What Is Foam Tape Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for what is foam tape

Navigating the complexities of sourcing foam tape can pose significant challenges for international B2B buyers. With applications ranging from industrial sealing to mounting and insulation, understanding the nuances of foam tape is critical for ensuring optimal performance and cost-effectiveness. This comprehensive guide delves into the various types of foam tape available in the market, including single-sided and double-sided options, as well as the specific materials used, such as PVC and silicone.

Moreover, we explore the diverse applications of foam tape across different sectors, highlighting its versatility in replacing traditional fasteners and enhancing production efficiency. As buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable solutions, this guide empowers them to make informed purchasing decisions by providing insights into supplier vetting, cost analysis, and practical usage examples.

By the end of this guide, you will be equipped with the knowledge needed to select the right foam tape for your specific needs, ensuring that you not only optimize your operational efficiency but also achieve substantial cost savings. Whether you are in manufacturing, construction, or any other industry, understanding foam tape’s capabilities will help you navigate the global market with confidence.

Understanding what is foam tape Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Urethane Foam Tape | High flexibility, excellent adhesion, and durability | Automotive, aerospace, and construction | Pros: Strong bond, resistant to UV and moisture. Cons: Higher cost compared to other types. |

| Acrylic Foam Tape | High-performance bonding with temperature resistance | Electronics, signage, and HVAC applications | Pros: Excellent adhesion, long-lasting. Cons: Can be difficult to remove once applied. |

| Polyethylene Foam Tape | Lightweight, good cushioning, and insulation properties | Packaging, insulation, and cushioning | Pros: Cost-effective, easy to cut. Cons: Limited temperature resistance. |

| Silicone Foam Tape | Extreme temperature tolerance and chemical resistance | Medical devices and high-temperature applications | Pros: Versatile, good for harsh environments. Cons: Generally more expensive. |

| PVC Foam Tape | Strong and chemically stable, available in various thicknesses | General-purpose sealing and insulation | Pros: Reliable adhesion, wide availability. Cons: Less flexible than other types. |

What Are the Characteristics of Urethane Foam Tape?

Urethane foam tape is recognized for its exceptional flexibility and strong adhesive properties. It is highly durable, making it suitable for demanding environments such as automotive and aerospace industries. When considering B2B purchases, buyers should focus on its ability to withstand UV exposure and moisture, which enhances its longevity in outdoor applications. However, its higher price point may be a consideration for budget-conscious businesses.

How Does Acrylic Foam Tape Stand Out in Performance?

Acrylic foam tape is engineered for high-performance bonding, particularly in applications requiring temperature resistance. This type of tape is commonly used in electronics and signage, where a strong, lasting bond is critical. Buyers should consider the long-term adhesion benefits, as acrylic tapes are often difficult to remove without damaging surfaces. While they provide excellent durability, the initial investment may be higher compared to other options.

Why Choose Polyethylene Foam Tape for Cost-Effectiveness?

Polyethylene foam tape is lightweight and offers good cushioning and insulation properties, making it ideal for packaging and insulation applications. Its cost-effectiveness is a significant factor for B2B buyers, especially in large-scale operations. However, it is essential to note that this tape has limited temperature resistance, which may restrict its use in certain environments. Businesses should assess their specific needs to determine if polyethylene foam tape aligns with their operational requirements.

What Advantages Does Silicone Foam Tape Offer?

Silicone foam tape is known for its ability to withstand extreme temperatures and chemical exposures, making it an excellent choice for medical devices and high-temperature industrial applications. Buyers should consider its versatility and reliability in harsh conditions, as it can maintain performance where other tapes may fail. However, the cost is typically higher than other foam tape types, which could affect budget allocations for projects.

In What Situations is PVC Foam Tape Most Effective?

PVC foam tape is widely used for general-purpose sealing and insulation due to its strong and chemically stable properties. Its availability in various thicknesses allows for flexibility in applications across different industries. B2B buyers should appreciate its reliability and ease of application, but they should also consider its less flexible nature compared to other foam types, which may limit its use in certain dynamic applications.

Key Industrial Applications of what is foam tape

| Industry/Sector | Specific Application of what is foam tape | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sealing and gasketing in vehicle assembly | Enhanced insulation and noise reduction, leading to improved vehicle performance | Ensure compatibility with various materials and environmental conditions |

| Electronics | Mounting components in devices | Strong, reliable adhesion without damaging components | Consider temperature resistance and electrical insulation properties |

| Construction | Insulating gaps in building structures | Improved energy efficiency and moisture control | Assess thickness and compressibility based on installation requirements |

| Healthcare | Sealing medical devices for sterility | Ensures safety and compliance with health regulations | Verify biocompatibility and resistance to sterilization processes |

| Signage and Displays | Mounting promotional materials and displays | Quick installation and aesthetic appeal | Evaluate weight capacity and surface compatibility for optimal results |

How is Foam Tape Used in the Automotive Industry?

In the automotive sector, foam tape is widely utilized for sealing and gasketing applications during vehicle assembly. Its flexible properties allow it to conform to irregular surfaces, providing a reliable barrier against moisture, dust, and noise. This enhances the overall performance of vehicles by improving insulation and reducing vibrations. International buyers should prioritize sourcing foam tape that meets industry standards for temperature and chemical resistance, as these factors are crucial for ensuring longevity in diverse environmental conditions.

What Role Does Foam Tape Play in Electronics Manufacturing?

In electronics, foam tape serves as an effective solution for mounting components within devices. Its strong adhesive properties ensure that components remain securely in place without the risk of damage that traditional fasteners may pose. This is particularly important in products that require precision and reliability. Buyers should focus on foam tapes that offer high-temperature resistance and electrical insulation to meet the specific needs of electronic applications, particularly in regions with varying climate conditions.

How is Foam Tape Beneficial in Construction Applications?

Foam tape is increasingly adopted in the construction industry for insulating gaps in building structures. By filling voids, it helps to prevent air leakage and moisture ingress, which can lead to energy inefficiency and structural damage. This is especially relevant for projects aiming for sustainability and energy efficiency. When sourcing foam tape for construction, buyers should consider the thickness and compressibility of the tape to ensure it meets the specific requirements of their projects, particularly in areas with extreme weather conditions.

Why is Foam Tape Important in Healthcare Settings?

In the healthcare sector, foam tape is crucial for sealing medical devices, ensuring they maintain sterility and comply with health regulations. Its ability to form airtight seals makes it indispensable for high-risk equipment. Buyers in this industry must prioritize sourcing biocompatible foam tapes that can withstand sterilization processes, as well as those that meet stringent safety standards. This is particularly vital for international buyers who must adhere to varying regulatory requirements across different markets.

How is Foam Tape Used in Signage and Displays?

Foam tape is commonly used in the signage and displays sector for mounting promotional materials and signage. Its strong adhesion allows for quick and easy installation while maintaining a clean aesthetic. This is particularly beneficial for retail environments where visual appeal is key. Buyers should assess the weight capacity of the foam tape and its compatibility with various surfaces to ensure optimal performance in their specific applications.

3 Common User Pain Points for ‘what is foam tape’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Foam Tape Type

The Problem: B2B buyers often face challenges when trying to determine which type of foam tape is best suited for their specific application. With various options available—such as single-sided, double-sided, acrylic, and polyurethane—buyers may feel overwhelmed by the technical specifications and performance characteristics. This indecision can lead to delays in project timelines, potential compatibility issues, and ultimately, increased costs if the wrong type is chosen. For example, using a tape that is not resistant to moisture in a humid environment can compromise the integrity of the bond and lead to product failures.

The Solution: To effectively navigate this challenge, buyers should start by conducting a thorough needs assessment that considers the specific application requirements. Key factors to evaluate include the materials being bonded, the environmental conditions (like temperature and humidity), and the desired longevity of the bond. Consulting with suppliers who can provide samples and technical data sheets can also aid in making informed choices. It’s advisable to request assistance from manufacturers’ technical support teams, who can guide buyers in selecting the right foam tape based on application scenarios, such as mounting signage in outdoor settings or sealing HVAC systems. Additionally, consider conducting field tests with a few selected options to determine which performs best before making a bulk purchase.

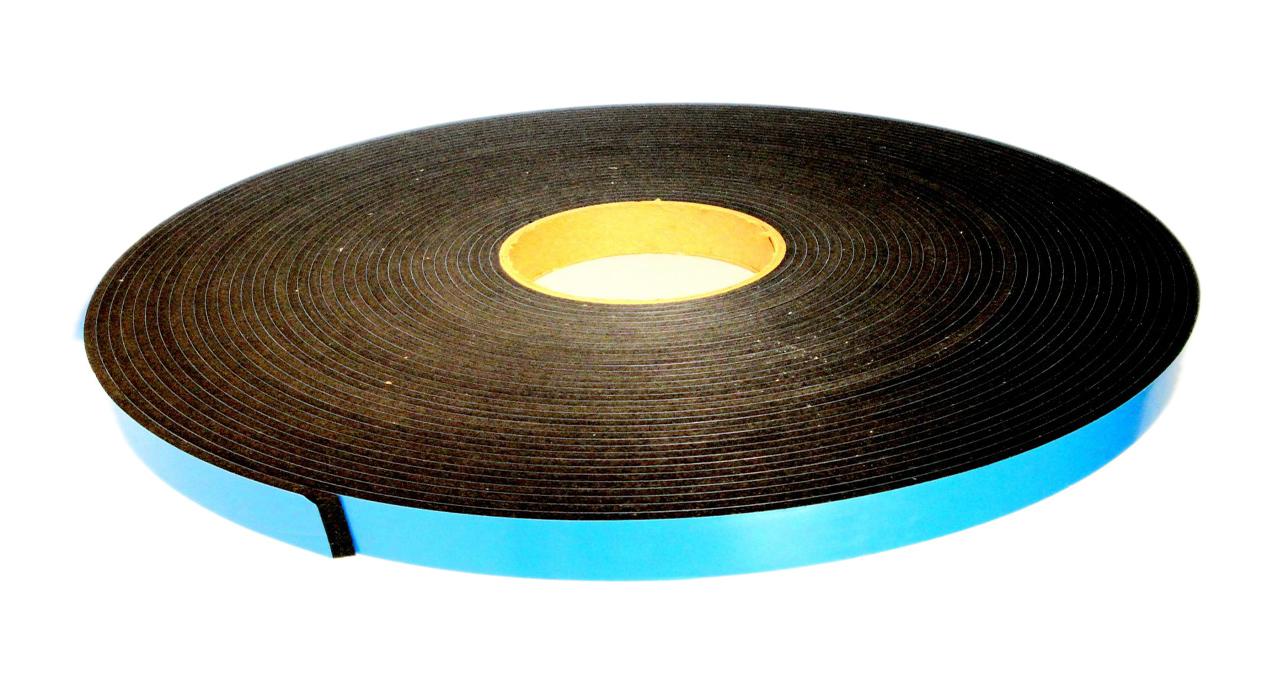

Illustrative image related to what is foam tape

Scenario 2: Adhesive Performance Under Extreme Conditions

The Problem: Many industries, especially those in manufacturing and automotive, require materials that can withstand extreme conditions, such as high temperatures or heavy vibrations. B2B buyers often worry about the adhesive performance of foam tape in these scenarios, fearing that standard products may fail and lead to costly rework or product recalls. For instance, a buyer in the automotive sector might need foam tape for sealing components that experience thermal expansion, and any failure in adhesion could result in compromised safety standards.

The Solution: To address this concern, buyers should focus on sourcing foam tapes specifically designed for high-performance applications. Look for products that are labeled as heat-resistant or vibration-dampening, and verify their specifications against industry standards. Engaging with suppliers that offer customizable solutions can also be beneficial; they may provide foam tapes that have been engineered to meet specific requirements, such as enhanced adhesive properties for high-temperature environments. Additionally, leveraging data from previous applications or case studies can guide buyers in understanding which products have proven reliable under similar conditions. Always ensure that the selected foam tape is rigorously tested and certified for the intended application to mitigate risks effectively.

Scenario 3: Managing Waste and Application Efficiency

The Problem: In manufacturing and assembly environments, managing waste and improving application efficiency are crucial for maintaining profitability. B2B buyers often find that traditional bonding methods, such as liquid adhesives, can lead to excess waste due to spillage, incorrect mixing, or over-application. This waste not only increases material costs but also adds time to the production process due to the need for cleanup and longer curing times.

The Solution: To optimize efficiency and reduce waste, buyers should consider switching to foam tape, particularly double-sided options, which offer a clean and straightforward application process. Foam tape eliminates the need for mixing and curing, allowing for immediate handling strength and faster production cycles. Buyers should invest in training for their teams to ensure they understand the correct application techniques for foam tape, such as surface preparation and pressure application, which can significantly enhance adhesion and performance. Additionally, implementing a waste management strategy that includes proper disposal of the release liners and other packaging materials can further streamline operations and contribute to sustainability goals. By integrating foam tape into their workflows, companies can achieve a cleaner, more efficient bonding solution that minimizes waste and maximizes productivity.

Illustrative image related to what is foam tape

Strategic Material Selection Guide for what is foam tape

What Are the Key Materials Used in Foam Tape?

When selecting foam tape for various applications, understanding the materials involved is crucial for ensuring optimal performance. Below, we analyze four common materials used in foam tape, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Polyurethane Foam Tape

Key Properties: Polyurethane foam tape exhibits excellent flexibility and resilience, making it suitable for applications requiring a strong bond under dynamic loads. It can withstand temperatures ranging from -40°C to 100°C, offering good resistance to moisture, chemicals, and UV light.

Pros & Cons: The primary advantage of polyurethane foam tape is its durability and adaptability, which allows it to conform to uneven surfaces. However, it can be more expensive compared to other foam types, and its manufacturing process may be complex, which could lead to longer lead times.

Impact on Application: This material is particularly effective in automotive and industrial applications where vibration dampening and sealing are critical. Its compatibility with various substrates enhances its utility across different sectors.

Illustrative image related to what is foam tape

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations and standards such as ASTM and ISO. The higher cost may necessitate a thorough cost-benefit analysis in budget-sensitive markets.

2. Polyethylene Foam Tape

Key Properties: Polyethylene foam tape is lightweight and offers excellent cushioning properties. It typically operates effectively in temperatures up to 80°C and provides good resistance to moisture and chemicals.

Pros & Cons: Its low cost and ease of manufacturing make polyethylene foam tape a popular choice for many applications. However, it may not perform as well under extreme temperatures or prolonged exposure to UV light, limiting its use in outdoor applications.

Impact on Application: This material is ideal for packaging, insulation, and cushioning applications where moisture resistance is essential. Its lightweight nature makes it suitable for shipping and handling.

Considerations for International Buyers: For buyers in the Middle East, where high temperatures are common, it’s crucial to assess the tape’s performance under local conditions. Compliance with regional standards can affect procurement decisions.

3. Acrylic Foam Tape

Key Properties: Acrylic foam tape is known for its exceptional bonding strength and temperature resistance, withstanding temperatures up to 120°C. It also provides excellent resistance to UV light, moisture, and solvents.

Pros & Cons: The key advantage of acrylic foam tape is its long-lasting adhesion, making it suitable for permanent applications. However, it is generally more expensive than other foam tapes, which may deter budget-conscious buyers.

Impact on Application: This type of foam tape is widely used in construction and automotive industries for bonding and sealing applications. Its strong performance in harsh environments enhances its appeal for critical applications.

Considerations for International Buyers: Buyers in Europe should pay attention to compliance with EU regulations regarding chemical safety. The high cost may require justification through performance benefits in competitive markets.

4. Sponge Rubber Foam Tape

Key Properties: Sponge rubber foam tape is characterized by its excellent compressibility and flexibility, making it suitable for sealing applications. It typically operates effectively in temperatures ranging from -30°C to 70°C and provides good resistance to weathering and ozone.

Pros & Cons: Its compressibility allows it to create effective seals against air and moisture, making it ideal for HVAC applications. However, sponge rubber foam tape may degrade faster than other materials when exposed to certain chemicals.

Impact on Application: This material is commonly used in construction and automotive applications for gasketing and sealing. Its ability to conform to irregular surfaces enhances its effectiveness.

Considerations for International Buyers: Buyers from countries like Nigeria should consider the availability of sponge rubber foam tape and its compliance with local environmental regulations. The cost may vary significantly based on local sourcing capabilities.

Summary Table of Foam Tape Materials

| Material | Typical Use Case for what is foam tape | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam Tape | Automotive and industrial applications | Excellent flexibility and durability | Higher cost and complex manufacturing | High |

| Polyethylene Foam Tape | Packaging and insulation | Low cost and lightweight | Limited performance in extreme conditions | Low |

| Acrylic Foam Tape | Construction and automotive bonding | Long-lasting adhesion | Generally more expensive | High |

| Sponge Rubber Foam Tape | Gasketing and sealing in HVAC | Effective sealing properties | May degrade with chemical exposure | Medium |

This strategic material selection guide provides a comprehensive overview of foam tape materials, facilitating informed decisions for B2B buyers across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for what is foam tape

What Are the Key Stages in the Manufacturing Process of Foam Tape?

The manufacturing process of foam tape involves several critical stages, each designed to ensure the quality and performance of the final product. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

1. Material Preparation: What Raw Materials Are Used for Foam Tape?

The first step in foam tape production is the preparation of raw materials. Foam tape is typically made from various types of foam, including polyurethane, polyethylene, and acrylic, each offering distinct properties suitable for different applications.

Illustrative image related to what is foam tape

-

Selection of Foam Type: The choice of foam impacts the tape’s flexibility, durability, and adhesive strength. For instance, polyurethane foam is known for its resilience, while polyethylene foam is more lightweight.

-

Adhesive Preparation: Adhesives used in foam tape are often pressure-sensitive, which means they bond upon contact. The formulation of the adhesive is tailored based on the intended application, whether for high-temperature resistance or moisture sealing.

2. Forming: How Is Foam Tape Shaped and Cut?

Once the materials are prepared, the next stage is forming. This involves shaping the foam into the desired dimensions.

-

Foam Cutting: The foam is cut into sheets or rolls, depending on the specifications required by the end user. This cutting can be done using various techniques such as die-cutting, water jet cutting, or laser cutting, ensuring precision in size and shape.

-

Adhesive Application: In this step, the adhesive is applied to the foam surface. This can be done through coating techniques such as extrusion or lamination, which ensure an even layer of adhesive is applied.

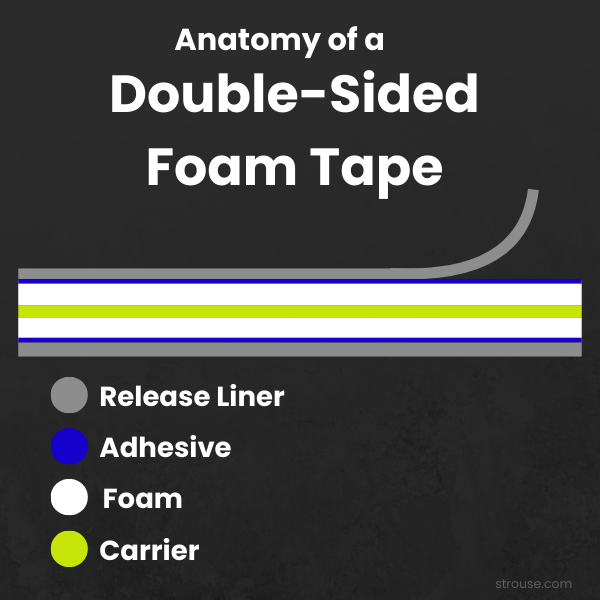

3. Assembly: How Are Different Components Joined Together?

The assembly stage involves combining the foam and adhesive into a cohesive product.

-

Lamination: If double-sided foam tape is being produced, the adhesive is laminated to both sides of the foam. This process must be carefully controlled to avoid bubbles or uneven application.

-

Quality Control Checks: During assembly, manufacturers perform initial quality checks to ensure that the adhesive has properly bonded to the foam and that there are no defects in the material.

4. Finishing: What Final Steps Are Taken to Prepare Foam Tape for Market?

The final stage of production is finishing, which involves several steps to prepare the foam tape for distribution.

-

Trimming and Rewinding: The foam tape is trimmed to the final specifications and rewound into rolls or cut into strips, depending on customer requirements.

-

Packaging: Proper packaging is crucial for maintaining the integrity of the foam tape during transportation. Manufacturers often use moisture-resistant materials to protect the adhesive properties.

What Quality Assurance Processes Are Essential for Foam Tape Production?

Quality assurance is a vital aspect of foam tape manufacturing, ensuring that the products meet industry standards and customer expectations. For B2B buyers, understanding these processes can help in selecting reliable suppliers.

Relevant International Standards: What Certifications Should B2B Buyers Look For?

Foam tape manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Other certifications may include CE marking for compliance with European safety standards and API standards for products used in the oil and gas industries.

-

ISO 9001: This certification ensures that a manufacturer has a systematic approach to managing processes, which can lead to improved efficiency and customer satisfaction.

-

CE Marking: For buyers in Europe, CE marking indicates that the product meets EU safety and health requirements, making it suitable for the European market.

What Are the Key Quality Control Checkpoints in Foam Tape Manufacturing?

Quality control (QC) in foam tape production typically involves several checkpoints, ensuring that products are consistently manufactured to the required standards.

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. It involves testing samples of foam and adhesive for compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the forming and assembly stages. This includes verifying the thickness of the adhesive layer and ensuring proper adhesion between foam and adhesive.

-

Final Quality Control (FQC): Once the foam tape is completed, a final inspection is performed to check for defects, proper dimensions, and adhesive performance. This may include peel tests to assess adhesive strength.

How Can B2B Buyers Verify the Quality Control of Foam Tape Suppliers?

Verifying the quality control processes of potential suppliers is crucial for B2B buyers, especially when sourcing from international markets.

What Methods Can Buyers Use to Conduct Supplier Audits?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and adherence to international standards. This can involve reviewing documentation and observing production practices firsthand.

-

Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, test results, and compliance with relevant standards. Buyers can request these documents as part of their due diligence.

Are Third-Party Inspections a Viable Option for Ensuring Quality?

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct random checks and testing to verify product quality before shipment.

What Nuances Should International B2B Buyers Be Aware of When Sourcing Foam Tape?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances when dealing with foam tape suppliers.

-

Regulatory Compliance: Different countries have varying regulatory requirements for adhesive products. Understanding these regulations is essential to avoid compliance issues.

-

Cultural Differences in Business Practices: Navigating cultural differences can impact negotiations and supplier relationships. Building rapport and understanding local business practices can facilitate smoother transactions.

-

Logistics and Supply Chain Considerations: When sourcing internationally, factors such as shipping times, tariffs, and local customs regulations can affect the overall cost and delivery schedule.

In conclusion, understanding the manufacturing processes and quality assurance measures in foam tape production is essential for B2B buyers looking to source reliable products. By focusing on these key areas, buyers can make informed decisions that enhance their operational efficiency and product quality.

Illustrative image related to what is foam tape

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is foam tape’

In the competitive landscape of B2B procurement, understanding the nuances of foam tape is essential for making informed purchasing decisions. This guide will help you navigate the sourcing process effectively, ensuring that you select the right foam tape for your specific applications.

Step 1: Define Your Technical Specifications

Before initiating your search for foam tape, it’s crucial to clearly outline your technical requirements. Consider factors such as thickness, adhesive type, and material compatibility with your substrates. This step ensures that you choose a product tailored to your operational needs, preventing costly mistakes later.

- Thickness and Density: Determine the required thickness based on the surfaces you will bond.

- Adhesive Type: Decide between acrylic, rubber, or silicone adhesives, as each has unique properties and applications.

Step 2: Identify Your Application Needs

Understanding how you intend to use foam tape will guide your selection process. Different applications—such as gasketing, mounting, or insulation—demand specific types of foam tape. This clarity will help you narrow down your options to those that are most effective for your intended use.

- Mounting vs. Sealing: Choose double-sided tape for mounting heavy objects and single-sided tape for sealing.

- Environmental Conditions: Consider factors like temperature, moisture, and exposure to chemicals that could affect tape performance.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is crucial to ensure quality and reliability. Request detailed information about their manufacturing processes, certifications, and customer testimonials. This step helps build confidence that you are sourcing from reputable companies that meet industry standards.

- Certifications: Look for ISO certifications or other relevant industry standards that indicate a commitment to quality.

- Customer References: Ask for case studies or references from similar industries to gauge supplier reliability.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the foam tape you are considering. Testing these samples in your specific environment will help you assess their performance and compatibility. This hands-on evaluation is critical to ensuring you make the right choice.

- Adhesion Strength: Test the tape’s bonding strength on various substrates to ensure it meets your requirements.

- Durability Assessment: Evaluate the tape’s resistance to environmental factors relevant to your application.

Step 5: Compare Pricing and Terms

Once you have narrowed down your options, compare pricing structures and payment terms among suppliers. Look for bulk pricing discounts and consider the total cost of ownership, including shipping and handling. This step is essential for maximizing your procurement budget.

- Volume Discounts: Inquire about pricing tiers for larger orders to optimize cost-efficiency.

- Payment Flexibility: Assess payment terms that align with your cash flow requirements.

Step 6: Confirm Delivery and Lead Times

Understanding the supplier’s delivery capabilities is vital for maintaining your project timelines. Confirm lead times and shipping options to ensure that you receive your foam tape when needed. This proactive approach minimizes potential delays in your operations.

- Local vs. International Shipping: Determine if suppliers can deliver to your location efficiently, especially if you are sourcing from different continents.

- Inventory Levels: Ask about stock availability to avoid backorders that could disrupt your supply chain.

Step 7: Establish a Long-term Relationship

Once you’ve made a successful purchase, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and insights into new products. Maintaining open communication will help you adapt to changing needs and ensure consistent quality.

- Regular Reviews: Schedule periodic evaluations of product performance and supplier service to keep the relationship beneficial.

- Feedback Loop: Provide feedback to your supplier to foster improvements and innovations in their offerings.

Following this checklist will empower you to make informed decisions when sourcing foam tape, ultimately enhancing your operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for what is foam tape Sourcing

Understanding the cost structure and pricing dynamics of foam tape is crucial for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis will outline the key components of cost, the factors influencing prices, and provide actionable tips for buyers to optimize their sourcing strategies.

Illustrative image related to what is foam tape

What Are the Key Cost Components of Foam Tape Production?

The cost structure of foam tape encompasses several critical components:

-

Materials: The primary raw materials for foam tape include various types of foam (e.g., polyurethane, polyethylene, acrylic) and adhesives. The choice of materials significantly affects the overall cost, with high-performance materials typically commanding a premium.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the manufacturing process. Countries with lower wage rates may offer more competitive pricing, but this can impact quality and consistency.

-

Manufacturing Overhead: This includes costs related to machinery, utilities, and facility maintenance. Efficient production processes can help mitigate overhead costs and improve pricing competitiveness.

-

Tooling: Initial setup costs for specialized manufacturing equipment can be significant, especially for customized foam tape products. Buyers should consider the amortization of tooling costs over larger order volumes.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. Investing in quality assurance can increase upfront costs but may reduce long-term expenses related to returns and defects.

-

Logistics: Transportation costs are influenced by distance, shipping methods, and tariffs. Buyers should factor in logistics when calculating total costs, particularly for international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position and the level of service provided.

What Influences Foam Tape Pricing in B2B Markets?

Several factors can significantly influence the pricing of foam tape:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to leverage bulk pricing.

-

Specifications and Customization: Custom foam tape products tailored to specific applications may incur additional costs. Understanding the balance between customization needs and cost implications is vital.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, ASTM) can enhance product performance but also increase costs. Buyers must assess the value of certifications in relation to their operational requirements.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographical location can affect pricing. Establishing long-term relationships with reliable suppliers can yield better pricing agreements.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) impact shipping costs and responsibilities. Buyers should clarify these terms to avoid unexpected expenses.

What Are Essential Buyer Tips for Cost-Efficient Foam Tape Sourcing?

To maximize cost-efficiency in sourcing foam tape, international buyers should consider the following strategies:

-

Negotiate Pricing and Terms: Building relationships with suppliers can facilitate better pricing negotiations. Be prepared to discuss volume commitments or longer contract terms for discounts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, application efficiency, and potential waste reduction when evaluating TCO.

-

Understand Pricing Nuances for International Markets: Different regions may have unique pricing structures due to local regulations, tariffs, and market conditions. Conduct thorough market research to identify competitive pricing in target markets.

-

Request Samples and Conduct Trials: Before placing large orders, request samples to evaluate product performance. Trials can help ascertain the suitability of foam tape for specific applications, minimizing the risk of costly mistakes.

-

Stay Informed on Market Trends: Regularly monitor market trends and material costs, as fluctuations can impact pricing. Staying informed allows for timely negotiations and potential cost savings.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of foam tape is essential for international B2B buyers. By leveraging insights into cost components, pricing influencers, and strategic sourcing tips, businesses can optimize their procurement processes and achieve better value in their foam tape investments. Always consult with suppliers for the most accurate and current pricing to ensure informed purchasing decisions.

Alternatives Analysis: Comparing what is foam tape With Other Solutions

Exploring Alternatives to Foam Tape: A Comprehensive Comparison

When considering adhesive solutions for industrial applications, it’s essential to evaluate various options against foam tape. While foam tape is a popular choice due to its versatility and ease of use, other alternatives may also meet specific needs effectively. This analysis compares foam tape with two viable alternatives: liquid adhesives and mechanical fasteners, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | What Is Foam Tape | Liquid Adhesives | Mechanical Fasteners |

|---|---|---|---|

| Performance | Strong bonding, flexible, shock-absorbent | High initial bond strength, but may weaken over time | Excellent load-bearing capacity, permanent |

| Cost | Generally low-cost and labor-efficient | Can be more expensive, especially for specialty adhesives | Higher material and installation costs |

| Ease of Implementation | Quick to apply, minimal preparation required | Requires mixing and curing time, can be messy | Installation requires tools and skilled labor |

| Maintenance | Low maintenance, long shelf life | May require reapplication or repairs over time | Durable, but can loosen and require tightening |

| Best Use Case | Ideal for mounting, sealing, and gasketing | Suitable for bonding materials that require a chemical bond | Best for structural applications needing high strength |

What Are the Advantages and Disadvantages of Liquid Adhesives?

Liquid adhesives are often chosen for their ability to create a strong chemical bond between materials. They can fill gaps and bond irregular surfaces effectively, making them suitable for applications where foam tape may not provide adequate adhesion. However, liquid adhesives can be messy, requiring careful application to avoid waste. They also typically have a longer cure time, which can slow down production processes. While they may offer strong initial bonding, their performance can diminish over time, particularly under stress or exposure to environmental factors.

What Are the Pros and Cons of Mechanical Fasteners?

Mechanical fasteners, such as screws and bolts, provide a robust and permanent solution for structural applications. They excel in situations where high load-bearing capacity is essential. However, their installation requires specialized tools and skilled labor, which can increase costs and time. Additionally, mechanical fasteners can lead to vibration and stress on materials, potentially causing damage over time. In contrast, foam tape offers a more flexible solution that can absorb shocks and accommodate thermal expansion, making it suitable for various applications without compromising material integrity.

Conclusion: How to Choose the Right Adhesive Solution for Your Needs

Selecting the right adhesive solution depends on several factors, including the specific application, budget constraints, and desired performance characteristics. Foam tape stands out for its versatility, cost-effectiveness, and ease of use, making it an excellent choice for many bonding and sealing applications. However, in cases where high structural integrity is required, mechanical fasteners may be more appropriate. Liquid adhesives can also be suitable for certain specialized applications but may introduce complexities in application and maintenance. Ultimately, understanding the unique needs of your project will guide you in making the best choice for your business.

Essential Technical Properties and Trade Terminology for what is foam tape

What Are the Key Technical Properties of Foam Tape That B2B Buyers Should Consider?

When selecting foam tape for industrial applications, understanding its technical properties is crucial for ensuring the right fit for your specific needs. Here are several key specifications to consider:

1. Material Grade

Foam tape can be made from various materials, including polyethylene (PE), polyurethane (PU), acrylic, and silicone. Each material offers different properties such as flexibility, temperature resistance, and adhesion strength. For instance, acrylic foam tapes are often preferred for their superior bonding capabilities, making them suitable for demanding environments. Understanding the material grade helps buyers select the right tape for their specific applications, ensuring optimal performance and longevity.

Illustrative image related to what is foam tape

2. Thickness

The thickness of foam tape significantly impacts its cushioning, sealing, and bonding capabilities. Typically ranging from 0.5 mm to 10 mm, thicker tapes can accommodate uneven surfaces better and provide enhanced insulation. For B2B buyers, selecting the appropriate thickness is essential for achieving desired performance levels in applications such as gasketing, mounting, or vibration dampening.

3. Adhesive Type

Foam tapes generally feature either rubber-based or acrylic-based adhesives. Rubber adhesives offer excellent initial tack, making them ideal for quick bonding applications, while acrylic adhesives provide better long-term durability and temperature resistance. Understanding the adhesive type is vital for buyers to ensure compatibility with the surfaces being bonded and the environmental conditions they will encounter.

4. Temperature Resistance

Foam tape’s ability to withstand temperature fluctuations is a critical factor in many industrial applications. Some tapes can endure temperatures as low as -40°C and as high as 120°C, making them suitable for environments ranging from refrigerated storage to high-heat manufacturing processes. For businesses operating in diverse climates, knowing the temperature resistance of foam tape helps avoid premature failure and costly repairs.

5. Density

The density of foam affects its compressibility and durability. Higher-density foams are generally more robust and resistant to deformation under stress, making them ideal for heavy-duty applications. B2B buyers should consider density alongside other properties to ensure the selected foam tape meets performance requirements without compromising on quality.

Illustrative image related to what is foam tape

What Are Common Trade Terms Related to Foam Tape in the B2B Market?

Navigating the foam tape market requires familiarity with specific trade jargon. Here are several essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For foam tape suppliers, working with OEMs often involves meeting stringent specifications and quality standards to ensure compatibility with the end product.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers, as it can affect inventory management and overall project costs. Negotiating favorable MOQs can lead to cost savings, especially for bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. For B2B buyers, submitting a detailed RFQ can lead to better pricing and service terms, as suppliers can provide tailored quotes based on specific needs.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk, and delivery responsibilities, facilitating smoother transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for B2B buyers to plan their projects effectively and ensure timely delivery of materials needed for production.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting foam tape, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the what is foam tape Sector

What Are the Current Market Dynamics and Key Trends in the Foam Tape Sector?

The foam tape market is experiencing significant growth driven by the increasing demand for versatile bonding solutions across various industries, including automotive, construction, electronics, and healthcare. Key market drivers include a shift towards lightweight materials in manufacturing and the need for efficient, cost-effective assembly processes. As businesses seek to streamline operations, foam tape’s ability to replace traditional fasteners and liquid adhesives is gaining traction, particularly in regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to what is foam tape

Emerging B2B technology trends, such as automation and digital procurement platforms, are reshaping the sourcing landscape. These technologies enable international buyers to access a broader range of suppliers and products, facilitating competitive pricing and quicker turnaround times. Additionally, the rise of e-commerce in B2B transactions is making it easier for companies in diverse markets, including Nigeria and Vietnam, to procure foam tape that meets their specific requirements.

Moreover, sustainability is becoming a pivotal factor in sourcing decisions. Buyers are increasingly looking for foam tape products that not only meet performance standards but also adhere to environmental regulations. This trend is influencing manufacturers to develop eco-friendly foam tape solutions, aligning with global sustainability goals.

How Is Sustainability Influencing the Foam Tape Industry and Ethical Sourcing Practices?

As environmental concerns grow, the foam tape industry is adapting to meet the demands for sustainable and ethically sourced products. The environmental impact of traditional adhesives and tapes has led to a surge in interest for alternatives that minimize waste and enhance recyclability. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainability, including those who utilize recycled materials or implement eco-friendly manufacturing processes.

Ethical supply chains are crucial for B2B buyers, particularly in regions where regulatory standards may vary. Companies are increasingly requiring certifications that validate the environmental and social practices of their suppliers. Certifications such as ISO 14001, which focuses on effective environmental management systems, or specific green certifications for materials, play a vital role in establishing credibility and trust in sourcing decisions.

Furthermore, the introduction of biodegradable and compostable foam tape options is aligning with the growing consumer demand for sustainable packaging and product solutions. This shift not only helps companies reduce their carbon footprint but also enhances their brand reputation in an increasingly environmentally-conscious market.

What Is the Evolution of Foam Tape and Its Relevance to B2B Buyers?

The evolution of foam tape dates back several decades, originally developed for basic sealing and insulation applications. Over the years, advancements in adhesive technology and material science have transformed foam tape into a versatile solution used across various sectors. This transformation has been marked by the development of different types of foam tapes, such as acrylic, polyurethane, and silicone-based options, each offering unique properties tailored to specific applications.

In the B2B context, this evolution is relevant as it reflects the industry’s response to changing market needs. Modern foam tapes are designed to provide enhanced bonding strength, flexibility, and resistance to environmental factors, making them suitable for demanding applications in construction, automotive, and electronics. As buyers seek innovative solutions to improve their operational efficiency, understanding the history and development of foam tape can provide valuable insights into selecting the right product for their specific needs.

By recognizing these trends and historical developments, B2B buyers can make informed decisions that align with their operational goals while contributing to sustainability initiatives in their respective industries.

Illustrative image related to what is foam tape

Frequently Asked Questions (FAQs) for B2B Buyers of what is foam tape

-

How do I choose the right foam tape for my application?

Choosing the appropriate foam tape involves assessing several factors such as the materials you intend to bond, the environmental conditions (like temperature and moisture), and the required thickness and width. For instance, double-sided foam tape is ideal for mounting and bonding tasks, while single-sided tape is better for sealing applications. Evaluate the specific needs of your project, including any industry standards, to ensure you select the most effective tape for your requirements. -

What types of foam tape are available for industrial applications?

There are several types of foam tape suitable for industrial use, including polyurethane, acrylic, PVC, and silicone foam tapes. Each type offers unique properties, such as chemical resistance or flexibility, making them suitable for different applications. For instance, acrylic foam tape is known for its high bonding strength and durability, while silicone foam tape provides excellent heat resistance. It’s essential to match the tape type to the specific demands of your project for optimal performance. -

What are the benefits of using foam tape over traditional bonding methods?

Foam tape offers numerous advantages compared to traditional methods like screws, bolts, or liquid adhesives. It provides a cleaner application, reduces labor time, and minimizes waste, as it doesn’t require mixing or additional cleanup. Additionally, foam tape can absorb vibrations and accommodate thermal expansion, making it a versatile choice for various applications. Businesses can also save costs by decreasing the need for heavy machinery or extensive labor associated with traditional bonding methods. -

How can I ensure the quality of foam tape from suppliers?

To ensure quality when sourcing foam tape, it’s crucial to vet suppliers thoroughly. Request samples to assess the tape’s adhesive strength, thickness, and durability under your specific conditions. Additionally, inquire about certifications or industry standards that the supplier adheres to, such as ISO certification. Establishing clear communication regarding your quality expectations and conducting site visits or audits can further help ensure that the products meet your requirements. -

What is the minimum order quantity (MOQ) for foam tape when sourcing internationally?

Minimum order quantities (MOQ) for foam tape can vary significantly between suppliers and regions. Typically, MOQs can range from a few rolls to several hundred, depending on the manufacturer’s production capabilities and your specific needs. When sourcing internationally, it’s advisable to clarify MOQ terms with potential suppliers early in discussions to ensure they align with your purchasing strategy and to explore options for bulk purchasing or consolidation. -

What payment terms should I expect when buying foam tape from international suppliers?

Payment terms for foam tape purchases can vary widely based on the supplier’s policies and the nature of the transaction. Common terms include upfront payments, partial payments upon order confirmation, or payment upon delivery. Additionally, international transactions may involve letters of credit or escrow services to protect both parties. It’s important to negotiate favorable terms that accommodate your cash flow while ensuring the supplier’s confidence in the transaction. -

How do I manage logistics and shipping for foam tape orders?

Managing logistics for foam tape orders involves coordinating with suppliers to ensure timely delivery. Discuss shipping methods (air, sea, or land) based on your timeline and budget. It’s also vital to understand customs regulations in your country to avoid delays at the border. Consider working with logistics providers who specialize in international shipping to streamline the process and mitigate potential challenges related to tariffs, duties, and documentation. -

What are the common applications of foam tape in different industries?

Foam tape is widely used across various industries, including automotive, construction, electronics, and healthcare. In the automotive sector, it serves as a sealing and bonding material for components, while in construction, it is utilized for insulation and gasketing. Electronics manufacturers often rely on foam tape for mounting and cushioning delicate components. Understanding these applications can help you identify how foam tape can enhance your operations and meet industry-specific requirements effectively.

Top 3 What Is Foam Tape Manufacturers & Suppliers List

1. RS Components – Foam Tape

Domain: uk.rs-online.com

Registered: 2001 (24 years)

Introduction: Foam tape is a pressure-sensitive self-adhesive tape made from foam and various backing materials, available in single-sided and double-sided variants. It comes in different lengths, widths, thicknesses, and colors, including white, black, grey, and clear. Key types include PVC foam tape, silicone foam tape, PE foam tape, and acrylic foam tape, each offering unique benefits such as chemical stabil…

2. IQS Directory – Foam Tape Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Foam tape is a pressure-sensitive adhesive tape made from foam material, available in various formats with adhesive on one or both sides. It is designed to adhere to uneven or textured surfaces, providing secure bonding. Types include single-sided (for sealing) and double-sided (for connecting materials). Foam tapes come in different densities: soft (for air and dust seals), medium (for gap-fillin…

3. Nadco – Foam Tape Solutions

Domain: nadco-inc.com

Registered: 2004 (21 years)

Introduction: Foam tape is an adhesive tape reinforced with various foam materials, available in different thicknesses, sizes, adhesive materials, and backings. It provides insulation, cushioning, sealing, sound dampening, and gasketing. Common materials include polyethylene (polyfoam) and polyvinyl chloride (PVC). Foam tape configurations are categorized into open cell and closed cell structures. Open cell foa…

Strategic Sourcing Conclusion and Outlook for what is foam tape

The integration of foam tape in various industrial applications has proven to be a game-changer for businesses worldwide. Its versatility in bonding, sealing, and insulating makes it a superior alternative to traditional fastening methods like screws and liquid adhesives. By strategically sourcing the right type of foam tape, companies can enhance operational efficiency, reduce costs, and improve product quality. The ability to select from various foam types—such as polyurethane, acrylic, and silicone—ensures that businesses can meet specific project requirements while maintaining competitive pricing.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe explore sourcing options, understanding the unique benefits of foam tape is essential. This product not only streamlines production processes but also offers durability and adaptability in challenging environments.

Looking ahead, companies that invest in high-quality foam tape solutions will find themselves better positioned to innovate and adapt to market demands. Engaging with reliable suppliers and leveraging strategic sourcing practices will be key to unlocking the full potential of foam tape in your operations. Take the next step towards enhancing your business capabilities by incorporating foam tape solutions into your sourcing strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is foam tape

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.