How to Source Agv Software Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for agv software

In an increasingly competitive global landscape, sourcing the right AGV software can be a daunting challenge for businesses looking to enhance operational efficiency. With the rise of automated guided vehicles (AGVs) in sectors such as manufacturing, warehousing, and logistics, companies are tasked with finding software solutions that not only optimize fleet management but also integrate seamlessly with existing systems. This comprehensive guide delves into the intricacies of AGV software, exploring essential types such as fleet management, navigation, and mapping software, as well as their diverse applications across various industries.

International B2B buyers, particularly those operating in dynamic markets like Nigeria, Brazil, and across Europe and the Middle East, will find valuable insights into supplier vetting processes, cost considerations, and best practices for implementation. By equipping decision-makers with the knowledge to assess different software offerings, this guide empowers organizations to make informed purchasing decisions that align with their unique operational needs.

Whether you are looking to automate complex logistics or streamline production processes, understanding the nuances of AGV software is crucial for maximizing return on investment and enhancing overall productivity. The following sections will provide actionable insights and strategies to help you navigate this evolving market effectively.

Understanding agv software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fleet Management Software | Centralized control of multiple AGVs, real-time monitoring | Warehousing, manufacturing | Pros: Optimizes fleet utilization; reduces downtime. Cons: Initial setup can be complex. |

| Navigation Software | Enables AGVs to navigate autonomously using various methods | Logistics, healthcare, retail | Pros: Increases operational efficiency; flexible navigation options. Cons: May require regular updates for optimal performance. |

| Mapping Software | Allows for environment mapping and route planning | Manufacturing, distribution centers | Pros: Enhances route optimization; improves safety. Cons: Mapping can be time-intensive. |

| Integration Software | Connects AGVs with existing systems like ERP and WMS | Supply chain management, production | Pros: Streamlines operations; enhances data visibility. Cons: Integration challenges with legacy systems. |

| Customization Software | Tailored software solutions to meet specific business needs | Diverse industries, specialized applications | Pros: Meets unique operational requirements; can improve ROI. Cons: Potentially higher costs and longer implementation times. |

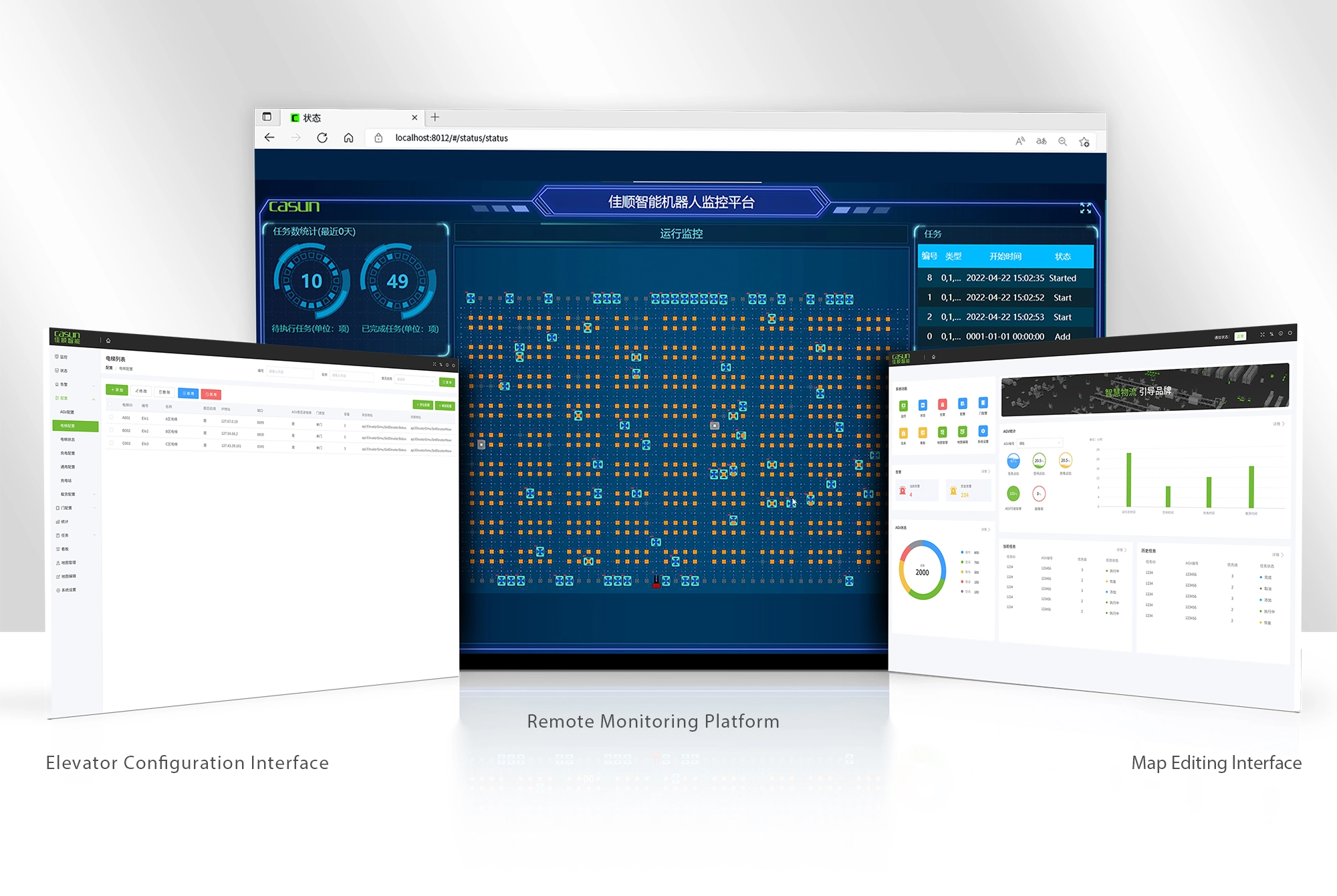

What are the Characteristics of Fleet Management Software?

Fleet Management Software serves as the backbone for managing a fleet of AGVs. It provides centralized control, enabling real-time monitoring of vehicle performance, task assignments, and maintenance schedules. This type of software is particularly suited for environments where multiple AGVs operate simultaneously, such as warehouses and manufacturing plants. B2B buyers should consider the scalability of the software and its compatibility with existing systems to maximize investment.

How Does Navigation Software Enhance AGV Operations?

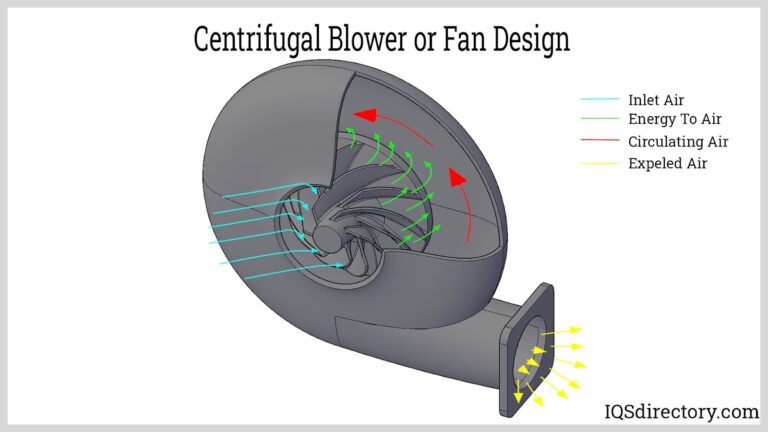

Navigation Software is critical for the autonomous movement of AGVs, utilizing technologies like natural navigation and mapping to determine optimal paths. This software is highly suitable for logistics and healthcare sectors, where precise navigation is essential. When purchasing, businesses should evaluate the software’s adaptability to various environments and its ease of use, as these factors significantly impact operational efficiency.

What Role Does Mapping Software Play in AGV Efficiency?

Mapping Software facilitates the mapping of operational environments, allowing for effective route planning and obstacle avoidance. This software is particularly beneficial in manufacturing and distribution centers, where safety and efficiency are paramount. Buyers should consider the time investment required for initial mapping and updates, as well as the software’s ability to adapt to changes in the operational layout.

Why is Integration Software Important for AGV Systems?

Integration Software connects AGVs with existing enterprise systems such as ERP and WMS, enabling seamless data flow and operational coordination. This software is vital for supply chain management and production environments, where real-time data visibility can enhance decision-making. Buyers should assess the integration capabilities of the software, particularly its ability to work with legacy systems, to ensure a smooth transition and ongoing operational efficiency.

How Can Customization Software Benefit Specific Business Needs?

Customization Software allows businesses to tailor AGV operations to their specific requirements, enhancing flexibility and efficiency. This type of software is applicable across diverse industries, including those with specialized operational needs. When considering customization, businesses should weigh the potential for improved ROI against the higher initial costs and longer implementation timelines that may be involved.

Key Industrial Applications of agv software

| Industry/Sector | Specific Application of agv software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Material Handling | Increases efficiency and reduces labor costs | Compatibility with existing machinery and systems |

| Warehousing | Inventory Management and Order Fulfillment | Enhances accuracy and speeds up processing times | Integration capabilities with WMS and ERP systems |

| Healthcare | Hospital Logistics and Supply Chain Management | Improves delivery speed of medical supplies | Compliance with health regulations and safety standards |

| Retail | In-Store Product Transport and Restocking | Optimizes inventory turnover and customer satisfaction | Flexibility for various store layouts and sizes |

| Automotive | Assembly Line Automation and Parts Transportation | Streamlines production processes and reduces downtime | Scalability and adaptability to different vehicle types |

How is AGV Software Transforming the Manufacturing Sector?

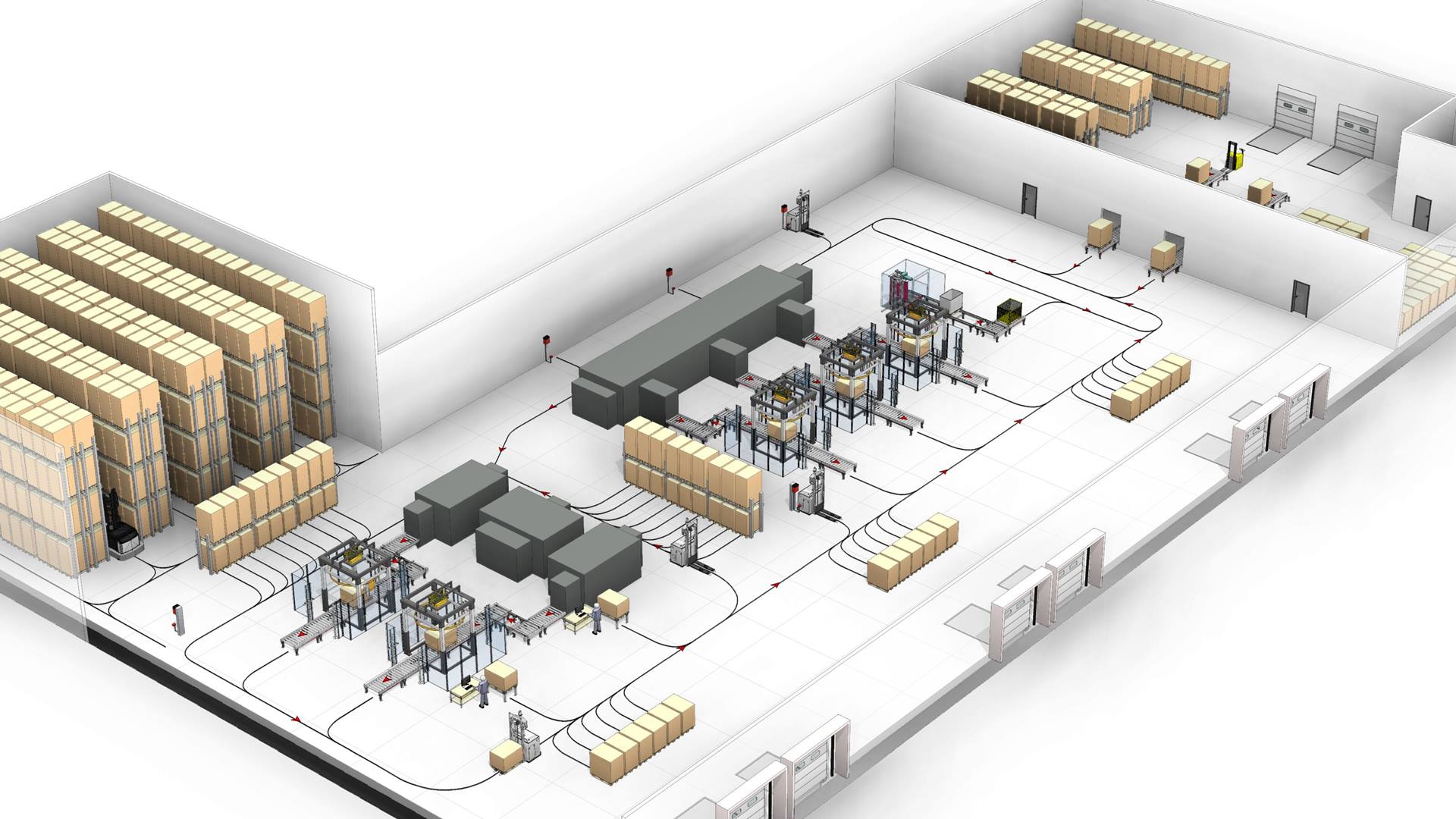

In manufacturing, AGV software is crucial for automating material handling processes. This software allows for real-time tracking and management of goods, ensuring that materials are delivered to the right place at the right time. By automating these processes, businesses can significantly reduce labor costs and improve operational efficiency. International buyers should ensure that the AGV software is compatible with their existing machinery and can be customized to meet specific production needs.

What Role Does AGV Software Play in Warehousing?

In the warehousing sector, AGV software is used for inventory management and order fulfillment. The software facilitates the automated transport of goods, ensuring accurate stock levels and faster order processing. This not only enhances operational efficiency but also improves customer satisfaction through timely deliveries. Buyers must consider integration capabilities with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems to maximize the benefits of AGV software.

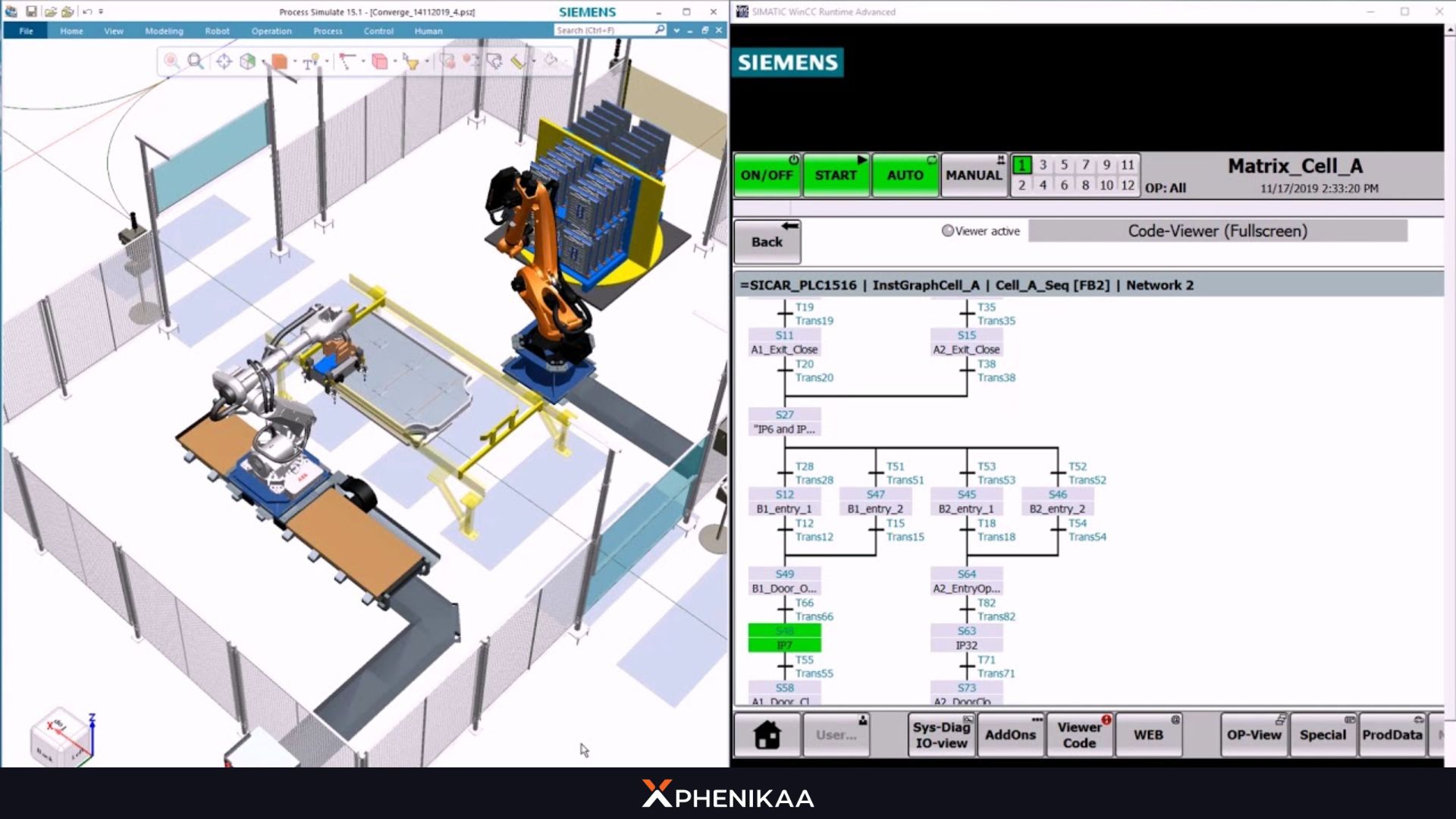

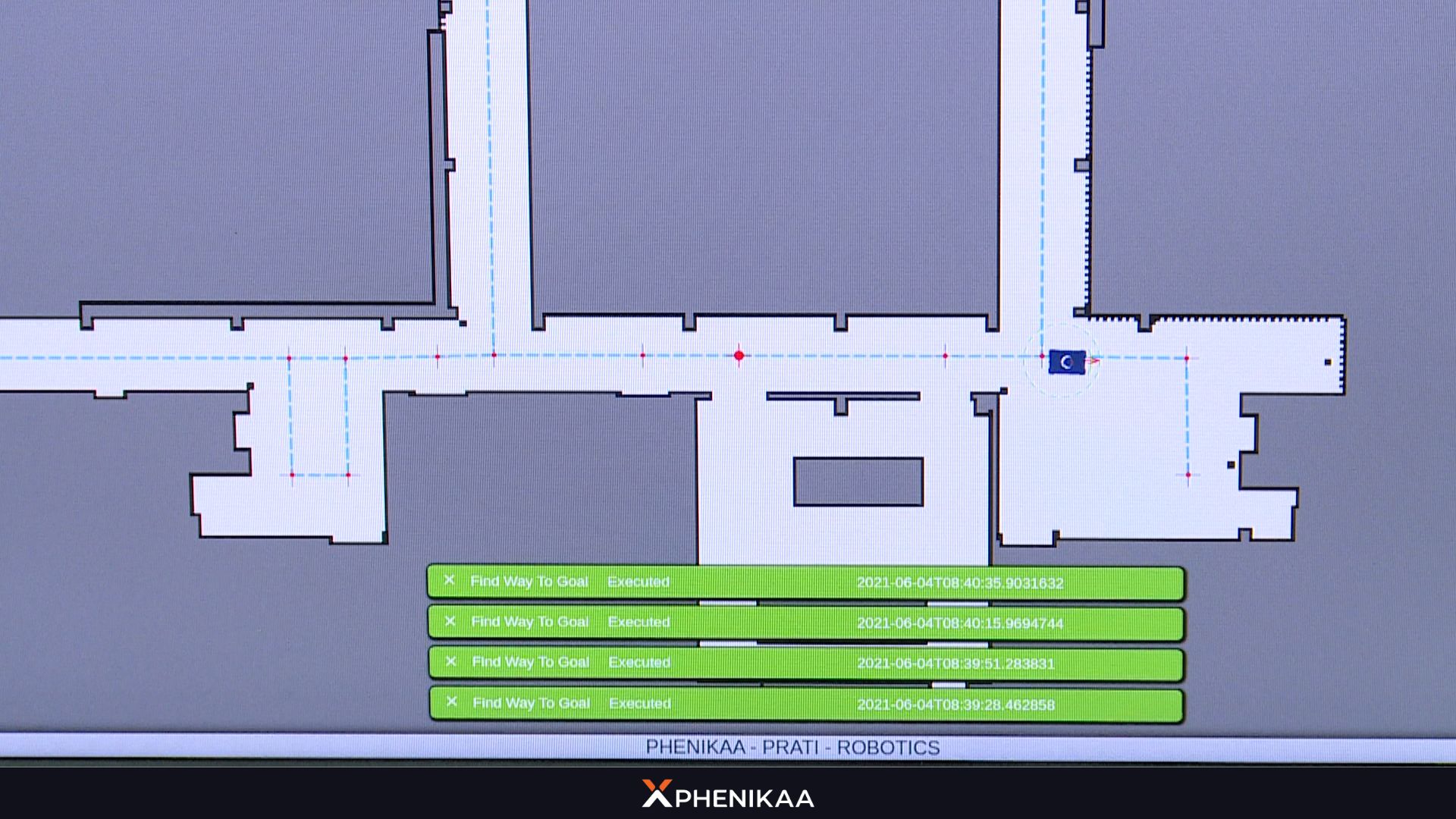

Illustrative image related to agv software

How Can AGV Software Improve Healthcare Logistics?

AGV software is increasingly being implemented in healthcare settings for logistics and supply chain management. It automates the delivery of medical supplies and equipment within hospitals, improving the speed and reliability of these critical services. This application is particularly important in regions where healthcare infrastructure may be under strain. Buyers in this sector should prioritize AGV solutions that comply with health regulations and ensure safety standards are met.

How is AGV Software Enhancing Retail Operations?

In the retail industry, AGV software aids in in-store product transport and restocking. Automated guided vehicles can move products from storage areas to sales floors, optimizing inventory turnover and enhancing customer satisfaction. This application is especially beneficial in large retail environments where manual restocking can lead to inefficiencies. Retailers should look for AGV solutions that offer flexibility to adapt to various store layouts and sizes.

What Benefits Does AGV Software Bring to the Automotive Industry?

In the automotive sector, AGV software is integral for assembly line automation and parts transportation. It streamlines production processes by ensuring that parts are delivered exactly when needed, reducing downtime and increasing overall productivity. Buyers in this industry should seek AGV solutions that are scalable and adaptable to different vehicle types to ensure long-term operational success.

Illustrative image related to agv software

3 Common User Pain Points for ‘agv software’ & Their Solutions

Scenario 1: Integrating AGV Software with Existing Systems

The Problem: Many B2B buyers face significant challenges when integrating AGV software with their existing Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES). This often leads to data silos, inefficient workflows, and increased operational costs. For instance, a manufacturing plant in Nigeria might struggle to synchronize real-time inventory data with their AGV fleet, resulting in delays and miscommunication in the supply chain.

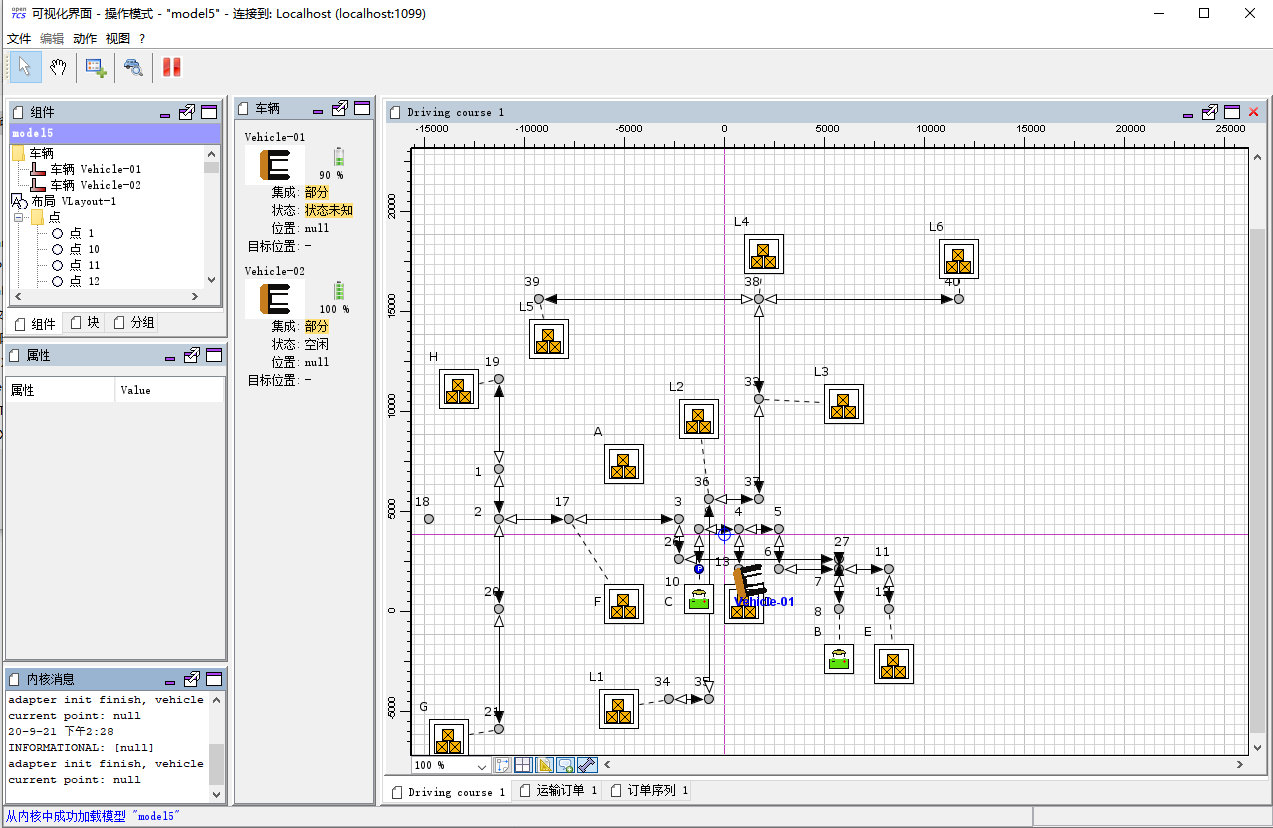

The Solution: To overcome these integration hurdles, it’s essential to select AGV software that offers robust APIs and support for industry-standard protocols like VDA 5050. Buyers should conduct a thorough assessment of their existing systems and identify key integration points. When evaluating AGV software providers, prioritize those that demonstrate a strong track record in seamless integrations and can provide case studies or testimonials from similar industries. Additionally, engage in a consultation with the software vendor to understand how they can tailor their solutions to fit your specific operational needs. This proactive approach can significantly enhance communication between systems, streamline processes, and ultimately drive cost savings.

Scenario 2: Navigating Complex Environments with AGV Software

The Problem: In regions such as Brazil and South Africa, companies often operate in complex environments where AGVs must navigate dynamic layouts, obstacles, and varying floor conditions. For example, an automotive parts manufacturer may need AGVs that can adapt to sudden changes in warehouse configuration or deal with unpredictable human traffic, leading to operational inefficiencies and safety concerns.

Illustrative image related to agv software

The Solution: The key to addressing these challenges lies in selecting AGV software equipped with advanced navigation and mapping capabilities. Look for solutions that incorporate features like real-time obstacle detection and adaptive path planning. When sourcing AGV software, request demos that showcase these capabilities in action. Additionally, consider software that allows for easy updates and modifications to the navigation algorithms as your environment changes. Collaborating with a vendor who offers training and support for your team can also ensure that your staff is well-prepared to manage these complexities efficiently. This way, your AGVs can operate safely and effectively, regardless of the challenges posed by the environment.

Scenario 3: Ensuring Scalability of AGV Software Solutions

The Problem: A common concern among B2B buyers is the scalability of AGV software solutions, especially when planning for future growth. Companies in the Middle East may start with a small fleet of AGVs but anticipate needing to expand significantly in a few years. Without scalable software, they risk investing in a system that may become obsolete or require costly upgrades as their operations grow.

The Solution: To ensure that AGV software can grow alongside your business, it’s crucial to choose a solution that is hardware-independent and supports a wide range of AGV types. During the selection process, inquire about the vendor’s roadmap for scalability and any limitations that may affect future expansion. Opt for software solutions that provide modular features, allowing you to add functionalities as your needs evolve. Additionally, consider vendors that offer flexible pricing models based on usage, which can provide a more sustainable financial approach as your fleet expands. Engaging with industry peers or consulting with experts can also provide insights into the scalability of different AGV software options, helping you make a well-informed decision that aligns with your long-term operational goals.

Strategic Material Selection Guide for agv software

What Are the Common Materials Used in AGV Software Development?

In the realm of AGV (Automated Guided Vehicle) software, the choice of materials is crucial not only for the physical components but also for ensuring software compatibility with various hardware configurations. Here, we analyze four common materials that play a significant role in AGV software applications.

1. Steel

Key Properties: Steel offers high tensile strength, durability, and excellent resistance to wear and tear, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, essential for environments with heavy machinery.

Pros & Cons: The primary advantage of steel is its durability and strength, which ensures longevity in demanding environments. However, it is relatively heavy, which can affect the overall weight and energy efficiency of AGVs. Additionally, steel is prone to corrosion, requiring protective coatings that may add to manufacturing complexity.

Impact on Application: Steel is often used in the structural components of AGVs, such as frames and chassis. Its compatibility with various media (e.g., lubricants and hydraulic fluids) is essential for maintaining operational efficiency.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local corrosion resistance standards, as environments may vary significantly. Compliance with ASTM or DIN standards can ensure that the steel used meets necessary quality benchmarks.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It performs well in various temperatures and is easily machinable, making it ideal for intricate designs.

Pros & Cons: The lightweight nature of aluminum enhances the energy efficiency of AGVs, allowing for faster speeds and reduced energy consumption. However, it is less durable than steel and can be more expensive, particularly when high-strength alloys are required.

Impact on Application: Aluminum is often used in the construction of AGV bodies and components where weight reduction is critical. Its compatibility with various software systems is generally high, making it a preferred choice for modern AGV designs.

Considerations for International Buyers: Buyers should ensure that aluminum components comply with local standards, such as JIS in Japan or EN in Europe. Additionally, understanding the cost implications in regions like the Middle East, where aluminum may be more readily available, can influence purchasing decisions.

3. Polycarbonate

Key Properties: Polycarbonate is a high-impact resistant plastic known for its transparency and lightweight properties. It can withstand a wide temperature range and offers good UV resistance.

Illustrative image related to agv software

Pros & Cons: The primary advantage of polycarbonate is its ability to absorb impact without cracking, making it suitable for protective covers and housings. However, it can be more susceptible to scratching compared to glass or metal, which may affect visibility in certain applications.

Impact on Application: Polycarbonate is often used in the protective casings of AGVs, especially in environments where visibility of internal components is necessary. Its lightweight nature supports overall vehicle efficiency.

Considerations for International Buyers: Buyers should be aware of the specific grades of polycarbonate that meet local safety standards. For instance, compliance with European EN standards for safety and impact resistance is crucial for ensuring product reliability.

4. Rubber

Key Properties: Rubber is flexible, durable, and provides excellent traction. It can withstand various environmental conditions, including temperature extremes and exposure to chemicals.

Pros & Cons: The flexibility of rubber allows for shock absorption, which is beneficial for AGVs operating on uneven surfaces. However, it may degrade over time when exposed to certain chemicals or UV light, necessitating regular maintenance and replacement.

Impact on Application: Rubber is commonly used in wheels and tires of AGVs, contributing to their maneuverability and stability. Its compatibility with various surfaces enhances the overall performance of the vehicle.

Considerations for International Buyers: Buyers should consider the specific rubber formulations that comply with local standards, particularly in regions like Nigeria or Brazil, where environmental conditions can vary widely. Understanding the local market for rubber products can also influence cost and availability.

Summary Table

| Material | Typical Use Case for AGV Software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High durability and strength | Heavy and prone to corrosion | Medium |

| Aluminum | AGV bodies and components | Lightweight and energy-efficient | Less durable and potentially more costly | High |

| Polycarbonate | Protective casings | High impact resistance | Susceptible to scratching | Medium |

| Rubber | Wheels and tires | Excellent traction and shock absorption | Degrades over time with exposure | Low |

This guide provides a comprehensive overview of material selection considerations for AGV software, helping international B2B buyers make informed decisions tailored to their specific regional needs and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for agv software

What Are the Main Stages in the Manufacturing Process of AGV Software?

The manufacturing process for AGV (Automated Guided Vehicle) software is multifaceted, involving several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the software meets operational requirements and quality standards.

How is Material Prepared for AGV Software Development?

Material preparation in AGV software development encompasses the gathering and organization of requirements and specifications. This stage often involves collaboration with clients to understand their operational needs and expectations. Software engineers and developers engage in brainstorming sessions to define the software architecture, programming languages, and development frameworks that will be utilized.

During this phase, various software tools, libraries, and APIs are selected based on compatibility with existing systems, such as ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems). This groundwork is essential for ensuring that the AGV software can seamlessly integrate with different hardware and software environments.

What Techniques are Used in Forming AGV Software Solutions?

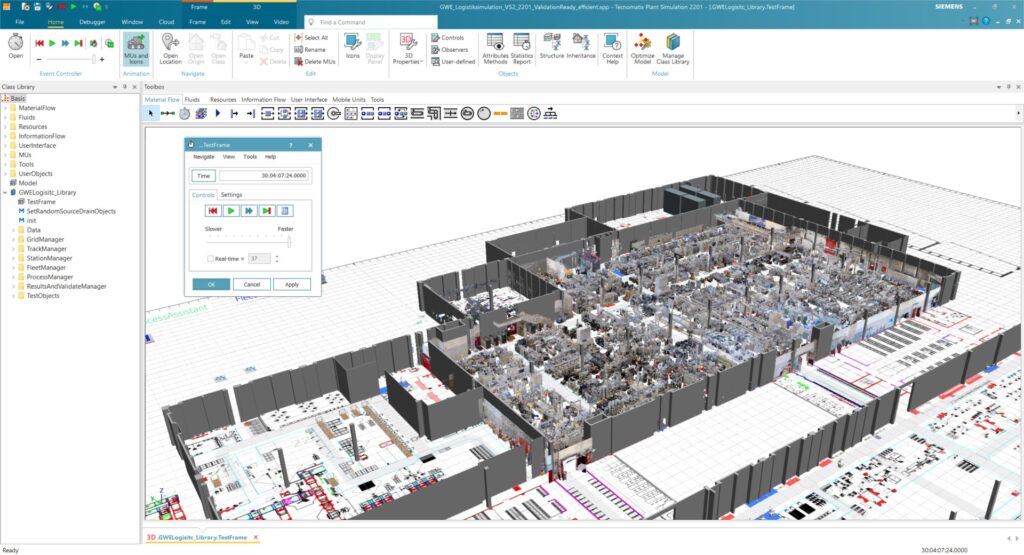

Forming the AGV software involves coding and developing the software modules that will enable navigation, fleet management, and communication with other systems. Key techniques during this stage include:

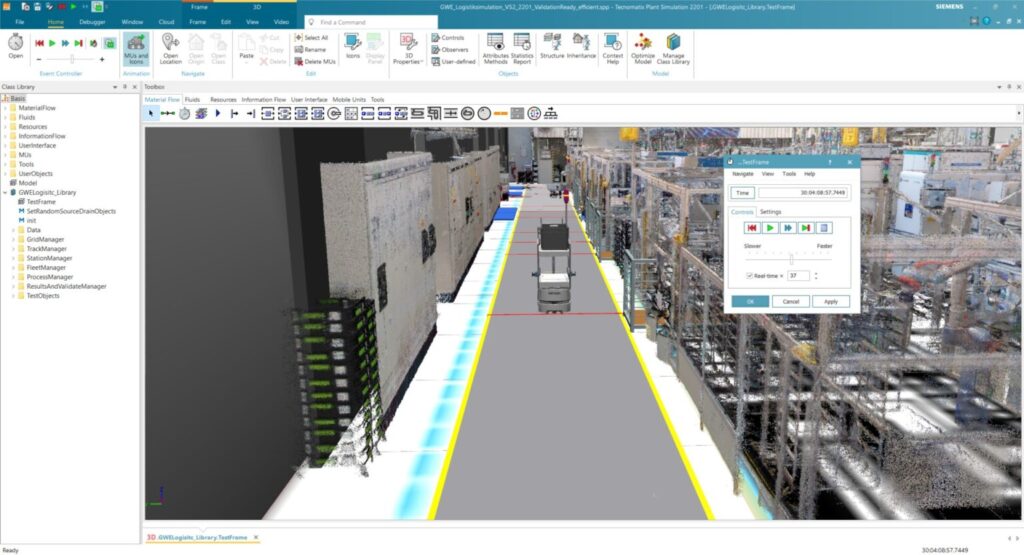

- Agile Development: Utilizing agile methodologies allows for iterative development, enabling teams to adapt to changes quickly and incorporate client feedback throughout the development cycle.

- Simulation and Testing Environments: Developers create virtual environments to simulate AGV operations. This helps in identifying potential issues early in the development process, allowing for adjustments before the software is deployed in real-world scenarios.

- Version Control Systems: Tools like Git are essential for managing changes to the codebase, enabling collaborative work among developers while maintaining a history of modifications.

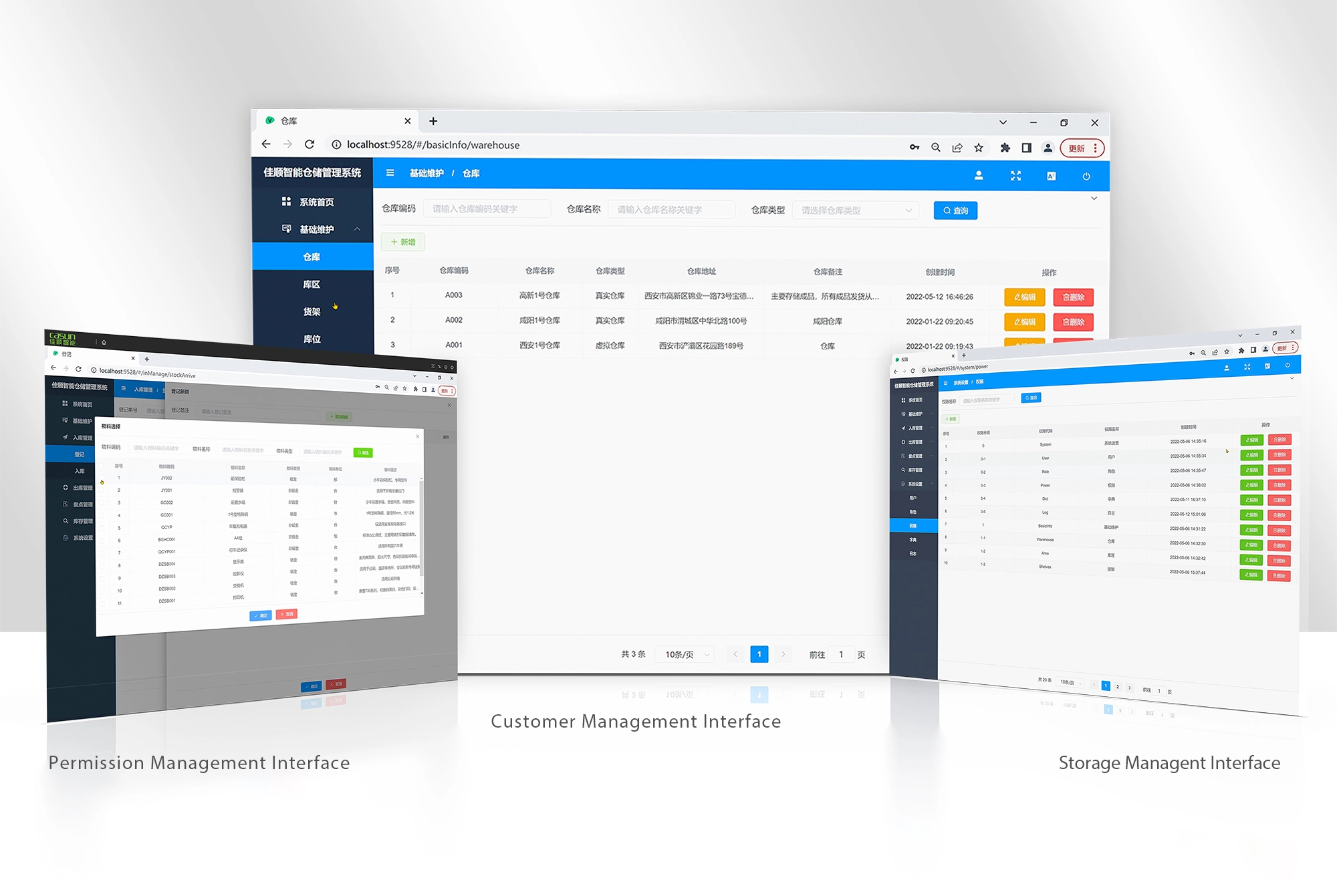

How Does the Assembly Stage Work for AGV Software?

The assembly stage in AGV software development involves integrating the various software components into a cohesive system. This includes:

- Integration of Modules: Developers combine navigation, fleet management, and communication modules into a single software package. This ensures that different functionalities work harmoniously.

- User Interface Design: Attention is given to creating intuitive user interfaces that facilitate ease of use for operators and managers, enhancing overall operational efficiency.

- Deployment Planning: This phase also includes planning for deployment, which involves preparing for installation in the client’s operational environment, ensuring minimal disruption during the transition.

What Are the Final Steps in Finishing AGV Software Development?

Finishing touches on AGV software involve thorough testing and validation to ensure the product meets the specified requirements. This includes:

Illustrative image related to agv software

- User Acceptance Testing (UAT): Clients test the software in a controlled environment to verify that it meets their operational needs.

- Documentation: Comprehensive documentation is created, detailing installation procedures, user manuals, and troubleshooting guides. This documentation is vital for training staff and facilitating future upgrades.

What Quality Assurance Standards Are Relevant for AGV Software?

Quality assurance (QA) in AGV software development is paramount to ensure reliability and performance. International standards such as ISO 9001 provide a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Other relevant industry-specific standards may include CE marking for compliance with European safety regulations and API standards for application programming interfaces.

What Are the Key Quality Control Checkpoints in AGV Software Development?

Quality control (QC) involves systematic processes to ensure that the software meets quality standards throughout its development lifecycle. Key QC checkpoints include:

- Incoming Quality Control (IQC): This step verifies that all inputs, including software libraries and tools, meet predefined quality standards before development begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the development phase helps catch defects early. This may involve code reviews and testing at various stages of development.

- Final Quality Control (FQC): Before deployment, comprehensive testing is conducted to ensure the software operates as intended and meets all quality benchmarks.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of AGV software suppliers:

- Conduct Audits: Schedule audits of potential suppliers to assess their manufacturing processes and quality assurance systems. This provides insight into their operational practices and commitment to quality.

- Request Quality Reports: Suppliers should provide documentation of their QC processes, including test results, compliance certifications, and records of past performance.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased evaluation of the supplier’s quality control measures and overall reliability.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate additional nuances in quality control:

- Cultural Differences in Quality Standards: Understanding regional differences in quality expectations and regulatory requirements is critical. Buyers should familiarize themselves with local standards, which may vary significantly from international norms.

- Supply Chain Transparency: Ensure that suppliers provide visibility into their supply chain processes, especially if components are sourced from various international locations. This transparency is vital for assessing potential risks associated with product quality.

- Post-Deployment Support: Quality assurance does not end at deployment. Buyers should evaluate the supplier’s commitment to ongoing support, including software updates, troubleshooting, and training for staff to ensure continued compliance with operational standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for AGV software is essential for B2B buyers looking to invest in automation solutions. By focusing on the critical stages of development and establishing robust quality control practices, buyers can make informed decisions that align with their operational needs and industry standards. Ensuring a thorough evaluation of potential suppliers will ultimately lead to enhanced operational efficiency and a successful integration of AGV systems into existing workflows.

Illustrative image related to agv software

Practical Sourcing Guide: A Step-by-Step Checklist for ‘agv software’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of AGV (Automated Guided Vehicle) software. By following this step-by-step checklist, businesses can ensure they make informed decisions, aligning their operational needs with the right software solutions for their AGV systems.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to clearly outline your technical requirements. This includes understanding the types of AGVs you will use, their operational environment (indoor vs. outdoor), and specific functionalities needed such as fleet management, navigation, and mapping capabilities. A well-defined specification will help you communicate effectively with potential suppliers and streamline the selection process.

Step 2: Assess Integration Capabilities

Evaluate how well the AGV software can integrate with your existing systems such as ERP or WMS (Warehouse Management Systems). Look for software that supports open APIs and industry standards like VDA 5050, which ensures compatibility with various hardware and reduces the risk of vendor lock-in. This step is crucial for ensuring seamless operations and data flow across your logistics and production processes.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from businesses within your industry or region. It’s important to assess their track record in delivering AGV solutions that meet your specific needs, as well as their ability to provide ongoing support and updates.

Step 4: Verify Compliance and Certifications

Ensure that the AGV software complies with relevant industry standards and safety regulations. Look for certifications that demonstrate the software’s reliability and security, particularly in sectors such as manufacturing and healthcare. Compliance not only mitigates risk but also enhances trust in the software’s capabilities.

Illustrative image related to agv software

Step 5: Request Demos and Trials

Engage with shortlisted suppliers to request demonstrations or trial versions of their AGV software. This hands-on experience is invaluable for assessing usability, functionality, and overall performance. During the demo, pay attention to the software’s interface, ease of navigation, and how it manages fleet operations in real time.

Step 6: Inquire About Customization Options

Discuss the possibility of customizing the AGV software to better suit your operational needs. Many suppliers offer tailored solutions that can significantly enhance efficiency and productivity. Understanding the extent of customization available will help ensure the software aligns perfectly with your business processes.

Step 7: Evaluate Total Cost of Ownership

Finally, consider the total cost of ownership, which includes initial purchase price, implementation costs, maintenance fees, and any additional costs for upgrades or support. A comprehensive cost analysis will help you understand the long-term financial implications of your software choice and ensure it fits within your budgetary constraints.

Illustrative image related to agv software

By following this structured checklist, B2B buyers can confidently navigate the complexities of sourcing AGV software, ensuring they select the best solution to enhance their operational efficiency and drive business success.

Comprehensive Cost and Pricing Analysis for agv software Sourcing

What Are the Key Cost Components for AGV Software?

When sourcing AGV software, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: This encompasses the hardware and software licenses required for AGV operation. High-quality components often lead to better performance and longevity, which can justify higher upfront costs.

-

Labor: Skilled labor is needed for the development, customization, and ongoing maintenance of AGV software. This includes costs associated with hiring engineers and software developers who can tailor the solutions to specific operational needs.

-

Manufacturing Overhead: This includes indirect costs related to the production of software, such as utilities, rent, and administrative expenses. A lower overhead can lead to more competitive pricing.

-

Tooling: In the context of software, this refers to the development tools and platforms used to create and maintain the AGV software. Investments in cutting-edge tools can enhance efficiency and reduce long-term costs.

-

Quality Control (QC): Ensuring that the software meets industry standards and performs reliably is essential. QC processes can add to the overall cost, but they are vital for minimizing future operational disruptions.

-

Logistics: While logistics typically pertains to physical products, in the software realm, this can include the costs associated with software deployment, updates, and support services.

-

Margin: Suppliers will include a margin in their pricing to ensure profitability. Understanding the typical margins in the AGV software market can help buyers gauge whether they are receiving a fair offer.

How Do Pricing Influencers Affect AGV Software Costs?

Several factors can influence the pricing of AGV software, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders or long-term contracts can often lead to volume discounts. Buyers should negotiate terms that align with their operational needs and budget.

-

Specifications and Customization: Tailored solutions that meet specific operational requirements will typically cost more than off-the-shelf software. Buyers should clearly define their needs to avoid unnecessary costs.

-

Materials and Quality Certifications: Software that is certified for specific industries or adheres to higher quality standards may command a premium price. However, this investment often leads to better reliability and compliance.

-

Supplier Factors: The reputation and experience of the supplier can significantly impact pricing. Well-established suppliers may charge more due to their proven track record, but they often provide greater assurance of quality and service.

-

Incoterms: Understanding the delivery terms and responsibilities can impact the total cost. For international transactions, clarifying who bears the costs of shipping and insurance can help avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in AGV Software Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term partnerships.

-

Total Cost of Ownership (TCO): Assess not only the initial price but also the long-term costs associated with maintenance, updates, and potential scalability. This broader perspective can lead to better investment decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that may apply when sourcing from international suppliers. These factors can significantly affect the overall cost.

-

Seek Multiple Quotes: Comparing quotes from different suppliers can help identify competitive pricing and service offerings. This practice also empowers buyers during negotiations.

-

Leverage Technology: Utilize tools like cost calculators or ROI estimators provided by suppliers to assess the financial implications of the software investment. These tools can offer valuable insights into potential savings and efficiencies.

Disclaimer

The pricing information and analysis provided are indicative and may vary based on specific supplier offerings, market conditions, and individual buyer circumstances. Always conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing agv software With Other Solutions

Understanding Alternatives to AGV Software

In the realm of automated material handling, AGV software plays a crucial role in optimizing operations. However, various alternative solutions exist that can also enhance efficiency, depending on specific business needs and environments. This analysis will compare AGV software with two notable alternatives: Automated Mobile Robots (AMR) and traditional conveyor systems. Each option offers distinct advantages and drawbacks that B2B buyers should consider when making decisions.

| Comparison Aspect | AGV Software | Automated Mobile Robots (AMR) | Conveyor Systems |

|---|---|---|---|

| Performance | High efficiency in structured environments | Excellent flexibility and adaptability | Reliable for consistent, high-volume flow |

| Cost | Moderate initial investment; lower operational costs | Higher initial investment; variable operational costs | Lower upfront cost; high maintenance costs |

| Ease of Implementation | Requires integration with existing systems | Can be deployed independently; easier to implement | Complex installation; often requires structural changes |

| Maintenance | Regular software updates needed; low physical maintenance | Moderate maintenance; software updates needed | High maintenance for mechanical parts |

| Best Use Case | Warehouses and manufacturing with defined paths | Dynamic environments with changing layouts | High-volume, linear processes like assembly lines |

What Are the Pros and Cons of Automated Mobile Robots (AMR)?

Automated Mobile Robots (AMR) represent a compelling alternative to AGV software. AMRs are designed to navigate autonomously in dynamic environments, adapting to changes in layout and workflow. One of their primary advantages is their flexibility; they can be deployed in various settings, from warehouses to hospitals. However, this adaptability comes at a cost—AMRs typically have a higher initial investment and can incur variable operational costs due to battery maintenance and software updates. They excel in applications where the environment is not static, making them suitable for businesses that experience frequent changes in layout or inventory.

How Do Traditional Conveyor Systems Compare?

Traditional conveyor systems have long been a staple in material handling, especially for high-volume applications. They offer reliability and consistent performance, particularly in linear processes like assembly lines. One of their significant advantages is the lower upfront cost compared to AGV systems. However, they are not without challenges; conveyor systems often require substantial infrastructure investment and can be costly to maintain due to mechanical wear and tear. They are best utilized in environments where the workflow is predictable and does not change frequently.

Making the Right Choice for Your Business Needs

Choosing the right solution for automated material handling involves evaluating your specific operational needs, budget constraints, and the flexibility required in your processes. AGV software provides an effective solution for structured environments that benefit from precise navigation and control. Conversely, AMRs offer flexibility and adaptability for changing layouts, while traditional conveyor systems are best for high-volume, consistent workflows. By analyzing these factors, B2B buyers can make informed decisions that align with their operational goals and financial resources, ultimately leading to enhanced productivity and efficiency.

Essential Technical Properties and Trade Terminology for agv software

What Are the Critical Technical Properties of AGV Software?

When evaluating AGV software, certain technical properties are essential to ensure that the system meets operational needs and integrates seamlessly into existing workflows. Here are several critical specifications:

-

Fleet Management Capability

– Definition: This feature allows for the centralized control and monitoring of multiple AGVs within a fleet. It encompasses scheduling, task assignment, and performance tracking.

– Importance: Effective fleet management maximizes efficiency and reduces downtime, enabling companies to optimize resource allocation, manage workloads, and improve overall productivity. -

Navigation Precision

– Definition: This refers to the accuracy with which AGVs can determine their position and navigate through a defined environment. This includes both indoor and outdoor navigation systems.

– Importance: High-precision navigation minimizes the risk of collisions and ensures that AGVs can operate in dynamic environments, thus enhancing safety and operational efficiency. -

Integration Flexibility

– Definition: The ability of AGV software to integrate with existing systems such as Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES) through APIs or middleware.

– Importance: Seamless integration reduces operational silos, enhances data flow, and allows for more informed decision-making, ultimately leading to smoother operations and better ROI. -

Scalability

– Definition: This property measures how easily the AGV system can expand to accommodate additional vehicles or increased workload without significant reconfiguration.

– Importance: Scalability ensures that businesses can grow and adapt their operations without the need for complete system overhauls, making it a critical factor for long-term investments. -

Real-Time Data Processing

– Definition: The software’s capability to process and analyze data in real-time, allowing for immediate responses to operational changes.

– Importance: Real-time data helps in making timely adjustments to operations, improving efficiency, and maintaining high service levels in fast-paced environments.

What Are Common Trade Terminologies in AGV Software?

Understanding industry jargon is crucial for effective communication and negotiation in the AGV software market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: In the context of AGVs, knowing OEMs helps buyers identify reliable suppliers and understand the compatibility of various components. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQs is essential for budget planning, especially for smaller businesses that may not need large quantities of AGVs or software licenses. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and other details for specific products or services.

– Importance: An RFQ allows buyers to gather competitive pricing and terms, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps businesses understand shipping responsibilities, costs, and risks, which is critical when sourcing AGVs from international suppliers. -

VDA 5050

– Definition: A communication standard for AGV systems that enables interoperability among different manufacturers’ vehicles.

– Importance: Adopting this standard enhances flexibility and allows businesses to mix AGVs from various vendors without compatibility issues, leading to more efficient fleet management.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting AGV software, ensuring alignment with their operational goals and industry standards.

Navigating Market Dynamics and Sourcing Trends in the agv software Sector

What Are the Current Market Dynamics and Key Trends in AGV Software?

The automated guided vehicle (AGV) software market is experiencing substantial growth driven by the global push for automation and efficiency in logistics and manufacturing. Key factors influencing this market include the increasing demand for operational efficiency, enhanced supply chain management, and the need for real-time data analytics. In regions like Africa and South America, rapid industrialization and urbanization are propelling investments in AGV technologies, while European markets focus on integrating advanced automation solutions to maintain competitiveness.

Emerging trends in AGV software sourcing include the adoption of universal fleet control systems that allow for the management of diverse robot types across various environments. This flexibility is particularly advantageous for international buyers who operate in multi-vendor ecosystems. Moreover, cloud-based solutions are gaining traction, enabling businesses to scale their operations without heavy upfront investments in hardware. As industries increasingly adopt Industry 4.0 principles, the integration of AGV software with existing systems such as ERP and WMS is becoming a crucial consideration for B2B buyers.

Illustrative image related to agv software

In addition, the rise of artificial intelligence (AI) and machine learning (ML) in AGV software is transforming operational capabilities, enhancing navigation and fleet management efficiency. This is particularly relevant for buyers in dynamic markets, where adaptability and responsiveness to changes in demand are critical.

How Does Sustainability Influence Sourcing Decisions in AGV Software?

Sustainability is becoming a critical factor in the sourcing of AGV software, driven by increasing environmental regulations and consumer demand for responsible business practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to reducing their environmental impact through sustainable practices. This encompasses the use of eco-friendly materials in the development of AGV systems and software, as well as energy-efficient operations.

Ethical sourcing is essential in the AGV software sector, where companies are expected to ensure that their supply chains uphold labor rights and promote fair trade practices. Buyers are increasingly looking for partners who can provide transparency in their sourcing processes and possess certifications that validate their commitment to sustainability.

Furthermore, the demand for ‘green’ certifications is rising, compelling software developers to adopt sustainable methodologies in their AGV solutions. This includes optimizing software for energy efficiency and enabling clients to monitor and reduce their carbon footprints through advanced analytics. By aligning with sustainable practices, businesses can enhance their brand reputation while also meeting regulatory requirements, making sustainability not just a moral imperative but a strategic business advantage.

What Is the Brief Evolution and History of AGV Software?

The evolution of AGV software can be traced back to the early 20th century when the first automated guided vehicles were introduced in manufacturing environments. Initially, these systems were rudimentary, relying on fixed paths and simple control mechanisms. However, as technology advanced, so did the complexity and functionality of AGV software. The introduction of sensors, advanced navigation algorithms, and real-time data processing revolutionized the capabilities of AGVs, allowing them to operate autonomously in dynamic environments.

The past two decades have seen a significant shift towards software that integrates seamlessly with other business systems, such as warehouse management and enterprise resource planning software. This integration has been essential for companies seeking to optimize their operations and improve overall efficiency. Today, AGV software continues to evolve, incorporating AI and machine learning to further enhance navigation and fleet management, making it a pivotal element in the ongoing automation revolution across various industries.

As a result, international B2B buyers must stay informed about these developments to leverage the full potential of AGV software in their operations, ensuring they choose the right solutions to meet their evolving needs.

Frequently Asked Questions (FAQs) for B2B Buyers of agv software

-

How do I choose the right AGV software for my business needs?

Choosing the right AGV software involves assessing your specific operational requirements, such as fleet size, navigation needs, and integration capabilities with existing systems (like ERP or WMS). Consider factors like software scalability, ease of use, and the level of customization required for your operations. Consulting with suppliers about their software features, support, and past client experiences can also help inform your decision. Additionally, consider conducting a pilot program to evaluate the software’s performance in your environment. -

What are the key features to look for in AGV software?

Key features to look for in AGV software include fleet management capabilities, advanced navigation options (such as natural navigation), mapping tools, and seamless integration with other software systems. Look for real-time monitoring and reporting features that allow for efficient management and optimization of AGV operations. Additionally, ensure the software supports different AGV types and can be easily customized to meet your specific operational needs. -

What is the average lead time for AGV software implementation?

The average lead time for implementing AGV software can vary significantly depending on the complexity of the system and the size of your fleet. Generally, implementation can take anywhere from a few weeks to several months. Factors that influence this timeline include the need for customization, integration with existing systems, and the training of staff. Early communication with the software provider about your timeline and expectations can help streamline the process. -

How can I ensure the AGV software is compatible with my existing systems?

To ensure compatibility, first, identify the software standards and protocols your existing systems utilize. Most modern AGV software providers offer integration capabilities with popular systems like MES and WMS. Request detailed documentation from potential vendors regarding their software’s integration capabilities and inquire about past experiences integrating with similar systems. A demo or trial phase can also help confirm compatibility before a full commitment. -

What are the typical payment terms for AGV software purchases?

Payment terms for AGV software can vary widely among suppliers. Common practices include upfront payments, payment upon delivery, or installment plans based on milestones. Some vendors may also offer subscription models for their software as a service (SaaS). It’s essential to discuss payment terms upfront and ensure they align with your budget and financial processes. Additionally, understanding warranty and support terms can provide further clarity on the overall cost. -

What customization options are available for AGV software?

Most AGV software providers offer a range of customization options to tailor the software to your specific operational needs. Customization can include adapting user interfaces, adjusting reporting features, or integrating specific functionalities relevant to your industry. Discuss your requirements with potential vendors early in the procurement process to understand the extent of customization they can provide and any associated costs. -

How do I evaluate AGV software vendors for quality assurance?

Evaluating AGV software vendors for quality assurance involves assessing their track record, client testimonials, and case studies. Look for vendors that provide comprehensive support and maintenance services, as well as those that adhere to industry standards. Certifications and compliance with international quality standards can also be indicators of a reliable vendor. Consider arranging site visits or consultations to gauge their operational capabilities and customer service. -

What logistical considerations should I keep in mind when sourcing AGV software internationally?

When sourcing AGV software internationally, consider logistics such as shipping times, customs regulations, and potential tariffs. Understand the vendor’s support capabilities in your region, including language barriers and time zone differences. Additionally, evaluate the vendor’s ability to provide timely updates and support remotely. Building strong communication channels with the supplier can help mitigate logistical challenges and ensure a smooth implementation process.

Top 9 Agv Software Manufacturers & Suppliers List

1. WEWO Techmotion – AGV Software Solutions

Domain: wewo-techmotion.com

Registered: 2019 (6 years)

Introduction: AGV Software from WEWO Techmotion includes advanced software solutions for automated guided vehicles (AGVs) that cover navigation, steering, transport management, and traffic control. Key components of the AGV software include: 1. Fleet Management Software: Controls and manages AGVs in various environments, compatible with other systems like MES or ERP. 2. Navigation Software: Supports natural nav…

2. MHI – Automated Guided Vehicles

Domain: spectra.mhi.com

Registered: 1998 (27 years)

Introduction: Automated Guided Vehicles (AGVs) are autonomous, driverless materials-handling machines used to move goods in various facilities such as warehouses, factories, and hospitals. They address labor shortages by automating repetitive tasks, allowing human workers to focus on more complex jobs. AGVs utilize internal navigation systems, which can include reflector tape or laser navigation, and are contro…

3. Navitec Systems – AGV & AMR Software Solutions

Domain: navitecsystems.com

Registered: 2013 (12 years)

Introduction: Navitec Systems offers AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) software solutions, including a complete software stack for navigation, AGV controls, and fleet management. Key features include:

– Universal Fleet Control compatible with VDA5050 for diverse fleets

– Indoor and full 3D outdoor advanced natural feature navigation

– Robust navigation capabilities in any envir…

4. KINEXON – AMR & AGV Fleet Management Solution

Domain: kinexon.com

Registered: 2013 (12 years)

Introduction: The KINEXON AMR & AGV Fleet Management solution offers real-time control and orchestration of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) from different vendors in a unified fleet management solution. Key features include:

– Vendor-agnostic software that allows for the integration of any robot type from any vendor.

– Ability to scale AGV/AMR projects across plants and diff…

5. Kollmorgen – Autonomous Mobile Solutions

Domain: kollmorgen.com

Registered: 1995 (30 years)

Introduction: Kollmorgen’s Autonomous Mobile Solutions (AGV & AMR) provide a complete automation solution for AGV and AMR providers, focusing on precision and reliability across various industries. Key components include:

1. **NDC Solutions**: An industry-leading AGV/AMR platform for driverless logistics automation, combining software for fleet management and hardware for vehicle navigation and control.

2. **S…

6. RoboTeq – RoboAGVSim

Domain: roboteq.com

Registered: 2002 (23 years)

Introduction: {“name”: “RoboAGVSim”,”version”: “v1.1″,”release_date”: “February 27, 2018″,”size”: “2.6 MB”,”description”: “RoboAGVSim is a PC-based simulator for simplifying development of line-following navigation and kinematics on Mobile Robots. With RoboAGVSim, Mobile Robots designers program, test and fine tune their Vehicles in the comfort of their PC. The simulated AGV will move according to the user prog…

7. Rocla – FleetController

Domain: rocla-agv.com

Registered: 2002 (23 years)

Introduction: FleetController is a next-generation software solution for Automated Guided Vehicles (AGVs) that enhances efficiency and ease of use. It connects with Warehouse Management Systems (WMS) to optimize orders and routes for material flow. Key features include a Dashboard for monitoring and managing AGV fleets, a flexible platform for easy integration, and proprietary Order and Route Optimizer algorith…

8. Dematic – Automated Guided Vehicles (AGVs)

Domain: dematic.com

Registered: 1997 (28 years)

Introduction: Automated Guided Vehicles (AGVs) are driverless robots used for transporting materials in warehouses, distribution centers, and manufacturing facilities. Key benefits include reduced labor costs, increased order throughput, improved accuracy, and enhanced productivity. AGVs operate autonomously, minimizing human errors and ensuring redundancy in system operation. They can lift, rotate, and shift l…

9. AGILOX – AMR & AGV Software Solutions

Domain: agilox.net

Registered: 2015 (10 years)

Introduction: AGILOX offers AMR & AGV software with X-SWARM technology, including products like AGILOX ONE, AGILOX OFL, AGILOX OCF, and AGILOX ODM. The software enables efficient material handling processes through in-house developed mechanics, electronics, automation, and navigation. Key features include:

– Fast integration: First AMR operational in under 12 hours, additional AMRs in under 20 minutes.

– Easy …

Strategic Sourcing Conclusion and Outlook for agv software

In the rapidly evolving landscape of automated guided vehicle (AGV) software, strategic sourcing emerges as a crucial lever for optimizing operational efficiency and driving competitive advantage. By investing in advanced AGV solutions that encompass fleet management, navigation, and mapping software, businesses can achieve seamless integration across their logistics and production environments. The ability to customize software to specific operational needs, as highlighted by industry leaders, ensures that companies can adapt to diverse applications and environments—from manufacturing to warehousing.

For international B2B buyers, particularly in emerging markets like Nigeria and Brazil, the strategic selection of AGV software can significantly enhance productivity while minimizing costs. Establishing partnerships with reputable AGV software providers not only facilitates access to cutting-edge technology but also ensures ongoing support and innovation tailored to regional challenges.

Illustrative image related to agv software

Looking ahead, the demand for AGV software is set to grow, fueled by the increasing need for automation and efficiency in logistics and manufacturing. We encourage businesses in Africa, South America, the Middle East, and Europe to explore the potential of AGV technology and leverage strategic sourcing to future-proof their operations. Engage with industry experts today to unlock the full potential of your automated systems and stay ahead in the competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to agv software