Caster 4: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for caster 4

In today’s competitive landscape, sourcing the right 4-inch casters presents a significant challenge for international B2B buyers. With diverse applications ranging from industrial carts to medical equipment, understanding the unique needs of your business is crucial. This guide aims to equip you with the knowledge necessary to navigate the complexities of the global caster market, focusing on essential aspects such as types of casters, their applications, supplier vetting processes, and pricing strategies.

As you explore this comprehensive resource, you will discover the various options available, including swivel and rigid casters, as well as those with integrated braking systems designed for specific environments. Each section is tailored to help you make informed decisions that can enhance operational efficiency and safety.

Whether you are based in Africa, South America, the Middle East, or Europe—countries like Vietnam and Germany—you will find valuable insights that address regional requirements and market trends. By leveraging the information in this guide, you can streamline your purchasing process, ensuring that you select the right casters that align with your operational needs while optimizing cost-effectiveness. Empower your business today by mastering the art of caster selection and procurement in the global marketplace.

Understanding caster 4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swivel Casters | Can rotate 360 degrees for maneuverability | Industrial carts, medical equipment, furniture | Pros: High maneuverability; suitable for tight spaces. Cons: May require more maintenance due to moving parts. |

| Rigid Casters | Fixed direction; only moves forward or backward | Heavy-duty carts, assembly lines, pallet jacks | Pros: Simple design; durable and stable. Cons: Limited maneuverability; may require more space for turns. |

| Locking Casters | Feature a brake to prevent movement | Warehousing, hospital furniture, mobile equipment | Pros: Enhanced safety; prevents unintended movement. Cons: Can add complexity to operation; brakes may wear over time. |

| Dual-Wheel Casters | Two wheels per caster for better weight distribution | Heavy machinery, large carts, and equipment | Pros: Improved stability; reduces floor damage. Cons: Typically heavier; may not fit in all applications. |

| Specialty Casters | Custom designed for specific applications | Medical carts, cleanroom environments, AGVs | Pros: Tailored solutions for unique needs; often high performance. Cons: Higher cost; longer lead times for production. |

What Are the Key Characteristics of Swivel Casters?

Swivel casters are designed to rotate 360 degrees, allowing for easy maneuverability in tight spaces. They are ideal for applications requiring frequent direction changes, such as in hospitals for medical equipment or in warehouses for industrial carts. When purchasing, consider the wheel material, as it affects durability and floor protection. Additionally, ensure that the load capacity meets your operational needs.

Why Choose Rigid Casters for Your Operations?

Rigid casters are fixed in one direction, making them suitable for straight-line movement. They excel in heavy-duty applications, such as on assembly lines or pallet jacks, where stability is crucial. Buyers should focus on the load capacity and material, ensuring they select casters that can withstand the intended use. Rigid casters are generally more durable but require more space for turning.

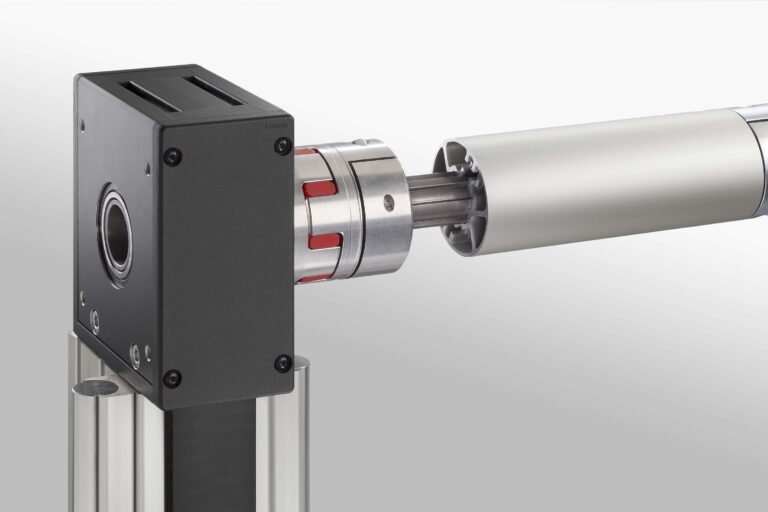

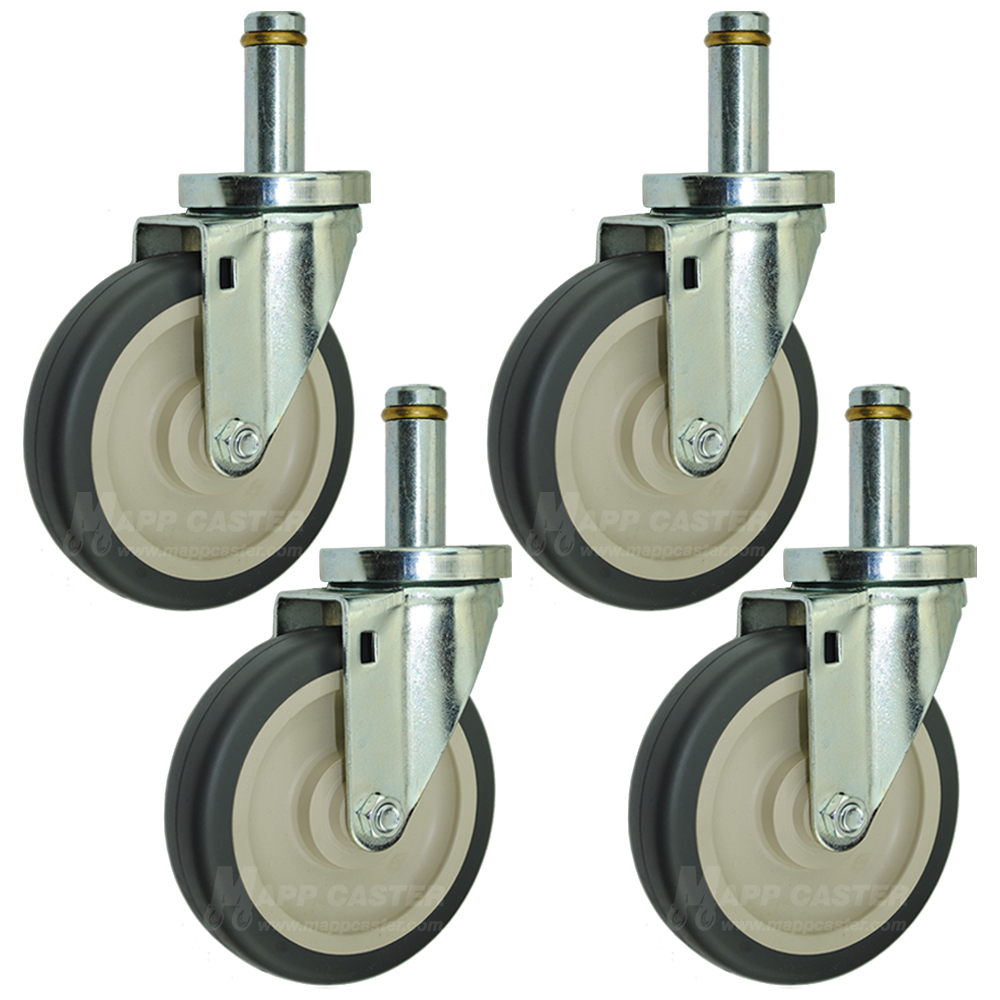

Illustrative image related to caster 4

How Do Locking Casters Enhance Safety?

Locking casters incorporate a braking mechanism to prevent unwanted movement, making them an excellent choice for environments where safety is paramount, such as in hospitals or warehouses. When selecting locking casters, consider the ease of use of the locking mechanism and the durability of the brake system. While they enhance safety, locking casters may complicate mobility and require regular maintenance.

What Are the Advantages of Dual-Wheel Casters?

Dual-wheel casters feature two wheels per caster, distributing weight more evenly and enhancing stability. They are particularly beneficial for heavy machinery and large carts, as they minimize floor damage and improve load handling. Buyers should assess the wheel material and design to ensure compatibility with their specific applications. While they provide stability, dual-wheel casters can be heavier and may not fit all equipment types.

When Should You Consider Specialty Casters?

Specialty casters are designed for specific applications, such as cleanrooms or automated guided vehicles (AGVs). They often feature unique materials and designs to meet particular performance standards. When considering specialty casters, evaluate the specific requirements of your application, including load capacity, environmental conditions, and any necessary certifications. While they can be more expensive, their tailored solutions often justify the investment in terms of efficiency and effectiveness.

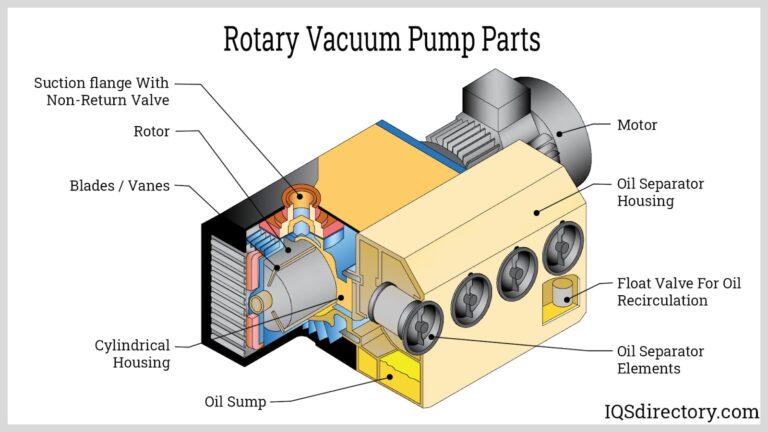

Illustrative image related to caster 4

Key Industrial Applications of caster 4

| Industry/Sector | Specific Application of caster 4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Carts and Equipment | Enhances mobility and efficiency in production lines | Load capacity, durability, and resistance to wear and tear |

| Healthcare | Hospital Beds and IV Carts | Improves patient mobility and care delivery | Sterilization capability, noise reduction, and ease of maneuvering |

| Warehousing | Pallet Trucks and Utility Carts | Facilitates quick and safe material handling | Wheel material, load capacity, and compatibility with existing systems |

| Retail | Display Stands and Shopping Carts | Increases customer engagement and ease of movement | Aesthetic design, braking options, and maneuverability |

| Food Service | Mobile Food Carts and Equipment | Streamlines service delivery and operational flow | Hygiene standards, wheel material for easy cleaning, and weight capacity |

How is ‘caster 4’ utilized in the manufacturing sector?

In the manufacturing industry, 4-inch casters are commonly employed in industrial carts and equipment, allowing for seamless movement of materials and products along production lines. These casters enhance operational efficiency by reducing manual labor and streamlining workflows. Buyers in this sector must consider load capacity and durability, as casters must withstand heavy loads and rigorous use. Furthermore, sourcing casters made from high-quality materials ensures longevity and reliability, which are crucial for maintaining productivity.

What role does ‘caster 4’ play in healthcare applications?

In healthcare settings, 4-inch casters are essential for hospital beds and IV carts, facilitating patient mobility and care delivery. These casters often feature noise-reduction capabilities and materials that are easy to clean, contributing to a sterile environment. For international buyers, particularly in regions with stringent health regulations, it is vital to select casters that meet hygiene standards and offer smooth maneuverability. The right choice of casters can significantly improve patient care and operational efficiency within healthcare facilities.

How do ‘caster 4’ solutions improve warehousing operations?

In warehousing, 4-inch casters are integral to pallet trucks and utility carts, enabling efficient material handling and transportation. Their design allows for easy navigation in tight spaces, which is essential for maximizing warehouse layout. Buyers should prioritize wheel material and load capacity when sourcing these casters to ensure they can handle the demands of heavy inventory. Additionally, compatibility with existing systems is crucial to avoid costly modifications and ensure a seamless integration into operations.

Why are ‘caster 4’ wheels valuable in retail environments?

Retail environments benefit from 4-inch casters through their use in display stands and shopping carts, enhancing customer engagement and ease of movement. These casters are designed to be aesthetically pleasing while providing functionality, with options for integrated brakes to ensure stability. When sourcing for retail applications, businesses should consider the design, maneuverability, and braking options of the casters. This attention to detail can significantly improve the shopping experience and operational efficiency.

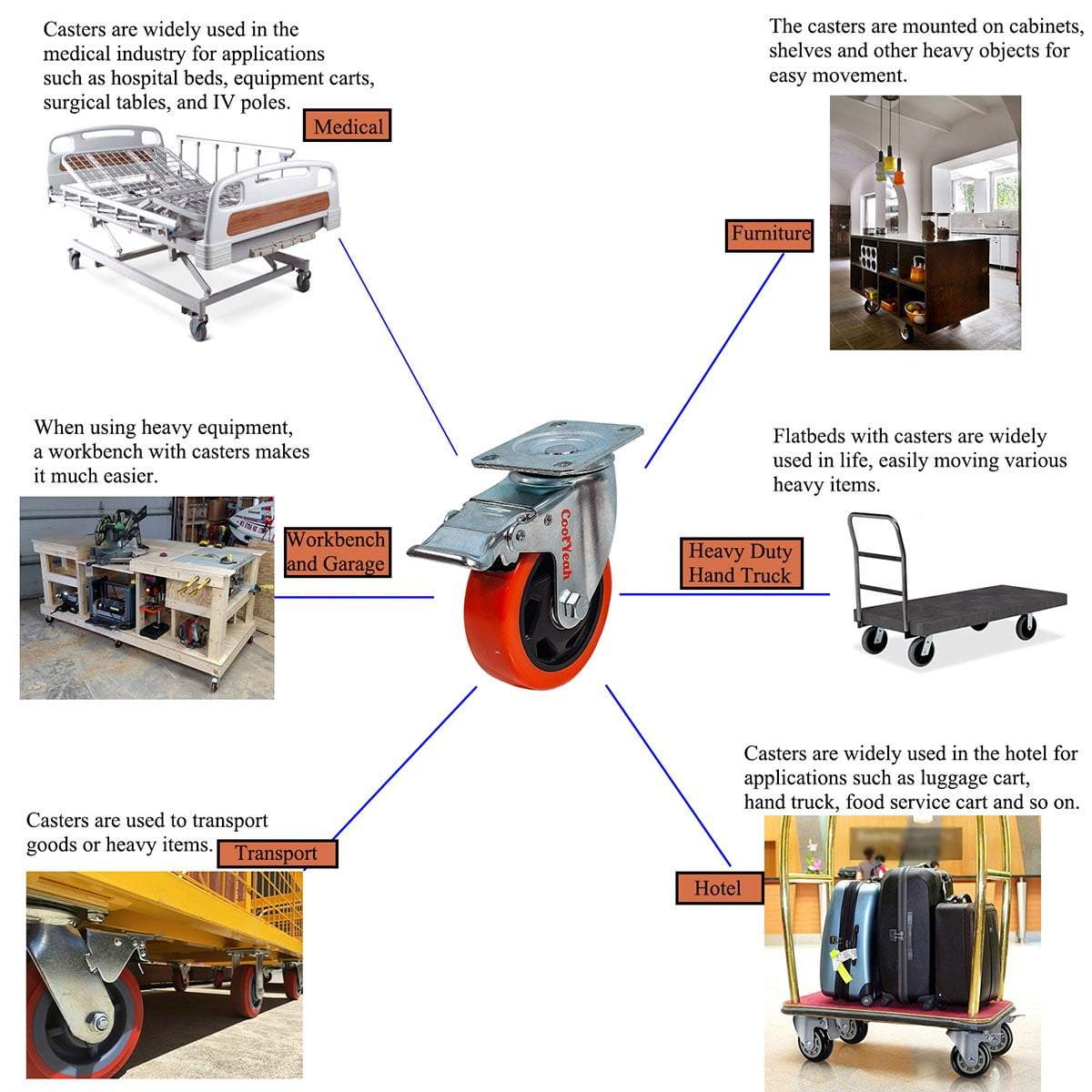

Illustrative image related to caster 4

How does ‘caster 4’ enhance food service operations?

In the food service industry, 4-inch casters are utilized in mobile food carts and equipment, streamlining service delivery and improving operational flow. These casters must comply with hygiene standards, making it essential for buyers to select options that are easy to clean and maintain. Additionally, the weight capacity of the casters is a critical consideration, as food service equipment can be heavy when fully loaded. By choosing the right casters, businesses can ensure smooth operations and a positive customer experience.

3 Common User Pain Points for ‘caster 4’ & Their Solutions

Scenario 1: Choosing the Right Caster for Heavy Loads

The Problem: B2B buyers often struggle with selecting the appropriate caster that can support the specific weight requirements of their equipment or products. For instance, in manufacturing environments, a buyer might need to move heavy machinery or materials using 4-inch casters but is uncertain about the weight capacity and durability of the options available. This can lead to inadequate performance, potential caster failure, and safety hazards, ultimately disrupting operations and incurring additional costs.

The Solution: To mitigate this issue, buyers should start by accurately assessing the weight of the loads they intend to move. It’s crucial to choose 4-inch casters with a load capacity exceeding the total weight of the items they will support. For example, if a cart carrying machinery weighs 400 pounds, selecting casters rated for at least 500 pounds each will ensure a safety buffer. Additionally, consider the material of the caster wheel; polyurethane wheels are often preferred for their durability and low rolling resistance. Buyers can consult manufacturer specifications for load ratings and materials, and request samples to test performance in their specific environment before making a bulk purchase.

Scenario 2: Navigating Different Caster Types and Features

The Problem: Another common pain point for buyers is understanding the different types of casters (swivel vs. rigid) and their features, which can be overwhelming. A logistics manager in a warehouse may need to outfit a fleet of carts but is confused about which caster type will provide the best maneuverability and stability, especially in tight spaces or on uneven surfaces. This indecision can lead to delays in procurement and inefficiencies in operations.

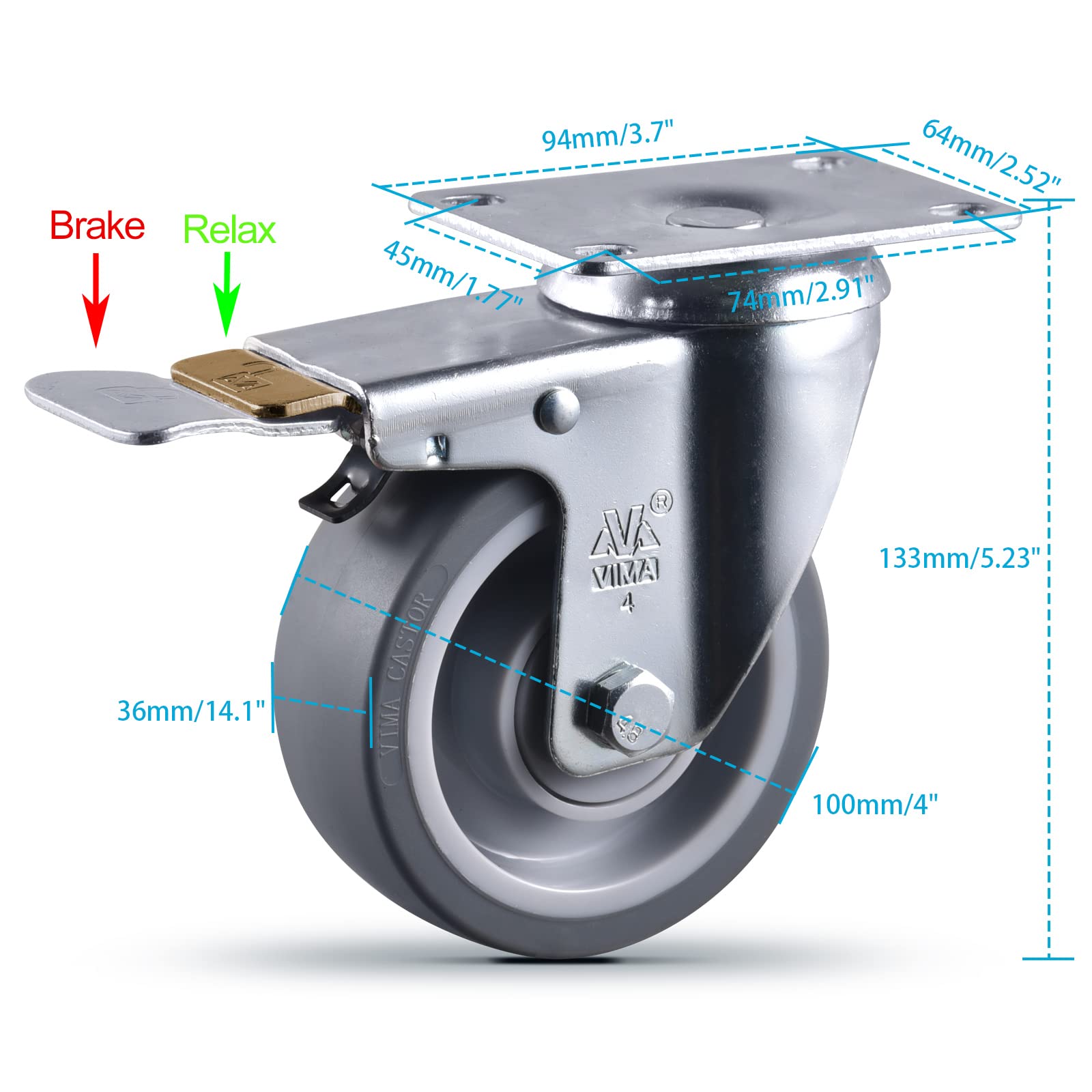

Illustrative image related to caster 4

The Solution: Buyers should begin by defining the intended use of the casters. For tight spaces, swivel casters are typically advantageous due to their ability to pivot, allowing for easy direction changes. Conversely, rigid casters provide stability when moving in a straight line. A practical approach is to use a combination of both: outfitting carts with swivel casters at the front for maneuverability and rigid casters at the back for stability. Furthermore, features such as locking mechanisms can enhance safety when loading or unloading. Buyers should also explore options that reduce noise and debris retention, especially for applications in medical or cleanroom environments. By mapping out their specific needs and consulting with suppliers on tailored solutions, buyers can make informed decisions.

Scenario 3: Ensuring Easy Installation and Compatibility

The Problem: Buyers frequently encounter compatibility issues when trying to replace or upgrade existing casters on their equipment. A company that operates a variety of carts may find that different models use various mounting styles, leading to confusion and installation delays. This can become a logistical nightmare, causing disruptions in workflow and increased labor costs due to downtime.

The Solution: To avoid installation issues, buyers should first document the mounting styles and sizes of their existing casters. They can then use this information to filter products from suppliers, ensuring compatibility before purchasing. Many manufacturers provide detailed specifications, including mounting plate dimensions and stem sizes, which are essential for matching new casters to existing setups. Additionally, buyers should seek casters that come with standard mounting options for easy integration. Some suppliers also offer installation guides or customer support to assist with the transition. By proactively addressing compatibility and installation concerns, companies can streamline their operations and reduce the risk of downtime due to caster changes.

Strategic Material Selection Guide for caster 4

What Are the Key Materials Used in Caster 4 Manufacturing?

When selecting casters, the choice of material significantly influences performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of 4-inch casters: polyurethane, rubber, steel, and nylon. Each material has distinct properties, advantages, and limitations that B2B buyers should consider.

How Does Polyurethane Impact Caster Performance?

Polyurethane is a popular choice for caster wheels due to its excellent balance of durability and performance. It offers a high load-bearing capacity and is resistant to abrasion, making it ideal for heavy-duty applications. Polyurethane wheels also provide a smooth ride and are less likely to mark floors compared to other materials.

Illustrative image related to caster 4

Pros: Polyurethane is highly durable, resistant to wear, and has good shock-absorbing properties. It performs well across a wide temperature range and is compatible with various surfaces, making it suitable for both indoor and outdoor applications.

Cons: The initial cost of polyurethane casters can be higher than rubber options. Additionally, they may not perform as well in extreme temperatures compared to specialized materials.

Impact on Application: Polyurethane is compatible with a variety of media, including chemicals and oils, making it suitable for applications in warehouses, manufacturing plants, and healthcare settings.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM and DIN, especially in industries like food processing and pharmaceuticals where hygiene is critical.

What Are the Benefits of Rubber Casters?

Rubber casters are known for their excellent grip and shock absorption, making them suitable for environments where noise reduction is a priority. They are often used in applications involving delicate surfaces or where equipment mobility is frequent.

Pros: Rubber is generally less expensive than polyurethane and provides good traction on various surfaces. It can also withstand moderate impacts without damage.

Cons: While rubber offers decent durability, it is prone to wear and tear over time, especially in high-load situations. It may also degrade when exposed to certain chemicals.

Illustrative image related to caster 4

Impact on Application: Rubber casters excel in environments where noise reduction is essential, such as hospitals, schools, and offices. However, they may not be the best choice for heavy industrial applications.

Considerations for International Buyers: Buyers should be aware of local regulations regarding material safety, particularly in regions with stringent environmental laws.

How Does Steel Enhance Caster Durability?

Steel casters are known for their strength and load-bearing capabilities, making them ideal for heavy-duty applications. They are often used in industrial settings where high durability is paramount.

Pros: Steel casters can handle significant weight and are resistant to deformation. They also offer excellent corrosion resistance when treated with protective coatings.

Cons: Steel is heavier than other materials, which can affect mobility. Additionally, steel casters can be more expensive to manufacture and may require additional maintenance to prevent rust.

Illustrative image related to caster 4

Impact on Application: Steel casters are suitable for environments that require heavy lifting, such as factories and warehouses. They are also used in outdoor applications when corrosion resistance is a priority.

Considerations for International Buyers: Compliance with industry standards such as JIS and ASTM is crucial, especially for buyers in Europe and Asia, where regulations may dictate material specifications for safety.

What Role Does Nylon Play in Caster Selection?

Nylon casters are lightweight and offer excellent resistance to chemicals and moisture, making them suitable for a variety of applications, including food processing and medical equipment.

Pros: Nylon is resistant to corrosion and has a low coefficient of friction, which allows for smooth movement. It is also lightweight, reducing the overall weight of the equipment.

Cons: Nylon casters may not be as durable under heavy loads compared to steel or polyurethane options. They can also be prone to wear when used on rough surfaces.

Impact on Application: Nylon is ideal for environments where chemical exposure is a concern, such as laboratories and food processing plants.

Considerations for International Buyers: Buyers should ensure that nylon casters meet local safety and quality standards, particularly in industries with stringent regulatory requirements.

Summary Table of Material Selection for Caster 4

| Material | Typical Use Case for caster 4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Heavy-duty applications in warehouses | Excellent durability and shock absorption | Higher initial cost | Medium |

| Rubber | Office and healthcare environments | Good traction and noise reduction | Prone to wear in high-load situations | Low |

| Steel | Industrial settings requiring heavy lifting | High load-bearing capacity | Heavier and requires maintenance | High |

| Nylon | Chemical and moisture-sensitive environments | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

This guide provides a comprehensive overview of the key materials used in 4-inch caster manufacturing, helping B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for caster 4

What Are the Main Stages of Manufacturing Processes for Caster 4?

The manufacturing process of 4-inch casters involves several critical stages, each designed to ensure the final product meets the specific performance and durability standards required by various industries. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to caster 4

Material Preparation: What Materials Are Used?

The selection of materials is pivotal in caster production. Common materials include high-quality steel for the frame and wheel components, as well as durable polymers like polyurethane for the wheel tread. These materials are chosen for their strength, wear resistance, and ability to withstand various loads and environmental conditions.

During the preparation phase, raw materials are sourced from reputable suppliers and undergo initial inspections to confirm they meet specified criteria. This ensures that only top-tier materials are used, which directly impacts the caster’s performance and longevity.

How Are Casters Formed?

The forming stage typically involves several techniques, including stamping, machining, and molding. For steel components, stamping is a common method, where flat sheets are cut and shaped into the desired forms using dies. Machining may also be employed for precision parts that require tight tolerances.

For the wheel assembly, molding techniques are used for polymer materials, where the polyurethane is injected into molds to create the wheel tread. This process ensures uniformity in the wheel’s shape and density, which is essential for performance.

Illustrative image related to caster 4

What Happens During the Assembly of Caster 4?

Once the individual components are formed, they move to the assembly stage. This involves the integration of wheels, brackets, and any braking mechanisms. Skilled workers or automated systems typically perform this assembly, ensuring that each caster is correctly configured for its intended use.

During assembly, quality checks are often performed to ensure that all components fit together seamlessly and function as expected. This may involve testing swivel mechanisms and ensuring that brake systems engage properly.

How Is the Finishing Process Conducted?

The finishing stage involves several treatments to enhance durability and aesthetics. Common practices include powder coating, galvanizing, or applying a zinc plating. These processes not only improve the visual appeal of the casters but also provide corrosion resistance, which is particularly important for applications in humid or harsh environments.

Illustrative image related to caster 4

After finishing, casters may undergo a final inspection to ensure the quality of the finish meets industry standards. This is crucial for maintaining the product’s integrity over its lifespan.

What Quality Control Standards Are Relevant for Caster 4?

Quality assurance is a vital component of the manufacturing process. International standards such as ISO 9001 are commonly adopted by manufacturers to ensure that their processes meet global quality management criteria. ISO 9001 focuses on various aspects, including process control, documentation, and continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with European safety standards, or API standards for specific industrial applications, may also be relevant. These certifications provide assurance to B2B buyers that the products adhere to recognized safety and quality benchmarks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in caster manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This is the first stage of quality assurance, where incoming materials are inspected for compliance with specifications. This ensures that only suitable materials are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed at different stages to monitor the quality of the components being produced. This may include dimensional checks, material testing, and functional assessments of moving parts.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection is conducted to ensure that the finished casters meet all design specifications and quality standards. This includes testing the load-bearing capacity and operational functionality.

What Common Testing Methods Are Employed?

Manufacturers utilize various testing methods to ensure quality, including:

- Load Testing: Casters are subjected to loads exceeding their rated capacity to evaluate performance and structural integrity.

- Durability Testing: Caster wheels may be rolled over various surfaces to assess wear and tear over time.

- Environmental Testing: This involves exposing casters to extreme conditions, such as humidity or temperature variations, to evaluate their resistance to environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps:

-

Request Audits and Certifications: Buyers should request documentation of ISO certifications or other relevant quality assurance certifications. This provides insight into the manufacturer’s commitment to quality.

-

Review Quality Control Reports: Suppliers should be willing to share quality control reports that detail inspection results, testing methodologies, and any corrective actions taken.

-

Engage Third-Party Inspectors: For added assurance, buyers may consider employing third-party inspection services to evaluate the manufacturing processes and final products.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various nuances when it comes to quality control. This includes understanding the regulatory requirements in their respective countries, which may differ significantly. For example, buyers in the European market may need to prioritize CE compliance, while those in the Middle East might focus on local standards.

Furthermore, language barriers and differences in business practices can complicate quality assurance processes. Therefore, establishing clear communication channels and expectations with suppliers is essential to ensure that quality standards are consistently met throughout the manufacturing process.

Conclusion: Ensuring Quality in Caster 4 Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance measures in place for 4-inch casters is critical. By focusing on material selection, manufacturing techniques, quality control standards, and testing methods, buyers can make informed decisions that ensure they source reliable and durable products. Engaging with suppliers transparently and verifying their quality control practices can further enhance the confidence in procurement decisions, ultimately leading to better operational efficiency and safety in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘caster 4’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring 4-inch casters effectively. With various options available, it’s essential to follow a structured approach to ensure that the selected casters meet your specific needs in terms of performance, durability, and compatibility. This checklist will help streamline your purchasing process, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for your casters. Consider factors such as load capacity, wheel material, and mounting type, as these will directly influence performance in your application.

– Load Capacity: Ensure that the casters can handle the maximum weight they will be subjected to, plus a safety margin.

– Wheel Material: Choose materials that suit your environment—polyurethane for smooth surfaces or rubber for outdoor use.

Step 2: Identify the Right Caster Type

Casters come in various configurations, primarily swivel and rigid. Selecting the appropriate type is crucial for the maneuverability and stability of your application.

– Swivel Casters: Ideal for navigating tight spaces, allowing for easy directional changes.

– Rigid Casters: Best suited for straight-line movement, providing stability for heavier loads.

Illustrative image related to caster 4

Step 3: Evaluate Supplier Credentials

Thoroughly vet potential suppliers to ensure they meet industry standards and have a reliable track record. Look for certifications that demonstrate compliance with safety and quality regulations.

– Certifications: Check for ISO certifications or other relevant quality assurance marks.

– Reputation: Seek reviews or testimonials from other businesses in your region or industry.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the casters you are considering. Testing samples in real-world conditions can reveal performance issues that specifications alone cannot.

– Performance Testing: Evaluate the casters under load to assess functionality and durability.

– Compatibility Checks: Ensure that the mounting options fit your existing equipment seamlessly.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to understand the market price for the casters you need. Be mindful of the total cost of ownership, not just the initial purchase price.

– Bulk Discounts: Inquire about pricing for larger orders to reduce costs.

– Shipping and Handling: Factor in shipping fees and delivery times, as these can significantly impact overall expenses.

Step 6: Confirm Warranty and After-Sales Support

Ensure that the supplier offers a comprehensive warranty and reliable after-sales support. This is essential for addressing any issues that may arise post-purchase.

– Warranty Duration: Look for warranties that cover defects and performance failures for an adequate period.

– Support Services: Confirm the availability of technical support or replacement parts if needed.

Step 7: Finalize Your Order

Once you have completed all due diligence and are satisfied with your supplier and product choice, proceed to finalize your order. Ensure that all specifications, quantities, and terms are clearly documented in the purchase agreement.

– Documentation: Keep a copy of the purchase order and any correspondence with the supplier.

– Follow-Up: Establish a follow-up plan to assess the product’s performance once received.

By following this checklist, B2B buyers can confidently navigate the procurement of 4-inch casters, ensuring they select the right products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for caster 4 Sourcing

What are the Key Cost Components in Caster 4 Sourcing?

When considering the costs associated with sourcing 4-inch casters, several critical components come into play. Firstly, materials significantly impact the cost structure. High-quality materials such as reinforced steel or durable polyurethane are often more expensive but contribute to the caster’s longevity and performance. Secondly, labor costs vary depending on the region and the complexity of the manufacturing process. In regions with higher wage standards, like Germany, labor costs can be a significant factor, while in countries like Vietnam, labor may be more cost-effective.

Manufacturing overhead includes expenses related to factory operations, utilities, and equipment maintenance. These costs can fluctuate based on the production scale and efficiency of the manufacturing facility. Tooling costs are also essential, particularly for customized casters, as they involve the design and creation of molds and dies. Additionally, quality control (QC) processes ensure that the casters meet industry standards, and while they add to the cost, they are crucial for maintaining reliability and safety.

Logistics costs encompass the expenses of transporting the casters from the manufacturer to the buyer, which can vary greatly based on distance, shipping methods, and Incoterms. Finally, the margin that suppliers add to their costs will depend on market competition and perceived value.

How Do Pricing Influencers Affect Caster 4 Costs?

Several factors influence the pricing of 4-inch casters in the B2B market. Volume and minimum order quantities (MOQ) are significant; suppliers often provide discounts for bulk purchases, making it more economical for buyers to source larger quantities. The specifications and customization of casters can also drive up prices. Unique features such as load capacity, braking mechanisms, or specific tread materials may require additional investments in materials and manufacturing processes.

The quality of the materials used and any certifications (like ISO or ANSI) that the products possess can further affect pricing. Buyers should also consider supplier factors; established suppliers with a good reputation may charge more due to their reliability and service quality. Moreover, understanding Incoterms is vital for international transactions, as they dictate shipping responsibilities and costs, influencing the overall pricing structure.

Illustrative image related to caster 4

What Buyer Tips Should International B2B Buyers Consider?

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can help in negotiating better prices for 4-inch casters. Start by researching and understanding the market to identify fair pricing and potential suppliers. Establishing a relationship with suppliers can lead to better terms and pricing over time.

Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance costs, durability, and the lifespan of the casters. Investing in higher-quality casters might result in lower long-term costs due to reduced replacements and repairs.

When negotiating, be transparent about your needs and explore options for customization that might better meet your operational requirements. Lastly, be aware of pricing nuances; currency fluctuations, tariffs, and international shipping costs can all impact the final price. Always request detailed quotes that break down costs to understand where you might find savings.

Disclaimer on Pricing

While this analysis provides a comprehensive overview of the cost and pricing factors associated with 4-inch casters, prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always verify current prices with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing caster 4 With Other Solutions

Exploring Alternatives to Caster 4: Key Comparisons

In the realm of mobility solutions for industrial applications, the choice of casters can significantly impact efficiency and safety. While ‘Caster 4’ offers a robust option for various environments, it is essential to consider alternative solutions that may better suit specific operational needs or preferences. Below, we compare ‘Caster 4’ with two viable alternatives: Polyurethane Wheels and Heavy-Duty Industrial Casters.

Illustrative image related to caster 4

| Comparison Aspect | ‘Caster 4’ | Polyurethane Wheels | Heavy-Duty Industrial Casters |

|---|---|---|---|

| Performance | Good for light to medium loads | Excellent grip and shock absorption | Superior load capacity and durability |

| Cost | Mid-range pricing (approx. $10-$50) | Generally lower-cost options | Higher initial investment (starting at $50) |

| Ease of Implementation | Standard mounting options available | Easy installation; versatile usage | May require specialized mounting |

| Maintenance | Low maintenance; durable materials | Requires periodic cleaning | May need regular inspections |

| Best Use Case | General utility carts and equipment | Perfect for uneven surfaces or floors | Ideal for heavy machinery and loads |

In-Depth Analysis of Alternatives

Polyurethane Wheels

Polyurethane wheels are favored for their excellent shock absorption and traction, making them suitable for uneven surfaces often found in warehouses and manufacturing floors. Their cost-effectiveness and versatility allow for broad applications, from light-duty carts to specialized equipment. However, they may require more frequent cleaning to maintain optimal performance, especially in environments with high debris. While they are less expensive than ‘Caster 4’, their durability may not match that of heavier-duty options.

Heavy-Duty Industrial Casters

Heavy-duty industrial casters are designed to handle significantly larger loads, making them ideal for machinery and equipment that require robust support. These casters often feature reinforced materials and specialized designs for maximum durability. Although the initial investment can be higher, their longevity and minimal maintenance requirements can yield cost savings over time. However, they may not be suitable for all applications, particularly in environments where mobility and ease of maneuverability are critical.

Conclusion: Making the Right Choice for Your Needs

When selecting the right caster solution, B2B buyers must assess their specific operational requirements, including load capacity, surface conditions, and mobility needs. While ‘Caster 4’ provides a solid middle-ground option for general applications, alternatives like polyurethane wheels or heavy-duty industrial casters may offer distinct advantages depending on the context. By carefully evaluating performance, cost, and maintenance factors, businesses can choose the most effective caster solution to enhance their operational efficiency and safety.

Essential Technical Properties and Trade Terminology for caster 4

What Are the Key Technical Properties of a 4-Inch Caster?

Understanding the technical specifications of 4-inch casters is essential for making informed purchasing decisions. Below are critical properties that should be considered:

1. Wheel Diameter

The wheel diameter, typically 4 inches for this category, significantly impacts mobility and load capacity. A larger wheel can handle uneven surfaces better, while a smaller wheel may be more suitable for smoother floors. For B2B applications, selecting the right wheel size ensures optimal performance in the intended environment, whether it be a warehouse or an office space.

Illustrative image related to caster 4

2. Load Capacity

Load capacity refers to the maximum weight a caster can support safely. This specification is crucial for preventing equipment failure and ensuring safety during operation. It is advisable to choose casters with a load capacity that exceeds the actual load to account for dynamic forces and avoid wear and tear over time.

3. Tread Material

The material used for the wheel tread—such as polyurethane, rubber, or nylon—affects the caster’s performance on different surfaces. For instance, polyurethane wheels offer a good balance of durability and floor protection, making them ideal for industrial applications. In contrast, rubber casters are better suited for quieter environments. Selecting the appropriate tread material is vital for minimizing noise and protecting flooring.

4. Brake Type

Brakes are an essential feature for many applications, particularly when dealing with heavy loads or inclined surfaces. Casters may come with locking mechanisms that secure the wheel in place, preventing unwanted movement. Understanding the brake options available, such as foot-operated or hand-activated, can enhance safety and efficiency in operational settings.

Illustrative image related to caster 4

5. Fastening Type

The fastening type indicates how the caster attaches to the equipment. Common options include plate and stem mounts. Matching the fastening type to your equipment is critical for ensuring stability and ease of installation. This consideration is particularly important for buyers looking to replace existing casters.

6. Finish

The finish of the caster can impact both aesthetics and durability. Options such as chrome, zinc plating, or stainless steel not only provide visual appeal but also enhance resistance to corrosion. For B2B buyers, selecting the right finish can lead to longer-lasting products, especially in environments prone to moisture or chemical exposure.

What Common Trade Terms Should B2B Buyers Know for Casters?

Familiarity with industry jargon can streamline communication and enhance understanding during the purchasing process. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify quality and compatibility when sourcing replacement parts or new equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for B2B buyers who need to manage budgets and inventory effectively. Knowing the MOQ can also help in negotiating better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. This term is essential for buyers looking to compare pricing and terms from different vendors, ensuring they get the best deal for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers involved in cross-border purchases, as they govern shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is important for inventory planning and managing supply chain logistics. Knowing the lead time can help businesses avoid operational disruptions.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the product’s quality and performance over a specified period. Understanding warranty terms helps buyers assess the value and reliability of their investment, ensuring they are protected against defects or failures.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right 4-inch casters for their specific applications and needs.

Illustrative image related to caster 4

Navigating Market Dynamics and Sourcing Trends in the caster 4 Sector

What Are the Key Trends Driving the Global Caster 4 Market?

The global market for 4-inch casters is influenced by several key trends that are shaping the sourcing and purchasing decisions of B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. One significant driver is the rise of automation in various industries, including warehousing and logistics, leading to increased demand for reliable and durable caster solutions that can withstand heavy loads and rigorous usage. Additionally, the growing emphasis on ergonomic designs has prompted manufacturers to innovate, resulting in casters that enhance mobility and reduce worker strain.

Emerging technologies such as IoT (Internet of Things) are also impacting the caster market. Smart casters equipped with sensors for load monitoring and performance tracking are gaining traction, offering businesses real-time data to optimize their operations. Furthermore, customization is becoming a trend, as buyers seek casters tailored to specific applications, whether for medical equipment, industrial carts, or furniture.

International B2B buyers must navigate fluctuating material costs and supply chain disruptions, which have been exacerbated by geopolitical tensions and the global pandemic. This calls for agile sourcing strategies that not only ensure quality but also prioritize suppliers with robust inventories and reliable delivery timelines.

Illustrative image related to caster 4

How Is Sustainability Shaping the Caster 4 Supply Chain?

Sustainability is increasingly vital in the caster sector, driven by both regulatory pressures and consumer demand for ethical business practices. B2B buyers are placing greater importance on sourcing from suppliers that demonstrate environmental responsibility. This includes using eco-friendly materials, such as recycled metals and sustainable plastics, which can significantly reduce the environmental impact of caster production.

In addition to material sourcing, companies are pursuing certifications that validate their commitment to sustainability, such as ISO 14001 for environmental management. Buyers should seek out manufacturers that emphasize transparency in their supply chains, ensuring that their sourcing practices do not contribute to environmental degradation or exploitative labor practices.

The movement towards sustainability is not just a trend; it is becoming a core component of corporate responsibility. Adopting ‘green’ certifications and materials not only enhances brand reputation but can also lead to cost savings through improved energy efficiency and waste reduction in manufacturing processes.

What Is the Historical Context of Caster 4 Development?

The evolution of casters, particularly the 4-inch variants, has been a response to the changing demands of various industries. Initially designed for simple mobility solutions, casters have transformed significantly since their inception. The introduction of new materials and manufacturing processes has enhanced the durability and functionality of casters, making them suitable for a wide range of applications—from medical equipment to industrial machinery.

Historically, the development of casters paralleled advancements in transportation and manufacturing technologies. With the industrial revolution, the need for efficient material handling led to innovations in caster design, including swivel and locking mechanisms. Today, the focus on ergonomic designs and smart technologies continues to drive the evolution of 4-inch casters, ensuring they meet the needs of modern businesses while adapting to emerging trends in automation and sustainability.

Through understanding these dynamics, international B2B buyers can make informed sourcing decisions that align with current market trends and future innovations in the caster sector.

Frequently Asked Questions (FAQs) for B2B Buyers of caster 4

-

How do I choose the right 4″ caster for my application?

Choosing the right 4″ caster involves considering several factors. First, identify whether you need a swivel or rigid caster based on your maneuverability requirements. Next, assess the weight capacity needed; ensure the caster can support your intended load with a safety margin. Additionally, consider the wheel material; polyurethane offers durability and floor protection, while rubber provides excellent traction. Finally, check the installation type, such as plate or stem mount, to ensure compatibility with your equipment. -

What is the best material for 4″ casters in industrial applications?

For industrial applications, polyurethane wheels are often the best choice for 4″ casters. They provide a good balance of durability, load-bearing capacity, and floor protection, making them suitable for various surfaces. Additionally, stainless steel or heavy-duty steel frames enhance the casters’ overall strength and longevity in harsh environments. If your operation involves exposure to chemicals or moisture, consider stainless steel casters for their corrosion resistance. -

What are the key considerations when sourcing 4″ casters internationally?

When sourcing 4″ casters internationally, it’s crucial to evaluate the supplier’s reputation and reliability. Look for manufacturers with certifications that align with your quality standards, such as ISO 9001. Understand the import regulations in your country, including tariffs and customs duties. It’s also beneficial to request samples for quality assessment before placing larger orders. Finally, consider the supplier’s ability to provide consistent supply and timely delivery to avoid operational disruptions. -

What is the minimum order quantity (MOQ) for 4″ casters?

The MOQ for 4″ casters can vary significantly by supplier and product type. Many manufacturers set MOQs ranging from 50 to 500 units, depending on the caster’s material, features, and customization options. It’s advisable to discuss your specific needs with the supplier to explore any flexibility in MOQs. Some suppliers might offer lower MOQs for standard products or allow for a mixed order of different caster types to meet the minimum. -

How can I ensure the quality of 4″ casters from international suppliers?

To ensure the quality of 4″ casters from international suppliers, implement a robust supplier vetting process. Request detailed product specifications and quality assurance documentation. Conduct factory audits if feasible, or utilize third-party inspection services to verify manufacturing practices. Establish clear quality control standards in your purchase agreement, including acceptable tolerances and testing methods. Additionally, consider starting with a trial order to evaluate the casters’ performance before committing to larger purchases. -

What payment terms should I negotiate with my caster supplier?

When negotiating payment terms with your caster supplier, aim for terms that balance risk and cash flow. Common arrangements include a 30% deposit upon order confirmation, with the remaining 70% due before shipment. For first-time orders, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify any potential penalties for late payments or early shipment discounts, and ensure these terms are documented in your purchase agreement. -

What are the logistics considerations for importing 4″ casters?

Logistics considerations for importing 4″ casters include selecting the right shipping method based on urgency and cost. Ocean freight is economical for large orders but may take longer, while air freight offers speed at a higher cost. Ensure that your supplier can provide accurate shipping documentation, including invoices and packing lists, to facilitate customs clearance. Be aware of any import duties and taxes in your country, and work with a reliable freight forwarder to streamline the shipping process. -

Can I customize 4″ casters for specific applications?

Yes, many manufacturers offer customization options for 4″ casters to meet specific application requirements. Customizations can include wheel material, tread design, braking mechanisms, and mounting configurations. When discussing customization, provide detailed specifications and application context to help the supplier recommend suitable options. Be mindful that customization may impact lead times and MOQs, so plan accordingly to ensure that your unique needs are met without significant delays.

Top 5 Caster 4 Manufacturers & Suppliers List

1. Faultless Caster – Heavy-Duty Casters with 4 Diameter Wheels

Domain: faultlesscaster.com

Registered: 1995 (30 years)

Introduction: Casters with 4″ Diameter Wheels; Free shipping on orders over $150; Common plate sizes: 4″ x 4.5″ (for 2″ wide wheels), 4.5″ x 6.25″ (for 3″ wide wheels); Load capacities: 1.25″ wide wheel up to 350 lbs., 2″ wide wheel up to 1,250 lbs., 3″ wide wheel (heavy duty) up to 4,200 lbs.; USA-made options available; 3-year warranty on select products; Various wheel widths available: 1″, 1.25″, 2″, 3″; Cat…

2. Caster Specialists – 4 Wheel Diameter Casters

Domain: casterspecialists.com

Registered: 2002 (23 years)

Introduction: 4″ Wheel Diameter Casters | Top Quality Store | ANSI Tested for Safety & Performance | FREE shipping on orders $250+ | Capacity options: to 350 lbs, 350-1250 lbs, 1250-3000 lbs, > 3000+ lbs | USA-Made | Heavy Duty | Ergonomic | Kingpinless | Maintenance-Free | Stainless Steel | Low Profile | Medical | Wheel Types: Polyurethane, Rubber, Pneumatic, Metal, Nylon, Phenolic, Plastic | Accessories avail…

3. Caster Connection – 4 Casters

Domain: casterconnection.com

Registered: 1999 (26 years)

Introduction: 4″ Casters available in various types including Swivel, Rigid, Kingpin, Kingpinless, Maintenance-Free, and Spring-Loaded. Load capacities range from Light Duty (under 500 lbs) to Heavy Duty (over 2000 lbs). Wheel materials include Polyurethane, Cast Iron, and Ductile Steel. Features include adjustable height, noise reduction, floor protection, and ergonomic performance. Options for specific applic…

4. Next Day Casters – Heavy Duty Caster Wheels

Domain: nextdaycasters.com

Registered: 2019 (6 years)

Introduction: 4 inch Heavy Duty Caster Wheels; ANSI tested for safety & performance; Free shipping on orders over $250; Available types: Swivel casters, Rigid casters, Locking casters, Total lock brake casters, Heavy duty casters, Kingpinless casters, Ergonomic casters, Value line casters, Floor protective wheels, Never-Flat wheels; USA-made casters; Top plate sizes: 2-5/8″ x 3-3/4″, 4″ x 4-1/2″, 4-1/2″ x 6-1/4…

5. Access Casters – 4 Medium Duty Casters

Domain: accesscasters.com

Registered: 2003 (22 years)

Introduction: 4″ Medium Duty Casters with capacities up to 1,250 pounds.

Strategic Sourcing Conclusion and Outlook for caster 4

In summary, strategic sourcing of 4-inch casters is essential for optimizing operational efficiency and ensuring reliability across various applications. Buyers must consider critical factors such as caster type, load capacity, materials, and installation compatibility to align with their specific needs. For instance, selecting between swivel and rigid casters can significantly impact maneuverability in tight spaces, while the choice of wheel material can enhance durability and performance on different surfaces.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate their sourcing decisions, the value of leveraging a diverse supplier base cannot be overstated. Engaging with manufacturers that offer customized solutions and robust support can lead to enhanced productivity and cost savings.

Looking ahead, the demand for high-quality, versatile casters is poised to grow, driven by advancements in manufacturing and logistics. We encourage you to explore the latest innovations in caster technology and supplier offerings to ensure your operations remain competitive. Take the next step in your strategic sourcing journey by connecting with trusted suppliers who understand your unique market challenges and can provide tailored solutions for your caster needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.