Bike Predator Helmet Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bike predator helmet

Navigating the intricate landscape of the global market for bike predator helmets presents a unique challenge for international B2B buyers. With a growing demand for high-quality, safe, and stylish helmets, sourcing the right products that comply with local regulations and safety standards can be daunting. This guide aims to illuminate the complexities of the bike predator helmet market by examining various types and applications, detailing supplier vetting processes, and providing insights into pricing structures.

As buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Nigeria and Saudi Arabia—seek to make informed purchasing decisions, understanding the nuances of the market becomes essential. The guide not only highlights the technological advancements in helmet design, such as lightweight materials and enhanced safety features, but also addresses the importance of selecting suppliers who prioritize quality and compliance with international safety standards.

By offering a comprehensive overview of critical factors such as product specifications, market trends, and supplier reliability, this guide empowers B2B buyers to navigate the global market with confidence. The objective is to ensure that every purchasing decision is backed by thorough research and industry insights, ultimately leading to safer and more appealing helmet options for consumers worldwide.

Understanding bike predator helmet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DH6-X Air | Made from pre-preg carbon fiber; lightweight; spherical visor for optimal visibility. | High-performance cycling, competitive sports. | Pros: Superior strength-to-weight ratio; excellent aerodynamics. Cons: Higher price point may limit accessibility. |

| FR7 Certified | Lightweight open-face design; low-profile; suitable for various personal electric vehicles. | Skateboarding, park skating, recreational cycling. | Pros: Versatile use; comfortable fit. Cons: Less protection than full-face options. |

| DH6-Xe | Constructed with pre-preg fiberglass; heat-cured for enhanced durability. | General cycling, casual riding. | Pros: Strong yet affordable; good ventilation. Cons: Heavier than carbon fiber variants. |

| Uno Elite | Ultralight design; optimized for multi-impact protection; ideal for water sports. | Kayaking, canoe racing, adventure sports. | Pros: Excellent for high-impact activities; lightweight. Cons: May not offer full coverage for motorcycling. |

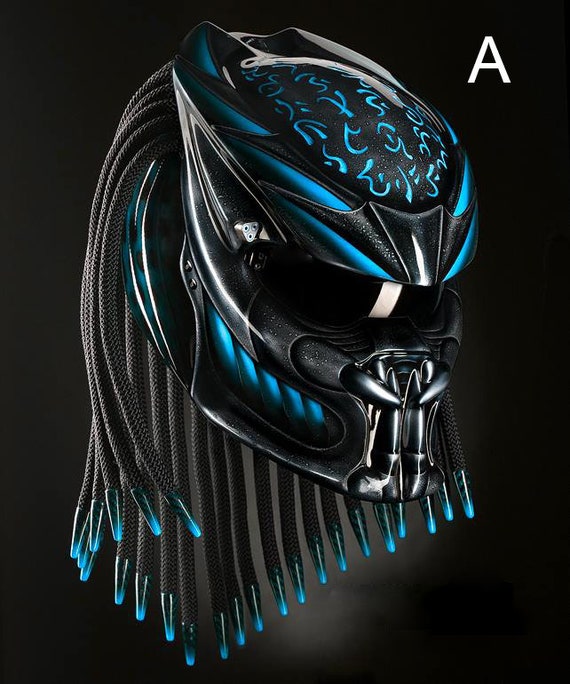

| Predator Hunter | Customizable designs; based on proven motorcycle helmet models; DOT/ECE certified. | Motorcycle riding, custom helmet markets. | Pros: Unique aesthetics; meets safety standards. Cons: Customization may increase lead times. |

What are the characteristics of the DH6-X Air bike predator helmet?

The DH6-X Air helmet stands out due to its construction from pre-preg carbon fiber, which provides a remarkable strength-to-weight ratio. The spherical visor is designed for optical clarity, enhancing visibility for riders. This helmet is particularly suitable for high-performance cycling and competitive sports, making it ideal for B2B buyers focused on quality and performance. When considering this model, businesses should note its premium price point, which may limit its appeal in budget-sensitive markets.

How does the FR7 Certified helmet cater to diverse riding styles?

The FR7 Certified helmet is a lightweight, open-face design that caters to various riding styles, including skateboarding and personal electric vehicle (PEV) use. Its low-profile fit ensures comfort and stability, making it a popular choice for recreational activities. B2B buyers should evaluate its versatility and comfort against the trade-off of reduced head protection compared to full-face helmets. Its affordability and broad application make it an attractive option for diverse markets.

What advantages does the DH6-Xe helmet offer for casual riders?

Constructed from heat-cured pre-preg fiberglass, the DH6-Xe helmet combines durability with affordability, making it suitable for casual riding. It offers good ventilation and comfort, appealing to everyday cyclists. For B2B buyers, this model represents a balance between quality and cost, making it accessible for various demographics. However, its weight is slightly higher than carbon fiber alternatives, which may affect its desirability among performance-focused buyers.

In what scenarios is the Uno Elite helmet most effective?

The Uno Elite helmet is designed for ultralight performance, specifically optimized for water sports such as kayaking and canoe racing. Its multi-impact protection features make it ideal for high-risk environments. B2B buyers targeting adventure sports markets should consider its lightweight design and protective capabilities, although it may not be suitable for full motorcycle use. Its specialized application can help businesses differentiate their product offerings in niche markets.

How does the Predator Hunter helmet meet safety and customization needs?

The Predator Hunter helmet is notable for its customizable designs based on proven motorcycle helmet models, ensuring it meets DOT/ECE safety certifications. This feature appeals to businesses looking to offer unique, stylish options to their customers. While the customization aspect can enhance marketability, B2B buyers should be aware that it may extend lead times for delivery. This helmet’s combination of safety and aesthetics positions it well in the custom helmet market.

Key Industrial Applications of bike predator helmet

| Industry/Sector | Specific Application of bike predator helmet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cycling and Outdoor Sports | High-performance cycling and mountain biking | Enhanced safety and comfort for riders, promoting brand loyalty | Compliance with international safety standards, lightweight materials, and custom designs |

| Emergency Services | Protective gear for paramedics and rescue teams | Improved head protection during high-risk operations | Durability in extreme conditions, visibility features, and easy communication integration |

| Motorcycle Tours and Rentals | Helmets for rental services and guided tours | Attracts customers with stylish, safe options, boosting sales | Cost-effectiveness, bulk purchasing options, and brand customization |

| Film and Media Production | Props and safety gear for stunt performers | Unique designs enhance visual appeal while ensuring safety | Customization options for branding, lightweight materials, and safety certifications |

| Military and Security | Tactical helmets for security personnel and military use | Provides essential protection while maintaining mobility | Compliance with military standards, availability of accessories, and customization capabilities |

How Are Bike Predator Helmets Utilized in Cycling and Outdoor Sports?

In the cycling and outdoor sports industry, bike predator helmets are essential for high-performance cycling and mountain biking. These helmets are designed with advanced materials such as carbon fiber and fiberglass, providing both safety and lightweight comfort. They address common issues such as head injuries during falls and heat discomfort during long rides. For international buyers, particularly in regions like Africa and South America, sourcing helmets that comply with local safety regulations while offering customization options for branding is crucial.

Illustrative image related to bike predator helmet

What Role Do Bike Predator Helmets Play in Emergency Services?

Emergency services utilize bike predator helmets as protective gear for paramedics and rescue teams. These helmets are engineered to withstand harsh environments and provide maximum head protection during emergency operations. They solve the critical problem of safety in high-risk situations while also allowing for features like communication systems. Buyers in the Middle East and Europe should consider sourcing helmets that meet stringent safety standards and offer features such as high visibility for better identification in emergencies.

How Do Motorcycle Tours and Rentals Benefit from Bike Predator Helmets?

Motorcycle tours and rental companies benefit significantly from incorporating bike predator helmets into their offerings. These helmets not only enhance the safety of riders but also appeal to customers with their unique and stylish designs. The use of high-quality materials ensures durability and comfort, thereby increasing customer satisfaction and brand loyalty. B2B buyers in regions like Nigeria and Saudi Arabia should focus on cost-effective sourcing solutions that allow for bulk purchases and customization options to stand out in a competitive market.

In What Ways Are Bike Predator Helmets Used in Film and Media Production?

In the film and media production sector, bike predator helmets serve as both props and safety gear for stunt performers. Their bold designs add to the visual impact of action scenes while ensuring the safety of the actors involved. The helmets can be customized to fit the specific aesthetic of a production, making them appealing for filmmakers looking for unique and safe options. International buyers must prioritize sourcing helmets that comply with safety regulations while offering customization features to meet specific production needs.

How Are Bike Predator Helmets Relevant to Military and Security Applications?

In military and security applications, bike predator helmets are utilized as tactical headgear, providing essential protection without sacrificing mobility. These helmets are designed to meet military standards for durability and safety, addressing the critical need for reliable protective equipment in challenging environments. Buyers in the defense sector should consider sourcing helmets that offer additional features such as communication systems and compatibility with tactical gear, ensuring they meet the unique demands of military operations.

3 Common User Pain Points for ‘bike predator helmet’ & Their Solutions

Scenario 1: Sourcing High-Quality Materials for Durability

The Problem: B2B buyers often struggle to identify suppliers that provide high-quality materials for bike predator helmets, especially when considering safety certifications and performance standards. In regions like Africa and South America, where local manufacturing capabilities may be limited, buyers face the challenge of ensuring that the helmets meet international safety standards while also being cost-effective. This can lead to concerns about the reliability of suppliers and the overall quality of the products.

The Solution: To effectively source high-quality bike predator helmets, buyers should prioritize suppliers with proven track records in using advanced materials such as pre-preg carbon fiber and fiberglass. It’s essential to request documentation that verifies compliance with safety certifications like DOT and ECE standards. Establishing relationships with manufacturers that offer transparency in their production processes can provide reassurance. Additionally, engaging in pilot programs or ordering sample products before committing to large orders can help assess quality firsthand. Utilizing platforms that aggregate reviews and ratings of suppliers can also guide buyers in making informed decisions.

Scenario 2: Ensuring Proper Fit and Comfort for End Users

The Problem: Another significant pain point for B2B buyers is ensuring that bike predator helmets fit properly and provide comfort for a wide range of end users. This is particularly crucial in markets with diverse demographic characteristics, where variations in head sizes and shapes can lead to dissatisfaction and potential safety issues. Poor fit can result in helmets not being worn, which directly impacts the buyer’s reputation and the safety of riders.

The Solution: Buyers should collaborate closely with manufacturers to develop a comprehensive sizing guide that accounts for regional demographics. This might involve collecting data on local head size distributions and preferences. Offering a range of adjustable helmets or those with customizable padding can enhance comfort and fit. Additionally, conducting focus groups or surveys with potential users can provide insights into fit preferences. Ensuring that the helmets come with clear return policies can also mitigate risks related to sizing issues, allowing buyers to confidently stock products that meet user needs.

Scenario 3: Navigating Regulatory Compliance and Shipping Challenges

The Problem: B2B buyers face significant hurdles in navigating the regulatory landscape surrounding the import and sale of bike predator helmets, especially in regions with stringent customs regulations and varying safety requirements. In markets like the Middle East and Europe, compliance with local laws can lead to delays in shipping, increased costs, and potential legal issues if regulations are not met.

The Solution: To effectively navigate these challenges, buyers should invest time in understanding the regulatory requirements specific to each target market. Engaging with local legal experts or compliance consultants can provide valuable insights into the necessary certifications and paperwork needed for import. It’s also beneficial to partner with logistics companies that specialize in handling goods with specific regulatory requirements, ensuring that shipping processes are streamlined and compliant. Furthermore, maintaining open communication with suppliers regarding shipping timelines and potential customs issues can help buyers plan better and avoid unexpected delays. Creating a compliance checklist that outlines necessary steps for each market can also serve as a practical guide for future transactions.

Strategic Material Selection Guide for bike predator helmet

What Are the Key Materials Used in Bike Predator Helmets?

When selecting materials for bike predator helmets, several factors come into play, including safety, weight, comfort, and cost. Below is an analysis of four common materials used in the manufacturing of these helmets, tailored to the needs of international B2B buyers.

How Does Carbon Fiber Enhance Helmet Performance?

Carbon fiber is a leading choice for high-performance bike helmets due to its exceptional strength-to-weight ratio. It can withstand high temperatures and pressures, making it suitable for rigorous biking conditions. Carbon fiber helmets typically exhibit excellent impact resistance, crucial for protecting riders during falls.

Illustrative image related to bike predator helmet

Pros:

– Lightweight and durable, enhancing comfort during long rides.

– High strength allows for thinner designs without compromising safety.

– Corrosion-resistant, ensuring longevity.

Cons:

– Higher manufacturing costs compared to other materials.

– More complex production processes may lead to longer lead times.

Impact on Application:

Carbon fiber is compatible with various biking activities, including downhill and racing, where performance is critical.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with safety standards such as ECE and DOT, which are critical for market entry.

Why is Fiberglass a Popular Choice for Helmet Construction?

Fiberglass is another widely used material that offers a good balance between cost and performance. It is known for its robustness and ability to absorb impact, making it a popular choice for entry-level to mid-range helmets.

Pros:

– Cost-effective compared to carbon fiber, making it accessible for broader markets.

– Good impact resistance, providing adequate safety for recreational riders.

– Easier to mold into various shapes, allowing for diverse designs.

Cons:

– Heavier than carbon fiber, which may affect rider comfort over long distances.

– Less durable than carbon fiber, potentially leading to shorter product lifespans.

Impact on Application:

Fiberglass helmets are suitable for general biking and casual use, appealing to a wider audience.

Illustrative image related to bike predator helmet

Considerations for International Buyers:

Buyers in Africa and South America should consider local manufacturing capabilities, as fiberglass can be easier to source and produce locally.

How Do Thermoplastics Contribute to Helmet Safety?

Thermoplastics, such as polycarbonate and ABS, are often used in budget-friendly helmets. These materials are known for their impact resistance and ease of manufacturing.

Pros:

– Economical, making them ideal for mass production.

– Good impact absorption properties, providing basic safety for casual riders.

– Lightweight, enhancing comfort.

Cons:

– Generally less durable than fiberglass and carbon fiber, leading to potential safety concerns over time.

– Limited design flexibility compared to composite materials.

Impact on Application:

Thermoplastic helmets are suitable for urban commuting and casual biking, where extreme performance is not a priority.

Considerations for International Buyers:

Compliance with local safety standards is crucial, particularly in regions with strict regulations, such as Europe.

What Role Does EPS Foam Play in Helmet Safety?

Expanded Polystyrene (EPS) foam is a critical component in helmet construction, providing essential cushioning and impact absorption.

Pros:

– Excellent energy absorption, significantly enhancing rider safety.

– Lightweight, contributing to overall helmet comfort.

– Cost-effective, making it easy to incorporate into various helmet designs.

Illustrative image related to bike predator helmet

Cons:

– Limited lifespan; EPS can degrade over time and may need replacement after significant impacts.

– Not suitable for high-temperature applications, as it can lose structural integrity.

Impact on Application:

EPS foam is universally applicable across all types of helmets, ensuring basic safety standards are met.

Considerations for International Buyers:

Buyers should verify that EPS foam used in helmets meets relevant safety certifications, as this can vary by region.

Illustrative image related to bike predator helmet

Summary Table of Material Selection for Bike Predator Helmets

| Material | Typical Use Case for bike predator helmet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber | High-performance racing helmets | Exceptional strength-to-weight ratio | High manufacturing costs | High |

| Fiberglass | Entry-level to mid-range helmets | Cost-effective and robust | Heavier than carbon fiber | Medium |

| Thermoplastics | Budget-friendly helmets | Economical and lightweight | Less durable than composites | Low |

| EPS Foam | All helmet types | Excellent energy absorption | Limited lifespan | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to source bike predator helmets that meet safety, performance, and cost requirements in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for bike predator helmet

What Are the Key Stages in the Manufacturing Process of Bike Predator Helmets?

The manufacturing process for bike predator helmets involves several critical stages, each designed to ensure the highest quality and safety standards. Here’s a breakdown of these stages:

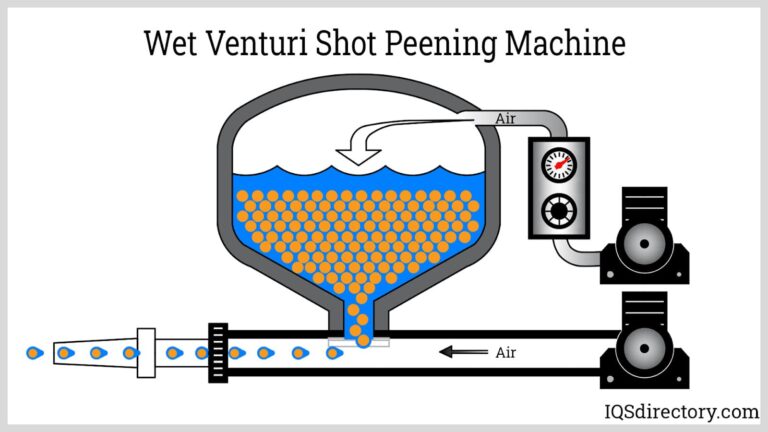

1. Material Preparation

The first step in producing bike predator helmets is the selection and preparation of raw materials. High-performance materials such as pre-preg carbon fiber and fiberglass are commonly used due to their excellent strength-to-weight ratio. These materials undergo rigorous testing to ensure they meet specific safety and performance criteria before being cut into the required shapes for helmet shells.

2. Forming and Molding Techniques

Once the materials are prepared, they are formed into the helmet shape through advanced molding techniques. The pre-preg materials are placed in molds and then subjected to heat and pressure in an autoclave. This process not only ensures uniform curing but also enhances the structural integrity of the helmet. The use of spherical visors is also a common feature, as they provide optical clarity and reduce distortion, crucial for rider safety.

3. Assembly Process

After the shell is formed, the assembly process begins. This includes integrating components such as the visor, inner foam padding, and fastening systems. Each helmet must be carefully assembled to ensure a snug fit and optimal comfort. Quality checks are performed at this stage to confirm that all parts meet the specifications outlined in the design phase.

Illustrative image related to bike predator helmet

4. Finishing Touches

The final stage of manufacturing involves applying surface finishes, which may include paint, decals, or other aesthetic enhancements. This step not only contributes to the helmet’s visual appeal but also adds an extra layer of protection against environmental elements. Each helmet is then subjected to a final inspection to ensure it meets all design and quality standards before it is packaged for distribution.

What Are the International Standards and Quality Assurance Protocols for Bike Predator Helmets?

Quality assurance in helmet manufacturing is crucial to ensure safety and compliance with international standards. B2B buyers should be aware of the following key standards and protocols:

Relevant International Standards

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) that organizations must follow to ensure consistent quality in their products and services. Compliance with ISO 9001 indicates that a manufacturer has a robust quality management system in place.

-

CE Marking: In Europe, helmets must meet the requirements set forth by the European Committee for Standardization (CEN), which focuses on safety, performance, and labeling. Helmets with the CE mark have passed rigorous testing and are deemed safe for use.

-

DOT Certification: In the United States, the Department of Transportation (DOT) sets safety standards for helmets. Helmets that meet these standards are tested for impact resistance and structural integrity.

-

API Standards: While more common in the petroleum and automotive industries, API standards may apply to specific helmet components, particularly those designed for high-performance applications.

Quality Control Checkpoints

Quality control (QC) is an integral part of the manufacturing process, ensuring that each helmet produced meets safety standards. Key checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify their compliance with specified standards. This is crucial for ensuring that only high-quality materials are used in production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor quality at various stages. This includes checking the curing process, assembly accuracy, and fitment of components.

-

Final Quality Control (FQC): Before helmets are packaged, a final inspection is performed to ensure that every product meets the required specifications. This step often includes testing for impact resistance, comfort, and aesthetic quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to ensure that their suppliers adhere to stringent quality control practices. Here are some actionable strategies:

Conducting Supplier Audits

Regular audits of suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. During these audits, buyers should assess compliance with international standards, inspect production facilities, and review quality control documentation. This not only helps in verifying the supplier’s claims but also builds a stronger business relationship.

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers, including test results for impact resistance and compliance with safety standards. These documents should clearly outline the testing methods used and the results obtained. Transparency in reporting fosters trust and ensures that buyers are receiving safe and compliant products.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These services can conduct thorough inspections at various stages of the manufacturing process, ensuring adherence to safety standards and quality benchmarks. This is especially important for international buyers who may not have the resources for on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control. Here are some nuances to consider:

Understanding Regional Standards

Different regions may have varying safety standards and regulations governing helmet manufacturing. Buyers must familiarize themselves with these standards to ensure compliance. For example, while the CE marking is essential for helmets sold in Europe, buyers in the Middle East may have different certification requirements.

Illustrative image related to bike predator helmet

Navigating Customs and Import Regulations

Buyers should be aware of customs and import regulations that may affect the importation of helmets. This includes understanding potential tariffs, taxes, and documentation required for compliance. Failure to navigate these regulations can lead to delays and increased costs.

Building Relationships with Local Authorities

Establishing relationships with local regulatory authorities can be beneficial for ensuring compliance with regional standards. Engaging with these entities can provide buyers with insights into emerging regulations and best practices for helmet safety.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing bike predator helmets, ensuring they procure products that meet stringent safety and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bike predator helmet’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure bike predator helmets. Understanding the nuances of sourcing high-quality helmets is essential for ensuring safety, compliance with regulations, and meeting market demands. This checklist outlines key steps to streamline the procurement process, helping you make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of effective procurement. Consider factors such as material type (e.g., carbon fiber, fiberglass), weight, safety certifications (DOT, ECE), and design features like ventilation and visor functionality. This clarity ensures that the helmets you source will meet your customers’ needs and comply with local safety standards.

- Material Quality: Look for helmets made from high-impact materials for enhanced durability.

- Weight Considerations: Lighter helmets can improve rider comfort, particularly for long-distance use.

Step 2: Identify Target Markets and Compliance Requirements

Different regions may have specific compliance requirements for safety standards. Familiarize yourself with the regulations in your target markets, particularly in Africa, South America, the Middle East, and Europe. Ensuring compliance not only enhances safety but also avoids potential legal issues.

- Regional Certifications: Verify if the helmets meet local certifications (e.g., DOT for the USA, ECE for Europe).

- Market Preferences: Understand design preferences and features that resonate with consumers in different regions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request detailed company profiles, product catalogs, and references from other businesses in similar industries. This due diligence helps ensure that the supplier can deliver quality products consistently.

Illustrative image related to bike predator helmet

- Check Reviews and Testimonials: Look for feedback from other buyers to gauge supplier reliability.

- Assess Production Capacity: Confirm that the supplier can meet your volume requirements without compromising quality.

Step 4: Request Samples and Conduct Quality Tests

Before finalizing your order, request samples of the helmets for quality assessment. Conduct thorough inspections and tests to ensure they meet your specifications and safety standards. This step is vital to avoid potential issues post-purchase.

- Impact Resistance Testing: Ensure that the helmets can withstand impacts as per safety regulations.

- Comfort and Fit Testing: Evaluate the comfort and fit to enhance user satisfaction.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to establish pricing and payment terms. Consider bulk purchase discounts, payment schedules, and shipping costs. Clear agreements can lead to better long-term relationships and cost savings.

- Discuss Minimum Order Quantities: Understand the supplier’s minimum order requirements to align with your budget.

- Inquire About Warranty and Return Policies: Ensure that the terms are favorable in case of defective products.

Step 6: Plan for Logistics and Distribution

Effective logistics planning is essential for ensuring timely delivery of the helmets to your location. Coordinate with your supplier to understand shipping timelines, customs regulations, and potential tariffs that may apply.

- Shipping Options: Explore various shipping methods to optimize delivery time and costs.

- Customs Clearance: Familiarize yourself with import regulations to avoid delays upon arrival.

Step 7: Monitor Market Trends and Customer Feedback

Post-purchase, continuously monitor market trends and gather customer feedback on the helmets. This information will be invaluable for future procurement decisions and product development, ensuring that you remain competitive in a dynamic market.

Illustrative image related to bike predator helmet

- Feedback Mechanisms: Establish channels for customers to share their experiences and suggestions.

- Adapt to Trends: Stay informed about emerging trends in helmet design and technology to meet evolving consumer demands.

Comprehensive Cost and Pricing Analysis for bike predator helmet Sourcing

What Are the Key Cost Components in Sourcing Bike Predator Helmets?

When sourcing bike predator helmets, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the pricing. Helmets made from pre-preg carbon fiber or high-impact fiberglass are typically more expensive due to their strength and lightweight properties. For example, premium models can range from $439 to $650, reflecting the quality of materials used.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs can provide savings; however, this may impact quality. It’s crucial to evaluate the balance between cost and craftsmanship.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities and facility maintenance. Efficient manufacturing processes can help reduce these overheads, positively influencing the final price.

-

Tooling: Initial tooling costs for molds and specialized equipment can be substantial, particularly for custom or uniquely designed helmets. This is an important consideration for buyers looking for bespoke solutions.

-

Quality Control (QC): Implementing strict QC processes ensures product safety and compliance with international standards (like DOT/ECE). Enhanced QC can add to overall costs but is vital for maintaining brand reputation and customer safety.

-

Logistics: Shipping costs can vary dramatically based on the destination, mode of transport, and Incoterms used. For instance, air freight is faster but more expensive than sea freight. Understanding logistics can help buyers optimize their total cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This can vary widely, so it’s essential to compare multiple suppliers to find the best deal.

How Do Pricing Influencers Affect Bike Predator Helmet Costs?

Several factors influence the pricing of bike predator helmets, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often attract lower per-unit costs, making it advantageous for businesses to order larger quantities.

-

Specifications and Customization: Custom designs or specific certifications (like safety standards) can significantly increase costs. Buyers should assess whether customization is necessary for their market.

-

Quality and Certifications: Helmets that meet higher safety certifications typically command higher prices. Buyers should prioritize quality to ensure compliance with local regulations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers might offer higher-quality products but at a premium.

-

Incoterms: Different shipping terms can affect total costs. For example, “FOB” (Free on Board) can lead to lower costs for the buyer compared to “CIF” (Cost, Insurance, and Freight), where the seller bears more responsibility.

What Tips Can Help Buyers Negotiate Better Prices for Bike Predator Helmets?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies:

-

Negotiation: Don’t hesitate to negotiate prices, especially when placing large orders. Suppliers may have flexibility in pricing that can lead to significant savings.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential returns. Sometimes, spending more upfront for higher quality can reduce long-term costs.

-

Understanding Pricing Nuances: Be aware of currency fluctuations and import duties, which can affect the final landed cost of products. This is particularly relevant for buyers in countries with volatile currencies.

-

Supplier Relationships: Build strong relationships with suppliers. A good rapport can lead to better pricing, priority on orders, and more favorable payment terms.

Conclusion: What Should Buyers Keep in Mind?

In conclusion, sourcing bike predator helmets requires a comprehensive understanding of the cost structure and pricing influencers. By analyzing material choices, labor costs, manufacturing overheads, and logistics, buyers can make informed decisions. Always consider negotiation strategies and the total cost implications, particularly in the context of international trade. Prices for bike predator helmets can fluctuate widely, so it’s crucial to conduct thorough market research and supplier evaluations to achieve the best value.

Alternatives Analysis: Comparing bike predator helmet With Other Solutions

When considering the procurement of protective gear for biking enthusiasts, it is essential to explore various alternatives to the Bike Predator Helmet. Different solutions may offer similar safety features, aesthetics, and comfort levels. This analysis will compare the Bike Predator Helmet against two viable alternatives: the Full-Face Carbon Fiber Helmet and the Open-Face Classic Helmet. Each option has distinct characteristics that cater to different user preferences and requirements.

Comparison Table

| Comparison Aspect | Bike Predator Helmet | Full-Face Carbon Fiber Helmet | Open-Face Classic Helmet |

|---|---|---|---|

| Performance | High impact resistance, DOT certified | Superior protection, lightweight | Moderate protection, breathable |

| Cost | $499-$650 | $300-$500 | $100-$250 |

| Ease of Implementation | Ready to use, various designs available | Minimal assembly required | Simple design, easy to wear |

| Maintenance | Removable liners for cleaning | Requires occasional checks | Low maintenance, easy to clean |

| Best Use Case | Extreme sports, aggressive riding | Racing, high-speed biking | Casual rides, urban commuting |

Detailed Breakdown of Alternatives

Full-Face Carbon Fiber Helmet

This helmet is designed for riders who prioritize maximum protection, especially during high-speed biking. Its full-face design ensures that the entire head is shielded from impacts. The use of carbon fiber makes it lightweight yet incredibly strong, enhancing comfort during long rides. However, it may come at a higher price point, making it less accessible for budget-conscious buyers. Additionally, some riders might find the full-face design restrictive, especially in hot weather.

Illustrative image related to bike predator helmet

Open-Face Classic Helmet

The open-face classic helmet is an excellent alternative for those who prefer a more traditional design. Its lightweight and breathable nature make it ideal for casual rides and urban commuting. Riders benefit from increased visibility and airflow, which can be particularly appealing in warm climates. However, the trade-off is a lack of comprehensive head protection compared to full-face helmets. This option is typically more affordable, making it accessible for a broader range of users.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the most suitable helmet for biking, B2B buyers should evaluate their target audience’s preferences and riding conditions. The Bike Predator Helmet excels in performance and safety, making it ideal for extreme sports enthusiasts. In contrast, the Full-Face Carbon Fiber Helmet offers superior protection for competitive riders, while the Open-Face Classic Helmet caters to those who value comfort and ease of use for everyday riding. By understanding the unique features and benefits of each option, buyers can make informed decisions that align with their customers’ needs and market demands.

Essential Technical Properties and Trade Terminology for bike predator helmet

What Are the Key Technical Properties of a Bike Predator Helmet?

When considering the purchase of a bike predator helmet, understanding its technical properties is essential for ensuring safety, performance, and compliance with industry standards. Here are several critical specifications that buyers should be aware of:

1. Material Composition: Why Is It Important?

The primary materials used in bike predator helmets typically include carbon fiber and fiberglass. Carbon fiber offers an excellent strength-to-weight ratio, making helmets lightweight yet highly durable. In contrast, fiberglass provides robust protection at a lower cost. B2B buyers should prioritize helmets constructed from these materials as they meet safety standards while enhancing rider comfort during long rides.

2. Impact Resistance Rating: What Does It Indicate?

Impact resistance is often assessed using certifications such as DOT (Department of Transportation) or ECE (Economic Commission for Europe). These ratings ensure that the helmet has undergone rigorous testing to withstand significant impacts. For international buyers, understanding these certifications is crucial, as they reflect the helmet’s reliability and effectiveness in protecting against head injuries.

Illustrative image related to bike predator helmet

3. Ventilation System: How Does It Affect Performance?

A well-designed ventilation system is vital for maintaining comfort during rides, especially in hot climates. Helmets equipped with multiple air vents facilitate airflow, reducing heat buildup and preventing discomfort. For buyers in regions with warmer temperatures, such as parts of Africa and the Middle East, prioritizing helmets with effective ventilation can enhance user experience significantly.

4. Weight: What Should Buyers Consider?

The weight of the helmet plays a critical role in rider comfort and safety. Lightweight helmets reduce neck strain during extended use, making them preferable for long-distance riding. B2B buyers should look for helmets weighing between 1,700g and 2,000g, as these are generally considered optimal for performance without sacrificing safety.

5. Liner Density: Why Is It Significant?

The density of the helmet’s foam liner directly impacts its ability to absorb shock during an impact. Helmets with a high-density EPS (Expanded Polystyrene) liner provide superior protection against concussions and other head injuries. Buyers should ensure that the helmets they select feature advanced liner technology that meets or exceeds safety standards.

6. Visor Quality: How Does It Enhance Visibility?

The visor’s design and materials can significantly impact visibility and protection. Optically correct visors reduce distortion, while anti-fog and UV-resistant coatings enhance visibility and comfort. For B2B buyers, investing in helmets with high-quality visors ensures that riders can maintain clear vision in various conditions, which is crucial for safety.

Illustrative image related to bike predator helmet

What Are Common Trade Terminologies Related to Bike Predator Helmets?

Understanding industry jargon is equally important for effective communication and negotiation in B2B transactions. Here are several common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. In the context of bike helmets, working with an OEM can allow businesses to provide customized helmets that meet specific market demands while leveraging established manufacturing capabilities.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of products a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. It can vary significantly based on the supplier and product type, influencing purchasing decisions.

3. RFQ (Request for Quotation): How Is It Used?

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. For buyers looking to procure bike predator helmets, issuing an RFQ can help gather competitive pricing and ensure that they understand the terms of sale, including lead times and payment conditions.

4. Incoterms: What Do They Govern?

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in transactions. They cover aspects such as shipping, insurance, and delivery. Familiarity with Incoterms is critical for international buyers to avoid misunderstandings and ensure compliance with shipping regulations.

5. Lead Time: Why Is It Important?

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for inventory planning and meeting market demands, particularly in regions with fluctuating demand patterns.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right bike predator helmets to meet their business needs and regulatory requirements.

Illustrative image related to bike predator helmet

Navigating Market Dynamics and Sourcing Trends in the bike predator helmet Sector

What Are the Current Market Dynamics and Key Trends for Bike Predator Helmets?

The global market for bike predator helmets is experiencing significant growth, driven by an increase in cycling participation, heightened safety awareness, and evolving consumer preferences for stylish yet functional headgear. Emerging markets in Africa, South America, and the Middle East are witnessing a surge in demand as urbanization and recreational cycling gain momentum. In regions like Nigeria and Saudi Arabia, local governments are investing in cycling infrastructure, contributing to a burgeoning market for protective gear.

Technological advancements in helmet design and materials are reshaping the sector. B2B buyers are increasingly focused on helmets that incorporate cutting-edge materials such as carbon fiber and advanced foam systems, which offer better impact resistance while reducing weight. Additionally, features like anti-fog visors, ventilation systems, and customizable designs are becoming essential selling points. As competitive pricing remains crucial, manufacturers are exploring cost-effective sourcing strategies without compromising quality.

Moreover, the integration of smart technologies—such as built-in LED lights and communication systems—has started to capture the interest of both consumers and B2B buyers. These innovations not only enhance safety but also add value by appealing to tech-savvy riders. As the market matures, businesses should remain agile to adapt to these shifts and leverage e-commerce platforms to reach broader audiences.

How Is Sustainability and Ethical Sourcing Impacting the Bike Helmet Sector?

The emphasis on sustainability and ethical sourcing is reshaping the bike predator helmet industry. With increasing consumer awareness regarding environmental issues, B2B buyers are prioritizing partnerships with suppliers who demonstrate a commitment to sustainable practices. Helmets made from recyclable materials or those that utilize eco-friendly manufacturing processes are becoming essential for buyers looking to enhance their brand image and appeal to environmentally-conscious consumers.

The environmental impact of production processes is under scrutiny, prompting manufacturers to seek certifications such as ISO 14001 for environmental management. Additionally, sourcing materials from suppliers with ethical labor practices is not just a trend but a necessity for companies looking to build long-term relationships with customers who value corporate social responsibility. As such, the demand for ‘green’ certifications and materials—like biodegradable plastics or sustainably sourced composites—is rising.

For businesses in Africa, South America, and the Middle East, aligning product offerings with sustainability goals can create a competitive edge. Buyers are encouraged to engage with suppliers who can transparently demonstrate their environmental impact and sourcing practices, ensuring that their investments align with global sustainability goals.

What Is the Brief Evolution and History of Bike Predator Helmets?

The evolution of bike predator helmets can be traced back to the late 20th century when safety standards for headgear began to gain traction. Initially, helmets were primarily designed for functionality, focusing on basic protection features. However, as cycling became more popular and diversified, the demand for helmets that offered both safety and style surged.

In the 2000s, advancements in materials science, particularly the introduction of lightweight composites like carbon fiber and fiberglass, revolutionized helmet design. These materials not only enhanced safety but also catered to the aesthetic preferences of riders. The rise of custom designs and personalized options further differentiated brands in the marketplace, allowing for greater individual expression.

Today, bike predator helmets represent a fusion of safety, technology, and design, reflecting the evolving needs of a diverse global cycling community. As international B2B buyers explore sourcing opportunities, understanding this historical context can provide valuable insights into consumer preferences and market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of bike predator helmet

-

How can I determine the right size of a bike predator helmet for my customers?

To select the correct size for a bike predator helmet, refer to the manufacturer’s size chart, which typically includes head circumference measurements in centimeters or inches. It’s crucial to measure the head size accurately, ensuring that the measurement is taken just above the eyebrows and around the widest part of the head. Consider offering a fitting guide or samples for your customers to try before purchasing, as this can enhance customer satisfaction and reduce returns. -

What are the best materials used in bike predator helmets?

The best bike predator helmets are constructed from high-quality materials such as pre-preg carbon fiber and fiberglass. These materials provide an optimal strength-to-weight ratio, ensuring durability and lightweight design for comfort during rides. Additionally, helmets should feature high-density EPS liners for impact protection and anti-fog visors for clear visibility. When sourcing, prioritize suppliers who adhere to international safety standards, such as DOT or ECE certification. -

What customization options are available for bike predator helmets?

Many manufacturers offer customization options, including color choices, design patterns, and branding elements such as logos or decals. This can be a significant selling point for B2B buyers looking to differentiate their offerings in the market. Be sure to inquire about minimum order quantities (MOQs) for customized products, as this may vary by supplier. Discuss lead times for production and shipping to ensure timely delivery for your customers. -

What are the minimum order quantities (MOQs) for bike predator helmets?

MOQs for bike predator helmets typically depend on the supplier and the specific model being ordered. Commonly, MOQs can range from 50 to 100 units, but it’s essential to clarify this with potential suppliers. Understanding MOQs helps in budgeting and inventory planning, ensuring that you can meet customer demand without overextending your resources. -

How should I vet suppliers of bike predator helmets?

Vetting suppliers is crucial to ensure product quality and reliability. Start by checking their certifications, such as ISO or safety standards compliance. Request samples to assess the helmet quality firsthand and verify their manufacturing processes. Additionally, review customer testimonials and ratings online, and consider visiting the supplier’s facility if feasible. Establishing a good rapport with your supplier can also facilitate smoother transactions and communication. -

What payment terms should I expect when ordering bike predator helmets internationally?

Payment terms vary by supplier and region but typically include options such as advance payment, letter of credit, or net 30/60 terms. It is advisable to negotiate terms that provide security for both parties, especially for larger orders. Be aware of any additional costs, such as currency conversion fees or international transaction fees, which could affect your overall costs. -

How can I ensure quality assurance (QA) for bike predator helmets?

Implementing a robust QA process is essential when sourcing bike predator helmets. Request detailed specifications from the supplier and establish clear quality criteria, including safety standards and material quality. Consider arranging for third-party inspections during production or before shipment to confirm that the helmets meet your requirements. Additionally, maintaining open communication with the supplier throughout the process can help address any quality issues promptly. -

What logistics considerations should I be aware of when importing bike predator helmets?

Logistics for importing bike predator helmets involve understanding shipping methods, customs regulations, and potential duties or taxes. Discuss with your supplier the best shipping options, whether by air or sea, based on your budget and timeline. Familiarize yourself with the customs clearance process in your country, including necessary documentation. Partnering with a reliable freight forwarder can streamline the logistics process, ensuring timely delivery and compliance with international trade regulations.

Top 2 Bike Predator Helmet Manufacturers & Suppliers List

1. Predator Helmets – DH6-X Air

Domain: predatorhelmets.com

Registered: 2002 (23 years)

Introduction: {“products”:[{“name”:”DH6-X Air”,”price”:”$499.00″,”description”:”The DH6-X Air shell is made from pre-preg carbon fibre cloth that is heat-cured under pressure for optimal strength and light weight. The visor is spherical so viewing is optically correct while the operation of the visor is smooth, precise.”},{“name”:”FR7-X”,”price”:”$89.95″,”description”:”The FR7-X is the ultimate lightweight open…

2. Predator – Helmets for Sale

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Predator Helmets available for sale on eBay. Key details include:

– Categories: Motorcycle & Powersport Helmets, Balaclavas, Masks & Tubes, Helmet Accessories, etc.

– Sizes: S, M, L, XL, XXL, 3XL, 4XL, Not Specified

– Types: Full Face, Half Helmet, Modular, Open Face, Off-Road, Dual Sport, Vintage, Not Specified

– Colors: Black, Multicolor, White, Red, Blue, Green, Silver, Orange, Yellow, Pink

– B…

Strategic Sourcing Conclusion and Outlook for bike predator helmet

In summary, the strategic sourcing of bike predator helmets presents significant opportunities for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. By focusing on high-quality materials like carbon fiber and fiberglass, suppliers can ensure helmets meet rigorous safety standards while offering lightweight comfort. The integration of advanced features, such as anti-fog visors and customizable designs, not only enhances user experience but also appeals to the growing demand for unique and stylish products.

As global demand for cycling gear continues to rise, establishing strong supplier relationships will be crucial. B2B buyers should prioritize sourcing from manufacturers that adhere to international safety certifications, such as DOT and ECE, ensuring product reliability and compliance in diverse markets.

Illustrative image related to bike predator helmet

Looking ahead, the market for bike predator helmets is poised for growth, driven by increasing awareness of safety and the expanding cycling culture. Engage with reliable suppliers today to capitalize on this trend, ensuring your offerings stand out in a competitive landscape. Together, we can enhance rider safety and experience, paving the way for a thriving future in the cycling industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.