A B2B Buyer’s Guide to Exposed Hinges For Kitchen Cabinets: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for exposed hinges for kitchen cabinets

As international B2B buyers increasingly seek high-quality exposed hinges for kitchen cabinets, navigating this complex market can pose significant challenges. With a plethora of options available, sourcing the right hinges that meet specific design and functional requirements is critical for enhancing both aesthetics and performance in cabinetry. This comprehensive guide delves into the various types of exposed hinges, their applications across different cabinet styles, and essential considerations when selecting the right products for your business needs.

Throughout this guide, you will discover valuable insights into the different types of exposed hinges, including overlay and inset options, as well as their respective advantages and best uses. Additionally, we will provide practical tips for vetting suppliers to ensure you partner with reputable manufacturers who meet international quality standards. Understanding cost structures, shipping logistics, and regional compliance will also be addressed, empowering you to make informed purchasing decisions.

Designed specifically for B2B buyers in Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this guide equips you with the knowledge necessary to navigate the global market confidently. By leveraging the insights provided, you can optimize your sourcing process, ensuring that you select hinges that align with your operational goals and customer expectations.

Understanding exposed hinges for kitchen cabinets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overlay Hinges | Covers the cabinet frame, allowing for a seamless look. | Residential and commercial cabinetry. | Pros: Aesthetic appeal, easy installation. Cons: Limited adjustment options. |

| Inset Hinges | Mounted inside the cabinet frame, allowing doors to sit flush. | High-end cabinetry and custom designs. | Pros: Clean look, precise alignment. Cons: More complex installation. |

| Self-Closing Hinges | Automatically closes the cabinet door when nearly shut. | High-traffic environments, kitchens. | Pros: Convenience, enhanced safety. Cons: May require adjustment over time. |

| Soft-Close Hinges | Gently closes doors to prevent slamming. | Premium kitchen and furniture applications. | Pros: Noise reduction, improved durability. Cons: Higher cost compared to standard hinges. |

| Demountable Hinges | Designed for easy removal and reinstallation of cabinet doors. | Modular cabinetry systems. | Pros: Simplifies maintenance, flexible design options. Cons: May lack aesthetic appeal. |

What Are Overlay Hinges and Their Applications in B2B Settings?

Overlay hinges are designed to cover the cabinet frame, creating a sleek and modern appearance. These hinges are widely used in both residential and commercial cabinetry applications due to their ease of installation and aesthetic benefits. B2B buyers should consider the overlay hinge’s compatibility with cabinet designs and the desired visual outcome. While they provide a seamless look, buyers should also be aware that they may have limited adjustment options compared to other hinge types.

How Do Inset Hinges Enhance Cabinetry Design?

Inset hinges are installed within the cabinet frame, allowing cabinet doors to sit flush with the frame. This type of hinge is particularly suited for high-end cabinetry and custom designs where precision and alignment are crucial. B2B buyers in the luxury market should prioritize inset hinges for their clean, sophisticated look. However, the installation process can be more complex and may require specialized knowledge, which is an important consideration for suppliers and contractors.

Why Choose Self-Closing Hinges for High-Traffic Areas?

Self-closing hinges are engineered to automatically close cabinet doors when they are pushed nearly shut. These hinges are ideal for high-traffic environments, such as kitchens in commercial settings, where convenience and safety are paramount. Buyers should evaluate the durability and reliability of self-closing mechanisms, as they can enhance user experience. However, it is essential to note that these hinges may need periodic adjustments to maintain their functionality over time.

What Advantages Do Soft-Close Hinges Offer?

Soft-close hinges are designed to gently close cabinet doors, preventing slamming and reducing noise. These hinges are particularly popular in premium kitchen and furniture applications, where quality and user experience are prioritized. B2B buyers should consider the long-term benefits of investing in soft-close hinges, including enhanced durability and customer satisfaction. However, the higher initial cost compared to standard hinges may be a consideration for budget-conscious buyers.

How Do Demountable Hinges Support Modular Designs?

Demountable hinges allow for easy removal and reinstallation of cabinet doors, making them ideal for modular cabinetry systems. These hinges are particularly advantageous in environments where frequent maintenance or design changes are expected. B2B buyers should consider the flexibility and ease of use that demountable hinges provide, especially in commercial settings. However, it is important to note that they may not offer the same aesthetic appeal as other hinge types, which could impact design choices.

Key Industrial Applications of exposed hinges for kitchen cabinets

| Industry/Sector | Specific Application of Exposed Hinges for Kitchen Cabinets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Restaurant kitchen cabinetry and storage units | Enhanced durability and ease of access for staff | Compliance with food safety standards, corrosion resistance |

| Furniture Manufacturing | Custom kitchen furniture production | Aesthetic appeal and functionality in design | Variety of finishes, load-bearing capacity |

| Retail | Display cabinets in kitchen appliance stores | Improved product visibility and accessibility | Customization options, strength for heavy appliances |

| Construction | Modular kitchen installations in residential projects | Quick assembly and maintenance ease | Compatibility with diverse cabinet styles and sizes |

| Interior Design | Residential kitchen renovations | Design flexibility and enhanced user experience | Aesthetic considerations, material durability |

How are Exposed Hinges for Kitchen Cabinets Used in the Hospitality Sector?

In the hospitality industry, particularly within restaurant kitchens, exposed hinges are essential for cabinetry and storage units. These hinges facilitate quick access to kitchen supplies and equipment, which is crucial during busy service periods. The durability of these hinges is paramount, as they must withstand constant use and exposure to varying temperatures and humidity levels. International buyers in this sector should prioritize sourcing hinges that comply with food safety standards and exhibit corrosion resistance to ensure longevity and hygiene.

What Role Do Exposed Hinges Play in Furniture Manufacturing?

Exposed hinges are integral to the production of custom kitchen furniture, providing both aesthetic appeal and functionality. Manufacturers can leverage various finishes to match the design ethos of their products, catering to different market segments. Buyers in this industry need to consider the load-bearing capacity of the hinges, especially when designing cabinets intended to hold heavy kitchen equipment. Sourcing hinges that offer a seamless integration with cabinet designs can enhance product value and consumer satisfaction.

How are Exposed Hinges Utilized in Retail Settings?

In retail, particularly in stores selling kitchen appliances, exposed hinges are used in display cabinets to showcase products effectively. These hinges enhance product visibility and allow for easy access, which can improve customer interaction and sales. Retailers should focus on sourcing hinges that allow for customization to match branding and store aesthetics. Additionally, hinges must be strong enough to support the weight of heavy appliances, ensuring the safety and durability of the displays.

Illustrative image related to exposed hinges for kitchen cabinets

Why are Exposed Hinges Important in Construction Projects?

In construction, especially during modular kitchen installations, exposed hinges play a critical role in ensuring quick assembly and maintenance of kitchen cabinets. They allow for easier adjustments and replacements, which can be particularly beneficial in projects with tight timelines. Buyers in this sector should consider the compatibility of hinges with various cabinet styles and sizes, ensuring a cohesive installation process. Sourcing hinges that are versatile and adaptable to different designs can streamline project execution.

How Do Exposed Hinges Enhance Interior Design Projects?

For interior design professionals, exposed hinges offer significant design flexibility in residential kitchen renovations. These hinges can enhance the overall user experience by providing a functional yet stylish solution for cabinet doors. Designers should source hinges that not only meet aesthetic considerations but also ensure material durability to withstand daily use. The right choice of exposed hinges can elevate a kitchen’s design, making it both practical and visually appealing to homeowners.

3 Common User Pain Points for ‘exposed hinges for kitchen cabinets’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Hinge Type for Kitchen Cabinets

The Problem: B2B buyers often struggle with selecting the appropriate type of exposed hinge for specific kitchen cabinet configurations. With a myriad of options like overlay, inset, and semi-overlay hinges, the decision can become overwhelming. This complexity can lead to miscommunication with suppliers, incorrect orders, and ultimately delays in project timelines. The wrong hinge can compromise both aesthetics and functionality, creating frustration for buyers and their clients.

The Solution: To mitigate this issue, it is essential to conduct a thorough needs assessment before sourcing hinges. Start by measuring the cabinet doors and understanding the overlay requirements for your specific cabinetry design. Create a detailed specification sheet that outlines the desired hinge type, dimensions, and material preferences. Collaborate closely with suppliers who offer a comprehensive guide on hinge types and can provide samples. Utilizing visualization tools or software can help buyers see how different hinges will look and function on the cabinets, ensuring the right choice is made and minimizing the risk of errors.

Scenario 2: Inadequate Support for Installation and Maintenance

The Problem: Another common pain point is the lack of proper support during the installation and maintenance of exposed hinges. B2B buyers often find that suppliers do not provide adequate installation instructions or after-sales support, leaving their teams to troubleshoot issues independently. This can lead to improper installation, resulting in functional problems or even damage to the cabinets, which can be costly in terms of repairs and delays.

The Solution: To address this challenge, buyers should prioritize suppliers who offer comprehensive installation guides, tutorials, and customer support. Look for suppliers that provide video demonstrations or on-site training sessions to ensure the installation team is well-equipped to handle the task. Additionally, consider establishing a maintenance schedule that includes regular checks on hinge performance. Building a relationship with a supplier who can offer ongoing support and advice can significantly reduce installation headaches and enhance the longevity of the cabinetry.

Scenario 3: Limited Aesthetic Choices Affecting Design Flexibility

The Problem: Many B2B buyers encounter a significant limitation in the aesthetic options available for exposed hinges, which can constrain the overall design of kitchen cabinetry. As trends shift toward more personalized and stylish interiors, buyers may find that the standard finishes and styles do not align with their project requirements or client expectations. This can lead to dissatisfaction and a lack of confidence in the product offerings.

The Solution: To overcome this issue, buyers should seek out suppliers that provide a wide range of finishes and customizable options for exposed hinges. Engage in discussions with manufacturers about the possibility of special orders for unique finishes or designs that cater to specific project needs. Attending industry trade shows or design expos can also be beneficial in discovering innovative hinge solutions and networking with suppliers who focus on aesthetics. By expanding the search beyond traditional suppliers, buyers can find hinges that not only function well but also enhance the visual appeal of the cabinetry, meeting the demands of modern design.

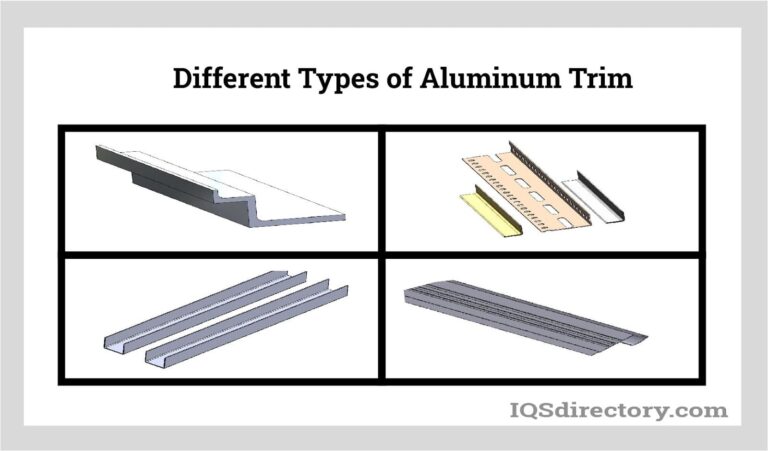

Strategic Material Selection Guide for exposed hinges for kitchen cabinets

When selecting materials for exposed hinges in kitchen cabinets, it is essential to consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the manufacturing of exposed hinges, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Steel for Exposed Hinges?

Steel, especially stainless steel, is a popular choice for exposed hinges due to its strength and durability. It typically offers excellent corrosion resistance, particularly when treated with coatings or finishes such as galvanization. Steel can withstand high temperatures and pressures, making it suitable for various kitchen environments.

Pros: Steel hinges are highly durable and can support heavy cabinet doors, making them ideal for commercial applications. They are also relatively cost-effective compared to other materials.

Illustrative image related to exposed hinges for kitchen cabinets

Cons: While stainless steel is resistant to rust, it can still corrode if not properly maintained. Additionally, the manufacturing process may be more complex, requiring specialized equipment for cutting and shaping.

Impact on Application: Steel hinges are compatible with a wide range of cabinet styles and finishes, but buyers should ensure that they are treated for moisture resistance, especially in humid climates.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe and the Middle East may prefer hinges that meet specific corrosion resistance ratings.

How Does Brass Compare as a Material for Exposed Hinges?

Brass is another common material for exposed hinges, known for its aesthetic appeal and corrosion resistance. It is an alloy of copper and zinc, providing a warm, golden appearance that many consumers find attractive.

Pros: Brass hinges are highly resistant to corrosion and tarnishing, making them suitable for humid environments. They also provide a classic look that enhances the overall design of kitchen cabinetry.

Cons: Brass can be more expensive than steel and may not be as strong, limiting its use in heavy-duty applications. Additionally, it may require regular polishing to maintain its appearance.

Impact on Application: Brass hinges are well-suited for decorative applications, but their strength limitations should be considered when used in high-traffic areas.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and finishes that comply with local standards. In regions like Africa and South America, preferences for aesthetics may drive the choice of brass over other materials.

What are the Advantages of Plastic Hinges for Kitchen Cabinets?

Plastic hinges, often made from high-density polyethylene or polyoxymethylene, are gaining popularity due to their lightweight nature and resistance to moisture.

Pros: Plastic hinges are resistant to corrosion and do not rust, making them ideal for kitchen environments. They are also lightweight, which can ease installation and reduce the overall weight of cabinetry.

Cons: While cost-effective, plastic hinges may not provide the same strength as metal options, limiting their use in heavy-duty applications. They may also be less aesthetically pleasing for high-end cabinetry.

Illustrative image related to exposed hinges for kitchen cabinets

Impact on Application: Plastic hinges are suitable for lightweight cabinet doors and can be used in environments where moisture is a concern, but they may not withstand heavy use.

Considerations for International Buyers: Compliance with environmental regulations regarding plastic materials is essential, especially in regions with strict waste management policies.

How Do Zinc-Alloy Hinges Perform in Kitchen Applications?

Zinc-alloy hinges are another option, offering a balance between cost and performance. These hinges are typically coated to enhance corrosion resistance.

Pros: Zinc-alloy hinges are relatively inexpensive and provide good corrosion resistance when properly coated. They are also easy to manufacture, making them widely available.

Cons: While they offer decent strength, zinc-alloy hinges may not be as durable as stainless steel or brass options. They can also be prone to wear over time, particularly in high-friction applications.

Impact on Application: Zinc-alloy hinges are suitable for standard kitchen cabinets but may not be ideal for heavy-duty or high-end applications.

Considerations for International Buyers: Buyers should check for compliance with relevant standards and consider the environmental impact of zinc production, especially in regions with strict sustainability practices.

Summary Table of Material Selection for Exposed Hinges

| Material | Typical Use Case for Exposed Hinges for Kitchen Cabinets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty cabinets in commercial kitchens | High durability and strength | Can corrode without proper treatment | Medium |

| Brass | Decorative cabinets in residential settings | Aesthetic appeal and corrosion resistance | Higher cost and requires maintenance | High |

| Plastic | Lightweight cabinets and moisture-prone environments | Corrosion-resistant and lightweight | Limited strength and aesthetics | Low |

| Zinc-Alloy | Standard kitchen cabinets | Cost-effective and widely available | Less durable than steel or brass | Low |

In conclusion, selecting the right material for exposed hinges in kitchen cabinets involves understanding the specific needs of the application, including durability, aesthetic preferences, and environmental conditions. International buyers should consider local standards and regulations to ensure compliance and suitability for their markets.

In-depth Look: Manufacturing Processes and Quality Assurance for exposed hinges for kitchen cabinets

What Are the Key Stages in the Manufacturing Process of Exposed Hinges for Kitchen Cabinets?

The manufacturing of exposed hinges for kitchen cabinets involves several critical stages, each designed to ensure the final product meets both functional and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in hinge manufacturing is the selection and preparation of raw materials, typically metals such as stainless steel, brass, or zinc alloys. These materials are chosen for their strength, durability, and resistance to corrosion. The selected metal is then cut into specific sizes using precision cutting machines, ensuring that every piece meets the required specifications. Quality checks are performed at this stage to ensure that the material has the necessary characteristics, such as thickness and surface quality.

Illustrative image related to exposed hinges for kitchen cabinets

Forming Techniques

Once the materials are prepared, the next stage involves forming the hinge components. This can be achieved through various techniques, including stamping, forging, or machining. For example, stamping is commonly used to create the flat plates of the hinge, while forging may be employed for more complex shapes that require greater strength. Each method has its advantages, such as cost-effectiveness in high-volume production or precision for custom designs. Advanced technologies like CNC (Computer Numerical Control) machining may also be used to enhance accuracy and reduce waste.

Assembly Process

After forming, the hinge components are assembled. This step can involve manual labor or automated machinery, depending on the scale of production. Key components such as hinge pins, springs, and plates are brought together to form the final product. Careful attention is paid to the alignment and fit of each part, as improper assembly can lead to performance issues later. Quality control checkpoints during this phase include inspections for proper assembly and functionality tests to ensure that the hinges operate smoothly.

Finishing Touches

The final stage in the manufacturing process is finishing, which not only enhances the aesthetic appeal of the hinges but also provides additional protection against wear and corrosion. Common finishing techniques include electroplating, powder coating, or painting. Each method offers unique benefits; for instance, electroplating can improve corrosion resistance while powder coating provides a durable and attractive surface. After finishing, hinges undergo final inspections to ensure that they meet visual and performance standards.

How Is Quality Assurance Implemented in the Manufacturing of Exposed Hinges?

Quality assurance (QA) is a vital aspect of hinge manufacturing, ensuring that every product meets international and industry-specific standards. The QA process typically involves adherence to ISO 9001 and other relevant certifications such as CE marking, which indicate compliance with European safety, health, and environmental protection standards.

Quality Control Checkpoints

Quality control in hinge manufacturing is structured through various checkpoints:

-

Incoming Quality Control (IQC): This initial phase involves the inspection of raw materials before production begins. Suppliers must provide certification of material quality, and random samples are tested for compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted to catch defects early. This includes checking dimensions, material properties, and assembly integrity at various stages of production.

-

Final Quality Control (FQC): After assembly and finishing, each batch of hinges undergoes a final inspection. This includes functional testing, dimensional checks, and visual inspections to ensure that the hinges meet the established quality criteria.

Testing Methods Commonly Used

Various testing methods are employed to ensure the performance and durability of exposed hinges. These may include:

- Load Testing: To assess the strength and durability of the hinge under normal and extreme conditions.

- Corrosion Testing: To evaluate how well the hinge will withstand environmental factors, particularly important for hinges used in humid or coastal areas.

- Cycle Testing: To determine the lifespan of the hinge through repeated opening and closing motions.

How Can B2B Buyers Verify Supplier Quality Control Standards?

For B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control standards is crucial. Here are several strategies to ensure that suppliers meet necessary quality benchmarks.

Conducting Audits

Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. These audits can be performed by the buyer or a third-party organization to ensure an unbiased evaluation. Auditors assess compliance with international standards, documentation practices, and operational procedures.

Requesting Quality Reports

Buyers should request detailed quality assurance reports from suppliers. These reports should outline the testing methods used, results obtained, and any corrective actions taken for identified issues. This transparency helps buyers gauge the reliability of the supplier’s quality control practices.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an additional layer of assurance. These independent firms can perform on-site inspections during various production stages, ensuring that the supplier adheres to agreed-upon quality standards. This is particularly beneficial for international buyers who may not have the capacity to conduct on-site evaluations themselves.

What Nuances Should International B2B Buyers Consider Regarding Quality Control and Certifications?

International B2B buyers must navigate several nuances regarding quality control and certifications when sourcing exposed hinges. Understanding regional standards and compliance requirements is essential to avoid potential legal and operational pitfalls.

Regional Compliance Standards

Different regions may have specific compliance requirements that manufacturers must adhere to. For instance, European buyers will be particularly concerned with CE marking, which indicates compliance with EU directives. In contrast, buyers in the Middle East may look for certifications specific to their local regulations. Buyers should familiarize themselves with these standards to ensure that suppliers can meet them.

Cultural Considerations in Quality Assurance

Cultural differences can also influence quality assurance practices. For example, suppliers in some regions may prioritize speed over strict adherence to quality standards. B2B buyers should engage in open discussions with suppliers about their quality assurance philosophies and practices to establish mutual expectations.

Illustrative image related to exposed hinges for kitchen cabinets

Supply Chain Transparency

Finally, maintaining supply chain transparency is crucial. Buyers should consider the entire supply chain, from raw materials to finished products, to ensure that quality is maintained at every stage. This may involve working closely with suppliers to understand their sourcing practices and any potential risks associated with the materials used in hinge production.

By understanding the manufacturing processes, quality assurance practices, and nuances involved in sourcing exposed hinges, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exposed hinges for kitchen cabinets’

To effectively source exposed hinges for kitchen cabinets, B2B buyers must navigate several critical steps to ensure they procure quality products that meet their specific needs. This guide provides a structured checklist to facilitate informed decision-making in the sourcing process.

Step 1: Define Your Technical Specifications

Clearly outlining the technical requirements for the hinges is essential. Consider the type of cabinet design, door weight, and frequency of use. This will help you determine the appropriate hinge size, load capacity, and style, ensuring compatibility with the cabinets you intend to use.

- Key Specifications to Determine:

- Overlay Type: Full, half, or inset overlay hinges.

- Material Considerations: Stainless steel for durability or decorative finishes for aesthetics.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in cabinet hardware. Utilize online directories, trade shows, and industry recommendations to compile a list of potential vendors.

- What to Look For:

- Industry Experience: Established suppliers are often more reliable.

- Product Range: Ensure they offer a variety of hinges suitable for your needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet your shortlisted suppliers rigorously. Request company profiles, product catalogs, and references from other businesses in your industry. This due diligence helps mitigate risks associated with quality and service.

- Important Evaluation Criteria:

- Customer Reviews: Look for feedback on product performance and supplier responsiveness.

- Compliance Certifications: Check for adherence to international quality standards.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality, functionality, and aesthetic appeal of the hinges in your specific application.

- Testing Considerations:

- Durability Tests: Assess for wear under regular usage conditions.

- Aesthetic Match: Ensure the finish aligns with your design specifications.

Step 5: Assess Pricing and Payment Terms

Compare pricing from different suppliers, but don’t base your decision solely on cost. Consider the total cost of ownership, including shipping, taxes, and potential duties. Clarify payment terms to avoid any unexpected financial burdens.

Illustrative image related to exposed hinges for kitchen cabinets

- Pricing Factors to Consider:

- Volume Discounts: Inquire about bulk purchasing options.

- Shipping Costs: Factor in logistics, especially for international orders.

Step 6: Confirm Lead Times and Delivery Schedules

Establish clear timelines for production and delivery. Understanding lead times is crucial for your project planning and inventory management.

- What to Discuss:

- Production Capacity: Ensure the supplier can meet your demands within the required timeframe.

- Shipping Methods: Discuss options that align with your urgency and budget.

Step 7: Finalize Contracts and Agreements

Once you select a supplier, ensure that all terms are documented in a formal contract. This should include product specifications, pricing, lead times, and return policies.

- Contract Essentials:

- Clear Terms of Agreement: Include warranties and service level expectations.

- Dispute Resolution: Outline procedures for addressing any issues that may arise post-purchase.

By following this checklist, B2B buyers can streamline their sourcing process for exposed hinges, ensuring they make informed decisions that align with their operational needs and design standards.

Comprehensive Cost and Pricing Analysis for exposed hinges for kitchen cabinets Sourcing

What Are the Key Cost Components in Sourcing Exposed Hinges for Kitchen Cabinets?

When sourcing exposed hinges for kitchen cabinets, understanding the cost structure is crucial for effective budgeting and negotiations. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Common materials for exposed hinges include stainless steel, brass, and zinc alloys, with stainless steel typically being the most expensive due to its durability and corrosion resistance.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of manufacturing processes. For example, regions with lower labor costs may offer competitive pricing, but this should be weighed against potential quality concerns.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, benefiting the final pricing.

-

Tooling: Tooling costs are incurred for the creation of molds and dies necessary for production. High-quality tooling can lead to better product consistency, but it also increases initial costs. Buyers should consider the tooling implications, especially for custom designs.

-

Quality Control (QC): Implementing rigorous quality control measures is essential to ensure product reliability. While this may add to costs, it can prevent costly returns and enhance brand reputation.

-

Logistics: Shipping and handling fees can vary significantly based on the source location and destination. Factors such as shipping method, distance, and freight charges should be considered in total cost assessments.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. Understanding the typical margins in the industry can aid buyers in negotiating better deals.

How Do Price Influencers Affect the Cost of Exposed Hinges?

Several factors can influence the pricing of exposed hinges, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and consider bulk purchasing to reduce costs.

-

Specifications/Customization: Customized hinges will generally incur higher costs due to the additional design and manufacturing processes involved. Clearly defining specifications upfront can help manage costs.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, CE) typically command higher prices. Buyers should balance the need for quality with budget constraints.

-

Supplier Factors: Supplier reliability, reputation, and location can affect pricing. Establishing long-term relationships with suppliers can lead to better pricing and service.

-

Incoterms: The terms of trade (e.g., FOB, CIF) can significantly impact the total landed cost. Understanding these terms is vital for international transactions to avoid unexpected charges.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Exposed Hinges?

To optimize sourcing strategies, buyers should consider the following tips:

-

Negotiate Effectively: Leverage volume purchases and long-term contracts to negotiate better pricing. Suppliers are often willing to offer discounts for large or repeat orders.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the costs related to shipping, handling, and potential returns due to quality issues. A lower upfront cost may result in higher TCO.

-

Understand Pricing Nuances for International B2B Buyers: Different regions have varying pricing structures influenced by local economies, tariffs, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors when comparing suppliers.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the product meets your specifications.

-

Stay Informed on Market Trends: Regularly research market trends and pricing fluctuations in the hinge industry to make informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for exposed hinges can vary widely based on the aforementioned factors. Therefore, it is essential to consult with suppliers for accurate and current pricing tailored to specific requirements.

Illustrative image related to exposed hinges for kitchen cabinets

Alternatives Analysis: Comparing exposed hinges for kitchen cabinets With Other Solutions

Introduction: Exploring Alternatives to Exposed Hinges for Kitchen Cabinets

In the world of kitchen cabinetry, exposed hinges are a popular choice for their aesthetic appeal and functionality. However, they are not the only option available. B2B buyers should consider various alternatives that may better suit their specific requirements, whether those are cost-efficiency, design preferences, or ease of installation. This analysis compares exposed hinges with concealed hinges and pivot hinges, providing insights into their respective advantages and disadvantages.

Comparison Table

| Comparison Aspect | Exposed Hinges For Kitchen Cabinets | Concealed Hinges | Pivot Hinges |

|---|---|---|---|

| Performance | Good visibility and accessibility | Clean look, hidden when closed | Allows for unique door designs |

| Cost | Generally lower cost | Higher initial investment | Moderate cost |

| Ease of Implementation | Simple installation | Requires precise alignment | May need special framing |

| Maintenance | Easy to replace and adjust | More complex, hidden parts | Minimal, but can be tricky |

| Best Use Case | Rustic or traditional styles | Modern, sleek designs | Space-saving applications |

Detailed Breakdown of Alternatives

Concealed Hinges: What Are Their Benefits and Drawbacks?

Concealed hinges are a popular alternative that offers a clean, modern look, making them ideal for contemporary kitchen designs. They are hidden from view when the cabinet doors are closed, creating a seamless appearance. However, the installation process can be more complex, requiring precise alignment to ensure that the doors function properly. Additionally, concealed hinges typically come at a higher cost compared to exposed hinges, which may be a consideration for budget-conscious buyers. Maintenance can also be more challenging due to the hidden nature of the components.

Pivot Hinges: How Do They Compare?

Pivot hinges provide a unique solution by allowing doors to rotate on a pivot point rather than a traditional hinge. This can create a striking visual effect and is particularly useful in applications where space is limited. While pivot hinges can facilitate innovative door designs and space-saving features, they may require specialized framing and installation techniques, which can complicate the implementation process. The cost of pivot hinges generally falls between that of exposed and concealed hinges, making them a moderate investment.

Conclusion: Making the Right Choice for Your Kitchen Cabinet Needs

When selecting the appropriate hinge solution for kitchen cabinets, B2B buyers should carefully weigh the performance, cost, ease of implementation, and maintenance of each option. Exposed hinges offer an accessible and cost-effective choice, especially for rustic or traditional designs. In contrast, concealed hinges provide a sleek, modern aesthetic at a higher price point, while pivot hinges present innovative solutions for unique spaces. Ultimately, the decision should align with the specific needs of the project, budget constraints, and desired aesthetic outcomes. By considering these factors, buyers can make an informed choice that enhances the functionality and appeal of their kitchen cabinetry.

Essential Technical Properties and Trade Terminology for exposed hinges for kitchen cabinets

What Are the Key Technical Properties of Exposed Hinges for Kitchen Cabinets?

Understanding the essential technical properties of exposed hinges is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade of hinges typically ranges from stainless steel, brass, and zinc alloy to plastic. Stainless steel is favored for its corrosion resistance, making it ideal for humid kitchen environments. Brass offers aesthetic appeal but may be less durable. Selecting the right material can significantly affect the hinge’s lifespan and functionality, which is critical for maintaining cabinet performance.

2. Load Capacity

Load capacity refers to the maximum weight a hinge can support without compromising its integrity. This specification is vital for ensuring that the cabinets can hold the intended contents without warping or failing. B2B buyers should assess the expected load of the cabinet doors to choose hinges that provide adequate support, enhancing product reliability.

Illustrative image related to exposed hinges for kitchen cabinets

3. Opening Angle

The opening angle indicates how far a cabinet door can swing open, typically ranging from 90° to 180°. A larger opening angle allows for easier access to cabinet contents, which is particularly beneficial in commercial settings. Understanding the required opening angle is essential for optimizing kitchen design and functionality.

4. Finish Type

The finish of a hinge can affect both its appearance and durability. Common finishes include satin nickel, polished chrome, and oil-rubbed bronze. The choice of finish can impact the hinge’s resistance to wear and tear, as well as its aesthetic compatibility with kitchen decor. Buyers should consider how the finish aligns with overall design trends in their target markets.

5. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in hinge dimensions and performance. For instance, tighter tolerances can lead to better alignment and function, particularly in precision applications. Ensuring the correct tolerance levels can prevent issues such as misalignment and premature wear, thus enhancing customer satisfaction.

6. Closing Mechanism

Hinges can be equipped with various closing mechanisms, such as soft-close or self-closing features. Soft-close hinges prevent slamming, which is important for durability and noise reduction in residential and commercial settings. B2B buyers should evaluate the preferences of their target market regarding closing mechanisms, as this can influence purchasing decisions.

Which Trade Terms Are Essential for Understanding the Exposed Hinges Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are sold under another company’s brand name. Understanding the role of OEMs can help buyers identify reliable manufacturers that can meet their specific needs, ensuring quality and consistency in product supply.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is a critical consideration for B2B buyers, as it affects inventory management and capital investment. Knowing the MOQ helps businesses plan their purchasing strategies and manage cash flow efficiently.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and other details from suppliers for specific products. This process is essential for gathering competitive bids, allowing buyers to compare options and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B transactions, especially for international buyers, to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. It is crucial for inventory planning and customer satisfaction. Buyers should inquire about lead times to align their production schedules and meet market demand effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing exposed hinges for kitchen cabinets, ultimately leading to more successful procurement strategies and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the exposed hinges for kitchen cabinets Sector

What Are the Current Market Dynamics and Key Trends in the Exposed Hinges for Kitchen Cabinets Sector?

The global market for exposed hinges in kitchen cabinets is witnessing significant transformations driven by evolving consumer preferences and technological advancements. One of the primary drivers is the increasing demand for customizable and aesthetically pleasing kitchen designs, which has led to a surge in the use of exposed hinges. These hinges are favored for their visibility and ability to enhance the overall look of cabinetry, appealing particularly to consumers in regions like Europe and the Middle East, where design sophistication is paramount.

Emerging B2B tech trends, such as the integration of e-commerce platforms and advanced supply chain management systems, are reshaping sourcing practices. International buyers, especially from Africa and South America, are increasingly utilizing digital tools for procurement, allowing them to source exposed hinges from a wider range of suppliers and manufacturers. This shift not only enhances accessibility but also fosters competitive pricing.

Additionally, the market is experiencing a growing inclination toward soft-close and self-closing hinge technologies, which offer enhanced functionality and convenience. Manufacturers are also exploring innovative materials and finishes that align with contemporary design trends, such as brushed metals and matte finishes. The demand for sustainable and eco-friendly products is another emerging trend, with buyers increasingly prioritizing suppliers who adhere to environmentally responsible practices.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Exposed Hinges Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the exposed hinges sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under scrutiny. Buyers are increasingly recognizing the importance of partnering with suppliers who prioritize sustainable practices, such as using recycled materials or employing energy-efficient manufacturing methods.

Ethical supply chains are essential not only for compliance with regulations but also for enhancing brand reputation. Buyers who source exposed hinges from manufacturers with robust ethical standards can leverage this as a unique selling proposition in their markets. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the push for ‘green’ materials in product offerings is reshaping the landscape of hinge manufacturing. Suppliers that invest in developing eco-friendly finishes and coatings will likely see increased demand from conscientious buyers looking to align their product lines with consumer values around sustainability.

Illustrative image related to exposed hinges for kitchen cabinets

What Is the Evolution of Exposed Hinges in the Kitchen Cabinet Sector?

The evolution of exposed hinges can be traced back to traditional woodworking practices where functionality took precedence over aesthetics. Initially, hinges were purely utilitarian, focusing on durability and ease of use. However, as kitchen designs became more integrated and visually driven, the role of hinges evolved significantly.

In the 20th century, the introduction of modern materials and manufacturing techniques allowed for more intricate designs and finishes, paving the way for exposed hinges to become a design feature rather than just a functional component. Today, exposed hinges are not only about utility but also about style, offering various options that cater to diverse aesthetic preferences. As a result, they have become a staple in contemporary cabinetry, particularly in regions that emphasize design and craftsmanship, such as Europe and the Middle East.

This evolution reflects broader trends in the furniture and cabinetry industry, where the fusion of form and function continues to shape product development and consumer choices.

Frequently Asked Questions (FAQs) for B2B Buyers of exposed hinges for kitchen cabinets

-

How do I determine the right type of exposed hinges for my kitchen cabinets?

To choose the right exposed hinges, first consider the cabinet door overlay type—full, half, or partial overlay. Measure the thickness of your cabinet doors and the space available for hinge installation. It’s also essential to think about the aesthetic finish that matches your cabinetry and overall design. Lastly, evaluate whether you need self-closing features or soft-close options for smoother operation. Consulting with suppliers who offer samples can help in making a more informed decision. -

What is the best finish for exposed hinges in kitchen cabinets?

The best finish for exposed hinges largely depends on the design style of your kitchen. Common finishes include stainless steel for a modern look, antique brass for a vintage feel, and matte black for a contemporary aesthetic. Additionally, consider the durability of the finish in relation to your environment—coastal areas may require rust-resistant finishes. Always check with suppliers for the availability of finishes that match your project requirements. -

How can I ensure quality when sourcing exposed hinges for kitchen cabinets?

To ensure quality, first vet your suppliers by checking their certifications and industry reputation. Request product samples to assess the hinge’s material, finish, and functionality. Additionally, inquire about their quality control processes and warranty policies. Establishing a solid relationship with a trusted supplier can also provide insights into their product reliability and customer service. -

What are the minimum order quantities (MOQs) for exposed hinges?

Minimum order quantities can vary significantly between suppliers. Some manufacturers may have MOQs as low as 100 units, while others may require orders of 1,000 or more, especially for custom products. It’s essential to discuss your requirements upfront with potential suppliers to understand their policies and see if they can accommodate smaller orders, particularly for pilot projects or new market entries. -

What payment terms should I expect when ordering exposed hinges internationally?

Payment terms can vary based on supplier policies and your negotiating power. Common arrangements include full payment in advance, a 30% deposit with the balance due before shipment, or net 30/60 terms upon delivery. It’s crucial to clarify payment options, including currency, method (bank transfer, credit card, etc.), and any applicable fees. Establishing clear payment terms can help avoid misunderstandings and ensure smoother transactions. -

How do I handle logistics and shipping for my hinge orders?

When managing logistics, consider factors such as shipping methods, lead times, and customs regulations. Engage with suppliers who offer comprehensive shipping solutions, including freight forwarders who can assist with documentation. Ensure you understand the Incoterms (like FOB, CIF) that dictate the responsibilities of buyers and sellers in shipping. Additionally, factor in potential delays and plan your inventory accordingly to maintain supply continuity. -

What customization options are available for exposed hinges?

Many manufacturers offer customization options, including size, color, and functionality of exposed hinges. You can request specific finishes, adjust hinge dimensions to fit unique cabinet designs, or add features like soft-close mechanisms. Discuss your needs with suppliers during the inquiry process to explore available options and ensure the final product meets your specifications. -

How can I verify the reliability of international suppliers for hinges?

To verify supplier reliability, start by researching their business history and client reviews. Look for industry certifications and affiliations with trade organizations, which can indicate credibility. Additionally, request references from other clients and consider conducting a factory visit or virtual inspection if feasible. Utilizing platforms that offer supplier vetting services can also enhance your confidence in their reliability before making significant purchases.

Top 6 Exposed Hinges For Kitchen Cabinets Manufacturers & Suppliers List

1. HingeOutlet – Overlay Cabinet Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Overlay Cabinet Hinges – HingeOutlet offers a variety of cabinet hinges suitable for both residential and commercial applications. The product category includes options such as concealed cabinet hinges, self-closing cabinet hinges, soft close cabinet hinges, and more. HingeOutlet provides expert support and guidance on selecting the right cabinet hinge, installation instructions, and measuring cab…

2. Hardwaresource – Semi-Concealed Cabinet Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Semi-Concealed Cabinet Hinges are designed for face frame cabinets, featuring half of the hinge visible on the face frame and the other half hidden, mounted to the back of the cabinet door. They come in various finishes including Oil Rubbed Bronze, Polished Chrome, Polished Brass, Satin Nickel, Antique Brass, Black Iron, and Stainless Steel. The product range includes options such as 1/2″ Inset, 1…

3. Salice – Soft-Close Hidden Hinge

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Salice soft-close hidden hinge for 3/8 rabbeted door, available at Rockler for $4.99 per pair. Exposed hinges in chrome or brushed chrome also available, with multiple finishes.

4. Blum – Soft Close 110 Blumotion Hinges

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Blum soft close 110 Blumotion clip top inset hinges for frameless cabinets; recommended brands: Blum and Mepla; hinge specifications: face frame hinges with 1 1/4″ overlay for 1 1/2″ face frame.

5. Erin Evolving – Cabinet Door Hinge Solutions

Domain: erinevolving.com

Registered: 2019 (6 years)

Introduction: Favorite hinge for cabinet doors, hinge for doors on cabinets with pull-out shelves, hinge jig kit, electric drill, tape measure, Phillips head screwdriver, sturdy work surface, wood filler.

6. Pinterest – Cabinet Hinges Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Cabinets with exposed hinges, off-the-shelf cabinet hinges, hidden hinges, installation guide for hidden cabinet hinges, types of cabinet doors, cabinet hinge materials, visible cabinet hinges, soft close hinges, rustic cabinet hinges, antique cabinet hinge styles, DIY kitchen renovation, kitchen cabinet hinge replacement.

Strategic Sourcing Conclusion and Outlook for exposed hinges for kitchen cabinets

In conclusion, the strategic sourcing of exposed hinges for kitchen cabinets presents significant opportunities for international B2B buyers. Understanding the diverse range of hinges available—from overlay to concealed options—enables businesses to enhance their product offerings and meet specific customer needs. By prioritizing quality, durability, and design aesthetics, companies can differentiate themselves in competitive markets across Africa, South America, the Middle East, and Europe.

Implementing a strategic sourcing approach not only optimizes procurement processes but also fosters strong supplier relationships, leading to better pricing, availability, and innovation. As the demand for customizable and functional kitchen solutions continues to rise, buyers should remain agile and informed about emerging trends and technologies in hinge design.

Looking ahead, it is essential for B2B buyers to actively engage with suppliers, explore new markets, and leverage data-driven insights to make informed purchasing decisions. By doing so, businesses can capitalize on the evolving landscape of kitchen cabinetry, ensuring they remain at the forefront of industry developments. Embrace the potential of strategic sourcing today to drive growth and success in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.