Components Of A Bearing Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for components of a bearing

In the complex landscape of global manufacturing, sourcing high-quality components of a bearing is a critical challenge that can significantly impact operational efficiency. Bearings are essential for reducing friction and ensuring smooth rotation in a myriad of applications—from automotive to industrial machinery. With a diverse range of types and specifications, international B2B buyers must navigate a sea of options, each with unique performance characteristics and cost implications. This guide serves as a comprehensive resource, addressing key aspects such as the various types of bearing components, their specific applications, supplier vetting processes, and cost considerations.

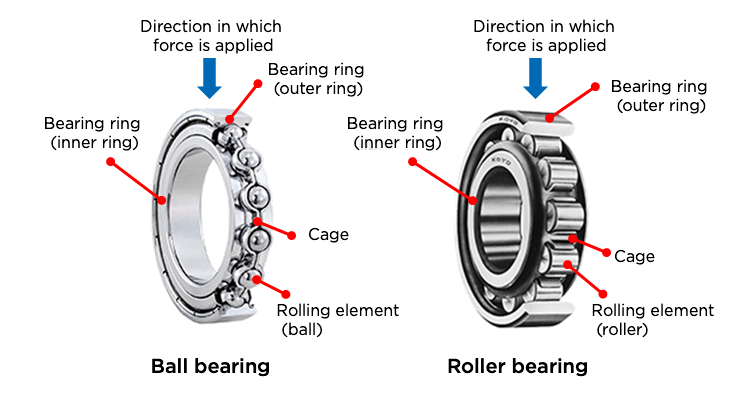

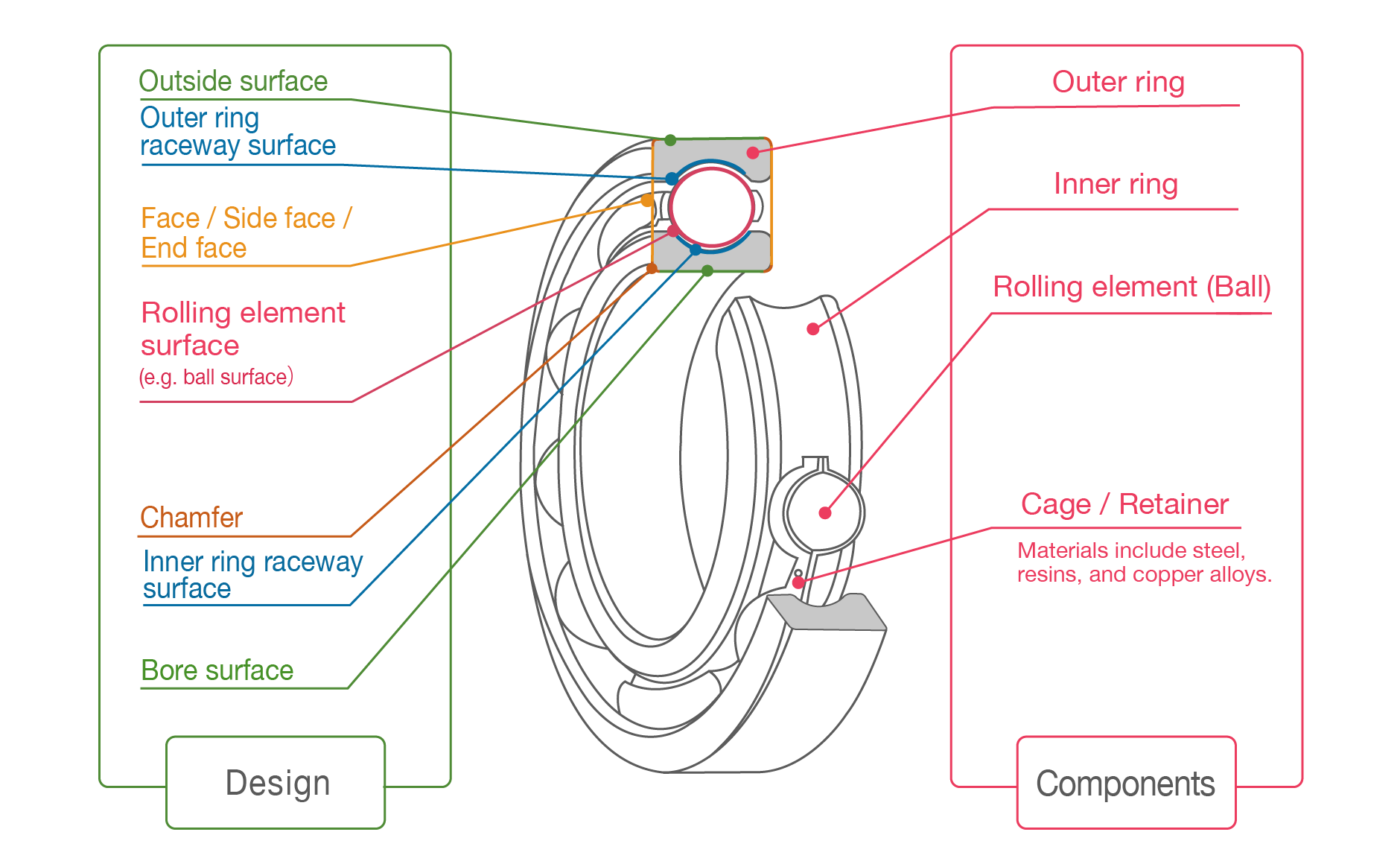

By delving into the intricacies of bearing components—including bearing rings, rolling elements, cages, and lubricants—this guide empowers buyers from Africa, South America, the Middle East, and Europe (including regions like Vietnam and Nigeria) to make informed purchasing decisions. Understanding the structural elements and their functions is essential for selecting the right bearing to meet specific operational needs. Additionally, insights into supplier reliability and market pricing will help you establish fruitful partnerships and optimize your procurement strategies. Equip yourself with the knowledge necessary to enhance your supply chain efficiency and drive competitive advantage in your industry.

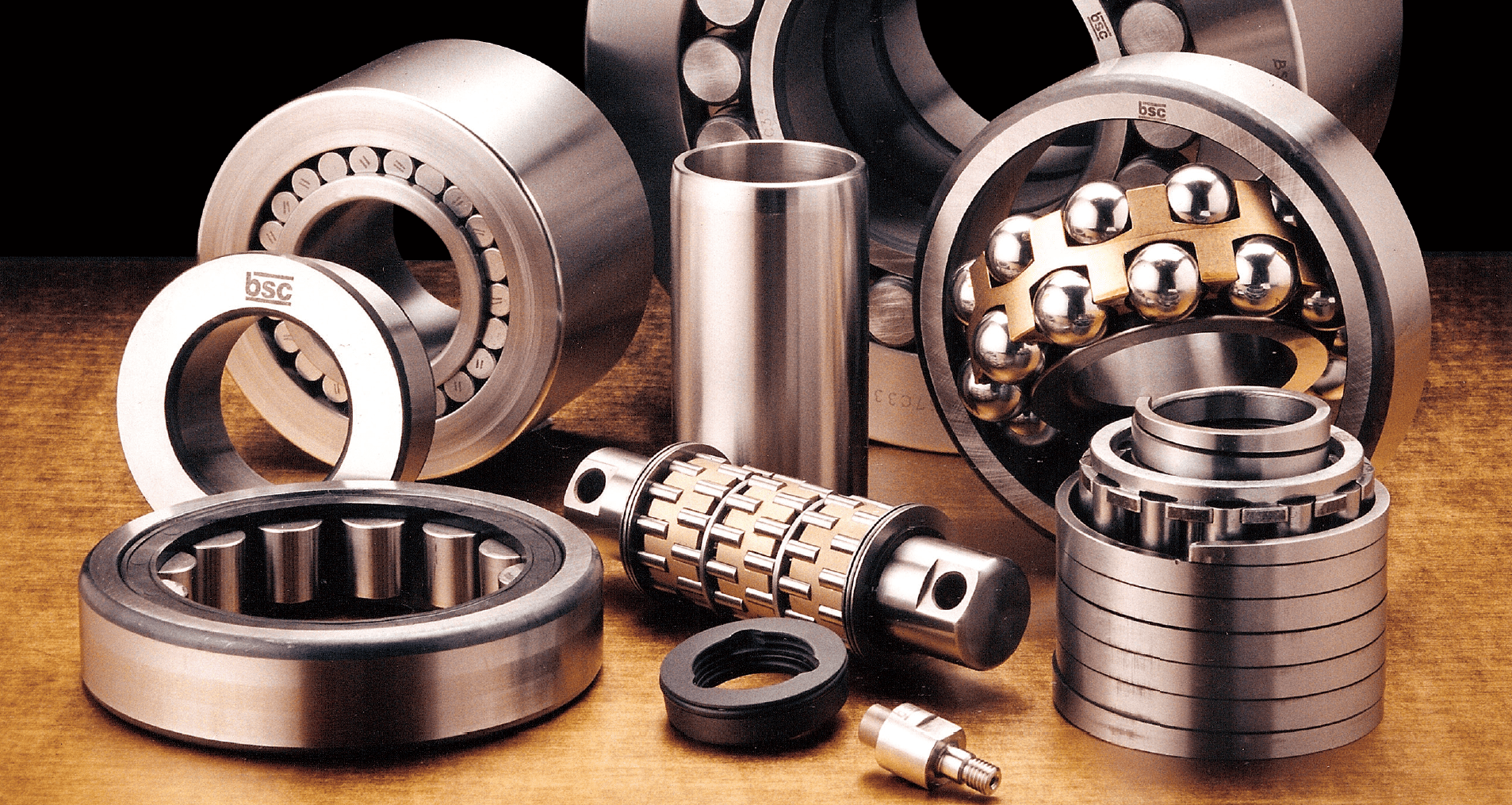

Understanding components of a bearing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Bearings | Spherical rolling elements, low friction, versatile | Automotive, machinery, home appliances | Pros: High speed, low friction; Cons: Lower load capacity compared to rollers. |

| Roller Bearings | Cylindrical or tapered rolling elements, high load capacity | Heavy machinery, construction equipment | Pros: High load-bearing capacity; Cons: More friction than ball bearings. |

| Thrust Bearings | Designed to handle axial loads, flat surfaces | Gearboxes, turbines, marine applications | Pros: Effective in axial load applications; Cons: Limited radial load capacity. |

| Needle Bearings | Long, thin rollers, compact design | Automotive, industrial machinery | Pros: Space-efficient, high load capacity; Cons: Sensitive to misalignment. |

| Magnetic Bearings | Uses magnetic levitation for frictionless operation | High-speed applications, aerospace | Pros: Minimal wear, high reliability; Cons: Complex design and higher cost. |

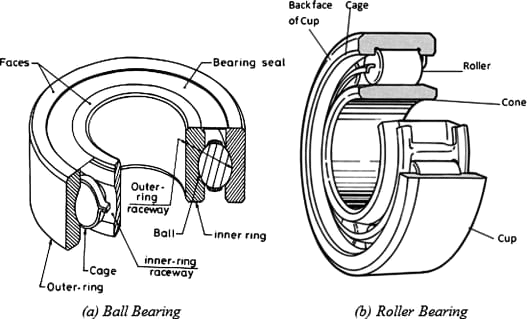

What Are the Characteristics of Ball Bearings and Their Suitability for B2B Applications?

Ball bearings are characterized by their spherical rolling elements, which allow for smooth rotation with minimal friction. They are highly versatile and can be used in various applications, including automotive components, machinery, and home appliances. When purchasing ball bearings, B2B buyers should consider the load capacity and speed requirements of their applications, as ball bearings are ideal for high-speed operations but may have limitations in load-bearing capabilities compared to other types.

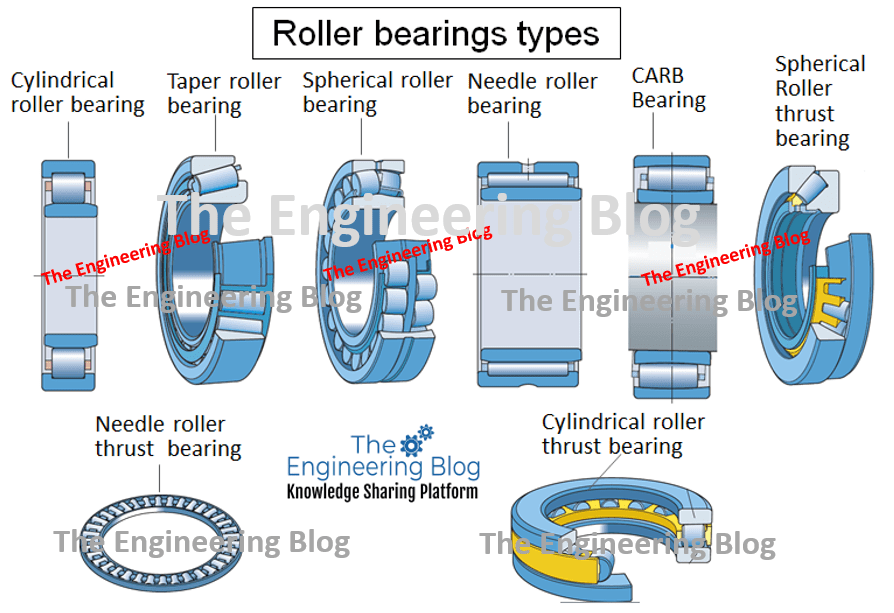

How Do Roller Bearings Differ and What Are Their Key Applications?

Roller bearings feature cylindrical or tapered rolling elements that provide a higher load capacity than ball bearings. They are commonly used in heavy machinery and construction equipment where substantial loads are present. B2B buyers should evaluate the specific load and speed requirements of their equipment when selecting roller bearings, as these bearings may introduce more friction, impacting efficiency in high-speed applications.

What Makes Thrust Bearings Unique and When Should They Be Used?

Thrust bearings are specifically designed to manage axial loads, featuring flat surfaces that support forces parallel to the shaft. They are essential in applications such as gearboxes and turbines, where axial forces are prevalent. Buyers should consider the thrust bearing’s ability to handle specific axial loads, while also recognizing that they typically have limited capacity for radial loads, which may require additional support from other bearing types.

Illustrative image related to components of a bearing

Why Choose Needle Bearings for Space-Constrained Applications?

Needle bearings utilize long, thin rollers, making them an excellent choice for applications where space is limited. They offer high load capacity despite their compact design, making them suitable for automotive and industrial machinery. However, B2B buyers must be cautious of needle bearings’ sensitivity to misalignment, which can lead to premature failure if not properly installed.

What Are the Advantages and Challenges of Magnetic Bearings?

Magnetic bearings leverage magnetic levitation to eliminate friction between moving parts, resulting in minimal wear and high reliability. They are particularly beneficial in high-speed applications, such as aerospace and advanced manufacturing. However, the complexity of their design and higher costs can be a barrier for some buyers. When considering magnetic bearings, businesses should weigh the long-term benefits of reduced maintenance against the initial investment and technical requirements.

Key Industrial Applications of components of a bearing

| Industry/Sector | Specific Application of components of a bearing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wheel hubs and transmission systems | Enhanced vehicle performance and longevity | Quality standards, load ratings, and environmental factors |

| Industrial Machinery | Conveyor systems and manufacturing equipment | Increased efficiency and reduced maintenance costs | Material specifications, lubrication compatibility, and reliability |

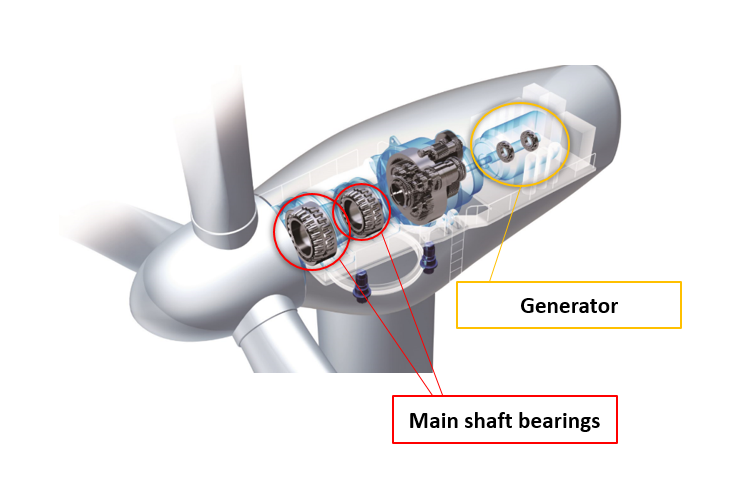

| Renewable Energy | Wind turbine rotor assemblies | Improved energy capture and reduced downtime | Resistance to extreme conditions and lifecycle costs |

| Mining and Construction | Heavy machinery and equipment like excavators and drills | Enhanced durability and operational efficiency | Load capacity, resistance to contaminants, and sourcing local suppliers |

| Aerospace | Engine components and landing gear systems | Critical reliability and safety in high-stakes applications | Compliance with aviation standards and weight considerations |

How Are Components of a Bearing Utilized in the Automotive Sector?

In the automotive industry, components of a bearing are crucial for applications such as wheel hubs and transmission systems. Bearings facilitate smooth rotation and help reduce friction, which enhances vehicle performance and extends the lifespan of components. International buyers must prioritize quality standards and ensure that bearings meet specific load ratings suitable for various vehicle types, considering regional environmental factors that may affect performance.

What Role Do Bearings Play in Industrial Machinery?

In industrial machinery, bearings are integral to conveyor systems and manufacturing equipment. They help maintain operational efficiency by allowing for smooth movement and reducing wear and tear on machinery, which translates to lower maintenance costs. Buyers in this sector should focus on material specifications that match their operational environment, as well as compatibility with lubricants to ensure long-term reliability.

Why Are Bearings Important in Renewable Energy Applications?

In the renewable energy sector, particularly in wind turbine rotor assemblies, the components of a bearing are essential for maximizing energy capture while minimizing downtime. Bearings in this context must withstand extreme conditions, including high winds and varying temperatures. B2B buyers should evaluate the resistance of bearings to environmental factors and consider lifecycle costs to ensure sustainable operations.

How Are Bearings Used in Mining and Construction Equipment?

Heavy machinery in mining and construction, such as excavators and drills, relies heavily on robust bearing components. These bearings must endure high loads and harsh conditions, providing enhanced durability and operational efficiency. Buyers should consider load capacity and resistance to contaminants, as well as sourcing from local suppliers to reduce lead times and support regional economies.

What Are the Critical Requirements for Aerospace Bearings?

In the aerospace industry, components of a bearing are vital for applications such as engine components and landing gear systems, where reliability and safety are paramount. Bearings must comply with stringent aviation standards and be lightweight to improve fuel efficiency. International buyers need to focus on sourcing bearings that meet these high standards, ensuring they can withstand the unique stresses of flight while maintaining safety and performance.

3 Common User Pain Points for ‘components of a bearing’ & Their Solutions

Scenario 1: Difficulty in Identifying Suitable Bearing Components for Specific Applications

The Problem: B2B buyers often struggle to identify the right components of a bearing suitable for their specific applications. For instance, a manufacturer in the automotive sector might require bearings that can withstand high speeds and loads, while another in the agricultural sector may need components that resist corrosion and dirt. This confusion can lead to incorrect purchases, increased costs, and unscheduled downtime, which are detrimental to productivity and profitability.

The Solution: To navigate this challenge, buyers should start by conducting a thorough analysis of their operational requirements. This includes understanding load types (radial or axial), environmental conditions (temperature, humidity, exposure to chemicals), and speed ratings. Engaging with suppliers who offer technical expertise and can provide detailed specifications for their products is crucial. Buyers should also consider utilizing software tools or online calculators that can help determine the right bearing components based on their unique application parameters. Regular training sessions and workshops with suppliers can further enhance understanding and ensure the right choices are made.

Scenario 2: Challenges with Bearing Lubrication and Maintenance

The Problem: A common pain point for B2B buyers is effectively managing lubrication and maintenance of bearing components. Inadequate lubrication can lead to increased friction, overheating, and ultimately, bearing failure. For companies operating in harsh environments, such as mining or heavy manufacturing, the challenge is even greater as contaminants can degrade lubricants more rapidly, leading to frequent breakdowns and increased maintenance costs.

The Solution: To address lubrication challenges, buyers should implement a proactive maintenance schedule that includes regular inspections and lubricant analysis. Opting for high-quality, application-specific lubricants that are designed to withstand extreme conditions can significantly improve bearing performance. Additionally, buyers should invest in automated lubrication systems that ensure consistent application of the right amount of lubricant over time. Training maintenance personnel on the importance of lubrication and signs of wear can also empower them to take preventive measures, minimizing unexpected failures and prolonging the life of the bearings.

Scenario 3: Understanding the Impact of Bearing Component Quality on Performance

The Problem: Many B2B buyers are often unaware of how the quality of bearing components directly affects overall performance and reliability. Choosing low-cost components may seem appealing in the short term, but this can lead to premature failures and increased operational costs due to repairs and replacements. This scenario is particularly critical for industries that rely on precision and efficiency, such as aerospace and manufacturing.

The Solution: Buyers should prioritize sourcing components from reputable manufacturers known for high-quality standards and reliability. This can be achieved by reviewing certifications, customer testimonials, and performance data. Establishing long-term relationships with suppliers who provide comprehensive warranties and support can also help ensure that any issues are addressed promptly. Furthermore, conducting regular audits of the supply chain to assess component quality can help mitigate risks associated with inferior products. Investing in quality components upfront can lead to greater efficiency and cost savings in the long run, making it a strategic decision for any B2B operation.

Strategic Material Selection Guide for components of a bearing

What Are the Key Materials Used in Bearing Components?

When selecting materials for bearing components, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. This analysis covers four common materials: steel, ceramic, polymer, and bronze. Each material has distinct characteristics that can significantly impact performance and application in various industries.

How Does Steel Perform as a Bearing Material?

Steel is the most widely used material for bearing components due to its exceptional strength and durability. High-carbon steel, often treated for hardness, can withstand significant loads and has a high-temperature rating, making it suitable for demanding applications. However, steel is susceptible to corrosion, especially in humid or corrosive environments, unless properly treated or coated.

Pros: Steel bearings are generally cost-effective, easy to manufacture, and have excellent load-bearing capabilities. They are suitable for a wide range of applications, including automotive and industrial machinery.

Cons: The primary limitation is their susceptibility to rust and corrosion, which can lead to premature failure if not properly maintained. Additionally, steel bearings can be heavier than alternatives like ceramics or polymers.

Impact on Application: Steel bearings are compatible with various lubricants and can operate in diverse media, but they require careful consideration of environmental factors to avoid corrosion.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN for steel grades and treatments. In regions like Africa and South America, sourcing locally available materials can also reduce costs.

Illustrative image related to components of a bearing

What Advantages Do Ceramics Offer in Bearing Applications?

Ceramic materials, such as silicon nitride, are increasingly popular in bearing applications due to their excellent wear resistance and low friction properties. Ceramics can operate at higher temperatures than steel and are inherently resistant to corrosion and chemical attack.

Pros: The key advantage of ceramic bearings is their longevity and ability to maintain performance under extreme conditions. They are lightweight, which can enhance the efficiency of machinery.

Cons: The main drawback is their brittleness; ceramics can fracture under shock loads. Additionally, they tend to be more expensive than steel bearings, which can be a barrier for some applications.

Illustrative image related to components of a bearing

Impact on Application: Ceramics are ideal for high-speed applications and environments where corrosion is a concern, such as in the chemical industry.

Considerations for International Buyers: Buyers should verify that ceramic materials meet relevant international standards, and they may need to consider the availability of specialized suppliers in their region.

How Do Polymers Compare as Bearing Materials?

Polymer bearings, made from materials like PTFE or PEEK, are known for their low friction and self-lubricating properties. They are lightweight and can operate effectively in a wide temperature range.

Pros: The primary advantage of polymer bearings is their resistance to corrosion and chemical exposure, making them suitable for harsh environments. They also offer noise reduction and vibration dampening.

Cons: However, polymer bearings may not handle heavy loads as effectively as steel or ceramic options. They can also have a shorter lifespan under high-stress conditions.

Impact on Application: These bearings are particularly useful in food processing and pharmaceutical industries where hygiene is paramount, and metal contamination must be avoided.

Illustrative image related to components of a bearing

Considerations for International Buyers: Compliance with food safety standards and regulations is critical for buyers in these sectors. Additionally, understanding the local market for polymers can help in sourcing the right materials.

What Role Does Bronze Play in Bearing Components?

Bronze is another traditional material used in bearing applications, particularly in bushings and sleeves. It offers good wear resistance and can withstand moderate loads.

Pros: Bronze bearings are known for their excellent corrosion resistance and ability to operate in marine environments. They also provide good thermal conductivity.

Cons: The main limitation is that bronze can be more expensive than steel, and its performance can degrade under high loads compared to other materials.

Impact on Application: Bronze is often used in applications requiring good lubrication and resistance to wear, such as in shipbuilding and heavy machinery.

Illustrative image related to components of a bearing

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM B505 for bronze alloys, and consider the cost implications of importing bronze versus sourcing locally.

Summary of Material Selection for Bearing Components

| Material | Typical Use Case for components of a bearing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive and industrial machinery | High strength and durability | Susceptible to corrosion | Medium |

| Ceramic | High-speed and corrosive environments | Excellent wear resistance | Brittle and expensive | High |

| Polymer | Food processing and pharmaceutical industries | Corrosion resistant and lightweight | Limited load capacity | Medium |

| Bronze | Marine applications and heavy machinery | Good corrosion resistance | Higher cost and lower load capacity | Medium |

This strategic material selection guide provides insights into the properties and considerations for each material, aiding international B2B buyers in making informed decisions tailored to their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for components of a bearing

What Are the Key Stages in the Manufacturing Process of Bearing Components?

The manufacturing of bearing components involves several critical stages that ensure the final product meets the required specifications for performance and durability. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Bearing Components?

Material preparation is the foundation of the manufacturing process. High-quality steel or advanced materials, such as ceramics or composites, are commonly used for bearings. The selection of material is crucial as it affects the bearing’s load capacity, durability, and resistance to wear.

Once the material is selected, it undergoes processes such as forging or casting to create the initial shape. This is followed by heat treatment processes, such as quenching and tempering, which enhance the material’s mechanical properties. Rigorous testing for material integrity often occurs at this stage, including hardness and tensile strength tests, to ensure the raw materials meet industry standards.

What Forming Techniques Are Employed in Bearing Manufacturing?

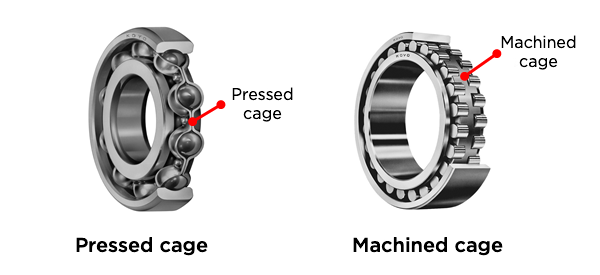

Forming techniques are pivotal in shaping the bearing components accurately. Common methods include:

- Machining: This involves processes like turning, milling, and grinding to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are often utilized for high precision.

- Stamping: For certain components like cages, stamping can be used to form the shape from sheet metal quickly and efficiently.

- Injection Molding: This technique is typically used for polymer components, such as seals or cages, allowing for complex shapes and high production rates.

Each forming method is chosen based on the specific component’s requirements, balancing cost-effectiveness with precision.

How Are Bearing Components Assembled?

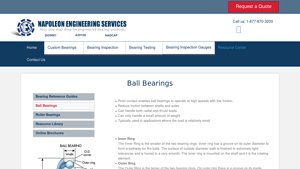

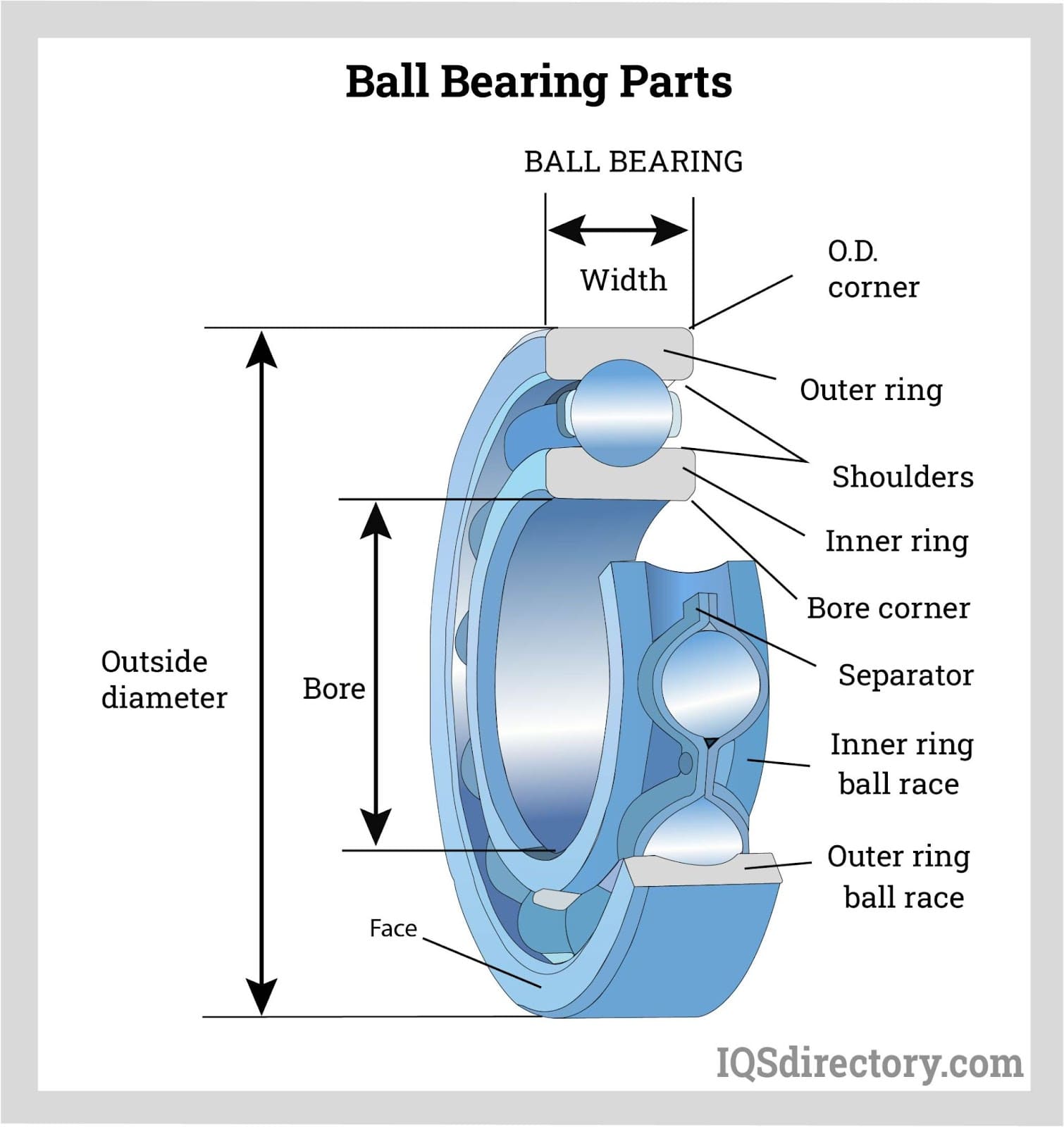

The assembly of bearing components is a delicate process that requires meticulous attention to detail. This stage typically involves:

- Cleanliness Protocols: Ensuring all components are free from contaminants, as even minute particles can affect performance.

- Component Alignment: Precise alignment of the inner and outer rings, rolling elements, and cages is crucial for optimal function.

- Lubrication: Application of the appropriate lubricant is essential to reduce friction and wear during operation.

Automation is increasingly being incorporated into the assembly process to enhance efficiency and consistency. However, skilled technicians often perform final inspections to ensure each bearing meets specific operational standards.

What Finishing Processes Are Critical for Bearing Components?

Finishing processes significantly impact the performance and longevity of bearing components. These processes typically include:

- Surface Treatment: Techniques such as shot peening, polishing, or coating improve surface hardness and reduce friction.

- Final Machining: Ensures that all dimensions are within specified tolerances and that surface finishes meet the required standards.

- Heat Treatment: Additional heat treatment may be applied post-assembly to relieve stresses and improve material properties.

These finishing steps are vital to enhance the bearing’s durability and performance under operational stresses.

What Quality Control Measures Are Implemented in Bearing Manufacturing?

Quality control (QC) is integral to ensuring that bearing components perform reliably in demanding applications. Implementing robust QC measures helps manufacturers comply with international standards and meet customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers typically adhere to several international standards to ensure quality and safety. The most notable include:

- ISO 9001: This standard focuses on quality management systems, ensuring a consistent approach to manufacturing and customer satisfaction.

- ISO/TS 16949: Particularly relevant in automotive applications, this standard emphasizes continuous improvement and defect prevention.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For bearings used in the oil and gas sector, API specifications ensure reliability in extreme conditions.

Understanding these standards helps B2B buyers verify the quality and safety of the products they procure.

What Are the Key Quality Control Checkpoints in Bearing Manufacturing?

Quality control checkpoints are strategically implemented throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring critical stages of production to catch defects early, which can reduce waste and rework.

- Final Quality Control (FQC): Conducting thorough inspections and testing of the finished product, including dimensional checks and performance testing.

Common testing methods at these checkpoints may include non-destructive testing (NDT), fatigue testing, and life cycle simulations to assess performance under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can be achieved through:

- Supplier Audits: Conducting on-site audits to assess manufacturing processes, quality management systems, and compliance with standards.

- Reviewing Quality Control Reports: Requesting documentation that outlines QC processes and results from previous inspections and tests.

- Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing process and product quality, ensuring an unbiased assessment.

These steps are particularly important for international buyers from regions such as Africa, South America, the Middle East, and Europe, where supply chain complexities can impact quality.

What Are the Specific Quality Assurance Nuances for International Buyers?

International buyers must be aware of specific nuances in quality assurance that can affect procurement. Factors to consider include:

- Cultural Differences: Understanding local manufacturing practices and attitudes towards quality can influence the effectiveness of QC measures.

- Regulatory Compliance: Different regions may have varying regulations regarding materials, safety, and environmental impacts, necessitating thorough due diligence.

- Logistics and Supply Chain Challenges: Transporting components across borders can introduce risks related to damage or loss, emphasizing the need for robust packaging and handling protocols.

By focusing on these aspects, international B2B buyers can enhance their procurement strategies and ensure they receive high-quality bearing components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘components of a bearing’

When sourcing components of a bearing, it’s essential to follow a structured approach to ensure you select high-quality materials that meet your operational needs. This checklist will guide you through the critical steps necessary for successful procurement.

Illustrative image related to components of a bearing

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the bearing components you need. This includes dimensions, load capacity, material type, and environmental considerations. Defining these specifications upfront helps to narrow down your options and ensures compatibility with your machinery.

Step 2: Research Different Bearing Types

Familiarize yourself with the various types of bearings and their components, such as ball bearings, roller bearings, and thrust bearings. Understanding the differences can help you select the right type for your application, ensuring optimal performance and longevity.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough research on their reputation and capabilities. Look for:

– Company profiles and case studies: These will provide insight into their experience and expertise.

– Customer references: Reach out to existing clients to gauge satisfaction and reliability.

Step 4: Request Samples and Specifications

Always request samples of the bearing components you intend to purchase. This allows you to:

– Inspect quality and performance: Evaluate the materials and craftsmanship.

– Test compatibility: Ensure that the components meet your technical specifications in real-world conditions.

Step 5: Verify Supplier Certifications

Check that your suppliers have the necessary certifications and quality assurance processes in place. Look for:

– ISO certifications: These indicate adherence to international quality standards.

– Industry-specific certifications: Depending on your application, certain certifications may be crucial, especially in sectors like automotive or aerospace.

Step 6: Assess Lead Times and Inventory Levels

Understanding the supplier’s lead times and inventory levels is crucial for planning your production schedules. Confirm:

– Delivery timelines: Ensure they can meet your deadlines.

– Stock availability: This will help mitigate any potential delays in your supply chain.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of your purchase. Discuss:

– Pricing structures: Ensure transparency in costs, including potential discounts for bulk orders.

– Return policies and warranties: Clarify terms to protect your investment in case of defects or incompatibilities.

By following this checklist, you will be better equipped to source the right components of a bearing, ensuring reliability and efficiency in your operations.

Comprehensive Cost and Pricing Analysis for components of a bearing Sourcing

What Are the Key Cost Components for Bearing Components?

When sourcing components of bearings, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. Common materials include high-carbon steel, ceramics, and polymers. Advanced materials like stainless steel or specialized alloys can increase costs but also enhance performance and longevity.

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Skilled labor is often required for precision machining and assembly, which can increase costs in developed regions compared to emerging markets.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including facility expenses, utilities, and maintenance. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: Initial tooling costs for custom components can be substantial, especially for unique designs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the overall cost. Certifications such as ISO 9001 can enhance credibility but may also require additional investment.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors like distance, mode of transport, and customs duties can all influence logistics costs.

-

Margin: Supplier margins vary widely based on market conditions and competition. Understanding typical margins in your target region can aid in negotiations.

How Do Price Influencers Impact Bearing Components?

Several factors influence the pricing of bearing components, which can vary significantly between regions such as Africa, South America, the Middle East, and Europe:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower unit prices due to economies of scale. Negotiating for larger orders can yield significant savings.

-

Specifications and Customization: Custom components tailored to specific applications can increase costs. Be clear about your requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of material impacts both performance and price. Additionally, components that meet specific quality certifications may command higher prices due to the assurance of reliability.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more for their experience and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for cost management in international trade. Different terms can shift responsibility for costs like insurance and transportation, impacting the overall price.

What Tips Can Help Buyers Negotiate Effectively?

For international B2B buyers, particularly from emerging markets, effective negotiation strategies can lead to better pricing and cost efficiency:

-

Research and Benchmarking: Gather data on prevailing market prices and competitor offerings to strengthen your negotiation position.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, operational efficiency, and potential downtime. This holistic view can justify higher initial costs for components that offer greater reliability and performance.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better terms and pricing. Suppliers are often more willing to negotiate with partners they trust.

-

Flexibility in Specifications: If feasible, be open to alternative materials or designs that can reduce costs without compromising essential performance criteria.

-

Timing and Market Conditions: Stay informed about market trends and economic conditions that might affect pricing. Timing your orders based on demand cycles can lead to cost advantages.

Conclusion: Understanding Costs and Pricing Nuances in Bearing Sourcing

Navigating the complexities of bearing component sourcing requires a solid grasp of cost structures and pricing influencers. By being informed and strategic in negotiations, buyers can achieve favorable outcomes that enhance their supply chain efficiency. Always consider the broader context of total cost and long-term supplier relationships to maximize value. Keep in mind that prices can fluctuate due to market conditions, so obtaining indicative prices is essential for accurate budgeting.

Illustrative image related to components of a bearing

Alternatives Analysis: Comparing components of a bearing With Other Solutions

Introduction to Alternatives in Bearing Solutions

In the quest for optimal machinery performance, the components of a bearing play a critical role in reducing friction and enabling smooth rotation. However, businesses must often evaluate alternative solutions that may provide similar benefits. This analysis compares traditional bearing components with two viable alternatives: magnetic bearings and fluid bearings. Understanding the strengths and weaknesses of each solution is essential for B2B buyers looking to enhance operational efficiency while managing costs.

Comparison Table of Bearing Components and Alternatives

| Comparison Aspect | Components Of A Bearing | Magnetic Bearings | Fluid Bearings |

|---|---|---|---|

| Performance | High efficiency and durability; reduces friction effectively | Exceptional performance in high-speed applications; minimal friction | Offers smooth operation with consistent performance under varying loads |

| Cost | Generally lower initial cost, but ongoing maintenance may be required | Higher initial investment; potential savings in maintenance | Moderate cost, influenced by complexity of design and installation |

| Ease of Implementation | Relatively straightforward installation and integration | More complex installation requiring specialized knowledge | Installation can be challenging; requires precise setup and maintenance |

| Maintenance | Regular maintenance needed to ensure longevity | Low maintenance due to fewer moving parts | Requires regular monitoring and maintenance of fluid levels |

| Best Use Case | Suitable for a wide range of applications, from automotive to industrial machinery | Ideal for high-speed and precision applications, such as aerospace | Best for heavy-duty applications where load stability is critical |

Detailed Breakdown of Alternatives

Magnetic Bearings

Magnetic bearings utilize magnetic fields to levitate rotating shafts, minimizing contact and friction. This technology excels in high-speed applications, such as aerospace and advanced manufacturing, where traditional bearings may fail due to excessive wear. The main advantages include reduced maintenance needs and increased efficiency. However, the initial investment can be significantly higher than conventional bearings, making them less accessible for cost-sensitive projects. Additionally, the complexity of installation and the need for specialized knowledge can deter some businesses from adopting this solution.

Fluid Bearings

Fluid bearings operate by using a thin layer of fluid to support the rotating elements, providing a frictionless environment that enhances performance. These bearings are particularly beneficial in heavy-duty applications, such as turbines and large machinery, where consistent load support is necessary. While they offer smooth operation and can handle substantial loads, they require careful monitoring and maintenance of fluid levels to prevent operational failures. The cost of fluid bearings can vary, as they often necessitate a more complex design, making them a moderate investment compared to traditional bearings.

Conclusion: Choosing the Right Bearing Solution

When selecting a bearing solution, B2B buyers must consider their specific operational needs, budget constraints, and the complexity of implementation and maintenance. Components of a bearing offer a reliable and cost-effective choice for a wide range of applications, while magnetic and fluid bearings present advanced alternatives for specialized scenarios. Each option has its unique advantages and drawbacks, so businesses should evaluate their requirements carefully to determine the best fit for their operations. By analyzing performance, cost, and maintenance needs, buyers can make informed decisions that enhance efficiency and drive long-term success.

Essential Technical Properties and Trade Terminology for components of a bearing

What Are the Key Technical Properties of Bearing Components?

Understanding the technical properties of bearing components is crucial for B2B buyers, particularly when selecting bearings that meet specific operational demands. Here are some essential specifications to consider:

1. Material Grade

The material grade of bearing components, typically ranging from carbon steel to stainless steel and ceramic, directly affects durability and performance. High-quality materials can withstand extreme loads and corrosive environments, making them ideal for heavy industrial applications. Selecting the right material grade can enhance the longevity of bearings, reducing replacement costs and downtime.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension, such as the diameter of bearing rings or the width of rolling elements. Tight tolerances are essential for ensuring proper fit and function within machinery. Inaccurate tolerances can lead to increased friction, heat generation, and premature bearing failure. Understanding tolerance specifications is vital for ensuring compatibility with existing systems.

3. Load Rating

Load rating indicates the maximum load a bearing can support while maintaining its functionality. This property is critical for determining the suitability of a bearing for specific applications, especially in high-load environments. Buyers must assess both dynamic and static load ratings to ensure bearings can handle expected operational stresses without failure.

Illustrative image related to components of a bearing

4. Lubrication Type

The type of lubrication used in bearings—whether grease or oil—affects both performance and maintenance needs. Grease provides better protection against contaminants but may require periodic replacement, while oil can offer better cooling and lower friction. Understanding lubrication requirements helps buyers optimize bearing performance and extend service life.

5. Operating Temperature Range

Each bearing type has a specified operating temperature range. Exceeding these limits can lead to material degradation, loss of lubrication, and eventual failure. Buyers should ensure that the bearings chosen are suitable for the environmental conditions of their application, particularly in industries with extreme temperatures.

What Are Common Trade Terms in the Bearing Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the bearing market. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are purchased by another company for resale under the latter’s brand. Understanding OEM relationships is vital for buyers looking for reliable sources of high-quality bearings that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is significant for buyers to assess inventory needs and manage cash flow effectively. Knowing the MOQ helps in planning purchases to avoid excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It is a common practice in B2B transactions, helping buyers gather competitive pricing and terms. Crafting a clear RFQ can streamline the procurement process and lead to better deals.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations in international transactions, reducing the risk of misunderstandings and disputes.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the goods. In the bearing industry, lead times can vary based on manufacturing processes and inventory levels. Understanding lead times is crucial for effective project planning and ensuring timely operations.

By comprehensively understanding both the technical properties of bearing components and the relevant trade terminology, B2B buyers can make informed decisions that enhance their operational efficiency and reduce costs.

Illustrative image related to components of a bearing

Navigating Market Dynamics and Sourcing Trends in the components of a bearing Sector

What Are the Current Market Dynamics and Key Trends in the Components of a Bearing Sector?

The global bearing market is currently influenced by several key drivers, including the rapid growth of automation in manufacturing, increasing demand for electric vehicles, and advancements in materials science. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for informed sourcing decisions. The rise of Industry 4.0 has led to the integration of smart technologies in bearing components, promoting predictive maintenance and reducing downtime. This trend is particularly beneficial for buyers looking to enhance operational efficiency and reduce costs.

Emerging technologies such as 3D printing and advanced materials are transforming the production of bearing components. Buyers can leverage these innovations to source customized solutions that meet specific performance requirements. Additionally, there is a noticeable shift towards the use of hybrid and ceramic bearings, which offer superior performance and durability in demanding environments. Buyers should also consider the growing trend of digital sourcing platforms, which streamline procurement processes and enhance supplier transparency.

How Are Sustainability and Ethical Sourcing Impacting the Bearing Component Market?

Sustainability has become a pivotal concern for B2B buyers in the bearing component sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. Ethical sourcing is not only a moral imperative but also a competitive advantage. Buyers are increasingly favoring suppliers with certifications such as ISO 14001 (Environmental Management) and those that utilize recycled or sustainably sourced materials.

Illustrative image related to components of a bearing

Incorporating green materials into the production of bearing components can significantly reduce the carbon footprint. For instance, using bio-based lubricants or lightweight composite materials enhances both sustainability and performance. Furthermore, buyers should evaluate suppliers on their commitment to reducing waste and energy consumption throughout their operations. By prioritizing sustainability and ethical sourcing, businesses can improve their brand image and meet the demands of environmentally conscious consumers.

What Is the Evolution of Bearing Components and Its Significance for B2B Buyers?

The evolution of bearing components dates back centuries, with significant advancements occurring in the last few decades. Initially, bearings were simple devices designed to reduce friction; however, modern bearings have evolved into complex assemblies that enhance performance in various applications. The introduction of precision engineering and high-performance materials has expanded the capabilities of bearing components, allowing them to operate under extreme conditions.

For B2B buyers, understanding this evolution is critical as it informs their choices in sourcing high-quality components that align with their operational needs. Today’s bearings are designed not only for durability but also for efficiency and reliability, which are essential for maintaining competitive advantage in fast-paced markets. Buyers who stay abreast of these advancements can leverage improved product offerings to enhance their operational performance and reduce maintenance costs.

Frequently Asked Questions (FAQs) for B2B Buyers of components of a bearing

-

How do I select the right components for my bearing needs?

Selecting the right components for your bearings involves considering several factors, such as load capacity, speed, and environmental conditions. Start by determining the type of bearing required (e.g., ball or roller bearings) based on your application. Assess the bearing dimensions, material compatibility, and lubrication needs. It’s also essential to consult with manufacturers or suppliers who can provide technical specifications and support. Always verify that the components meet international standards for quality and safety to ensure optimal performance in your machinery. -

What are the most common types of bearing components?

The primary components of a bearing include bearing rings (inner and outer), rolling elements (balls or rollers), and a cage or separator that keeps the rolling elements spaced evenly. Each component plays a critical role in reducing friction and ensuring smooth rotation. Additional components may include seals or shields to protect against contamination and lubricants that enhance performance and longevity. Understanding these components will help you make informed decisions when sourcing bearings for your specific applications. -

How can I vet potential suppliers of bearing components?

To effectively vet suppliers, begin by researching their reputation in the industry. Look for certifications such as ISO 9001, which indicate adherence to quality management standards. Request samples or references from previous clients to assess product quality and service reliability. Additionally, inquire about their manufacturing processes, lead times, and after-sales support. Establishing clear communication and understanding their terms of service will also help ensure a strong partnership. -

What are the typical minimum order quantities (MOQs) for bearing components?

Minimum order quantities can vary significantly based on the supplier and the specific components you require. Generally, MOQs for standard bearing components may range from 100 to 1,000 units. However, some suppliers may offer flexibility for custom orders or smaller quantities, especially for high-value or specialized components. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your production schedules and budget constraints. -

What payment terms should I expect when sourcing bearing components internationally?

Payment terms can differ widely among suppliers, but common practices include payment in advance, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for large orders or custom components. When sourcing internationally, consider factors such as currency exchange rates, transaction fees, and potential delays in payment processing. Clear communication about payment terms upfront can help avoid misunderstandings and ensure smooth transactions. -

How do I ensure quality assurance for bearing components?

To ensure quality assurance, request documentation such as certificates of conformity or quality inspection reports from your supplier. Many reputable manufacturers conduct rigorous testing on their components to meet industry standards. It’s also beneficial to establish a quality control process on your end, including inspections upon receipt of goods. Collaborating with suppliers who have a robust quality management system can further enhance confidence in the components you purchase. -

What logistics considerations should I keep in mind when importing bearing components?

When importing bearing components, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner experienced in international shipping to help navigate any complexities. Be aware of import duties and taxes that may apply in your country, as these can impact overall costs. Additionally, ensure proper documentation is in place, including invoices and packing lists, to facilitate smooth customs clearance. -

Can I customize bearing components for specific applications?

Yes, many suppliers offer customization options for bearing components to meet specific application needs. Customizations can include variations in size, material, lubrication, or even specialized coatings for enhanced performance in extreme conditions. When seeking custom components, provide detailed specifications to your supplier and discuss lead times and costs associated with the modifications. Custom solutions can significantly improve efficiency and reliability in your machinery.

Top 5 Components Of A Bearing Manufacturers & Suppliers List

1. Koyo – Bearings Structure Components

Domain: koyo.jtekt.co.jp

Introduction: The structure of bearings includes the following components: 1. Bearing rings (races) – ring-shaped components that support the rolling elements. 2. Rolling elements – components that roll between the bearing rings, which can be either balls or rollers. 3. Cage – maintains a fixed gap between rolling elements to prevent contact. Bearings can be categorized into radial bearings (using balls or roll…

2. NSK – Bearings

Domain: nsk.com

Registered: 1996 (29 years)

Introduction: Bearings are crucial machine components that increase the efficiency of movement by reducing friction, leading to longer equipment life. There are two main types of bearings: plain (sliding) bearings and rolling (rolling-element) bearings. Rolling bearings include various types such as ball bearings (deep groove, angular contact, self-aligning, thrust), roller bearings (cylindrical, tapered, spher…

3. Bearing Wizard – Essential Bearing Components

Domain: bearingwizard.com

Registered: 2023 (2 years)

Introduction: Main components of rolling bearings include: Inner ring, outer ring, rolling elements, and cage. Optionally, a seal can be installed in a groove on the inner and outer ring. Lubrication with grease or oil reduces friction and wear. Bearings can be classified as axial or radial based on the direction of the load. Axial bearings have a contact angle between 45° and 90°, while radial bearings have a …

4. Tameson – Ball Bearings

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: A ball bearing is a circular joint that connects a rotating part to a stationary part of a machine, reducing friction during rotation. Key components include two grooved raceways and a set of balls (ball bearing rollers). Types of ball bearings include: 1. Deep Groove Ball Bearings – suitable for both radial and axial loads. 2. Angular Contact Ball Bearings. 3. Self-Aligning Ball Bearings. 4. Thru…

5. Nes Bearings – Ball Bearings

Domain: nesbearings.com

Registered: 2002 (23 years)

Introduction: Ball bearings are crucial components in various machinery and equipment, providing support and reducing friction between moving parts. They are available in different types, including deep groove, angular contact, and thrust ball bearings, each designed for specific applications. Key features include high load capacity, durability, and the ability to operate at high speeds. Common materials used i…

Strategic Sourcing Conclusion and Outlook for components of a bearing

Why Is Strategic Sourcing Crucial for Bearing Components?

In the competitive landscape of bearing components, strategic sourcing emerges as a vital approach for international B2B buyers. By understanding the intricate structures—such as bearing rings, rolling elements, and cages—companies can make informed decisions that enhance performance and reliability. Prioritizing quality and compatibility ensures not only the longevity of machinery but also reduces operational costs through improved efficiency.

Moreover, as global supply chains become increasingly complex, sourcing from reputable manufacturers can mitigate risks associated with material shortages and fluctuating prices. Engaging with suppliers who prioritize innovation and sustainability will provide a competitive edge in diverse markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for advanced bearing solutions is projected to grow. Companies that invest in strategic sourcing now will be well-positioned to capitalize on emerging trends, such as the integration of smart technology and eco-friendly materials in bearing design. We encourage you to evaluate your sourcing strategies and align them with market demands to ensure your organization remains at the forefront of the industry. Embrace the future of bearing components—optimize your sourcing today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.