Unlocking Value: A Strategic Analysis of the Ideas For Cable Reels Market

Introduction: Navigating the Global Market for ideas for cable reels

In an increasingly interconnected world, sourcing innovative ideas for cable reels presents both a challenge and an opportunity for international B2B buyers. Whether you are looking to enhance your supply chain with durable products or seeking creative applications for cable reels in various industries, this guide provides invaluable insights to navigate the global market effectively. Understanding the diverse types of cable reels, their applications, and the nuances of supplier vetting is crucial for making informed purchasing decisions that align with your business goals.

This comprehensive resource delves into the myriad possibilities of cable reels, from traditional uses in electrical and telecommunications sectors to emerging trends in DIY decor and outdoor furniture. We will explore the cost implications and value propositions associated with different materials and designs, helping you assess the best options for your specific needs. Additionally, we address the unique considerations for B2B buyers from regions like Africa, South America, the Middle East, and Europe, such as logistical challenges and regional supplier availability.

By equipping you with actionable insights and practical tips, this guide aims to empower you to make strategic choices that not only fulfill your immediate requirements but also enhance your long-term operational efficiency. Discover how to leverage the potential of cable reels to foster innovation and sustainability in your business.

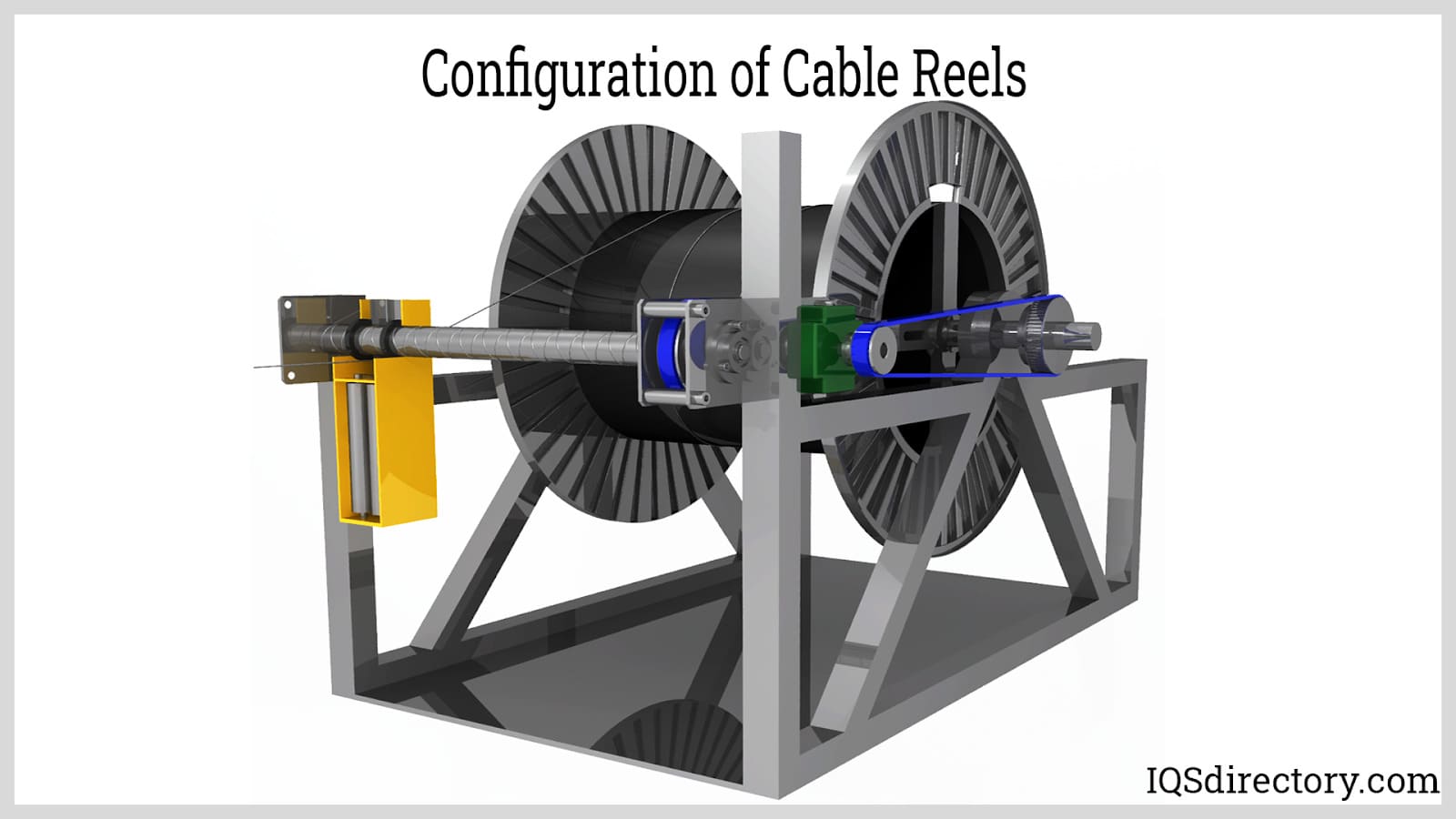

Understanding ideas for cable reels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wooden Cable Reels | Durable, rustic aesthetic, customizable sizes | Outdoor furniture, gardening | Pros: Eco-friendly, versatile; Cons: Requires maintenance, limited weather resistance. |

| Metal Cable Reels | Robust construction, corrosion-resistant | Industrial applications, shipping | Pros: High durability, long lifespan; Cons: Heavier, can be more expensive. |

| Plastic Cable Reels | Lightweight, resistant to moisture and chemicals | Electrical distribution, storage | Pros: Easy handling, resistant to environmental factors; Cons: Less sturdy than wood or metal. |

| Retractable Cable Reels | Mechanism for automatic retraction, compact design | Construction sites, workshops | Pros: Space-saving, convenient; Cons: Mechanical parts may require maintenance. |

| Customizable Cable Reels | Tailored dimensions and features based on needs | Specialized manufacturing, unique projects | Pros: Exact fit for specific applications; Cons: Potentially longer lead times, higher costs. |

What Are the Key Characteristics of Wooden Cable Reels?

Wooden cable reels are popular for their natural aesthetic and durability. They are often used in outdoor furniture and gardening applications, as their rustic appearance blends well with nature. When considering a purchase, B2B buyers should evaluate the wood type, size, and potential for upcycling. Although eco-friendly, wooden reels may require regular maintenance to protect against weather damage.

How Do Metal Cable Reels Stand Out in Industrial Applications?

Metal cable reels are designed for heavy-duty use, making them ideal for industrial environments. Their robust construction ensures they can withstand harsh conditions, while their corrosion resistance is vital for longevity. Buyers should assess the reel’s weight capacity and dimensions to ensure compatibility with their operations. While they offer superior durability, metal reels can be heavier and more costly compared to alternatives.

What Are the Advantages of Using Plastic Cable Reels?

Plastic cable reels are lightweight and resistant to moisture and chemicals, making them suitable for electrical distribution and storage in various environments. Their ease of handling is a significant advantage for companies needing frequent transport or setup. B2B buyers should consider the reel’s load capacity and environmental resistance when selecting plastic options. However, they may not provide the same sturdiness as wood or metal reels.

Why Choose Retractable Cable Reels for Convenience?

Retractable cable reels are designed for ease of use, featuring a mechanism that allows for automatic retraction and compact storage. They are particularly beneficial in construction sites and workshops where space is limited. Buyers should look for features like cord length and retraction speed. While these reels enhance convenience, they may require maintenance of mechanical parts to ensure proper functionality over time.

What Should Buyers Know About Customizable Cable Reels?

Customizable cable reels allow businesses to specify dimensions and features tailored to their unique needs. This flexibility is advantageous for specialized manufacturing or unique project requirements. B2B buyers should consider lead times and costs, as customization may lead to longer wait periods and higher expenses. However, the benefit of having a reel that perfectly fits specific applications can outweigh these drawbacks.

Key Industrial Applications of ideas for cable reels

| Industry/Sector | Specific Application of ideas for cable reels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Utilities | Storage and organization of electrical cables | Improved safety and efficiency in managing cables | Durability, size specifications, and ease of transport |

| Telecommunications | Temporary cable management during installations | Enhanced workflow and reduced downtime during setup | Compatibility with various cable sizes and types |

| Construction | Use as portable workstations or tool storage | Increased productivity and organization on job sites | Weight capacity, weather resistance, and mobility features |

| Event Management | Customizable furniture for outdoor events | Unique branding opportunities and enhanced guest experience | Aesthetic appeal, ease of assembly, and portability |

| Landscaping and Design | Decorative elements in outdoor spaces | Improved aesthetic appeal and functionality in garden design | Material quality, finish options, and size versatility |

How Are Ideas for Cable Reels Used in Electrical Utilities?

In the electrical utilities sector, cable reels serve as essential tools for storing and organizing electrical cables. This application addresses the common problem of tangled and damaged wires, which can lead to safety hazards and inefficiencies. Buyers in this sector must consider durability and size specifications to ensure that the reels can withstand heavy usage and environmental conditions. Additionally, ease of transport is crucial for utility companies operating in diverse geographical regions, particularly in Africa and South America.

What Role Do Cable Reels Play in Telecommunications?

In telecommunications, cable reels are utilized for temporary cable management during installations. This application enhances workflow and minimizes downtime by allowing technicians to manage cables efficiently without tangling or damage. For B2B buyers, compatibility with various cable sizes and types is a critical consideration, as different projects may require different specifications. Ensuring that the reels can support the weight and length of cables used in telecommunications is essential for seamless operations.

How Are Cable Reels Applied in Construction?

In the construction industry, cable reels can be repurposed as portable workstations or tool storage solutions. This innovative use not only helps in organizing tools but also increases productivity by providing accessible workspaces on job sites. Buyers should look for reels with robust weight capacities, weather resistance, and mobility features to accommodate the dynamic nature of construction environments. These considerations are particularly relevant for international buyers, who may encounter varying conditions across different regions.

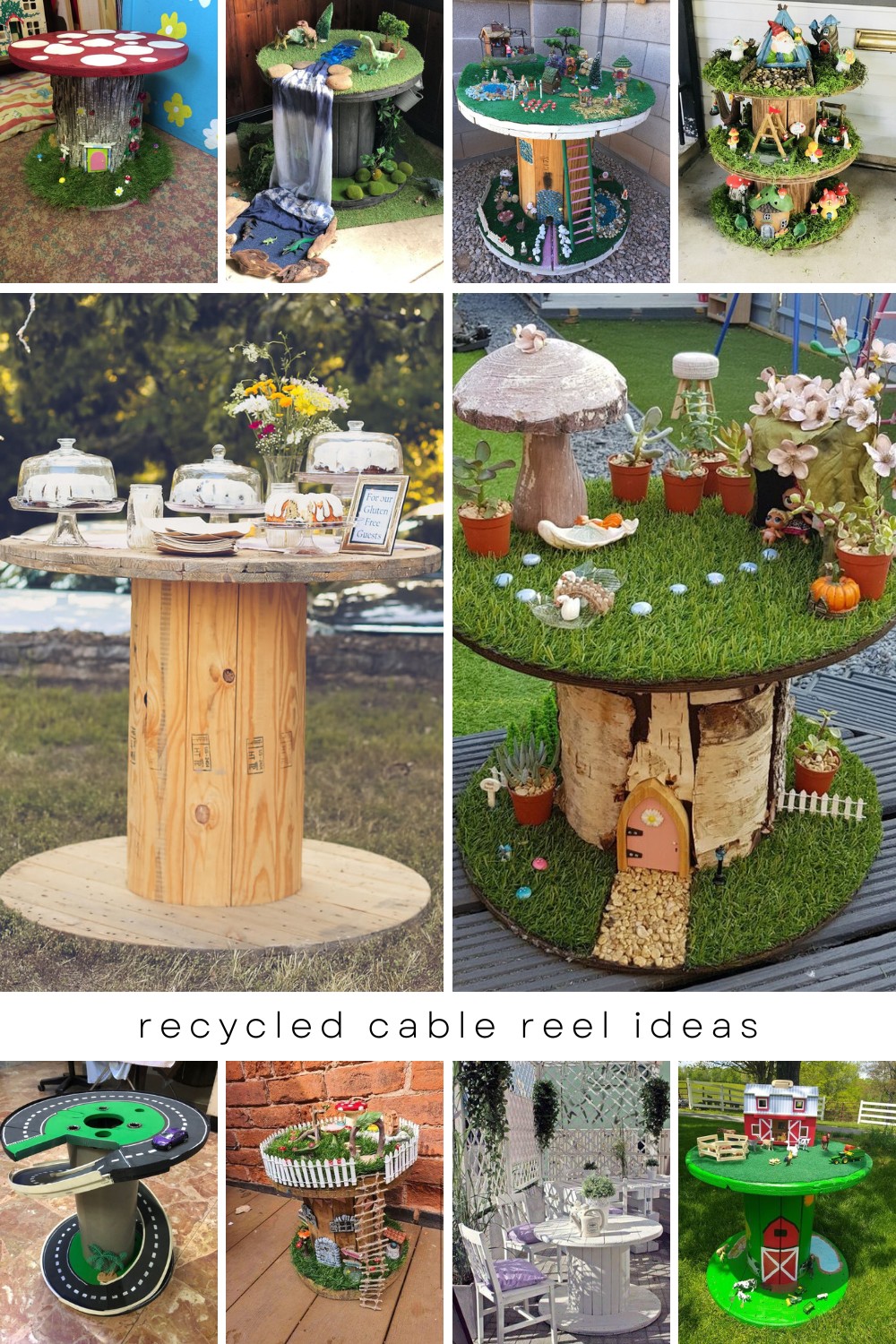

What Are the Benefits of Using Cable Reels in Event Management?

Event management companies can transform cable reels into customizable furniture pieces for outdoor events, enhancing both functionality and aesthetics. This application offers unique branding opportunities while providing guests with a memorable experience. When sourcing cable reels for this purpose, event planners should consider aesthetic appeal, ease of assembly, and portability, ensuring that the furniture complements the event theme and can be easily transported between venues.

How Do Landscaping and Design Benefit from Cable Reels?

In landscaping and design, cable reels can be creatively used as decorative elements in outdoor spaces. This application not only improves the aesthetic appeal of gardens and parks but also adds functionality, such as serving as seating or plant stands. Buyers should focus on material quality, finish options, and size versatility to ensure that the reels fit seamlessly into their design vision. These considerations are especially important for buyers in Europe and the Middle East, where design trends may vary significantly.

3 Common User Pain Points for ‘ideas for cable reels’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Cable Reels for Long-Term Use

The Problem: Many B2B buyers struggle to find high-quality cable reels that can withstand the rigors of outdoor use, particularly in challenging environments like those found in Africa and South America. Buyers often encounter issues with reels that deteriorate quickly due to exposure to elements such as moisture, UV radiation, or extreme temperatures. This not only leads to increased costs due to frequent replacements but also impacts project timelines and overall operational efficiency.

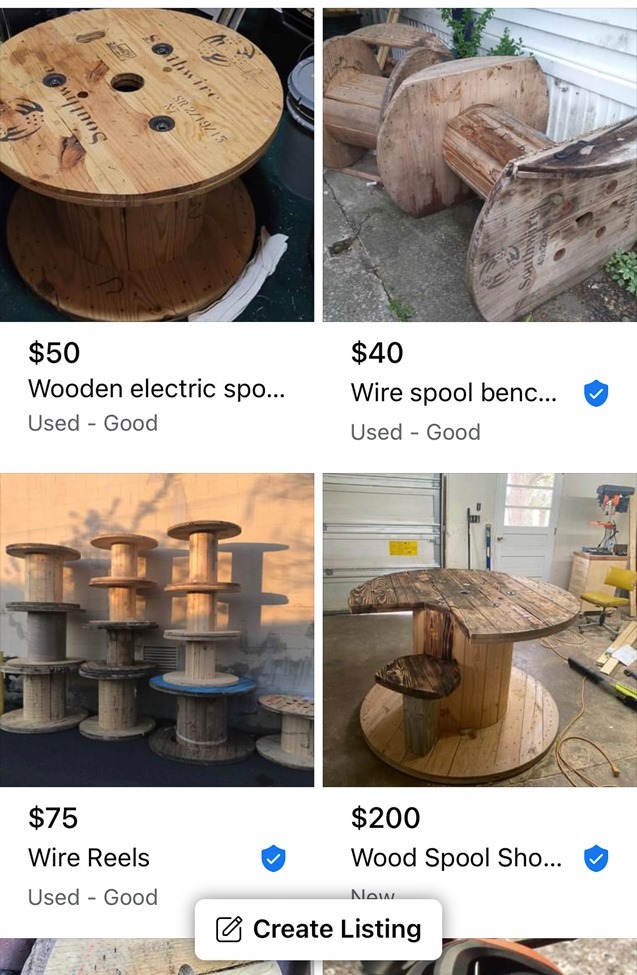

Illustrative image related to ideas for cable reels

The Solution: To ensure sourcing durable cable reels, buyers should seek manufacturers that specialize in weather-resistant materials and offer warranties on their products. It’s essential to inquire about the specifications of the reels, including the type of wood or composite materials used, and to request samples for testing. Buyers can also benefit from establishing relationships with local suppliers who understand the regional climate and can recommend products specifically designed for longevity in those environments. Additionally, consider investing in protective coatings or treatments that can enhance the reels’ resistance to weather-related wear and tear.

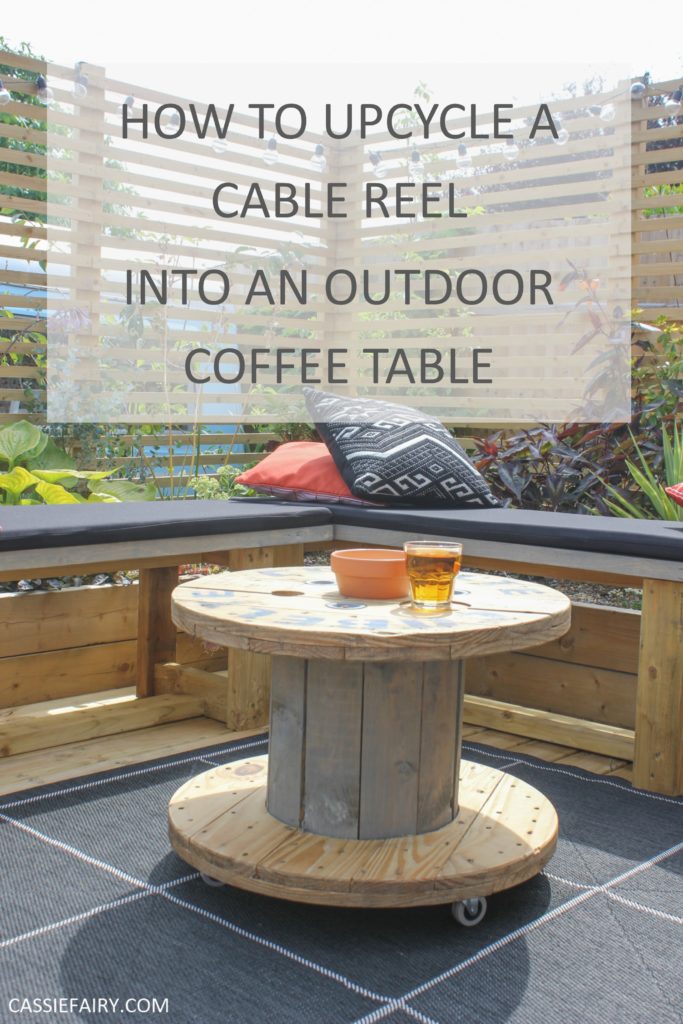

Scenario 2: Limited Creative Applications for Cable Reels in Projects

The Problem: B2B buyers often face challenges in envisioning innovative uses for cable reels beyond their traditional roles. This limitation can lead to underutilization of resources, particularly when working on projects that require unique or customizable solutions. For buyers in sectors such as construction or event planning, the inability to creatively repurpose cable reels can hinder their ability to stand out and meet client demands effectively.

The Solution: To unlock the potential of cable reels, buyers should explore various design ideas and applications that can be adapted to their specific needs. Engaging with design professionals or consultants who specialize in upcycling can provide fresh perspectives on how to repurpose these reels for functional and aesthetic purposes. For instance, cable reels can be transformed into outdoor furniture, planters, or even art installations, depending on the project requirements. Additionally, buyers can leverage online resources and social media platforms to gather inspiration and learn from other companies that have successfully integrated cable reels into their designs.

Scenario 3: Ensuring Safety and Compliance in Using Cable Reels

The Problem: Safety concerns are paramount in industries such as construction and manufacturing, where improperly used cable reels can pose significant hazards. B2B buyers often worry about the stability and weight capacity of the reels they purchase, which can lead to accidents or equipment damage. This issue is especially critical in environments where heavy cables are involved, as inadequate support can result in serious injuries or costly downtime.

The Solution: To address safety concerns, buyers must prioritize the specifications of cable reels they choose, ensuring they meet industry standards for load-bearing capacity. Implementing a thorough vetting process that includes examining product certifications and safety ratings is crucial. Additionally, training employees on the proper handling and usage of cable reels can mitigate risks associated with misuse. Buyers can also consider investing in cable reels with built-in safety features, such as anti-slip surfaces or reinforced structures, to enhance stability and reduce the likelihood of accidents. Regular maintenance checks can further ensure that the reels remain in safe working condition throughout their use.

Illustrative image related to ideas for cable reels

Strategic Material Selection Guide for ideas for cable reels

What Materials Are Commonly Used for Cable Reels?

When selecting materials for cable reels, it’s essential to consider the properties, advantages, and limitations of each option. This analysis focuses on four common materials: wood, plastic, metal, and composite materials. Each material has unique characteristics that can significantly influence the performance and suitability of the cable reel for various applications.

How Does Wood Perform as a Material for Cable Reels?

Wood is a traditional choice for cable reels, particularly for electrical wiring. Its key properties include natural insulation and high strength-to-weight ratio. However, wood can be susceptible to moisture and pests, which may compromise its durability over time.

Pros: Wood is generally low-cost and easy to manufacture, making it a popular choice for many applications. It is also biodegradable, which can be a selling point for environmentally conscious buyers.

Cons: The main limitation of wooden reels is their vulnerability to environmental factors such as humidity and temperature fluctuations. Additionally, they may not be suitable for high-pressure applications.

Impact on Application: Wooden reels are typically used for low to medium voltage applications and are compatible with various types of wiring. However, they may not be the best choice for environments with high moisture or extreme temperatures.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Europe, the use of treated wood may be necessary to meet environmental regulations.

Illustrative image related to ideas for cable reels

What Advantages Do Plastic Cable Reels Offer?

Plastic reels, often made from materials like polypropylene or polyethylene, are becoming increasingly popular due to their lightweight and corrosion-resistant properties.

Pros: Plastic reels are durable and resistant to moisture, chemicals, and UV light, making them suitable for outdoor applications. They are also lightweight, which can reduce shipping costs.

Cons: While generally more durable than wood, plastic reels may have lower load-bearing capacities. They can also be more expensive than wooden reels.

Impact on Application: Plastic reels are ideal for high-humidity environments and applications involving corrosive substances. They are commonly used in telecommunications and electrical industries.

Illustrative image related to ideas for cable reels

Considerations for International Buyers: Buyers should check for compliance with international standards like JIS for plastics. In regions such as Africa and South America, the availability of specific plastic materials may vary, impacting sourcing decisions.

How Do Metal Cable Reels Compare?

Metal reels, typically made from steel or aluminum, offer exceptional durability and strength. They are often used in industrial applications where high load capacities are required.

Pros: Metal reels are highly resistant to damage and can withstand extreme conditions, including high temperatures and pressures. They are also recyclable, contributing to sustainability efforts.

Cons: The primary drawback is their weight, which can increase shipping costs and make handling more difficult. Additionally, metal reels can be susceptible to corrosion if not properly treated.

Impact on Application: Metal reels are suitable for heavy-duty applications, including mining and construction. They can handle high-voltage cables and are often used in environments where durability is paramount.

Illustrative image related to ideas for cable reels

Considerations for International Buyers: Compliance with standards such as ASTM for metals is crucial, especially in Europe and the Middle East. Buyers should also consider local corrosion resistance requirements based on environmental conditions.

What Role Do Composite Materials Play in Cable Reel Manufacturing?

Composite materials, which combine different materials to achieve specific properties, are increasingly being used for cable reels.

Pros: Composites can offer the best of both worlds—lightweight yet strong, and resistant to corrosion and environmental factors. They can also be designed for specific applications, enhancing performance.

Illustrative image related to ideas for cable reels

Cons: The manufacturing process for composite materials can be complex and costly, which may deter some buyers. Additionally, they may not be as widely available as traditional materials.

Impact on Application: Composite reels are suitable for specialized applications, particularly in environments where traditional materials might fail. They are often used in aerospace and high-tech industries.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards. In regions like South America and Africa, the availability of composite materials may be limited, requiring careful sourcing strategies.

Summary Table of Material Selection for Cable Reels

| Material | Typical Use Case for ideas for cable reels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Low to medium voltage applications | Low-cost and easy to manufacture | Vulnerable to moisture and pests | Low |

| Plastic | Telecommunications and electrical wiring | Durable and corrosion-resistant | Lower load-bearing capacity | Medium |

| Metal | Heavy-duty industrial applications | Exceptional durability and strength | Heavy and susceptible to corrosion | High |

| Composite | Specialized high-tech applications | Lightweight and customizable | Complex and costly manufacturing process | High |

This table provides a concise overview of the key considerations for B2B buyers when selecting materials for cable reels. Understanding these factors will help ensure the right choice for specific applications and environments.

In-depth Look: Manufacturing Processes and Quality Assurance for ideas for cable reels

What Are the Main Stages of the Manufacturing Process for Cable Reels?

The manufacturing of cable reels involves several key stages, each integral to ensuring the final product meets quality and performance standards. Understanding these stages helps B2B buyers identify the capabilities and reliability of potential suppliers.

Material Preparation: How Are Raw Materials Sourced and Prepared?

The first stage in the manufacturing process is material preparation. Common materials for cable reels include wood, metal, and plastic. For wooden reels, suppliers often source high-quality hardwood or softwood, depending on the application. These materials undergo drying and treatment processes to prevent warping and decay, ensuring durability.

For metal reels, steel or aluminum is commonly used. These materials are cut into appropriate sizes and shapes, followed by processes such as galvanization to enhance corrosion resistance. Plastic reels may involve the use of high-density polyethylene (HDPE) or polypropylene, which are molded into shape using injection molding techniques.

Forming: What Techniques Are Used to Shape Cable Reels?

The forming stage is critical in determining the structural integrity of the cable reels. For wooden reels, techniques such as lamination and CNC machining are employed. Lamination involves gluing together layers of wood to create a strong, lightweight structure. CNC machines then cut and shape the wood into the desired dimensions with precision.

For metal reels, processes like stamping and welding are common. Stamping shapes the metal into the desired form, while welding ensures the pieces are securely joined. Injection molding is the technique used for plastic reels, allowing for complex shapes and designs to be manufactured efficiently.

Assembly: How Are Different Components Joined Together?

The assembly stage brings together the various components of the cable reel. This may include attaching the hub, flanges, and core in the case of wooden reels. Automated assembly lines often facilitate this process, ensuring consistency and speed.

Illustrative image related to ideas for cable reels

For metal and plastic reels, components are typically fastened using screws, bolts, or welding techniques. Quality control measures are often implemented at this stage to ensure that each assembly meets design specifications.

Finishing: What Processes Enhance the Aesthetics and Durability of Cable Reels?

Finishing processes are vital in enhancing both the aesthetics and durability of cable reels. For wooden reels, this may involve sanding, staining, or sealing to protect against moisture and wear. Metal reels often undergo powder coating or painting, which provides a protective layer against corrosion.

Plastic reels might simply require a quality check for surface finish since they are often produced in vibrant colors through the molding process. These finishing touches not only improve the visual appeal but also extend the lifespan of the product.

What Quality Assurance Measures Are Implemented in Cable Reel Manufacturing?

Quality assurance (QA) is crucial for ensuring that cable reels meet international standards and customer expectations. This involves systematic processes at various checkpoints throughout production.

Illustrative image related to ideas for cable reels

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are foundational for ensuring quality management systems are in place. Suppliers should be certified under these standards to demonstrate their commitment to quality. Additionally, industry-specific certifications like CE marking for European markets and API standards for products used in the oil and gas industry may apply.

B2B buyers should verify that their suppliers adhere to these standards, as compliance can significantly impact product reliability and safety.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to maintaining product integrity. These typically include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): During manufacturing, this phase involves monitoring production processes to ensure they are operating within defined parameters. Any deviations are addressed immediately to prevent defects.

-

Final Quality Control (FQC): Once production is complete, the finished cable reels undergo thorough inspections. This may include dimensional checks, weight assessments, and visual inspections for surface defects.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain rigorous quality control standards, B2B buyers can engage in several verification methods:

Illustrative image related to ideas for cable reels

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This firsthand observation is invaluable for understanding a supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s performance history, including defect rates and corrective actions taken.

-

Third-Party Inspections: Utilizing third-party inspection services can lend credibility to the quality assurance processes. These independent entities can provide unbiased assessments of the supplier’s compliance with international standards.

What Are the Unique QC Considerations for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, face unique challenges and considerations in quality control.

Are There Regional Standards and Certifications to Consider?

Different regions may have specific certifications and standards that affect the quality of cable reels. For example, European buyers may prioritize CE marking, while Middle Eastern markets might require compliance with GSO standards. Buyers should familiarize themselves with these regional requirements to ensure compliance.

How Do Cultural and Economic Factors Influence Quality Control?

Cultural attitudes towards quality and manufacturing practices can vary significantly by region. In some markets, there may be a greater emphasis on price over quality, leading to potential compromises. B2B buyers should assess suppliers’ commitment to quality and safety, especially when sourcing from regions with differing economic conditions.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial for B2B Buyers?

A comprehensive understanding of manufacturing processes and quality assurance measures is essential for B2B buyers looking to procure cable reels. By being informed about the stages of production and the relevant quality control practices, buyers can make educated decisions, ensuring they partner with suppliers that prioritize quality, compliance, and reliability. This knowledge not only safeguards their investments but also enhances their ability to deliver superior products to their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ideas for cable reels’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring innovative ideas for cable reels. Whether you’re seeking to enhance your product offerings or looking for unique applications for cable reels in various industries, following this guide will ensure a well-informed purchasing decision.

Step 1: Identify Your Target Market Needs

Understanding the specific requirements of your target market is crucial. Analyze customer preferences, industry trends, and regional demands—especially if you’re targeting markets in Africa, South America, the Middle East, or Europe. This knowledge will guide you in selecting cable reels that align with customer expectations and market gaps.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications needed for your cable reels. Consider factors such as material type, dimensions, weight capacity, and design features. These specifications will not only help you communicate effectively with suppliers but also ensure that the products meet industry standards and safety regulations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, including certifications, product samples, and client testimonials. Look for suppliers with experience in your target market, as they will have a better understanding of local regulations and customer preferences.

Illustrative image related to ideas for cable reels

- Check for certifications: Ensure suppliers hold relevant industry certifications that guarantee product quality and safety.

- Request references: Speak to other businesses that have worked with the supplier to gauge their reliability and service quality.

Step 4: Assess Product Versatility and Applications

Consider the versatility of the cable reels and their potential applications in various industries. For instance, wooden cable reels can be repurposed for outdoor decor, furniture, or gardening solutions. Analyzing these applications can help you identify unique selling propositions that differentiate your offerings in the market.

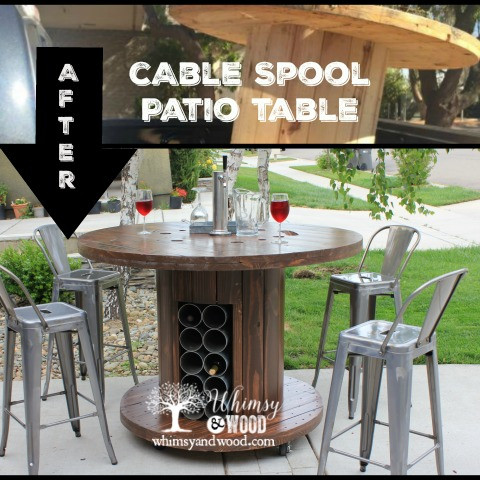

Step 5: Review Pricing and Terms of Sale

Conduct a thorough review of pricing structures and terms of sale from different suppliers. Evaluate not only the cost per unit but also bulk pricing, shipping costs, and payment terms. Understanding the total cost will help you budget effectively and maximize your profit margins.

- Negotiate terms: Don’t hesitate to negotiate for better pricing or terms based on order volume or long-term partnerships.

- Consider total cost of ownership: Factor in logistics, storage, and potential returns when assessing overall costs.

Step 6: Establish Quality Control Measures

Implement quality control measures to ensure that the cable reels meet your required standards upon delivery. Set clear expectations regarding quality inspections, and discuss how discrepancies will be handled with your suppliers.

- Set inspection protocols: Define what quality checks will be performed before accepting the shipment.

- Document quality standards: Ensure that both parties have a clear understanding of the quality standards expected.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics strategy for the procurement and distribution of your cable reels. Identify reliable shipping partners and establish a timeline for delivery. Efficient logistics planning will minimize delays and ensure that you can meet customer demands promptly.

Illustrative image related to ideas for cable reels

By following this checklist, B2B buyers can navigate the complexities of sourcing cable reels effectively, ensuring they select the right products that meet market demands and enhance their business offerings.

Comprehensive Cost and Pricing Analysis for ideas for cable reels Sourcing

When sourcing cable reels, understanding the cost structure and pricing dynamics is essential for B2B buyers. This section delves into the various cost components, price influencers, and offers strategic buyer tips tailored for international markets, particularly in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Cable Reel Sourcing?

The cost structure for cable reels typically encompasses several critical components:

-

Materials: The primary material for cable reels is wood, though plastic and metal options exist. Prices can fluctuate based on the type and quality of wood, with hardwoods often commanding higher prices due to durability and aesthetic appeal.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as certain parts of Africa or South America, the overall production cost can be reduced. However, labor costs in Europe, particularly in Germany, tend to be higher, reflecting the skilled workforce and higher living standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and management. Efficient production processes can minimize these costs, which is vital for maintaining competitive pricing.

-

Tooling: Initial tooling costs for specialized machinery can be substantial. Buyers should consider suppliers that offer flexible tooling options to mitigate these upfront costs, especially for customized designs.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability but adds to the overall cost. Certifications (e.g., ISO) may also be required, impacting pricing depending on the level of compliance needed.

-

Logistics: Transportation and shipping costs are influenced by distance, mode of transport, and Incoterms. Understanding these factors is crucial for calculating the total landed cost.

-

Margin: Suppliers typically add a markup to cover costs and generate profit. The margin can vary based on market conditions and competitive pressures.

What Influences Pricing in Cable Reel Sourcing?

Several factors can significantly impact pricing for cable reels:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their operational needs to achieve better pricing.

-

Specifications and Customization: Custom designs or specific material requirements can elevate costs. It’s essential to balance the need for customization with budget constraints.

-

Quality and Certifications: Higher quality materials and compliance with international standards may increase costs but can result in better durability and customer satisfaction.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can influence pricing. Engaging with multiple suppliers to compare offers can yield cost advantages.

-

Incoterms: Understanding the terms of shipping and responsibility for costs (e.g., CIF, FOB) is crucial. This knowledge affects the total cost and negotiation strategies.

What Tips Can Help Buyers Achieve Cost-Efficiency?

To optimize sourcing strategies and enhance cost-efficiency, consider the following tips:

-

Negotiate Effectively: Leverage volume commitments or long-term contracts to negotiate better pricing with suppliers. Building strong relationships can lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial purchase price, consider the entire lifecycle cost, including maintenance, durability, and potential savings from quality products.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade agreements that may affect pricing. Suppliers may offer different pricing structures based on the buyer’s location.

-

Conduct Market Research: Regularly analyze market trends and competitors to ensure that your pricing strategy remains competitive and aligns with current economic conditions.

By understanding these components and strategies, B2B buyers can make informed decisions that optimize their sourcing of cable reels, ultimately leading to cost savings and enhanced operational efficiency.

Alternatives Analysis: Comparing ideas for cable reels With Other Solutions

Exploring Alternatives to Cable Reels: A Comparative Analysis

In the realm of cable management and storage solutions, cable reels are a popular choice due to their versatility and functionality. However, various alternatives exist that may better suit specific business needs or contexts. This analysis will compare ideas for cable reels against two viable alternatives: Cable Management Systems and Wire Storage Baskets. By evaluating these options, B2B buyers can make informed decisions that align with their operational requirements.

Illustrative image related to ideas for cable reels

| Comparison Aspect | Ideas For Cable Reels | Cable Management Systems | Wire Storage Baskets |

|---|---|---|---|

| Performance | Highly effective for large cables; can be customized for various sizes. | Excellent for organized, secure storage of multiple cables; often includes labeling systems. | Good for lightweight cables; less secure than reels. |

| Cost | Generally low-cost; wooden or plastic reels are inexpensive. | Moderate to high; depends on complexity and features. | Low-cost; typically made from wire or lightweight materials. |

| Ease of Implementation | Simple to use; requires minimal setup. | More complex; may require installation and configuration. | Very easy to implement; simply place cables inside. |

| Maintenance | Low maintenance; can be cleaned easily. | Moderate maintenance; may require adjustments or replacements over time. | Low maintenance; just needs periodic cleaning. |

| Best Use Case | Ideal for construction sites and outdoor settings where cables need to be managed effectively. | Best suited for offices or environments needing organized cable storage and accessibility. | Effective for temporary setups or small operations with less cable volume. |

Understanding the Pros and Cons of Cable Management Systems

Cable Management Systems are sophisticated solutions designed to organize and secure cables in various environments. They typically feature compartments, labeling systems, and even cable trays that can be mounted on walls or desks.

Pros: These systems enhance organization, reduce the risk of tangling, and improve safety by minimizing tripping hazards. They are particularly beneficial in office settings where aesthetics and accessibility are important.

Cons: The initial investment can be higher compared to cable reels, and the installation process may require specialized skills or tools. Maintenance can also be more involved, as adjustments may be needed over time to accommodate changing cable needs.

Evaluating Wire Storage Baskets

Wire Storage Baskets offer a simplistic approach to cable management, designed primarily for lightweight cables. These baskets can be easily placed in various locations, providing an accessible way to store and retrieve cables.

Illustrative image related to ideas for cable reels

Pros: Their affordability and ease of implementation make them attractive for small businesses or temporary setups. They are lightweight and can be moved easily, which is beneficial for dynamic environments.

Cons: However, wire baskets do not provide the same level of security or organization as cable reels or management systems. Cables stored in baskets are more prone to tangling and may not be suitable for heavier or more complex cable systems.

Making the Right Choice: How to Select the Best Solution

When choosing between cable reels and their alternatives, B2B buyers should assess their specific requirements, including the types and volumes of cables they manage, the environment in which they operate, and their budget constraints. For businesses that prioritize portability and low costs, cable reels may be the best option. Conversely, those needing structured organization and safety in an office environment might find cable management systems more beneficial. Wire storage baskets can serve well in casual settings or for lighter cable management needs. Ultimately, aligning the chosen solution with operational demands will lead to greater efficiency and effectiveness in cable management.

Essential Technical Properties and Trade Terminology for ideas for cable reels

What Are the Key Technical Properties of Cable Reels?

When sourcing cable reels, understanding their technical properties is crucial for ensuring that they meet specific operational needs. Here are several essential specifications to consider:

1. Material Grade

Cable reels are typically constructed from various materials, including wood, plastic, and metal. The material grade dictates the reel’s strength, durability, and resistance to environmental factors. For instance, metal reels may offer greater longevity in harsh conditions but can be heavier and more expensive than wooden options. Choosing the right material is vital for applications that require mobility versus those needing sturdiness.

2. Load Capacity

This specification indicates the maximum weight a cable reel can support without structural failure. Load capacity is critical for B2B buyers, especially in industries such as construction and telecommunications, where the weight of the cable can be substantial. Selecting a reel with an appropriate load capacity ensures safety and operational efficiency.

3. Diameter and Width

The dimensions of a cable reel, including diameter and width, impact both storage and transportation. Larger reels may accommodate more cable but can be cumbersome to handle. Understanding these measurements aids in optimizing storage space and ensures compatibility with existing equipment, such as trucks or storage facilities.

4. Tolerance Levels

Tolerance refers to the acceptable range of variation in the dimensions of the cable reel. High tolerance levels ensure that the reel fits perfectly with specific cable types and machinery. For B2B buyers, precise tolerances are essential in industries where even minor discrepancies can lead to operational inefficiencies or safety hazards.

5. Treatment and Coating

Many cable reels undergo treatments or coatings to enhance their resistance to moisture, corrosion, or UV damage. These treatments are particularly important for reels used outdoors or in varying climates. B2B buyers should consider the environmental conditions their reels will face to select the appropriate treatment.

What Are Common Trade Terms Related to Cable Reels?

Familiarity with industry jargon can greatly enhance communication with suppliers and partners. Here are some commonly used terms in the cable reel market:

Illustrative image related to ideas for cable reels

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the cable reel industry, understanding OEM relationships can help buyers identify reputable suppliers and ensure that they are sourcing quality products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it affects inventory management and budgeting. Knowing the MOQ helps businesses plan their purchases effectively, avoiding overstock or understock situations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of products. This is a standard practice in B2B transactions, allowing buyers to compare offers and negotiate better terms. A well-crafted RFQ can lead to favorable deals and long-term supplier relationships.

Illustrative image related to ideas for cable reels

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is essential for B2B transactions, especially for international buyers who need to navigate customs and shipping logistics.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. In the cable reel industry, lead times can vary significantly based on material availability and manufacturing processes. Understanding lead times helps businesses plan their operations and project timelines effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing cable reels, ensuring that they meet their operational requirements while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the ideas for cable reels Sector

What Are the Global Drivers Influencing the Cable Reels Market?

The cable reels market is experiencing notable growth, driven primarily by the increasing demand for efficient cable management solutions across various industries, including telecommunications, construction, and utilities. The surge in renewable energy projects, particularly in Africa and South America, has also catalyzed a need for robust cable handling equipment. Furthermore, advancements in manufacturing technologies and the growing trend toward automation are reshaping sourcing strategies. B2B buyers from regions like Europe, particularly Germany, are increasingly adopting smart sourcing practices, leveraging digital platforms to streamline procurement processes and enhance supply chain visibility.

Illustrative image related to ideas for cable reels

Emerging trends such as the integration of IoT in cable management systems present opportunities for international buyers to enhance operational efficiency. Additionally, the shift towards modular designs allows for greater customization, catering to diverse project requirements. Buyers are increasingly looking for suppliers who can provide not only products but also innovative solutions, such as modular and multi-functional cable reels that support eco-friendly initiatives.

How Is Sustainability Reshaping the Sourcing of Cable Reels?

Sustainability is becoming a central theme in the sourcing of cable reels, as businesses recognize the importance of ethical supply chains. The environmental impact of production processes, particularly in terms of resource extraction and waste generation, is prompting buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials in the production of cable reels, which not only reduces waste but also lowers the carbon footprint associated with manufacturing.

Moreover, certifications such as FSC (Forest Stewardship Council) for wood products are gaining traction among B2B buyers. These certifications assure that materials are sourced from responsibly managed forests, appealing to environmentally conscious consumers. As buyers increasingly prioritize suppliers with a demonstrated commitment to sustainability, those who adopt green manufacturing processes and materials will likely gain a competitive edge.

What Is the Historical Context of Cable Reels in B2B Markets?

The evolution of cable reels can be traced back to their initial purpose of facilitating the storage and transportation of electrical cables. Historically, these reels were primarily made from wood, which provided durability and strength. Over time, advancements in materials science led to the introduction of metal and plastic reels, offering enhanced performance and longevity.

In recent years, the focus has shifted toward multifunctional designs that cater to the diverse needs of industries, such as telecommunications and renewable energy. This evolution reflects broader trends in B2B markets, where innovation and sustainability are increasingly intertwined, influencing buyer preferences and sourcing decisions. As the market continues to evolve, suppliers that adapt to these changes will be well-positioned to meet the demands of international buyers.

Illustrative image related to ideas for cable reels

Frequently Asked Questions (FAQs) for B2B Buyers of ideas for cable reels

1. How do I solve challenges in sourcing cable reels for my business?

Sourcing cable reels can present challenges such as quality assurance, supplier reliability, and compliance with local regulations. To mitigate these issues, start by conducting thorough research on potential suppliers. Evaluate their certifications, read customer reviews, and request samples to assess product quality. Engage in direct communication to discuss your specific requirements, including size, material, and design. Establish clear contractual terms to safeguard against supply chain disruptions, and consider diversifying your supplier base to minimize risks associated with reliance on a single source.

2. What is the best type of cable reel for outdoor use?

The ideal cable reel for outdoor applications is typically made from weather-resistant materials, such as treated wood or durable plastics. Look for reels that have UV protection to prevent fading and deterioration from sunlight exposure. Additionally, consider designs that include features like drainage holes to prevent water accumulation and rusting. Customization options may also be beneficial to meet specific environmental conditions or aesthetic preferences. Always verify that the reel meets relevant safety standards for outdoor use in your target market.

3. How can I customize cable reels to meet my specific business needs?

Customizing cable reels involves selecting materials, sizes, and designs that align with your operational requirements. Start by collaborating with your supplier to discuss your desired specifications, such as dimensions, weight capacity, and material type. Many manufacturers offer customization options that include branding, color choices, and additional features like handles or locking mechanisms. Be sure to request prototypes or samples before placing large orders to ensure that the final product meets your expectations.

4. What are the minimum order quantities (MOQs) for cable reels?

Minimum order quantities for cable reels vary significantly by supplier and region. Typically, MOQs can range from as few as 50 units to several hundred, depending on the manufacturer’s production capacity and the level of customization required. When negotiating with suppliers, inquire about their MOQ policies and whether they offer flexibility for first-time orders or smaller businesses. Consider forming a cooperative with other buyers to meet MOQ requirements while diversifying your product offerings.

5. What payment terms should I expect when sourcing cable reels internationally?

Payment terms for international purchases of cable reels can vary widely based on the supplier’s policies and the buyer’s creditworthiness. Common payment methods include wire transfers, letters of credit, and PayPal, with terms often ranging from 30% upfront and 70% upon delivery to full payment in advance. It’s crucial to negotiate terms that protect both parties, ensuring that you have a clear understanding of the payment schedule, currencies accepted, and any additional fees involved in the transaction.

6. How can I ensure quality assurance when purchasing cable reels?

To ensure quality assurance when sourcing cable reels, establish clear quality standards and specifications with your supplier before production begins. Request product samples for inspection and consider conducting third-party quality audits or inspections at the manufacturing site. Implement a quality control checklist that includes criteria for materials, dimensions, and functionality. Additionally, maintain open lines of communication with your supplier throughout the production process to address any concerns that may arise.

7. What logistics considerations should I keep in mind for international shipping of cable reels?

When planning for international shipping of cable reels, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable logistics partner familiar with your destination country’s import requirements. Ensure that your packaging is robust enough to protect the reels during transit and complies with international shipping standards. Additionally, factor in potential delays caused by customs clearance and establish a buffer in your delivery schedule to accommodate unforeseen circumstances.

8. How can I vet suppliers for cable reels effectively?

Vetting suppliers for cable reels involves a systematic approach to evaluating their reliability and capability. Start by researching potential suppliers through online directories, trade shows, and industry referrals. Check for certifications and compliance with international quality standards. Request references from previous clients and verify their experiences. Conduct background checks on the supplier’s financial health and operational history. Engaging in direct communication and visiting the manufacturing site, if possible, can provide further insights into their production capabilities and business practices.

Top 5 Ideas For Cable Reels Manufacturers & Suppliers List

1. Pinterest – Cable Reel Projects

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Projects with Cable Reels, 90 Pins, Spool Furniture, Spool Tables, Recycled Pallet Wooden Spools, Wooden Cable Spools, Cable Spool Furniture, Wooden Spool Candle Holders, Rustic Wooden Cable Spool Shelf, Cable Drum Table, Wooden Spool Projects, Wooden Playground, Pallet Garden Furniture, Pallet Patio Furniture.

2. Pinterest UK – Creative Cable Reel Projects

Domain: uk.pinterest.com

Registered: 2009 (16 years)

Introduction: Cable reel ideas, DIY projects, wooden spools, outdoor tables, small world play surfaces, recycled crafts, outdoor learning, preschool playground ideas, giant spool upcycling, hand-painted wooden spool tables, cable drum fairy gardens, outdoor science labs for kids, mud kitchens, construction play areas.

3. Facebook – Recycled Cable Spool Ideas

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: 25 Recycled Cable Spool Ideas For Your Home And Garden

4. Reddit – Upcycled Cable Spools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Small cable spools can be upcycled into various items such as cat towers, tables, chairs (though not suitable for adult furniture), plant shelves, book shelves, end tables, cat scratchers, tools organizers, preschool cafe tables, and mushroom stools. Suggestions include using carpet remnants for upholstery and ensuring non-toxic materials are used for pet-related projects.

5. House Digest – Wooden Cable Spools

Domain: housedigest.com

Registered: 2012 (13 years)

Introduction: Wooden cable spools are durable, large wooden structures ideal for repurposing into various outdoor decor and furniture items. They can be used as planters, plant stands, tables, coolers, BBQ grills, fire pits, chairs, benches, and ottomans. The spools can be customized with paint or stain to match outdoor aesthetics and can serve both functional and decorative purposes in backyard and garden sett…

Strategic Sourcing Conclusion and Outlook for ideas for cable reels

The exploration of innovative ideas for cable reels reveals a wealth of opportunities for businesses looking to enhance their product offerings and sustainability efforts. By leveraging the potential of wooden and metal cable reels, companies can not only meet market demand for eco-friendly solutions but also create unique, value-added products that resonate with customers in diverse regions. From stylish outdoor furniture to functional gardening solutions, the versatility of cable reels presents significant advantages for B2B buyers seeking to differentiate themselves in competitive markets.

Strategic sourcing plays a crucial role in this process, enabling businesses to identify high-quality materials and suppliers that align with their brand values and customer expectations. Establishing strong partnerships within the supply chain is essential for ensuring a steady flow of resources and maintaining product integrity.

As international B2B buyers from Africa, South America, the Middle East, and Europe consider their next steps, the call to action is clear: invest in innovative uses for cable reels, embrace sustainable practices, and forge relationships with reliable suppliers. The future holds promising prospects for those who are willing to adapt and innovate in response to evolving market needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.