Dust Collector Bag House: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for dust collector bag house

Navigating the global market for dust collector bag houses can be a daunting task for B2B buyers, particularly when faced with the challenge of selecting the right system for their specific industrial applications. With a myriad of options available, from cartridge collectors to cyclone systems, understanding which dust collector bag house meets both performance and regulatory requirements is crucial. This comprehensive guide aims to demystify the complexities associated with sourcing dust collector bag houses, offering insights into various types, applications, and performance specifications tailored to industries across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

In this guide, we will explore the different types of baghouse systems, their operational principles, and their suitability for diverse applications ranging from metal fabrication to pharmaceutical manufacturing. Additionally, we’ll provide actionable strategies for vetting suppliers, understanding cost factors, and ensuring compliance with international standards. By equipping international B2B buyers with the necessary knowledge and tools, this guide empowers you to make informed purchasing decisions that not only enhance operational efficiency but also safeguard employee health and meet environmental regulations.

Prepare to navigate the intricacies of the dust collector market with confidence and clarity, ensuring that your investment aligns with your operational goals and industry demands.

Understanding dust collector bag house Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pulse Jet Baghouse | Uses high-pressure air pulses to clean filter bags. | Metal fabrication, woodworking, pharmaceuticals | Pros: Efficient cleaning, high dust collection capacity. Cons: Requires compressed air, may have higher maintenance costs. |

| Reverse Air Baghouse | Utilizes reverse airflow to clean bags without pressure. | Cement production, grain handling | Pros: Low energy consumption, quieter operation. Cons: Less effective for sticky dust, may require larger footprint. |

| Modular Baghouse | Configurable units that can be expanded as needed. | Power generation, foundries | Pros: Scalability, easy maintenance. Cons: Initial setup costs can be higher. |

| Cyclone Baghouse | Integrates cyclone separation before filtration. | Mining, bulk material handling | Pros: Reduces load on filters, effective for coarse dust. Cons: Less effective for fine particulate, requires additional filtration for complete dust removal. |

| Cartridge Collector | Compact design with cartridge filters instead of bags. | Small workshops, light manufacturing | Pros: Space-efficient, easy to change filters. Cons: Limited capacity for heavy dust loads. |

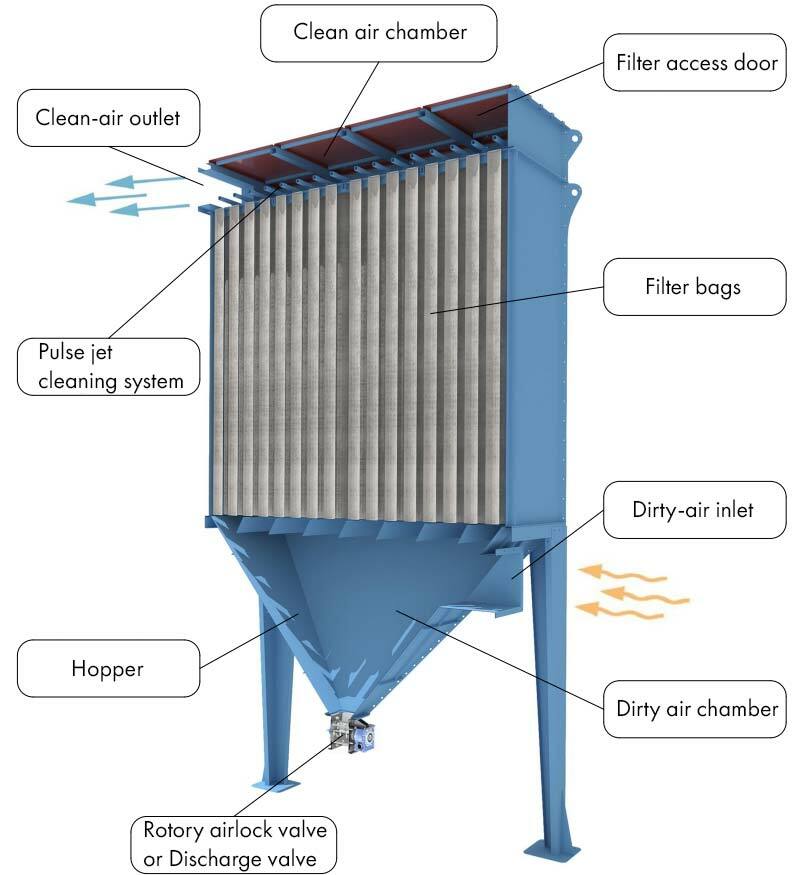

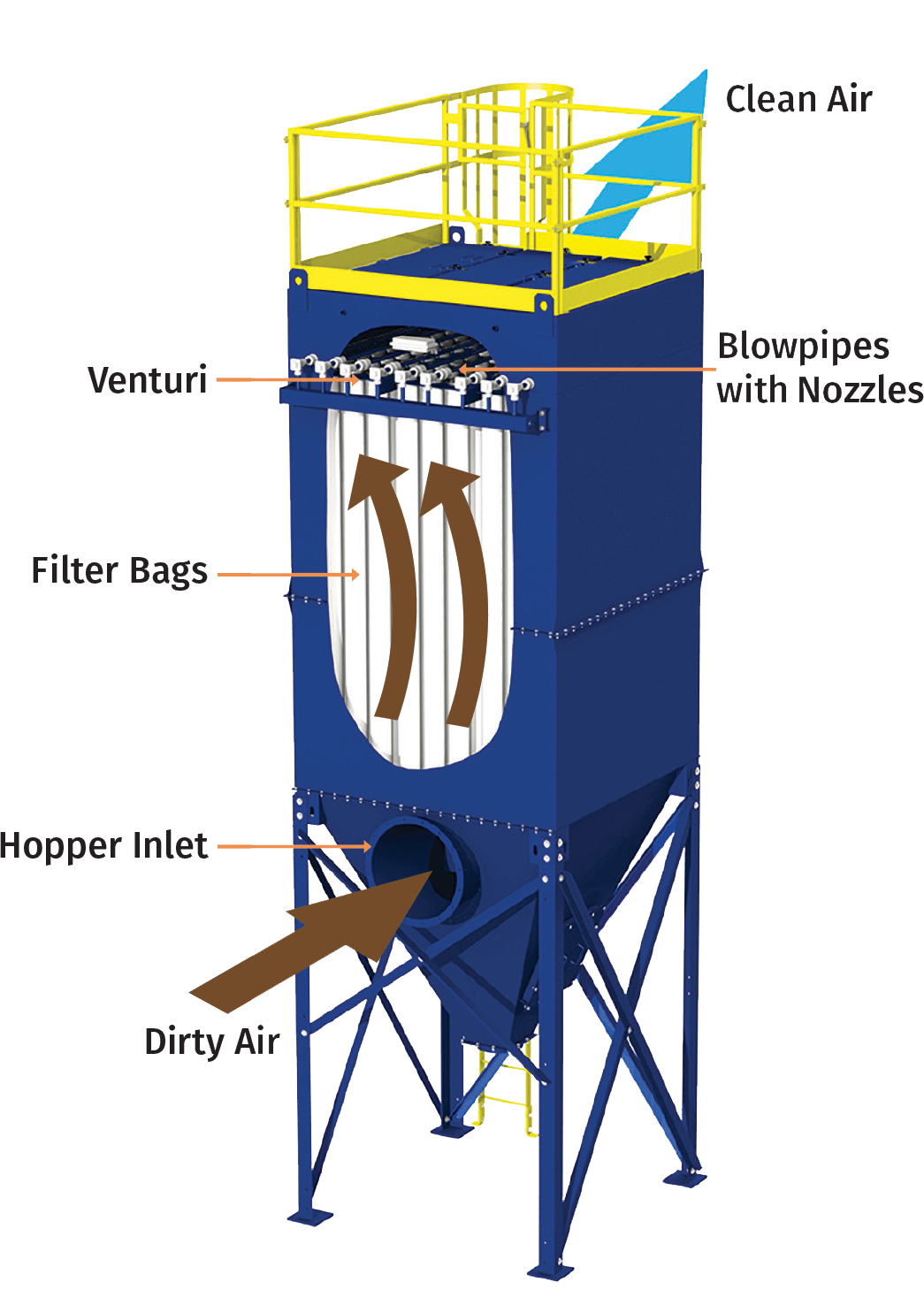

What Are the Key Characteristics of a Pulse Jet Baghouse?

Pulse jet baghouses are recognized for their ability to use bursts of compressed air to clean filter bags effectively. This technology allows for continuous operation while maintaining optimal airflow and dust collection efficiency. They are particularly suitable for industries with high dust loads, such as metal fabrication and woodworking. When purchasing, buyers should consider the availability of compressed air, as this is essential for operation, along with the potential for higher maintenance due to the complexity of the cleaning system.

How Does a Reverse Air Baghouse Operate?

Reverse air baghouses function by utilizing a reverse airflow to clean the filter bags without the need for high-pressure air. This design results in quieter operation and lower energy consumption, making it ideal for applications like cement production and grain handling. Buyers should evaluate their dust type, as this system may not be as effective for sticky or heavy dust. Additionally, the larger footprint may require more space than other types.

What Makes a Modular Baghouse Ideal for Growing Operations?

Modular baghouses are designed for scalability, allowing businesses to start with a smaller unit and expand as their dust collection needs grow. This flexibility makes them particularly beneficial for industries such as power generation and foundries, where production levels can fluctuate. When considering a modular baghouse, buyers should weigh the initial setup costs against the long-term benefits of adaptability and ease of maintenance.

In What Scenarios is a Cyclone Baghouse Most Effective?

Cyclone baghouses combine cyclone separation with bag filtration, making them suitable for industries like mining and bulk material handling. By removing larger particles before they reach the filters, they reduce the load on the filtration system, extending filter life. However, buyers should be aware that while effective for coarse dust, additional filtration may be necessary for fine particulate, which can add to the overall system complexity.

What Are the Advantages of Cartridge Collectors?

Cartridge collectors offer a compact alternative to traditional baghouses, using cartridge filters instead of fabric bags. This design is particularly advantageous for small workshops and light manufacturing environments where space is limited. Buyers should consider the specific dust load and type, as cartridge collectors may not handle heavy dust loads effectively. The ease of filter replacement is a key selling point, making maintenance simpler and more efficient.

Key Industrial Applications of dust collector bag house

| Industry/Sector | Specific Application of dust collector bag house | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Dust collection during cutting, grinding, and welding processes | Enhances air quality, reduces health risks, and complies with regulations | Compatibility with existing systems and capacity requirements |

| Woodworking | Capture of wood dust and particulate from sawing and sanding | Improves worker safety and equipment longevity | Filter material durability and ease of maintenance |

| Cement Production | Collection of fine dust during material handling and processing | Minimizes environmental impact and meets emission standards | Ability to handle high dust loads and temperature variations |

| Pharmaceutical Manufacturing | Dust control during powder handling and mixing processes | Ensures product purity and compliance with health regulations | Customization options for specific dust types and sizes |

| Mining | Air filtration in mineral processing and material transfer | Protects worker health and improves operational efficiency | Robust construction to withstand harsh environments |

How is a dust collector bag house used in metal fabrication?

In the metal fabrication industry, dust collector bag houses are essential for capturing harmful dust generated during processes such as cutting, grinding, and welding. These systems help maintain a safe working environment by removing fine particulate matter from the air, which can lead to respiratory issues if inhaled. Buyers in this sector should consider the compatibility of the dust collector with their existing equipment, as well as the system’s capacity to handle varying dust loads and types.

What role does a dust collector bag house play in woodworking?

Woodworking operations generate significant amounts of wood dust, which can be hazardous to workers and machinery. Dust collector bag houses are employed to efficiently capture this dust during processes like sawing and sanding, enhancing air quality and reducing fire hazards. For international buyers, especially in regions like Africa and South America, sourcing durable filters that can withstand varying humidity levels is crucial, along with ensuring compliance with local health and safety regulations.

Why is dust collection important in cement production?

Cement production involves the handling of fine dust during the mixing and processing of raw materials. A bag house dust collector effectively captures this dust, minimizing environmental pollution and ensuring compliance with stringent emission standards. Buyers should focus on the system’s ability to manage high dust loads and withstand the high temperatures often associated with cement production, particularly in regions with developing infrastructure.

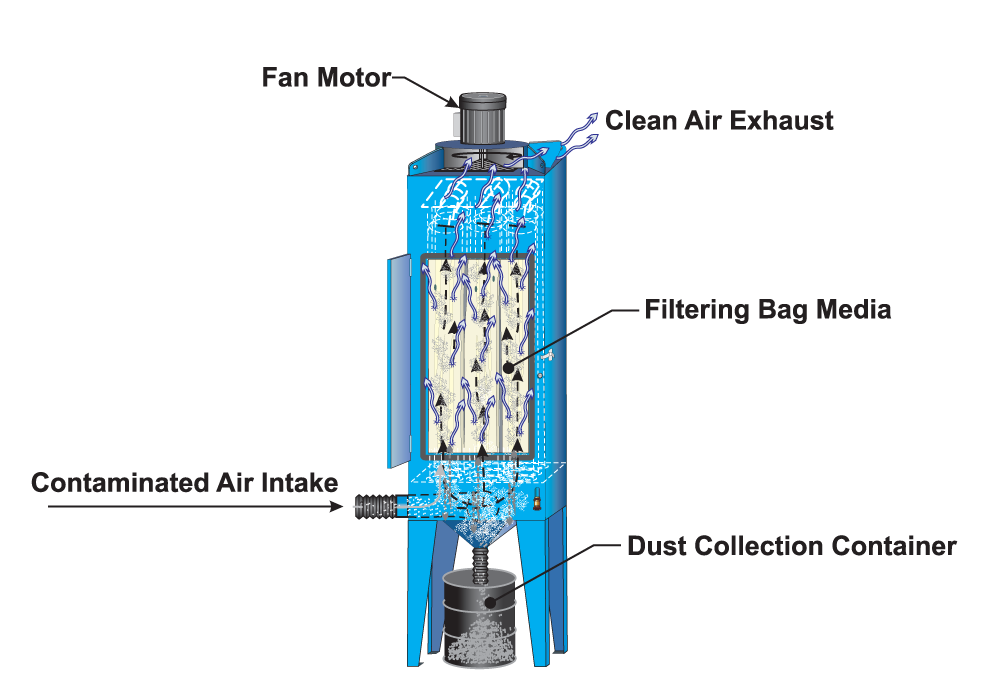

Illustrative image related to dust collector bag house

How does a dust collector bag house benefit pharmaceutical manufacturing?

In pharmaceutical manufacturing, maintaining product purity is paramount. Dust collector bag houses are utilized to capture airborne particles generated during powder handling and mixing, thus preventing contamination. Buyers in this industry must prioritize customization options that allow for the filtration of specific dust types, as well as ensuring compliance with stringent health regulations, particularly in European markets where standards are rigorous.

What are the applications of dust collector bag houses in mining?

In mining operations, dust collector bag houses play a critical role in air filtration during mineral processing and material transfer activities. These systems protect worker health by capturing harmful dust and improving air quality. When sourcing dust collectors, buyers should consider the robustness of the equipment to endure harsh mining environments, as well as the system’s efficiency in handling various types of dust generated in different mining processes.

3 Common User Pain Points for ‘dust collector bag house’ & Their Solutions

Scenario 1: Selecting the Right Size for Your Baghouse System

The Problem: A common issue faced by B2B buyers is selecting a dust collector baghouse that is inadequately sized for their specific application. This can lead to subpar performance, increased operational costs, and potential compliance issues with local regulations regarding air quality. Buyers often rely on sales representatives who may prioritize cost over performance, leading to frustration and costly adjustments later.

The Solution: To avoid this pitfall, it’s crucial to conduct a thorough needs assessment before purchasing a baghouse. Start by analyzing the type and volume of dust produced in your operation, as well as the air flow rate required for effective collection. Engage with multiple suppliers and request detailed specifications for their systems, ensuring they can provide tailored recommendations based on your specific requirements. Utilize tools like airflow calculators and dust load estimators available on manufacturers’ websites to guide your decision. Additionally, consider investing in a modular baghouse that can be scaled up or down based on future needs, ensuring longevity and adaptability in your dust collection solution.

Illustrative image related to dust collector bag house

Scenario 2: Maintenance Challenges Affecting Performance

The Problem: Many B2B buyers struggle with the ongoing maintenance of baghouse systems, which can be time-consuming and complex. Inadequate maintenance can lead to decreased filtration efficiency, increased energy consumption, and even system failure. As a result, companies may face unplanned downtimes and repair costs that disrupt production schedules.

The Solution: To enhance maintenance efficiency, select a baghouse model that incorporates user-friendly features such as top-load filters and automated cleaning systems. Regularly scheduled maintenance is essential; develop a maintenance calendar that includes routine inspections, filter replacements, and system cleaning. Train your staff on the specific maintenance requirements for your chosen system, and ensure they understand how to troubleshoot common issues. Consider partnering with a service provider who can offer scheduled maintenance and emergency support, providing peace of mind and ensuring your system operates at peak efficiency.

Scenario 3: Compliance with Environmental Regulations

The Problem: Navigating the complex landscape of environmental regulations can be daunting for B2B buyers of dust collector baghouses. Companies are often unprepared for the stringent standards related to air quality, which can vary significantly by region. Failure to comply can lead to fines, legal repercussions, and damage to a company’s reputation.

The Solution: To ensure compliance, start by researching the specific regulations applicable to your industry and location. Collaborate with environmental consultants who specialize in air quality regulations to understand the necessary standards for dust emissions. Choose a baghouse that not only meets but exceeds these standards, as this will provide a buffer against potential regulatory changes. Additionally, invest in monitoring technology that can provide real-time data on emissions, enabling proactive adjustments to your dust collection strategy. By prioritizing compliance from the outset, you can safeguard your business against future liabilities and demonstrate your commitment to environmental responsibility.

Strategic Material Selection Guide for dust collector bag house

What Are the Key Materials Used in Dust Collector Bag Houses?

When selecting materials for dust collector bag houses, it’s essential to consider their properties, advantages, and limitations. The choice of material directly impacts the performance, durability, and suitability of the dust collection system for specific applications. Below, we analyze four common materials used in the construction of dust collector bag houses.

What Are the Key Properties of Polyester in Dust Collector Bag Houses?

Polyester is one of the most widely used materials for filter bags in dust collectors. Its key properties include a temperature rating of up to 190°F (88°C) and good chemical resistance, making it suitable for a variety of applications.

Pros: Polyester is durable, lightweight, and relatively low-cost, offering a good balance between performance and affordability. It is also easy to manufacture and can be treated for enhanced properties, such as water and oil repellency.

Illustrative image related to dust collector bag house

Cons: However, polyester has limitations in high-temperature applications and may degrade when exposed to certain aggressive chemicals. Its performance can also diminish in very humid conditions, which may lead to issues like bag blinding.

Impact on Application: Polyester is ideal for industries such as woodworking and food processing, where the dust is not excessively hot or chemically aggressive.

Considerations for International Buyers: When sourcing polyester bags, buyers should ensure compliance with local standards, such as ASTM in the U.S. or DIN in Germany, to guarantee performance and safety.

How Does Polypropylene Compare for Dust Collector Applications?

Polypropylene is another popular choice for dust collector bags, particularly in applications involving moisture-laden or acidic dust. It can withstand temperatures up to 200°F (93°C) and offers excellent chemical resistance.

Pros: The material is lightweight, cost-effective, and has good moisture resistance, making it suitable for various industries, including agriculture and chemical processing.

Cons: Polypropylene is less durable than polyester and may not perform well in high-temperature environments. Its susceptibility to UV degradation is also a concern for outdoor applications.

Illustrative image related to dust collector bag house

Impact on Application: This material is particularly effective in environments where dust contains moisture or acidic components, such as in grain handling.

Considerations for International Buyers: Buyers should be aware of local regulations regarding chemical exposure and ensure that the material meets necessary compliance standards.

What Are the Benefits of Aramid Fiber in Dust Collector Systems?

Aramid fibers, such as Nomex, are engineered for high-performance applications, offering superior temperature resistance (up to 500°F or 260°C) and excellent durability.

Illustrative image related to dust collector bag house

Pros: Aramid is highly resistant to abrasion and chemical degradation, making it suitable for harsh environments, including metal fabrication and power generation.

Cons: The primary disadvantage is the higher cost associated with aramid materials, which can be a significant factor for budget-conscious buyers. Additionally, aramid fibers can be more complex to manufacture.

Impact on Application: These fibers are ideal for high-temperature applications where other materials may fail, ensuring consistent performance and longevity.

Considerations for International Buyers: Buyers should verify that aramid materials are produced under recognized quality standards, such as ISO, to ensure reliability in demanding applications.

Illustrative image related to dust collector bag house

Why Choose Teflon-Coated Fabrics for Specialized Applications?

Teflon-coated fabrics are increasingly popular for dust collection in industries dealing with sticky or oily dust. They can handle temperatures up to 500°F (260°C) and provide excellent non-stick properties.

Pros: The key advantage of Teflon is its ability to resist fouling, which minimizes maintenance needs and downtime. It also offers superior chemical resistance.

Cons: The main limitation is the high cost of Teflon-coated materials, which may not be feasible for all budgets. Additionally, the complexity of manufacturing can lead to longer lead times.

Impact on Application: This material is particularly suited for industries such as food processing and pharmaceuticals, where cleanliness and compliance are paramount.

Considerations for International Buyers: Buyers should ensure that Teflon-coated fabrics meet the relevant food safety standards and certifications in their region.

Summary Table of Material Selection for Dust Collector Bag Houses

| Material | Typical Use Case for Dust Collector Bag House | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Woodworking, food processing | Durable and cost-effective | Limited high-temperature resistance | Medium |

| Polypropylene | Agriculture, chemical processing | Lightweight and moisture-resistant | Susceptible to UV degradation | Low |

| Aramid Fiber | Metal fabrication, power generation | High-temperature resistance | Higher cost and manufacturing complexity | High |

| Teflon-Coated Fabric | Food processing, pharmaceuticals | Excellent non-stick properties | High cost and longer lead times | High |

Choosing the right material for dust collector bag houses is crucial for optimal performance and compliance with industry standards. By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

In-depth Look: Manufacturing Processes and Quality Assurance for dust collector bag house

What Are the Key Stages in the Manufacturing Process of Dust Collector Bag Houses?

The manufacturing process of dust collector bag houses involves several critical stages, each designed to ensure optimal performance and durability. Understanding these stages can help B2B buyers make informed decisions when selecting a supplier.

How Is Material Prepared for Dust Collector Bag Houses?

The first step in manufacturing dust collector bag houses is material preparation. Manufacturers typically use high-quality materials, such as carbon steel, stainless steel, or specialized alloys, depending on the application. These materials must meet specific criteria for strength, corrosion resistance, and temperature tolerance.

Before production, raw materials undergo inspection and testing to verify compliance with industry standards. This process may involve checking the chemical composition, mechanical properties, and surface quality of the materials to ensure they are fit for manufacturing. Buyers should inquire about the suppliers’ material sourcing and verification processes to ensure that only the best materials are used in the production of bag houses.

What Forming Techniques Are Commonly Used in Baghouse Production?

Once materials are prepared, the next phase is forming. This stage involves cutting, bending, and shaping the materials into components such as filter housings, dust collection bins, and support frames. Advanced techniques like laser cutting and CNC machining are often employed to achieve precise dimensions and complex geometries.

Illustrative image related to dust collector bag house

These techniques not only enhance the quality of the components but also contribute to the overall efficiency of the dust collector. B2B buyers should look for manufacturers that utilize state-of-the-art technology in their forming processes, as this can significantly impact the performance and longevity of the dust collection system.

How Does Assembly Happen in Dust Collector Manufacturing?

The assembly stage is where individual components come together to create the complete bag house system. This process typically involves welding, bolting, or fastening parts together, ensuring that the structure is robust and leak-proof. Quality control checkpoints are established at this stage to verify that all components meet design specifications and are assembled correctly.

In addition, manufacturers may implement modular assembly techniques, allowing for easier customization and scalability of the dust collector systems. Buyers should inquire about the assembly methods used by potential suppliers and whether they allow for flexibility in adapting the system to specific industrial needs.

What Finishing Processes Are Important for Dust Collector Bag Houses?

Finishing processes, such as painting, powder coating, or galvanizing, are essential for enhancing the durability and aesthetic appeal of dust collector bag houses. These treatments protect the metal surfaces from corrosion and wear, especially in demanding environments.

Moreover, finishing processes may also involve the application of specialized coatings that enhance dust release and improve cleaning efficiency. B2B buyers should ask about the types of finishes offered by manufacturers and the expected lifespan of these treatments under various operational conditions.

How Is Quality Assurance Managed in Dust Collector Bag House Production?

Quality assurance (QA) is a critical aspect of manufacturing dust collector bag houses. Implementing robust QA practices ensures that the final products meet both international and industry-specific standards.

Which International Standards Should Buyers Be Aware Of?

Most reputable manufacturers adhere to international quality standards, such as ISO 9001, which outlines the requirements for a quality management system. This certification indicates that the manufacturer consistently meets customer and regulatory requirements.

Additionally, products may also comply with industry-specific standards like CE marking for the European market, which signifies compliance with safety, health, and environmental protection standards. Buyers from regions like Africa and South America should verify whether the manufacturer meets local regulations and standards relevant to their specific industries.

What Are the Key Quality Control Checkpoints in Production?

Quality control checkpoints are established throughout the manufacturing process to ensure that each stage meets predefined standards. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify and rectify issues in real time.

- Final Quality Control (FQC): The final product undergoes rigorous testing and inspection before shipment, ensuring it meets all performance criteria.

B2B buyers should inquire about the frequency and rigor of these quality control measures when assessing potential suppliers.

What Testing Methods Are Commonly Used in Baghouse Quality Assurance?

Common testing methods include pressure testing, flow rate testing, and filtration efficiency tests. These assessments help ensure that the dust collector operates efficiently and meets the required performance standards. For instance, filtration efficiency tests can determine the collector’s ability to capture fine particulate matter, which is crucial for maintaining air quality in industrial settings.

Additionally, manufacturers may conduct stress tests to evaluate the durability and reliability of the bag house under various operational conditions. Buyers should request information on the specific testing methods employed by potential suppliers and any certifications obtained from third-party testing organizations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier adheres to high-quality standards, B2B buyers can take several steps:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include on-site visits to evaluate facilities and equipment.

- Requesting Quality Reports: Buyers should ask for detailed quality control reports that outline testing results, compliance with standards, and any corrective actions taken in response to quality issues.

- Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of verification. These agencies can perform independent assessments of the manufacturing processes and final products to ensure compliance with industry standards.

What Nuances Should International Buyers Consider?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of the specific regulations and standards that apply to their markets. This includes understanding import regulations, compliance requirements, and any necessary certifications for equipment used in their industries.

Moreover, buyers should consider potential language barriers and cultural differences that may affect communication with suppliers. Establishing a clear line of communication and understanding the supplier’s capabilities can help mitigate risks and ensure successful procurement of dust collector bag houses.

In summary, understanding the manufacturing processes and quality assurance practices of dust collector bag houses is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and stringent quality control measures, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dust collector bag house’

To assist international B2B buyers in procuring dust collector baghouses effectively, this guide outlines essential steps and considerations. By following this checklist, you can ensure that your selection process is thorough, leading to a reliable and efficient dust collection solution tailored to your operational needs.

Illustrative image related to dust collector bag house

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. Consider factors such as the type and volume of dust generated, airflow capacity, and specific industry compliance standards. Documenting these specifications will help suppliers provide suitable options that meet your operational demands.

Step 2: Research Different Baghouse Types

Familiarize yourself with the various types of baghouses available, such as pulse jet, reverse air, and shaker systems. Each type has distinct advantages depending on the application, such as handling sticky dust or high dust loads. Understanding these differences will enable you to choose a system that optimally suits your operational conditions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and expertise. Request detailed company profiles, case studies, and references from existing clients within your industry. Look for suppliers with a proven track record in your geographical region, as they will be more familiar with local regulations and operational challenges.

Step 4: Check for Compliance and Certifications

Ensure that the suppliers you consider have the necessary certifications and compliance with international standards, such as ISO and OSHA regulations. This step is crucial for avoiding legal issues and ensuring that the equipment meets safety and environmental guidelines. Verify that the equipment is designed for your specific industry’s compliance requirements.

Step 5: Assess Customization Options

Consider whether the supplier offers customization options for their baghouse systems. Many operations have unique needs that may not be met by standard configurations. Discuss potential modifications with suppliers to tailor the system to your specific dust collection challenges, which can enhance efficiency and performance.

Illustrative image related to dust collector bag house

Step 6: Review Maintenance and Support Services

Inquire about the maintenance services and support options available post-purchase. A reliable supplier should offer comprehensive maintenance packages and readily available technical support. Understanding these services will help you maintain optimal performance and longevity of your dust collector system.

Step 7: Request Quotes and Compare Costs

Once you have narrowed down your options, request detailed quotes from multiple suppliers. Pay attention to not only the initial costs but also the long-term operational costs, including maintenance, energy consumption, and potential downtime. Comparing these factors will help you make a cost-effective decision that balances upfront investment with ongoing operational efficiency.

By following this structured checklist, B2B buyers can approach the procurement of dust collector baghouses with confidence, ensuring they select the right equipment to enhance their operational efficiency and comply with industry standards.

Comprehensive Cost and Pricing Analysis for dust collector bag house Sourcing

What Are the Key Cost Components of Dust Collector Bag House Systems?

When sourcing a dust collector bag house, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include carbon steel, stainless steel, and various filter media. High-performance fabrics can increase the price but may offer superior filtration efficiency and durability.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is often required for installation, particularly for complex systems or those needing customization.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Suppliers with more efficient operations may offer competitive pricing.

-

Tooling: Custom tooling for unique designs can add to the initial costs. However, investing in the right tooling can lead to better quality and more efficient production runs.

-

Quality Control (QC): Rigorous QC processes ensure the durability and reliability of the dust collector. While these processes can increase upfront costs, they often reduce long-term maintenance expenses.

-

Logistics: Shipping costs vary based on the distance, weight, and dimensions of the equipment. International buyers should be aware of potential customs duties and tariffs that could affect overall costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary widely based on the supplier’s positioning in the market.

How Do Price Influencers Impact Dust Collector Bag House Costs?

Several factors can influence the pricing of dust collector bag houses:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often results in significant discounts. Buyers should assess their needs to determine if they can leverage bulk purchasing.

-

Specifications and Customization: Custom specifications, including size, filtration efficiency, and additional features, can raise costs. Buyers should balance their specific needs against budget constraints.

-

Materials Used: The choice of materials not only affects the initial cost but also the longevity and maintenance of the equipment. Premium materials may have a higher upfront cost but can lead to lower Total Cost of Ownership (TCO).

-

Quality and Certifications: Equipment that meets international quality standards or has specific certifications (e.g., ISO, OSHA) may come at a premium but can provide assurance of reliability and compliance.

-

Supplier Factors: The supplier’s reputation, experience, and service offerings can influence pricing. Established suppliers may charge more but often provide better support and warranty options.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, impacting overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency in Dust Collector Bag House Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

Illustrative image related to dust collector bag house

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer discounts or better payment terms to secure a deal.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and operational costs over the equipment’s lifespan. A higher initial investment in quality can lead to savings in the long run.

-

Research Multiple Suppliers: Obtain quotes from various suppliers to compare costs and features. This can also provide leverage in negotiations.

-

Understand Local Regulations: Be aware of any local regulations that may impact operational costs, such as environmental compliance costs, which can affect the choice of dust collector.

-

Plan for Logistics: Factor in logistics costs, including shipping, duties, and taxes. Opting for suppliers with local distribution centers can reduce these expenses.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of dust collector bag houses is vital for B2B buyers. By considering the key cost components, recognizing price influencers, and applying effective sourcing strategies, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary widely, and it’s advisable to seek multiple quotes and thoroughly evaluate the Total Cost of Ownership before making a purchase.

Alternatives Analysis: Comparing dust collector bag house With Other Solutions

Exploring Alternative Solutions to Dust Collector Bag Houses

When it comes to industrial dust collection, selecting the right solution is crucial for operational efficiency and regulatory compliance. While dust collector bag houses are among the most popular choices due to their effectiveness and scalability, there are alternative systems available that may better suit specific applications or budget constraints. This analysis will compare dust collector bag houses with two viable alternatives: cyclone dust collectors and cartridge collectors.

Comparison Table

| Comparison Aspect | Dust Collector Bag House | Cyclone Dust Collector | Cartridge Collector |

|---|---|---|---|

| Performance | High efficiency for fine and hazardous dust; excellent air quality control | Good for larger particles; lower efficiency for fine dust | High filtration efficiency; handles varying dust types well |

| Cost | Moderate to high initial investment; long-term savings through durability | Generally lower initial cost; can be less effective in certain applications | Moderate cost; cost-effective for smaller operations |

| Ease of Implementation | May require significant installation time and expertise | Easier to install; less complex design | Compact design allows for easier installation and integration |

| Maintenance | Regular maintenance needed; filter replacement can be cumbersome | Low maintenance; self-cleaning capabilities in some models | Moderate maintenance; easier filter replacement than bag houses |

| Best Use Case | Ideal for high-volume, fine dust applications in various industries | Best for larger, heavier particles in less critical environments | Suitable for smaller operations with diverse dust types |

Detailed Breakdown of Alternatives

Cyclone Dust Collectors

Cyclone dust collectors utilize centrifugal force to separate dust particles from the air stream. This method is particularly effective for larger particles and is often used in woodworking and metalworking applications.

Pros:

– Lower initial investment compared to bag houses.

– Simple design leads to easier installation and lower operational complexity.

– Self-cleaning capabilities in some models reduce maintenance needs.

Cons:

– Not as effective for fine dust particles, which can lead to air quality issues.

– May require additional filtration systems for compliance in sensitive industries.

Cartridge Collectors

Cartridge collectors are compact dust collection systems that use pleated filters to capture dust particles. They are commonly found in operations with varying dust types, making them versatile and efficient.

Pros:

– High filtration efficiency, particularly for fine particles.

– Compact design allows for easy integration into existing setups.

– Easier filter replacement compared to bag houses, leading to reduced downtime.

Illustrative image related to dust collector bag house

Cons:

– Moderate initial costs can be a consideration for smaller operations.

– May not handle extremely high dust loads as effectively as bag houses.

Conclusion: How to Choose the Right Dust Collection Solution

For B2B buyers, selecting the optimal dust collection solution requires careful consideration of operational needs, budget, and facility constraints. Dust collector bag houses provide excellent performance for high-volume and hazardous dust applications but may come with higher costs and maintenance requirements. Cyclone dust collectors offer a budget-friendly option for larger particles, while cartridge collectors present a compact and versatile alternative suitable for diverse dust types. Ultimately, the choice will depend on the specific requirements of the operation, including dust type, volume, and regulatory compliance needs. Engaging with a knowledgeable supplier can help ensure the right fit for your business, enhancing efficiency and safety in your facility.

Essential Technical Properties and Trade Terminology for dust collector bag house

What Are the Essential Technical Properties of a Dust Collector Bag House?

Understanding the technical specifications of dust collector bag houses is crucial for B2B buyers aiming to select the right system for their operational needs. Here are some key properties to consider:

1. Filter Material Grade

The filter bags in a baghouse are typically made from materials like polyester, polypropylene, or aramid. Each material offers different resistance levels to heat, chemicals, and abrasion. For instance, aramid filters are ideal for high-temperature applications, while polyester is suitable for general-purpose use. Choosing the right material is vital as it impacts the longevity and efficiency of the dust collection system.

2. Airflow Capacity

Measured in cubic feet per minute (CFM), airflow capacity is a critical specification that dictates how much air can be processed by the baghouse. Selecting a baghouse with an appropriate CFM rating ensures that your operation can maintain optimal air quality and comply with environmental regulations. Underestimating this requirement may lead to inadequate dust control and increased operational costs.

3. Pressure Drop

The pressure drop refers to the resistance encountered by the air as it passes through the filter bags. A lower pressure drop indicates less energy consumption and operational efficiency. However, if the pressure drop is too low, it may signal that the system is not capturing dust effectively. Understanding the ideal pressure drop for your specific application helps in selecting a baghouse that balances performance with energy savings.

4. Cleaning Mechanism

Baghouses utilize various cleaning mechanisms, such as pulse jet, shaker, or reverse air systems. The choice of cleaning method affects maintenance frequency and filter life. For instance, pulse jet systems are known for their efficiency in cleaning bags without interrupting airflow, making them suitable for high-volume operations. Knowing the cleaning mechanism can guide buyers in evaluating long-term operational costs and maintenance requirements.

5. Dust Collection Efficiency

This specification indicates how effectively a baghouse can capture particulate matter from the air. Typically expressed as a percentage, higher efficiency ratings (e.g., 99% or above) are preferable, especially in industries handling hazardous materials. Buyers should consider their specific dust characteristics and regulatory compliance needs when evaluating this property.

6. Modularity and Scalability

Many modern baghouses are designed to be modular, allowing for easy expansion or customization. This flexibility is essential for businesses anticipating growth or changes in their dust collection needs. Investing in a modular system can lead to significant cost savings and operational efficiency in the long run.

What Are Common Trade Terms in the Dust Collector Industry?

Familiarity with industry jargon can empower B2B buyers to navigate discussions and negotiations effectively. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM produces components that are used in another company’s end product. In the context of dust collectors, working with an OEM ensures that buyers receive high-quality, compatible parts, which can lead to better performance and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs helps buyers gauge their purchasing power and plan their inventory effectively. This is particularly important for businesses that may need to balance costs with operational needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. Crafting an effective RFQ can ensure that you receive competitive bids tailored to your specifications, facilitating better procurement decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand shipping costs and liabilities, ensuring smoother transactions across borders.

5. Ducting

Ducting refers to the pipes or channels that transport dust-laden air to the baghouse. Proper duct design is critical for maintaining airflow efficiency and ensuring that the dust collector operates at its optimal capacity.

Illustrative image related to dust collector bag house

6. Static Pressure

Static pressure is the pressure exerted by the air in the ducting system when the air is not moving. It is an important metric for assessing the efficiency of the dust collection system and ensuring that it can handle the required airflow without excessive energy consumption.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when selecting a dust collector bag house that meets their operational requirements and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the dust collector bag house Sector

What Are the Key Market Dynamics in the Dust Collector Bag House Sector?

The global dust collector bag house market is driven by several factors, including stringent environmental regulations and the increasing demand for clean air in industrial operations. Industries such as metal fabrication, woodworking, and pharmaceuticals are heavily investing in efficient dust collection systems to comply with regulations and maintain operational efficiency. Additionally, the rise in manufacturing activities across emerging markets in Africa, South America, and the Middle East is propelling the demand for reliable dust collection solutions.

Current trends indicate a shift towards automation and integration of smart technologies in dust collection systems. For international B2B buyers, especially those from Nigeria and Germany, sourcing dust collector bag houses that incorporate IoT capabilities for real-time monitoring and maintenance can enhance operational efficiency. Moreover, customization is becoming increasingly important, as different industries have unique dust collection needs. Manufacturers offering modular systems that can be tailored to specific applications will likely gain a competitive edge.

Furthermore, the market is witnessing an increase in partnerships between manufacturers and technology providers to innovate solutions that improve energy efficiency and reduce overall operational costs. This trend is particularly relevant for B2B buyers looking for long-term investments in sustainable technologies.

How Can Sustainability and Ethical Sourcing Impact the Dust Collector Bag House Sector?

Sustainability is becoming a critical consideration for B2B buyers in the dust collector bag house sector. The environmental impact of industrial operations, particularly in terms of air quality and waste management, has led to a heightened awareness of sustainable practices. For buyers, choosing suppliers that prioritize environmentally friendly materials and processes is not just a trend but a necessity for compliance with international regulations.

Ethical sourcing is also paramount, as companies face scrutiny over their supply chains. B2B buyers should seek manufacturers that adhere to ethical labor practices and demonstrate transparency in their sourcing processes. Certifications like ISO 14001 for environmental management and LEED for energy efficiency are valuable indicators of a manufacturer’s commitment to sustainability.

Investing in dust collector bag houses made from recyclable or sustainable materials can further enhance a company’s green credentials. By prioritizing suppliers with these certifications, buyers can ensure they are contributing to a more sustainable future while also meeting regulatory requirements and consumer expectations for corporate responsibility.

What Is the Evolution of Dust Collector Bag Houses in the Industrial Sector?

The dust collector bag house has evolved significantly since its inception in the early 20th century. Originally designed as simple fabric filters, advancements in materials and technology have transformed them into sophisticated systems capable of handling various industrial applications. The introduction of pulse jet cleaning technology in the 1960s marked a significant milestone, allowing for more efficient dust removal and reduced maintenance downtime.

In recent years, the focus has shifted towards creating modular and customizable baghouse solutions that cater to the specific needs of different industries. This evolution is crucial for B2B buyers, as it allows them to invest in systems that not only meet their immediate operational requirements but can also adapt to future challenges. The integration of smart technology and automation in modern baghouses further exemplifies how the sector is responding to the demands of today’s industrial landscape, making these systems more efficient and easier to manage than ever before.

In summary, understanding the market dynamics, sustainability imperatives, and historical evolution of dust collector bag houses can empower international B2B buyers to make informed decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of dust collector bag house

-

How do I select the right dust collector baghouse for my application?

Choosing the right dust collector baghouse involves evaluating your specific application requirements, such as the type and volume of dust produced, airflow rate, and space constraints. Start by assessing the characteristics of the dust, including particle size and chemical properties, to determine the best filtration media. Consult with suppliers who offer a range of products and can provide tailored recommendations based on your operational needs, ensuring that the selected unit complies with local regulations and industry standards. -

What are the typical maintenance requirements for a baghouse dust collector?

Maintenance for baghouse dust collectors typically includes regular inspection of filter bags, cleaning mechanisms, and dust collection systems. It’s essential to monitor pressure drop across the filters to assess their efficiency. Scheduled maintenance might involve replacing worn-out filters, checking for leaks, and ensuring that cleaning systems are functioning properly. Establishing a preventive maintenance plan can minimize downtime and extend the lifespan of your equipment, contributing to operational efficiency. -

What is the minimum order quantity (MOQ) for dust collector baghouses?

Minimum order quantities (MOQ) for dust collector baghouses can vary significantly between suppliers. Some manufacturers may require a minimum order for cost-effective production, while others may offer flexibility for smaller operations. It’s advisable to discuss your specific needs with potential suppliers, as many are willing to accommodate varying order sizes, especially for customized solutions. Understanding your production requirements can help negotiate better terms and pricing. -

How can I ensure the quality and reliability of a dust collector baghouse?

To ensure quality and reliability, vet potential suppliers by checking their certifications, industry experience, and customer reviews. Request references and case studies that demonstrate successful implementations similar to your requirements. Additionally, inquire about the materials used in construction and the manufacturer’s warranty terms. A reputable supplier should provide clear documentation regarding quality assurance processes and offer post-installation support to address any issues that may arise. -

What payment terms should I expect when purchasing a dust collector baghouse?

Payment terms for dust collector baghouses can vary by supplier and are often negotiable. Standard practices may include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers might offer financing options or extended payment terms for larger orders. It’s crucial to clarify all payment conditions upfront and ensure they align with your budgeting and cash flow requirements to avoid any disruptions during the procurement process. -

What customization options are available for baghouse dust collectors?

Most manufacturers offer a range of customization options for baghouse dust collectors, including varying sizes, filtration media, and cleaning mechanisms tailored to specific applications. Custom configurations can address unique challenges such as high dust loads or specific environmental conditions. Discuss your operational needs with suppliers to explore available modifications, ensuring that the final product meets both performance and regulatory requirements. -

How does international shipping impact the procurement of dust collector baghouses?

International shipping can significantly impact the procurement process for dust collector baghouses, affecting lead times and costs. Be aware of customs regulations, import duties, and shipping methods that may influence delivery schedules. Collaborate with suppliers who have experience in international logistics to streamline the shipping process. Additionally, consider establishing clear communication channels regarding shipping updates and documentation to facilitate a smooth transaction. -

What are the common applications for baghouse dust collectors in different industries?

Baghouse dust collectors are versatile and widely used across various industries, including metal fabrication, woodworking, food processing, pharmaceuticals, and cement production. They are particularly effective in environments that generate fine particulate matter and hazardous dust. Understanding the specific requirements of your industry can help in selecting the appropriate baghouse design and filtration technology, ensuring compliance with health and safety regulations while optimizing dust control efficiency.

Top 2 Dust Collector Bag House Manufacturers & Suppliers List

1. Baghouse.com – Industrial Dust Collection Systems

Domain: baghouse.com

Registered: 1999 (26 years)

Introduction: Industrial Dust Collection Systems offered by Baghouse.com include various types such as Cartridge Collectors, Baghouse Collectors, Cyclone Collectors, and Bin Vents. Key features include:

– Custom manufacturing to meet specific customer needs.

– High-quality construction and reliability.

– Easy maintenance with features like expanded inlet diffusers and clean-on-demand controllers.

– Pulse Jet Ba…

2. Donaldson – Baghouse Dust Collectors

Domain: donaldson.com

Registered: 1995 (30 years)

Introduction: Baghouse dust collectors are industrial dust collectors that utilize 6 to 900 felt bags to filter dusty air from manufacturing and processing applications. Key models include:

1. **Dalamatic® G2** – Advanced technology for sticky dust control.

2. **Rugged Pleat RF Series** – High performance with maintenance-friendly design.

3. **RF Series** – Handles heavy dust loads without needing compressed a…

Strategic Sourcing Conclusion and Outlook for dust collector bag house

In today’s industrial landscape, the strategic sourcing of baghouse dust collectors is not merely a procurement decision but a critical factor in ensuring operational efficiency and regulatory compliance. Key takeaways emphasize the importance of selecting the right type and size of dust collector tailored to specific applications, as well as the necessity of investing in high-quality systems that can handle the demands of various industries, from metal fabrication to pharmaceuticals.

Buyers must prioritize vendors with a broad product range and expertise, ensuring that they receive tailored solutions rather than one-size-fits-all proposals. This approach not only enhances performance but also mitigates the risk of operational downtime and compliance issues. Furthermore, understanding the evolving technologies in dust collection can provide significant competitive advantages in maintaining a safe and sustainable workplace.

As you consider your next investment in dust collection systems, look ahead to the opportunities for innovation and efficiency. Engage with reputable suppliers who understand the nuances of your specific market demands—whether in Africa, South America, the Middle East, or Europe. By making informed decisions now, you can secure a cleaner, safer, and more productive future for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.