Everything You Need to Know About Flat Electric Plug Sourcing in 2025

Introduction: Navigating the Global Market for flat electric plug

In an increasingly interconnected world, sourcing flat electric plugs poses unique challenges for international B2B buyers. The need for efficient, high-quality electrical solutions that meet diverse regional standards is paramount, particularly for businesses operating across Africa, South America, the Middle East, and Europe. This guide serves as an essential resource, equipping decision-makers with the insights required to navigate the complexities of the global market for flat electric plugs.

Within these pages, you will discover a thorough examination of the various types of flat electric plugs available, their applications across different industries, and the nuances of regional compliance standards. Additionally, this guide delves into the critical aspects of supplier vetting, ensuring that you partner with reputable manufacturers who adhere to quality assurance protocols. Cost considerations, shipping logistics, and negotiation tactics are also addressed to empower you to make informed purchasing decisions.

By consolidating key information and actionable strategies, this comprehensive guide aims to demystify the procurement process for flat electric plugs. It is designed to empower international B2B buyers, enabling them to source the right products that align with their operational needs while ensuring compliance with local regulations. Whether you’re a business in Vietnam looking to expand your product line or a distributor in Saudi Arabia seeking reliable suppliers, this guide is your roadmap to success in the global market.

Understanding flat electric plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 1-15 | Two flat parallel pins, no grounding | Household appliances, electronics | Pros: Widely used; affordable. Cons: No grounding; limited to low-power devices. |

| Type C (Europlug) | Two round pins, compatible with various sockets | Consumer electronics, chargers | Pros: Versatile; compact. Cons: Limited current rating; not suitable for high-power appliances. |

| Type G (UK Plug) | Three rectangular pins, fused for safety | Industrial equipment, power tools | Pros: High safety standards; robust. Cons: Bulkier design; less compatibility globally. |

| Type I (Australian Plug) | Two flat pins in a V-shape, with a grounding pin | Appliances, power boards | Pros: Grounding feature enhances safety. Cons: Limited to specific regions; larger footprint. |

| Type M (South African Plug) | Three large round pins, similar to Type D but larger | Heavy machinery, high-power devices | Pros: Suitable for high currents; durable. Cons: Not widely compatible outside South Africa. |

What are the characteristics of the NEMA 1-15 flat electric plug?

The NEMA 1-15 is a prevalent flat electric plug type primarily used in North America. It features two flat parallel pins and lacks a grounding pin, making it suitable for low-power applications such as household appliances and electronics. B2B buyers should consider its affordability and widespread availability, but they must also note that its lack of grounding limits its use to devices that do not require high safety standards.

How does the Type C (Europlug) flat electric plug stand out?

The Type C plug, or Europlug, is characterized by its two round pins and compatibility with multiple socket types across Europe. Its compact design makes it ideal for consumer electronics and chargers, particularly in international markets. B2B buyers should appreciate its versatility; however, its lower current rating may restrict its application to smaller devices, necessitating careful consideration for high-power requirements.

Why is the Type G (UK Plug) favored in industrial applications?

The Type G plug features three rectangular pins, including a fuse for enhanced safety, making it a preferred choice for industrial equipment and power tools. Its robust design ensures reliability in demanding environments. For B2B buyers, the high safety standards are a significant advantage, though the bulkier design may limit compatibility with some international sockets, which is a critical factor when sourcing for diverse markets.

What makes the Type I (Australian Plug) a reliable choice?

The Type I plug is distinguished by its two flat pins arranged in a V-shape and an additional grounding pin, enhancing safety for various appliances and power boards. This plug type is especially suitable for regions like Australia and New Zealand. B2B buyers should consider its grounding feature as a plus for safety, while its larger footprint may pose installation challenges in compact setups.

How does the Type M (South African Plug) cater to high-power needs?

The Type M plug, featuring three large round pins, is designed for high-power applications, making it suitable for heavy machinery and devices that require substantial electrical current. B2B buyers in sectors like construction and manufacturing will find this plug type indispensable for its durability and reliability. However, its limited compatibility outside South Africa necessitates careful planning for international procurement strategies.

Key Industrial Applications of flat electric plug

| Industry/Sector | Specific Application of flat electric plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Power supply for compact devices like laptops | Space-saving design enhances portability and usability | Compliance with international safety standards and certifications |

| Home Appliances | Connection for kitchen gadgets and tools | Streamlined design reduces clutter and enhances aesthetics | Durability and heat resistance to ensure longevity |

| Automotive | Charging systems for electric vehicles (EVs) | Facilitates efficient charging, improving user experience | Compatibility with various EV models and charging stations |

| Hospitality | Power supply for hotel room electronics | Improves guest experience through convenience and accessibility | Customization options to fit diverse room designs |

| Telecommunications | Connectivity for networking equipment | Reliable power supply ensures uninterrupted service | Voltage ratings and compatibility with regional standards |

How Are Flat Electric Plugs Used in Consumer Electronics?

In the consumer electronics sector, flat electric plugs are essential for powering compact devices such as laptops, tablets, and portable chargers. Their slim profile allows for easier integration into tight spaces, making them ideal for modern, minimalistic designs. This application addresses the common issue of bulky plugs taking up excessive space, particularly in crowded power strips or wall outlets. International buyers should ensure that the plugs comply with regional safety standards, as well as voltage and amperage specifications, to guarantee safe usage across different markets.

What Role Do Flat Electric Plugs Play in Home Appliances?

Flat electric plugs are increasingly used in home appliances, particularly for kitchen gadgets like blenders, toasters, and coffee makers. Their design contributes to a neater appearance, reducing clutter on countertops and improving user experience. By solving the problem of large, cumbersome plugs, manufacturers can enhance the aesthetic appeal of their products. For B2B buyers, sourcing considerations include ensuring that the plugs are made from durable materials that can withstand heat and wear, as well as meeting local electrical codes for safety.

How Are Flat Electric Plugs Beneficial in the Automotive Industry?

In the automotive sector, flat electric plugs are integral to the charging systems of electric vehicles (EVs). They facilitate efficient and safe charging, ensuring that consumers have a seamless experience when powering their vehicles. This application addresses the growing demand for accessible charging solutions as the EV market expands. B2B buyers in this space should focus on sourcing plugs that are compatible with various EV models and charging stations, while also considering the need for robust insulation and weather resistance to withstand outdoor conditions.

How Do Flat Electric Plugs Enhance Hospitality Services?

In the hospitality industry, flat electric plugs are used to power electronics in hotel rooms, including lamps, chargers, and entertainment systems. Their compact design not only improves the aesthetic of hotel interiors but also enhances guest convenience by providing easy access to power outlets. This application addresses the need for a user-friendly environment in guest accommodations. Buyers should consider customization options for flat electric plugs to match the unique designs of hotel rooms, while also ensuring compliance with international safety standards.

What Advantages Do Flat Electric Plugs Offer in Telecommunications?

In telecommunications, flat electric plugs are crucial for providing a reliable power supply to networking equipment, such as routers and switches. This application is vital for maintaining uninterrupted service in both residential and commercial settings. By solving the issue of bulky connectors that can obstruct airflow and cause overheating, flat plugs ensure optimal performance of equipment. B2B buyers in this sector should prioritize sourcing plugs with appropriate voltage ratings and compatibility with regional electrical standards to ensure safety and efficiency.

3 Common User Pain Points for ‘flat electric plug’ & Their Solutions

Scenario 1: Limited Space in Urban Offices

The Problem: B2B buyers in urban settings often face constraints related to limited space in office environments. Traditional plugs can occupy considerable room, making it challenging to organize workstations efficiently. This issue is particularly pronounced in co-working spaces or smaller offices where every square inch counts. The bulky nature of standard plugs can lead to unsightly clutter and reduced accessibility to power outlets, creating frustration for employees and hampering productivity.

The Solution: To tackle this issue, sourcing flat electric plugs designed specifically for space-constrained environments is crucial. Look for models that feature a low-profile design and can easily fit behind furniture or in tight corners without obstructing other outlets. When specifying these plugs, ensure they meet international safety standards, as this will prevent potential electrical hazards. Furthermore, consider adopting power strips with flat plugs, which can consolidate multiple connections while minimizing the space occupied. Training staff on optimal cable management practices can also enhance workspace organization and aesthetics.

Scenario 2: Compatibility with International Standards

The Problem: B2B buyers operating across various regions, particularly in Africa, South America, the Middle East, and Europe, often encounter compatibility issues with electric plugs. Different countries have distinct electrical standards and plug designs, making it challenging for businesses that import or export electronic devices to ensure compatibility. This can result in operational delays, increased costs, and the need for additional adapters, which may not always be readily available.

The Solution: To address this compatibility challenge, it is essential to conduct thorough research on the electrical standards of target markets before purchasing flat electric plugs. Opt for universal flat plugs that are compliant with multiple international standards, such as Type C or Type G, which are commonly used in various regions. Additionally, establishing partnerships with local suppliers can help ensure that the products meet regional requirements and are readily available. Providing employees with information on the correct plug usage and potential adapters can further streamline operations and minimize disruptions.

Scenario 3: Durability and Safety Concerns

The Problem: B2B buyers often worry about the durability and safety of flat electric plugs, especially in industrial or high-traffic environments. Frequent plugging and unplugging can lead to wear and tear, increasing the risk of electrical faults and potential safety hazards. Moreover, inadequate insulation or substandard materials can pose risks of short circuits, leading to equipment damage and safety incidents, which can have severe financial and reputational repercussions for businesses.

The Solution: To mitigate these risks, it is imperative to source flat electric plugs from reputable manufacturers known for their quality and safety standards. Look for plugs that are constructed from high-grade materials with robust insulation and strain relief features to withstand the rigors of heavy use. Conducting regular inspections and maintenance checks on electrical equipment and plugs can also identify wear and prevent accidents. Additionally, providing training on safe plug usage and the importance of reporting damaged plugs can foster a culture of safety within the organization. Investing in high-quality, durable products may incur a higher upfront cost, but it will ultimately save money by reducing replacement frequency and minimizing safety risks.

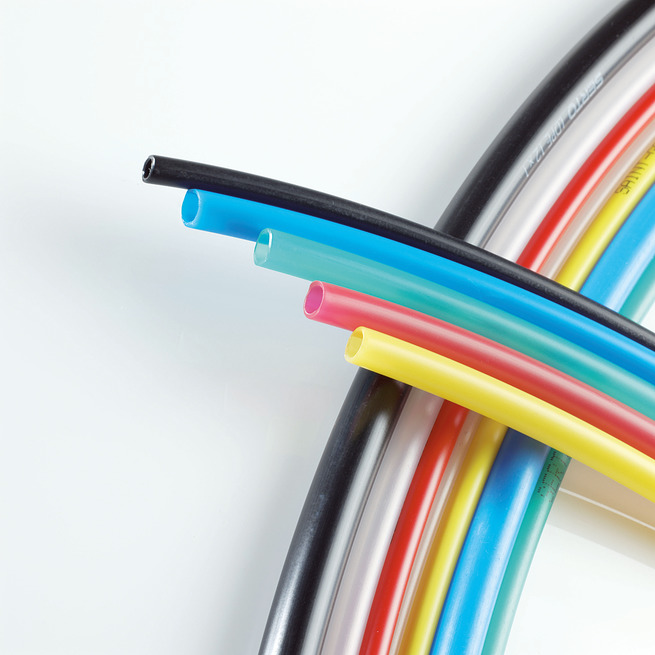

Illustrative image related to flat electric plug

Strategic Material Selection Guide for flat electric plug

When selecting materials for flat electric plugs, it is crucial to consider various factors that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacture of flat electric plugs, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Polycarbonate in Flat Electric Plugs?

Polycarbonate is a popular choice for flat electric plugs due to its excellent impact resistance and thermal stability. With a temperature rating typically between -40°C to 120°C, polycarbonate can withstand high temperatures without deforming. Additionally, it exhibits good electrical insulation properties, making it suitable for various electrical applications.

Pros: Polycarbonate is highly durable, lightweight, and resistant to UV radiation, which is beneficial for outdoor applications. Its manufacturing process is relatively straightforward, allowing for mass production at a lower cost.

Cons: Despite its advantages, polycarbonate can be prone to scratching and may not offer the same level of chemical resistance as other materials. This can be a limitation in environments where exposure to harsh chemicals is common.

Impact on Application: Polycarbonate’s compatibility with high-temperature environments makes it ideal for residential and commercial applications, especially in regions with varying climates such as Africa and the Middle East.

How Does PVC Compare as a Material for Flat Electric Plugs?

Polyvinyl chloride (PVC) is another widely used material for flat electric plugs, known for its flexibility and chemical resistance. PVC can handle temperatures from -15°C to 70°C, making it suitable for indoor applications.

Pros: PVC is cost-effective and offers good electrical insulation. Its flexibility allows for easier installation in tight spaces, which is a significant advantage in compact electrical designs.

Cons: However, PVC is less durable than polycarbonate and can become brittle over time, especially when exposed to UV light. This may limit its suitability for outdoor applications or in regions with high sun exposure.

Impact on Application: PVC is often used in residential settings and is compliant with various international standards, making it a popular choice in regions like South America and Europe.

Illustrative image related to flat electric plug

What Are the Advantages of Using Nylon for Flat Electric Plugs?

Nylon is a robust material known for its high tensile strength and resistance to abrasion. It can withstand temperatures ranging from -40°C to 120°C, similar to polycarbonate, and offers excellent electrical insulation.

Pros: The durability of nylon makes it suitable for heavy-duty applications, and its resistance to chemicals enhances its appeal in industrial settings. Nylon also has a lower density, contributing to lightweight designs.

Cons: The main drawback of nylon is its higher cost compared to PVC and polycarbonate. Additionally, nylon can absorb moisture, which may affect its electrical properties if not properly treated.

Impact on Application: Nylon’s strength and resistance make it suitable for industrial applications, particularly in regions like Europe, where compliance with stringent safety standards is crucial.

Why is Metal a Viable Option for Flat Electric Plugs?

Metal, particularly brass or copper, is often used in the conductive components of flat electric plugs. Metals provide excellent electrical conductivity and durability, making them essential for effective power transmission.

Illustrative image related to flat electric plug

Pros: Metal components can handle higher currents and have a long lifespan. They are also resistant to corrosion when properly coated, which is vital for plugs used in humid or saline environments.

Cons: The primary disadvantage of metal is its susceptibility to oxidation, which can lead to decreased performance over time. Additionally, metal plugs can be heavier and more expensive to produce than plastic alternatives.

Impact on Application: Metal components are crucial in high-performance applications, especially in regions with strict electrical standards, such as Europe and the Middle East.

Summary Table of Material Selection for Flat Electric Plugs

| Material | Typical Use Case for flat electric plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Residential and commercial applications | High impact resistance and thermal stability | Prone to scratching and lower chemical resistance | Medium |

| PVC | Indoor residential settings | Cost-effective and flexible | Less durable and UV sensitive | Low |

| Nylon | Industrial applications | High tensile strength and abrasion resistance | Higher cost and moisture absorption | High |

| Metal | High-performance electrical applications | Excellent conductivity and durability | Susceptible to oxidation | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in flat electric plugs, helping them make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flat electric plug

What Are the Key Stages in the Manufacturing Process of Flat Electric Plugs?

The manufacturing process of flat electric plugs is intricate, involving several critical stages that ensure functionality, safety, and compliance with international standards.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing process involves selecting high-quality materials. Flat electric plugs typically utilize thermoplastic materials for the casing and copper for the conductive parts. Thermoplastics like polycarbonate or nylon are preferred due to their durability and resistance to heat, while copper ensures excellent conductivity. Manufacturers often source these materials from certified suppliers to guarantee compliance with international quality standards.

How Is the Forming Process Executed?

Once the materials are prepared, the forming process begins. This stage usually involves injection molding for the plastic components and stamping or extrusion for the metal parts. Injection molding allows for precise shaping of the plug casing, while metal parts are formed into the required shapes to fit into the plug assembly. Advanced techniques such as multi-cavity molds can increase production efficiency, allowing manufacturers to produce several plugs simultaneously.

What Does the Assembly Process Entail?

Following the forming stage, the next step is assembly. This process typically involves combining the plastic casing with the metal components, which may include pins and connectors. Automated assembly lines are common, as they enhance speed and accuracy. Skilled workers often conduct final assembly checks to ensure that each plug meets the required specifications, ensuring the integrity of the product before it proceeds to the finishing stage.

Illustrative image related to flat electric plug

How Is the Finishing Process Conducted?

The finishing stage encompasses several important activities, including surface treatment and quality checks. Surface treatments may involve polishing, coating, or applying labels, which not only improve aesthetics but also add to the durability of the plugs. After finishing, products are often subjected to additional quality checks to confirm that they are free from defects and meet all safety regulations.

What Are the International Standards for Quality Assurance in Flat Electric Plug Manufacturing?

Quality assurance is paramount in the manufacturing of flat electric plugs, ensuring that products are safe, reliable, and compliant with various regulations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a crucial role in the quality management systems of manufacturers. This standard emphasizes a process-driven approach to quality assurance and continuous improvement. Additionally, certifications like CE mark in Europe and UL certification in North America indicate compliance with safety and performance standards, which is essential for B2B buyers looking to ensure the reliability of their purchases.

What Are the Industry-Specific Certifications to Consider?

For buyers operating in specific sectors, industry-specific certifications may also apply. For instance, electrical products might require compliance with IEC standards, especially in regions like the Middle East and Europe. Understanding these certifications can help B2B buyers assess the credibility of potential suppliers and their commitment to quality.

What Are the Key Quality Control Checkpoints in Flat Electric Plug Production?

Quality control (QC) is integrated into various stages of the manufacturing process, with specific checkpoints to ensure product integrity.

What Are the Stages of Quality Control?

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the manufacturing facility. Inspectors evaluate the quality of materials against predefined specifications before they are used in production.

-

In-Process Quality Control (IPQC): During production, IPQC monitors the processes to catch defects early. This may include monitoring temperatures during molding or checking dimensions at various assembly stages.

-

Final Quality Control (FQC): After production is complete, FQC involves comprehensive testing of the finished products. This includes electrical testing, durability tests, and visual inspections to ensure that the plugs meet safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control measures.

What Are Effective Verification Methods?

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their manufacturing processes and quality assurance practices firsthand. This can be scheduled or surprise visits to ensure compliance.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insights into their quality assurance processes. These reports should include information on testing methods, failure rates, and corrective actions taken for any defects.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. This is especially valuable when dealing with international suppliers, as it can help mitigate risks associated with overseas transactions.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control and certification, especially when sourcing from regions like Africa, South America, the Middle East, and Europe.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations that affect quality assurance practices. For instance, while European standards may focus heavily on environmental impact, Middle Eastern standards might prioritize electrical safety. B2B buyers should be familiar with these regional differences to ensure that their suppliers meet the necessary compliance requirements.

What Additional Steps Can Buyers Take?

To further mitigate risks, buyers should consider establishing long-term relationships with trusted suppliers who have a proven track record in quality assurance. Additionally, participating in trade shows and industry conferences can provide valuable insights into best practices in manufacturing and quality control, helping buyers make informed decisions.

By understanding the manufacturing processes and quality assurance measures involved in the production of flat electric plugs, B2B buyers can better assess potential suppliers and ensure they are receiving high-quality, compliant products that meet their specific needs.

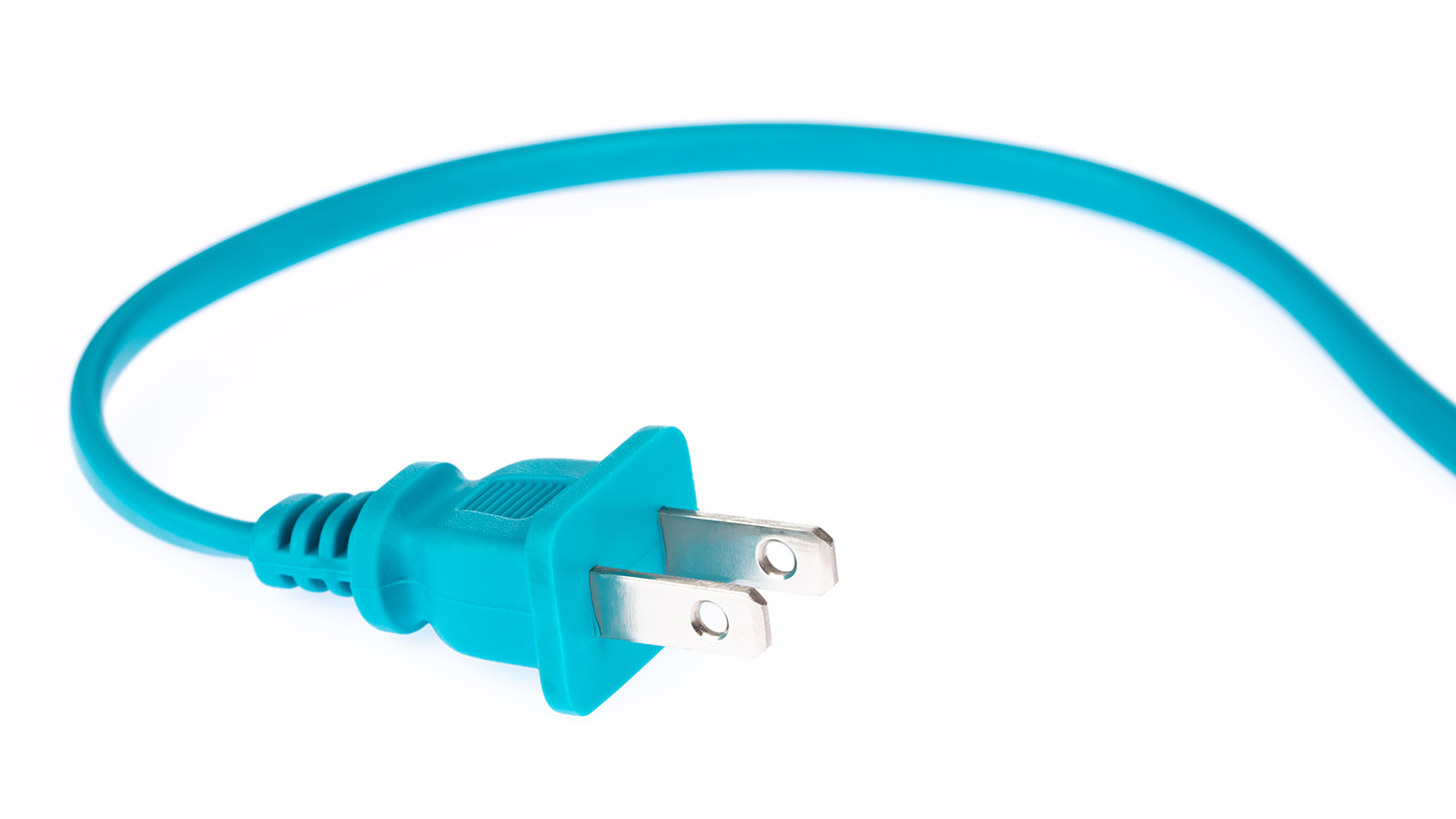

Illustrative image related to flat electric plug

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flat electric plug’

This guide serves as a practical checklist for B2B buyers seeking to procure flat electric plugs, ensuring a streamlined sourcing process that meets both technical and regulatory requirements. By following these steps, buyers can make informed decisions that align with their business needs and regional standards.

Step 1: Define Your Technical Specifications

Understanding the technical specifications of flat electric plugs is crucial for ensuring compatibility with your intended applications. Identify the voltage and current ratings, plug configurations, and safety standards required in your target markets. Consider factors such as environmental conditions and specific use cases that may influence your choice.

Step 2: Research Regulatory Compliance

Compliance with local and international standards is essential to avoid legal issues and ensure safety. Research the relevant certifications and regulations that apply to flat electric plugs in your target regions, such as CE marking in Europe or IEC standards. Ensure that your suppliers can provide documentation proving compliance with these standards.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, thorough evaluation is vital. Request detailed company profiles, product samples, and case studies showcasing their experience in manufacturing flat electric plugs. Look for reviews and testimonials from other buyers, especially those in similar industries or regions, to gauge reliability and product quality.

Step 4: Request Samples for Quality Testing

Always request samples before placing bulk orders to assess the quality of the flat electric plugs. Conduct rigorous testing to ensure that the plugs meet your specifications and industry standards. This step helps to identify any potential issues with durability, safety, and performance before committing to a larger investment.

Illustrative image related to flat electric plug

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and pricing. Consider not only the unit price but also payment terms, shipping costs, and lead times. A clear understanding of these factors can significantly impact your overall budget and supply chain efficiency.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Set up regular check-ins and updates with your chosen supplier to discuss progress, address concerns, and adjust orders as necessary. Clear communication can prevent misunderstandings and ensure that both parties remain aligned throughout the sourcing process.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan for the distribution of your flat electric plugs. Consider factors such as shipping methods, customs regulations, and delivery timelines to your target markets. A well-structured logistics strategy can help minimize delays and reduce costs, ensuring that you meet your business objectives efficiently.

By following this checklist, B2B buyers can navigate the complexities of sourcing flat electric plugs with confidence, ensuring that they select the right products and suppliers for their needs.

Illustrative image related to flat electric plug

Comprehensive Cost and Pricing Analysis for flat electric plug Sourcing

What Are the Key Cost Components in Sourcing Flat Electric Plugs?

When sourcing flat electric plugs, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts costs. Common materials used in flat electric plugs include thermoplastics for casing and copper for conductors. The price of these raw materials can fluctuate based on market conditions and sourcing locations.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer more competitive pricing, but it’s essential to assess the skill level and training of the workforce to ensure quality standards.

-

Manufacturing Overhead: This encompasses costs associated with production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, translating to better pricing for buyers.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs. Buyers should consider how these costs are amortized over production runs, as larger orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Ensuring that flat electric plugs meet international safety standards requires a robust QC process. The costs associated with testing and certification should be factored into the overall pricing strategy.

-

Logistics: Transportation costs can vary greatly depending on the origin and destination of the plugs. Factors such as shipping method, distance, and customs duties play a crucial role in total logistics expenses.

-

Margin: Suppliers will add a margin to cover their risks and profit. Understanding the typical margins in the industry can aid buyers in evaluating offers.

How Do Price Influencers Affect Flat Electric Plug Sourcing?

Several factors can influence the pricing of flat electric plugs, making it essential for buyers to be aware of these elements:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes typically lead to discounts, while lower quantities may incur higher per-unit costs. Buyers should negotiate MOQs that align with their needs.

-

Specifications and Customization: Custom features or specifications can increase costs. While tailored solutions may enhance functionality, they often come with additional expenses. Buyers should weigh the benefits against the costs when considering customization.

-

Materials and Quality Certifications: Higher quality materials and certifications (like CE or UL) may result in increased costs but can provide assurance of product safety and reliability. This is particularly important in regions with strict regulatory standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence costs. Established suppliers may charge a premium for their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects the distribution of responsibilities and costs between buyers and suppliers. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate cost estimation.

What Tips Can Help Buyers Optimize Costs When Sourcing Flat Electric Plugs?

To maximize cost-efficiency in sourcing flat electric plugs, buyers should consider the following strategies:

-

Negotiation: Strong negotiation skills can lead to better pricing. Be prepared to discuss terms and demonstrate your value as a long-term partner, especially when placing large orders.

-

Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider factors such as durability, warranty, and maintenance costs to determine the TCO. A higher upfront cost may be justified if the product lasts longer and requires less maintenance.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and local economic conditions that can affect pricing. Building relationships with local suppliers may also offer advantages in terms of support and logistics.

-

Stay Informed: Regularly review market trends and raw material prices to anticipate changes that could impact sourcing costs. This proactive approach can help buyers make informed decisions and negotiate better deals.

Conclusion

Understanding the comprehensive cost structure and pricing factors associated with flat electric plug sourcing is essential for international B2B buyers. By considering materials, labor, logistics, and other influencing factors, buyers can make informed decisions that enhance their sourcing strategies while optimizing costs. Always remember that prices are subject to change, and it’s advisable to seek multiple quotes and conduct thorough market research before finalizing any agreements.

Alternatives Analysis: Comparing flat electric plug With Other Solutions

Introduction: Why Consider Alternatives to Flat Electric Plugs?

In the evolving landscape of electrical connectivity, flat electric plugs have gained popularity for their space-saving design and versatility. However, businesses must evaluate alternative solutions to determine the most suitable option for their specific needs. This analysis will compare flat electric plugs with two viable alternatives: traditional round electric plugs and smart plugs. By understanding their respective performance, costs, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions.

Comparison Table

| Comparison Aspect | Flat Electric Plug | Traditional Round Electric Plug | Smart Plug |

|---|---|---|---|

| Performance | High compatibility with slim outlets | Good compatibility but bulkier | Varies; dependent on Wi-Fi connectivity |

| Cost | Moderate | Low to moderate | Moderate to high |

| Ease of Implementation | Simple installation | More complex due to size | Requires app setup |

| Maintenance | Minimal maintenance | Minimal maintenance | Regular firmware updates needed |

| Best Use Case | Ideal for tight spaces and modern designs | General use in various settings | Smart home automation and energy monitoring |

Detailed Breakdown: What Are the Pros and Cons of Each Alternative?

Traditional Round Electric Plug

Traditional round plugs have been the standard for decades and are widely recognized. Their main advantage is affordability; they are generally cheaper to manufacture and purchase. However, their bulkier design can be a disadvantage in tight spaces, limiting their use in modern, compact environments. They are also compatible with a wide range of devices, making them versatile for general applications. However, their size may hinder aesthetics in contemporary setups.

Smart Plug

Smart plugs represent a modern solution that enables remote control and automation of electrical devices. They can be easily integrated into smart home systems, allowing users to monitor energy usage and schedule devices from mobile apps. While they offer innovative features and convenience, smart plugs come at a higher price point and may require additional setup, including Wi-Fi configuration. Maintenance involves regular updates, which can be seen as a drawback for businesses seeking straightforward solutions. Their best use case lies in environments prioritizing automation and energy efficiency.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the ideal electrical plug solution, B2B buyers should carefully assess their unique requirements. Flat electric plugs are perfect for modern, space-conscious environments, while traditional round plugs serve as a cost-effective option for general applications. Smart plugs offer advanced features for those looking to enhance energy management and automation. By weighing the pros and cons of each alternative against their specific operational needs, businesses can make an informed choice that aligns with their strategic objectives and enhances overall efficiency.

Essential Technical Properties and Trade Terminology for flat electric plug

What Are the Key Technical Properties of Flat Electric Plugs?

When sourcing flat electric plugs, understanding critical technical specifications is essential for ensuring quality, compatibility, and safety. Here are some of the most important properties to consider:

1. Material Grade

The material used in the construction of flat electric plugs significantly impacts their durability and performance. Common materials include thermoplastic, which offers excellent insulation and resistance to heat, and copper for conductors, known for its high conductivity. Selecting the right material can enhance product longevity and reduce the risk of electrical failures, making it crucial for buyers to specify their material grade requirements.

2. Voltage and Current Ratings

Flat electric plugs are rated for specific voltage and current levels, typically expressed in volts (V) and amperes (A). For instance, a plug designed for 250V and 10A is suitable for general household applications in many regions. Buyers must ensure that the plug’s ratings match their electrical systems to prevent overheating or malfunctioning, which could lead to safety hazards.

3. Tolerance Levels

Tolerance refers to the allowable deviation in the dimensions of the plug components. For flat electric plugs, this includes the size of the prongs and the overall dimensions of the housing. Maintaining strict tolerance levels is vital to ensure compatibility with sockets and to guarantee secure connections. For B2B buyers, specifying tolerance levels can prevent costly returns and customer dissatisfaction.

4. Safety Certifications

Safety certifications, such as CE, UL, and IEC standards, indicate that the flat electric plug has been tested and meets specific safety criteria. These certifications are crucial for market acceptance in different regions, as they assure buyers of the product’s reliability and compliance with local regulations. Understanding the necessary certifications for target markets can aid in making informed purchasing decisions.

5. Environmental Resistance

Flat electric plugs are often exposed to various environmental conditions, such as moisture, dust, and extreme temperatures. Specifications for environmental resistance, like IP ratings (Ingress Protection), indicate the plug’s ability to withstand these conditions. Buyers should assess the intended application environments to select plugs that will perform reliably under specific conditions.

What Are Common Trade Terms Related to Flat Electric Plugs?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key trade terms relevant to flat electric plugs:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then rebranded and sold by another company. In the context of flat electric plugs, understanding OEM relationships can help buyers source high-quality components that meet their specifications without incurring additional branding costs.

Illustrative image related to flat electric plug

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This term is critical for B2B buyers as it impacts inventory management and overall purchasing costs. Understanding MOQ allows buyers to negotiate better terms or find alternative suppliers that can accommodate smaller orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For flat electric plugs, sending an RFQ helps buyers obtain competitive pricing and terms, making it a valuable tool for budgeting and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including the delivery of goods, insurance, and risk management. Familiarity with these terms is essential for B2B buyers to understand their obligations and costs associated with shipping flat electric plugs across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. For flat electric plugs, understanding lead times is crucial for project planning and inventory management. Buyers should communicate their timelines clearly to suppliers to ensure timely delivery and avoid delays in production.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing flat electric plugs, ultimately enhancing their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the flat electric plug Sector

What Are the Key Market Dynamics and Trends in the Flat Electric Plug Sector?

The flat electric plug market is witnessing significant growth, driven by the increasing demand for space-saving electrical solutions across various industries. With urbanization and the rise of compact living spaces, particularly in regions like Europe and Asia, the need for flat electric plugs that can fit into tight spaces is becoming more pronounced. Additionally, the global shift towards smart homes and IoT devices is driving innovation in plug design, with features such as USB integration and smart connectivity gaining traction.

Emerging technologies, such as wireless charging and energy-efficient designs, are becoming essential considerations for B2B buyers looking to meet consumer expectations for convenience and sustainability. Furthermore, the growing emphasis on safety standards and certifications, especially in markets like the Middle East and Africa, is prompting manufacturers to adapt their products to comply with international regulations, ensuring both quality and reliability.

International buyers should also be aware of the competitive landscape, where manufacturers are increasingly collaborating with technology firms to integrate advanced functionalities into their products. By staying attuned to these market dynamics and sourcing trends, B2B buyers can make informed decisions that align with current demands and future innovations.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Flat Electric Plug Industry?

Sustainability and ethical sourcing are becoming critical factors for B2B buyers in the flat electric plug sector. As environmental concerns continue to rise, companies are under pressure to adopt sustainable practices throughout their supply chains. This includes selecting materials that minimize environmental impact, such as recyclable plastics and eco-friendly metals, which not only reduce the carbon footprint but also resonate with increasingly eco-conscious consumers.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are encouraged to partner with manufacturers who prioritize fair labor practices and transparency in their sourcing processes. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. These certifications not only enhance brand reputation but also open doors to new markets, particularly in regions like Europe, where consumers are more inclined to support sustainable brands.

Illustrative image related to flat electric plug

Ultimately, integrating sustainability into sourcing strategies can provide a competitive edge, leading to improved customer loyalty and compliance with regulatory standards, particularly in emerging markets where such regulations are becoming increasingly stringent.

How Has the Flat Electric Plug Evolved Over Time?

The evolution of the flat electric plug has been marked by technological advancements and shifting consumer needs. Initially designed for basic electrical connectivity, flat plugs have transformed into multifunctional devices that cater to modern demands. The introduction of compact designs allowed for better space management, especially in urban environments where outlet accessibility is often limited.

Over the years, the integration of safety features, such as surge protection and child safety locks, has become standard, reflecting a growing awareness of electrical safety concerns. Furthermore, the rise of smart technology has led to the development of smart plugs that not only offer connectivity but also energy monitoring capabilities.

As the market continues to evolve, B2B buyers must stay informed about these historical trends to anticipate future developments and align their sourcing strategies accordingly. Understanding the trajectory of the flat electric plug market can provide valuable insights into consumer preferences and emerging technologies, ensuring that businesses remain competitive in a dynamic landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of flat electric plug

-

How do I ensure the quality of flat electric plugs before purchasing?

To guarantee the quality of flat electric plugs, consider requesting samples from potential suppliers. This allows you to assess their craftsmanship and adherence to international safety standards. Additionally, verify that the supplier has relevant certifications, such as ISO or CE marking, which demonstrate compliance with quality benchmarks. Establishing a clear quality assurance process, including inspections during production and before shipment, can further mitigate risks associated with poor-quality products. -

What are the key specifications to look for in flat electric plugs?

When sourcing flat electric plugs, focus on specifications such as voltage rating, current rating, material quality, and compatibility with local electrical standards. It’s essential to ensure that the plugs meet the requirements of the regions where they will be used, especially for markets in Africa, South America, the Middle East, and Europe. Additionally, consider factors like durability, weather resistance, and whether the plugs are designed for specific applications, such as residential or industrial use. -

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, assess the financial stability of your supplier and their willingness to accommodate flexible terms. Common arrangements include a deposit upfront, followed by the balance upon delivery or after inspection. Consider using secure payment methods like letters of credit or escrow services to protect your investment. Additionally, ensure that payment terms are clearly outlined in the contract to avoid misunderstandings later. -

How can I customize flat electric plugs for my specific market needs?

To customize flat electric plugs, communicate your specific requirements to potential suppliers early in the negotiation process. Discuss aspects such as design, color, branding, and packaging that align with your market preferences. Some manufacturers may offer design services or modifications for bulk orders, allowing you to create products that cater to local standards and consumer preferences. Ensure that any customization adheres to relevant safety regulations in your target markets. -

What is the minimum order quantity (MOQ) for flat electric plugs?

The MOQ for flat electric plugs can vary significantly based on the supplier and the complexity of the product. Typically, manufacturers may set an MOQ ranging from 500 to several thousand units. When sourcing, it’s crucial to discuss MOQs upfront to ensure they align with your purchasing capacity. If the MOQ is higher than your needs, consider negotiating with the supplier or exploring alternative manufacturers who can accommodate smaller orders. -

What logistics considerations should I keep in mind when importing flat electric plugs?

When importing flat electric plugs, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Opt for reliable shipping partners and clarify the incoterms (e.g., FOB, CIF) to understand your responsibilities for shipping and insurance. Be aware of import tariffs and duties that may apply in your country, and ensure that all documentation, including invoices and certificates of origin, is prepared accurately to facilitate a smooth customs clearance process. -

How can I vet suppliers for flat electric plugs effectively?

To vet suppliers, conduct thorough research and due diligence. Start by checking their business credentials, such as registration and certifications. Request references from previous clients and assess their reputation through online reviews or industry forums. Consider visiting the supplier’s manufacturing facility if possible, or utilize third-party inspection services to evaluate their production capabilities. Establishing a strong relationship with your supplier is essential for long-term collaboration. -

What are the common safety standards for flat electric plugs in international markets?

Flat electric plugs are subject to various safety standards, which can differ by region. In Europe, for instance, plugs must comply with the IEC standards, while in the U.S., they need to meet UL certifications. For markets in Africa and South America, local standards may apply, such as SANS in South Africa or INMETRO in Brazil. Ensure that your chosen suppliers are familiar with and compliant with the relevant safety standards to prevent regulatory issues and ensure consumer safety.

A Look at Flat Electric Plug Manufacturers & Suppliers

We are currently compiling a detailed list of top flat electric plug suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for flat electric plug

What Are the Key Takeaways for B2B Buyers in Flat Electric Plug Sourcing?

In summary, the strategic sourcing of flat electric plugs presents a unique opportunity for international B2B buyers to enhance their product offerings while optimizing costs. Understanding regional compliance standards and consumer preferences is essential, especially in diverse markets across Africa, South America, the Middle East, and Europe. By focusing on reliable suppliers with a proven track record in quality and sustainability, businesses can mitigate risks and ensure product integrity.

How Can Strategic Sourcing Enhance Your Supply Chain Efficiency?

Investing in strategic sourcing not only streamlines procurement processes but also fosters long-term partnerships that can lead to innovation. As the demand for flat electric plugs continues to rise, particularly in fast-growing economies, staying ahead of market trends will be crucial. Leveraging data analytics and market insights can empower buyers to make informed decisions, aligning product specifications with emerging consumer needs.

Illustrative image related to flat electric plug

What’s Next for International B2B Buyers?

Looking ahead, the landscape for flat electric plugs is ripe for innovation and growth. As sustainability becomes a pivotal concern, incorporating eco-friendly materials and energy-efficient designs into your sourcing strategy will not only meet regulatory demands but also resonate with environmentally conscious consumers. Now is the time to reassess your sourcing strategy—engage with forward-thinking suppliers and explore new markets to secure your competitive edge in this evolving sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.