Altitude Chambers: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for altitude chambers

Navigating the complexities of sourcing altitude chambers for diverse applications poses a significant challenge for international B2B buyers. As industries from sports and military training to medical research increasingly recognize the benefits of hypoxic environments, understanding the intricacies of these systems becomes essential. This comprehensive guide delves into the multifaceted world of altitude chambers, exploring various types—including modular and conversion chambers—alongside their diverse applications.

Buyers will gain insights into crucial factors such as supplier vetting, technical specifications, and cost considerations, empowering them to make informed purchasing decisions. Whether you’re a business in Nigeria seeking altitude training solutions for athletes, or a research facility in Europe aiming to enhance your hypoxia studies, this guide is tailored to meet your specific needs.

By addressing the unique requirements of international markets, particularly in Africa, South America, the Middle East, and Europe, we provide actionable insights that facilitate strategic investments in altitude chamber technology. With this knowledge, buyers can confidently navigate the global market, ensuring they select the right altitude chamber to enhance performance, safety, and research outcomes.

Understanding altitude chambers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conversion Chamber | Utilizes existing spaces, customizable size and design | Fitness centers, rehabilitation clinics | Pros: Cost-effective; Cons: Limited scalability if space is constrained. |

| Modular Chamber | Prefabricated, expandable, and relocatable | Research facilities, military training | Pros: Versatile; Cons: Higher initial investment. |

| Environmental Chamber | Simulates various climates along with altitude | Environmental research, product testing | Pros: Comprehensive; Cons: Complex operation and maintenance. |

| Hypobaric Chamber | Creates hypoxic conditions through pressure changes | Aviation training, military applications | Pros: Realistic altitude simulation; Cons: Requires heavy-duty materials and safety measures. |

| Normobaric Chamber | Maintains air pressure while reducing oxygen levels | Sports training, acclimatization for athletes | Pros: Safe and flexible; Cons: May require specific technical expertise for setup. |

What are the Characteristics of Conversion Chambers?

Conversion chambers are designed to transform existing spaces into altitude training environments. They can be installed in various locations, from small rooms to larger facilities, making them a flexible option for businesses looking to implement altitude training without extensive renovations. These chambers are particularly suitable for fitness centers and rehabilitation clinics where space is already at a premium. Buyers should consider the dimensions of the existing space and the intended usage patterns to ensure optimal functionality.

How Do Modular Chambers Enhance Versatility?

Modular chambers offer prefabricated designs that can be expanded, disassembled, and relocated, making them ideal for organizations with changing needs. They cater to research facilities and military training environments where adaptability is crucial. When purchasing a modular chamber, businesses should assess their long-term requirements, including potential expansion and relocation needs, as well as the initial investment costs associated with these systems.

What Makes Environmental Chambers Unique?

Environmental chambers are capable of simulating a wide range of climate conditions, including temperature and humidity variations alongside altitude adjustments. This versatility makes them suitable for environmental research and product testing. Companies looking to invest in an environmental chamber should evaluate the complexity of operations and maintenance, as well as the specific environmental parameters required for their testing protocols.

Why Choose Hypobaric Chambers for Military and Aviation Training?

Hypobaric chambers create hypoxic conditions by altering air pressure, which is essential for realistic training scenarios in aviation and military applications. These chambers are built to high industrial standards, ensuring safety and reliability. However, buyers should be aware of the significant investment in materials and the necessary safety protocols required for operation. Organizations must weigh the benefits of realistic training against the logistical challenges of installation and maintenance.

How Do Normobaric Chambers Benefit Athletes?

Normobaric chambers maintain ambient air pressure while reducing oxygen levels, offering a safe and flexible training environment for athletes. They are particularly beneficial for sports training and acclimatization, allowing users to experience altitude effects without the risks associated with pressure changes. When considering a normobaric chamber, buyers should focus on the technical expertise required for setup and operation, as well as the adaptability of the chamber for various training regimens.

Key Industrial Applications of altitude chambers

| Industry/Sector | Specific Application of Altitude Chambers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Fitness | Altitude Training for Athletes | Enhances endurance, speed, and recovery in athletes | Customization for specific sports, size, and user capacity |

| Aviation and Aerospace | Hypoxia Training for Aircrew | Prepares personnel for high-altitude flight conditions | Compliance with aviation standards and safety regulations |

| Military | Rapid Decompression and Hypoxia Training | Ensures readiness for high-altitude missions | Robust construction to handle rigorous training scenarios |

| Healthcare and Rehabilitation | Therapy for Respiratory Conditions | Aids in patient recovery and acclimatization | Integration with medical facilities and climate control features |

| Research and Development | Environmental and Climatic Studies | Facilitates research on human performance in extreme conditions | Versatility in design for various research parameters |

How Are Altitude Chambers Used in Sports and Fitness Training?

Altitude chambers are integral to sports training, allowing athletes to simulate high-altitude environments. This controlled setting helps improve oxygen efficiency, enhancing endurance, speed, and recovery times. For B2B buyers in regions like Africa and South America, sourcing altitude chambers involves ensuring they meet specific athletic needs, including customization for various sports and accommodating multiple users simultaneously. The ability to integrate climate control features is also vital for optimizing training conditions.

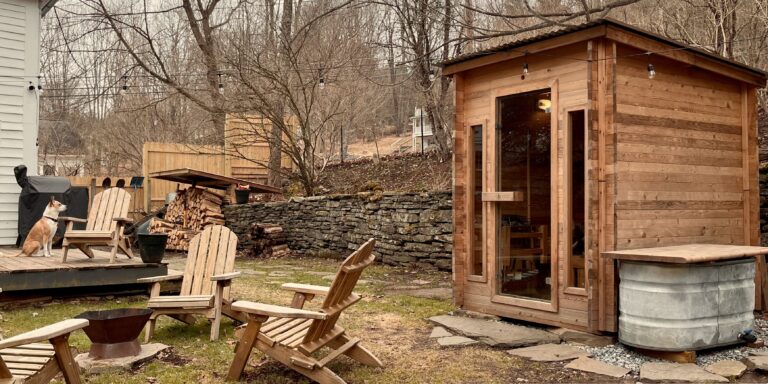

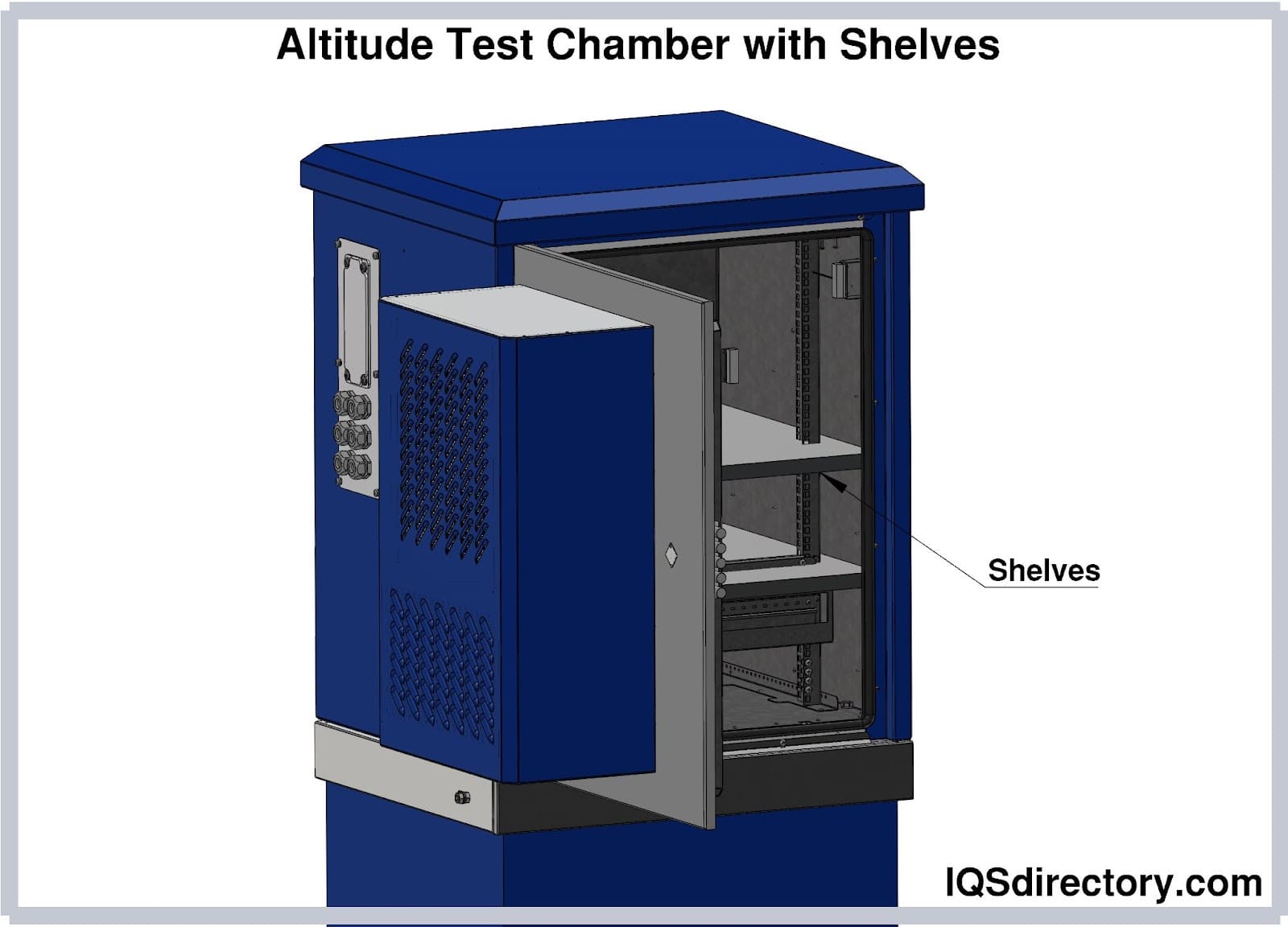

Illustrative image related to altitude chambers

What Role Do Altitude Chambers Play in Aviation and Aerospace Training?

In the aviation sector, altitude chambers are crucial for hypoxia training, enabling aircrew to experience low-oxygen conditions safely. This training prepares personnel for the physiological challenges faced at high altitudes, ensuring they can recognize and respond to hypoxia effectively. Buyers in Europe and the Middle East must consider compliance with strict aviation standards and the capability for automated training scenarios. Additionally, the chambers should be designed for easy monitoring and control to enhance training effectiveness.

How Are Military Applications Enhanced by Altitude Chambers?

Military organizations utilize altitude chambers for rapid decompression and hypoxia training, essential for preparing personnel for high-altitude operations. These chambers simulate the rapid pressure changes that can occur in flight, allowing soldiers to practice emergency response procedures. For buyers in regions with active military training programs, sourcing durable chambers that can withstand intensive use is crucial. Considerations should include safety features and the ability to conduct various training exercises simultaneously.

In What Ways Do Altitude Chambers Benefit Healthcare and Rehabilitation?

In healthcare, altitude chambers are used for therapeutic purposes, particularly for patients with respiratory conditions. They create a controlled environment that aids in acclimatization and recovery, making them valuable assets in rehabilitation centers. B2B buyers from the healthcare sector need to ensure that chambers are integrated with medical facilities and equipped with advanced climate control features. Additionally, compliance with health regulations is essential for safe patient use.

How Do Altitude Chambers Support Research and Development?

Altitude chambers are increasingly utilized in research settings to study human performance under extreme conditions. They enable scientists to conduct experiments on how altitude affects physiology, which is critical for developing training programs and safety protocols. Buyers in research institutions should prioritize versatility in design to accommodate various experimental setups. Furthermore, sourcing chambers with precise control over environmental variables, such as temperature and humidity, is vital for accurate research outcomes.

3 Common User Pain Points for ‘altitude chambers’ & Their Solutions

Scenario 1: Managing Operational Costs of Altitude Chambers

The Problem: B2B buyers often face the challenge of high operational costs associated with altitude chambers, particularly in regions where energy prices are volatile or where infrastructure may not support advanced technologies. These costs can stem from energy consumption during operation, maintenance of sophisticated systems, and the need for specialized personnel to manage the equipment. For businesses operating in Africa or South America, where budgets may be tight, these expenses can deter investment in altitude training solutions.

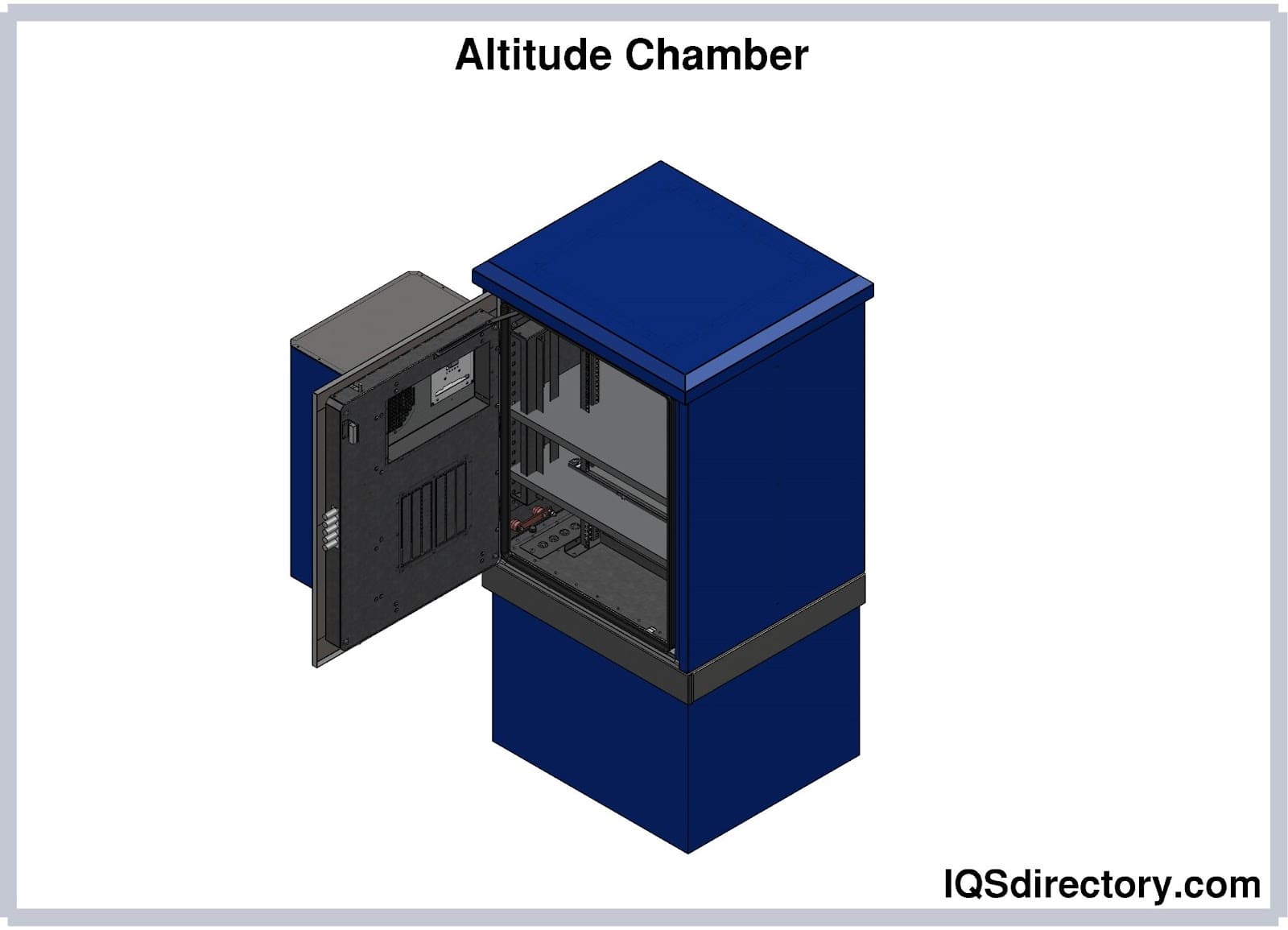

Illustrative image related to altitude chambers

The Solution: To mitigate operational costs, buyers should consider investing in altitude chambers designed for energy efficiency. When sourcing these chambers, look for features such as EcoMode settings that optimize energy use without compromising performance. Additionally, consider modular systems that allow for scalability; as your needs grow, you can expand your chamber without the need for a complete overhaul. Furthermore, investing in training for existing personnel can reduce the reliance on specialized technicians. This approach not only minimizes operational costs but also enhances the chamber’s usability in various applications, from athletic training to rehabilitation.

Scenario 2: Ensuring Flexibility in Chamber Usage

The Problem: Many organizations struggle with the inflexibility of altitude chambers, which can limit their applications. For instance, a sports organization might require different altitude settings for various athletes, while a research facility may need to simulate specific environmental conditions. This lack of adaptability can lead to underutilization of the chamber, ultimately affecting return on investment.

The Solution: Buyers should prioritize altitude chambers that offer customizable settings and multiple operational modes. For instance, chambers with features that allow users to adjust altitude and oxygen concentration levels with precision can cater to diverse training and research needs. Look for systems that integrate climate control options, enabling users to simulate various environments such as humidity and temperature alongside altitude. Additionally, consider chambers that offer remote access and control via smartphones or tablets, allowing for real-time adjustments and scheduling flexibility. This adaptability ensures that the altitude chamber can be effectively utilized across different scenarios, maximizing its value.

Illustrative image related to altitude chambers

Scenario 3: Overcoming Safety Concerns with Altitude Training

The Problem: Safety is a paramount concern for organizations using altitude chambers, especially in sectors like military training or medical rehabilitation. Buyers often worry about the risks associated with hypoxia, rapid decompression, and other physiological effects that can occur during altitude simulation. These concerns can hinder the adoption of altitude chambers, as organizations seek to avoid liability and ensure the well-being of users.

The Solution: To address safety concerns, it is crucial for buyers to choose altitude chambers built with rigorous safety standards and features. Opt for chambers that provide comprehensive safety training for users and operators, ensuring they are well-informed about the physiological effects of altitude and how to respond in emergencies. Look for systems equipped with automated safety protocols, such as pressure monitoring and automatic oxygen adjustments, which can prevent hypoxia and other risks. Additionally, chambers that include real-time monitoring capabilities can alert users to any unsafe conditions. By prioritizing safety features and training, organizations can create a secure environment for altitude training, thus alleviating concerns and encouraging broader adoption.

Strategic Material Selection Guide for altitude chambers

When selecting materials for altitude chambers, it is essential to consider properties that impact performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the construction of altitude chambers, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Aluminum for Altitude Chambers?

Aluminum is a lightweight, corrosion-resistant metal often used in the construction of altitude chambers. Its excellent strength-to-weight ratio allows for easy installation and modification, making it suitable for both modular and conversion chambers. Aluminum can withstand varying temperatures and pressures, which is crucial for maintaining the integrity of the chamber during operation.

Pros: Aluminum’s lightweight nature reduces transportation costs and installation complexity. It is also relatively affordable compared to other metals, making it a cost-effective choice for many applications.

Cons: While durable, aluminum can be prone to denting and scratching, which may affect its long-term performance. Additionally, it may require protective coatings to enhance its resistance to certain chemicals.

Impact on Application: Aluminum’s compatibility with various environmental conditions makes it suitable for diverse applications, including sports training and military simulations. However, buyers should ensure that any coatings used do not interfere with the chamber’s hypoxic environment.

Illustrative image related to altitude chambers

How Does Stainless Steel Compare as a Material for Altitude Chambers?

Stainless steel is another popular choice for altitude chambers, known for its exceptional corrosion resistance and strength. It can withstand high pressures and temperatures, making it ideal for environments where durability is paramount.

Pros: The longevity of stainless steel is a significant advantage, as it requires less frequent replacement and maintenance. Its robust nature also allows for the construction of chambers that can accommodate a wide range of users and applications.

Cons: The primary drawback of stainless steel is its higher cost compared to aluminum. Additionally, it is heavier, which can complicate installation and relocation.

Impact on Application: Stainless steel is particularly well-suited for military and research applications where safety and durability are critical. Buyers must consider local regulations regarding material specifications, especially in regions with stringent safety standards.

What Role Does Composite Material Play in Altitude Chambers?

Composite materials, such as fiberglass or carbon fiber, are increasingly being used in altitude chamber construction due to their lightweight and high-strength properties. These materials are often utilized in modular designs, allowing for easy expansion and relocation.

Pros: Composites offer excellent thermal insulation and resistance to corrosion, which can enhance the chamber’s efficiency. Their lightweight nature simplifies transportation and installation.

Cons: Composites can be more expensive than traditional materials and may require specialized manufacturing processes. Additionally, they may not be as readily available in certain regions, which could impact lead times.

Impact on Application: Composites are ideal for high-performance applications, such as athlete training and rehabilitation. International buyers should verify the availability of composite materials in their region and consider potential supply chain challenges.

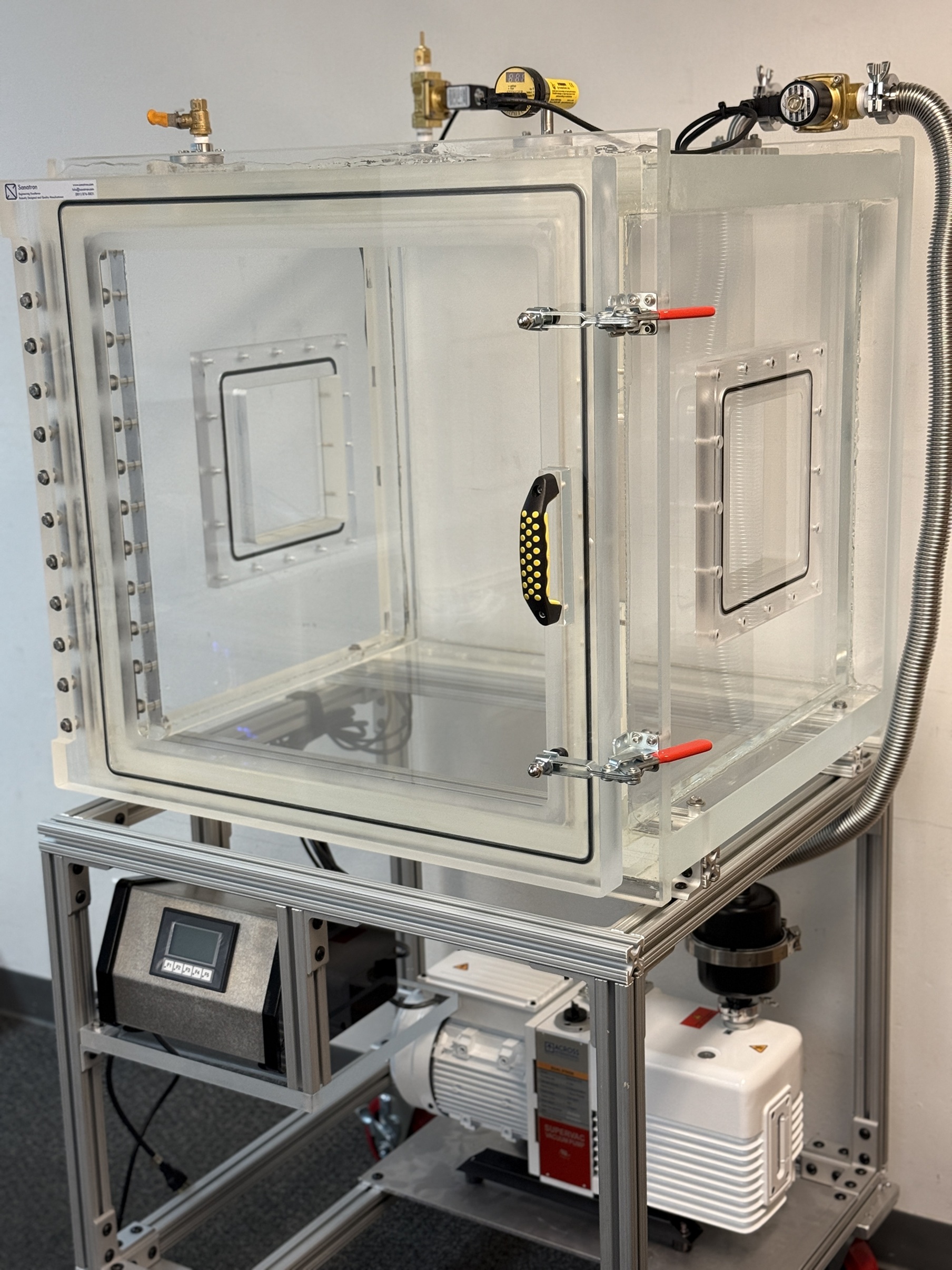

Why is Polycarbonate a Viable Option for Altitude Chambers?

Polycarbonate is a thermoplastic material known for its high impact resistance and optical clarity. It is often used for windows and viewing ports in altitude chambers, allowing for visibility while maintaining structural integrity.

Illustrative image related to altitude chambers

Pros: Polycarbonate is lightweight and provides excellent insulation properties. Its impact resistance makes it a safe choice for environments where accidents may occur.

Cons: While durable, polycarbonate can be susceptible to scratching and UV degradation over time. It may also require additional treatments to enhance its longevity.

Impact on Application: Polycarbonate is particularly useful in applications where visibility is essential, such as in training environments for athletes. Buyers should ensure that the chosen polycarbonate meets relevant safety and quality standards.

Illustrative image related to altitude chambers

Summary of Material Selection for Altitude Chambers

| Material | Typical Use Case for altitude chambers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Modular and conversion chambers | Lightweight and cost-effective | Prone to denting and scratching | Medium |

| Stainless Steel | Military and research applications | Exceptional durability and corrosion resistance | Higher cost and heavier weight | High |

| Composite | High-performance training environments | Excellent thermal insulation and lightweight | More expensive and may require special manufacturing | High |

| Polycarbonate | Windows and viewing ports | High impact resistance and visibility | Susceptible to scratching and UV degradation | Medium |

This guide provides a comprehensive overview of material options for altitude chambers, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for altitude chambers

What Are the Main Stages in the Manufacturing Process of Altitude Chambers?

The manufacturing process of altitude chambers is a multi-stage operation that demands precision and expertise to ensure optimal functionality and safety. The key stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials that can withstand the specific requirements of altitude simulation. Manufacturers typically utilize stainless steel or aluminum for their durability and resistance to corrosion. Materials undergo rigorous quality checks to ensure they meet international standards.

-

Forming: This stage involves cutting and shaping the materials into components such as walls, ceilings, and bases. Advanced techniques like laser cutting and CNC machining are employed to achieve precise dimensions. This precision is critical, as any miscalculations can lead to inefficiencies in the chamber’s performance.

-

Assembly: The assembly process requires skilled labor to put together the pre-manufactured components. This includes integrating systems for oxygen control, climate regulation, and airflow management. Each assembly line typically follows detailed engineering drawings to ensure that every component is correctly installed.

-

Finishing: The final stage includes surface treatments, painting, and quality assurance checks. Finishing not only enhances the aesthetic appeal of the altitude chamber but also protects against environmental wear and tear. This stage may also include the installation of user interfaces and safety features.

What Quality Control Standards Are Relevant for Altitude Chambers?

Quality control (QC) is a crucial aspect of manufacturing altitude chambers, ensuring that they meet both safety and performance standards. Various international and industry-specific standards guide the QC processes.

-

ISO 9001: This standard outlines the criteria for a quality management system. It is applicable to organizations that aim to enhance customer satisfaction through effective quality management practices. B2B buyers should look for suppliers certified under ISO 9001, as it indicates a commitment to quality and continuous improvement.

-

CE Marking: For products sold in the European market, CE marking is mandatory. It indicates that the product complies with EU safety, health, and environmental protection standards. Suppliers should provide documentation proving that their altitude chambers have undergone necessary evaluations.

-

API Standards: The American Petroleum Institute (API) sets standards that can be relevant for altitude chambers used in oil and gas training scenarios. These standards ensure that the chambers can perform under specific operational conditions.

What Are the Key QC Checkpoints During Manufacturing?

Quality control involves multiple checkpoints throughout the manufacturing process to ensure that each altitude chamber meets the required specifications.

Illustrative image related to altitude chambers

-

Incoming Quality Control (IQC): At this initial stage, raw materials and components are inspected upon arrival. This ensures that only materials meeting quality standards are used in the production process.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the assembly and integration of components. This includes verifying the accuracy of dimensions and the functionality of installed systems.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection is performed. This includes thorough testing of the altitude simulation capabilities, safety features, and overall system performance. Certifications and compliance documentation are often reviewed at this stage.

What Common Testing Methods Are Used for Altitude Chambers?

Testing methods are essential for validating the performance and safety of altitude chambers. Common techniques include:

-

Functional Testing: This involves simulating various altitude conditions to ensure that the chamber operates correctly and maintains the desired atmospheric parameters.

-

Safety Testing: Safety features, such as pressure relief valves and emergency shut-off systems, are rigorously tested to confirm they function as intended.

-

Durability Testing: Manufacturers may subject chambers to extended use conditions to assess their performance over time. This can include cycling through various altitude and pressure conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers adhere to high-quality manufacturing standards. Here are some actionable strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control practices, and adherence to international standards.

-

Request Quality Reports: Suppliers should be willing to provide documentation related to their quality control processes, including inspection reports, testing results, and certifications.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality assurance practices. These inspectors can verify compliance with relevant standards and provide detailed reports.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital:

-

Regional Compliance: Different regions may have specific regulations regarding safety and performance. Buyers should familiarize themselves with local standards to ensure compliance.

-

Documentation Requirements: When importing altitude chambers, customs may require specific documentation proving compliance with international standards. Buyers should ensure that suppliers provide all necessary paperwork.

-

Cultural Considerations: Communication barriers may arise when dealing with international suppliers. Establishing clear channels for discussing quality expectations and certifications can mitigate misunderstandings.

In summary, the manufacturing and quality assurance processes for altitude chambers are intricate and require careful attention to detail. B2B buyers should prioritize suppliers who demonstrate a commitment to quality through standardized processes and robust testing methods. By understanding these nuances, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘altitude chambers’

When sourcing altitude chambers, a systematic approach is essential to ensure you find a solution that meets your operational needs and budget constraints. This checklist provides a step-by-step guide to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements of the altitude chamber you need. Consider factors such as:

– Altitude Range: Determine the maximum altitude simulation required for your applications, whether for training or research.

– User Capacity: Identify how many active and passive users will utilize the chamber simultaneously.

Defining these specifications upfront ensures you select a chamber that aligns with your goals and operational constraints.

Step 2: Research Supplier Options

Conduct thorough research on potential suppliers of altitude chambers. Look for companies with a strong reputation in the industry and a proven track record. Key aspects to consider include:

– Experience and Expertise: Seek suppliers with extensive experience in manufacturing altitude chambers tailored to your specific needs.

– Client Testimonials: Review case studies and testimonials from similar organizations to gauge satisfaction and reliability.

A well-researched supplier list can significantly streamline your procurement process.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet each supplier meticulously. Request detailed information including:

– Company Profiles: Obtain insights into their manufacturing capabilities and technological innovations.

– Certifications and Compliance: Verify that the supplier meets international safety and quality standards relevant to altitude chambers.

This evaluation is crucial to ensure you partner with a reliable supplier capable of delivering high-quality products.

Step 4: Request Customization Options

Discuss customization possibilities with shortlisted suppliers. Given the diverse applications of altitude chambers, customization is often necessary. Pay attention to:

– Design Flexibility: Ensure the chamber can be tailored to fit your specific space requirements.

– Operational Features: Inquire about advanced features such as climate control, remote access, and safety protocols.

Customization can enhance the functionality of the chamber, aligning it more closely with your operational needs.

Illustrative image related to altitude chambers

Step 5: Assess Ongoing Support and Maintenance

Consider the level of ongoing support and maintenance offered by the supplier. A robust support system is vital for long-term operational efficiency. Look for:

– Technical Support: Ensure that the supplier provides comprehensive technical support for installation and operation.

– Maintenance Services: Inquire about routine maintenance packages to keep the chamber in optimal working condition.

Reliable support can prevent costly downtimes and ensure the chamber operates at peak performance.

Step 6: Compare Pricing and Financing Options

Obtain detailed quotes from multiple suppliers to facilitate price comparisons. When reviewing pricing, consider:

– Total Cost of Ownership: Evaluate not just the initial purchase price but also installation, maintenance, and operational costs.

– Financing Options: Explore financing alternatives that may be available, particularly for large-scale purchases.

A thorough financial analysis will help you make an informed decision that aligns with your budget constraints.

Step 7: Finalize Your Purchase Agreement

Once you’ve selected a supplier, ensure all terms are clearly defined in a purchase agreement. Key elements to include:

– Delivery Timeline: Specify expected delivery dates and any penalties for delays.

– Warranty Terms: Ensure warranty coverage is clearly stated to protect your investment.

A well-structured agreement can safeguard against potential disputes and ensure a smooth transaction.

By following this checklist, B2B buyers can navigate the complexities of sourcing altitude chambers with confidence, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for altitude chambers Sourcing

What are the Key Cost Components of Altitude Chambers?

When sourcing altitude chambers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to altitude chambers

-

Materials: The choice of materials significantly influences the cost. High-quality components for the chamber’s structure, insulation, and technology systems are essential for durability and performance. For instance, using standard building materials can reduce costs compared to specialized materials required for hypobaric chambers.

-

Labor: Installation and assembly labor costs can vary based on the complexity of the chamber design and the location of installation. Custom chambers may require skilled labor for both assembly and ongoing maintenance.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: Custom tooling may be needed for specialized designs. This initial investment can affect the pricing, particularly for unique or highly customized chambers.

-

Quality Control (QC): Ensuring the chamber meets safety and performance standards involves rigorous testing and quality assurance processes, which add to the overall cost. Certifications from recognized standards can further influence pricing.

-

Logistics: Shipping and handling costs vary widely based on the chamber’s size and weight, as well as the distance to the buyer’s location. International shipping may also involve tariffs and customs fees.

-

Margin: Supplier margins can differ based on their market positioning and brand reputation. Established manufacturers often charge higher prices due to their reliability and service history.

What Influences the Price of Altitude Chambers?

Several factors can influence the pricing of altitude chambers, including:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Manufacturers may offer tiered pricing based on the minimum order quantity (MOQ), making it advantageous for buyers looking to equip multiple facilities.

-

Specifications/Customization: Custom features such as specific altitude ranges, climate controls, or integration with existing systems can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality: Higher-quality materials and advanced technology will naturally drive up costs. Buyers should assess the long-term benefits of investing in quality against the initial price.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge a premium but often provide greater assurance in terms of product performance and customer support.

-

Incoterms: Understanding the agreed Incoterms can affect the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping and insurance costs, impacting the final pricing.

What Tips Can Help Buyers Optimize Costs for Altitude Chambers?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, here are actionable tips to optimize costs:

-

Negotiate Terms: Engage suppliers in discussions to negotiate better terms, especially for bulk purchases. Leverage competitive quotes from multiple suppliers to enhance your bargaining position.

-

Focus on Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, installation, maintenance, and operational costs. A lower initial price may lead to higher costs in the long run if the chamber requires frequent repairs or inefficient operation.

-

Understand Pricing Nuances: Be aware of regional pricing differences and currency fluctuations, which can impact costs when importing chambers. Consider local suppliers who can provide more favorable terms and lower logistics costs.

-

Request Detailed Quotes: Ensure quotes include all components of the pricing structure. This transparency helps identify potential hidden costs and provides a clearer picture for budget planning.

Conclusion

Sourcing altitude chambers involves a multifaceted cost structure influenced by various factors. By understanding these components and price influencers, international B2B buyers can make more informed decisions, negotiate better deals, and ultimately optimize their investment in altitude chamber technology. Always request indicative pricing from suppliers while considering the specific needs of your application and market conditions.

Alternatives Analysis: Comparing altitude chambers With Other Solutions

Understanding Alternatives to Altitude Chambers

When considering altitude training or hypoxia simulation, altitude chambers are a popular choice. However, various alternative solutions and methods exist that may cater to specific needs or preferences. Understanding these options can help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison of Altitude Chambers and Alternative Solutions

| Comparison Aspect | Altitude Chambers | Hypobaric Chambers | Portable Hypoxia Training Systems |

|---|---|---|---|

| Performance | Simulates up to 30,000 feet; adjustable oxygen levels; safe and flexible | Simulates high altitude through pressure changes; requires strict safety protocols | Provides controlled hypoxia conditions; limited to specific training scenarios |

| Cost | Varies; often more cost-effective due to standard materials; long-term investment | Generally more expensive due to complex construction and maintenance | Lower initial cost, but limited functionalities may require additional purchases |

| Ease of Implementation | Customizable; can be integrated into existing spaces; minimal construction | Requires significant space and specialized construction; not easily relocatable | Highly portable; easy setup; ideal for small-scale training |

| Maintenance | Requires routine checks; low maintenance with standard components | High maintenance due to complex systems and safety requirements | Minimal maintenance needed; easy to transport and store |

| Best Use Case | Ideal for athletic training, rehabilitation, and research; versatile for various environments | Best for military and aviation training; suitable for high-pressure environment simulations | Excellent for field training and small group sessions; convenient for remote locations |

In-Depth Look at Alternative Solutions

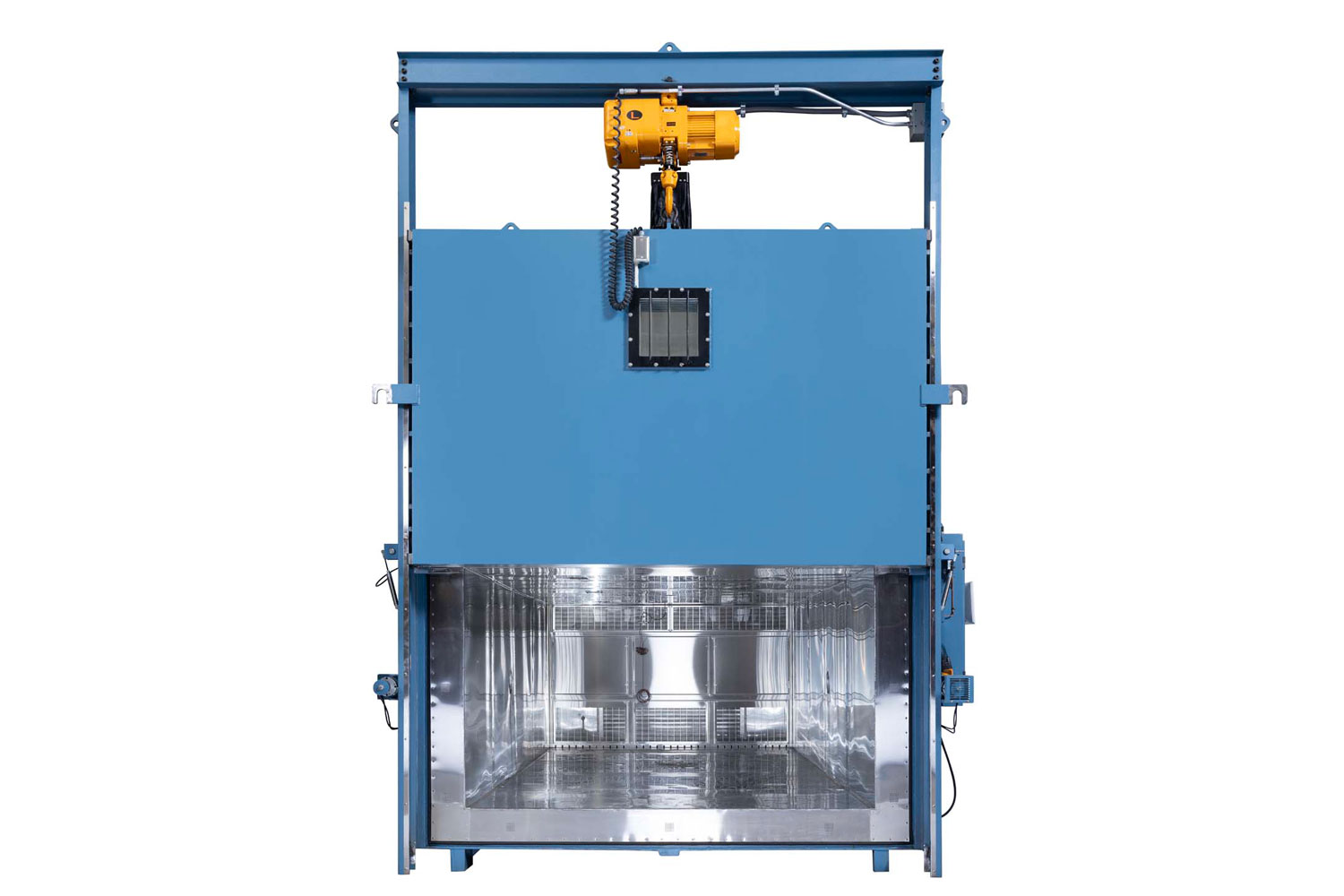

Hypobaric Chambers

Hypobaric chambers simulate high-altitude conditions by reducing atmospheric pressure. While they can effectively replicate the physiological effects of high altitudes, they come with significant drawbacks. The construction involves specialized materials and safety measures to prevent risks associated with pressure changes, making them costly and complex to implement. Their primary use case revolves around military and aviation training, where precise control over pressure changes is essential.

Illustrative image related to altitude chambers

Portable Hypoxia Training Systems

Portable hypoxia training systems offer a more accessible solution for simulating low-oxygen environments. These systems are designed for easy transport and quick setup, making them ideal for field training scenarios or smaller groups. However, they tend to provide limited functionalities compared to altitude chambers and are best suited for specific training sessions rather than comprehensive altitude acclimatization. Their lower initial costs are appealing, but they may not deliver the same level of training depth as altitude chambers.

Making the Right Choice for Your Organization

Choosing between altitude chambers and their alternatives depends largely on your specific requirements and operational context. If your focus is on versatility and comprehensive training for various applications, altitude chambers present a robust solution. In contrast, if budget constraints or portability are key considerations, exploring portable hypoxia training systems may be beneficial. Hypobaric chambers, while effective for specialized training, require a higher investment and commitment to safety protocols. Ultimately, evaluating the unique needs of your organization will guide you in selecting the most appropriate solution for altitude training and hypoxia simulation.

Essential Technical Properties and Trade Terminology for altitude chambers

What Are the Essential Technical Properties of Altitude Chambers?

When considering the procurement of altitude chambers, understanding their technical specifications is crucial for ensuring they meet operational needs. Here are some key properties to consider:

1. Altitude Simulation Range

Altitude chambers can simulate conditions from sea level up to 30,000 feet. This range is vital for various applications, including athletic training, research, and military simulations. B2B buyers should assess their specific altitude requirements to ensure the chamber can accommodate their operational needs without compromise.

2. Airflow Capacity

The airflow capacity, measured in liters per minute, determines how effectively the chamber can maintain hypoxic conditions. For instance, a high-capacity system may provide up to 16,000 liters per minute, supporting multiple users simultaneously. This specification is particularly important for commercial applications where efficiency and user experience are paramount.

3. Construction Materials

Altitude chambers are typically constructed from durable materials that can withstand varying pressure and environmental conditions. The choice of materials affects not only the chamber’s longevity but also its safety and operational efficiency. Buyers should inquire about the material grades used to ensure compliance with industry standards and regulations.

4. Control Systems

Modern altitude chambers come equipped with sophisticated control systems that allow for precise adjustments to oxygen levels, temperature, and humidity. Features such as remote access via smartphone or tablet enhance usability, enabling operators to monitor and adjust conditions in real-time. Understanding these control features is essential for optimizing chamber performance.

5. Safety Features

Safety is paramount in altitude chamber design. Look for features such as multi-level access controls, automated emergency protocols, and CO2 monitoring systems. These elements are critical for protecting users and ensuring compliance with health and safety regulations, making them a focal point for B2B buyers.

Which Trade Terminology Should B2B Buyers Understand in the Altitude Chamber Market?

Navigating the altitude chamber market requires familiarity with specific trade terminology. Here are some common terms that can aid decision-making:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of altitude chambers, knowing the OEM can help buyers gauge the quality and reliability of the equipment, as well as the potential for customization.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ for altitude chambers can help businesses manage inventory and budget considerations effectively, especially for smaller companies or those testing the market.

Illustrative image related to altitude chambers

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific products or services. For altitude chambers, issuing an RFQ allows buyers to compare pricing, features, and terms from multiple manufacturers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk management, and the logistics of acquiring altitude chambers from international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the context of altitude chambers, understanding lead times is essential for project planning, especially for businesses that require quick implementation for training or research purposes.

By grasping these essential technical properties and industry terms, B2B buyers can navigate the altitude chamber market more effectively, ensuring they make informed decisions that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the altitude chambers Sector

What Are the Current Market Dynamics and Key Trends in the Altitude Chambers Sector?

The altitude chambers market is witnessing significant growth, propelled by a variety of global drivers. The increasing demand for altitude simulation in sectors such as sports training, military applications, and medical research is a primary factor. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in altitude chambers due to the rising awareness of hypoxia training benefits and its applications in acclimatization, rehabilitation, and performance enhancement.

Emerging technologies are reshaping the sourcing landscape. Innovations such as normobaric hypoxia systems, which allow for flexible chamber designs without needing heavy industrial materials, are gaining traction. This trend provides B2B buyers with options that are not only cost-effective but also easier to install and maintain. Furthermore, digital integration through remote access capabilities for monitoring and controlling altitude settings via mobile devices is becoming essential, allowing for streamlined operations in various environments.

Another notable trend is the increasing customization of altitude chambers. As businesses seek tailored solutions that meet specific operational needs, manufacturers are responding with modular and conversion chambers that can be adapted to various spaces. This flexibility is particularly appealing to buyers in diverse markets, enabling them to integrate altitude chambers into existing facilities or new constructions seamlessly. As the market evolves, understanding these dynamics will be crucial for B2B buyers aiming to capitalize on the growing demand for altitude simulation technologies.

How Is Sustainability and Ethical Sourcing Addressed in the Altitude Chambers Industry?

Sustainability has become a focal point in the altitude chambers sector, driven by increasing consumer awareness and regulatory pressures. B2B buyers are now prioritizing environmentally responsible sourcing practices, recognizing that the materials and processes involved in manufacturing altitude chambers can significantly impact the environment. Companies are encouraged to choose suppliers that utilize sustainable materials and practices, such as recyclable components and energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for manufacturers who demonstrate transparency in their sourcing practices and labor policies. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability. These certifications not only assure buyers of the ecological impact of their purchases but also enhance brand reputation in a competitive marketplace.

Moreover, the push for sustainable practices aligns with global trends towards reducing carbon footprints and promoting corporate social responsibility. As altitude chamber technology continues to advance, the integration of eco-friendly materials and processes will likely become a key differentiator among suppliers, impacting purchasing decisions across various industries.

How Have Altitude Chambers Evolved Over Time to Meet B2B Needs?

The evolution of altitude chambers has been marked by significant technological advancements that cater to the specific needs of various industries. Initially, altitude simulation was limited to hypobaric chambers that required complex and costly setups, making them accessible only to elite athletes or specialized military training programs. However, the introduction of normobaric hypoxia systems has transformed the landscape, allowing for the simulation of high-altitude conditions without the need for heavy-duty construction or safety concerns associated with pressure differentials.

Over the years, the versatility of altitude chambers has expanded dramatically. Today, businesses can choose from a range of options, including modular and conversion chambers that can be easily integrated into existing infrastructures. The incorporation of digital technologies, such as automated control systems and remote monitoring capabilities, has further enhanced user experience and operational efficiency.

As the market continues to grow, ongoing innovations are likely to focus on increasing accessibility and affordability, ensuring that altitude chambers can serve a broader audience across diverse sectors. Understanding this evolution is essential for B2B buyers looking to leverage altitude chamber technology to improve performance, training, and research outcomes.

Frequently Asked Questions (FAQs) for B2B Buyers of altitude chambers

-

1. How do I determine the right altitude chamber for my needs?

To select the right altitude chamber, consider factors such as the intended use (e.g., athletic training, research, or rehabilitation), the number of users, and the specific altitude range required. Evaluate whether you need a conversion chamber that can adapt existing spaces or a modular chamber that allows for future expansion. Additionally, discuss your requirements with suppliers to understand their capabilities and get tailored recommendations based on your operational needs and space constraints. -

2. What are the key features to look for in an altitude chamber?

When assessing altitude chambers, prioritize features such as customizable altitude settings, climate control capabilities, user-friendly interfaces, and safety mechanisms. Look for systems that allow remote access for monitoring and control, as well as options for both manual and automated operation. Additionally, inquire about the chamber’s construction materials and whether it includes features for monitoring oxygen levels and other environmental factors, which can greatly enhance the user experience. -

3. What are the typical lead times for ordering altitude chambers?

Lead times can vary significantly based on the manufacturer, customization options, and shipping logistics. Generally, expect a timeline of 6 to 12 weeks from order confirmation to delivery, particularly for customized chambers. It’s advisable to plan ahead and confirm lead times with suppliers during the initial inquiry phase, especially if you have specific deadlines for installation or operational readiness. -

4. What are the payment terms for purchasing altitude chambers?

Payment terms can differ by supplier, but they typically range from 30% to 50% upfront, with the balance due upon delivery or installation. Some manufacturers may offer financing options or extended payment plans for larger orders. Always clarify payment structures and any potential additional costs, such as shipping, installation, and ongoing maintenance, to avoid surprises down the line. -

5. How can I vet a supplier for altitude chambers?

To vet suppliers, start by reviewing their experience and expertise in manufacturing altitude chambers. Check for customer testimonials and case studies that demonstrate their reliability and product performance. Additionally, inquire about certifications, quality assurance processes, and after-sales support. Engaging in direct communication with their team can also provide insights into their responsiveness and customer service quality. -

6. Are altitude chambers customizable to fit specific operational requirements?

Yes, many manufacturers offer customizable altitude chambers designed to meet specific operational needs. Customization can include size adjustments, feature enhancements, and integration with existing systems. Discuss your specific requirements with potential suppliers to ensure they can deliver a solution that aligns with your unique application, whether it’s for a gym, research facility, or military training. -

7. What are the logistics considerations when importing altitude chambers?

Logistics for importing altitude chambers involve multiple factors, including shipping methods, customs clearance, and local regulations. Ensure your supplier provides assistance with shipping documentation and compliance with international trade laws. It’s also crucial to factor in costs related to freight, insurance, and potential tariffs. Partnering with a logistics provider experienced in handling specialized equipment can streamline the process. -

8. How do I ensure quality assurance for altitude chambers?

To ensure quality assurance, request information about the manufacturer’s quality control processes, including testing protocols and certifications for their chambers. Inquire about warranties and maintenance support, as these indicate the manufacturer’s commitment to product quality. Additionally, consider visiting the manufacturing facility if possible, or ask for third-party quality assessments to verify the reliability and safety of the altitude chambers before making a purchase.

Top 5 Altitude Chambers Manufacturers & Suppliers List

1. Hypoxico – Customizable Altitude Chambers

Domain: hypoxico.com

Registered: 1999 (26 years)

Introduction: Altitude Chambers are fully customizable, allowing for tailored size, design, installation, and operation. They simulate altitude from sea level up to 30,000 feet and operate 24/7 with remote access via smartphone, tablet, or computer. Features include full climate control, hyperoxic capabilities, and multiple operational modes (Manual, Scheduler, EcoMode). Chamber types include Conversion Chamber…

2. ETC – FALCON Hypobaric Chamber

Domain: etcaircrewtraining.com

Registered: 2002 (23 years)

Introduction: ETC’s altitude chamber provides a safe, controlled, and medically monitored environment for military hypoxia training and research. Key features include:

– FALCON Hypobaric Chamber for training and research on rapid pressure, oxygen concentration, temperature, and humidity changes.

– Man-Rated Chamber built to high industrial standards for safe and reliable operation.

– Automated and Repeatable…

3. AF Research Lab – Altitude Chambers

Domain: afresearchlab.com

Registered: 2017 (8 years)

Introduction: The Research Altitude Chambers (RAC) are a family of four computer-controlled altitude chambers managed by the Air Force Research Laboratory’s 711th Human Performance Wing. They are designed for various studies to ensure the durability of flight equipment and to determine the effects of altitude on the human body. The chambers also provide training capabilities for air crews.

– Chamber 1: Studie…

4. Russell’s Tech – Altitude Chambers

Domain: russells-tech.com

Registered: 1996 (29 years)

Introduction: Altitude chambers are designed for pressure or altitude testing essential for aerospace, industrial, and consumer applications. They simulate low-pressure environments and rapid decompression, conforming to military and aviation test standards like MIL-STD-810 and RTCA DO-160. Key features include:

– **Altitude Simulation**: Capable of replicating conditions up to 100,000 ft, with extended ranges…

5. Altitude Training – Treadmill Workouts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: High altitude chamber training with oxygen levels equivalent to 2500m (8200ft). Offers treadmill workouts up to 3 times per week for 60 minutes. Designed for individuals training at sea level, particularly beneficial for those preparing for races at altitude.

Strategic Sourcing Conclusion and Outlook for altitude chambers

As businesses increasingly recognize the benefits of altitude chambers across various sectors—from athletic training to military applications—the importance of strategic sourcing becomes paramount. By carefully evaluating suppliers, buyers can ensure they select altitude chambers that meet their specific operational needs, whether it’s a modular design for flexibility or a high-flow system for large groups. Key factors to consider include customization capabilities, safety features, ongoing support, and the technological advancements that can enhance user experience.

International buyers from regions like Africa, South America, the Middle East, and Europe should leverage their unique market insights to negotiate favorable terms and identify suppliers with a proven track record, such as those offering normobaric solutions that simplify use and maximize efficiency.

Looking ahead, the demand for altitude chambers is set to grow as industries continue to explore their diverse applications. Now is the time for B2B buyers to invest in this innovative technology, ensuring they remain competitive and responsive to emerging market trends. Engage with leading suppliers to secure the best solutions tailored to your requirements and take the next step in enhancing your operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.