certain applications compared to metals.

Impact on Application and Considerations for International Buyers

International buyers must consider the specific standards related to plastics in their regions, such as ISO standards, to ensure compliance. Understanding local market preferences for plastic materials can also influence procurement decisions.

Summary Table of Material Selection for Deburring Equipment

| Material | Typical Use Case for deburring equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrous Metals | Automotive and construction parts | High strength and durability | Prone to rust and corrosion | Medium |

| Non-Ferrous Metals | Aerospace and medical devices | Lightweight and corrosion-resistant | Higher cost and machining complexity | High |

| Sheet Metal | Building construction and automotive | Versatile and cost-effective | Burrs can cause safety hazards | Medium |

| Plastics | Consumer goods and electronics | Lightweight and corrosion-resistant | Susceptible to damage during deburring | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for deburring equipment

Manufacturing deburring equipment involves a series of meticulous processes designed to ensure that the final product meets stringent quality standards. Understanding these processes and the quality assurance measures in place can empower B2B buyers to make informed decisions when sourcing deburring machines for their operations.

What Are the Main Stages in the Manufacturing Process of Deburring Equipment?

How Is Material Prepared for Deburring Equipment Manufacturing?

The manufacturing process begins with the selection and preparation of raw materials. Common materials include high-grade steel, aluminum, and specialized plastics, chosen for their durability and suitability for machining. Suppliers often conduct preliminary inspections to ensure that materials meet specified grades. This can include testing for tensile strength and surface finish, which are crucial for the longevity and performance of the equipment.

What Forming Techniques Are Used in Deburring Equipment Production?

Once the materials are prepared, the forming stage involves several techniques such as machining, welding, and forming. CNC (Computer Numerical Control) machining is prevalent, allowing for high precision in cutting and shaping components. This precision is critical as components must fit together seamlessly to function correctly. Other methods include laser cutting and water jet cutting, which are employed to achieve complex geometries while maintaining tight tolerances.

How Is Assembly Conducted in Deburring Equipment Manufacturing?

After the components are formed, the assembly process begins. This stage is crucial as it integrates all the individual parts into a cohesive unit. Skilled technicians perform this task, often using jigs and fixtures to ensure accuracy. Automated systems may assist in repetitive tasks, enhancing efficiency and consistency. During assembly, initial quality checks, including visual inspections and functional testing, are conducted to identify any discrepancies early in the production process.

What Finishing Techniques Are Commonly Used?

The finishing stage involves processes that enhance the aesthetic and functional properties of the deburring equipment. Techniques such as surface grinding, polishing, and coating are commonly used. These processes not only improve the visual appeal of the equipment but also contribute to its resistance to wear and corrosion. A final inspection is typically performed to ensure that all finishes meet the required specifications before the equipment is packaged for shipment.

What Quality Assurance Standards Are Relevant for Deburring Equipment?

How Do International Standards Like ISO 9001 Apply to Deburring Equipment?

Quality assurance in deburring equipment manufacturing is governed by international standards such as ISO 9001. This standard emphasizes a process-oriented approach to quality management, ensuring that manufacturers consistently meet customer and regulatory requirements. Adhering to ISO 9001 involves rigorous documentation and regular audits, which can be a selling point for B2B buyers looking for reliable suppliers.

What Industry-Specific Certifications Should Buyers Look For?

In addition to ISO certifications, industry-specific standards such as CE marking (for products sold in the European Economic Area) and API certification (for products used in the oil and gas industry) are crucial. These certifications demonstrate compliance with safety and performance regulations, which can be particularly relevant for buyers in regions with stringent regulatory environments.

What Are the Key Quality Control Checkpoints in Deburring Equipment Manufacturing?

What Are the Stages of Quality Control in Manufacturing?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should inquire about the supplier’s IQC procedures to confirm that materials are consistently of high quality.

-

In-Process Quality Control (IPQC): During manufacturing, various inspections are conducted to monitor critical parameters such as dimensions and tolerances. This ensures that any issues are identified and addressed promptly.

-

Final Quality Control (FQC): At the end of the manufacturing process, a comprehensive inspection is conducted. This may include functional testing, performance evaluations, and visual inspections to ensure the equipment meets all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

What Methods Can Buyers Use to Ensure Quality in Their Suppliers?

B2B buyers should adopt a proactive approach to verifying supplier quality control. Some methods include:

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing facility, review quality control procedures, and evaluate compliance with relevant standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including failure rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the equipment’s quality before shipment. This is particularly important for buyers in regions where they cannot easily visit suppliers.

What Are the Quality Control and Certification Nuances for International Buyers?

How Do Regional Regulations Affect Quality Control in Deburring Equipment?

For international buyers, understanding regional regulations is crucial. Different regions may have varying standards that affect the quality and certification of deburring equipment. For instance, buyers in Europe may require CE marking, while those in the Middle East may need to comply with specific local standards. It’s essential for buyers to communicate their quality requirements clearly to suppliers and ensure that they can meet the necessary certifications for their target markets.

Illustrative image related to deburring equipment

How Can Buyers Navigate the Complexity of International Sourcing?

Navigating the complexities of international sourcing can be challenging, especially when it comes to quality assurance. Buyers should consider establishing long-term relationships with reputable suppliers who have proven track records in quality management. Additionally, leveraging local representatives or agents can facilitate communication and ensure that quality standards are maintained throughout the supply chain.

In conclusion, understanding the manufacturing processes and quality assurance measures for deburring equipment is vital for B2B buyers. By focusing on these elements, companies can ensure they source high-quality equipment that meets their operational needs and regulatory requirements, ultimately leading to improved productivity and safety in their manufacturing processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘deburring equipment’

In the competitive landscape of manufacturing, sourcing the right deburring equipment is essential for ensuring product quality and operational efficiency. This guide provides a practical step-by-step checklist for B2B buyers seeking to procure deburring machines that meet their specific needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements based on the types of materials you will be processing and the production volumes you expect. Consider factors such as the size, shape, and complexity of the parts that require deburring. Understanding these parameters will help you narrow down the equipment options that align with your operational needs.

- Material Types: Identify whether you’ll be working with ferrous metals, non-ferrous metals, plastics, or wood, as different materials may require specialized deburring methods.

- Volume Requirements: Assess whether you need equipment for low-volume custom jobs or high-volume production runs, which will influence the type of machinery you should consider.

Step 2: Research Equipment Types

Familiarize yourself with the various types of deburring equipment available in the market. Each type offers distinct advantages depending on your application.

- Vibratory Machines: Ideal for small, complex parts, these machines use abrasive media to smooth edges efficiently.

- Thermal and Electrochemical Options: Consider these for intricate components where precision is critical, such as in aerospace or medical device manufacturing.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers to ensure they can meet your technical and service needs. Request company profiles, case studies, and references from buyers in similar industries or regions to validate their expertise.

- Supplier Experience: Look for suppliers with a proven track record in your industry.

- Customer Support: Assess the level of technical support and service the supplier offers post-purchase.

Step 4: Request Demonstrations and Samples

Arrange for product demonstrations and samples from potential suppliers to evaluate the effectiveness of the equipment. This hands-on experience can provide invaluable insights into the machine’s performance and ease of use.

- Test Runs: Conduct test runs with your materials if possible to ensure compatibility and effectiveness.

- User Feedback: Gather input from your production team on usability and operational efficiency.

Step 5: Verify Compliance and Certifications

Ensure that the deburring equipment complies with relevant industry standards and regulations. This is crucial for maintaining quality and safety in your manufacturing processes.

- Quality Certifications: Check for ISO certifications or other relevant quality assurance benchmarks.

- Safety Standards: Ensure the equipment adheres to safety regulations specific to your industry and region.

Step 6: Consider Total Cost of Ownership

When evaluating deburring equipment, assess the total cost of ownership beyond the initial purchase price. This includes maintenance, energy consumption, and potential downtime.

- Maintenance Costs: Inquire about the frequency and cost of maintenance services.

- Energy Efficiency: Look for energy-efficient models that can help reduce operational costs over time.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of the purchase, including pricing, delivery timelines, and warranty conditions.

- Flexible Terms: Seek flexible payment options or financing if needed.

- Warranty and Support: Ensure the warranty covers key components and that you have access to reliable customer support.

By following this checklist, B2B buyers can make informed decisions when sourcing deburring equipment, ensuring they select the best solutions for their manufacturing needs.

Comprehensive Cost and Pricing Analysis for deburring equipment Sourcing

What Are the Key Cost Components in Deburring Equipment Pricing?

When sourcing deburring equipment, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used significantly affect the overall cost. High-quality components, such as robust motors or durable abrasive materials, can drive prices higher but often result in better performance and longevity.

-

Labor: Labor costs include not only manufacturing labor but also skilled technicians involved in equipment assembly and testing. For suppliers in regions with higher labor costs, this will be reflected in the equipment price.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thus lowering the final product price.

-

Tooling: Specialized tooling may be required for specific deburring processes, contributing to the overall cost. Custom tooling can be particularly expensive, so it’s important to consider standard equipment that meets your needs.

-

Quality Control (QC): Ensuring that equipment meets safety and performance standards incurs costs. A rigorous QC process can enhance the equipment’s reliability and performance, justifying higher prices.

-

Logistics: Shipping and handling costs can vary significantly depending on the supplier’s location and the buyer’s destination. Import duties and taxes also play a crucial role, especially for international transactions.

-

Margin: Suppliers will add their profit margin to the cost of production, which can vary widely based on market conditions, competition, and perceived value of the equipment.

What Influences the Price of Deburring Equipment?

Several factors can influence the pricing of deburring equipment:

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger volumes can lead to discounts. Understanding the supplier’s MOQ is crucial for negotiating favorable pricing.

-

Specifications and Customization: Customized solutions tailored to specific applications often come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Material Quality and Certifications: Equipment made from high-grade materials or compliant with international standards (e.g., ISO certifications) may be priced higher, reflecting their enhanced durability and performance.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and reliable support services.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect shipping responsibilities and costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter total expenses significantly.

How Can Buyers Negotiate for Better Pricing on Deburring Equipment?

Effective negotiation strategies can lead to better pricing and terms. Here are some actionable tips:

-

Leverage Volume Purchases: If you anticipate ongoing needs, negotiate bulk purchasing agreements to secure lower prices.

-

Request Quotes from Multiple Suppliers: Gathering quotes allows for comparison and can serve as leverage in negotiations. Highlight competitive offers to encourage suppliers to adjust their pricing.

-

Discuss Total Cost of Ownership (TCO): Emphasize the long-term value rather than just the initial purchase price. Highlighting potential savings from lower maintenance costs or enhanced durability can justify a higher upfront investment.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and local market conditions in regions like Africa, South America, the Middle East, and Europe. These factors can significantly impact the total cost and should be factored into negotiations.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better terms and pricing over time. Loyalty can sometimes yield discounts or priority service.

Conclusion: Navigating the Costs of Deburring Equipment

Purchasing deburring equipment requires a comprehensive understanding of cost components and pricing influencers. By focusing on strategic negotiation and considering the total cost of ownership, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. While indicative prices can vary widely based on the discussed factors, thorough research and planning can lead to favorable outcomes in sourcing deburring equipment.

Illustrative image related to deburring equipment

Alternatives Analysis: Comparing deburring equipment With Other Solutions

Understanding Alternatives to Deburring Equipment

In the manufacturing landscape, achieving a smooth and safe finish on machined parts is critical. While deburring equipment is a well-established solution for removing burrs and imperfections, there are alternative methods that can also address these challenges. This section provides a comparative analysis of deburring equipment against two viable alternatives: manual deburring and chemical deburring. Each method offers unique advantages and disadvantages, making it essential for B2B buyers to carefully evaluate their options based on specific production needs.

| Comparison Aspect | Deburring Equipment | Manual Deburring | Chemical Deburring |

|---|---|---|---|

| Performance | High throughput and consistency | Variable, depends on skill | Effective for intricate parts |

| Cost | High initial investment, but low long-term operating costs | Low initial cost, high labor costs | Moderate cost, depends on chemicals used |

| Ease of Implementation | Requires training and setup | Minimal training required | Requires safety protocols and handling procedures |

| Maintenance | Regular maintenance needed | Minimal maintenance | Requires safe chemical storage |

| Best Use Case | High-volume production environments | Low-volume or custom work | Delicate parts with complex geometries |

Pros and Cons of Manual Deburring

Manual deburring involves using handheld tools, such as files, sanders, or scrapers, to remove burrs from parts. One of the primary advantages of this method is its low initial investment. It is easily accessible, requiring minimal training for operators. However, the performance can vary significantly based on the operator’s skill level, leading to inconsistent results. Manual deburring is best suited for low-volume production or custom work, where precision is paramount, but it can become labor-intensive and costly in terms of time for larger operations.

Pros and Cons of Chemical Deburring

Chemical deburring employs specific chemical solutions to dissolve burrs without damaging the part’s structure. This method is particularly advantageous for intricate components with hard-to-reach areas, as it can effectively clean complex geometries. However, it requires strict adherence to safety protocols, including proper handling and storage of chemicals, which can complicate implementation. The costs can also vary based on the chemicals used, making it essential for buyers to consider the long-term implications of chemical procurement and disposal. Chemical deburring is ideal for delicate parts, such as those found in the aerospace or medical sectors, where precision and surface integrity are critical.

Choosing the Right Solution for Your Needs

When deciding between deburring equipment and its alternatives, B2B buyers should assess their production volume, the complexity of the parts being processed, and the overall budget. Deburring equipment offers high performance and efficiency for large-scale operations, while manual and chemical methods may be more appropriate for niche applications or lower production volumes. By understanding the strengths and limitations of each approach, manufacturers can make informed decisions that align with their operational goals and quality standards.

Essential Technical Properties and Trade Terminology for deburring equipment

What Are the Key Technical Properties of Deburring Equipment?

Understanding the technical specifications of deburring equipment is essential for B2B buyers to make informed purchasing decisions. Here are some critical properties to consider:

Illustrative image related to deburring equipment

1. Material Grade

The material grade of deburring machines, often composed of high-strength steel or alloys, determines their durability and resistance to wear. Equipment made from high-grade materials can endure the rigors of continuous operation, reducing maintenance costs and downtime. For manufacturers in demanding industries, selecting machinery with superior material quality can enhance production efficiency and longevity.

2. Tolerance Levels

Tolerance levels indicate the precision with which a deburring machine can remove burrs and achieve surface smoothness. Measured in micrometers (µm), tighter tolerances are crucial in industries like aerospace and medical devices, where even minor imperfections can lead to product failure. Understanding the required tolerance levels helps buyers select equipment that meets stringent quality standards.

3. Processing Capacity

This property refers to the volume of parts a deburring machine can handle within a specified timeframe, usually measured in parts per hour (PPH). For businesses with high production demands, investing in equipment with a greater processing capacity ensures that manufacturing schedules are met without compromising quality. Evaluating processing capacity helps buyers align their equipment choices with operational requirements.

4. Automation Level

The level of automation in deburring equipment can significantly impact labor costs and production speed. Fully automated systems reduce the need for manual intervention, thereby minimizing human error and increasing consistency. Companies aiming for high efficiency and reduced labor costs should consider equipment that offers advanced automation features.

5. Versatility

Versatility refers to a machine’s ability to process various materials and part geometries. Equipment that can handle multiple materials—such as metals, plastics, and composites—offers manufacturers flexibility in production. This is particularly valuable for companies that work with diverse product lines or expect to adapt to changing market demands.

6. Energy Efficiency

Energy-efficient deburring machines consume less power while maintaining performance, resulting in lower operational costs. This property is increasingly important for manufacturers looking to reduce their environmental impact and comply with sustainability standards. Evaluating energy efficiency can lead to long-term savings and a stronger corporate responsibility profile.

What Are Common Trade Terms in Deburring Equipment Procurement?

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce equipment or components that are sold under another brand name. In the context of deburring equipment, understanding whether a supplier is an OEM can inform buyers about the quality and reliability of the machinery being offered.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it can affect inventory management and cash flow. Buyers should assess whether the MOQ aligns with their production needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. For deburring equipment, an RFQ helps buyers compare offerings from different manufacturers, ensuring they make cost-effective decisions that meet their technical requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help buyers understand shipping responsibilities, risk allocation, and cost implications when procuring deburring equipment from overseas suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the equipment. Understanding lead times is essential for production planning, especially in industries with tight deadlines. Buyers should inquire about lead times to ensure timely delivery aligns with their operational schedules.

Illustrative image related to deburring equipment

6. Warranty

A warranty is a promise from the manufacturer regarding the performance and reliability of the deburring equipment. Knowing the warranty terms can provide buyers with peace of mind regarding potential repairs or replacements, making it an essential factor in the decision-making process.

By understanding these technical properties and trade terms, B2B buyers can navigate the procurement of deburring equipment more effectively, ensuring they invest in solutions that align with their operational goals and industry standards.

Navigating Market Dynamics and Sourcing Trends in the deburring equipment Sector

What Are the Key Market Dynamics Influencing Deburring Equipment Sourcing?

The deburring equipment sector is currently experiencing significant growth driven by the increasing demand for precision-engineered components across various industries, including automotive, aerospace, and electronics. Key market dynamics include the rise of automation and Industry 4.0 technologies, which are enabling manufacturers to optimize their production processes and enhance efficiency. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced deburring solutions that not only improve product quality but also reduce operational costs.

Emerging trends include the adoption of smart deburring systems equipped with IoT capabilities that allow for real-time monitoring and predictive maintenance. This shift towards connected machinery is appealing to buyers looking to enhance productivity and minimize downtime. Additionally, the growing emphasis on customization is driving manufacturers to invest in versatile deburring solutions that can handle a variety of materials and part geometries.

In regions like Saudi Arabia and Nigeria, local industries are rapidly evolving, necessitating reliable deburring equipment that meets international quality standards. Buyers in these markets should focus on suppliers that provide comprehensive support, including training and after-sales service, to ensure seamless integration of equipment into existing production lines.

How Can Sustainability and Ethical Sourcing Influence Deburring Equipment Procurement?

Sustainability has become a critical consideration in the procurement of deburring equipment. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek greener alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices, such as using energy-efficient machinery and recyclable materials in their equipment.

Ethical sourcing is also gaining traction, with buyers looking for manufacturers that maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical standards.

Incorporating ‘green’ certifications into procurement strategies not only enhances corporate responsibility but can also improve brand reputation and customer loyalty. Buyers should consider engaging with suppliers who are innovating in the area of eco-friendly deburring solutions, including those utilizing water-based or biodegradable abrasives, which reduce environmental impact without compromising performance.

What Is the Historical Context of Deburring Equipment Development?

The evolution of deburring equipment can be traced back to the early days of industrial manufacturing, where manual deburring methods such as filing and sanding were common. As manufacturing processes became more complex, the need for more efficient and consistent deburring solutions emerged, leading to the development of mechanized systems in the mid-20th century.

The introduction of vibratory and tumbling machines revolutionized the industry, allowing for batch processing of parts and significant reductions in labor costs. With advancements in technology, modern deburring equipment now incorporates automation and smart features, reflecting the industry’s shift towards efficiency and precision. This historical context is crucial for B2B buyers as it highlights the continual innovation within the sector, ensuring that they invest in equipment that meets contemporary manufacturing demands while also being adaptable for future advancements.

By understanding these dynamics, sustainability considerations, and historical developments, B2B buyers can make informed decisions that align with their operational goals and market conditions.

Frequently Asked Questions (FAQs) for B2B Buyers of deburring equipment

-

How do I solve burr formation issues in my manufacturing process?

To address burr formation, start by analyzing the machining processes contributing to burr generation. Consider optimizing cutting speeds, tool geometry, and material selection to minimize burrs. Implementing deburring equipment tailored to your specific production requirements can also help. For instance, using vibratory deburring machines for small parts or brush deburring systems for flat surfaces can effectively eliminate burrs. Regular maintenance of tools and machinery will further enhance precision and reduce burr occurrences. -

What is the best deburring equipment for metal parts?

The best deburring equipment for metal parts often depends on the part’s size, shape, and production volume. For smaller, intricate components, vibratory deburring machines are ideal as they provide gentle yet effective finishing. For larger, heavier parts, tumbling barrels or brush deburring machines may be more suitable. Evaluate your specific needs, including production speed and desired surface finish, to select the most effective deburring solution. -

How can I ensure the quality of deburring equipment from international suppliers?

To ensure quality when sourcing deburring equipment internationally, conduct thorough due diligence on potential suppliers. Verify certifications, such as ISO 9001, which indicate adherence to quality management standards. Request samples or case studies showcasing their equipment’s performance. Additionally, establishing clear communication regarding your specifications and expectations can help align quality standards. Engaging third-party inspection services can also mitigate risks before finalizing your purchase. -

What are the minimum order quantities (MOQs) for deburring equipment?

Minimum order quantities for deburring equipment can vary significantly by supplier and equipment type. Some manufacturers may offer flexible MOQs for small businesses or first-time buyers, while others may have stricter requirements. It’s advisable to discuss your needs directly with the supplier to negotiate terms that suit your purchasing capabilities. Consider placing a larger initial order to benefit from volume discounts, especially if you anticipate ongoing demand. -

What payment terms should I expect when buying deburring equipment?

Payment terms for deburring equipment can differ based on the supplier’s policies and your relationship with them. Common terms include upfront payments, deposits, or net terms ranging from 30 to 90 days. International buyers should be cautious of exchange rates and potential transaction fees. It’s wise to negotiate payment terms that provide sufficient cash flow while ensuring the supplier’s confidence in fulfilling the order. Always review the contract thoroughly before proceeding. -

What logistics considerations should I keep in mind when importing deburring equipment?

When importing deburring equipment, consider logistics factors such as shipping methods, customs duties, and lead times. Collaborate with logistics experts to select the most cost-effective and timely shipping options. Be aware of import regulations in your country, as they can affect delivery times and costs. Additionally, ensure that the supplier provides necessary documentation, such as certificates of origin and compliance, to facilitate a smooth customs process. -

Can deburring equipment be customized to meet specific production needs?

Yes, many suppliers offer customization options for deburring equipment to align with your specific production requirements. Customizations may include adjustments in machine size, tooling, or automation features to enhance efficiency. Discuss your needs with the supplier to explore available options. Custom solutions can lead to improved processing times and quality outcomes, making them a worthwhile investment for specialized applications. -

What are the common maintenance practices for deburring equipment?

Regular maintenance of deburring equipment is essential for optimal performance and longevity. Common practices include routine inspections to check for wear and tear, cleaning of components to prevent dust and debris buildup, and lubrication of moving parts to ensure smooth operation. Establishing a maintenance schedule based on the equipment’s usage can help identify potential issues before they escalate. Training staff on proper operation and care will also contribute to the equipment’s efficiency and lifespan.

Top 8 Deburring Equipment Manufacturers & Suppliers List

1. Deburring Machinery – Deburring Equipment Solutions

Domain: deburringmachinery.com

Registered: 2000 (25 years)

Introduction: Deburring Machinery offers a variety of deburring equipment and solutions, including:

– Deburring Machines: Equipment designed to remove burrs from machined parts.

– Deburring Media: Materials used in the deburring process, such as ceramic or plastic pellets.

– Deburring Tumblers: Machines that utilize tumbling action for deburring and polishing.

– Tumbler Polishing Equipment: Equipment specifical…

2. Timesavers – Industrial Deburring Machines

Domain: timesaversinc.com

Registered: 1996 (29 years)

Introduction: Timesavers offers a range of industrial deburring machines designed to remove imperfections from machined metal products, ensuring a smooth, high-quality finish. Key product series include:

– **11 Series**: Wet operation with integrated product dryer and paper belt filter, 9″ wide conveyor belt.

– **12 Series**: Dry deburring machine, a standard in the metal industry for over 40 years, used for …

3. CM Topline – High Energy Centrifugal Barrel Tumblers

Domain: cmtopline.com

Registered: 2017 (8 years)

Introduction: {“products”:[{“name”:”CB-100 High Energy Centrifugal Barrel Tumbler”,”price”:”$42,300.00 USD”},{“name”:”CB-60 High Energy Centrifugal Barrel Tumbler”,”price”:”$33,500.00 USD”},{“name”:”CB-30 High Energy Centrifugal Barrel Tumbler”,”price”:”$24,400.00 USD”},{“name”:”Mr. Deburr DB600 (6.5 Cubic Foot)”,”price”:”$7,355.00 USD”},{“name”:”Mr. Deburr QDB3 (Portable, Quiet 3 Cubic Foot)”,”price”:”From $5,…

4. ARKU – Deburring Machines

Domain: arku.com

Registered: 1999 (26 years)

Introduction: ARKU offers a range of deburring machines designed for efficiently processing the edges of metal parts, sheets, and plates. Key features include:

– Automated deburring machines tailored for various applications, including thin sheet metal and heavy plates.

– Solutions for deburring laser cut and punched parts using the Edgebreaker® model, suitable for a broad range of materials and dimensions.

…

5. Advanced Deburring – Metal Finishing Solutions

Domain: advanceddeburring.com

Registered: 1999 (26 years)

Introduction: Advanced Deburring & Finishing offers a comprehensive range of products and systems for metal finishing, including: 1. Precision Parts Cleaning and Washing: – Cabinet Spray Washers – Continuous Flow Washing Systems – Heavy Duty Washers – Immersion Parts Washers – Solvent Cleaning Systems 2. Surface Finishing and Refinement: – Round Bowl Vibratory Machines – Tub-Style Deburring Machines – Vibratory…

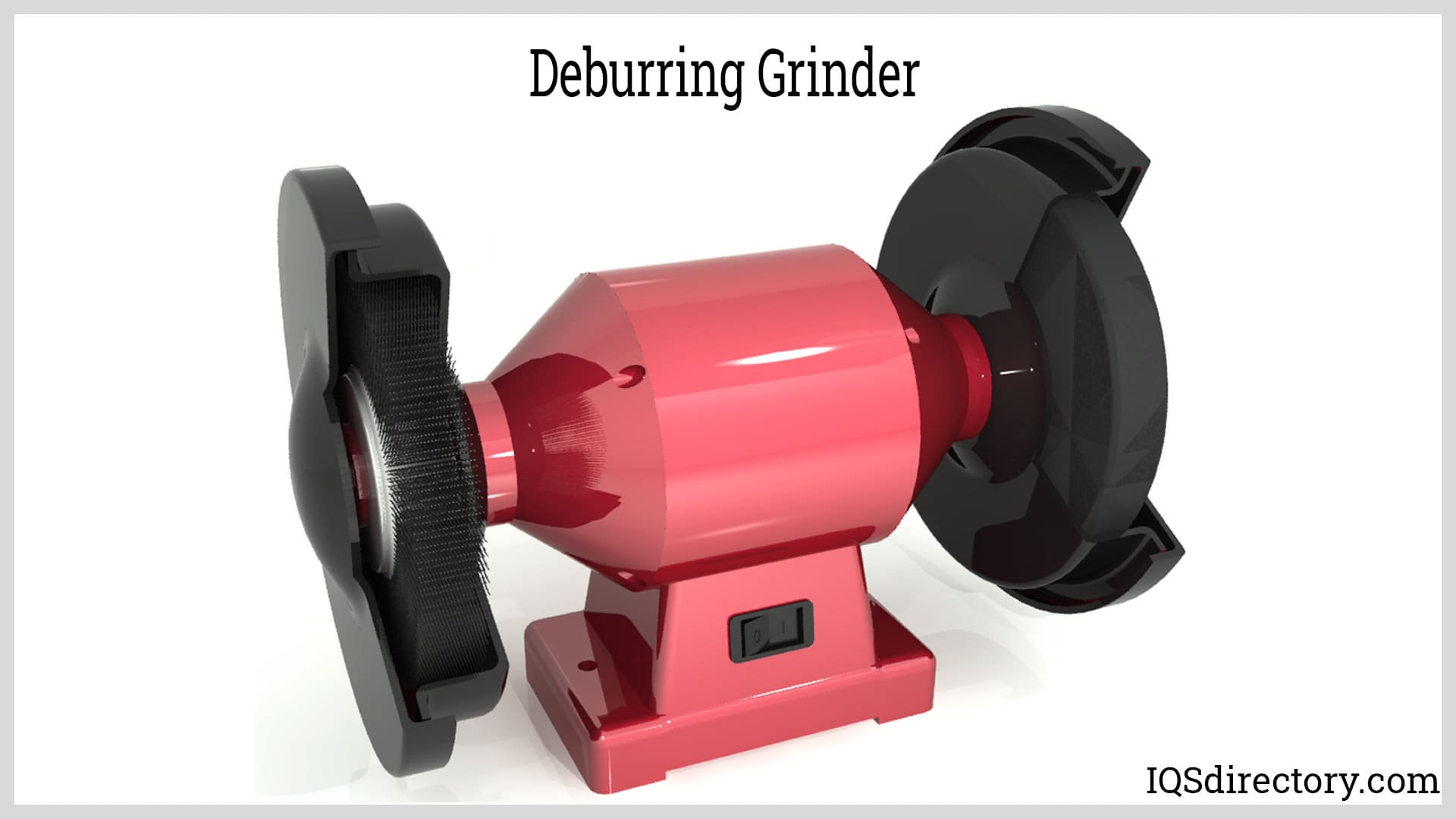

6. IQS Directory – Deburring Equipment

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Deburring equipment is essential for removing raised edges and excess material (burrs) from machined parts. It employs various techniques including mechanical, electrochemical, and thermal methods. Key types of deburring processes include automated mechanical deburring machines, abrasive flow deburring, thermal energy method (TEM), vibratory finishing, electrochemical deburring (ECD), chemical etc…

7. Trick Tools – Deburring Machines

Domain: trick-tools.com

Registered: 2001 (24 years)

Introduction: This company, Trick Tools – Deburring Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. KBC – Pneumatic Hand Chamfer & Deburr Tool

Domain: kbctools.com

Registered: 1998 (27 years)

Introduction: [{‘name’: ‘KBC PNEUMATIC HAND CHAMFER & DEBURR TOOL’, ‘sku’: ‘1-829-1305’, ‘brand’: ‘KBC’, ‘price’: ‘$109.99’, ‘stock’: ’11 In Stock’, ‘uom’: ‘EA’}, {‘name’: ‘KBC CHAMFERING & DEBURRING MACHINE’, ‘sku’: ‘1-548-100’, ‘brand’: ‘KBC’, ‘price’: ‘$1,040.09’, ‘stock’: ‘5 In Stock’, ‘uom’: ‘EA’}, {‘name’: ‘REPLACEMENT CUTTER FOR KBC CHAMFER’, ‘sku’: ‘1-548-105’, ‘brand’: ‘KBC’, ‘price’: ‘$285.52’, ‘stock…

Strategic Sourcing Conclusion and Outlook for deburring equipment

In conclusion, strategic sourcing of deburring equipment is essential for optimizing manufacturing processes and ensuring product quality across various industries. By understanding the unique requirements of different materials and production volumes, businesses can select the most suitable deburring solutions that enhance efficiency, reduce labor costs, and improve safety. Moreover, investing in advanced deburring technologies can lead to significant long-term benefits, including increased durability and aesthetic appeal of finished products.

International B2B buyers from Africa, South America, the Middle East, and Europe should prioritize collaboration with reputable suppliers who can provide tailored solutions for their specific needs. As the demand for precision and quality continues to rise, the role of effective deburring processes will only become more critical in maintaining competitive advantage.

Embrace the opportunity to elevate your manufacturing capabilities by exploring innovative deburring equipment options. Engage with suppliers to discover solutions that not only meet your operational requirements but also contribute to sustainability and cost-effectiveness. The future of your manufacturing success begins with strategic sourcing today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to deburring equipment

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.