Nissan Vias Solenoid: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for nissan vias solenoid

The global market for Nissan VIAS solenoids presents a unique challenge for B2B buyers seeking reliable components for automotive applications. As industries across Africa, South America, the Middle East, and Europe increasingly rely on advanced vehicle technologies, sourcing high-quality VIAS solenoids becomes essential for maintaining optimal engine performance. This guide offers a comprehensive overview of the Nissan VIAS solenoid, detailing its types, applications, and the critical role it plays in enhancing engine efficiency and compliance with emissions standards.

In the following sections, we will delve into the various types of Nissan VIAS solenoids available, their specific applications across different vehicle models, and the vital considerations for vetting suppliers. Understanding the nuances of pricing structures, warranties, and shipping logistics will empower international B2B buyers to make informed purchasing decisions. By equipping yourself with the knowledge found in this guide, you can navigate the complexities of sourcing Nissan VIAS solenoids effectively, ensuring that your business remains competitive in a rapidly evolving automotive landscape. Whether you are sourcing for a fleet or a retail operation, this guide serves as an essential resource for maximizing value and performance in your procurement strategy.

Understanding nissan vias solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM VIAS Control Solenoid | Genuine Nissan parts, high reliability, 12-month warranty | Automotive repair shops, dealerships | Pros: Guaranteed fit, high durability. Cons: Higher cost compared to aftermarket options. |

| Aftermarket VIAS Solenoid | Variety of brands, often lower price point | Independent repair shops, budget-conscious buyers | Pros: Cost-effective, wider availability. Cons: Variable quality, may lack warranty. |

| Performance VIAS Solenoid | Enhanced airflow capabilities, designed for performance | Tuning shops, motorsports applications | Pros: Improved engine performance. Cons: May not be suitable for standard vehicles. |

| Universal VIAS Solenoid | Non-specific fitment, adaptable for various models | Custom builds, DIY enthusiasts | Pros: Versatile, can be used in multiple applications. Cons: Risk of improper fitment and reliability issues. |

| Digital VIAS Control Solenoid | Integrated electronic controls for precise operation | Advanced automotive engineering, electric vehicles | Pros: Enhanced precision, better control over air intake. Cons: Higher complexity and cost. |

What are the Characteristics of OEM VIAS Control Solenoids?

OEM VIAS Control Solenoids are designed specifically for Nissan vehicles, ensuring compatibility and reliability. They often come with a 12-month warranty, reflecting the manufacturer’s confidence in their durability. These solenoids are ideal for B2B buyers in automotive repair shops and dealerships looking for parts that guarantee fit and performance, reducing the risk of future failures. While they typically come at a higher price, their reliability can lead to greater customer satisfaction and repeat business.

How Do Aftermarket VIAS Solenoids Differ?

Aftermarket VIAS Solenoids provide a cost-effective alternative for B2B buyers, especially independent repair shops and budget-conscious automotive businesses. These solenoids come from various manufacturers, offering a range of prices and features. While they can be less expensive, quality may vary significantly, making it crucial for buyers to assess supplier reputations and product reviews to ensure they are purchasing a reliable part.

What Benefits Do Performance VIAS Solenoids Offer?

Performance VIAS Solenoids are designed for enhanced airflow, making them suitable for tuning shops and motorsports applications. They can improve engine performance and throttle response, appealing to businesses focused on high-performance upgrades. However, these solenoids may not be appropriate for standard vehicles, and their installation can require additional modifications, which is a key consideration for B2B buyers.

Why Consider Universal VIAS Solenoids?

Universal VIAS Solenoids are adaptable components that can fit various Nissan models, making them popular among custom builders and DIY enthusiasts. Their versatility allows businesses to stock a single part that can serve multiple applications, reducing inventory costs. However, the risk of improper fitment and potential reliability issues should be considered, as these solenoids may not meet the same quality standards as OEM parts.

What Are the Advantages of Digital VIAS Control Solenoids?

Digital VIAS Control Solenoids integrate advanced electronic controls for precise operation, making them suitable for advanced automotive engineering and electric vehicles. These components can enhance the efficiency of the intake system, appealing to businesses focused on cutting-edge technology. However, their complexity and higher cost may deter some buyers, particularly those in markets where budget constraints are a primary concern.

Key Industrial Applications of nissan vias solenoid

| Industry/Sector | Specific Application of Nissan VIAS Solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Control of variable intake systems in gasoline engines | Enhances engine performance and fuel efficiency, reducing emissions | Ensure OEM quality standards; consider warranty and compatibility |

| Vehicle Maintenance | Replacement parts for Nissan vehicles | Minimizes downtime and ensures reliable vehicle performance | Prioritize genuine parts for optimal fit and function |

| Automotive Aftermarket | Upgrades for performance tuning in modified vehicles | Improves throttle response and overall engine dynamics | Look for parts with proven performance metrics and reviews |

| Fleet Management | Maintenance of commercial vehicle engines | Reduces operational costs through improved fuel efficiency | Evaluate bulk purchasing options and supplier reliability |

| Export and Import | Distribution of automotive parts in emerging markets | Expands market reach and caters to growing demand for spare parts | Research local regulations and logistics for efficient shipping |

How is the Nissan VIAS Solenoid Used in Automotive Manufacturing?

In the automotive manufacturing sector, the Nissan VIAS solenoid is integral to controlling variable intake systems in gasoline engines. It regulates the vacuum signal for power valve control, optimizing engine performance and enhancing fuel efficiency. For manufacturers, using high-quality OEM parts like the Nissan VIAS solenoid ensures compliance with emissions regulations, which is crucial for market acceptance, especially in Europe and other environmentally conscious regions. Buyers must verify compatibility with specific engine models to avoid costly errors during production.

What Role Does the Nissan VIAS Solenoid Play in Vehicle Maintenance?

For vehicle maintenance, the Nissan VIAS solenoid serves as a critical replacement part for Nissan vehicles experiencing performance issues, such as the P1800 error code. By addressing solenoid failures, automotive technicians can restore optimal engine function, thereby reducing downtime for vehicle owners. International buyers should consider sourcing genuine parts to maintain vehicle integrity and reliability, as counterfeit parts can lead to further complications and increased maintenance costs.

How is the Nissan VIAS Solenoid Utilized in the Automotive Aftermarket?

In the automotive aftermarket, the Nissan VIAS solenoid is often sought after for performance tuning in modified vehicles. By upgrading to a high-performance solenoid, car enthusiasts can improve throttle response and overall engine dynamics. This application is particularly appealing to buyers in regions with a strong automotive culture, such as South America and Europe, where performance modifications are popular. Buyers should look for products backed by performance metrics and customer reviews to ensure reliability and effectiveness.

Why is the Nissan VIAS Solenoid Important for Fleet Management?

Fleet management companies rely on the Nissan VIAS solenoid to maintain commercial vehicle engines efficiently. By ensuring that engines operate at peak performance, fleets can reduce operational costs associated with fuel consumption and maintenance. For international buyers, especially in regions like Africa and the Middle East, understanding local supply chains and sourcing options is vital to ensure timely availability of replacement parts, minimizing vehicle downtime.

How Does the Nissan VIAS Solenoid Impact Export and Import Activities?

The Nissan VIAS solenoid plays a significant role in the export and import of automotive parts, especially in emerging markets. As demand for Nissan spare parts increases, international buyers can capitalize on this trend by sourcing quality components for distribution. However, they must navigate local regulations and logistics to ensure efficient shipping and compliance with import standards. Understanding market dynamics and establishing reliable supplier relationships are crucial for success in this sector.

3 Common User Pain Points for ‘nissan vias solenoid’ & Their Solutions

Scenario 1: Difficulty in Locating the Right VIAS Solenoid for Specific Models

The Problem: B2B buyers often struggle to identify the correct VIAS solenoid for various Nissan models, particularly when dealing with older vehicles or less common models. This confusion can lead to purchasing incorrect parts, resulting in wasted time, increased costs, and potential delays in vehicle repairs or maintenance. Additionally, the lack of clear fitment information can frustrate procurement teams who need to ensure compatibility before finalizing orders.

The Solution: To effectively source the correct VIAS solenoid, buyers should utilize comprehensive OEM parts databases or consult with authorized Nissan parts suppliers. Before placing an order, ensure to have the vehicle’s VIN, year, make, model, and engine specifications on hand. Many suppliers offer tools that allow buyers to input this information to confirm fitment. Furthermore, fostering relationships with local dealerships or authorized distributors can provide access to expert advice and support in navigating complex parts lists, helping to minimize errors and enhance supply chain efficiency.

Scenario 2: Concerns About Quality and Authenticity of Replacement Solenoids

The Problem: In the competitive automotive parts market, buyers often encounter counterfeit or substandard replacement parts that do not meet OEM specifications. This issue is particularly critical for components like the VIAS solenoid, which can significantly impact engine performance and vehicle safety. B2B buyers must be vigilant in ensuring that they procure genuine parts to avoid the risk of failure and warranty complications.

The Solution: Buyers should prioritize sourcing from reputable suppliers who guarantee the authenticity of their products. Look for parts that are labeled as “Genuine OEM” and verify that they come with a warranty, such as the minimum 12-month coverage typically provided for Nissan parts. Additionally, buyers can request certification of authenticity or provenance from their suppliers. Implementing a strict vendor evaluation process that includes checking reviews, ratings, and previous client experiences can also help in identifying reliable partners. By focusing on quality and supplier integrity, businesses can protect their investments and maintain operational reliability.

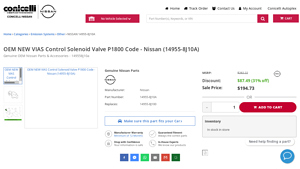

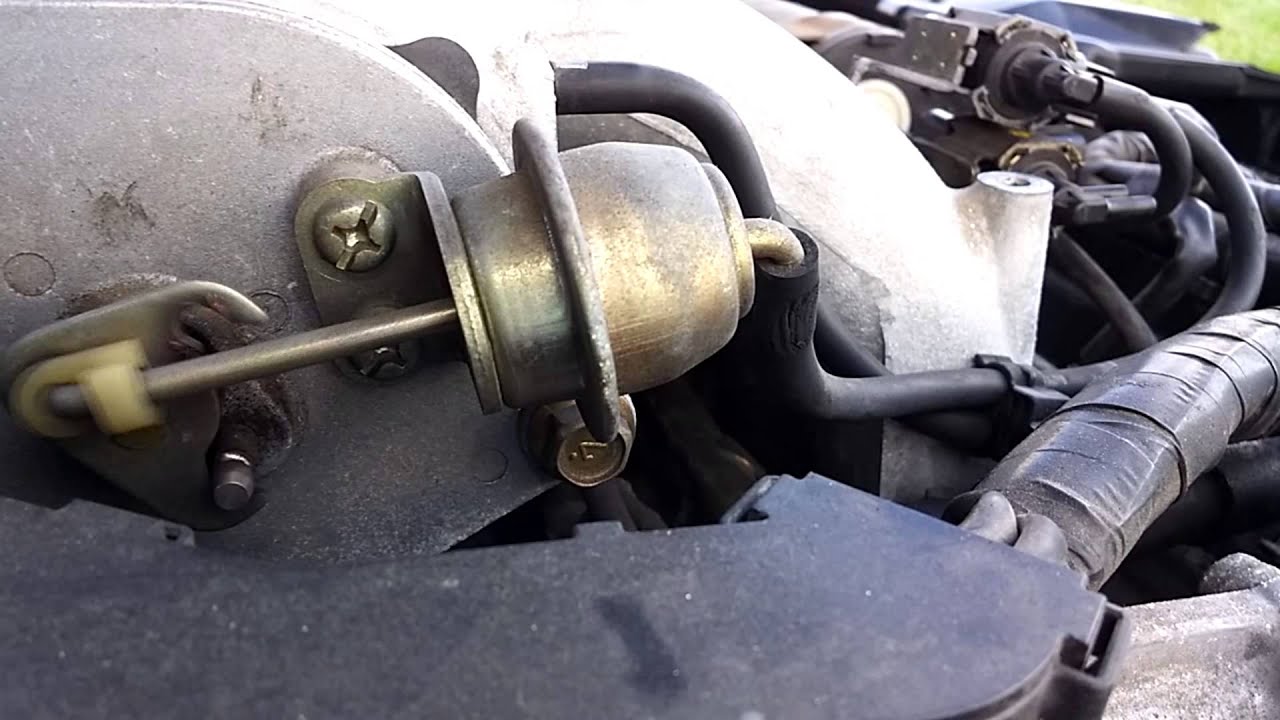

Illustrative image related to nissan vias solenoid

Scenario 3: Navigating Installation Challenges for the VIAS Solenoid

The Problem: Many B2B buyers face challenges when it comes to the installation of the VIAS solenoid, particularly in models where accessibility is limited. Technicians may find themselves needing to dismantle significant parts of the vehicle to reach the solenoid, which can lead to increased labor costs and downtime. This complexity can be daunting for repair shops that aim to provide quick turnaround times for their clients.

The Solution: To mitigate installation challenges, buyers should invest in detailed service manuals or online resources that provide step-by-step instructions for the installation of the VIAS solenoid specific to the vehicle model. Additionally, attending training sessions or workshops focused on Nissan vehicles can equip technicians with the skills needed for efficient repairs. When sourcing the VIAS solenoid, inquire about any installation kits or tools that may be available, as these can streamline the process. Collaborating with experienced technicians to develop a checklist for installation can also help ensure that no steps are overlooked, ultimately reducing time and labor costs associated with the installation process.

Strategic Material Selection Guide for nissan vias solenoid

What Are the Common Materials Used in Nissan VIAS Solenoids?

When selecting materials for the Nissan VIAS solenoid, it is crucial to consider their properties, advantages, and limitations. The choice of material directly impacts the solenoid’s performance, durability, and compatibility with various operating conditions. Below, we analyze four common materials used in manufacturing Nissan VIAS solenoids: aluminum, stainless steel, brass, and plastic composites.

How Does Aluminum Perform in Nissan VIAS Solenoids?

Aluminum is a lightweight and corrosion-resistant material that is often used in automotive applications. Its excellent thermal conductivity allows for efficient heat dissipation, which is essential in solenoid operation. Aluminum typically has a temperature rating of up to 150°C and can withstand moderate pressure levels.

Pros: Aluminum is durable yet lightweight, making it cost-effective for mass production. Its resistance to corrosion enhances the longevity of the solenoid.

Cons: However, aluminum may not be suitable for high-pressure applications, and its mechanical strength is lower than that of metals like steel.

For international buyers, aluminum components must comply with standards such as ASTM B211 and EN 573, ensuring quality and performance across different markets.

What Advantages Does Stainless Steel Offer for VIAS Solenoids?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a preferred choice for demanding environments. It can handle high temperatures (up to 300°C) and pressures, which is beneficial for solenoids operating in various conditions.

Pros: The durability and strength of stainless steel contribute to the solenoid’s reliability, especially in harsh environments. It also offers good compatibility with various media, including oils and fuels.

Cons: The primary drawback is its higher cost compared to aluminum and brass, which may impact budget-sensitive projects.

International buyers should look for compliance with standards like ASTM A240 and ISO 9444, ensuring that the stainless steel used meets the required specifications for performance and safety.

Why Choose Brass for Nissan VIAS Solenoids?

Brass, an alloy of copper and zinc, is commonly used in solenoid valves due to its excellent machinability and resistance to corrosion. It typically operates well in temperatures up to 200°C and can handle moderate pressure levels.

Pros: Brass is cost-effective and provides good electrical conductivity, which is essential for solenoid operation. Its resistance to corrosion makes it suitable for automotive applications.

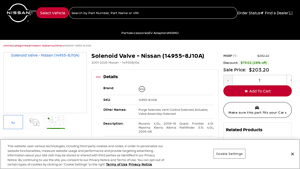

Illustrative image related to nissan vias solenoid

Cons: However, brass may not be as strong as stainless steel, making it less suitable for high-pressure applications.

For B2B buyers, ensuring compliance with standards such as ASTM B36 and JIS H3250 is crucial, particularly in regions like Europe and Asia, where quality assurance is paramount.

How Do Plastic Composites Fit Into the VIAS Solenoid Design?

Plastic composites are increasingly being used in solenoid manufacturing due to their lightweight and versatile properties. They can withstand temperatures up to 100°C and are often used in applications where weight reduction is critical.

Pros: The use of plastic composites can significantly reduce manufacturing costs and weight, making them ideal for automotive applications where efficiency is key.

Illustrative image related to nissan vias solenoid

Cons: However, their lower temperature and pressure ratings may limit their use in high-performance applications.

International buyers should consider compliance with standards such as ISO 9001 for quality management, especially when sourcing from regions like Africa and South America, where manufacturing practices may vary.

Summary Table of Material Selection for Nissan VIAS Solenoids

| Material | Typical Use Case for nissan vias solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight solenoid housing | Corrosion resistance and lightweight | Lower mechanical strength | Medium |

| Stainless Steel | High-performance solenoid applications | Exceptional strength and durability | Higher cost | High |

| Brass | General automotive solenoid applications | Good machinability and conductivity | Limited strength under high pressure | Low |

| Plastic Composites | Lightweight solenoid components | Cost-effective and versatile | Lower temperature and pressure limits | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing Nissan VIAS solenoids. By understanding the properties and implications of each material, buyers can align their choices with specific application requirements and regional compliance standards.

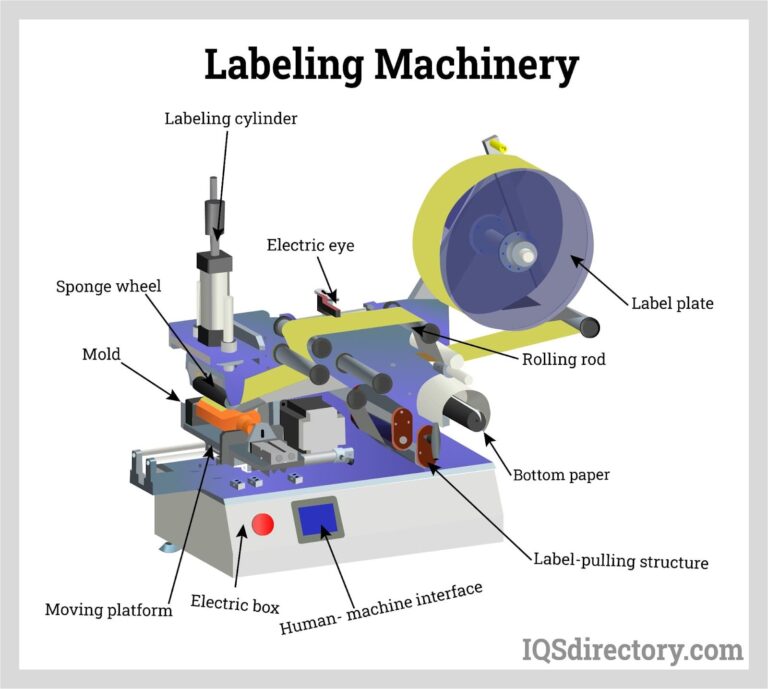

In-depth Look: Manufacturing Processes and Quality Assurance for nissan vias solenoid

What Are the Main Stages of Manufacturing a Nissan VIAS Solenoid?

The manufacturing process for the Nissan VIAS solenoid involves several critical stages to ensure the final product meets stringent quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with selecting high-grade materials, typically aluminum and robust plastics, to ensure durability and performance. These materials undergo rigorous inspection to verify their compliance with international quality standards, such as ISO 9001. Only materials that pass this initial inspection are used in production.

Forming: The forming stage involves precision machining to create the solenoid’s components. This includes processes like CNC machining for the housing and injection molding for plastic parts. Advanced techniques such as die casting may also be employed to achieve intricate designs and tight tolerances, which are essential for the solenoid’s functionality.

Assembly: After forming, the components are assembled with a focus on precision and accuracy. Automated assembly lines are often utilized to enhance efficiency and minimize human error. Each component is meticulously placed to ensure optimal functionality of the solenoid, which is crucial for its performance in controlling the intake manifold vacuum.

Finishing: The finishing stage includes surface treatments and quality checks. Components may undergo anodizing or painting to enhance corrosion resistance and aesthetic appeal. Final inspections ensure that the solenoid meets all dimensional and functional specifications before it is packaged for distribution.

Illustrative image related to nissan vias solenoid

How is Quality Assurance Integrated into the Manufacturing Process of Nissan VIAS Solenoids?

Quality assurance (QA) is a critical aspect of the manufacturing process for Nissan VIAS solenoids, ensuring that every unit meets the required standards before reaching the market.

What International Standards Are Relevant for Quality Assurance?

Manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards not only enhances product reliability but also boosts the manufacturer’s credibility in the global market. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, may also apply, indicating that the product meets safety and environmental requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps detect defects early. This may include measuring tolerances and conducting functional tests on the solenoid parts.

- Final Quality Control (FQC): A comprehensive inspection of the finished solenoid is performed to verify that it meets all functional and performance criteria.

What Common Testing Methods Are Employed?

Testing methods for Nissan VIAS solenoids typically include electrical testing, pressure testing, and performance testing under simulated operational conditions. These tests ensure that each solenoid operates correctly and reliably under various conditions, reducing the likelihood of failures in the field.

Illustrative image related to nissan vias solenoid

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensuring product reliability.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Buyers can request to visit the manufacturing facility to observe production practices and quality checks firsthand. During the audit, buyers should review the supplier’s quality management system documentation, including compliance certificates and process flow charts.

How Can Buyers Utilize QC Reports and Certifications?

Requesting quality control reports and certifications can provide insights into a supplier’s adherence to quality standards. Reports should detail the results of testing and inspections conducted at various stages of production. Buyers should look for certifications from recognized bodies that affirm the supplier’s commitment to quality.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection agencies can add an additional layer of assurance. These agencies can conduct independent inspections of the manufacturing processes and final products, ensuring compliance with international standards. This is particularly important for buyers who may not have the resources to conduct thorough audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when sourcing components like the Nissan VIAS solenoid. Understanding the quality control nuances can aid in making informed purchasing decisions.

How Do Regulatory Standards Vary by Region?

Different regions have varying regulatory standards that affect the manufacturing and quality assurance of automotive components. For example, CE marking is mandatory for products sold in the European Union, while other regions may have different requirements. Buyers should familiarize themselves with these regulations to ensure compliance.

What Are the Implications of Cultural Differences on Quality Assurance?

Cultural differences can influence the perception and implementation of quality assurance practices. Buyers should consider the local manufacturing culture and practices when evaluating suppliers. This understanding can lead to better communication and expectations regarding quality standards.

How Can Buyers Build Long-Term Relationships with Suppliers?

Building long-term relationships with reliable suppliers can enhance quality assurance over time. Regular communication, feedback on product performance, and collaboration on quality improvement initiatives can foster a partnership that benefits both parties. By investing in supplier relationships, buyers can ensure consistent quality and reliability in their supply chain.

Conclusion

The manufacturing processes and quality assurance practices for Nissan VIAS solenoids are designed to deliver reliable, high-performance components that meet the needs of B2B buyers worldwide. By understanding these processes and actively engaging in quality verification, buyers can make informed decisions that enhance their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nissan vias solenoid’

In today’s competitive market, sourcing the right components like the Nissan VIAS solenoid is crucial for ensuring the efficiency and reliability of your automotive products. This guide provides a structured checklist to streamline the procurement process, enabling international B2B buyers to make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the VIAS solenoid meets your vehicle’s requirements. Identify the exact part number (e.g., 14955-8J10A) and understand the solenoid’s operational parameters, such as voltage ratings and compatibility with different Nissan models. This step helps avoid costly errors and ensures the correct fitment for your applications.

Step 2: Conduct Market Research

Understanding the market landscape is vital for sourcing effectively. Research various suppliers to gauge pricing, availability, and delivery times for the VIAS solenoid. Pay attention to geographical factors, especially if you are sourcing from regions like Africa, South America, or Europe, as logistics can significantly affect lead times and costs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who specialize in OEM parts and have a strong reputation for quality and reliability. This diligence minimizes risks associated with poor-quality components.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications, such as ISO 9001 or equivalent, which demonstrate their commitment to quality management systems. Certifications can be indicators of a supplier’s adherence to international standards and regulatory compliance. This step is crucial for maintaining your product’s quality and reliability.

Step 5: Assess Warranty and Return Policies

Review the warranty and return policies offered by suppliers. A minimum warranty of 12 months, as seen with OEM parts, indicates confidence in the product’s durability. Understand the procedures for returns or exchanges in case the solenoid does not meet your specifications or fails to perform as expected.

Step 6: Request Samples for Testing

Before finalizing your order, request samples of the VIAS solenoid for testing. This step allows you to assess the part’s quality and compatibility with your systems firsthand. Testing samples also helps identify any potential issues that could arise during installation or operation.

Step 7: Finalize Pricing and Payment Terms

Once you have selected a supplier, negotiate pricing and payment terms. Ensure that the pricing is competitive while reflecting the quality of the components. Consider discussing payment terms that align with your cash flow needs, such as net 30 or net 60 days, to facilitate smoother financial management.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing Nissan VIAS solenoids, ensuring they procure high-quality components that meet their operational needs while optimizing costs.

Comprehensive Cost and Pricing Analysis for nissan vias solenoid Sourcing

When sourcing Nissan VIAS solenoids, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers. This section delves into the various cost components, price influencers, and essential tips for negotiation and procurement, particularly for buyers in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Nissan VIAS Solenoids?

The total cost of sourcing Nissan VIAS solenoids comprises several critical components:

-

Materials: The primary material used in the manufacturing of solenoids includes high-grade metals and plastics, which ensure durability and reliability. The cost of raw materials can fluctuate based on global market trends, impacting the overall price.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer more competitive pricing, but this can sometimes affect quality. It’s essential to balance cost savings with the need for skilled labor to ensure product reliability.

-

Manufacturing Overhead: This includes expenses related to the production facility, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: The initial investment in tooling for solenoid production can be substantial. This cost is often amortized over larger production runs, meaning higher volume orders may result in lower per-unit costs.

-

Quality Control (QC): Implementing stringent QC processes is essential for ensuring product reliability, especially for components critical to vehicle performance. This can incur additional costs but is vital for maintaining high standards.

-

Logistics: Shipping and handling costs vary depending on the destination and chosen shipping methods. International buyers should consider potential customs duties and tariffs, which can significantly impact total cost.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the competitive landscape can provide insights into reasonable margins within the market.

What Influences the Pricing of Nissan VIAS Solenoids?

Several factors can influence the pricing of Nissan VIAS solenoids:

-

Volume/MOQ: Ordering larger quantities often leads to discounts due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQ) that align with their budget.

-

Specifications and Customization: Custom features or specific certifications may increase costs. Buyers should clearly outline their requirements to ensure accurate pricing.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or IATF) can add to the cost but also enhance reliability and longevity, which is vital for performance-critical components.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven quality and service, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk during shipping. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost.

What Are the Best Practices for Negotiating and Sourcing Nissan VIAS Solenoids?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Conduct Thorough Market Research: Understanding market prices and competitor offerings allows buyers to negotiate effectively. Utilize industry reports and supplier quotes for benchmarking.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, downtime, and disposal. A higher upfront cost might be justified by lower operational costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and reliability can foster trust and potentially lower costs.

-

Be Prepared for Negotiation: Knowing your budget and being clear about your requirements can facilitate negotiations. Don’t hesitate to ask for discounts on larger orders or inquire about loyalty programs.

-

Stay Informed on Regulatory Changes: Changes in trade agreements or tariffs can affect pricing. Keeping abreast of these changes can help in making informed purchasing decisions.

Disclaimer on Pricing

The prices mentioned for Nissan VIAS solenoids, such as the MSRP of $282.22, are indicative and subject to change based on market conditions, supplier pricing strategies, and negotiation outcomes. Buyers should request current pricing directly from suppliers for the most accurate and relevant information.

Alternatives Analysis: Comparing nissan vias solenoid With Other Solutions

Introduction to Alternative Solutions for Nissan Vias Solenoid

When considering the Nissan Vias solenoid, it’s essential to evaluate alternative solutions that may offer comparable or superior performance for specific applications. The Vias solenoid is designed to control the intake manifold vacuum, impacting engine efficiency and performance. However, other technologies and methods can achieve similar outcomes, each with unique advantages and drawbacks. This analysis will compare the Nissan Vias solenoid with two viable alternatives: the Electronic Throttle Control (ETC) system and the Variable Valve Timing (VVT) system.

Comparison Table

| Comparison Aspect | Nissan Vias Solenoid | Electronic Throttle Control (ETC) | Variable Valve Timing (VVT) |

|---|---|---|---|

| Performance | Effective for managing air intake | Provides precise throttle response | Optimizes engine performance across RPM |

| Cost | Approximately $194.73 | Varies widely, generally higher initial cost | Varies by vehicle, often integrated |

| Ease of Implementation | Moderate complexity in installation | Typically requires advanced calibration | Moderate complexity, depends on engine type |

| Maintenance | Requires periodic checks for function | Minimal maintenance; electronic reliability | Regular checks needed for optimal function |

| Best Use Case | Ideal for specific Nissan models | Best for newer vehicles with electronic systems | Beneficial for performance-oriented engines |

Detailed Breakdown of Alternatives

Electronic Throttle Control (ETC)

The Electronic Throttle Control (ETC) system replaces traditional mechanical linkages between the accelerator pedal and the throttle body with electronic signals. This system allows for more precise control of the engine’s air intake, leading to improved fuel efficiency and reduced emissions. However, the initial investment can be higher, and installation may require advanced calibration. The ETC system is best suited for newer vehicle models where electronic systems are standard, offering a high level of responsiveness and adaptability.

Variable Valve Timing (VVT)

Variable Valve Timing (VVT) adjusts the timing of the valve openings and closings in the engine, optimizing performance across a range of engine speeds. This technology enhances fuel efficiency and power output, making it an excellent choice for performance-oriented vehicles. VVT systems can be more complex and may require regular maintenance to ensure optimal performance. While the cost can vary depending on the vehicle, VVT is often integrated into modern engines, making it a valuable alternative for buyers looking to enhance engine performance without replacing components.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between the Nissan Vias solenoid and its alternatives, B2B buyers should consider their specific application requirements, budget constraints, and the intended use case of the vehicle. The Nissan Vias solenoid is a reliable option for controlling intake manifold vacuum in specific Nissan models, while ETC and VVT provide broader performance enhancements for modern engines. By evaluating the performance, cost, ease of implementation, maintenance needs, and best use cases of each solution, buyers can make informed decisions that align with their operational goals and ensure optimal vehicle performance.

Essential Technical Properties and Trade Terminology for nissan vias solenoid

What Are the Key Technical Properties of the Nissan VIAS Solenoid?

When considering the Nissan VIAS solenoid for procurement, it is crucial to understand its technical specifications that directly impact performance and compatibility. Here are several essential properties:

-

Material Composition

The Nissan VIAS solenoid is typically constructed from high-grade plastic and metal components. The choice of materials influences durability and resistance to environmental factors such as heat and corrosion. Understanding the material grade is vital for ensuring the solenoid can withstand the operating conditions of various Nissan models. -

Electrical Resistance

The solenoid operates using electrical signals from the engine control module (ECM). Its electrical resistance, measured in ohms, dictates how efficiently it can convert electrical energy into mechanical movement. A solenoid with proper resistance ensures optimal performance and responsiveness, reducing the risk of failure or malfunction. -

Pressure Ratings

The VIAS solenoid is designed to manage vacuum levels within the intake manifold. Knowing the pressure ratings is essential for ensuring compatibility with specific engine designs, as improper pressure management can lead to performance issues, including poor fuel efficiency and emissions problems. -

Operating Temperature Range

The solenoid must function effectively across a range of temperatures, typically from -40°C to +125°C. Understanding this range is crucial for buyers in regions with extreme climates, as it ensures the component will perform reliably under varying conditions. -

Tolerance Levels

Tolerance specifications refer to the acceptable range of deviation in the solenoid’s dimensions and performance parameters. High tolerance levels are important for ensuring a precise fit within the engine assembly, which minimizes the risk of leaks and operational failures. -

Interchangeability

This property indicates whether the VIAS solenoid can be replaced with similar models or part numbers (e.g., 14955-8J100). This is particularly important for inventory management and cost-efficiency, allowing buyers to source alternatives without compromising on quality.

What Are Common Trade Terms Related to the Nissan VIAS Solenoid?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms associated with the Nissan VIAS solenoid:

-

OEM (Original Equipment Manufacturer)

This term refers to parts that are made by the vehicle manufacturer, ensuring compatibility and reliability. For B2B buyers, sourcing OEM parts like the Nissan VIAS solenoid guarantees that they are receiving components that meet the original specifications. -

MOQ (Minimum Order Quantity)

This represents the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for businesses looking to maintain stock levels for repairs or resale. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific parts. For B2B buyers, issuing an RFQ for the Nissan VIAS solenoid can streamline the procurement process, ensuring they receive competitive pricing and clear terms. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings during cross-border transactions. -

Warranty Period

This term refers to the duration during which a part is guaranteed to function correctly. Understanding the warranty period associated with the Nissan VIAS solenoid (typically 12 months) is vital for assessing long-term investment risks and ensuring quality assurance. -

DTC (Diagnostic Trouble Code)

A DTC is a code generated by the vehicle’s onboard diagnostic system when a fault is detected. For example, the P1800 code relates to issues with the VIAS solenoid. Understanding DTCs can help buyers anticipate maintenance needs and make informed purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can navigate the procurement of Nissan VIAS solenoids with confidence, ensuring they select the right components for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the nissan vias solenoid Sector

What Are the Key Market Drivers and Trends for the Nissan VIAS Solenoid Sector?

The global automotive market is witnessing significant shifts, driven by technological advancements, regulatory changes, and evolving consumer preferences. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The Nissan VIAS solenoid sector is currently influenced by several key trends.

First, the demand for genuine OEM parts, such as the Nissan VIAS solenoid (part number 14955-8J10A), is on the rise as buyers prioritize quality and reliability over cost-cutting alternatives. The market is increasingly leaning towards digital procurement solutions, allowing buyers to source parts efficiently through online platforms. Additionally, as electric vehicles (EVs) gain traction globally, there’s a growing need for components that enhance engine performance and efficiency, placing the VIAS solenoid in a pivotal role in internal combustion engine (ICE) vehicles.

Emerging markets, particularly in Africa and South America, are expanding their automotive sectors, leading to increased demand for parts. This trend is coupled with the rise of localized manufacturing and assembly, reducing lead times and costs. Buyers should also be aware of fluctuations in raw material prices and supply chain disruptions, which can affect availability and pricing of solenoids.

How Is Sustainability and Ethical Sourcing Impacting the Nissan VIAS Solenoid Market?

Sustainability is becoming a cornerstone of B2B sourcing strategies across various sectors, including automotive parts like the Nissan VIAS solenoid. The environmental impact of sourcing practices is gaining attention, prompting buyers to consider the sustainability of their supply chains. Ethical sourcing is not just a trend; it’s increasingly seen as a competitive advantage.

For Nissan VIAS solenoids, buyers should prioritize suppliers who demonstrate commitment to sustainable practices, such as using recyclable materials and minimizing waste. Certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as indicators of a supplier’s dedication to sustainability. Furthermore, as the automotive industry shifts towards greener technologies, suppliers who invest in reducing their carbon footprint will likely gain favor among B2B buyers.

By aligning with suppliers who prioritize environmental responsibility, businesses can enhance their brand reputation and appeal to a growing segment of environmentally-conscious consumers. Moreover, ethical sourcing practices can mitigate risks associated with supply chain disruptions, fostering long-term partnerships based on shared values.

What Is the Evolution of the Nissan VIAS Solenoid in the Automotive Sector?

The Nissan VIAS solenoid has evolved significantly since its introduction, reflecting broader trends in automotive engineering and technology. Initially designed to enhance engine performance by controlling the intake manifold vacuum, the VIAS solenoid has adapted to meet stricter emissions regulations and the growing demand for fuel efficiency.

Over the years, advancements in materials and manufacturing processes have improved the reliability and performance of solenoids. As automakers shift focus towards hybrid and electric vehicles, components like the VIAS solenoid are being re-evaluated for their roles in optimizing combustion processes. The evolution of this component not only highlights the adaptability of automotive technology but also underscores the importance of keeping pace with innovations in sourcing strategies to ensure the availability of high-quality parts.

Illustrative image related to nissan vias solenoid

In summary, B2B buyers in the Nissan VIAS solenoid sector must navigate a landscape characterized by technological advancements, sustainability imperatives, and evolving market dynamics. By understanding these factors, buyers can make informed sourcing decisions that align with their operational goals and the broader demands of the automotive market.

Frequently Asked Questions (FAQs) for B2B Buyers of nissan vias solenoid

-

How do I solve a P1800 error code related to the Nissan VIAS solenoid?

To resolve a P1800 error code, first, inspect the VIAS solenoid for any electrical issues such as broken wires or faulty connections. The solenoid is typically located underneath the intake manifold, making access challenging. If the solenoid is confirmed to be defective, replace it with a genuine OEM part (like the 14955-8J10A) to ensure compatibility and performance. Additionally, after replacement, it may be necessary to reset the vehicle’s ECU to clear the error code. -

What is the best way to source Nissan VIAS solenoids for international buyers?

For international buyers, sourcing Nissan VIAS solenoids involves identifying reputable suppliers that specialize in OEM parts. Platforms like B2B marketplaces can connect you with manufacturers and distributors. Ensure that the supplier has a strong track record, offers warranties, and provides clear documentation regarding fitment and specifications. Additionally, consider local suppliers who may have established shipping routes to your region to reduce lead times and costs. -

What are the minimum order quantities (MOQs) for Nissan VIAS solenoids?

Minimum order quantities can vary by supplier and region. Many manufacturers may set MOQs at 10-100 units, depending on the part and the market demand. It’s advisable to negotiate MOQs with your supplier, especially if you are testing the market or if you have budget constraints. Discussing your specific needs can also lead to favorable terms, especially for long-term partnerships. -

What payment terms should I expect when purchasing Nissan VIAS solenoids internationally?

Payment terms typically range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your negotiation power. For larger orders, suppliers may offer installment plans or letters of credit. It’s essential to establish clear terms in your purchase agreement, including payment methods (bank transfer, credit card, etc.) and any associated fees. Always ensure that the payment method is secure to protect your investment. -

How can I vet suppliers of Nissan VIAS solenoids to ensure quality?

Vetting suppliers is crucial for ensuring product quality. Start by reviewing their business credentials, including years of operation, certifications (like ISO), and customer reviews. Request samples of the VIAS solenoid to assess quality before placing larger orders. Additionally, consider suppliers who provide warranties and clear return policies, as this indicates confidence in their products. Networking within industry forums can also yield valuable insights about supplier reputation. -

What logistics considerations should I keep in mind when importing Nissan VIAS solenoids?

When importing, consider shipping methods (air vs. sea), customs duties, and delivery timelines. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure your supplier can provide the necessary documentation for customs clearance, including invoices and packing lists. Additionally, familiarize yourself with local regulations regarding automotive parts to avoid any compliance issues upon arrival. -

Can I customize Nissan VIAS solenoids for specific applications?

Customization options depend on the supplier’s capabilities. Some manufacturers may offer modifications for specific applications, such as changes to voltage ratings or housing materials. Discuss your requirements with potential suppliers and inquire about the feasibility of custom orders. Be aware that customization may affect lead times and costs, so it’s essential to factor this into your procurement strategy. -

What quality assurance processes should I expect when sourcing Nissan VIAS solenoids?

Reputable suppliers should have established quality assurance processes, including testing and inspection protocols for each batch of solenoids. Look for suppliers who conduct tests for electrical performance, durability, and fitment accuracy. Request documentation of their quality assurance practices and any certifications that validate their compliance with industry standards. This will help ensure that the solenoids you receive meet your performance expectations.

Top 3 Nissan Vias Solenoid Manufacturers & Suppliers List

1. Nissan – OEM NEW VIAS Control Solenoid Valve

Domain: parts.conicellinissan.com

Registered: 1999 (26 years)

Introduction: {“part_number”:”14955-8J10A”,”description”:”OEM NEW VIAS Control Solenoid Valve P1800 Code”,”manufacturer”:”Nissan”,”condition”:”New”,”replaces”:”14955-8J100″,”MSRP”:”$282.22″,”discount”:”$87.49 (31% off)”,”sale_price”:”$194.73″,”warranty”:”Minimum of 12 Months”,”fitment_years”:”2002-2020″,”compatible_models”:[“Murano”,”Quest”,”Frontier”,”Maxima”,”Xterra”,”Altima”,”Pathfinder”],”engine_options”:[“…

2. Nissan – Solenoid Valve

Domain: parts.nissanusa.com

Registered: 2001 (24 years)

Introduction: Part Number: 14955-8J10A

Product Name: Solenoid Valve

Compatibility: 2001-2025 Nissan models

Promotion: Labor Day Savings – Up to 15% off select Genuine Nissan Parts (Aug 29–Sep 8)

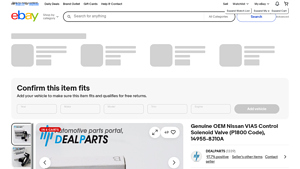

3. Nissan – OEM VIAS Control Solenoid Valve

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Genuine OEM Nissan VIAS Control Solenoid Valve (P1800 Code)”, “Part Number”: “14955-8J10A”, “Condition”: “New”, “Price”: “US $58.99”, “Seller”: “DEALPARTS”, “Seller Rating”: “97.7% positive”, “Quantity Available”: “5”, “Compatibility”: “Compatible with 557 vehicle(s)”, “Shipping”: “Does not ship to Israel”, “Returns”: “Seller does not accept returns”, “Country of Manufacture”: “J…

Strategic Sourcing Conclusion and Outlook for nissan vias solenoid

In today’s competitive automotive landscape, the strategic sourcing of the Nissan VIAS solenoid is essential for ensuring optimal vehicle performance and compliance with environmental standards. By opting for genuine OEM parts, businesses can guarantee fitment and reliability, significantly reducing the risk of costly repairs and downtime. The Nissan VIAS solenoid (part number 14955-8J10A) not only plays a critical role in the Variable Induction Air Control System but also enhances engine efficiency, making it a pivotal component for various Nissan models from 2001 to 2025.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize sourcing from reputable suppliers that offer comprehensive warranties and expert support. This commitment to quality sourcing will not only ensure seamless integration of parts but also foster long-term relationships with manufacturers, enabling businesses to capitalize on emerging market opportunities.

As the automotive industry evolves, leveraging strategic sourcing will be key to maintaining a competitive edge. Engage with trusted suppliers today to secure the parts necessary for sustaining vehicle performance and meeting future demands in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to nissan vias solenoid