Everything You Need to Know About Hazardous Waste Evaporators Sourcing in 2025

Introduction: Navigating the Global Market for hazardous waste evaporators

In today’s global market, sourcing efficient hazardous waste evaporators poses a significant challenge for industries aiming to manage waste responsibly while minimizing disposal costs. As regulations tighten and environmental concerns grow, businesses across Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil, are increasingly seeking reliable solutions to reduce hazardous waste volumes. This comprehensive guide delves into the various types of hazardous waste evaporators available, their applications across industries, and essential criteria for supplier vetting.

By exploring the intricacies of evaporator technology—from thermal and vacuum heat pump systems to integrated water treatment solutions—this resource equips B2B buyers with the knowledge needed to make informed purchasing decisions. Additionally, we will cover cost considerations, operational efficiencies, and the latest advancements in the field, ensuring that buyers can effectively compare options tailored to their unique needs.

With a focus on empowering international buyers, this guide not only highlights the benefits of investing in advanced evaporator systems but also addresses common concerns such as energy efficiency, automation, and compliance with local regulations. By leveraging the insights provided, businesses can streamline their hazardous waste management processes while contributing to a more sustainable future.

Understanding hazardous waste evaporators Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermal Evaporator | High-temperature operation, typically electrically heated | Industrial wastewater treatment | Pros: High efficiency, suitable for various wastes. Cons: Energy-intensive, may require significant upfront investment. |

| Vacuum Heat Pump Evaporator | Utilizes heat pump technology for energy efficiency | Chemical manufacturing, electronics | Pros: Energy-efficient, reduces operational costs. Cons: Higher initial cost, may require specialized maintenance. |

| Multi-Effect Evaporator | Multiple stages of evaporation to maximize efficiency | Pharmaceutical, food processing | Pros: Very efficient, suitable for large volumes. Cons: Complex setup, higher initial costs. |

| Drum Evaporator | Compact design, suitable for smaller operations | Small-scale industrial applications | Pros: Low footprint, cost-effective for limited volumes. Cons: Limited capacity, may not handle large waste streams effectively. |

| Slurry Dryer | Designed for dewatering sludges and slurries | Mining, wastewater treatment | Pros: Versatile, handles varying waste compositions. Cons: May require additional processing for solid waste disposal. |

What are the Key Characteristics of Thermal Evaporators?

Thermal evaporators are designed to operate at high temperatures, effectively evaporating water from various types of hazardous waste. They are commonly used in industrial wastewater treatment applications where efficiency is crucial. Buyers should consider the energy requirements and the potential for high operational costs, especially in energy-intensive industries. The upfront investment is often significant, but the long-term benefits can outweigh initial expenditures, particularly in high-volume scenarios.

How Do Vacuum Heat Pump Evaporators Enhance Energy Efficiency?

Vacuum heat pump evaporators leverage advanced heat pump technology to transfer heat rather than generate it, making them significantly more energy-efficient than traditional electric evaporators. This technology is particularly suitable for industries such as chemical manufacturing and electronics, where energy costs are a major concern. While they offer reduced operational expenses, the initial investment can be higher, and specialized maintenance may be necessary. Buyers should evaluate their energy consumption and potential savings when considering this option.

What Advantages Do Multi-Effect Evaporators Offer?

Multi-effect evaporators utilize a series of evaporation stages to maximize efficiency and minimize energy use, making them ideal for large-scale applications like pharmaceuticals and food processing. Their ability to handle substantial volumes of wastewater with minimal energy consumption is a key selling point. However, the complexity of the setup and higher initial costs may deter some buyers. Organizations should assess their processing needs and budget constraints before investing in this technology.

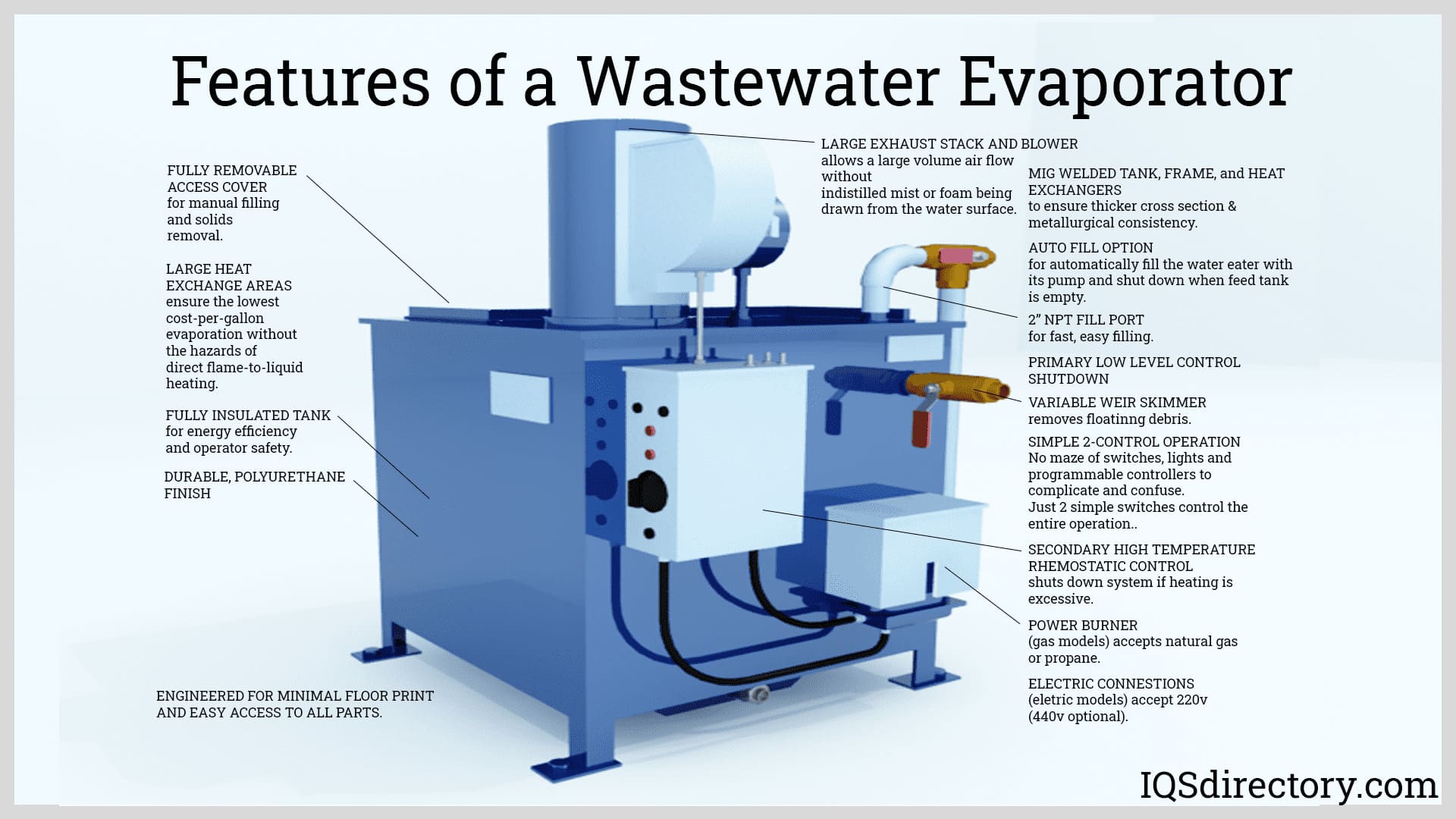

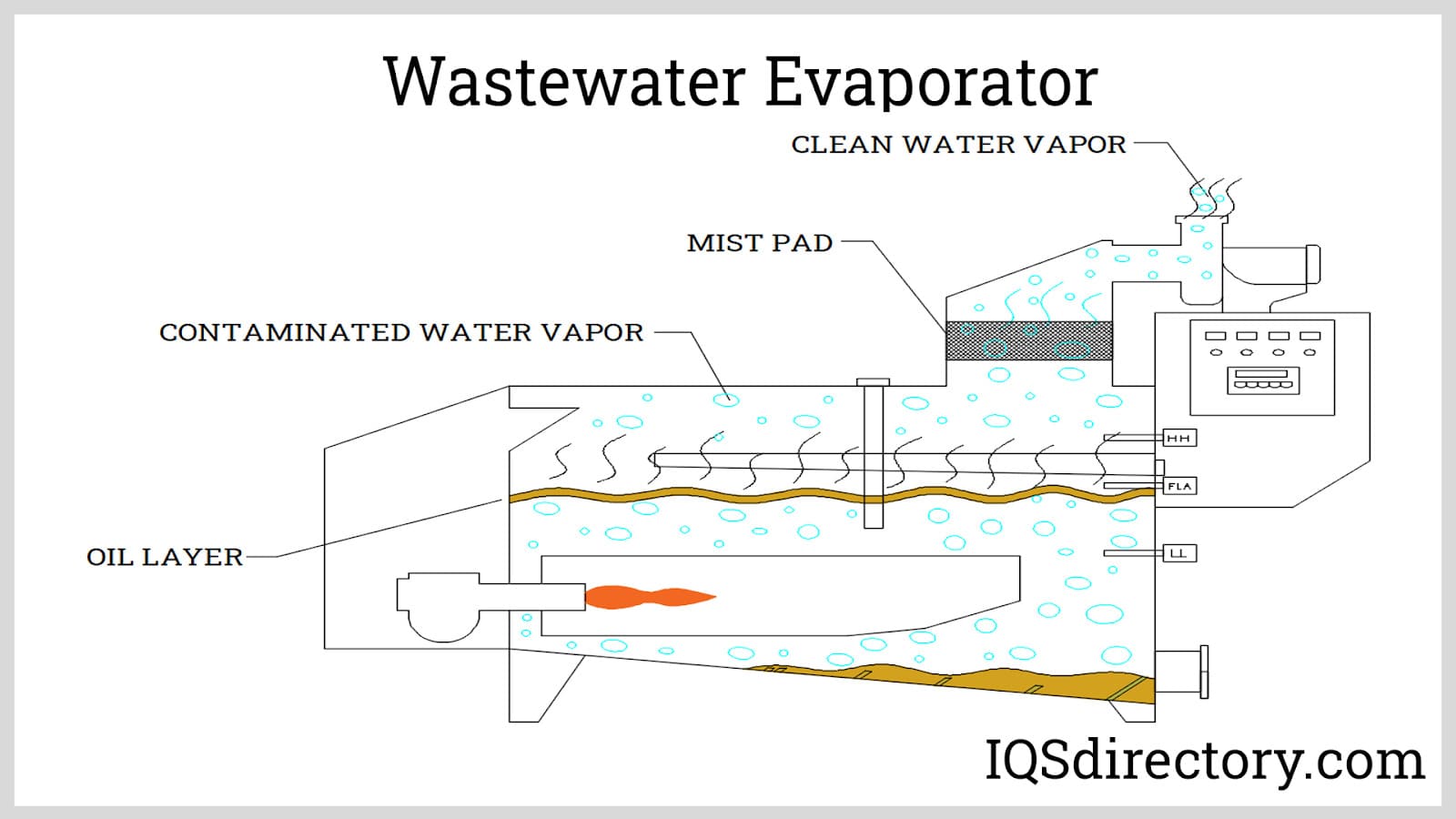

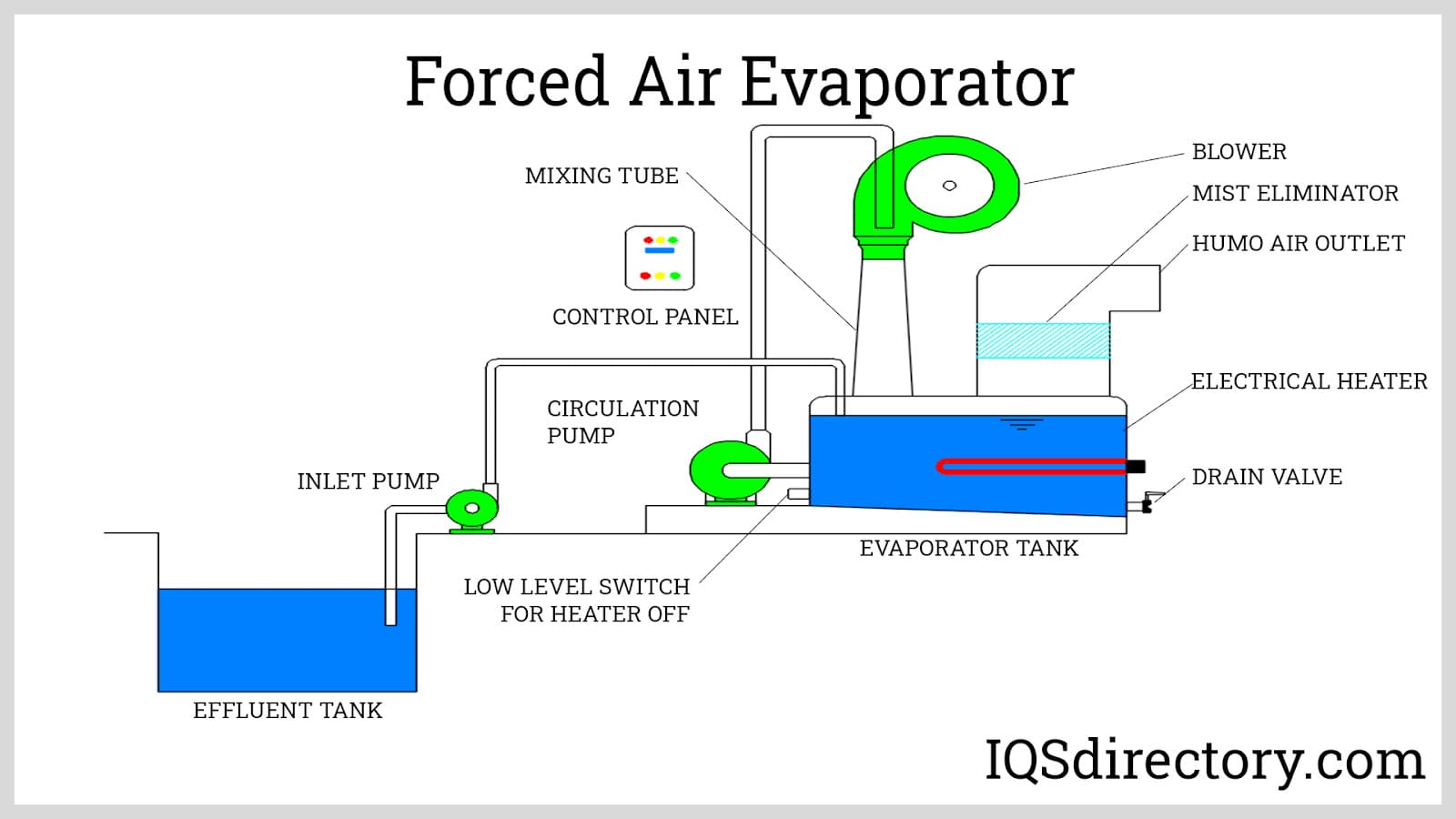

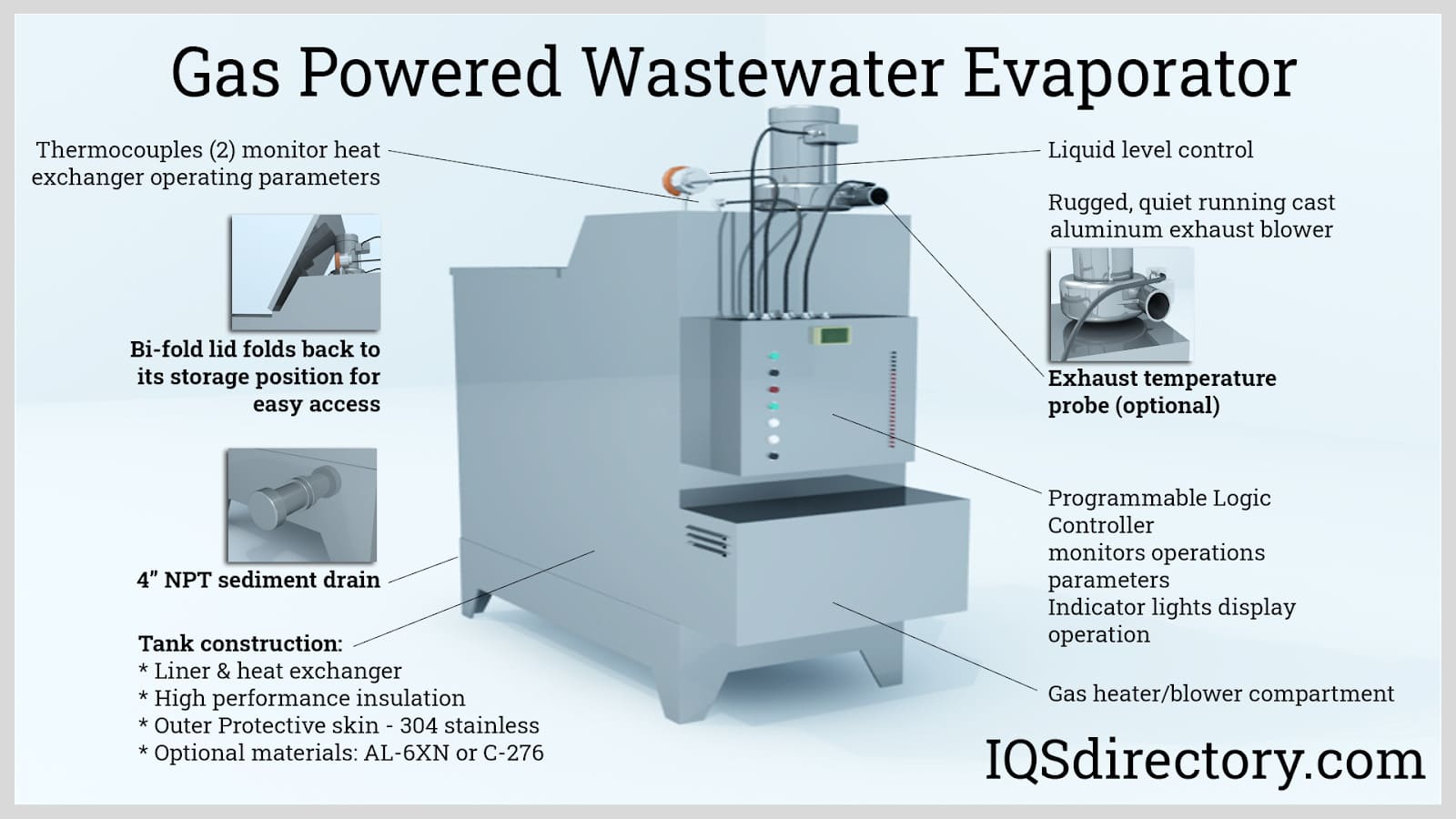

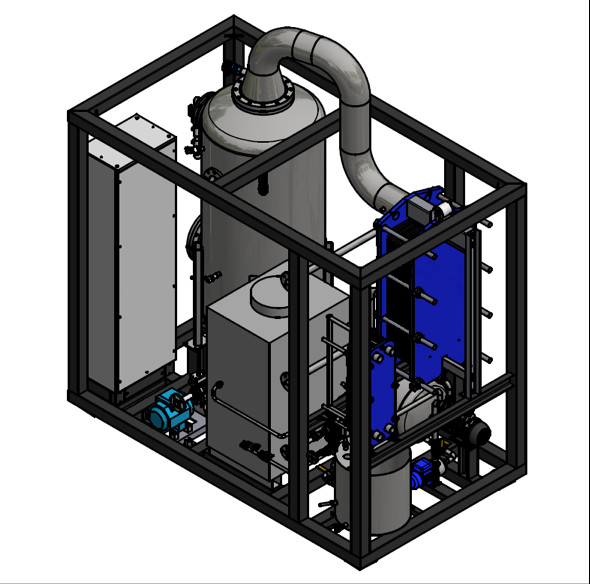

Illustrative image related to hazardous waste evaporators

Why Choose Drum Evaporators for Smaller Operations?

Drum evaporators are compact and designed for smaller operations, making them an attractive option for businesses with limited space or lower waste volumes. They provide a cost-effective solution for small-scale industrial applications, allowing for manageable waste disposal without requiring extensive infrastructure. However, their limited capacity may not suffice for larger waste streams, so potential buyers should consider their operational scale and future growth when selecting this equipment.

What Makes Slurry Dryers Suitable for Diverse Waste Types?

Slurry dryers are engineered to dewater sludges and slurries, making them versatile for industries such as mining and wastewater treatment. Their design accommodates varying waste compositions, allowing for flexibility in processing. While they can effectively reduce waste volume, additional processing may be required for solid waste disposal, which could increase overall operational complexity. Buyers should weigh the advantages of versatility against potential additional processing needs when considering slurry dryers for their operations.

Key Industrial Applications of hazardous waste evaporators

| Industry/Sector | Specific Application of Hazardous Waste Evaporators | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Treatment of SMT Wastewater | Reduces disposal costs and minimizes waste volume | Need for automatic operation, compatibility with cleaning systems |

| Chemical Processing | Concentration of Chemical Waste | Enhances recovery of valuable chemicals, reduces waste | High energy efficiency and materials resistant to corrosion |

| Oil and Gas | Treatment of Produced Water | Complies with environmental regulations and reduces disposal costs | Robust design to handle high salinity and temperature variations |

| Pharmaceuticals | Disposal of Hazardous Solvents | Ensures compliance with regulations and minimizes liability | Need for precise control over evaporation rates and safety features |

| Food Processing | Evaporation of Wastewater from Cleaning Processes | Reduces treatment costs and improves sustainability | Compatibility with food-grade standards and materials |

How Are Hazardous Waste Evaporators Used in Electronics Manufacturing?

In the electronics manufacturing sector, hazardous waste evaporators are primarily employed to treat wastewater generated during the stencil cleaning process. This wastewater contains solder pastes and other contaminants that require careful disposal. By evaporating the water content, businesses can reduce hundreds of gallons of liquid waste to just a few pounds of solid waste, significantly lowering disposal costs. International buyers, particularly from regions with strict environmental regulations, must consider sourcing evaporators that operate automatically and are compatible with existing cleaning systems to streamline operations.

What Role Do Hazardous Waste Evaporators Play in Chemical Processing?

In chemical processing, hazardous waste evaporators are utilized to concentrate chemical waste streams, allowing for the recovery of valuable materials. This process not only minimizes the volume of hazardous waste but also enhances the efficiency of resource recovery, which is vital for maintaining profitability. Buyers in this sector should focus on evaporators that offer high energy efficiency and are constructed from materials resistant to corrosion, as these factors significantly impact long-term operational costs and compliance with environmental standards.

How Are Hazardous Waste Evaporators Applied in the Oil and Gas Industry?

The oil and gas industry faces stringent regulations regarding the treatment of produced water, which often contains hazardous components. Hazardous waste evaporators are instrumental in treating this produced water, allowing companies to comply with environmental regulations while reducing disposal costs. Buyers should prioritize robust evaporator designs capable of handling high salinity and temperature variations, ensuring reliability and efficiency in harsh operational conditions.

What Benefits Do Hazardous Waste Evaporators Offer in Pharmaceuticals?

In the pharmaceutical industry, hazardous waste evaporators are used to manage the disposal of hazardous solvents and other waste byproducts. This technology not only ensures compliance with regulatory standards but also minimizes liability associated with hazardous waste disposal. Buyers should consider evaporators with precise control features that allow for safe and effective evaporation rates, as well as safety mechanisms to prevent accidents during operation.

How Are Hazardous Waste Evaporators Used in Food Processing?

In food processing, hazardous waste evaporators are employed to evaporate wastewater generated during cleaning operations. This process reduces treatment costs and enhances sustainability by minimizing the volume of waste sent for disposal. International buyers in this sector must ensure that the evaporators comply with food-grade standards and are made from materials suitable for food processing environments, thereby safeguarding product integrity and consumer safety.

3 Common User Pain Points for ‘hazardous waste evaporators’ & Their Solutions

Scenario 1: Managing High Disposal Costs of Hazardous Waste

The Problem: In many industries, particularly those in manufacturing or chemical processing, the costs associated with disposing of hazardous waste can be exorbitant. B2B buyers often find themselves grappling with escalating disposal fees, which can significantly impact their bottom line. As regulatory pressures increase and waste volumes rise, organizations must find ways to reduce disposal costs without compromising safety or compliance. This situation is exacerbated in regions where waste management infrastructure is underdeveloped or where hazardous waste is subject to stringent regulations, making disposal both challenging and costly.

The Solution: Investing in a high-efficiency hazardous waste evaporator can drastically reduce the volume of waste that requires disposal, thereby cutting costs. Buyers should focus on selecting evaporators that offer high evaporation rates and energy efficiency, such as vacuum heat pump models that can evaporate large volumes with minimal energy consumption. It’s essential to conduct a thorough cost-benefit analysis, comparing the upfront costs of the evaporator against long-term savings in disposal fees. Additionally, organizations should consider integrating the evaporator with existing processes to streamline operations and maximize efficiency. Regular maintenance and staff training on the proper use of the evaporator can further ensure optimal performance, reducing the risk of costly downtime.

Scenario 2: Ensuring Compliance with Environmental Regulations

The Problem: Navigating the complex landscape of environmental regulations regarding hazardous waste can be daunting for B2B buyers. Regulations often vary by region, and non-compliance can lead to hefty fines and reputational damage. Companies may struggle with identifying the right technology that not only meets regulatory standards but also aligns with their operational needs. This challenge is particularly pronounced in international markets where regulations may differ significantly.

The Solution: To ensure compliance, buyers should partner with reputable manufacturers that offer hazardous waste evaporators designed to meet international standards. It is crucial to consult with environmental compliance experts during the selection process to understand local regulations and ensure that the chosen evaporator is equipped with necessary features such as emission controls and safety interlocks. Manufacturers often provide documentation and certification that can assist buyers in demonstrating compliance during audits. Furthermore, implementing a comprehensive training program for staff on regulatory requirements and operational protocols related to the evaporator will enhance compliance efforts and mitigate risks associated with improper waste handling.

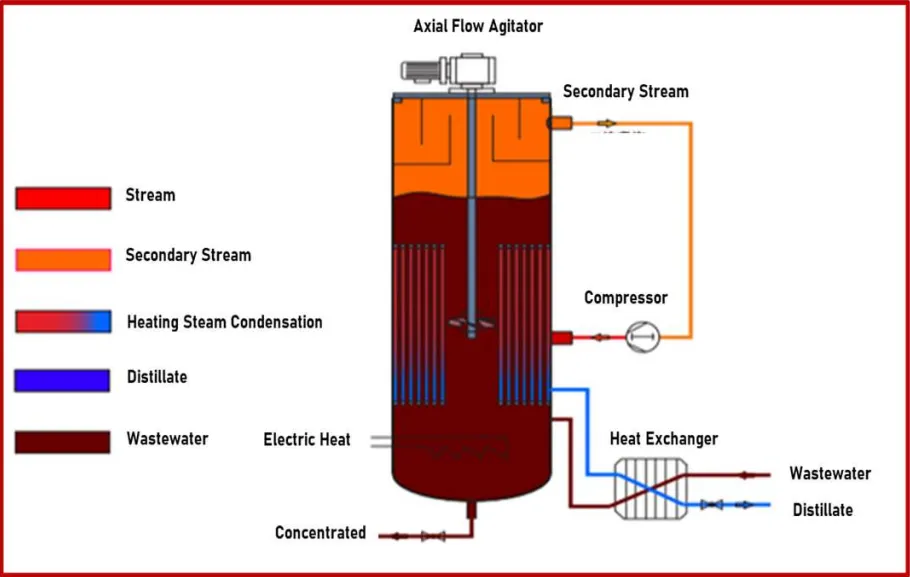

Illustrative image related to hazardous waste evaporators

Scenario 3: Handling Diverse Waste Streams Effectively

The Problem: Industries often produce a variety of hazardous waste streams, each with unique properties and requirements for treatment. B2B buyers may face difficulties when their existing waste management systems are ill-equipped to handle fluctuating waste compositions. This can lead to inefficiencies, increased costs, and the potential for waste mismanagement, especially in operations where waste characteristics change frequently.

The Solution: Selecting a versatile hazardous waste evaporator that can accommodate diverse waste streams is key. Buyers should look for models that offer adjustable settings for temperature and flow rates, allowing for flexibility in processing different types of waste. Additionally, considering integrated systems that combine evaporation with pre-treatment processes can provide a comprehensive solution. For example, evaporators that include slurry drying capabilities can effectively process both liquid and solid waste, minimizing the need for separate equipment. Engaging with manufacturers that have experience in handling specific waste types can provide valuable insights and recommendations, ensuring the selected evaporator meets the unique challenges of the buyer’s operations. Regularly monitoring waste characteristics and adjusting operational parameters accordingly will further enhance efficiency and effectiveness in waste management.

Strategic Material Selection Guide for hazardous waste evaporators

What Are the Key Materials Used in Hazardous Waste Evaporators?

When selecting materials for hazardous waste evaporators, it is crucial to consider properties like temperature and pressure ratings, corrosion resistance, and overall durability. The following analysis covers common materials used in the construction of these systems, focusing on their performance characteristics and implications for international B2B buyers.

Stainless Steel: A Reliable Choice for Evaporators

Stainless steel is widely used in hazardous waste evaporators due to its excellent corrosion resistance and high-temperature tolerance. Typically, grades like 304 and 316 are preferred for their durability and ability to withstand harsh chemicals and environments.

Illustrative image related to hazardous waste evaporators

Pros: Stainless steel is highly durable, relatively easy to fabricate, and offers good thermal conductivity, making it suitable for high-temperature applications. It also has a long lifespan, which can reduce replacement costs over time.

Cons: The primary drawback is its cost, which can be higher than other materials. Additionally, while it is resistant to many chemicals, it may not be suitable for all corrosive substances, particularly strong acids or chlorides.

Impact on Application: Stainless steel’s compatibility with a wide range of media makes it a versatile option for various hazardous waste types. However, buyers should verify compatibility with specific waste streams.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East should ensure that the stainless steel used meets local regulations regarding material safety and environmental impact.

Carbon Steel: Cost-Effective but Limited

Carbon steel is another common material used in evaporators, particularly in less corrosive environments. It offers good strength and is cost-effective compared to stainless steel.

Pros: The main advantage of carbon steel is its lower cost, making it an attractive option for budget-conscious projects. It is also readily available and easy to fabricate.

Cons: Carbon steel is prone to rust and corrosion, particularly in humid or chemically aggressive environments. This can lead to higher maintenance costs and shorter lifespans.

Impact on Application: While suitable for some applications, carbon steel may not be ideal for evaporators handling highly corrosive waste. Buyers should assess the specific waste characteristics to determine suitability.

Illustrative image related to hazardous waste evaporators

Considerations for International Buyers: Buyers from regions with high humidity or corrosive waste streams, such as parts of South America, should be cautious when considering carbon steel. Compliance with local environmental regulations is also crucial.

High-Density Polyethylene (HDPE): A Lightweight Alternative

HDPE is increasingly used in hazardous waste evaporators, particularly for applications involving non-corrosive liquids. It is lightweight and resistant to many chemicals.

Pros: HDPE is cost-effective, easy to mold, and resistant to a wide range of chemicals, making it suitable for various applications. Its lightweight nature can reduce shipping costs.

Cons: While HDPE is resistant to many chemicals, it has lower temperature and pressure ratings compared to metals. This limits its use in high-temperature applications.

Impact on Application: HDPE is ideal for evaporators processing less aggressive waste streams. However, its limitations in temperature and pressure must be considered when designing systems.

Considerations for International Buyers: Buyers should ensure that HDPE materials meet relevant international standards. In regions like Africa and Brazil, where chemical compatibility may vary, thorough testing is recommended.

Titanium: The Premium Option for Corrosive Environments

Titanium is known for its exceptional corrosion resistance, making it suitable for the most aggressive waste streams. It is often used in specialized applications where other materials fail.

Pros: Titanium’s strength-to-weight ratio is excellent, and its resistance to corrosion extends its lifespan significantly, making it a long-term investment.

Cons: The main drawback is its high cost and complexity in manufacturing. This can limit its use to specific applications where performance justifies the expense.

Impact on Application: Titanium is ideal for evaporators dealing with highly corrosive materials, ensuring minimal maintenance and downtime.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations, such as Europe, will find titanium compliant with many standards. However, they should also consider the higher upfront costs.

Summary Table of Material Selection for Hazardous Waste Evaporators

| Material | Typical Use Case for hazardous waste evaporators | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General-purpose evaporators | Excellent corrosion resistance and durability | Higher cost compared to other materials | High |

| Carbon Steel | Budget-friendly applications | Cost-effective and easy to fabricate | Prone to rust and corrosion | Low |

| High-Density Polyethylene (HDPE) | Non-corrosive waste streams | Lightweight and resistant to many chemicals | Lower temperature and pressure ratings | Medium |

| Titanium | Highly corrosive waste streams | Exceptional corrosion resistance | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material options for hazardous waste evaporators, aiding international buyers in making informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hazardous waste evaporators

What are the Main Stages of Manufacturing Hazardous Waste Evaporators?

The manufacturing of hazardous waste evaporators is a multi-stage process that involves meticulous planning and execution to ensure the final product meets industry standards and customer expectations. Here are the primary stages involved:

Material Preparation

The first step in the manufacturing process is material preparation. High-quality materials, such as stainless steel and specialized alloys, are selected for their durability and resistance to corrosion. Suppliers must provide material certifications to confirm that the materials meet specific mechanical and chemical properties. This stage may also involve cutting and shaping raw materials into manageable sizes for further processing.

Forming Techniques in Evaporator Manufacturing

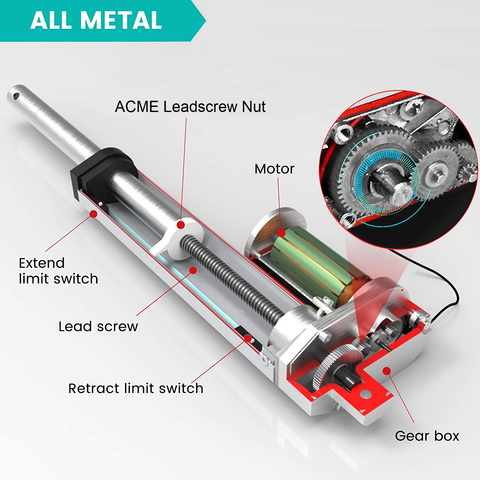

Once the materials are prepared, forming techniques are employed. Common methods include:

- Welding: This is a critical process for assembling components of the evaporator. Techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding are frequently used to ensure strong, leak-proof joints.

- Bending and Rolling: Stainless steel sheets are often bent or rolled into the desired shapes for the evaporator’s body and internal components.

- Machining: Precision machining techniques, including CNC (Computer Numerical Control) milling, are utilized to create intricate parts that require high accuracy.

Assembly of Hazardous Waste Evaporators

After the components are formed, they undergo assembly. This stage involves:

- Integration of Components: All parts, including heat exchangers, pumps, and control systems, are integrated into the main structure.

- Electrical and Control Systems Installation: Automation and control systems are installed to ensure the evaporator operates efficiently. This includes wiring, sensors, and control panels, which require careful calibration.

- Initial Testing: Before moving to the finishing stage, the assembled unit may undergo preliminary tests to check for functionality and leaks.

Finishing Processes for Enhanced Durability

The final stage involves finishing processes that enhance the durability and aesthetic appeal of the evaporators. This includes:

- Surface Treatment: Techniques such as passivation or polishing are employed to improve corrosion resistance and cleanability.

- Coating: Protective coatings may be applied to further enhance the lifespan of the evaporator in harsh environments.

How is Quality Assurance Implemented in the Manufacturing of Evaporators?

Quality assurance (QA) in the manufacturing of hazardous waste evaporators is crucial to ensure safety, compliance, and performance. Here are the key aspects of QA relevant to B2B buyers:

What International Standards Guide Quality Assurance for Evaporators?

Manufacturers of hazardous waste evaporators typically adhere to several international standards, including:

- ISO 9001: This standard focuses on quality management systems and emphasizes a process approach to enhance customer satisfaction and continuous improvement.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards that may be applicable for evaporators used in oil and gas applications.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that every component meets the required standards. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival for compliance with specifications.

- In-Process Quality Control (IPQC): Inspections are conducted at various stages of the manufacturing process to identify defects early, which helps reduce waste and rework.

- Final Quality Control (FQC): After assembly, the complete evaporator undergoes thorough testing to verify its performance, safety, and compliance with relevant standards.

What Common Testing Methods are Used for Hazardous Waste Evaporators?

Various testing methods are employed to ensure that the evaporators function correctly and safely. These may include:

- Hydrostatic Testing: This test checks for leaks and ensures the integrity of welded joints by pressurizing the evaporator with water.

- Performance Testing: Each unit is tested to confirm it meets specified evaporation rates and energy efficiency metrics.

- Material Testing: Tests such as tensile strength, hardness, and corrosion resistance are conducted on materials used in the manufacturing process to ensure they meet industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure reliability and compliance. Here are some strategies:

Illustrative image related to hazardous waste evaporators

Conducting Supplier Audits

Regular audits of potential suppliers can help assess their manufacturing processes and quality management systems. Buyers should consider requesting:

- Audit Reports: These reports provide insights into the supplier’s adherence to quality standards and their corrective action processes.

- Certifications: Ensure the supplier holds relevant certifications (e.g., ISO 9001, CE) and verify their validity.

Requesting Quality Control Documentation

Buyers should request documentation that outlines the QC processes the supplier employs, including:

- Quality Control Plans: A detailed plan that outlines the QC methodologies used during manufacturing.

- Testing Reports: Documentation of the results from various testing methods applied to the evaporators.

Engaging Third-party Inspection Services

For added assurance, buyers may opt for third-party inspection services to evaluate the manufacturing process and final product. This independent verification can provide an objective assessment of the supplier’s capabilities and compliance with international standards.

What are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of certain nuances in quality control:

- Regulatory Compliance: Different regions may have unique regulations governing hazardous waste management and equipment safety. Buyers must ensure that suppliers comply with both local and international regulations.

- Cultural Considerations: Communication styles and business practices may vary significantly across regions. Establishing clear expectations and understanding local practices can enhance collaboration and ensure quality outcomes.

- Logistical Challenges: Consider potential logistical issues related to transporting hazardous materials or equipment across borders, which may impact quality control during shipping and handling.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing hazardous waste evaporators, ensuring they partner with reliable suppliers that deliver high-quality, compliant products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hazardous waste evaporators’

Introduction

When sourcing hazardous waste evaporators, it’s crucial to follow a systematic approach to ensure you select the right equipment for your operational needs. This guide provides a checklist that will help international B2B buyers navigate the procurement process, focusing on essential factors to consider, from technical specifications to supplier evaluation.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements of the evaporator. Consider factors such as the volume of wastewater generated, the types of hazardous materials involved, and desired evaporation rates. This will guide your selection and ensure compatibility with existing systems.

- Volume Capacity: Determine the gallons per hour (GPH) needed based on your waste generation rates.

- Material Compatibility: Ensure the evaporator can handle the specific chemicals or contaminants in your wastewater.

Step 2: Research Industry Standards and Regulations

Familiarize yourself with local and international regulations governing hazardous waste treatment. Compliance is essential to avoid legal penalties and ensure safe operation.

- Environmental Regulations: Identify specific environmental laws in your region, such as those set by the EPA or equivalent authorities.

- Safety Standards: Ensure the evaporator meets safety standards like ISO or CE certifications, which may be required in your market.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s essential to vet suppliers thoroughly. Assess their reputation, reliability, and experience in manufacturing hazardous waste evaporators.

- Company Background: Request company profiles that detail their history, expertise, and number of installations.

- Customer References: Seek testimonials or case studies from clients in similar industries or regions to gauge satisfaction and performance.

Step 4: Compare Features and Technologies

Different evaporators employ various technologies, each with its advantages and disadvantages. Compare features to find a solution that aligns with your needs and budget.

- Energy Efficiency: Look for models that utilize heat pump technology or other energy-saving mechanisms, as these can significantly reduce operational costs.

- Automation Level: Consider whether you need a fully automated system that can operate unattended, which can lower labor costs and improve efficiency.

Step 5: Request Quotes and Evaluate Pricing Structures

Once you have shortlisted potential suppliers, request detailed quotes. Evaluate pricing structures while considering total cost of ownership, not just the initial purchase price.

- Cost Breakdown: Ensure quotes include installation, maintenance, and potential operational costs.

- Rental Options: Inquire about rental or leasing options, which can provide flexibility and reduce upfront capital expenditure.

Step 6: Conduct Site Visits and Demos

If possible, arrange site visits to suppliers or request demonstrations of the evaporators in action. This provides valuable insights into their performance and operational efficiency.

- Operational Insights: Observe the equipment’s operation, maintenance requirements, and user interface.

- Fit for Purpose: Ensure the evaporator meets your specific needs in a real-world setting, considering factors like space and workflow integration.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, review the purchase agreement thoroughly. Ensure all terms are clear, including warranty, service agreements, and delivery timelines.

- Service and Support: Confirm the level of post-purchase support, including training and technical assistance.

- Warranty Coverage: Understand warranty terms and what is covered, as this will impact long-term operational reliability.

By following this structured approach, you can confidently procure a hazardous waste evaporator that meets your operational needs while ensuring compliance and efficiency.

Comprehensive Cost and Pricing Analysis for hazardous waste evaporators Sourcing

What Are the Key Cost Components for Hazardous Waste Evaporators?

Understanding the cost structure for hazardous waste evaporators is essential for B2B buyers aiming for a successful procurement process. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the overall cost. Stainless steel, often used for its durability and corrosion resistance, can be more expensive than other materials. The quality of components, such as pumps and heating elements, also affects pricing.

-

Labor: Skilled labor is essential for the assembly and quality assurance of these systems. Labor costs can vary based on the geographical location of the manufacturer and their workforce quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturers often have lower overhead costs, which can translate to better pricing for buyers.

-

Tooling: Custom evaporators may require specialized tooling, which increases initial costs. However, such tooling can lead to more efficient production runs, potentially lowering long-term costs.

-

Quality Control (QC): Investing in robust QC processes ensures that the evaporators meet industry standards and certifications. While this adds to the upfront costs, it can save buyers from future liabilities and operational issues.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and any special handling requirements for hazardous materials. Understanding Incoterms is crucial for clarifying responsibilities and costs related to transportation.

-

Margin: Suppliers typically mark up prices to cover their costs and achieve a profit margin. This margin can vary based on market demand, competitive landscape, and the supplier’s reputation.

How Do Price Influencers Affect Hazardous Waste Evaporator Pricing?

Several factors influence the pricing of hazardous waste evaporators, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders often come with discounts, making it vital for buyers to consider their purchasing needs. Minimum Order Quantities (MOQs) can also impact pricing.

-

Specifications/Customization: Custom features or specialized designs can significantly increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (like ISO or CE) can elevate costs. However, these investments may lead to enhanced performance and reliability.

-

Supplier Factors: The supplier’s experience, market reputation, and geographic location can influence pricing. Established suppliers with proven track records may charge a premium but often provide superior products and support.

-

Incoterms: Understanding Incoterms is crucial as they define the responsibilities of buyers and sellers in shipping. This knowledge can help buyers avoid unexpected costs and clarify risk allocation.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

When sourcing hazardous waste evaporators, international buyers should consider several strategies to enhance cost-efficiency and secure favorable terms.

-

Negotiate: Engage suppliers in price negotiations, especially for larger orders. It’s often possible to secure discounts based on volume or long-term commitments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term operational expenses. Factors like energy efficiency, maintenance costs, and potential downtime should be factored into the TCO.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Africa may have different pricing structures compared to those in Europe or the Middle East due to local economic conditions and material availability.

-

Conduct Supplier Audits: Evaluate potential suppliers by visiting their facilities or reviewing their production processes. This can provide insights into their operational efficiency and product quality, which are crucial for long-term partnerships.

-

Request Samples and Trials: Before committing to large orders, request samples or trial runs. This can help assess product quality and ensure it meets your specific needs without incurring unnecessary risks.

Disclaimer on Indicative Prices

Prices for hazardous waste evaporators can fluctuate based on market conditions, material availability, and specific project requirements. It is advisable for buyers to obtain quotes from multiple suppliers and conduct thorough comparisons to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing hazardous waste evaporators With Other Solutions

Introduction

When dealing with hazardous waste, businesses must carefully evaluate the most effective methods for waste management. While hazardous waste evaporators are a popular choice for reducing waste volume and enabling easier disposal, there are alternative solutions available. This analysis compares hazardous waste evaporators with two viable alternatives: reverse osmosis systems and chemical treatment methods. Understanding the strengths and weaknesses of each option can help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Hazardous Waste Evaporators | Reverse Osmosis Systems | Chemical Treatment Methods |

|---|---|---|---|

| Performance | Reduces waste volume by up to 99% | High efficiency in contaminant removal | Effective for neutralizing hazardous substances |

| Cost | Moderate initial cost, low operating costs | High installation and maintenance costs | Variable costs depending on chemicals used |

| Ease of Implementation | Generally straightforward installation | Complex setup and requires skilled labor | Simple to implement, but requires monitoring |

| Maintenance | Low maintenance; periodic checks required | High maintenance; requires regular filter changes | Moderate; depends on chemical storage and handling |

| Best Use Case | Ideal for facilities with high liquid waste volumes | Best for facilities needing high purity water | Suitable for specific waste types requiring neutralization |

Detailed Breakdown

What are the Pros and Cons of Reverse Osmosis Systems?

Reverse osmosis (RO) systems are designed to remove contaminants from water by pushing it through a semi-permeable membrane. One of the key advantages of RO systems is their high efficiency in removing various impurities, making them suitable for applications requiring purified water. However, the initial installation costs can be significant, and ongoing maintenance, including regular filter replacements, can also add to operational expenses. Additionally, RO systems generate waste brine that must be disposed of, which can complicate waste management processes.

How Do Chemical Treatment Methods Compare?

Chemical treatment methods involve adding reagents to hazardous waste to neutralize or transform harmful substances into less hazardous forms. These methods can be highly effective for specific types of waste, such as heavy metals or acids. The implementation is often straightforward, and it can be done on-site with minimal setup. However, the need for proper chemical storage, handling, and monitoring can increase operational complexity and safety risks. Additionally, the variability in costs for chemicals and potential regulatory compliance issues should be considered.

Conclusion

When selecting a waste management solution, B2B buyers should carefully assess their unique circumstances, including waste composition, volume, budget, and regulatory requirements. Hazardous waste evaporators provide a reliable method for volume reduction and are particularly advantageous for facilities generating large amounts of liquid waste. However, for those needing specific contaminant removal or neutralization, exploring alternatives like reverse osmosis or chemical treatment methods may be beneficial. Ultimately, the right choice will depend on the specific operational needs and long-term sustainability goals of the organization.

Illustrative image related to hazardous waste evaporators

Essential Technical Properties and Trade Terminology for hazardous waste evaporators

What Are the Key Technical Properties of Hazardous Waste Evaporators?

Understanding the technical properties of hazardous waste evaporators is essential for B2B buyers to make informed purchasing decisions. Here are several critical specifications that you should consider:

1. Material Grade

The construction material of an evaporator significantly impacts its durability and resistance to corrosion. Most high-quality evaporators are constructed from stainless steel, which offers excellent resistance to rust and chemical degradation. This is particularly important in environments where hazardous waste may contain corrosive substances. Selecting a unit made from superior material grades ensures longevity and minimizes maintenance costs.

2. Evaporation Rate

The evaporation rate, usually measured in gallons per hour (GPH), indicates how much wastewater the evaporator can process within a specific timeframe. For instance, models may vary from 4 to 4,000 GPH, depending on the technology used (e.g., thermal, vacuum heat pump). A higher evaporation rate can result in reduced operational time and lower disposal costs, making it a crucial factor for businesses with large volumes of waste.

Illustrative image related to hazardous waste evaporators

3. Operating Temperature

The operating temperature of an evaporator determines its efficiency in converting liquid waste into vapor. Many systems operate at temperatures ranging from 140°F to 200°F, depending on the type of waste being processed. Understanding the optimal temperature for your specific waste type can enhance the effectiveness of the evaporation process, ensuring that hazardous materials are adequately handled.

4. Energy Efficiency

Energy efficiency is a critical specification, especially for businesses looking to reduce operational costs. Some advanced evaporators utilize heat pump technology, which can be five times more energy-efficient than traditional electric resistance models. Evaluating the energy consumption of different evaporators can help companies achieve significant savings in utility costs over time.

5. Control Systems

Modern hazardous waste evaporators often come equipped with automated control systems that allow for unattended operation. Features like high and low-level sensors, temperature controls, and alerts for safe operation are essential. These systems not only enhance safety but also reduce labor costs, making them appealing for businesses looking for efficient waste management solutions.

6. Recovery Rate

The recovery rate indicates how much steam can be condensed back into liquid for reuse. This is particularly beneficial for businesses looking to minimize water usage and maximize resource recovery. A higher recovery rate not only enhances sustainability but also reduces overall operating costs associated with water procurement.

What Trade Terminology Should Buyers Know When Purchasing Evaporators?

Familiarity with industry jargon can streamline the purchasing process. Here are several common terms related to hazardous waste evaporators:

Illustrative image related to hazardous waste evaporators

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers to ensure compatibility and quality in replacement parts and equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers, as it can affect inventory costs and supply chain management. Knowing the MOQ helps businesses plan their purchases and negotiate better terms.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific goods or services. This is a common practice in B2B transactions, allowing buyers to compare prices and services from multiple vendors, ultimately leading to more informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for international buyers, as they define shipping responsibilities, risk management, and cost allocation.

Illustrative image related to hazardous waste evaporators

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This is a critical factor for businesses that rely on timely waste management solutions, as longer lead times can disrupt operations and impact compliance with environmental regulations.

6. Certification Standards

Certification standards refer to the compliance with industry regulations and safety standards, such as ISO or CE certifications. Understanding these standards ensures that the evaporators meet safety and environmental regulations, which is crucial for international trade and local compliance.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing hazardous waste evaporators more effectively, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the hazardous waste evaporators Sector

What are the Current Market Dynamics and Key Trends in Hazardous Waste Evaporators?

The hazardous waste evaporators market is experiencing significant growth, driven by increasing regulatory pressures and rising disposal costs. Governments worldwide are tightening regulations on waste management, pushing industries to adopt efficient waste minimization technologies. In regions such as Africa, South America, the Middle East, and Europe, this trend is particularly pronounced as countries aim to enhance their environmental standards and sustainability initiatives.

Emerging technologies, such as vacuum heat pump evaporators and multi-effect evaporators (MVR), are gaining traction due to their energy efficiency and lower operational costs. For instance, vacuum heat pumps can achieve energy savings up to five times greater than traditional systems, making them an attractive option for B2B buyers focused on cost reduction. Moreover, integrated systems that combine evaporation with water treatment are becoming a popular choice, allowing businesses to streamline operations and enhance their sustainability profiles.

International B2B buyers should also be aware of the growing trend towards automation in evaporator systems. Fully automated solutions reduce the need for manual intervention, thereby lowering labor costs and minimizing human error. This is particularly relevant for buyers in regions like Saudi Arabia and Brazil, where labor costs can be significant.

How is Sustainability Impacting the Sourcing of Hazardous Waste Evaporators?

Sustainability is increasingly influencing procurement strategies in the hazardous waste evaporators sector. As organizations recognize the environmental impact of their operations, ethical sourcing has become a priority. Buyers are now looking for manufacturers that adhere to sustainable practices and offer ‘green’ certifications, such as ISO 14001, which signifies robust environmental management systems.

The use of environmentally friendly materials in the production of evaporators is gaining traction. For instance, stainless steel construction not only enhances the durability of equipment but also minimizes rust and corrosion, thereby extending the life cycle of the evaporator. Additionally, many suppliers are now providing options that use non-volatile organic compound (VOC) compliant detergents, ensuring that the wastewater treatment process aligns with environmental regulations.

B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability, as this not only enhances their corporate responsibility profile but also mitigates risks associated with regulatory compliance. Engaging with manufacturers who invest in sustainable technologies can lead to long-term cost savings and improved operational efficiencies.

What is the Brief Evolution and Historical Context of Hazardous Waste Evaporators?

The evolution of hazardous waste evaporators can be traced back to the early 1970s when regulatory frameworks began to take shape in response to growing environmental concerns. Initially, evaporators were rudimentary, primarily focused on volume reduction without consideration for energy efficiency or automation. Over the decades, advancements in technology have transformed these systems into sophisticated, energy-efficient solutions capable of handling a variety of waste streams.

By the 1990s, the introduction of more advanced thermal and vacuum evaporation technologies set new standards in the industry, allowing for higher recovery rates and reduced operational costs. The shift towards automation and integrated systems has been particularly influential in the 21st century, enabling organizations to achieve greater efficiency and compliance with stringent environmental regulations.

Today, the hazardous waste evaporators market stands at a pivotal point, where sustainability and technological innovation are driving its future. As international B2B buyers navigate this landscape, understanding the historical context can provide valuable insights into current trends and future directions.

Frequently Asked Questions (FAQs) for B2B Buyers of hazardous waste evaporators

-

How do I choose the right hazardous waste evaporator for my business?

Choosing the right hazardous waste evaporator involves assessing your specific waste characteristics, volume, and regulatory requirements. Consider the evaporator’s capacity, efficiency, and technology type (e.g., thermal, vacuum heat pump). Evaluate the energy consumption and operational costs, as well as the ability to handle varying waste compositions. Additionally, consult with suppliers to understand customization options that can meet your unique processing needs. -

What are the key features to look for in a hazardous waste evaporator?

Key features to consider include energy efficiency, automation capabilities, construction material (preferably corrosion-resistant like stainless steel), and safety mechanisms such as level sensors and exhaust systems. Look for models with high evaporation rates and low operational costs. Ensure the evaporator can handle your specific waste type and has a reliable support system for maintenance and troubleshooting. -

What are the typical lead times for ordering hazardous waste evaporators?

Lead times can vary significantly based on the manufacturer, model, and any customization required. Generally, standard units may have lead times of 4-8 weeks, while customized solutions could take 12 weeks or longer. It’s advisable to discuss timelines with your supplier early in the negotiation process to ensure timely delivery aligns with your operational needs. -

What is the minimum order quantity (MOQ) for hazardous waste evaporators?

The MOQ can differ between suppliers and may depend on the type of evaporator and any customization involved. Many manufacturers allow for single-unit purchases for standard models, while custom configurations might have higher MOQs. Always confirm with your supplier regarding MOQ, as this can affect your purchasing strategy, especially in regions with specific waste management regulations. -

How do I ensure quality assurance when sourcing evaporators internationally?

To ensure quality assurance, vet suppliers by checking certifications, past performance, and customer reviews. Request detailed specifications and documentation for the evaporators, including compliance with international safety and environmental standards. Consider visiting the manufacturing facility or requesting a virtual tour. Establish clear quality control benchmarks in your purchase agreement to safeguard your investment. -

What payment terms are commonly accepted for international purchases of hazardous waste evaporators?

Common payment terms for international purchases include letters of credit, wire transfers, and payment upon delivery. Some suppliers may offer financing options or installment payments, especially for larger orders. Clarify payment terms upfront to avoid misunderstandings and ensure that they align with your financial processes. -

What logistics considerations should I be aware of when importing hazardous waste evaporators?

When importing, consider shipping methods, customs regulations, and potential tariffs. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices, certificates of origin, and compliance certificates. It’s beneficial to work with logistics experts familiar with hazardous materials to navigate shipping safely and efficiently while adhering to all local regulations. -

Can hazardous waste evaporators be customized for specific waste types?

Yes, many manufacturers offer customization options to tailor evaporators for specific types of hazardous waste. This may include adjustments to the evaporation technology, capacity, and materials used in construction. Discuss your specific waste characteristics with potential suppliers to ensure that the evaporator meets your operational requirements and complies with local regulations.

Top 5 Hazardous Waste Evaporators Manufacturers & Suppliers List

1. ENCON – Wastewater Evaporators

Domain: evaporator.com

Registered: 1996 (29 years)

Introduction: ENCON Evaporators designs and manufactures American-made wastewater evaporators that reduce disposal volume by up to 99%. They have over 30 years of experience and 2,000+ installations worldwide, offering reliable, energy-efficient solutions for industrial wastewater minimization. Key products include: 1. Thermal Evaporator: 8-650 Gallons Per Hour 2. Vacuum Heat Pump Evaporator: 20-70 Gallons Per …

2. Smart Sonic – SE-1 Wastewater Evaporator

Domain: smartsonic.com

Registered: 1996 (29 years)

Introduction: Model: SE-1 Wastewater Evaporator

Type: Electrical-fired evaporator

Material: 100% stainless steel

Evaporation Rate: 4-6 gallons per hour

Operation: Fully automatic, operates unattended

Compatibility: Works with any Smart Sonic Stencil Cleaner

Features:

– High and low level sensors to prevent overfilling

– Built-in exhaust blower for up to 15′ duct run

– Control panel for automatic operation

– Al…

3. IQS Directory – Wastewater Evaporators

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Wastewater evaporators transform water-based waste into vapor, separating impurities and reducing waste volume. They utilize thermodynamics and mass transfer principles, applying thermal energy to liquid waste to vaporize water. Common fuel sources include natural gas, electricity, oil, or steam. Key components include a feed pump for liquid transfer, a heat exchanger for heating, a blower for vap…

4. Condorchem – Industrial Vacuum Evaporators

Domain: condorchem.com

Registered: 2003 (22 years)

Introduction: Condorchem Enviro Solutions offers industrial vacuum evaporators for wastewater treatment, designed for the treatment and reuse of wastewater and recovery of raw materials and by-products. Key features include: a wide range of evaporators for various contaminants and volumes, customization for efficiency and durability, and support for zero liquid discharge (ZLD) systems. The evaporators can achie…

5. Samsco – Water Treatment Solutions

Domain: samsco.com

Registered: 1998 (27 years)

Introduction: Samsco Water Evaporator II, WasteSaver (Vacuum Distillation), Envirostill MVR, Water Treatment Technologies, Poly Atmospheric Evaporators, Auxiliary Equipment.

Strategic Sourcing Conclusion and Outlook for hazardous waste evaporators

In the realm of hazardous waste management, strategic sourcing of evaporators presents a pivotal opportunity for businesses aiming to optimize waste disposal processes. By investing in advanced technologies, such as energy-efficient and automated systems, organizations can significantly reduce hazardous waste volume—often by up to 99%. This not only lowers disposal costs but also aligns with sustainability goals, making it an attractive proposition for buyers in diverse markets, including Africa, South America, the Middle East, and Europe.

Furthermore, understanding the unique operational needs and regulatory requirements in these regions can enhance sourcing decisions. Companies like ENCON and Smart Sonic exemplify the innovation in this sector, offering tailored solutions that ensure compliance and efficiency. As global environmental standards tighten, the importance of selecting the right evaporator will only increase.

Looking ahead, international buyers should prioritize suppliers who demonstrate a commitment to quality, sustainability, and technological advancement. Engaging in strategic partnerships can foster long-term benefits and drive operational excellence. Now is the time to act—evaluate your options, embrace innovation, and invest in sustainable waste management solutions that will propel your organization into a greener future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.