A B2B Buyer’s Guide to Hydraulic Lift Garage: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for hydraulic lift garage

In an increasingly competitive landscape, sourcing the right hydraulic lift garage solutions can be a daunting task for international B2B buyers. The challenge lies not only in identifying high-quality equipment but also in ensuring that it meets the unique operational demands of various markets, particularly in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Saudi Arabia. This comprehensive guide addresses these concerns by offering a detailed exploration of hydraulic lift garages, covering a range of types—from four-post lifts to portable models—alongside their diverse applications in automotive maintenance, storage solutions, and more.

Throughout this guide, buyers will gain insights into critical aspects of the procurement process, including supplier vetting, cost considerations, and compliance with regional safety standards. With the right knowledge at their fingertips, B2B buyers can make informed purchasing decisions that align with their business objectives and operational requirements. By understanding the nuances of hydraulic lift technology and its applications, companies can enhance their service offerings, improve efficiency, and ultimately drive profitability. Whether you’re a seasoned professional or new to the industry, this guide serves as a vital resource in navigating the complexities of the global hydraulic lift garage market.

Understanding hydraulic lift garage Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 4-Post Lifts | Versatile, heavy-duty, often used for vehicle storage | Auto repair shops, dealerships, storage | Pros: High capacity, stable, versatile; Cons: Requires more space, may need bolting down. |

| 2-Post Lifts | Space-efficient, ideal for maintenance and inspections | Auto service centers, fleet maintenance | Pros: Compact, easy access for undercarriage work; Cons: Limited lifting height, less stable for heavy vehicles. |

| Portable Lifts | Mobile, lightweight, and easy to store | Small garages, mobile mechanics | Pros: Flexibility, easy to transport; Cons: Lower capacity, may lack stability compared to fixed lifts. |

| Scissor Lifts | Compact design, provides vertical lifting | Warehouses, auto body shops | Pros: Space-saving, ideal for tight areas; Cons: Limited horizontal reach, not suitable for heavy vehicles. |

| Tri-Level Lifts | Innovative design allows stacking multiple vehicles | High-density parking, car dealerships | Pros: Maximizes parking space, efficient for storage; Cons: Higher initial investment, complex installation. |

What Are the Key Characteristics of 4-Post Lifts for B2B Buyers?

4-post lifts are renowned for their versatility and heavy-duty capabilities, making them ideal for both vehicle storage and maintenance. These lifts can handle a wide range of vehicle types, from standard cars to larger SUVs and trucks. They often feature advanced hydraulic systems that enhance operational efficiency and safety. For B2B buyers, the ability to use these lifts for both parking and service tasks is a significant advantage, especially for businesses dealing with high vehicle turnover. However, they require a larger footprint and may need to be bolted down for stability.

Why Choose 2-Post Lifts for Vehicle Maintenance?

2-post lifts are designed for efficiency in tight spaces, making them a popular choice for auto service centers and fleet maintenance operations. Their compact design allows for easy access to the vehicle’s undercarriage, facilitating quick inspections and repairs. While they are generally more affordable and easier to install than 4-post lifts, buyers should consider their limited lifting height and stability, especially when working with heavier vehicles. These lifts are best suited for shops that prioritize quick service and have the necessary space for maneuverability.

How Do Portable Lifts Benefit Small Garage Operations?

Portable lifts are lightweight and designed for easy transport, making them perfect for small garages or mobile mechanics. Their ability to be set up and dismantled quickly allows for flexibility in operations. However, they typically have lower weight capacities and may not offer the same stability as fixed lifts. For businesses that need versatility and space-saving solutions, portable lifts can be an attractive option, especially in regions where workshop space is limited.

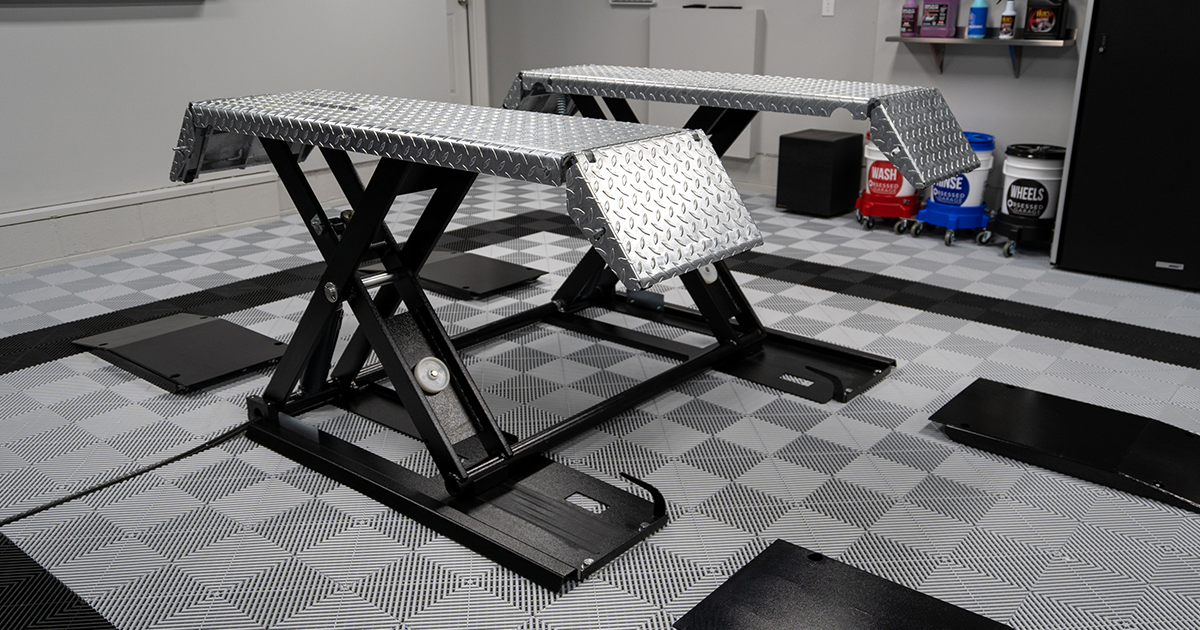

What Makes Scissor Lifts a Viable Choice for Tight Spaces?

Scissor lifts are characterized by their compact design, which allows for vertical lifting without occupying excessive horizontal space. They are especially useful in warehouses and auto body shops where maneuverability is crucial. However, their limited horizontal reach and lower weight capacity compared to 4-post and 2-post lifts may restrict their applications. For B2B buyers focused on maximizing space efficiency, scissor lifts represent a practical solution.

Why Consider Tri-Level Lifts for Parking Solutions?

Tri-level lifts are designed to maximize parking capacity by allowing multiple vehicles to be stacked in a single parking space. This innovative design is particularly beneficial for dealerships and high-density parking areas. While they require a higher initial investment and more complex installation, the ability to triple parking capacity can lead to significant long-term savings and efficiency improvements. B2B buyers in urban environments or those managing large vehicle inventories will find tri-level lifts a compelling option to optimize their operations.

Key Industrial Applications of hydraulic lift garage

| Industry/Sector | Specific Application of hydraulic lift garage | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Vehicle maintenance and servicing | Increases efficiency and safety during vehicle servicing. | Ensure compatibility with various vehicle types and weights. |

| Logistics & Warehousing | Stacking and storing vehicles in tight spaces | Maximizes storage capacity and optimizes floor space. | Assess lifting capacity and space requirements for installation. |

| Construction | Lifting construction equipment and materials | Enhances productivity and safety on job sites. | Look for models with high weight capacities and durability. |

| Marine Industry | Dry-docking boats for maintenance | Protects vessels from damage and reduces maintenance costs. | Consider corrosion resistance and height capabilities. |

| Automotive Showrooms | Displaying vehicles in a visually appealing manner | Attracts customers and enhances showroom aesthetics. | Evaluate lift design and height options for vehicle visibility. |

How is Hydraulic Lift Garage Used in the Automotive Repair Industry?

In the automotive repair sector, hydraulic lift garages are indispensable for servicing a wide range of vehicles, from compact cars to heavy trucks. These lifts allow mechanics to access the undercarriage and components of vehicles safely and efficiently. By elevating vehicles, they reduce strain on technicians and enable them to work at optimal heights. International buyers, particularly in regions like Africa and the Middle East, should prioritize lifts with varying weight capacities to accommodate diverse vehicle types and ensure compliance with local safety regulations.

What Role Does Hydraulic Lift Garage Play in Logistics and Warehousing?

In logistics and warehousing, hydraulic lift garages facilitate the stacking and storage of vehicles in limited spaces. This capability is vital in urban areas where space is at a premium. By utilizing four-post lifts, businesses can effectively maximize vertical space, allowing for the storage of multiple vehicles in a single footprint. Buyers in South America and Europe should consider the lift’s footprint and load capacity, ensuring that it meets the specific needs of their operational environment.

Illustrative image related to hydraulic lift garage

How is Hydraulic Lift Garage Beneficial in the Construction Industry?

Hydraulic lifts are also widely used in the construction industry for lifting heavy equipment and materials. They enhance productivity by allowing workers to safely access elevated areas without the need for scaffolding or ladders. This is especially important in regions with rugged terrain or limited access. Buyers in this sector should focus on sourcing models that offer high weight capacities and robust construction to withstand the demands of construction sites.

Why is Hydraulic Lift Garage Important for the Marine Industry?

In the marine industry, hydraulic lift garages are crucial for dry-docking boats for maintenance and repairs. By lifting vessels out of the water, businesses can prevent damage from corrosion and facilitate thorough inspections and repairs. This not only saves on maintenance costs but also extends the lifespan of the boats. Buyers should look for lifts designed with corrosion-resistant materials, especially in coastal regions, to ensure longevity and reliability.

How Does Hydraulic Lift Garage Enhance Automotive Showroom Operations?

For automotive showrooms, hydraulic lifts serve as an effective tool for displaying vehicles in an eye-catching manner. By elevating cars, dealerships can create a dynamic visual experience that attracts potential customers. This application is particularly beneficial in competitive markets where presentation plays a crucial role in sales. Buyers should assess the design and height capabilities of lifts to ensure they align with their showroom’s aesthetic and operational needs.

3 Common User Pain Points for ‘hydraulic lift garage’ & Their Solutions

Scenario 1: Difficulty in Maximizing Space Efficiency in Workshops

The Problem: In many regions, especially in urban areas of Africa and South America, the availability of workshop space is limited. B2B buyers often face the challenge of accommodating multiple vehicles for servicing and storage without sacrificing operational efficiency. The lack of effective space utilization can lead to cramped working conditions, reduced productivity, and ultimately, a negative impact on profit margins.

The Solution: To tackle space constraints, consider investing in high-capacity hydraulic lifts designed for vertical storage. Look for models that allow for the stacking of vehicles, such as tri-level parking lifts that can park multiple vehicles in a single footprint. When sourcing a hydraulic lift, ensure it has a compact design while offering sufficient lifting height and weight capacity for your specific needs. Additionally, evaluate the option of mobile hydraulic lifts that can be repositioned as necessary, allowing for flexible usage throughout the workshop. Collaborating with suppliers who understand local building codes and can provide tailored solutions for your unique space can further enhance operational efficiency.

Illustrative image related to hydraulic lift garage

Scenario 2: Inconsistent Hydraulic System Performance Leading to Safety Concerns

The Problem: Safety is paramount in any automotive service environment, yet many B2B buyers encounter issues with hydraulic lift performance, such as slow or uneven lifting. These inconsistencies can create hazardous situations for technicians working beneath vehicles. Such performance problems often stem from inadequate maintenance, poor-quality components, or insufficient training on lift operation.

The Solution: To mitigate safety risks, prioritize the selection of hydraulic lifts from reputable manufacturers known for high-quality engineering and robust safety features. Look for lifts with advanced hydraulic systems that include leak-proof cylinders and integrated flow restrictors for controlled descent. Additionally, implement a rigorous maintenance schedule that includes regular inspections and servicing of hydraulic components. Providing comprehensive training for your staff on the proper use and maintenance of hydraulic lifts is essential. This not only ensures safety but also prolongs the lifespan of the equipment, ultimately protecting your investment.

Scenario 3: Challenges in Complying with Regional Regulations and Standards

The Problem: International B2B buyers, particularly in regions like the Middle East and Europe, often struggle to navigate the complex landscape of local regulations and standards for automotive lifts. Compliance with safety and building codes is not just a legal requirement but also crucial for ensuring operational safety and avoiding costly fines. However, understanding these regulations can be overwhelming, especially for businesses that are new to the market.

The Solution: To ensure compliance, engage with local experts or consultants who specialize in automotive regulations in your specific region. When sourcing hydraulic lifts, look for manufacturers that provide documentation confirming compliance with local standards and regulations, such as ANSI/ALI ALCTV-2017 in the U.S. or relevant European directives. Furthermore, consider lifts that come with installation services that adhere to local codes, reducing the burden of ensuring compliance on your end. Establishing a clear line of communication with your lift supplier regarding regional requirements can help streamline the procurement process and ensure that your operations remain compliant and safe.

Strategic Material Selection Guide for hydraulic lift garage

What Are the Common Materials Used in Hydraulic Lift Garages?

When selecting materials for hydraulic lift garages, several factors such as durability, corrosion resistance, and cost-effectiveness must be considered. Below, we analyze four common materials: steel, aluminum, composite materials, and stainless steel. Each material offers unique properties and implications for performance, particularly for international B2B buyers.

Illustrative image related to hydraulic lift garage

How Does Steel Perform in Hydraulic Lift Applications?

Key Properties: Steel is known for its high tensile strength and excellent load-bearing capacity, making it a preferred material for hydraulic lifts. It can withstand high temperatures and pressures, essential for hydraulic systems.

Pros & Cons: Steel’s durability is a significant advantage; however, it is susceptible to corrosion if not properly treated. While it is generally cost-effective, the manufacturing complexity can increase with the need for protective coatings, especially in humid or corrosive environments.

Impact on Application: Steel is compatible with various hydraulic fluids but may require additional protective measures in harsh environments to prevent rust and degradation.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for structural integrity and corrosion resistance. Familiarity with ASTM and DIN standards can aid in selecting the right steel grades.

What Advantages Does Aluminum Offer for Hydraulic Lifts?

Key Properties: Aluminum is lightweight yet strong, with good corrosion resistance. It performs well under moderate temperature and pressure conditions, making it suitable for various hydraulic applications.

Illustrative image related to hydraulic lift garage

Pros & Cons: The primary advantage of aluminum is its lower weight, which can reduce installation costs and ease mobility. However, it is generally more expensive than steel and may not handle heavy loads as effectively.

Impact on Application: Aluminum is compatible with most hydraulic fluids but may require specific formulations to prevent chemical reactions.

Considerations for International Buyers: Buyers in Europe may prefer aluminum for its lightweight properties, especially in applications where mobility is critical. Compliance with EU regulations on material safety should also be considered.

How Do Composite Materials Enhance Hydraulic Lift Performance?

Key Properties: Composite materials, often made from a combination of polymers and fibers, offer excellent strength-to-weight ratios and high resistance to corrosion and chemical exposure.

Pros & Cons: Composites are highly durable and can be tailored for specific applications, but they can be more expensive and complex to manufacture. Their long-term performance in high-stress environments is still under evaluation.

Illustrative image related to hydraulic lift garage

Impact on Application: These materials are ideal for environments where chemical exposure is a concern, providing compatibility with various hydraulic media.

Considerations for International Buyers: Buyers from South America and Africa should assess the availability of composite materials and their compliance with local regulations. Understanding the lifecycle and environmental impact of composites is also crucial.

Why Is Stainless Steel a Popular Choice for Hydraulic Lifts?

Key Properties: Stainless steel combines the strength of steel with superior corrosion resistance due to its chromium content. It can withstand high pressures and temperatures, making it ideal for hydraulic applications.

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements. However, it is more expensive than regular steel and can be challenging to machine.

Impact on Application: Stainless steel is compatible with a wide range of hydraulic fluids and is particularly beneficial in environments prone to corrosion.

Considerations for International Buyers: Buyers in regions with high humidity or corrosive environments, such as coastal areas in Africa or the Middle East, should prioritize stainless steel for its durability. Compliance with international standards like ASTM and JIS is also essential.

Illustrative image related to hydraulic lift garage

Summary Table of Material Selection for Hydraulic Lift Garages

| Material | Typical Use Case for hydraulic lift garage | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and frames | High strength and load capacity | Susceptible to corrosion | Medium |

| Aluminum | Lightweight lifts and portable models | Lightweight and easy to handle | Higher cost and lower load capacity | High |

| Composite | Specialized applications in chemical environments | Excellent corrosion resistance | Expensive and complex to manufacture | High |

| Stainless Steel | Environments prone to corrosion | Long-lasting and low maintenance | Higher cost and machining difficulty | High |

This analysis provides a comprehensive overview of the materials used in hydraulic lift garages, helping B2B buyers make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic lift garage

What Are the Key Stages in the Manufacturing Process of Hydraulic Lifts?

The manufacturing of hydraulic lifts involves a systematic approach to ensure safety, reliability, and performance. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: This initial stage involves selecting high-quality raw materials such as high-strength steel for frames and hydraulic components. Suppliers often provide certification to ensure that materials meet specific industry standards, such as ASTM for steel. Before production begins, materials undergo inspection for quality and compliance.

Forming: Once the materials are prepared, they are shaped into required components through various processes such as cutting, bending, and welding. Advanced techniques like laser cutting and CNC machining are commonly used for precision and efficiency. The forming stage is critical; any inaccuracies can affect the lift’s overall performance and safety.

Assembly: After forming, components are assembled into the final product. This stage often involves integrating hydraulic systems, safety features, and control mechanisms. Quality checks are performed during assembly to ensure parts fit correctly and function as intended. For instance, hydraulic lines must be securely connected to prevent leaks and ensure smooth operation.

Illustrative image related to hydraulic lift garage

Finishing: The final stage involves coating and painting to protect the lifts from corrosion and wear. Durable finishes can enhance the aesthetic appeal and longevity of the product. This stage may also include additional quality inspections to ensure that the lift meets all design specifications and safety regulations.

How is Quality Assurance Implemented in Hydraulic Lift Manufacturing?

Quality assurance (QA) is paramount in hydraulic lift manufacturing to ensure that products meet safety and performance standards. Manufacturers typically adhere to international standards such as ISO 9001, which emphasizes a systematic approach to quality management.

International Standards Compliance: ISO 9001 outlines the requirements for a quality management system (QMS) and is widely recognized globally. In addition to ISO, specific industry standards like CE marking in Europe and API standards for hydraulic systems are crucial for market acceptance. Compliance with these standards demonstrates a commitment to quality and safety.

Quality Control Checkpoints: Quality control (QC) involves various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): During manufacturing, continuous inspections are performed to identify defects or deviations from standards.

– Final Quality Control (FQC): Once the hydraulic lifts are fully assembled, they undergo thorough testing and inspection before shipment. This may include load testing, hydraulic pressure testing, and functionality assessments.

Illustrative image related to hydraulic lift garage

What Testing Methods Are Commonly Used for Hydraulic Lifts?

Several testing methods are critical to ensuring that hydraulic lifts perform safely and effectively. These include:

- Load Testing: This involves applying the maximum rated load to the lift to ensure it can handle the weight without failure. It simulates real-world conditions and checks for structural integrity.

- Hydraulic Pressure Testing: This test checks for leaks and ensures that the hydraulic system operates within its specified pressure range.

- Functional Testing: The lift is operated to verify that all components, including safety features, control systems, and emergency stops, function as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure supplier compliance:

- Supplier Audits: Conducting on-site audits of the manufacturing facility allows buyers to assess the quality management systems in place. This includes reviewing documentation, observing manufacturing processes, and evaluating compliance with international standards.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, testing results, and any corrective actions taken in response to past issues.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. This is particularly valuable when dealing with suppliers in different countries where local regulations may vary.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various nuances related to quality control, particularly when sourcing hydraulic lifts from different regions. Here are some considerations:

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should ensure that the supplier’s products comply with both local and international standards.

- Cultural Differences: Understanding cultural attitudes towards quality and safety can impact supplier relationships. Establishing clear communication regarding expectations and standards is essential.

- Logistical Challenges: Shipping products internationally can introduce risks, such as damage during transport. Ensuring that suppliers package products according to international standards can mitigate these risks.

Conclusion: Ensuring Quality in Hydraulic Lift Procurement

The manufacturing processes and quality assurance practices for hydraulic lifts are integral to ensuring safety and performance. By understanding these processes, B2B buyers can make informed decisions when sourcing hydraulic lifts. Effective verification of supplier quality control through audits, reports, and third-party inspections can significantly enhance procurement outcomes, ensuring that the hydraulic lifts meet the rigorous demands of various markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic lift garage’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure hydraulic lift garages. With the increasing demand for efficient vehicle service and storage solutions, making informed decisions on hydraulic lifts is crucial for operational success. This guide will help you navigate the essential steps in the procurement process, ensuring you select the right equipment for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the hydraulic lift meets your operational needs. Consider factors such as load capacity, lift height, and platform size. Additionally, think about the types of vehicles you will service and any specific features required, such as extra-wide or high-rise capabilities.

- Load Capacity: Identify the maximum weight your lift needs to handle, ranging from light-duty vehicles to heavy-duty trucks.

- Lift Height: Determine the height necessary for comfortable access under the vehicle.

Step 2: Research Different Types of Hydraulic Lifts

Understanding the various types of hydraulic lifts available is crucial for making an informed choice. Common options include two-post lifts, four-post lifts, and portable car lifts. Each type has its unique benefits tailored to specific applications.

- Two-Post Lifts: Ideal for quick access to vehicles for maintenance and repairs.

- Four-Post Lifts: Excellent for storage and servicing, especially for heavier vehicles or when stacking is necessary.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thoroughly vet their reputation and capabilities. Request company profiles, customer testimonials, and case studies that demonstrate their expertise in the industry. This step is crucial to ensure you are partnering with a reliable supplier.

- Industry Experience: Look for suppliers with a proven track record in hydraulic lift sales and service.

- Customer References: Ask for references from businesses in your region or industry to gauge satisfaction levels.

Step 4: Verify Supplier Certifications

Ensure that your chosen supplier complies with industry standards and certifications. This step is essential for ensuring safety, reliability, and adherence to regulations specific to your region.

- Safety Standards: Check for compliance with ANSI/ALI ALCTV and any local regulations regarding hydraulic lifts.

- Quality Assurance: Look for ISO certifications that indicate a commitment to quality and continuous improvement.

Step 5: Assess Warranty and Support Services

A robust warranty and reliable support services can save you time and money in the long run. Review the warranty terms and what is covered, as well as the availability of technical support and spare parts.

- Warranty Length: Determine the duration of the warranty and what components are covered.

- Support Availability: Ensure that the supplier offers accessible customer support, including installation assistance and maintenance services.

Step 6: Consider Delivery and Installation Logistics

Plan for the logistics of delivery and installation, as these can significantly impact your operations. Confirm delivery timelines and installation services offered by the supplier to avoid disruptions.

- Shipping Options: Discuss shipping costs and timelines, especially for international deliveries.

- Installation Services: Inquire if the supplier provides professional installation or if you will need to arrange it separately.

Step 7: Finalize Budget and Payment Terms

Establish a clear budget and understand the payment terms before proceeding with the purchase. This step is essential to ensure financial feasibility and avoid unexpected costs.

- Cost Breakdown: Request a detailed quote that includes all associated costs, such as shipping, installation, and any additional accessories.

- Payment Options: Discuss flexible payment terms that suit your cash flow and operational needs.

By following this checklist, B2B buyers can confidently navigate the procurement of hydraulic lift garages, ensuring that they invest in the right equipment for their specific requirements.

Illustrative image related to hydraulic lift garage

Comprehensive Cost and Pricing Analysis for hydraulic lift garage Sourcing

What Are the Key Cost Components for Hydraulic Lift Garage Sourcing?

When sourcing hydraulic lifts for garages, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The quality of materials used directly impacts the durability and functionality of hydraulic lifts. Common materials include high-grade steel for the frame, hydraulic components, and durable finishes to resist corrosion.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is required for assembly, especially for complex hydraulic systems. Depending on the region, labor rates can vary significantly.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent for manufacturing facilities, and equipment depreciation. Efficient operations can help reduce overhead costs.

-

Tooling: Specialized tools and equipment necessary for manufacturing hydraulic lifts can be significant investments. These costs are often amortized over the production volume.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each lift meets safety and performance standards. This may involve testing, certification, and compliance with industry regulations, which can add to the overall cost.

-

Logistics: Shipping and handling costs can vary based on the weight and dimensions of the lifts, as well as the distance to the destination. For international buyers, customs duties and tariffs can also impact overall logistics costs.

-

Margin: Suppliers typically include a profit margin that varies based on competition, market demand, and the perceived value of their products.

How Do Price Influencers Affect Hydraulic Lift Costs?

Several factors can influence pricing in the hydraulic lift market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to discounts, as manufacturers benefit from economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom features, such as specialized lifting capacities or additional safety equipment, can increase costs. Buyers should assess their actual needs versus desired features.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, ANSI) can increase initial costs but may result in lower maintenance and replacement costs over time.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their brand value and proven track record.

-

Incoterms: Understanding the agreed-upon Incoterms (e.g., FOB, CIF) is essential, as they define responsibilities for shipping costs, insurance, and customs clearance, directly impacting total costs.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Hydraulic Lifts?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiate Pricing: Leverage the competitive landscape by requesting quotes from multiple suppliers. Highlight your volume potential to negotiate better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality lifts may reduce long-term expenses.

-

Understand Pricing Nuances for International Trade: Be aware of currency fluctuations, potential import tariffs, and regional compliance requirements that can affect overall pricing. Engaging local distributors may mitigate some risks.

-

Prioritize Supplier Relationships: Building strong relationships with suppliers can lead to better support, favorable payment terms, and access to exclusive deals or early insights on new products.

Disclaimer on Indicative Prices

Prices for hydraulic lifts can vary significantly based on specifications, regional market conditions, and supplier factors. It is essential for buyers to conduct thorough market research and obtain detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing hydraulic lift garage With Other Solutions

Understanding Alternative Solutions to Hydraulic Lift Garages

When considering solutions for vehicle lifting and maintenance, hydraulic lift garages stand out due to their efficiency and versatility. However, there are alternative technologies that may suit specific business needs better. This section explores three viable alternatives, offering a comparative analysis to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Hydraulic Lift Garage | 2-Post Lift | Portable Car Lift |

|---|---|---|---|

| Performance | High lifting capacity, stability, and safety features for heavy-duty vehicles. | Suitable for light to medium vehicles; offers good access for repairs. | Limited lifting capacity; ideal for quick jobs and smaller vehicles. |

| Cost | Higher initial investment, ranging from $5,000 to $30,000 depending on capacity and features. | Moderate cost, typically between $3,000 and $10,000. | Lower cost, often between $1,000 and $3,000. |

| Ease of Implementation | Requires a permanent installation; may need bolting to the floor. | Also requires installation; less space-consuming than hydraulic lifts. | Extremely easy to set up; often portable and can be used in various locations. |

| Maintenance | Requires regular checks for hydraulic fluid and cylinder integrity. | Low maintenance but needs regular safety checks. | Minimal maintenance; battery-operated models require battery upkeep. |

| Best Use Case | Ideal for garages with high traffic, heavy vehicles, and long-term storage. | Best for workshops focusing on repairs with moderate vehicle access needs. | Perfect for mobile mechanics and occasional use, providing flexibility. |

Analyzing 2-Post Lifts

2-post lifts are a popular alternative to hydraulic lift garages, particularly in environments where space is limited. They offer a balance of cost and performance, making them suitable for small to medium repair shops. The primary advantage is their ability to provide access to the underside of vehicles, which facilitates easier maintenance and repairs. However, their lifting capacity is generally lower than hydraulic lifts, and they may not be suitable for larger vehicles or high-volume operations. Additionally, while installation is simpler than hydraulic systems, they still require proper anchoring to ensure safety.

Exploring Portable Car Lifts

Portable car lifts represent a flexible solution for those who require mobility and versatility. These lifts are often lightweight and can be easily transported, making them ideal for on-site repairs or limited garage space. Their lower cost is appealing for small businesses or startups. However, the trade-off includes limited lifting capacity and potentially less stability compared to hydraulic systems. Portable lifts are most effective for quick jobs and lighter vehicles, but they may not meet the demands of a high-traffic repair shop requiring heavy-duty lifting capabilities.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right vehicle lifting solution requires a comprehensive assessment of your specific business needs, including the types of vehicles serviced, space availability, and budget constraints. Hydraulic lift garages offer unparalleled performance for heavy-duty applications, while 2-post and portable lifts provide flexibility and cost-effectiveness for lighter jobs. By understanding the strengths and weaknesses of each option, B2B buyers can make informed choices that align with their operational requirements and financial objectives, ultimately enhancing productivity and service quality in their workshops.

Illustrative image related to hydraulic lift garage

Essential Technical Properties and Trade Terminology for hydraulic lift garage

What Are the Key Technical Properties of Hydraulic Lift Garages?

Hydraulic lift garages are essential in automotive maintenance and storage, and understanding their technical specifications is crucial for B2B buyers. Here are some critical properties to consider:

-

Load Capacity

The load capacity of a hydraulic lift indicates the maximum weight it can safely lift. Common capacities range from 7,000 lbs to over 40,000 lbs. For businesses, selecting a lift with an appropriate load capacity ensures it can handle the vehicles serviced, minimizing the risk of equipment failure and enhancing operational efficiency. -

Material Grade

The quality of materials used in constructing hydraulic lifts significantly impacts their durability and performance. High-grade steel is often preferred due to its strength and resistance to deformation. B2B buyers should ensure that the lifts meet international standards for material quality to avoid premature wear and ensure safety during operations. -

Hydraulic System Design

The design of the hydraulic system, including the type of hydraulic cylinder and the presence of safety features, is vital. Systems with hidden or integrated cylinders offer better aesthetics and reduced wear. A well-designed hydraulic system enhances lifting efficiency and prolongs the lift’s lifespan, ultimately affecting maintenance costs. -

Rise Height

The maximum rise height determines the clearance available for mechanics to work underneath vehicles. Lifts that can rise 80 inches or more are advantageous for servicing larger vehicles, such as SUVs and trucks. This specification is crucial for businesses that expect to service a diverse range of vehicle types. -

Footprint Size

The footprint size indicates the space the lift will occupy in a garage. Compact models are ideal for smaller workshops, while larger lifts may be necessary for high-capacity operations. Understanding the footprint helps businesses optimize their workspace and improve workflow efficiency. -

Safety Features

Safety features such as automatic locking mechanisms, overload protection, and emergency stop buttons are essential for preventing accidents. Lifts equipped with these features not only comply with regulatory standards but also protect both staff and vehicles, which is paramount for maintaining a safe work environment.

What Common Trade Terms Should B2B Buyers Know?

Understanding industry jargon is essential for effective communication and decision-making in the hydraulic lift market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hydraulic lifts, knowing the OEM can help buyers assess product quality and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. B2B buyers should be aware of MOQs to manage inventory effectively and avoid overcommitting resources, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing and terms from suppliers. This document is crucial for comparing offers from different vendors and making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping and delivery responsibilities, minimizing potential disputes. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. Knowing the lead time is essential for planning and inventory management, particularly for businesses that rely on timely service delivery. -

Warranty Period

The warranty period is the duration for which the manufacturer guarantees the lift against defects. A longer warranty period can provide peace of mind for buyers, indicating the manufacturer’s confidence in their product’s durability and reliability.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when investing in hydraulic lift garages, ensuring that they choose the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the hydraulic lift garage Sector

What Are the Key Trends Driving the Hydraulic Lift Garage Market?

The hydraulic lift garage sector is experiencing significant transformation, driven by several global factors. Increasing vehicle ownership in emerging markets such as Nigeria and Saudi Arabia is a primary driver, leading to heightened demand for efficient vehicle maintenance and storage solutions. Additionally, technological advancements in hydraulic systems are enhancing the performance and safety of lifts, making them more attractive to B2B buyers. Features like advanced hydraulic cylinders and integrated safety mechanisms are becoming standard, improving operational efficiency and reducing downtime.

Emerging trends also highlight the shift towards digitalization in the sourcing processes. B2B buyers are increasingly leveraging online platforms for procurement, enabling them to compare products, read reviews, and access real-time pricing. This trend is particularly relevant for international buyers who need to navigate diverse regional regulations and standards. Furthermore, the demand for versatile, multi-functional lifts—such as four-post lifts that can serve both maintenance and parking needs—is on the rise, reflecting a broader trend towards space optimization in garage designs.

Illustrative image related to hydraulic lift garage

How Is Sustainability and Ethical Sourcing Reshaping the Hydraulic Lift Garage Sector?

Sustainability is becoming a critical consideration in the hydraulic lift garage sector. The environmental impact of manufacturing processes and the materials used in lift production is under scrutiny. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of recycled materials and energy-efficient manufacturing techniques.

Ethical sourcing is equally important, with buyers seeking transparency in their supply chains. Certifications for ‘green’ materials and adherence to environmental standards are becoming key factors in procurement decisions. Companies that can provide evidence of sustainable practices not only appeal to environmentally conscious buyers but also mitigate risks related to regulatory compliance in different regions. As the global focus on sustainability intensifies, suppliers that align with these values are likely to gain a competitive edge in the market.

What Has Been the Evolution of Hydraulic Lift Technology?

The hydraulic lift technology has evolved significantly since its inception in the early 20th century. Initially designed for simple vehicle lifting, advancements in engineering have transformed hydraulic lifts into sophisticated systems equipped with safety features and enhanced lifting capabilities. Over the decades, technological innovations such as automatic controls and enhanced hydraulic cylinders have improved performance and user safety.

Illustrative image related to hydraulic lift garage

The introduction of digital technologies, such as IoT integration, is now paving the way for smart lifts that can monitor performance and provide real-time data to users. This evolution not only improves operational efficiency but also enhances the overall user experience. As the market continues to grow, the focus on innovation and technology integration will likely shape the future of hydraulic lift systems, making them more efficient and user-friendly for B2B buyers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic lift garage

-

How do I solve issues with hydraulic lift maintenance?

To effectively address hydraulic lift maintenance issues, establish a regular inspection schedule that includes checking hydraulic fluid levels, inspecting hoses for leaks, and ensuring that all safety features are functioning. Implement a maintenance log to track service history and identify recurring problems. Partnering with a qualified service provider can also help ensure that your lifts are maintained according to manufacturer specifications, enhancing safety and longevity. -

What is the best hydraulic lift for heavy-duty applications?

For heavy-duty applications, consider hydraulic lifts with a capacity of at least 14,000 lbs. Models like the HDS-14XT are designed for high-rise operations, offering extended runways and enhanced safety features. Look for lifts with robust construction and advanced hydraulic systems that ensure stability and reliability under demanding conditions. It’s also beneficial to choose lifts that come with a warranty and a reputation for durability in challenging environments. -

What should I look for in a supplier of hydraulic lifts?

When sourcing hydraulic lifts, prioritize suppliers with a solid track record in the industry and favorable reviews from previous clients. Ensure they provide comprehensive product specifications, certifications, and compliance with international safety standards. Additionally, assess their customer service responsiveness and the availability of technical support and spare parts. It’s also wise to request references from other buyers, particularly those in your region. -

What are the minimum order quantities (MOQs) for hydraulic lifts?

Minimum order quantities can vary significantly based on the manufacturer and the specific model of the hydraulic lift. Typically, MOQs for hydraulic lifts range from one unit for smaller suppliers to multiple units for larger manufacturers. It’s advisable to inquire directly with suppliers to understand their MOQ policies and whether they offer discounts for bulk purchases, especially if you’re looking to equip multiple locations. -

What payment terms are common when purchasing hydraulic lifts internationally?

Payment terms for international purchases often include options like advance payment, letter of credit, or payment upon delivery. Some suppliers may also offer financing options or installment payments for larger orders. Always clarify payment terms upfront and ensure they are documented in the contract to avoid misunderstandings. Additionally, consider using secure payment methods to protect your investment. -

How can I ensure quality assurance (QA) for my hydraulic lift order?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Consider arranging for third-party inspections before shipment to verify compliance with international standards. Additionally, inquire about the manufacturer’s quality control processes and warranties offered on their products. Establishing a clear communication channel with the supplier can help address any concerns during the production phase. -

What logistics considerations should I keep in mind for importing hydraulic lifts?

When importing hydraulic lifts, consider the shipping methods, customs regulations, and potential tariffs that may apply. Work with a logistics provider experienced in heavy machinery to ensure safe transport and timely delivery. Additionally, prepare all necessary documentation, including import permits and certificates of origin, to facilitate smooth customs clearance. It’s also wise to account for lead times in your project planning. -

Can hydraulic lifts be customized to fit specific needs?

Many suppliers offer customization options for hydraulic lifts, including adjustments in lifting capacity, runway length, and additional safety features. Discuss your specific requirements with potential suppliers to determine the available customization options. Custom lifts may come with longer lead times, so factor this into your planning. Always request documentation of the modifications to ensure compliance with safety standards.

Top 7 Hydraulic Lift Garage Manufacturers & Suppliers List

1. BendPak – Two-Post Lifts

Domain: bendpak.com

Registered: 1997 (28 years)

Introduction: BendPak Two-Post Lifts: Designed for auto lifting applications with a capacity up to 20,000 lbs. Models include:

1. XPR-9S-DC: 1/10 scale die-cast model, 22-lb capacity, starting at $280.00.

2. GrandPrix GP-9LC: 9,000-lb capacity, floorplate design for low ceilings, starting at $3,495.00.

3. GrandPrix GP-10C: 10,000-lb capacity, clearfloor design, starting at $3,695.00.

4. BendPak 10AP-SRT: 10,00…

2. Wrenchers – Portable Car Lifts

Domain: wrenchers.com

Registered: 2018 (7 years)

Introduction: Portable Car Lifts are designed for shops with limited space, allowing for easy movement and storage. They come in various capacities, small footprints, and are reliable and affordable. Suitable for servicing sports cars, family sedans, light-duty trucks, and SUVs, these lifts can handle up to 7,000 lbs. Available designs include scissor, pantograph, and two-post. Accessories include motorcycle an…

3. Nussbaum – Sprinter 7

Domain: obsessedgarage.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”Nussbaum Sprinter 7″,”regular_price”:”$6,860.65 USD”,”sale_price”:”$6,860.65 USD”},{“name”:”Nussbaum Jumbo HF 7″,”regular_price”:”$12,394.75 USD”,”sale_price”:”$12,394.75 USD”},{“name”:”Nussbaum Jumbo HF 9″,”regular_price”:”$15,762.73 USD”,”sale_price”:”$15,762.73 USD”},{“name”:”BendPak GrandPrix GP-9LC”,”regular_price”:”$3,495.00 USD”,”sale_price”:”$3,495.00 USD”}]}

4. Rotary Solutions – Car Lifts

Domain: rotarysolutions.com

Registered: 2009 (16 years)

Introduction: Car Lifts: Rotary Solutions offers a variety of car lifts including Two-Post Lifts, Four-Post Lifts, In-Ground Lifts, Scissor Lifts, Low-Rise Lifts, and Mid-Rise Lifts. They also provide accessories for car lifts. The company emphasizes their long-standing history in the industry, having invented the hydraulic automotive lift 100 years ago, and continues to innovate to enhance productivity and pro…

5. Carlift – Underground Garage Models

Domain: carlifthome.com

Registered: 2020 (5 years)

Introduction: Underground garage models: SL-3 and SL-6. SL-3: Intended for 1 car, maximum weight load 3000 kg (6614 lb). SL-6: Suitable for 2 cars, maximum weight load 6000 kg (13228 lb). Features include: masking finish to match surrounding area, wireless control via remote or smartphone app, modern LED lighting, 2-year warranty and lifetime technical support. Designed and manufactured in Poland with high-qual…

6. My Garage Supplies – Car Lifts

Domain: mygaragesupplies.com

Registered: 2023 (2 years)

Introduction: This company, My Garage Supplies – Car Lifts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Mohawk Lifts – Heavy Duty Vehicle Lifts

Domain: mohawklifts.com

Registered: 1997 (28 years)

Introduction: Four Post Lifts, Heavy Duty Lifts, Truck Lifts, Specialty Garage Lift Accessories, HD Truck Lifts, Two Post Truck Lifts, Mobile Columns, Heavy Duty Drive-On Lifts, Custom Lifts, Heavy Duty Vehicle Lifts by Capacity (7,000–18,000 LB, 19,000–30,000 LB, 25,000–75,000 LB, 75,000–120,000 LB), Two Post Auto Lifts, Two Post Drive-On Lifts, Automotive Storage Lifts, System IA: Two Post Lift, Speedlane: Tw…

Strategic Sourcing Conclusion and Outlook for hydraulic lift garage

In summary, strategic sourcing for hydraulic lift garages is paramount for international B2B buyers looking to enhance operational efficiency and safety. By prioritizing quality and reliability, businesses can select hydraulic lifts that not only meet their immediate needs but also accommodate future growth. The diverse range of four-post lifts available on the market allows buyers to find the right solutions tailored to specific requirements, whether for vehicle storage, maintenance, or display.

Investing in high-quality hydraulic lifts can significantly improve productivity, reduce long-term costs, and ensure compliance with safety standards. As markets in Africa, South America, the Middle East, and Europe evolve, the demand for reliable automotive service equipment will only increase.

International buyers are encouraged to take advantage of the latest innovations in hydraulic lift technology, focusing on features that enhance durability and operational efficiency. Engaging with reputable suppliers and understanding regional regulations will be crucial in making informed purchasing decisions. As the industry progresses, now is the ideal time to secure quality hydraulic lift solutions that will support your business for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hydraulic lift garage

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.