Double Acting Pneumatic Cylinder: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for double acting pneumatic cylinder

In today’s fast-paced industrial landscape, sourcing double acting pneumatic cylinders is a critical challenge for businesses seeking reliable, efficient, and versatile automation solutions. These essential components are integral to a variety of applications, including factory automation, packaging, and robotics, where precise movement and control are paramount. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Germany and Nigeria) navigate the complexities of global sourcing, understanding the nuances of double acting pneumatic cylinders becomes essential for making informed purchasing decisions.

This comprehensive guide delves into the various types of double acting pneumatic cylinders, their applications across different industries, and the key factors to consider when vetting suppliers. From evaluating cost-effectiveness to understanding performance metrics and compliance with international standards, this resource equips buyers with actionable insights to streamline their procurement processes. With the right knowledge, international B2B buyers can enhance operational efficiency, reduce downtime, and ultimately drive profitability in their organizations.

By addressing common challenges and providing expert recommendations, this guide empowers businesses to confidently navigate the global market for double acting pneumatic cylinders, ensuring they select the best solutions tailored to their unique operational needs.

Understanding double acting pneumatic cylinder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Double Acting | Two ports for air entry and exit; suitable for various strokes | Automation, material handling, robotics | Pros: Versatile and efficient; Cons: Higher cost than single acting. |

| Compact Double Acting | Smaller footprint; designed for space-constrained applications | Packaging machinery, assembly lines | Pros: Space-saving design; Cons: Limited force output compared to standard models. |

| Rodless Double Acting | Piston moves without a traditional rod; allows for linear motion in tight spaces | CNC machines, conveyor systems | Pros: Ideal for compact setups; Cons: More complex installation and maintenance. |

| Double Acting with Cushioning | Integrated cushioning to reduce impact at stroke ends | Heavy machinery, automotive applications | Pros: Reduced wear and tear; Cons: Higher initial investment. |

| Double Acting with Sensors | Equipped with sensors for position feedback and control | Robotics, advanced manufacturing | Pros: Enhanced precision and control; Cons: Increased complexity and cost. |

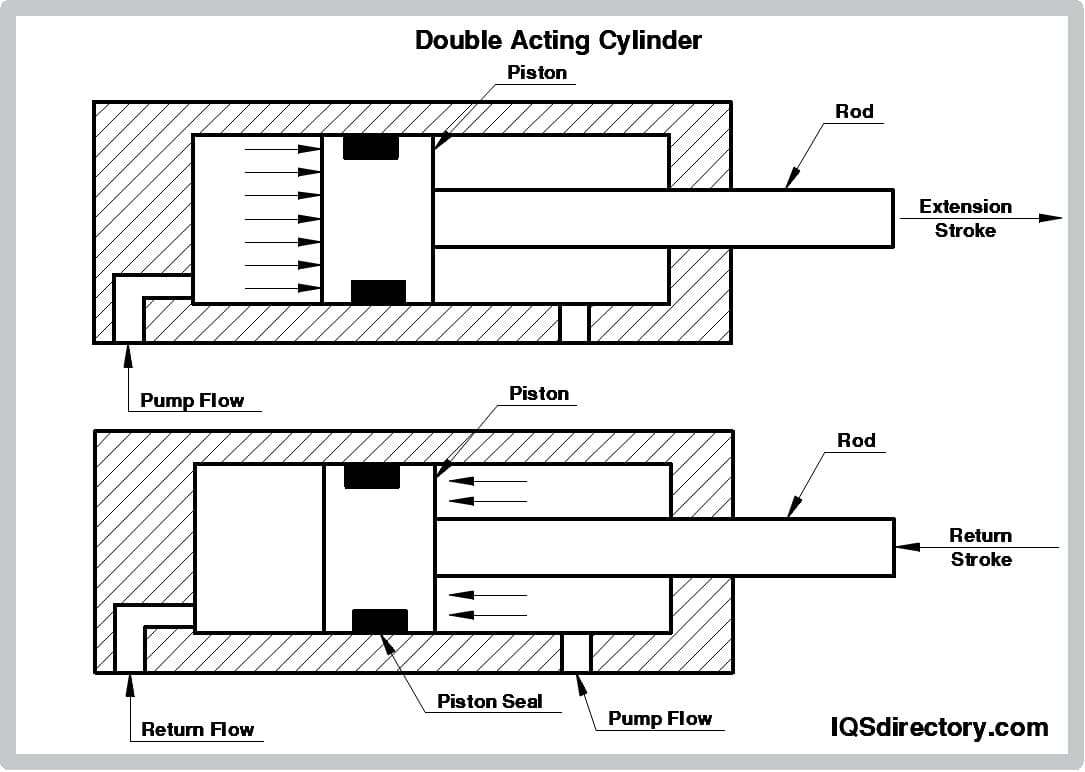

What Are the Characteristics and Suitability of Standard Double Acting Cylinders?

Standard double acting cylinders are characterized by their two ports, allowing compressed air to enter and exit, facilitating movement in both directions. They are widely used across industries such as automation, material handling, and robotics due to their versatility and efficiency. When purchasing, businesses should consider their specific operational needs, as these cylinders can handle various load requirements but may have a higher initial cost compared to single acting cylinders.

Why Choose Compact Double Acting Cylinders for Space-Constrained Applications?

Compact double acting cylinders are designed with a smaller footprint, making them ideal for applications where space is limited, such as in packaging machinery and assembly lines. Their design allows for efficient operation without sacrificing performance. Buyers should evaluate the force output required for their applications, as these cylinders may not deliver the same thrust as standard models but excel in tight environments.

How Do Rodless Double Acting Cylinders Function and What Are Their Applications?

Rodless double acting cylinders operate without a traditional rod, allowing the piston to move freely along a linear path, making them suitable for applications like CNC machines and conveyor systems. Their unique design enables operation in compact spaces, which is a significant advantage for modern manufacturing setups. Buyers need to consider the complexity of installation and maintenance, as these cylinders may require more attention than standard designs.

What Are the Benefits of Double Acting Cylinders with Cushioning Features?

Double acting cylinders with integrated cushioning features are designed to minimize impact at the stroke ends, making them ideal for heavy machinery and automotive applications. This cushioning reduces wear and tear, thereby extending the lifespan of the equipment. However, the initial investment is typically higher, so businesses should weigh the long-term benefits against upfront costs when considering this option.

How Do Double Acting Cylinders with Sensors Enhance Precision in Operations?

Double acting cylinders equipped with sensors provide real-time position feedback, enhancing precision and control in applications such as robotics and advanced manufacturing. This feature allows for more sophisticated automation processes, improving overall efficiency. Buyers should assess their need for precision against the increased complexity and cost, as these cylinders often require more intricate setups and maintenance.

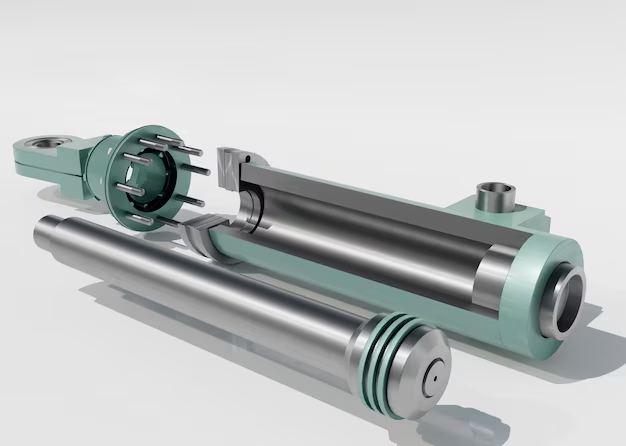

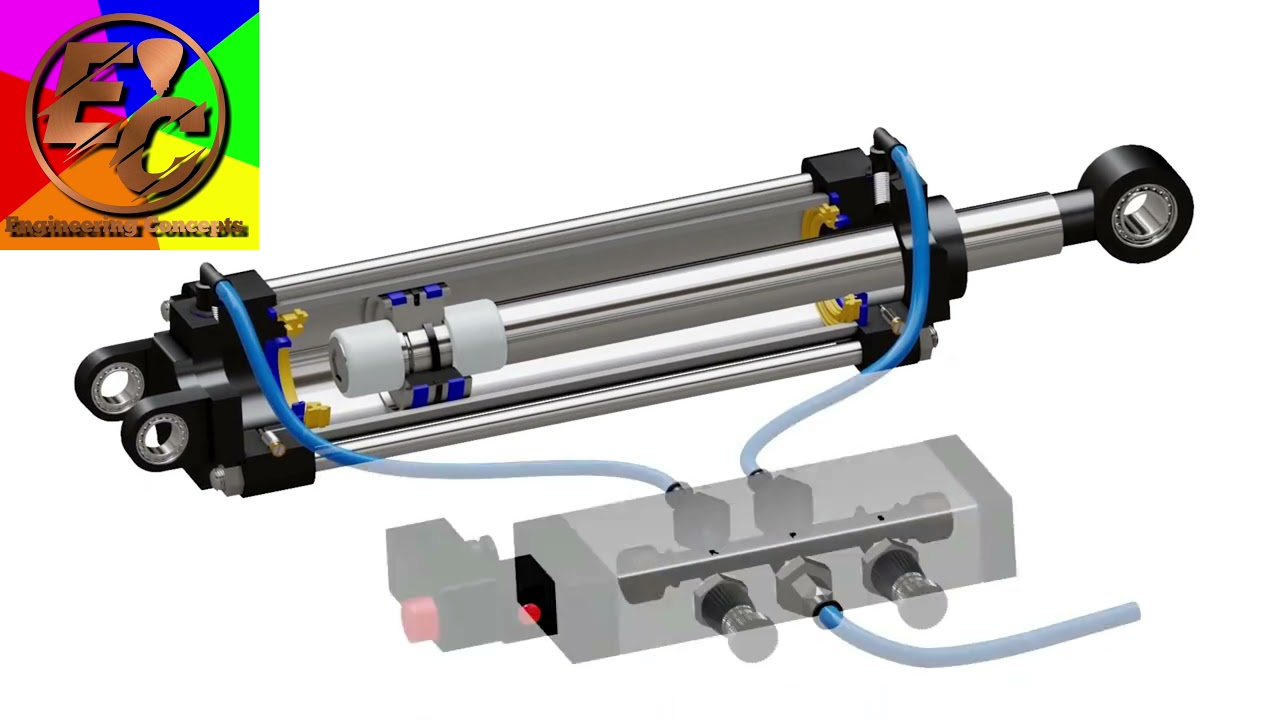

Illustrative image related to double acting pneumatic cylinder

Key Industrial Applications of double acting pneumatic cylinder

| Industry/Sector | Specific Application of double acting pneumatic cylinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines for component positioning | Increases production efficiency and reduces labor costs | ISO compliance, durability under continuous use, and air quality management |

| Packaging | Sealing and closing machines in packaging operations | Enhances speed and consistency in packaging processes | Compatibility with existing machinery, maintenance requirements, and energy efficiency |

| Automotive | Robotic arms for part handling and assembly | Improves precision and reduces cycle time in production | Customization options for stroke length and bore size, reliability under heavy loads |

| Food and Beverage | Filling and capping machines in bottling operations | Ensures hygiene and reduces contamination risks | Compliance with food safety standards, ease of cleaning, and air filtration systems |

| Construction and Heavy Equipment | Lifting and moving materials on construction sites | Increases safety and efficiency in material handling | Robust design for harsh environments, availability of spare parts, and service support |

How is the Double Acting Pneumatic Cylinder Used in Manufacturing?

In manufacturing, double acting pneumatic cylinders are integral to automated assembly lines where precise positioning of components is critical. They facilitate quick and reliable movements, thus enhancing production efficiency and significantly reducing labor costs. For international buyers, particularly those in Africa and South America, sourcing these cylinders involves ensuring they meet ISO compliance and can withstand continuous use in demanding environments. Additionally, attention must be paid to air quality management to avoid contamination that could disrupt operations.

What Role Does the Double Acting Pneumatic Cylinder Play in Packaging?

In packaging industries, double acting pneumatic cylinders are utilized in sealing and closing machines. They provide the speed and consistency required to efficiently package products, ensuring that operations keep pace with production demands. For businesses in the Middle East and Europe, sourcing considerations include compatibility with existing machinery and energy efficiency, as well as understanding the maintenance requirements to minimize downtime.

How are Double Acting Pneumatic Cylinders Essential in Automotive Applications?

In the automotive sector, double acting pneumatic cylinders are employed in robotic arms for handling and assembling parts. Their ability to deliver precise movements enhances production accuracy and reduces cycle times, which is crucial for maintaining competitive advantage. Buyers from regions like Germany should consider customization options for stroke length and bore size, as well as the reliability of these components under heavy loads to ensure optimal performance.

Why are Double Acting Pneumatic Cylinders Important in Food and Beverage Operations?

In the food and beverage industry, double acting pneumatic cylinders are used in filling and capping machines to ensure that products are sealed efficiently and hygienically. This application is vital for minimizing contamination risks and maintaining product quality. Buyers must ensure compliance with food safety standards, ease of cleaning, and the implementation of effective air filtration systems, particularly in regions where regulatory scrutiny is high.

How Do Double Acting Pneumatic Cylinders Enhance Construction and Heavy Equipment Operations?

In construction and heavy equipment, double acting pneumatic cylinders are crucial for lifting and moving materials, thus enhancing safety and operational efficiency. These cylinders enable quick response times and robust lifting capabilities, which are essential in dynamic work environments. Buyers should focus on sourcing robust designs that can withstand harsh conditions, as well as ensuring the availability of spare parts and reliable service support to maintain operational continuity.

3 Common User Pain Points for ‘double acting pneumatic cylinder’ & Their Solutions

Scenario 1: Inconsistent Performance Under Heavy Loads

The Problem: Many B2B buyers face challenges when double acting pneumatic cylinders are required to handle heavy loads. The inconsistency in performance can lead to operational delays and increased costs. For example, in manufacturing or assembly lines, if the cylinder fails to extend or retract with sufficient force, it can cause bottlenecks, production downtime, and even safety hazards. This issue often arises from inadequate sizing or improper application of the cylinder to the task at hand, leading to inefficiencies and potential damage to the equipment.

The Solution: To overcome this challenge, it is crucial to conduct a thorough analysis of the load requirements before selecting a double acting pneumatic cylinder. Start by calculating the force needed for the specific application, taking into account the weight of the load and any friction involved. Choose a cylinder with an appropriate bore size that can provide the necessary force without exceeding the cylinder’s pressure rating. Additionally, consider incorporating sensors to monitor the cylinder’s performance in real-time. This proactive approach not only ensures the right cylinder is selected but also helps in maintaining operational efficiency and safety.

Scenario 2: High Air Consumption Leading to Increased Operational Costs

The Problem: Another common pain point for businesses is the high air consumption associated with double acting pneumatic cylinders. Excessive air usage can significantly inflate operational costs, particularly in industries where compressed air is a primary energy source. Companies in sectors like food packaging or automotive manufacturing may find that their pneumatic systems are not only costly to run but also environmentally unsustainable, leading to greater scrutiny from stakeholders and regulatory bodies.

The Solution: To address air consumption issues, B2B buyers should focus on optimizing their pneumatic systems. This can be achieved by selecting cylinders designed for energy efficiency, such as those with lower air consumption rates and higher efficiency ratings. Additionally, implementing a centralized control system can help regulate air usage by managing the timing and duration of cylinder operations. Regular maintenance of the pneumatic system, including leak detection and the replacement of worn-out components, can also mitigate air loss. These strategies not only reduce costs but also contribute to a more sustainable operation.

Scenario 3: Challenges in Integration with Existing Systems

The Problem: When integrating double acting pneumatic cylinders into existing machinery, buyers often encounter compatibility issues. These can arise from varying specifications, such as port sizes, mounting configurations, and control systems. In sectors like automotive or aerospace, where precision and reliability are paramount, these compatibility challenges can lead to extended downtimes and increased labor costs as teams struggle to fit new components into older systems.

The Solution: To facilitate smoother integration, buyers should conduct a comprehensive review of their existing systems before purchasing double acting pneumatic cylinders. This includes understanding the specifications of the current machinery and consulting with manufacturers or suppliers to ensure compatibility. Additionally, consider investing in modular pneumatic systems that allow for easier upgrades and replacements. By standardizing components across various machinery, companies can streamline maintenance and reduce integration headaches. Seeking advice from technical experts during the planning phase can also provide valuable insights, ensuring that the new cylinders will function seamlessly within existing workflows.

Strategic Material Selection Guide for double acting pneumatic cylinder

When selecting materials for double acting pneumatic cylinders, it’s essential to consider the properties that directly impact performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of these cylinders, highlighting their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in Double Acting Pneumatic Cylinders?

Aluminum is a popular choice for double acting pneumatic cylinders due to its lightweight nature and good strength-to-weight ratio. It typically offers a temperature rating of up to 150°C and can withstand moderate pressure levels, making it suitable for various applications. Additionally, aluminum exhibits excellent corrosion resistance, especially when anodized, which extends its lifespan in hostile environments.

Pros: Aluminum is durable, lightweight, and cost-effective, facilitating easier handling and installation. Its corrosion resistance makes it ideal for applications in humid or corrosive environments.

Cons: While aluminum is strong, it may not be suitable for high-pressure applications exceeding its limits. Moreover, it can be more expensive than some other materials like steel, particularly when considering high-grade aluminum alloys.

Impact on Application: Aluminum cylinders are compatible with a wide range of media, including air and inert gases. However, they may not be suitable for aggressive chemicals without additional protective coatings.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that aluminum cylinders meet local standards (e.g., ASTM) for quality and safety. In Europe, compliance with ISO standards is critical.

How Does Steel Compare as a Material for Double Acting Pneumatic Cylinders?

Steel, particularly stainless steel, is another common material for double acting pneumatic cylinders. It boasts high tensile strength and can handle high pressures, often rated above 200°C. Stainless steel is also highly resistant to corrosion, making it suitable for applications in harsh environments.

Pros: Steel cylinders are incredibly durable and can withstand heavy loads and high pressures. Their longevity makes them a cost-effective choice in the long run, especially for industrial applications.

Cons: The primary drawback of steel is its weight, which can complicate installation and handling. Additionally, stainless steel can be more expensive than aluminum and may require more complex manufacturing processes.

Impact on Application: Steel cylinders are ideal for applications involving heavy machinery and high-pressure systems. However, they may not be suitable for environments with aggressive chemicals unless specifically treated.

Illustrative image related to double acting pneumatic cylinder

Considerations for International Buyers: Buyers in the Middle East and Europe should verify compliance with relevant standards like DIN or JIS, particularly for safety-critical applications.

What Role Does Composite Material Play in Double Acting Pneumatic Cylinders?

Composite materials, often a blend of polymers and fibers, are increasingly being used in double acting pneumatic cylinders. These materials can offer unique properties, such as high strength-to-weight ratios and excellent corrosion resistance, with temperature ratings typically around 100°C.

Pros: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. They are resistant to corrosion and chemical degradation, making them suitable for various environments.

Cons: The main limitation is their cost, as composites can be more expensive than traditional materials. Additionally, they may not handle high pressures as effectively as metals.

Impact on Application: Composite cylinders are ideal for applications where weight reduction is critical, such as in aerospace or automotive sectors. However, they may not be suitable for all media, particularly those that could degrade the composite material.

Considerations for International Buyers: Buyers should ensure that composite materials meet international safety standards and are suitable for the specific media used in their applications.

Why is Brass a Viable Option for Double Acting Pneumatic Cylinders?

Brass is sometimes used for smaller double acting pneumatic cylinders, particularly in applications requiring good corrosion resistance and moderate strength. It typically has a temperature rating of up to 120°C and can handle moderate pressures.

Pros: Brass is resistant to corrosion and has good machinability, making it easy to manufacture components. It is also relatively inexpensive compared to other metals.

Cons: Brass may not be suitable for high-pressure applications and can be less durable than aluminum or steel. Its mechanical properties can vary significantly based on the alloy used.

Illustrative image related to double acting pneumatic cylinder

Impact on Application: Brass cylinders are suitable for low-pressure applications and environments where corrosion is a concern. However, they may not be compatible with certain aggressive chemicals.

Considerations for International Buyers: Buyers should check for compliance with local standards and ensure that the brass used is of high quality to avoid issues with durability.

Summary Table of Material Selection for Double Acting Pneumatic Cylinders

| Material | Typical Use Case for double acting pneumatic cylinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications, moderate pressures | Excellent corrosion resistance | Limited high-pressure capacity | Medium |

| Steel | Heavy machinery, high-pressure systems | High tensile strength | Heavier, more complex to manufacture | High |

| Composite | Aerospace, automotive sectors | Lightweight, innovative designs | Higher cost, limited pressure handling | High |

| Brass | Low-pressure applications, corrosion-sensitive environments | Good machinability | Not suitable for high pressures | Low |

In conclusion, selecting the right material for double acting pneumatic cylinders involves balancing performance requirements, cost, and application suitability. Understanding these factors will help international B2B buyers make informed decisions that align with their operational needs and compliance standards.

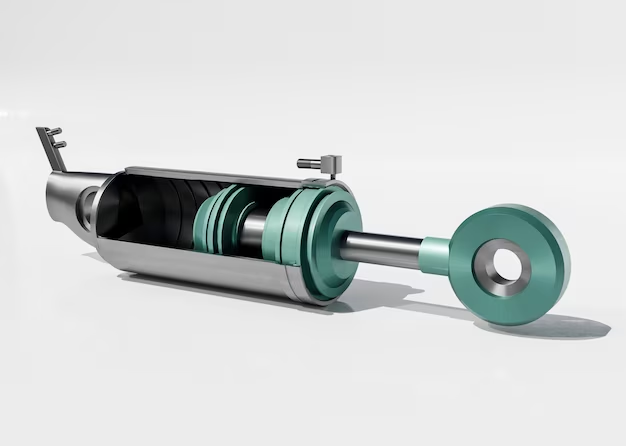

In-depth Look: Manufacturing Processes and Quality Assurance for double acting pneumatic cylinder

What Are the Key Manufacturing Processes for Double Acting Pneumatic Cylinders?

Double acting pneumatic cylinders are critical components in various industries, including automation, packaging, and automotive manufacturing. Their manufacturing processes involve several stages, each designed to ensure precision and reliability.

How Is Material Prepared for Double Acting Pneumatic Cylinders?

The manufacturing of double acting pneumatic cylinders begins with material selection. Common materials include aluminum for lightweight applications and steel for higher durability. The chosen materials undergo rigorous quality checks to ensure they meet specific mechanical properties and standards.

Once the materials are selected, they are subjected to cutting and shaping. This involves using CNC machines to achieve precise dimensions and tolerances. For instance, the cylinder tubes are typically extruded or drawn to achieve the necessary wall thickness and diameter.

What Forming Techniques Are Used in Double Acting Pneumatic Cylinder Manufacturing?

After material preparation, the next stage is forming. This involves processes such as machining, bending, and welding. CNC machining is critical for creating the cylinder’s end caps, piston rods, and other components. This technology allows for high precision, ensuring that all parts fit together seamlessly.

Welding may be required to assemble certain components, particularly in steel cylinders. Techniques such as TIG (Tungsten Inert Gas) welding are often employed to ensure strong joints that can withstand high pressure and stress during operation.

How Are Double Acting Pneumatic Cylinders Assembled?

The assembly of double acting pneumatic cylinders is a meticulous process. Each component, including the piston, seals, and ports, is carefully assembled in a clean environment to prevent contamination.

Seals are particularly important, as they prevent air leaks that can compromise the cylinder’s performance. O-rings and other sealing mechanisms are often tested for compatibility with the working environment, including temperature and chemical exposure.

What Finishing Processes Are Applied to Double Acting Pneumatic Cylinders?

Finishing processes enhance the durability and aesthetic appeal of double acting pneumatic cylinders. Common techniques include anodizing for aluminum parts, which increases corrosion resistance, and powder coating for steel components.

Illustrative image related to double acting pneumatic cylinder

These finishing treatments not only protect against wear and tear but also improve the cylinder’s lifespan. Quality control at this stage ensures that the finish meets the required specifications and standards.

What Quality Assurance Measures Are Essential in Double Acting Pneumatic Cylinder Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process for double acting pneumatic cylinders. Adhering to international standards and implementing rigorous QC checkpoints ensures that the final product meets the necessary performance criteria.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a key international standard for quality management systems that applies to the manufacturing of pneumatic cylinders. Compliance with this standard indicates that a manufacturer has established a quality management system that consistently provides products that meet customer and regulatory requirements.

In addition to ISO 9001, specific industry standards such as CE marking for European markets or API (American Petroleum Institute) standards for hydraulic applications may also be relevant. These certifications assure buyers of the product’s safety, reliability, and environmental compliance.

Illustrative image related to double acting pneumatic cylinder

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of double acting pneumatic cylinders typically includes several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Verification of material certifications and dimensional checks ensures that only high-quality inputs are used.

-

In-Process Quality Control (IPQC): During manufacturing, various processes are monitored to ensure that they conform to specified standards. This includes regular checks of machining tolerances and welding quality, as well as environmental conditions like humidity and temperature, which can affect assembly.

-

Final Quality Control (FQC): The final inspection is crucial. It includes comprehensive testing of completed cylinders for functionality, pressure resistance, and dimensional accuracy. Common testing methods may involve pressure testing, leak testing, and performance evaluations under simulated operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure compliance and reliability:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Audits should assess compliance with international standards, equipment maintenance practices, and employee training programs.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports, including inspection and testing results. This documentation should outline the methodologies used in quality checks and the outcomes of previous quality assessments.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing practices. These services can verify compliance with international standards and provide recommendations for improvements if necessary.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must be aware of nuances in quality control that can vary by region. For example, manufacturers in Europe may be subject to stricter regulations regarding environmental sustainability compared to those in other regions.

Illustrative image related to double acting pneumatic cylinder

Additionally, understanding the cultural and operational differences in manufacturing practices can help buyers tailor their quality assurance approaches. For instance, in regions where resources may be limited, ensuring that suppliers have contingency plans for material shortages or equipment failures is crucial.

In conclusion, understanding the manufacturing processes and quality assurance measures for double acting pneumatic cylinders is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing processes, alongside rigorous quality control protocols, buyers can ensure they procure reliable and high-performing pneumatic cylinders that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘double acting pneumatic cylinder’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure double acting pneumatic cylinders. With their ability to provide efficient linear motion in both directions, double acting cylinders are essential for various industrial applications. Following this guide will help ensure that you make informed decisions while sourcing high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the double acting pneumatic cylinder you need. This includes parameters such as stroke length, bore size, and mounting type. Defining these specifications upfront will help streamline the procurement process and ensure compatibility with your existing machinery.

- Stroke Length: Determine how far the piston needs to travel to perform its intended function.

- Bore Size: Calculate the required diameter for optimal force generation.

- Mounting Type: Identify whether you need standard, flange, or other mounting options based on your equipment setup.

Step 2: Identify Your Application Requirements

Understand the specific application where the pneumatic cylinder will be utilized. Double acting cylinders are often used in heavy-duty tasks like lifting, pushing, or pulling loads. Knowing your application will guide you in selecting the right model that can handle the operational demands.

- Load Capacity: Ensure the cylinder can manage the weight it will be moving.

- Speed and Frequency: Consider how fast the cylinder needs to operate and how often it will be used.

- Environmental Conditions: Assess any factors such as temperature, humidity, or exposure to contaminants that could affect performance.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of double acting pneumatic cylinders. Look for companies with a solid track record in your industry, and don’t hesitate to request information about their manufacturing processes, certifications, and quality control measures.

- Supplier Certifications: Verify that suppliers comply with relevant ISO standards and industry regulations.

- Experience: Focus on suppliers with experience in your specific application or industry sector.

- Customer Reviews: Look for testimonials or case studies that highlight the supplier’s reliability and product quality.

Step 4: Compare Product Offerings

Once you have a list of potential suppliers, compare their product offerings based on your technical specifications and application requirements. This step is crucial to ensure you choose a cylinder that not only meets your needs but also offers value for money.

- Product Features: Analyze features such as durability, maintenance requirements, and energy efficiency.

- Pricing Structure: Evaluate the total cost of ownership, including any additional costs for installation or maintenance.

- Customization Options: Inquire if the supplier offers customization for unique specifications.

Step 5: Request Quotes and Prototypes

After narrowing down your options, request detailed quotes from your shortlisted suppliers. If possible, ask for prototypes or samples to test the cylinders in your operational environment. This will help you assess performance and suitability before making a large purchase.

- Quote Clarity: Ensure that the quotes include all costs, including shipping and taxes.

- Testing: Evaluate the prototypes under actual working conditions to assess functionality and reliability.

- Lead Times: Confirm production and delivery timelines to align with your project schedules.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support and warranty options provided by the supplier. Strong customer service and a solid warranty can save you time and money in case of issues down the line.

- Technical Support: Check if the supplier offers ongoing technical assistance or training.

- Warranty Terms: Understand the warranty coverage to protect against defects or performance issues.

- Return Policy: Familiarize yourself with the return policy in case the product does not meet your expectations.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier and confirmed that all your requirements are met, finalize the purchase agreement. Ensure that the terms and conditions are clearly stated, including delivery schedules, payment terms, and any contingencies for unforeseen circumstances.

- Documentation: Keep a record of all communications and agreements for future reference.

- Payment Terms: Negotiate favorable payment terms that align with your cash flow management.

- Delivery Confirmation: Set up a system to confirm receipt of the cylinders and inspect them upon arrival.

Following these steps will not only enhance your sourcing process but also ensure that you acquire double acting pneumatic cylinders that meet your operational requirements efficiently and effectively.

Comprehensive Cost and Pricing Analysis for double acting pneumatic cylinder Sourcing

What Are the Key Cost Components for Double Acting Pneumatic Cylinders?

When sourcing double acting pneumatic cylinders, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include aluminum, stainless steel, and composite materials. High-quality materials not only enhance durability but also affect the price.

-

Labor: Labor costs vary based on the region of production. Skilled labor in Europe or North America may command higher wages than in parts of Africa or South America. This can influence overall pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Manufacturers with efficient operations may offer more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over the production volume, so larger orders can significantly reduce the per-unit tooling expense.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability but adds to manufacturing costs. Certifications (like ISO) may also require additional investments in quality processes.

-

Logistics: Shipping costs are influenced by distance, weight, and the chosen mode of transport. Buyers should consider local logistics infrastructure, which can vary widely between regions.

-

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on competition, market demand, and the perceived value of their products.

How Do Price Influencers Affect Double Acting Pneumatic Cylinder Costs?

Several factors can influence the pricing of double acting pneumatic cylinders:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to lower per-unit costs. Negotiating MOQs can be a strategic way to secure better pricing.

-

Specifications and Customization: Custom features, such as specific stroke lengths, bore sizes, or additional functionalities, can drive up costs. Standardized products tend to be more economical.

-

Materials and Quality Certifications: Premium materials and certifications ensure higher quality but come with increased costs. Buyers must balance quality needs with budget constraints.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of delivery can impact total costs. Understanding responsibilities related to shipping, insurance, and customs can prevent unforeseen expenses.

What Negotiation Strategies Can Help B2B Buyers Secure Better Pricing?

Effective negotiation is vital for optimizing costs. Here are some strategies:

-

Understand Total Cost of Ownership (TCO): Consider not just the initial purchase price but the entire lifecycle cost, including maintenance, downtime, and disposal. This holistic view can justify higher upfront costs for better quality products.

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher volume thresholds. This can lead to significant savings.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and more favorable terms. Trust can also facilitate smoother negotiations.

-

Research Market Trends: Stay informed about market conditions, material costs, and competitor pricing. This knowledge can empower buyers during negotiations.

-

Be Flexible with Specifications: Offering flexibility in specifications can lead to cost reductions. Discussing alternative materials or designs may uncover more economical options.

What Are the Unique Pricing Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face specific pricing challenges:

Illustrative image related to double acting pneumatic cylinder

-

Currency Fluctuations: Exchange rate volatility can impact costs. Buyers should consider hedging strategies or negotiating prices in stable currencies.

-

Regulatory Considerations: Import tariffs, taxes, and compliance with local regulations can significantly affect total costs. Understanding these factors is essential for accurate budgeting.

-

Cultural Differences: Different regions may have varying negotiation styles and expectations. Being culturally aware can facilitate smoother interactions and better agreements.

-

Supply Chain Dynamics: Global supply chains can introduce delays and additional costs. Buyers should assess the reliability of suppliers in their region and consider local options if feasible.

Disclaimer on Indicative Prices

Prices for double acting pneumatic cylinders can vary widely based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers and conduct thorough market research to establish a realistic budget.

Alternatives Analysis: Comparing double acting pneumatic cylinder With Other Solutions

Exploring Alternative Solutions to Double Acting Pneumatic Cylinders

In the realm of industrial automation, selecting the right actuation technology is crucial for operational efficiency. While double acting pneumatic cylinders are popular for their versatility and performance, it’s essential to consider alternative solutions that may align better with specific application requirements, budget constraints, or maintenance capabilities. Below, we explore two viable alternatives: electric actuators and hydraulic cylinders.

| Comparison Aspect | Double Acting Pneumatic Cylinder | Electric Actuator | Hydraulic Cylinder |

|---|---|---|---|

| Performance | Fast, precise movement; effective for repetitive tasks | High precision; excellent for complex control | High force output; suitable for heavy loads |

| Cost | Moderate initial cost; ongoing air supply expenses | Higher initial cost; lower operating costs | High initial cost; ongoing maintenance expenses |

| Ease of Implementation | Relatively straightforward; requires compressed air setup | Requires electrical infrastructure; complex integration | Requires hydraulic system setup; more complex |

| Maintenance | Lower maintenance needs; air quality management necessary | Low maintenance; durable over time | Higher maintenance; potential leaks and fluid management |

| Best Use Case | Assembly lines, packaging, robotics | Automation requiring precision and flexibility | Heavy machinery, construction, and automotive applications |

Understanding Electric Actuators: Advantages and Disadvantages

Electric actuators are gaining traction due to their precise control and the ability to easily integrate with modern control systems. They operate using electric motors to drive linear or rotary motion, making them suitable for applications requiring fine adjustments and speed control.

Pros: Electric actuators offer high precision and repeatability, are quieter, and generally have lower operating costs since they do not require compressed air. Their compact design can also save space in machinery layouts.

Illustrative image related to double acting pneumatic cylinder

Cons: The initial setup cost can be significantly higher than pneumatic solutions, particularly in environments that are not already equipped for electrical actuation. Additionally, they may require more complex programming and integration into existing systems.

Evaluating Hydraulic Cylinders: Strengths and Weaknesses

Hydraulic cylinders are known for their ability to generate high force output, making them ideal for heavy-duty applications such as construction and manufacturing. They operate by using pressurized hydraulic fluid to create movement.

Pros: Hydraulic systems excel in applications that require significant force and load handling. They can deliver smooth motion and are often preferred in environments where high torque is necessary.

Cons: The initial investment in hydraulic systems can be substantial, and ongoing maintenance can be complex due to potential fluid leaks and the need for regular checks on hydraulic fluid levels. Additionally, hydraulic systems are typically bulkier than pneumatic or electric options.

How to Choose the Right Solution for Your Needs

When selecting an actuation technology, B2B buyers should carefully evaluate their specific operational requirements, including load capacity, speed, precision, and environmental factors. Budget considerations are equally vital; while double acting pneumatic cylinders may offer a lower initial cost, the long-term operational expenses and maintenance needs of alternatives like electric or hydraulic systems should also be factored into the decision. Ultimately, understanding the nuances of each technology will empower buyers to make informed decisions that enhance their operational efficiency and align with their strategic goals.

Essential Technical Properties and Trade Terminology for double acting pneumatic cylinder

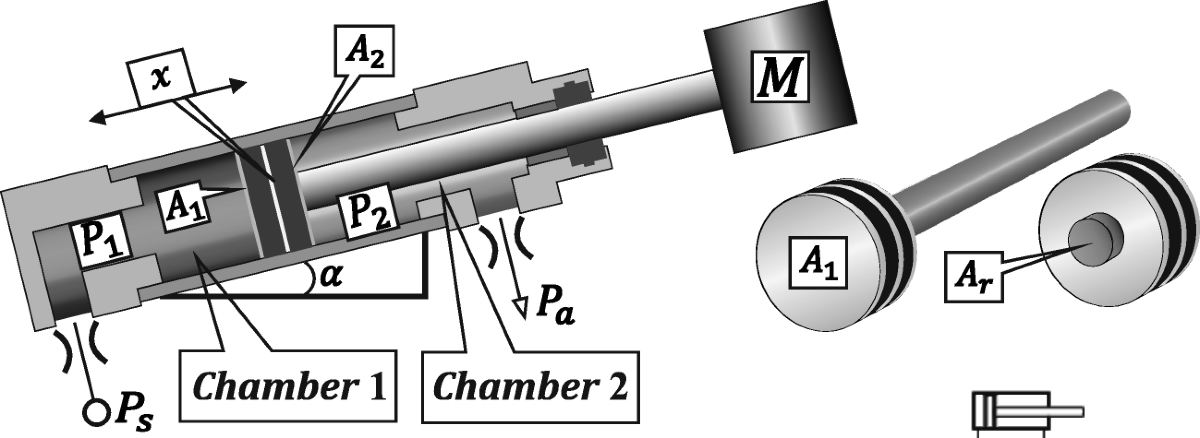

What Are the Essential Technical Properties of Double Acting Pneumatic Cylinders?

When selecting double acting pneumatic cylinders, understanding their technical properties is crucial for ensuring optimal performance in various applications. Below are several key specifications that B2B buyers should consider:

-

Bore Diameter

– The bore diameter refers to the internal diameter of the cylinder. It directly affects the force generated by the cylinder; larger diameters produce more force. In applications requiring heavy lifting or significant pushing, selecting the appropriate bore size is vital for efficiency and effectiveness. -

Stroke Length

– Stroke length is the distance the piston travels from its fully extended to fully retracted position. This specification is critical as it determines the range of motion available for the application. Buyers should assess the operational requirements to ensure the selected stroke length aligns with the intended use, whether for lifting, moving, or clamping. -

Material Grade

– The materials used in the construction of the pneumatic cylinder, such as aluminum or stainless steel, impact durability, weight, and resistance to corrosion. For industries operating in harsh environments (e.g., food processing or chemical manufacturing), selecting a material that can withstand specific conditions will enhance longevity and reduce maintenance costs. -

Operating Pressure

– This refers to the maximum pressure at which the cylinder can operate safely. Understanding the operating pressure is essential for ensuring that the pneumatic system functions correctly without risk of failure. Buyers need to match the cylinder’s operating pressure with their system’s specifications to avoid inefficiencies or equipment damage. -

Sealing Type

– The type of seals used in the cylinder affects its reliability and maintenance needs. Common sealing materials include polyurethane and nitrile rubber, each offering different levels of resistance to wear and environmental factors. Choosing the right sealing type can minimize leakage and extend the lifespan of the cylinder. -

ISO Compliance

– Many double acting pneumatic cylinders adhere to ISO standards, which ensure compatibility and interchangeability with other equipment. For international buyers, especially in regions like Europe, compliance with ISO standards can simplify procurement processes and enhance operational reliability.

What Are Common Trade Terms Related to Double Acting Pneumatic Cylinders?

Understanding industry jargon can significantly streamline communication between buyers and suppliers. Here are some common terms to be familiar with:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing pneumatic cylinders, knowing whether you’re dealing with an OEM can indicate the quality and reliability of the products being offered. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, particularly for businesses looking to stock up on components without overextending their finances. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products. This process is essential for B2B transactions, allowing buyers to compare offers and negotiate terms based on their requirements. -

Incoterms (International Commercial Terms)

– These terms define the responsibilities of buyers and sellers regarding the delivery of goods, including transportation costs and risk of loss. Familiarity with Incoterms helps in understanding the total cost of procurement and the logistics involved in importing pneumatic cylinders from international suppliers. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. In industries where pneumatic cylinders are critical to operations, knowing the lead time can influence project timelines and operational planning. -

Pneumatic Actuator

– This term encompasses any device that converts compressed air into mechanical motion, including double acting cylinders. Understanding this terminology is important for buyers looking to compare different types of actuators for their specific applications.

By comprehending these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing double acting pneumatic cylinders, ensuring they meet their operational requirements efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the double acting pneumatic cylinder Sector

Global demand for double acting pneumatic cylinders is on the rise, driven by advancements in automation, manufacturing efficiency, and the growing need for precision in industrial applications. As industries such as automotive, packaging, and robotics expand, the versatility of double acting cylinders—capable of both extending and retracting—positions them as essential components in complex machinery. Current trends highlight a shift towards integrating smart technologies within pneumatic systems, enhancing performance monitoring and predictive maintenance capabilities. This trend is particularly evident in regions like Europe, where industrial automation is becoming increasingly sophisticated, and in developing markets in Africa and South America, where manufacturers are embracing modern technologies to improve productivity.

International B2B buyers are also witnessing a growing emphasis on customization. Suppliers are offering a wider range of stroke lengths, bore sizes, and mounting options to accommodate specific application needs. Additionally, the rise of e-commerce platforms and digital marketplaces is facilitating easier access to a broader array of suppliers, enabling buyers from various regions to compare offerings and secure competitive pricing. As such, understanding regional preferences and regulations becomes crucial for effective sourcing strategies.

How Is Sustainability Influencing Sourcing Decisions for Double Acting Pneumatic Cylinders?

The environmental impact of pneumatic systems is gaining significant attention, prompting B2B buyers to prioritize sustainability in their sourcing decisions. The production and operation of double acting pneumatic cylinders can contribute to carbon emissions, particularly due to energy consumption during air compression. Consequently, many manufacturers are adopting greener practices, such as utilizing energy-efficient designs and sourcing materials with a lower environmental footprint.

Ethical supply chains are becoming increasingly important, as buyers seek to align with suppliers who adhere to sustainability standards. Certifications like ISO 14001 for environmental management systems are valuable indicators of a supplier’s commitment to reducing their ecological impact. Furthermore, the use of recycled materials and eco-friendly lubricants is on the rise, allowing businesses to enhance their sustainability profiles while ensuring high-performance standards in their pneumatic systems. By focusing on suppliers who prioritize sustainability, buyers not only contribute to environmental preservation but also enhance their brand reputation in an increasingly eco-conscious market.

What Are the Key Historical Milestones in the Development of Double Acting Pneumatic Cylinders?

The evolution of double acting pneumatic cylinders has been marked by significant technological advancements that have shaped their current applications in various industries. Initially developed in the early 20th century, pneumatic cylinders were primarily used for simple tasks in manufacturing. However, as industries advanced, the demand for more efficient and versatile actuators led to the refinement of double acting designs.

By the mid-20th century, the introduction of advanced materials and manufacturing techniques allowed for lighter, more durable cylinders, broadening their applications in sectors such as robotics and automotive. The late 20th and early 21st centuries saw the integration of electronic controls and sensors, enabling real-time performance monitoring and automation. Today, double acting pneumatic cylinders are at the forefront of modern manufacturing, offering enhanced speed, efficiency, and adaptability to meet the diverse needs of global industries. Understanding this evolution helps B2B buyers appreciate the technological sophistication and reliability of these critical components in contemporary applications.

Frequently Asked Questions (FAQs) for B2B Buyers of double acting pneumatic cylinder

-

How do I choose the right double acting pneumatic cylinder for my application?

Choosing the right double acting pneumatic cylinder involves considering factors such as the required stroke length, bore size, and application specifics. Assess your operational needs, such as load capacity, speed, and frequency of use. Additionally, evaluate environmental conditions, as some cylinders may require protection against dust or moisture. Consult with suppliers to ensure that the cylinder meets ISO standards and is compatible with your existing systems. Engaging in a dialogue with technical representatives can provide insights tailored to your unique requirements. -

What are the key advantages of using double acting pneumatic cylinders?

Double acting pneumatic cylinders offer several advantages over single acting cylinders. They provide more efficient movement, as they can extend and retract using pressurized air on both ends, allowing for quicker operation. This design results in higher force output and better control over the motion, making them ideal for complex applications in industries such as manufacturing and robotics. Moreover, they generally require less maintenance than single acting cylinders, as there are no springs involved that may wear out over time. -

What are the common applications of double acting pneumatic cylinders in various industries?

Double acting pneumatic cylinders are widely used across multiple industries due to their versatility. Common applications include material handling (such as lifting and moving items on conveyor belts), packaging automation, and industrial assembly lines. In the automotive sector, they are used for clamping and positioning components during assembly. Medical equipment and robotics also leverage double acting cylinders for precise movements. Understanding your industry’s specific needs will help you select the most effective cylinder for your operations. -

What should I consider when vetting suppliers for double acting pneumatic cylinders?

When vetting suppliers, assess their industry experience, product quality, and compliance with international standards. Look for certifications such as ISO 9001, which indicate a commitment to quality management. Evaluate their customer support services, including technical assistance and after-sales support. Additionally, consider their ability to provide customization options to meet your specific requirements. Reading customer reviews and seeking references from other businesses can also provide valuable insights into a supplier’s reliability and service quality. -

What is the typical minimum order quantity (MOQ) for double acting pneumatic cylinders?

Minimum order quantities for double acting pneumatic cylinders can vary significantly based on the supplier and specific product lines. Some manufacturers may have MOQs as low as 10 units, while others may require orders of 50 or more to ensure cost-effectiveness. It is advisable to discuss your needs directly with suppliers to negotiate favorable terms, especially if you are looking to test different models or designs. Some suppliers may also offer flexibility for first-time buyers or bulk orders. -

What payment terms are typically offered by suppliers of double acting pneumatic cylinders?

Payment terms can vary by supplier and may include options such as upfront payment, net 30, or net 60 days. Some suppliers may require a deposit before production, especially for customized orders, while others may offer credit terms based on your purchasing history. It’s crucial to clarify payment conditions early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that provide protection against fraud, especially when dealing with international transactions. -

How can I ensure quality assurance (QA) for double acting pneumatic cylinders?

To ensure quality assurance, request detailed documentation from suppliers that outlines their manufacturing processes and quality control measures. This may include certifications, test reports, and inspection protocols. Look for suppliers who conduct routine testing on their cylinders to confirm performance and reliability. Establishing a robust communication channel for feedback and addressing concerns post-purchase is also essential. Conducting periodic audits or assessments of the supplier’s facilities can further ensure adherence to quality standards. -

What logistical considerations should I keep in mind when importing double acting pneumatic cylinders?

Logistical considerations include shipping methods, customs regulations, and delivery timelines. Research the best shipping options that align with your budget and urgency, whether by sea, air, or land. Be aware of customs duties and import taxes in your country, as these can significantly affect overall costs. Collaborating with a freight forwarder can help navigate the complexities of international shipping. Additionally, confirm that suppliers can provide necessary documentation for customs clearance to avoid delays upon arrival.

Top 5 Double Acting Pneumatic Cylinder Manufacturers & Suppliers List

1. McMaster – Double-Acting Cylinders

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Double-Acting Cylinders, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Trimantec – Single Acting Pneumatic Cylinder

Domain: trimantec.com

Registered: 2014 (11 years)

Introduction: Single Acting Pneumatic Cylinder: 1 port for pressurized air, uses a spring or load for retraction, suitable for clamping, positioning, and punching. Types: Push (air pushes piston out) and Pull (air pulls piston in). Advantages: Simple design, low cost, reduced valve and piping costs. Disadvantages: Requires proper compressed air management. Double Acting Pneumatic Cylinder: 2 ports for air, allo…

3. Double Acting Air Cylinders – Key Product

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for Double Acting Air Cylinders include: 1. Various sizes available, including bore sizes ranging from up to 0.49″ to 6″ and larger. 2. Stroke ranges from up to 0.99″ to 8″ and longer. 3. Multiple brands offered such as Bimba, Festo, and Parker. 4. Prices range from $5.95 to $9.95 depending on the model. 5. Stock availability varies for each item, with quantities listed for eac…

4. Bimba – Double Acting Cylinders

Domain: bimba.com

Registered: 1996 (29 years)

Introduction: {“type”:”Double Acting”,”applications”:[“Agriculture”,”Automotive”,”Car Wash”,”Farming”,”Food processing”,”Sterilization”],”repairable”:[false,true],”bore_sizes”:[“1/4\””,”5/16\””,”3/8\””,”7/16\””,”1/2\””,”9/16\””,”3/4\””,”7/8\””,”1-1/16\””,”1-1/4\””,”1-1/2\””,”1-3/4\””,”2\””,”2-1/2\””,”3\””,”3-1/4\””,”4\””]}

5. MCE Automation – Single Acting Cylinders

Domain: mceautomation.com

Registered: 2017 (8 years)

Introduction: Single Acting Cylinders:

– Function: Develops thrust in one direction; piston returned by spring or external means.

– Applications: Clamping, positioning, marking, stroking, light assembly.

– Types: Push (thrusts piston forward) and Pull (thrusts piston backward).

– Advantages: Simple design, compact size, reduced valve and piping costs, halved air consumption compared to double acting.

– Dis…

Strategic Sourcing Conclusion and Outlook for double acting pneumatic cylinder

What Are the Key Insights for Sourcing Double Acting Pneumatic Cylinders?

In the landscape of industrial automation, double acting pneumatic cylinders stand out as essential components due to their efficiency, speed, and versatility. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the advantages of these cylinders—such as their ability to facilitate rapid and controlled movements—can significantly impact operational productivity.

Illustrative image related to double acting pneumatic cylinder

Strategic sourcing of these pneumatic cylinders is crucial. Considerations such as compliance with ISO standards, ongoing maintenance capabilities, and total cost of ownership should guide your procurement decisions. Investing in high-quality double acting cylinders can lead to reduced downtime and enhanced performance in applications ranging from factory automation to robotics.

How Can International Buyers Prepare for Future Trends in Pneumatic Technology?

As industries evolve, the demand for advanced pneumatic solutions will only increase. Buyers should stay informed about emerging technologies and innovations that enhance the functionality and efficiency of pneumatic systems. By fostering relationships with reputable suppliers and engaging in continuous market analysis, businesses can better position themselves to capitalize on future opportunities.

Take proactive steps today—evaluate your current pneumatic systems, assess your sourcing strategies, and explore partnerships that align with your growth objectives. The future of pneumatic technology is promising; being ahead of the curve can drive substantial competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.