The Definitive Guide to Atlanta Foam: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for atlanta foam

In an increasingly competitive landscape, sourcing high-quality Atlanta foam can present significant challenges for international B2B buyers. Whether you are looking for durable packaging solutions, specialized medical components, or effective insulation materials, understanding the nuances of foam types and their applications is crucial. This comprehensive guide delves into the diverse range of foam materials available, including polyethylene and polyurethane foams, and highlights their specific uses across various industries such as automotive, electronics, and healthcare.

As a buyer from regions like Africa, South America, the Middle East, or Europe, navigating supplier options can be daunting. This guide not only provides insights into the best practices for vetting suppliers but also outlines cost considerations and logistical factors that can impact your procurement process. By equipping you with the knowledge to make informed purchasing decisions, we empower you to select the right foam solutions tailored to your unique business needs.

Additionally, we will explore advanced fabrication techniques, such as CNC routing and die cutting, that can enhance the performance and customization of foam products. With a focus on innovation and quality, this guide serves as your roadmap to successfully sourcing Atlanta foam, ensuring you remain competitive in your market while meeting the highest standards of your industry.

Understanding atlanta foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed Cell Foam | Tightly packed cells, water-resistant, durable | Packaging, insulation, automotive parts | Pros: Excellent moisture resistance, high durability. Cons: Typically higher cost compared to open-cell foams. |

| Polyethylene Foam | Lightweight, flexible, and shock-absorbent | Medical devices, electronics packaging | Pros: Cost-effective, versatile, good cushioning. Cons: Limited temperature resistance. |

| Polyurethane Foam | Soft, flexible, and available in various densities | Furniture, bedding, automotive interiors | Pros: Comfortable, customizable density. Cons: Can degrade with moisture exposure. |

| Cross Linked Foam | Enhanced structural integrity, resistant to chemicals | Aerospace, military applications | Pros: High durability, superior performance in harsh conditions. Cons: More expensive than standard foams. |

| Beaded Polypropylene Foam | Lightweight, closed-cell structure, recyclable | Protective packaging, insulation | Pros: Eco-friendly, good thermal insulation. Cons: Lower impact resistance compared to other types. |

What Are the Characteristics of Closed Cell Foam and Its Suitability for B2B Applications?

Closed cell foam is characterized by its tightly packed cells that are sealed off, making it highly water-resistant and durable. This type of foam is particularly suitable for applications requiring moisture protection, such as insulation and packaging. B2B buyers should consider its higher cost compared to open-cell foams, but the long-term benefits in durability and performance can justify the investment, especially in sectors like automotive and construction.

How Does Polyethylene Foam Stand Out in the Market?

Polyethylene foam is lightweight, flexible, and known for its shock-absorbent properties. It is widely used in medical devices and electronics packaging due to its excellent cushioning capabilities. Buyers should note its cost-effectiveness and versatility, but also its limitations regarding temperature resistance. This foam is ideal for businesses that require reliable protection for sensitive equipment during shipping and handling.

Illustrative image related to atlanta foam

Why Choose Polyurethane Foam for Comfort and Customization?

Polyurethane foam is recognized for its soft and flexible nature, available in a variety of densities to suit different needs. It is commonly used in furniture, bedding, and automotive interiors. The ability to customize density makes it a favorite among manufacturers. However, buyers should be cautious of its moisture sensitivity, which can lead to degradation over time. Investing in high-quality polyurethane foam can enhance product comfort and longevity.

What Are the Advantages of Cross Linked Foam for High-Performance Applications?

Cross linked foam features enhanced structural integrity and is resistant to chemicals, making it ideal for high-performance applications in aerospace and military sectors. Its durability and superior performance in harsh environments make it a valuable choice for B2B buyers who prioritize reliability. However, the cost can be a consideration, as it is typically more expensive than standard foams. Businesses should weigh the performance benefits against the initial investment.

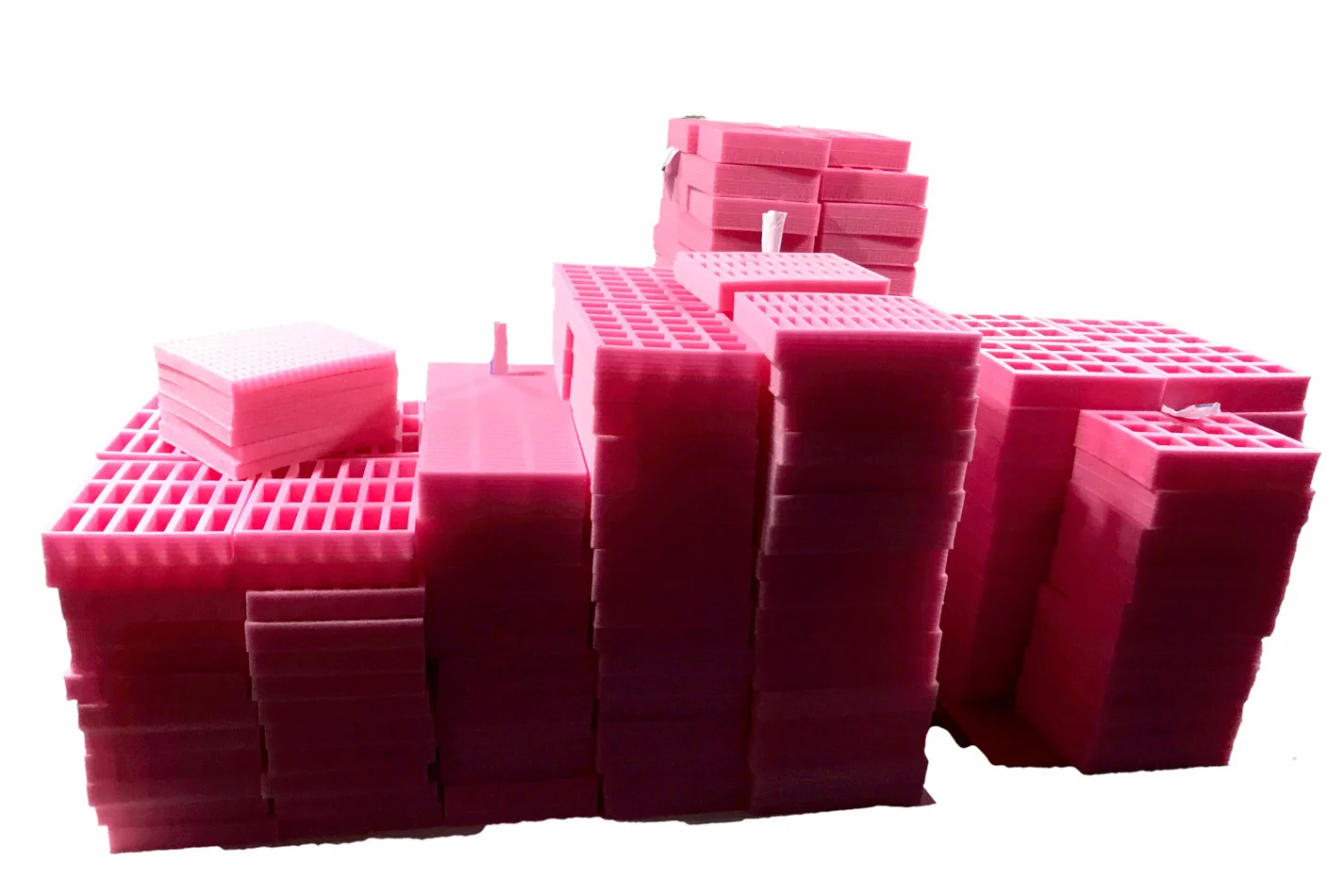

How Does Beaded Polypropylene Foam Contribute to Eco-Friendly Packaging Solutions?

Beaded polypropylene foam is lightweight and features a closed-cell structure that is recyclable, making it an environmentally friendly option. It is commonly utilized in protective packaging and insulation. While it offers good thermal insulation, buyers should be aware of its lower impact resistance compared to other foam types. Companies focused on sustainability will find this foam appealing, especially for applications where eco-friendly materials are a priority.

Key Industrial Applications of atlanta foam

| Industry/Sector | Specific Application of atlanta foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Foam components for sound insulation and cushioning | Reduces noise, enhances comfort, improves safety | Compliance with automotive standards, durability under stress |

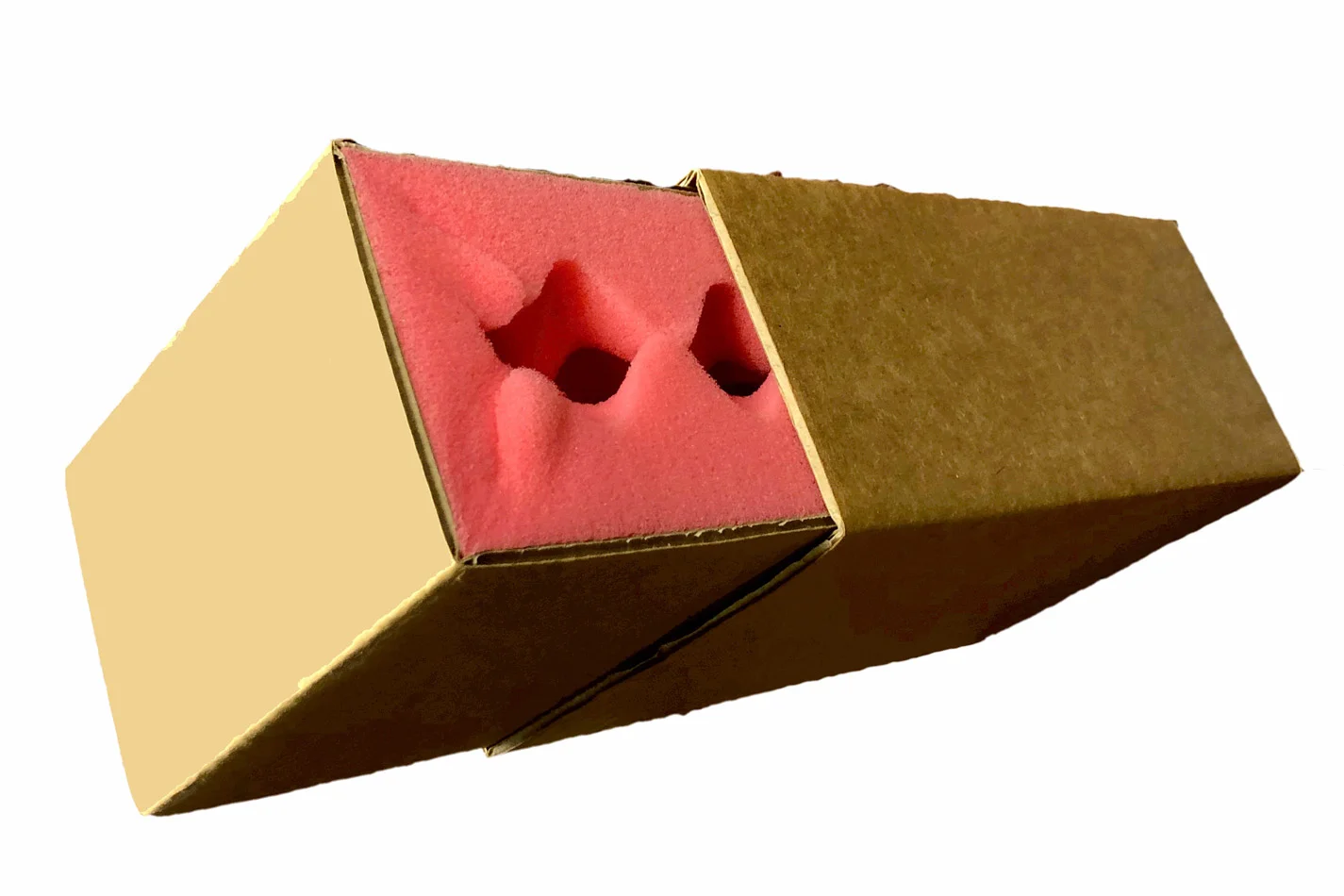

| Medical | Foam for packaging and cushioning of medical devices | Protects sensitive equipment, ensures sterility | Biocompatibility, regulatory compliance, custom shapes required |

| Aerospace | Lightweight foam for insulation and structural components | Reduces weight, improves fuel efficiency | High-performance materials, fire resistance, custom fabrication |

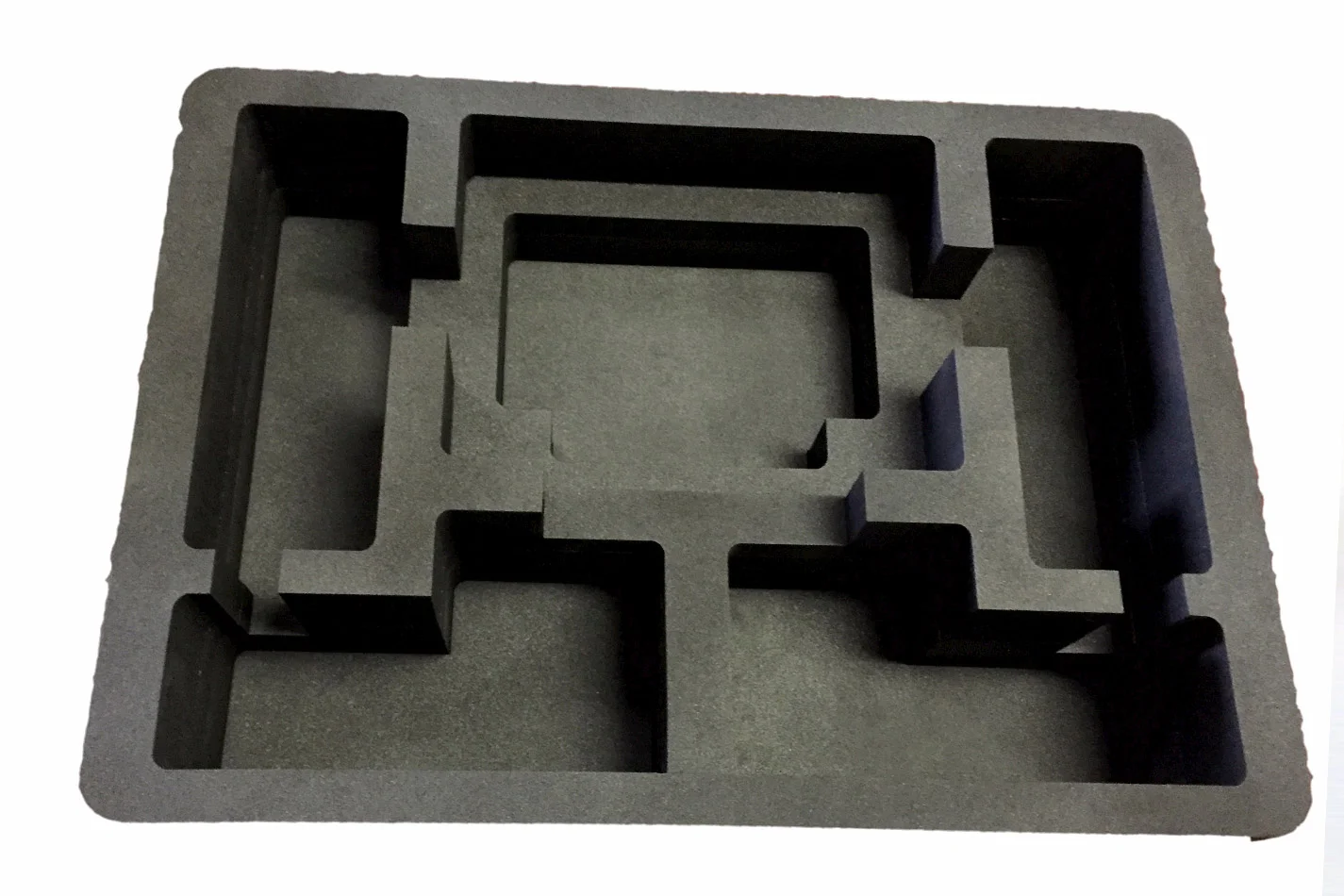

| Electronics | Foam inserts for protective packaging | Minimizes damage during transport, enhances branding | Custom sizes, anti-static properties, moisture resistance |

| Packaging | Custom foam solutions for fragile items | Reduces breakage, optimizes shipping costs | Material compatibility, eco-friendly options, precise dimensions |

How is Atlanta Foam Used in the Automotive Sector?

In the automotive industry, Atlanta foam is primarily utilized for sound insulation and cushioning components. These foam materials help mitigate noise levels within vehicles, enhancing passenger comfort and overall driving experience. Additionally, they contribute to safety by absorbing impact during collisions. International buyers must ensure that the foam meets stringent automotive standards for durability and performance, particularly in markets like Brazil and Saudi Arabia, where environmental conditions can vary significantly.

Illustrative image related to atlanta foam

What Role Does Atlanta Foam Play in the Medical Field?

In the medical sector, Atlanta foam serves as essential packaging and cushioning for sensitive medical devices and equipment. Its protective qualities ensure that devices remain intact during transportation and storage, while maintaining sterility. Buyers in this field must prioritize biocompatibility and compliance with industry regulations, particularly when sourcing for regions with strict healthcare standards, such as Europe and the Middle East.

Why is Foam Important in Aerospace Applications?

Aerospace applications leverage Atlanta foam for its lightweight properties and insulation capabilities. The use of specialized foam materials helps reduce the overall weight of aircraft, contributing to improved fuel efficiency and performance. Buyers in this sector should focus on acquiring high-performance materials that meet fire resistance standards, as well as custom fabrication options to fit unique aerospace designs.

How Does Atlanta Foam Enhance Electronics Packaging?

In the electronics industry, Atlanta foam is crucial for creating custom inserts that protect delicate components during shipping. These foam solutions minimize the risk of damage, ensuring that products arrive in pristine condition, which is vital for maintaining brand reputation. When sourcing foam for electronics, buyers should consider anti-static properties and moisture resistance, particularly in humid regions like South America.

What are the Benefits of Custom Foam Solutions in Packaging?

Atlanta foam plays a significant role in packaging, especially for fragile items that require extra protection. Custom foam solutions reduce breakage and optimize shipping costs by ensuring that products are securely held in place. B2B buyers must consider material compatibility and eco-friendly options, as sustainability becomes increasingly important in global markets, particularly in Europe and Africa.

3 Common User Pain Points for ‘atlanta foam’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Foam Material for Specific Applications

The Problem: B2B buyers often face challenges in determining the most suitable type of foam for their specific applications, whether it’s for packaging, insulation, or manufacturing. With various options like polyethylene, polyurethane, and closed-cell foams, the decision-making process can become overwhelming. This uncertainty can lead to delays in production, increased costs, and the risk of utilizing materials that do not meet industry standards or customer expectations.

The Solution: To effectively choose the right foam material, B2B buyers should start by clearly defining the application requirements, including thermal insulation properties, moisture resistance, density, and compliance with industry regulations. Engaging with suppliers like Atlanta Foam Fabricators can provide valuable insights into the characteristics and benefits of each foam type. It’s advisable to request samples for testing and consider conducting a cost-benefit analysis to evaluate the long-term performance and return on investment of different foam materials. Collaborating with engineering teams early in the design process can also help ensure that the selected foam aligns with both functionality and cost-effectiveness.

Scenario 2: Challenges with Custom Foam Fabrication and Prototyping

The Problem: Many businesses require custom foam products tailored to their specific needs, but they often encounter hurdles during the fabrication and prototyping stages. These challenges can include miscommunication regarding design specifications, longer lead times than expected, or subpar quality in the final product. Such issues can not only disrupt production schedules but also impact overall project timelines and budgets.

Illustrative image related to atlanta foam

The Solution: To mitigate these challenges, B2B buyers should prioritize clear communication with their foam fabricators from the outset. This includes providing detailed design specifications, including dimensions, density requirements, and functional characteristics. Utilizing advanced tools such as CAD software for design can facilitate more accurate prototypes. Additionally, establishing a timeline that includes milestones for review and feedback can help keep the project on track. Working with a reputable provider like Atlanta Foam Fabricators, known for their advanced fabrication capabilities and commitment to quality, can further ensure that the prototypes meet the necessary standards before moving into full production.

Scenario 3: Concerns Over Foam Material Compliance and Sustainability

The Problem: As businesses increasingly focus on sustainability and compliance with environmental regulations, B2B buyers often worry about the eco-friendliness of foam materials and their compliance with industry standards. This concern is particularly prevalent in industries such as automotive, aerospace, and medical, where regulations regarding material safety and environmental impact are stringent. Failure to select compliant materials can lead to legal repercussions and damage a company’s reputation.

The Solution: B2B buyers should conduct thorough research on the foam materials they intend to use, focusing on certifications and compliance with international standards such as ISO and ASTM. Partnering with foam fabricators like Atlanta Foam Fabricators, who emphasize quality and sustainability, can alleviate concerns regarding compliance. Buyers should inquire about the sourcing of raw materials, the manufacturing processes used, and any certifications that demonstrate a commitment to environmental responsibility. Incorporating eco-friendly foam options, such as biodegradable or recycled foams, can enhance a company’s sustainability profile while still meeting performance standards. Regular audits and supplier assessments can further ensure that materials remain compliant and sustainable over time.

Strategic Material Selection Guide for atlanta foam

What Are the Key Properties of Polyethylene Foam for Atlanta Foam Applications?

Polyethylene foam is a versatile closed-cell material known for its excellent cushioning properties and resistance to moisture, chemicals, and UV radiation. It typically operates effectively within a temperature range of -40°F to 180°F (-40°C to 82°C), making it suitable for various environmental conditions. Its closed-cell structure provides superior insulation, making it an ideal choice for packaging sensitive electronic components or thermal insulation in construction applications.

Illustrative image related to atlanta foam

Pros: Polyethylene foam is lightweight, durable, and cost-effective, making it a popular choice for bulk orders. It is easy to fabricate, allowing for custom shapes and sizes, which is beneficial for international buyers needing tailored solutions.

Cons: While it offers good durability, it may not withstand extreme temperatures as effectively as some other materials. Additionally, its performance can be compromised if exposed to prolonged high temperatures.

Impact on Application: Polyethylene foam is compatible with a wide range of media, including water and various chemicals, making it suitable for packaging, insulation, and automotive applications.

Illustrative image related to atlanta foam

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Understanding ASTM standards for polyethylene can also facilitate smoother transactions.

How Does Polyurethane Foam Compare in Terms of Performance and Cost?

Polyurethane foam is another popular choice, known for its excellent flexibility and resilience. It can withstand a temperature range of -20°F to 120°F (-29°C to 49°C) and provides good sound and thermal insulation. Its open-cell structure allows for breathability, making it suitable for applications requiring air circulation.

Pros: Polyurethane foam is highly customizable in terms of density and firmness, allowing for specific application needs. It is also relatively inexpensive compared to other materials, making it a cost-effective option for large-scale production.

Cons: The open-cell structure can absorb moisture, which may lead to degradation over time in humid environments. Additionally, it may not perform as well in applications requiring high chemical resistance.

Impact on Application: Its compatibility with various media, including air and light liquids, makes it ideal for applications in the automotive and medical sectors.

Considerations for International Buyers: Buyers should be aware of compliance with local standards, such as DIN or JIS, especially in regions like Europe and the Middle East, where regulations may be stricter.

What Are the Benefits and Limitations of Cross-Linked Polyethylene Foam?

Cross-linked polyethylene (XLPE) foam is a high-performance material known for its superior durability and resistance to chemicals, moisture, and UV light. It typically operates within a temperature range of -40°F to 200°F (-40°C to 93°C), making it suitable for a variety of applications, including insulation and protective packaging.

Pros: XLPE foam is exceptionally durable and maintains its properties over time, making it ideal for long-term applications. Its closed-cell structure provides excellent thermal insulation and sound absorption.

Cons: The manufacturing process for XLPE foam is more complex, which can lead to higher costs. Additionally, it may not be as readily available in some regions, limiting sourcing options for international buyers.

Illustrative image related to atlanta foam

Impact on Application: Its high resistance to moisture makes it suitable for applications in marine and outdoor environments, as well as in construction and automotive sectors.

Considerations for International Buyers: Buyers should verify compliance with international standards and ensure that suppliers can meet specific regional requirements, particularly in the Middle East and Europe.

How Does Beaded Polypropylene Foam Fit into the Atlanta Foam Product Line?

Beaded polypropylene foam is a lightweight, closed-cell material known for its excellent buoyancy and thermal insulation properties. It typically operates effectively within a temperature range of -20°F to 120°F (-29°C to 49°C).

Illustrative image related to atlanta foam

Pros: This material is highly resistant to moisture and chemicals, making it suitable for various applications, including packaging and insulation. Its lightweight nature reduces shipping costs, which is a significant advantage for international buyers.

Cons: Beaded polypropylene foam can be less durable than other foam types, particularly under heavy loads. Additionally, its performance in extreme temperatures may not be as reliable as other materials.

Impact on Application: Its buoyancy makes it ideal for marine applications, while its insulation properties suit construction and HVAC applications.

Considerations for International Buyers: Buyers should consider local regulations regarding material safety and environmental impact, particularly in Europe, where compliance with EU standards is crucial.

Illustrative image related to atlanta foam

Summary Table of Materials for Atlanta Foam

| Material | Typical Use Case for atlanta foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Foam | Packaging, insulation | Lightweight and cost-effective | Limited temperature resistance | Low |

| Polyurethane Foam | Automotive, medical applications | Highly customizable | Moisture absorption can degrade it | Med |

| Cross-Linked Polyethylene Foam | Insulation, protective packaging | Superior durability and chemical resistance | Higher manufacturing complexity | High |

| Beaded Polypropylene Foam | Marine applications, HVAC | Excellent buoyancy and insulation | Less durable under heavy loads | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for atlanta foam

What Are the Main Stages of the Manufacturing Process for Atlanta Foam?

The manufacturing process for foam products at Atlanta Foam typically unfolds in several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets the highest quality standards.

Material Preparation

In the initial phase, the selection and preparation of foam materials are crucial. Atlanta Foam utilizes a variety of high-quality materials, including polyethylene and polyurethane foams, which are chosen based on the specific requirements of the application. The materials undergo rigorous quality checks to ensure they meet the necessary specifications before moving on to the next phase.

Forming Techniques

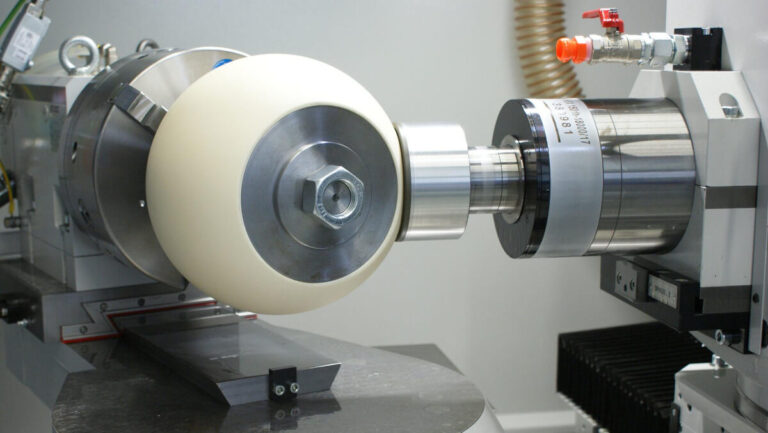

Once the materials are prepared, they enter the forming stage. This process may involve advanced techniques such as CNC routing, water jet cutting, and die cutting, which allow for precise shaping of the foam. These techniques enable Atlanta Foam to create customized shapes and sizes tailored to the client’s specifications. By leveraging state-of-the-art equipment, the company can achieve high levels of accuracy and consistency across production runs.

Illustrative image related to atlanta foam

Assembly

After forming, the foam components are assembled as needed. This could involve laminating layers of foam, contouring for specific applications, or creating complex packaging solutions. Skilled craftsmen and engineers at Atlanta Foam ensure that each assembly is performed with meticulous attention to detail, which is critical for applications that require a high degree of precision, such as automotive and medical components.

Finishing Touches

The final stage is finishing, where the foam products undergo additional quality checks and treatments. This may include surface treatments, additional cutting, or packaging preparations. Finishing is essential to ensure that the foam products not only meet functional requirements but also adhere to aesthetic standards expected by clients.

How Does Quality Assurance (QA) Ensure High Standards in Foam Manufacturing?

Quality assurance is integral to the manufacturing processes at Atlanta Foam, ensuring that every product meets both international and industry-specific standards. The company adheres to ISO 9001, a globally recognized standard that outlines the criteria for a quality management system.

International and Industry-Specific Standards

For international B2B buyers, understanding the certifications held by suppliers is crucial. Atlanta Foam’s compliance with ISO 9001 signifies its commitment to quality management principles, including strong customer focus, the involvement of top management, and a process-driven approach. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications further enhance the company’s credibility.

Quality Control Checkpoints

Quality control at Atlanta Foam includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon delivery to ensure they meet specified standards. This helps prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. Operators perform checks at various stages to identify and rectify issues in real time, which reduces waste and ensures product consistency.

-

Final Quality Control (FQC): Once the products are finished, a final inspection is conducted to verify that they meet all specifications and standards before shipping. This includes dimensional checks, visual inspections, and functional tests.

What Testing Methods Are Commonly Used in Foam Manufacturing Quality Control?

To uphold quality standards, Atlanta Foam employs various testing methods tailored to the types of foam products being manufactured. Common testing methods include:

-

Compression Testing: This assesses the foam’s ability to withstand loads without deforming, which is essential for applications requiring durability.

-

Tensile Testing: This method evaluates the foam’s strength and elasticity, helping to ensure that it can withstand forces during use.

-

Thermal Testing: Given that foam is often used in insulation applications, thermal testing ensures that the material meets specific thermal resistance criteria.

-

Chemical Resistance Testing: For certain industries, particularly automotive and medical, testing the foam’s resistance to chemicals is critical.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to mitigate risks. Here are actionable steps B2B buyers can take:

-

Conduct Audits: Request on-site audits of the manufacturing facility to gain insights into the quality control processes. This provides a direct view of the operational standards and practices.

-

Review Quality Control Reports: Suppliers should provide detailed QC reports that outline inspection results, testing methods, and compliance with relevant standards.

-

Engage Third-Party Inspectors: Utilize third-party inspection services to conduct independent assessments of the supplier’s quality control processes and products. This adds an additional layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

When engaging with suppliers like Atlanta Foam, international buyers should be aware of several nuances in quality control:

-

Cultural Differences: Understanding the business practices and regulatory environments in different regions can affect how quality control is implemented and perceived.

-

Regulatory Compliance: Different markets may have varying requirements for product certifications. Buyers should ensure that the supplier meets the specific regulatory standards of their target market.

-

Communication: Clear communication about quality expectations and specifications is vital. Buyers should establish open lines of communication with suppliers to address any concerns promptly.

By understanding these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing foam products from Atlanta Foam, ensuring they receive high-quality materials that meet their unique application needs.

Illustrative image related to atlanta foam

Practical Sourcing Guide: A Step-by-Step Checklist for ‘atlanta foam’

To assist B2B buyers in the procurement of Atlanta foam, this guide provides a structured checklist that outlines essential steps to ensure a successful sourcing process. By following these steps, you can make informed decisions that align with your specific business needs and industry standards.

Step 1: Define Your Technical Specifications

Understanding your requirements is the first step in the sourcing process. Clearly outline the type of foam you need—whether it’s polyethylene, polyurethane, or another variant—and specify the desired density, thickness, and size. This will help potential suppliers provide accurate quotes and ensure that the foam meets your application needs.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers that specialize in foam products. Look for companies with a proven track record in your industry, as well as positive customer reviews and testimonials. Utilize online directories and trade associations to compile a list of potential suppliers that cater to international markets, particularly in Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for certifications that validate the supplier’s quality control processes and compliance with international standards, such as ISO certifications.

Step 4: Request Samples for Testing

Once you’ve narrowed down your list of suppliers, request samples of the foam products you are considering. Testing samples allows you to evaluate the material’s properties, such as durability, flexibility, and performance in your intended application. This step is vital to ensure that the foam meets your quality expectations before placing a larger order.

Step 5: Assess Pricing and Payment Terms

Gather detailed quotations from each supplier, ensuring that you understand the pricing structure, including any additional costs such as shipping, customs duties, and taxes. Compare the total cost of ownership rather than just the upfront price. Additionally, clarify payment terms, including deposits, credit options, and any available discounts for bulk orders.

Step 6: Negotiate Contracts and Terms

Once you have selected a supplier, initiate contract negotiations. Focus on essential aspects such as delivery timelines, product warranties, and after-sales support. Ensure that the contract includes clear terms for addressing any potential disputes or quality issues, which can help protect your investment.

Step 7: Establish Communication Channels

Effective communication is key to a successful partnership. Set up regular check-ins with your supplier to discuss order status, potential changes, and any issues that may arise. Establishing a strong line of communication helps foster a collaborative relationship and can lead to better service and support.

By following this structured checklist, B2B buyers can streamline the sourcing process for Atlanta foam, ensuring that they partner with the right suppliers and receive high-quality products tailored to their specific needs.

Illustrative image related to atlanta foam

Comprehensive Cost and Pricing Analysis for atlanta foam Sourcing

What Are the Key Cost Components in Atlanta Foam Sourcing?

When sourcing foam products from Atlanta, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of foam material selected significantly impacts the overall cost. Options such as polyethylene, polyurethane, or specialized foams for medical or automotive applications can vary widely in price. High-density or specialty foams typically command higher prices due to their enhanced properties and certifications.

-

Labor: Labor costs encompass the wages of skilled craftsmen and engineers involved in foam fabrication. These costs can fluctuate based on the complexity of the product and the level of expertise required. Customization often necessitates more labor-intensive processes, which can increase expenses.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Advanced technologies such as CNC routing and water jet cutting contribute to higher overhead costs but also enhance production efficiency and product precision.

-

Tooling: Custom tooling for die cutting or specific fabrication processes can be a significant upfront cost. While it may seem high initially, amortizing these costs over larger production runs can yield better pricing per unit.

-

Quality Control (QC): Ensuring that products meet stringent quality standards is vital, particularly in industries like aerospace or medical. Implementing robust QC processes incurs additional costs but protects against defects and maintains customer satisfaction.

-

Logistics: Shipping and transportation costs are critical, especially for international buyers. Factors such as distance, shipping method, and freight terms (Incoterms) can influence these costs. Buyers should factor in the potential for customs duties and taxes when calculating total expenses.

-

Margin: Suppliers typically apply a markup on their costs to ensure profitability. Understanding the supplier’s margin can aid in negotiations and provide insight into pricing flexibility.

What Price Influencers Should International B2B Buyers Consider?

When sourcing foam from Atlanta, various price influencers can affect the final cost:

-

Volume/MOQ: Bulk purchases often lead to volume discounts. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Tailoring foam products to specific applications or designs can increase costs. Buyers should evaluate whether customization is necessary or if standard products can meet their needs.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO or ASTM) can elevate costs but may be essential for compliance in certain industries.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may charge more but offer greater reliability and service.

-

Incoterms: Understanding shipping terms is crucial for calculating total costs. Different Incoterms define responsibilities for shipping, insurance, and tariffs, which can significantly alter the final price.

What Are the Best Negotiation Tips for Sourcing Foam?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation can yield significant savings:

-

Research and Preparation: Familiarize yourself with market prices and supplier capabilities. This knowledge empowers you to negotiate confidently.

-

Leverage Volume Orders: If feasible, consolidate orders to achieve economies of scale, which can lead to lower prices.

-

Discuss Payment Terms: Explore flexible payment options that may allow for discounts or better terms, especially for bulk orders.

-

Focus on Total Cost of Ownership (TCO): Instead of concentrating solely on the purchase price, consider the total cost of ownership, including logistics, maintenance, and disposal costs. This holistic view can justify higher upfront costs for higher-quality products.

-

Be Aware of Regional Pricing Nuances: Understand the economic factors influencing foam pricing in your region. Currency fluctuations, trade agreements, and local demand can all impact costs.

Disclaimer Regarding Indicative Prices

While the above analysis provides a comprehensive overview of cost and pricing considerations, actual prices may vary based on specific requirements, market conditions, and negotiations. It is advisable for buyers to request quotes tailored to their unique needs to ensure accurate budgeting.

Alternatives Analysis: Comparing atlanta foam With Other Solutions

Understanding Alternatives to Atlanta Foam Solutions

In the realm of foam fabrication, businesses often seek solutions that align with their unique operational needs and budgetary constraints. While Atlanta Foam stands out for its comprehensive offerings, it’s essential to consider alternative solutions that may also meet specific requirements. This analysis will provide insights into how Atlanta Foam compares with other viable options in the market, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to atlanta foam

Comparison Table

| Comparison Aspect | Atlanta Foam | Polyurethane Foam | Closed Cell Foam |

|---|---|---|---|

| Performance | High durability and customization | Excellent cushioning and insulation | Water-resistant, strong structural integrity |

| Cost | Moderate to high | Generally lower cost | Moderate, depending on density |

| Ease of Implementation | Requires expertise for custom solutions | Easy to source and implement | Moderate complexity in installation |

| Maintenance | Minimal maintenance required | Routine cleaning and inspections | Low maintenance, but check for damage |

| Best Use Case | Automotive and medical components | Packaging and furniture | Marine applications and insulation |

Detailed Breakdown of Alternatives

Polyurethane Foam

Polyurethane foam is a versatile material known for its excellent cushioning properties. It is often used in packaging, furniture, and bedding industries. One of its main advantages is cost-effectiveness, making it an attractive option for businesses with budget constraints. However, while it offers good performance in cushioning, it may not match the durability and customization options available with Atlanta Foam. Additionally, polyurethane foam can degrade over time, requiring regular inspections and maintenance to ensure its effectiveness.

Closed Cell Foam

Closed cell foam is recognized for its water resistance and structural integrity, making it ideal for applications in marine environments and insulation. Its tightly packed cells provide excellent protection against moisture, air, and temperature variations. While it is moderately priced, its installation can be more complex compared to Atlanta Foam, which may require specialized skills. The low maintenance aspect is a significant advantage, although businesses must remain vigilant for any physical damage that could compromise its performance.

Conclusion: How to Choose the Right Foam Solution

When selecting the right foam solution, B2B buyers should carefully assess their specific needs, including application requirements, budget, and long-term maintenance capabilities. Atlanta Foam excels in customization and is particularly suitable for specialized applications in the automotive and medical sectors. Conversely, if cost is a primary concern and the application is less specialized, polyurethane foam might be the right choice. For businesses in marine or insulation applications, closed cell foam could provide the necessary performance and durability. Ultimately, understanding the strengths and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for atlanta foam

What Are the Essential Technical Properties of Atlanta Foam?

When sourcing foam materials from Atlanta Foam, it’s critical to understand key technical properties that can impact product performance and application suitability. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the specific classification of foam based on its chemical composition and physical properties. Common grades include polyethylene, polyurethane, and cross-linked polyethylene. Each grade possesses unique characteristics such as density, flexibility, and durability. For B2B buyers, selecting the appropriate material grade is vital for ensuring that the foam meets the performance requirements for its intended application, whether in packaging, insulation, or automotive components.

2. Density

Density is a measure of mass per unit volume, typically expressed in kilograms per cubic meter (kg/m³). It affects the foam’s weight, strength, and insulation properties. Higher density foams tend to be more durable and provide better support, making them ideal for applications requiring structural integrity. In contrast, lower density foams are lighter and may be preferred for packaging and temporary applications. Understanding density helps buyers choose the right foam for cost-effectiveness and performance.

3. Tolerance

Tolerance indicates the allowable deviation from specified dimensions in foam fabrication. It is critical in applications where precise fit and alignment are required, such as in automotive or medical devices. A tighter tolerance ensures that the foam components fit seamlessly into assemblies, reducing the risk of failure or defects. B2B buyers must communicate their tolerance requirements clearly to ensure that the manufactured foam meets their specifications.

4. Compression Set

Compression set is the measure of a material’s ability to return to its original thickness after being compressed. It is particularly important in applications where foam is subjected to repeated pressure, such as in seating or cushioning products. A low compression set indicates that the foam will retain its shape and provide long-lasting performance. Buyers should assess compression set values to ensure that the foam will perform reliably over time.

Illustrative image related to atlanta foam

5. Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat. This property is crucial for insulation applications, where lower thermal conductivity values indicate better insulating performance. B2B buyers in industries such as construction and HVAC should prioritize thermal conductivity to ensure energy efficiency and comfort in their products.

What Are Common Trade Terms in the Foam Industry?

Understanding industry jargon is essential for effective communication and negotiation in the foam manufacturing sector. Here are some common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the foam industry, an OEM may provide foam components that are integrated into larger products. Understanding OEM relationships is crucial for buyers looking to source foam solutions that align with their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts purchasing decisions and inventory management. Knowing the MOQ helps businesses plan their orders and manage costs effectively.

Illustrative image related to atlanta foam

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. It is essential for comparing quotes from multiple vendors and ensuring competitive pricing. Buyers should prepare detailed RFQs to receive accurate and comprehensive quotes from foam suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping agreements. They clarify who is responsible for shipping costs, insurance, and risk during transit. Familiarity with Incoterms helps B2B buyers negotiate better shipping arrangements and understand their obligations in international trade.

5. Custom Die Cutting

Custom die cutting is a fabrication process used to cut foam into specific shapes or sizes using a specialized tool called a die. This term is important for buyers who require foam components tailored to unique specifications for their products. Understanding this process allows buyers to communicate their needs effectively and ensure the final product meets their design criteria.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing foam from Atlanta Foam, ensuring they receive high-quality products that meet their specific needs.

Illustrative image related to atlanta foam

Navigating Market Dynamics and Sourcing Trends in the atlanta foam Sector

What Are the Current Market Dynamics and Key Trends in the Atlanta Foam Sector?

The Atlanta foam sector is experiencing significant growth, driven by a combination of global market demands and technological advancements. Key industries such as automotive, aerospace, medical, and packaging are increasingly relying on foam materials for insulation, cushioning, and component fabrication. International buyers from regions like Africa, South America, the Middle East, and Europe are particularly drawn to the diverse applications of foam, which include everything from high-density polyethylene for automotive parts to specialized foams for medical devices.

Emerging B2B tech trends are reshaping how foam products are sourced and produced. The integration of advanced manufacturing techniques, such as CNC routing and water jet cutting, allows for precision fabrication that meets specific client needs. Furthermore, the rise of online platforms for sourcing materials enables international buyers to access a broader range of suppliers and products, streamlining procurement processes. As companies aim to optimize their supply chains, there is a growing emphasis on just-in-time manufacturing, which reduces inventory costs and enhances responsiveness to market fluctuations.

Moreover, the demand for customized foam solutions is on the rise. Buyers increasingly seek suppliers who can provide tailored products that align with their unique specifications, leading to a greater emphasis on collaboration during the design and prototyping phases. This trend highlights the importance of strong supplier relationships and effective communication in ensuring successful project outcomes.

How Is Sustainability Shaping the Sourcing of Foam Products in the B2B Landscape?

Sustainability is becoming a critical consideration in the sourcing of foam products, with buyers increasingly prioritizing eco-friendly materials and ethical supply chains. The environmental impact of foam production, particularly in terms of resource consumption and waste generation, has prompted companies to seek alternatives that minimize their carbon footprint. This shift is evident in the growing popularity of closed-cell foams made from recycled materials or bio-based substances, which offer similar performance characteristics with reduced environmental impact.

In addition to material choices, ethical sourcing practices are gaining traction among international buyers. Companies are now more inclined to partner with suppliers who demonstrate transparency in their manufacturing processes and uphold fair labor practices. Certifications such as ISO 14001 (Environmental Management) and OEKO-TEX® (Standard for textiles) are increasingly sought after as indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, the emphasis on sustainable solutions is not merely a regulatory or compliance issue; it is also a competitive advantage. B2B buyers, particularly those in Europe and North America, are increasingly favoring suppliers who can provide green certifications and environmentally friendly products, influencing their purchasing decisions and long-term partnerships.

What Is the Historical Context of the Atlanta Foam Sector?

The Atlanta foam sector has evolved significantly over the past few decades, transitioning from traditional manufacturing methods to advanced, technology-driven fabrication processes. Initially focused on basic foam products, companies in the region have diversified their offerings to include specialized foams that cater to a variety of high-demand industries.

As global supply chains have expanded, Atlanta has positioned itself as a strategic hub for foam production, attracting international buyers seeking high-quality materials and innovative solutions. This evolution has been supported by a robust local workforce skilled in manufacturing technologies, enabling Atlanta foam fabricators to remain competitive in a rapidly changing marketplace.

With sustainability and customization at the forefront of industry trends, the Atlanta foam sector is well-equipped to meet the needs of global B2B buyers, offering products that align with both performance and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of atlanta foam

-

How do I choose the right foam material for my application?

Selecting the appropriate foam material depends on various factors, including the intended use, environmental conditions, and specific performance requirements. Atlanta Foam offers a wide range of options, such as beaded polyethylene for lightweight packaging and cross-linked polyethylene for durable insulation. Engage with Atlanta Foam’s team of experts to assess your needs, discuss application-specific properties, and receive tailored recommendations. A thorough understanding of the material properties can significantly impact product performance and longevity. -

What foam types are available for international shipping?

Atlanta Foam provides a variety of foam types suitable for international shipping, including closed-cell polyethylene and polyurethane foams. These materials are lightweight and can be efficiently packed to minimize shipping costs. Ensure that you communicate your specific needs, such as density and dimensions, to facilitate accurate quotes. Additionally, confirm compliance with any international shipping regulations, as different regions may have varying requirements regarding foam materials. -

What are the minimum order quantities (MOQs) for foam products?

Minimum order quantities can vary based on the type of foam, customization requirements, and production capabilities. Generally, Atlanta Foam accommodates flexible MOQs to cater to both small and large-scale orders. When placing an order, consider discussing your project specifications with the sales team to determine the most cost-effective approach and ensure timely delivery. -

What customization options are available for foam products?

Atlanta Foam offers extensive customization options, including various shapes, sizes, densities, and colors. Techniques such as CNC routing and die cutting allow for precise tailoring to meet your specifications. Collaborating with their design team during the prototyping phase can help you visualize the final product and make necessary adjustments before full-scale production, ensuring that the final output aligns perfectly with your needs. -

What payment terms does Atlanta Foam offer for international buyers?

Payment terms for international orders can vary based on the buyer’s location and order size. Typically, Atlanta Foam may require a deposit upfront, with the balance due upon shipment or delivery. It’s advisable to clarify payment methods, such as wire transfers or letters of credit, to ensure a smooth transaction process. Always review the terms before confirming your order to avoid potential misunderstandings. -

How does Atlanta Foam ensure quality assurance in its products?

Atlanta Foam employs a rigorous quality assurance process, including material inspections, in-process checks, and final product evaluations. This multi-step approach ensures that all foam products meet stringent industry standards and client specifications. Additionally, clients can request documentation of compliance with relevant regulations, providing peace of mind regarding the quality and safety of the foam solutions delivered. -

What logistics support does Atlanta Foam provide for international shipping?

Atlanta Foam collaborates with reliable logistics partners to facilitate efficient shipping for international buyers. They can assist in arranging freight forwarding, customs clearance, and delivery to your specified location. It’s crucial to discuss your shipping requirements upfront, including timelines and any special handling needs, to ensure a seamless logistics experience that aligns with your project deadlines. -

How can I vet suppliers when sourcing foam products internationally?

When sourcing foam products, it’s essential to conduct thorough due diligence. Start by reviewing the supplier’s credentials, certifications, and industry experience. Request references from previous clients and assess their reputation in the market. Additionally, consider visiting their facility, if possible, to evaluate their manufacturing capabilities and quality control processes firsthand. Engaging in open communication with potential suppliers can also provide insights into their reliability and customer service approach.

Top 5 Atlanta Foam Manufacturers & Suppliers List

1. Atlanta Foam Fabricators – Foam Materials & Fabrication Services

Domain: foamfabricating.net

Registered: 2001 (24 years)

Introduction: Atlanta Foam Fabricators offers a wide range of foam materials including beaded polyethylene, beaded polypropylene, high density polyethylene, cross linked polyethylene, and polyethylene foam rubber. Their fabrication capabilities include CNC routing, water jet cutting, contouring, custom die cutting, routing, die cutting, waterjet cutting, slitting, laminating, and convoluting. They serve various…

2. Atlanta Foam – Business Service

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Atlanta Foam – Business Service, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. LinkedIn – Professional Networking

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, LinkedIn – Professional Networking, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Atlanta Foam Fabricators – Company Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Atlanta Foam Fabricators – Company Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Atlanta Foam Fabricators – Foam Solutions

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Atlanta Foam Fabricators – Foam Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for atlanta foam

In summary, Atlanta Foam stands out as a premier provider of foam fabrication solutions, adept at meeting the diverse needs of industries including automotive, medical, and packaging. By leveraging advanced technologies and a commitment to quality, Atlanta Foam enables international buyers to access tailored foam products that enhance operational efficiency and product integrity. The strategic sourcing of foam materials not only improves supply chain resilience but also fosters innovation, allowing businesses to stay competitive in a rapidly evolving market.

For B2B buyers in Africa, South America, the Middle East, and Europe, partnering with Atlanta Foam offers a unique opportunity to benefit from their extensive expertise and customized services. As global markets continue to expand, the demand for high-quality foam solutions is on the rise. Now is the time to engage with Atlanta Foam to explore how their capabilities can support your business objectives and drive growth. Don’t miss the chance to elevate your projects with innovative foam solutions tailored to your specific needs. Reach out today to discover the advantages of strategic sourcing with Atlanta Foam.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to atlanta foam

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.