The Definitive Guide to Sandblasting Setup Diagram: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for sandblasting setup diagram

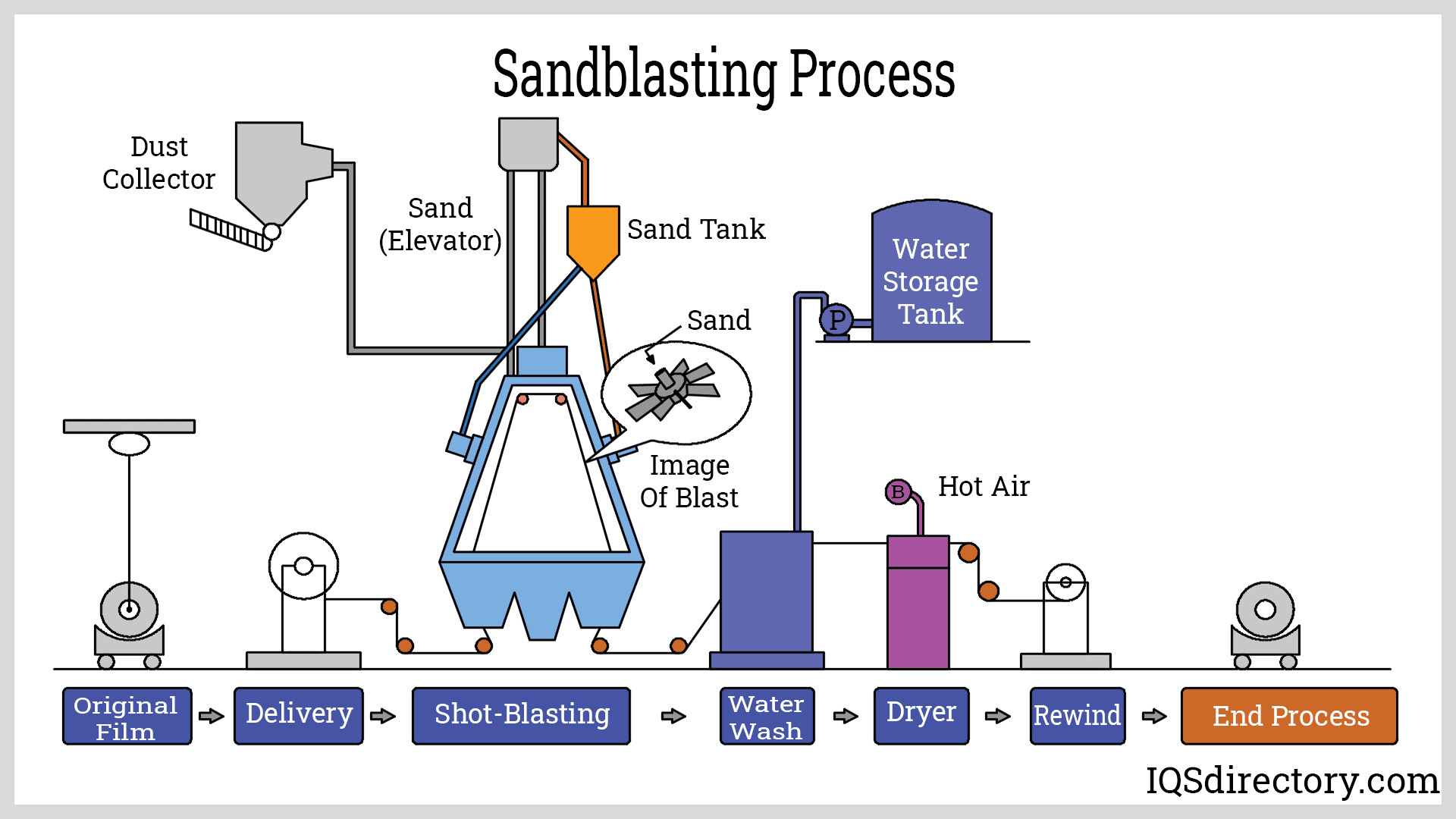

In the competitive landscape of industrial manufacturing, sourcing a reliable sandblasting setup diagram can pose significant challenges for B2B buyers seeking to enhance their operational efficiency. Whether you are involved in metal finishing, glass engraving, or surface preparation, understanding the intricacies of a sandblasting setup is crucial. This comprehensive guide delves into the various types of sandblasting systems, their applications, and the essential components necessary for effective operation.

From assessing different sandblasting techniques to evaluating potential suppliers, this resource equips international buyers—particularly from regions such as Africa, South America, the Middle East, and Europe—with the insights needed to make informed purchasing decisions. We will explore critical factors such as cost considerations, quality assurance, and supplier vetting processes, ensuring that you can navigate the global market with confidence.

By leveraging this guide, you can streamline your procurement process, mitigate risks associated with subpar equipment, and ultimately enhance your operational capabilities. The information presented will empower you to select the right sandblasting setup that meets your specific needs, allowing for improved productivity and quality in your operations.

Understanding sandblasting setup diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cabinet Sandblasting System | Enclosed workspace, integrated dust collection, versatile nozzle options | Automotive, Aerospace, Artisans | Pros: Controlled environment, less mess. Cons: Limited size for larger items. |

| Portable Sandblasting Setup | Lightweight, mobile, often uses a pressure pot | Construction, Field Repairs | Pros: High mobility, adaptable to various locations. Cons: May require more frequent refilling of materials. |

| Wet Sandblasting System | Uses water to reduce dust, minimizes surface damage | Stone, Concrete, Automotive | Pros: Reduced dust, less abrasive damage. Cons: Requires additional water source, potential for rust. |

| Suction Sandblasting System | Utilizes suction to draw abrasive from a hopper | Small-scale operations, DIY | Pros: Cost-effective, easy to set up. Cons: Less efficient for heavy-duty tasks. |

| Automated Sandblasting Machine | Fully automated, programmable for precision work | Mass production, Industrial | Pros: Consistent results, high efficiency. Cons: High initial investment, maintenance complexity. |

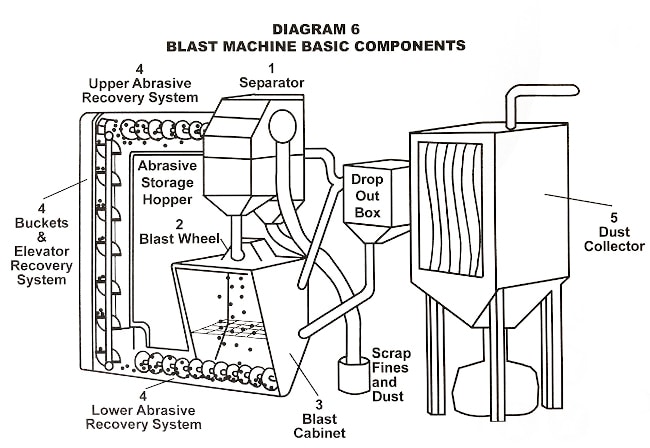

What Are the Characteristics of Cabinet Sandblasting Systems?

Cabinet sandblasting systems feature an enclosed workspace that allows for effective dust containment and material recovery. This setup is ideal for businesses that require a clean working environment, such as automotive repair shops or artisan studios. Buyers should consider the size of the cabinet, the type of abrasive materials used, and the system’s compatibility with various nozzle types. The controlled environment minimizes mess and enhances safety, but the limited workspace may restrict the size of the items that can be processed.

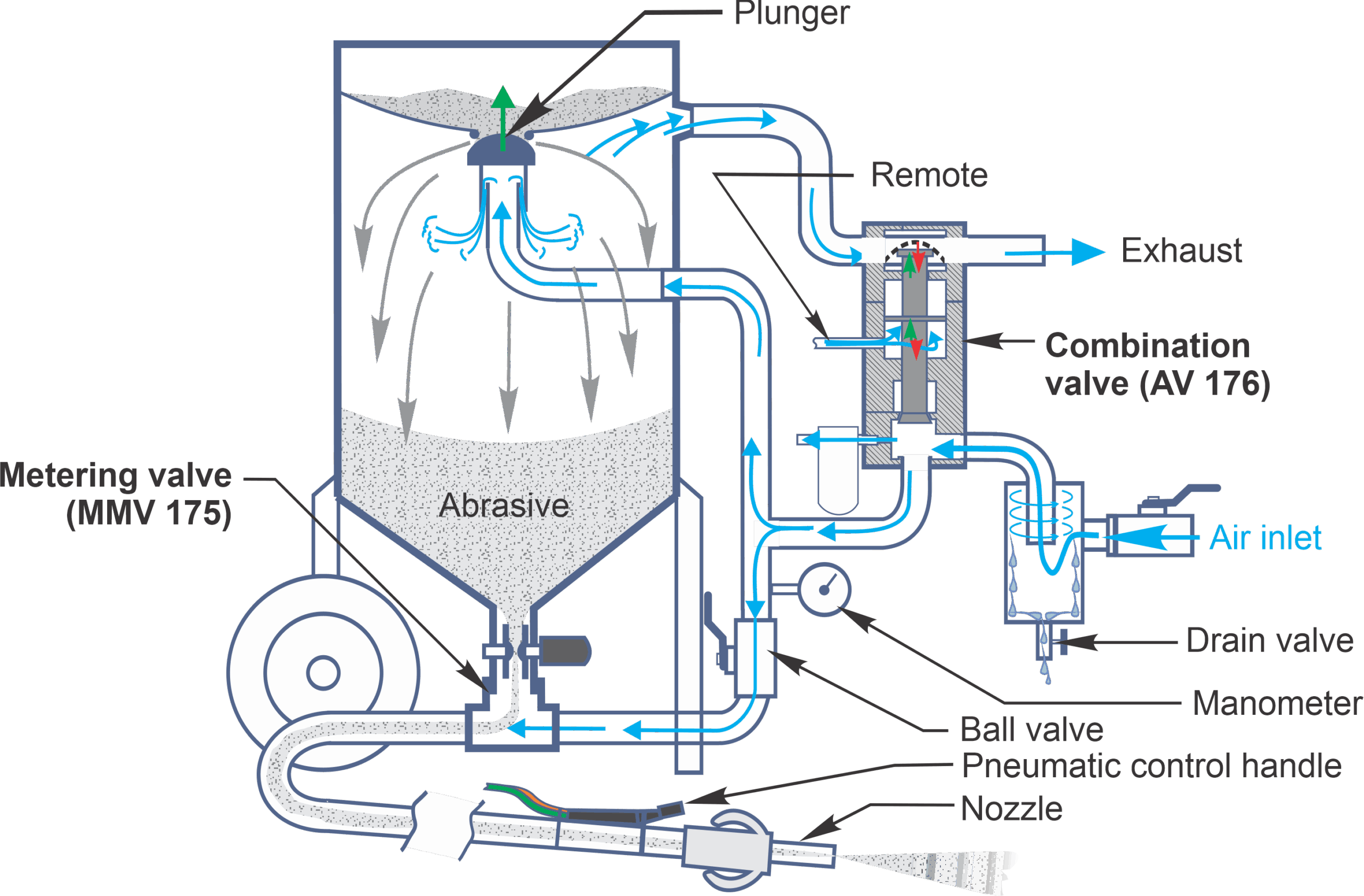

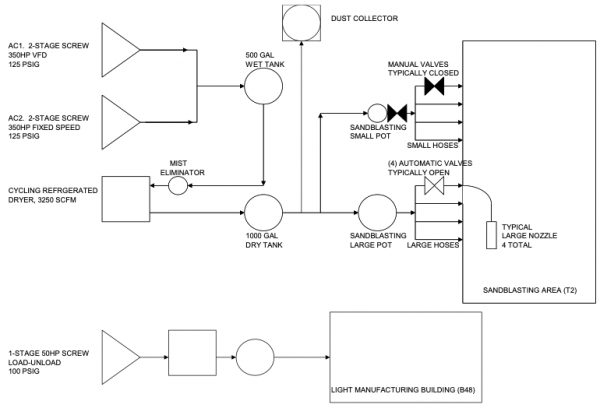

Illustrative image related to sandblasting setup diagram

How Do Portable Sandblasting Setups Benefit B2B Buyers?

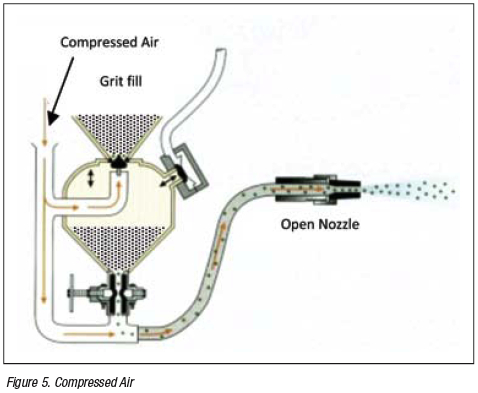

Portable sandblasting setups are designed for mobility, often utilizing a pressure pot that can be easily transported to different job sites. This type of system is particularly beneficial for construction companies and field repair services that need to perform sandblasting in various locations. When considering a portable setup, buyers should evaluate the weight, capacity, and ease of use. While these systems provide flexibility and adaptability, they may require more frequent refilling of abrasive materials, which can impact workflow efficiency.

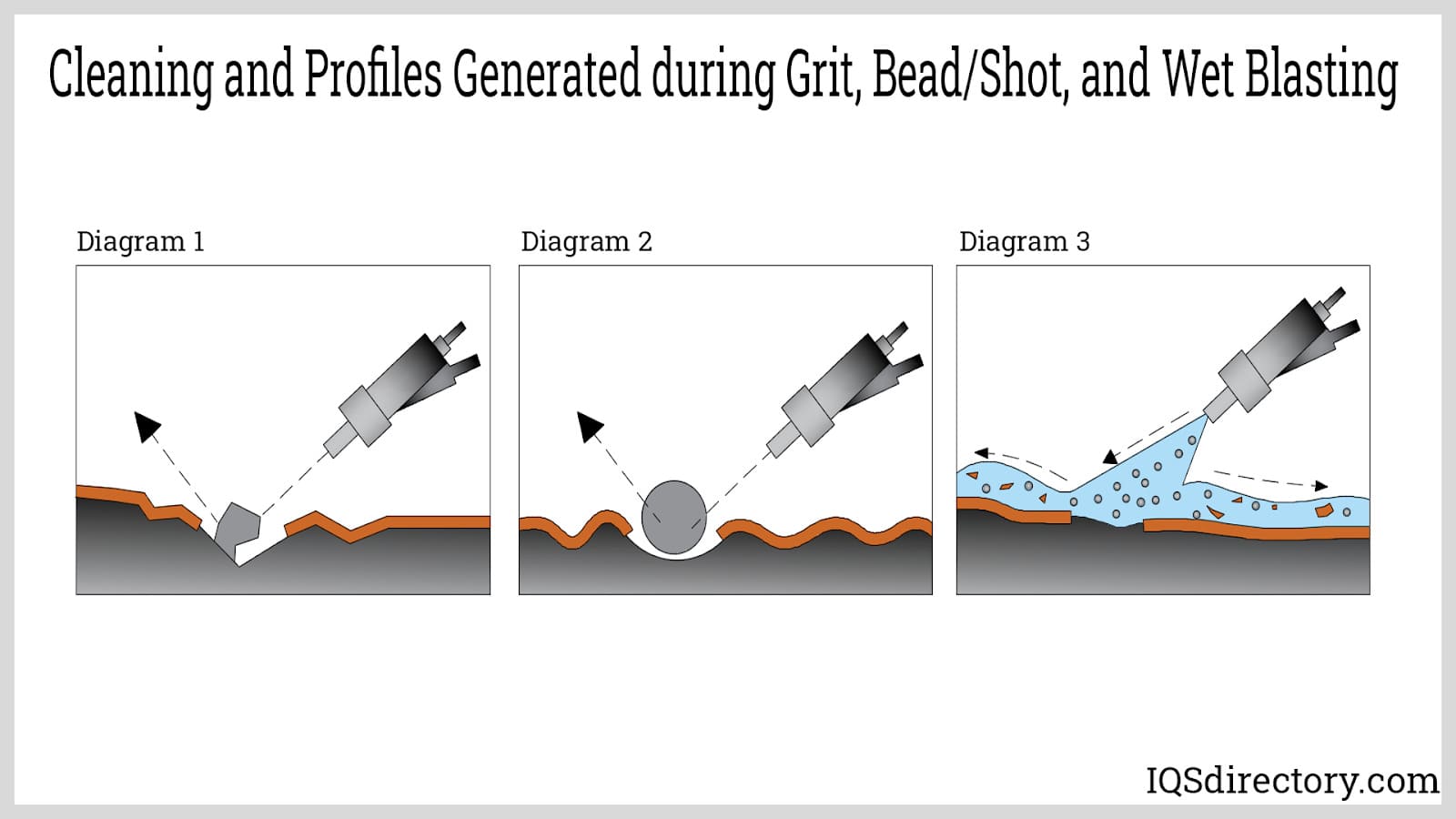

Why Choose a Wet Sandblasting System?

Wet sandblasting systems incorporate water into the blasting process to reduce dust emissions and minimize surface damage. This makes them suitable for applications in stone and concrete work, where preserving the integrity of the surface is crucial. Buyers should assess the system’s water requirements and its ability to handle various abrasive materials. The benefits include a cleaner working environment and reduced wear on equipment; however, the need for a water source and potential issues with rust may deter some buyers.

What Are the Advantages of Suction Sandblasting Systems?

Suction sandblasting systems operate by drawing abrasive material from a hopper, making them a cost-effective option for small-scale operations and DIY projects. They are relatively easy to set up and can be a great entry point for businesses looking to start sandblasting. Buyers should consider the system’s suction power and the types of abrasives it can handle. While these systems are affordable and simple to use, they may not be suitable for heavy-duty tasks, limiting their application in more demanding environments.

How Do Automated Sandblasting Machines Enhance Efficiency?

Automated sandblasting machines offer programmable settings for precision work, making them ideal for mass production and industrial applications. These systems ensure consistent results and high efficiency, which can significantly enhance productivity for manufacturers. Buyers should weigh the initial investment and maintenance requirements against the long-term benefits of automation. While the upfront costs may be high, the potential for increased output and reduced labor costs can make these systems a worthwhile investment for larger businesses.

Key Industrial Applications of sandblasting setup diagram

| Industry/Sector | Specific Application of sandblasting setup diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Surface preparation for aircraft components | Enhances adhesion for coatings, improving durability | High precision equipment; compliance with safety standards |

| Automotive | Rust removal and surface finishing on vehicles | Extends vehicle lifespan and improves aesthetics | Robust equipment; availability of various abrasive materials |

| Construction and Renovation | Surface cleaning of concrete and masonry | Prepares surfaces for painting, increasing longevity | Equipment adaptability for different substrates; ease of use |

| Metal Fabrication | Preparation of metal parts for welding or coating | Ensures strong bonds and uniform finishes | Versatility in abrasive types; compatibility with various metals |

| Glass and Stone Industries | Etching and engraving on glass and stone | Unique customization options for products | Precision control mechanisms; ability to handle delicate materials |

How is the sandblasting setup diagram utilized in the aerospace industry?

In the aerospace sector, the sandblasting setup diagram is crucial for surface preparation of aircraft components. This process removes contaminants and old paint, ensuring optimal adhesion for new coatings. By employing a precise sandblasting system, aerospace manufacturers can enhance the durability of their products while complying with stringent safety regulations. International buyers must ensure that the equipment meets industry standards and can handle the specific materials used in aviation applications.

What role does sandblasting play in the automotive industry?

For automotive applications, sandblasting setups are employed to remove rust and prepare surfaces for painting and finishing. This process not only improves the aesthetic appeal of vehicles but also extends their lifespan by preventing corrosion. Automotive manufacturers and repair shops must source equipment that can effectively handle various types of metals and offer flexibility in abrasive materials. Additionally, considerations for ease of use and maintenance are critical for maximizing operational efficiency.

Illustrative image related to sandblasting setup diagram

Why is sandblasting important in construction and renovation?

In the construction and renovation sectors, sandblasting setup diagrams guide the cleaning of concrete and masonry surfaces. This preparation is essential for ensuring that paints and sealants adhere properly, thereby increasing the longevity of structures. Buyers in these industries should look for systems that are adaptable to different substrates and capable of handling the specific challenges presented by various construction materials. Ease of operation and maintenance are also essential for maximizing productivity on job sites.

How does sandblasting benefit metal fabrication?

Metal fabrication relies heavily on sandblasting setups for preparing metal parts for welding or coating. The process ensures strong bonds and uniform finishes, which are vital for the integrity of fabricated components. Businesses in this sector should focus on sourcing versatile equipment that accommodates various abrasive types and is compatible with different metals. Furthermore, understanding the specific requirements of the materials being processed is crucial for achieving optimal results.

What applications does sandblasting have in the glass and stone industries?

In the glass and stone industries, sandblasting is used for etching and engraving, providing unique customization options for products. The setup diagram helps in configuring systems that can delicately handle these materials while achieving precise results. Buyers in this sector need to prioritize equipment that offers precision control mechanisms and the ability to manage different abrasive types without damaging the substrates. This ensures high-quality outcomes that meet customer expectations for bespoke designs.

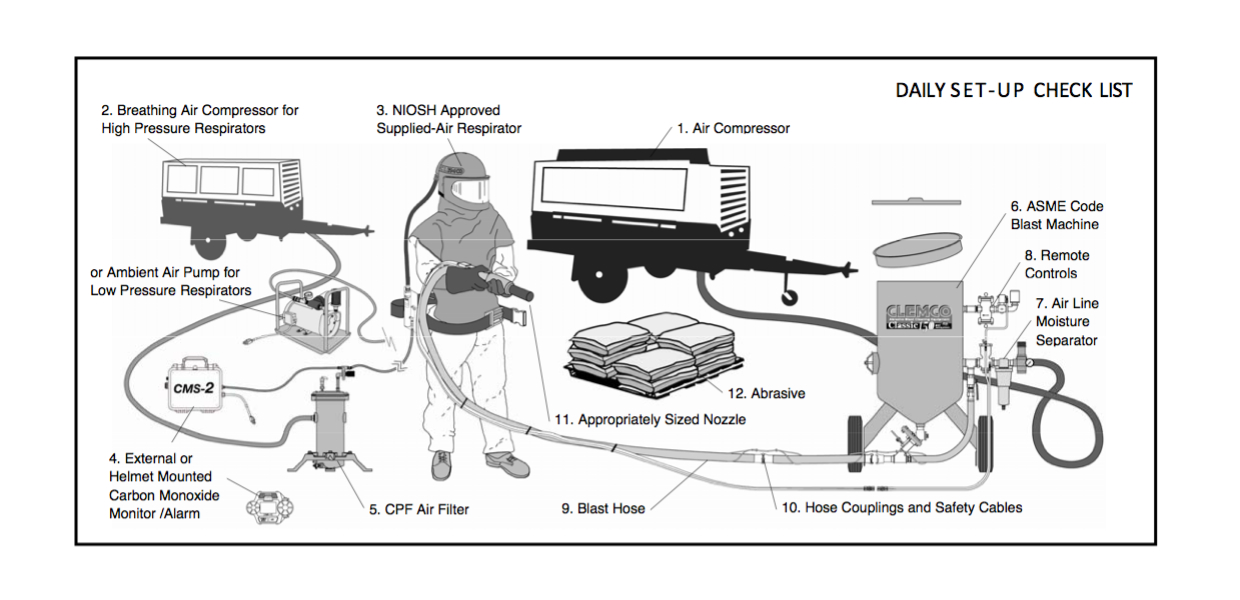

Illustrative image related to sandblasting setup diagram

3 Common User Pain Points for ‘sandblasting setup diagram’ & Their Solutions

Scenario 1: Difficulty in Switching Between Different Media Types

The Problem: Many B2B buyers encounter significant downtime when needing to switch the sandblasting media for different applications, such as moving from glass etching to wood or stone blasting. The process typically involves draining the pressure pot, cleaning it thoroughly, and recalibrating the entire setup to accommodate the new medium. This not only takes valuable time but can also lead to costly inefficiencies, especially in high-demand environments.

The Solution: To streamline the process of switching between different media types, consider investing in a dual-pressure pot system with dedicated setups for each medium. By employing a sandblasting setup diagram that illustrates the configuration of each pot, including separate valves and regulators for different media, you can minimize downtime significantly. Furthermore, ensure the system is equipped with quick-release fittings, allowing operators to change the pressure pot without extensive disassembly. Implementing a color-coded system for hoses and fittings can also help in quickly identifying the right setup for each type of media, reducing the likelihood of cross-contamination.

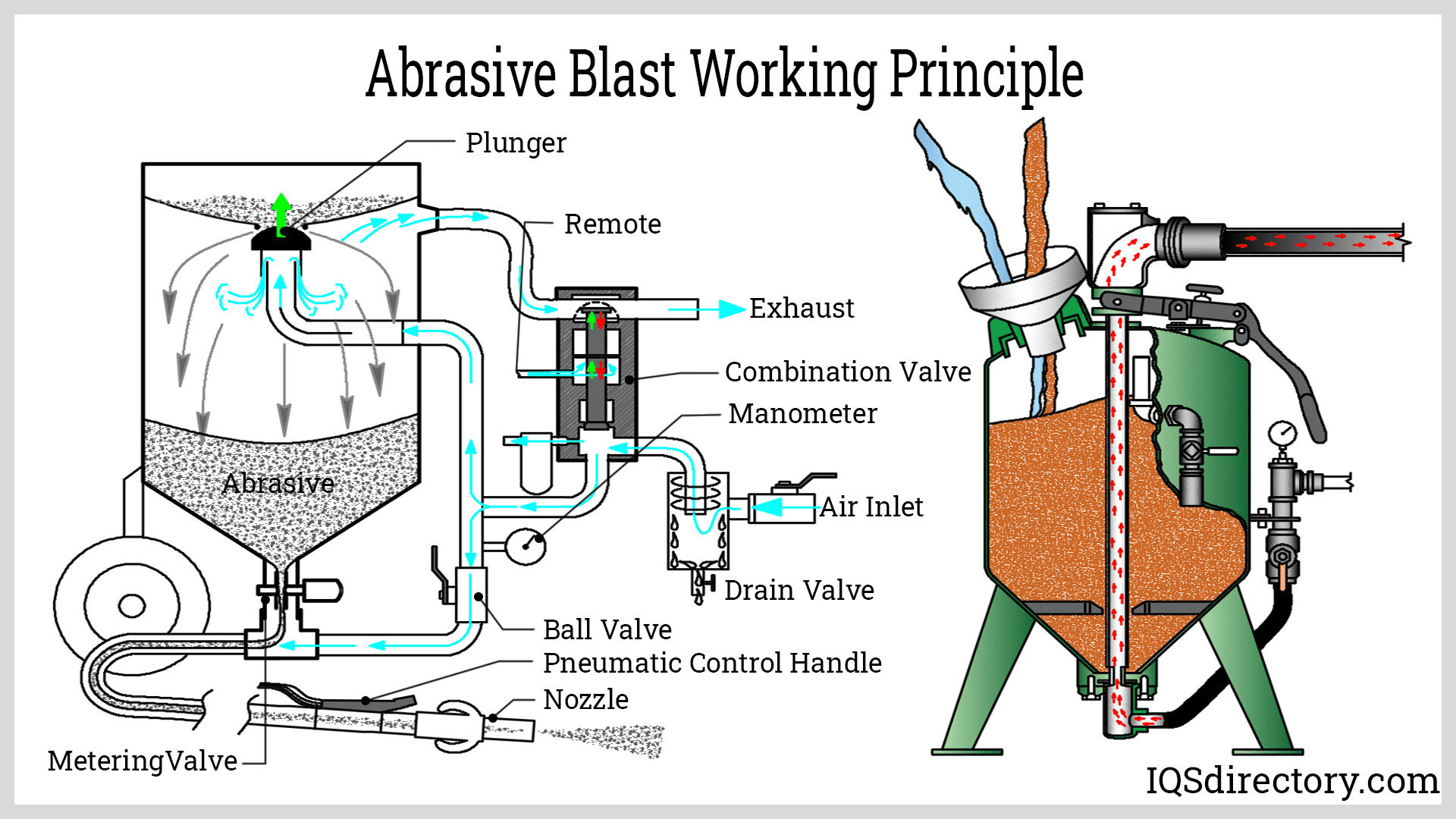

Scenario 2: Inefficient Pressure Regulation Leading to Poor Results

The Problem: Inconsistent pressure regulation is a common issue that leads to subpar blasting results. For many B2B buyers, particularly those working with varying materials, achieving the correct PSI is crucial. If the setup is not properly designed with adequate regulators and pressure monitoring, operators may experience uneven blasting, resulting in surface imperfections and dissatisfaction from clients.

The Solution: To ensure effective pressure regulation, utilize a comprehensive sandblasting setup diagram that clearly outlines the location and function of all regulators, gauges, and valves. Consider incorporating a secondary regulator specifically for the pressure pot to maintain optimal PSI levels. This can be achieved by installing a dedicated gauge that allows operators to monitor and adjust pressure settings in real-time, ensuring consistent performance. Additionally, investing in high-quality regulators and regularly performing maintenance checks can prevent pressure fluctuations and maintain the integrity of the blasting process.

Scenario 3: Safety Hazards Due to Poor Setup Design

The Problem: Safety is a paramount concern in sandblasting operations, yet many setups lack proper safety features due to poor design or oversight. B2B buyers might find that their current sandblasting configuration poses risks such as exposure to abrasive materials, insufficient ventilation, or inadequate dust collection, leading to potential health hazards for operators and compliance issues with safety regulations.

The Solution: To enhance safety within your sandblasting operation, it’s essential to design a sandblasting setup diagram that incorporates safety measures from the outset. This includes the installation of appropriate dust collection systems and ensuring that the workspace is adequately ventilated. Using a diagram, clearly mark safety equipment locations, such as emergency shut-off valves, fire extinguishers, and first aid kits. Additionally, ensure that all operators are trained on the safety protocols associated with the equipment and materials used. Regular safety audits should also be scheduled to assess the effectiveness of your setup and make necessary adjustments based on regulatory changes or operational needs.

By proactively addressing these common pain points through thoughtful design and operational strategies, B2B buyers can enhance efficiency, safety, and overall productivity in their sandblasting operations.

Strategic Material Selection Guide for sandblasting setup diagram

What Are the Key Materials Used in Sandblasting Setup Diagrams?

In the context of sandblasting setups, selecting the right materials is crucial for ensuring optimal performance and durability. This analysis focuses on four common materials used in sandblasting equipment, examining their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform in Sandblasting Applications?

Key Properties: Steel is known for its high tensile strength and durability, making it a preferred choice for pressure pots and cabinets in sandblasting setups. It typically withstands high pressures, often rated up to 150 PSI, and offers good corrosion resistance when treated with protective coatings.

Pros & Cons: The primary advantage of steel is its robustness and ability to handle abrasive materials without significant wear. However, it is susceptible to rust if not properly maintained, which can lead to higher long-term costs. Additionally, the manufacturing complexity can be higher, requiring specialized welding techniques.

Impact on Application: Steel is compatible with various abrasive media, including sand, glass beads, and aluminum oxide, making it versatile for different sandblasting tasks.

Considerations for International Buyers: Compliance with standards such as ASTM A36 (for carbon structural steel) is essential. Buyers in regions like Europe may prefer materials that meet DIN standards, while those in Africa and South America should consider local sourcing to minimize transportation costs.

What Role Does Aluminum Play in Sandblasting Equipment?

Key Properties: Aluminum is lightweight and resistant to corrosion, making it an attractive option for portable sandblasting setups. It typically has a lower pressure rating compared to steel, often around 100 PSI.

Pros & Cons: The main advantage of aluminum is its resistance to rust and ease of handling due to its lightweight nature. However, it is less durable than steel and may not withstand heavy-duty applications as effectively. The cost of aluminum can also be higher, depending on the market.

Impact on Application: Aluminum is suitable for lighter abrasive media, such as baking soda or glass beads, which are less abrasive.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards, such as JIS H 2000 in Japan or EN 573 in Europe. The lightweight nature of aluminum can also reduce shipping costs, making it an economical choice for international buyers.

Why Is Rubber Important in Sandblasting Systems?

Key Properties: Rubber is often used for seals and gaskets in sandblasting setups due to its flexibility and resistance to wear. It can typically handle temperatures up to 80°C and pressures around 60 PSI.

Pros & Cons: Rubber provides excellent sealing capabilities, preventing media leakage and ensuring efficient operation. However, it may degrade over time when exposed to certain abrasive materials, leading to increased maintenance costs.

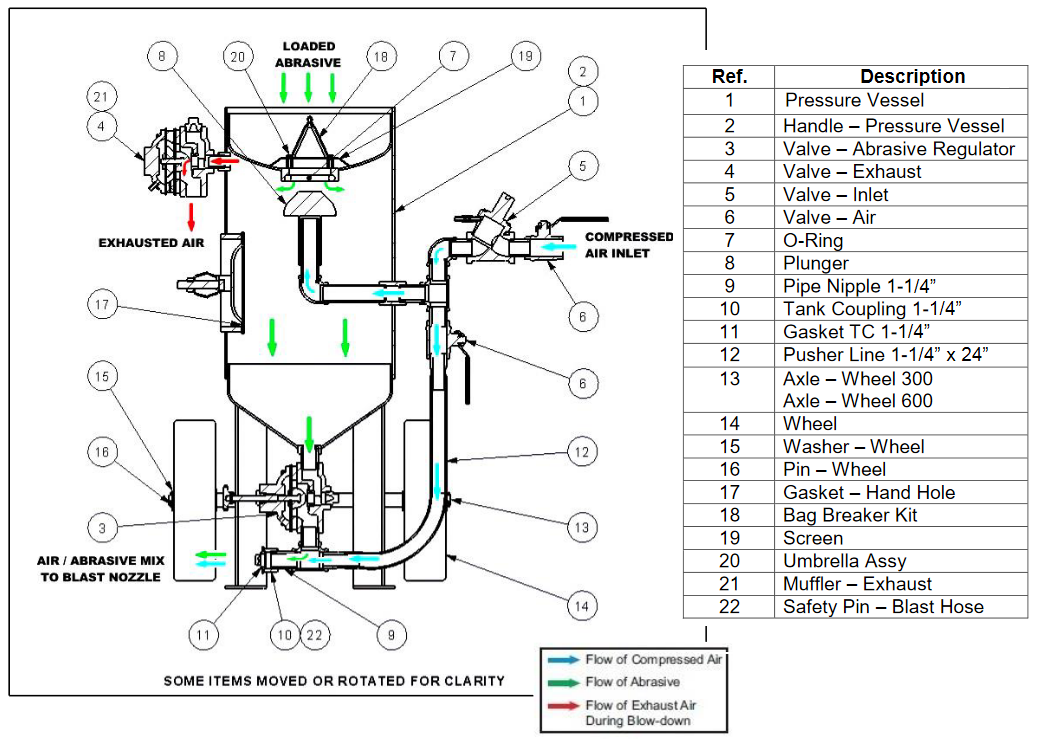

Illustrative image related to sandblasting setup diagram

Impact on Application: Rubber is compatible with various types of media but may not perform well with highly abrasive substances.

Considerations for International Buyers: Compliance with ASTM D2000 for rubber materials is crucial. Buyers should also consider the local climate, as extreme temperatures can affect rubber’s longevity.

How Does Glass Reinforced Plastic (GRP) Compare in Sandblasting Applications?

Key Properties: GRP is a composite material that combines glass fibers with resin, providing excellent strength-to-weight ratios and corrosion resistance. It can withstand pressures up to 100 PSI and is resistant to many chemicals.

Pros & Cons: The key advantage of GRP is its lightweight nature combined with high durability, making it ideal for portable sandblasting equipment. However, it can be more expensive than traditional materials like steel and may require specialized manufacturing processes.

Impact on Application: GRP is suitable for a variety of abrasive media, including garnet and glass beads, and is particularly effective in environments where corrosion is a concern.

Considerations for International Buyers: Buyers should ensure that GRP components meet relevant standards such as ISO 14692 for composite materials. The higher initial cost may be offset by lower maintenance requirements over time.

Summary Table of Material Selection for Sandblasting Setup Diagrams

| Material | Typical Use Case for sandblasting setup diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Pressure pots and cabinets | High durability and pressure rating | Susceptible to rust | Medium |

| Aluminum | Portable sandblasting setups | Lightweight and corrosion-resistant | Less durable under heavy use | High |

| Rubber | Seals and gaskets | Excellent sealing capabilities | Degrades over time | Low |

| Glass Reinforced Plastic (GRP) | Portable equipment and corrosion-prone areas | Lightweight and high durability | Higher manufacturing costs | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for sandblasting setups, emphasizing the importance of understanding the properties, advantages, and limitations of each material in relation to their specific applications and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sandblasting setup diagram

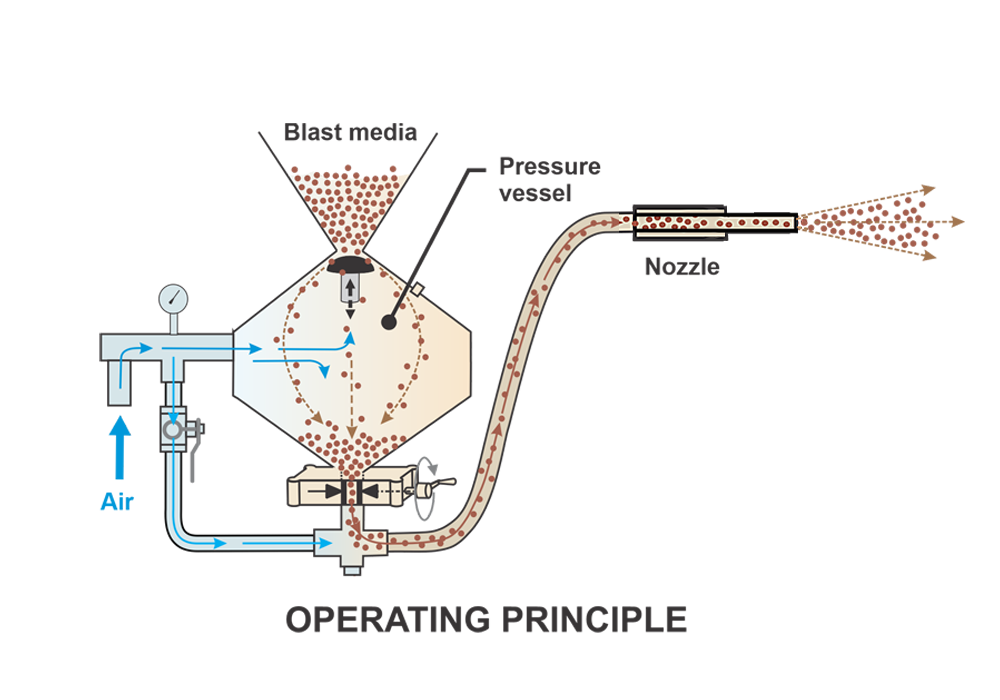

What Are the Main Stages of Manufacturing a Sandblasting Setup Diagram?

The manufacturing process for a sandblasting setup diagram involves several key stages, each critical to ensuring the functionality and longevity of the equipment. Understanding these stages helps B2B buyers to appreciate the complexities involved and the importance of quality assurance.

How Is Material Prepared for Sandblasting Systems?

Material preparation is the foundational stage of manufacturing a sandblasting setup. It begins with selecting high-grade materials suitable for the components of the sandblasting system, such as pressure pots, nozzles, and hoses. Common materials include steel, aluminum, and specialized plastics that can withstand abrasive materials and high pressures.

After selection, materials undergo cutting and machining processes to achieve precise dimensions and tolerances. This step often involves CNC (Computer Numerical Control) machining, which enhances accuracy and repeatability. Properly prepared materials are essential for ensuring that the final product can handle the rigors of sandblasting operations.

What Forming Techniques Are Used in Sandblasting Manufacturing?

Forming techniques play a significant role in shaping the components of the sandblasting system. Common methods include:

- Casting: Utilized for creating complex shapes, such as pressure pots and nozzles, casting can efficiently produce multiple units with high dimensional accuracy.

- Welding: Critical for assembling metal components, welding ensures structural integrity. Advanced techniques like TIG (Tungsten Inert Gas) welding are often employed for their precision.

- Machining: Post-forming, machining is essential to achieve the final specifications, especially for threaded parts and smooth surfaces where air and grit flow is crucial.

These techniques not only influence the performance of the sandblasting system but also its safety and durability, making them vital considerations for buyers.

How Are Sandblasting Systems Assembled?

Assembly is a critical stage where all manufactured components come together. This process typically involves:

- Sub-Assembly: Individual components, such as the pressure pot, nozzle, and controls, are initially assembled separately.

- Main Assembly: Sub-assemblies are then integrated into the overall sandblasting system. This includes connecting pneumatic lines, electrical components, and ensuring all parts fit securely.

- System Calibration: After assembly, calibration of pressure settings and flow rates is performed to ensure optimal operation. This step is crucial, as improper settings can lead to equipment malfunction or safety hazards.

Proper assembly techniques are essential for ensuring that the sandblasting setup operates efficiently and meets the required performance standards.

What Finishing Processes Are Applied to Sandblasting Equipment?

Finishing processes are the final touchpoints in the manufacturing process, enhancing both aesthetics and functionality. Common finishing techniques include:

- Surface Treatment: Components may undergo treatments such as anodizing or powder coating to improve corrosion resistance and durability.

- Quality Inspection: Each finished component is inspected for defects, ensuring that all parts meet design specifications.

- Assembly Testing: Complete systems undergo testing to ensure they perform as intended under operational conditions.

These finishing steps are vital for ensuring the longevity and reliability of the sandblasting setup, directly affecting customer satisfaction and operational efficiency.

How Is Quality Assurance Integrated into Sandblasting Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing sandblasting setups. It ensures that products meet both international standards and customer expectations.

Illustrative image related to sandblasting setup diagram

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are essential for ensuring a consistent quality management system. This standard focuses on process efficiency and customer satisfaction, making it a benchmark for quality assurance. Additionally, industry-specific certifications like CE marking for safety and compliance in Europe or API standards for oil and gas applications are crucial for buyers in those sectors.

B2B buyers should actively seek suppliers who adhere to these standards, as they are indicators of a commitment to quality and safety.

What Quality Control Checkpoints Are Important in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify issues early and ensure compliance with specifications. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet required standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to ensure adherence to specifications. This includes monitoring machining processes and assembly techniques.

- Final Quality Control (FQC): Once the sandblasting setup is fully assembled, it undergoes a thorough inspection and testing phase to ensure functionality and safety before shipping.

These checkpoints help maintain high-quality standards and reduce the risk of defects reaching the customer.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers can take several steps to verify the quality assurance practices of their suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and QC measures in place.

- Quality Reports: Requesting detailed quality reports can provide insight into the supplier’s performance and adherence to standards.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased assessment of the supplier’s quality practices and product reliability.

By taking these steps, buyers can ensure they are partnering with suppliers committed to maintaining high standards of quality.

What Are the Common Testing Methods Used for Sandblasting Equipment?

Testing methods for sandblasting equipment are essential to ensure that systems perform reliably under operational conditions. Common testing methods include:

- Pressure Testing: Ensures that all components can withstand the required pressure levels without leaks.

- Operational Testing: Involves running the system under normal conditions to assess performance, flow rates, and functionality.

- Durability Testing: Components are subjected to wear and tear simulations to evaluate their longevity and performance over time.

These testing methods help identify potential issues before products reach the market, ensuring that B2B buyers receive reliable and high-quality equipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances related to quality control when sourcing sandblasting setups. Different regions may have varying standards and regulations, impacting the compliance of equipment.

For instance, buyers from Europe may need to ensure that products are CE marked, while those in the Middle East might focus on local certifications. Additionally, understanding the supplier’s ability to meet local regulations and standards is crucial for avoiding legal and operational issues.

Illustrative image related to sandblasting setup diagram

In summary, B2B buyers should prioritize suppliers that demonstrate a robust quality assurance framework, adhere to international standards, and are transparent about their QC processes. By doing so, they can secure reliable sandblasting setups that meet their operational needs and enhance their business capabilities.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sandblasting setup diagram’

In this practical sourcing guide, we provide a comprehensive checklist for B2B buyers interested in procuring a sandblasting setup diagram. This guide will help streamline the sourcing process, ensuring you select the most suitable components and suppliers for your sandblasting needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is crucial for a successful sandblasting setup. Determine the materials you will be working with, the type of grit needed, and the pressure levels required for optimal performance.

– Considerations:

– What materials will you be blasting (metal, wood, glass)?

– What grit size and type are suitable for these materials?

Step 2: Research Industry Standards

Familiarize yourself with the relevant industry standards and regulations that govern sandblasting operations. This knowledge ensures compliance and safety in your operations.

– Key Standards to Review:

– ISO standards for abrasive blasting.

– Local regulations regarding air quality and worker safety.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to perform a thorough evaluation. Request company profiles, case studies, and references from other businesses in similar industries or regions.

– Assessment Criteria:

– Supplier’s experience with sandblasting equipment.

– Client testimonials and case studies demonstrating successful implementations.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, ask for detailed product specifications and diagrams. This information will help you verify whether the products meet your technical requirements.

– What to Look For:

– Detailed sandblasting setup diagrams showing component integration.

– Specifications for pressure pots, nozzles, and footswitch systems.

Step 5: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and quality assurance measures. This step is crucial for maintaining industry standards and ensuring product reliability.

– Certification Examples:

– ISO 9001 for quality management systems.

– Compliance with safety regulations relevant to sandblasting operations.

Illustrative image related to sandblasting setup diagram

Step 6: Assess After-Sales Support and Warranty

After-sales support is vital for maintaining your sandblasting equipment. Inquire about warranty terms and the availability of technical support to address any operational issues.

– Questions to Ask:

– What is the warranty period for the equipment?

– Is there a dedicated support team for troubleshooting?

Step 7: Compare Pricing and Terms

Finally, compare pricing and terms from different suppliers to ensure you’re getting the best value. Look beyond just the initial cost; consider shipping, installation, and maintenance support.

– Comparison Factors:

– Total cost of ownership, including hidden fees.

– Payment terms and financing options available.

By following this checklist, B2B buyers can effectively navigate the procurement process for a sandblasting setup diagram, ensuring they make informed decisions that align with their operational needs and budget constraints.

Illustrative image related to sandblasting setup diagram

Comprehensive Cost and Pricing Analysis for sandblasting setup diagram Sourcing

What Are the Key Cost Components in Sandblasting Setup Diagram Sourcing?

When sourcing a sandblasting setup diagram, understanding the comprehensive cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials can vary significantly based on the specifications required for the sandblasting system. Components such as pressure pots, footswitches, valves, and grit materials contribute to the overall cost. For example, specialized materials like BUNA-N rubber for pinch valves may incur higher costs due to their durability against abrasive materials.

-

Labor: Labor costs involve both direct labor for assembly and indirect labor for design and engineering. Depending on the region, labor rates can fluctuate, impacting the final price. Countries in Europe may have higher labor costs compared to South America or Africa, which can affect the pricing strategy.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, utilities, and indirect materials. A well-optimized manufacturing process can help reduce overhead costs, making the final product more competitive in the market.

-

Tooling: The initial investment in tooling is significant, especially for custom designs or high-volume production. Buyers should consider the amortization of tooling costs over production runs to understand the impact on pricing.

-

Quality Control: Ensuring that all components meet industry standards requires investment in QC processes. Certification and compliance with international standards (e.g., ISO certifications) may also add to the cost but can enhance the product’s marketability.

-

Logistics: Transportation and shipping costs can vary widely based on the origin and destination of the components. Factors such as Incoterms (International Commercial Terms) and freight methods (air vs. sea) will influence the overall logistics cost.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary depending on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect Sandblasting Setup Diagrams?

Several factors can influence the pricing of sandblasting setup diagrams, which international buyers must consider:

-

Volume/MOQ: Purchasing in bulk or meeting minimum order quantities (MOQs) can lead to significant discounts. Suppliers often offer better pricing for larger orders, encouraging buyers to consolidate their needs.

-

Specifications and Customization: Customization requests can increase costs due to the need for specialized materials or unique designs. Buyers should clarify their specifications early to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials that meet specific industry certifications can command higher prices. However, investing in quality can lead to lower maintenance costs and longer product life, improving the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their experience and service levels, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers. The chosen terms affect who is responsible for transportation costs, insurance, and duties, influencing the total price payable.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Sandblasting Setup Diagrams?

To maximize value when sourcing sandblasting setup diagrams, buyers should consider the following strategies:

-

Negotiation: Engaging suppliers in negotiations can lead to better pricing, especially for larger orders. Establishing long-term relationships can also provide leverage in future negotiations.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors like maintenance, replacement parts, and operational efficiency when assessing overall costs.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variations due to local economic conditions, currency fluctuations, and import tariffs. Building relationships with local suppliers can mitigate these challenges.

-

Seek Multiple Quotes: Obtaining multiple quotes from different suppliers can provide insight into the market rate and help identify the best value.

-

Review Payment Terms: Favorable payment terms can improve cash flow and reduce immediate financial strain. Discussing terms upfront can prevent misunderstandings later in the transaction.

Conclusion

Sourcing a sandblasting setup diagram involves navigating a complex landscape of costs and pricing influences. By understanding the key components, price influencers, and effective buyer strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary, and it’s advisable to seek indicative quotes tailored to specific requirements.

Alternatives Analysis: Comparing sandblasting setup diagram With Other Solutions

Introduction: Exploring Alternatives to Sandblasting Setup Diagrams

When evaluating sandblasting solutions, it’s crucial to consider various alternatives that can achieve similar outcomes in surface preparation, cleaning, or finishing processes. Each method presents unique advantages and potential drawbacks, influencing factors such as performance, cost, ease of implementation, and maintenance. This analysis will compare the traditional sandblasting setup diagram with two viable alternatives: abrasive waterjet cutting and dry ice blasting.

Comparison Table

| Comparison Aspect | Sandblasting Setup Diagram | Abrasive Waterjet Cutting | Dry Ice Blasting |

|---|---|---|---|

| Performance | High efficiency for tough materials, excellent for large surfaces | Versatile, effective on metals and composites, precise | Gentle cleaning, safe on sensitive surfaces |

| Cost | Moderate initial setup cost, ongoing media costs | Higher upfront equipment costs, lower media costs | High operational costs due to dry ice consumption |

| Ease of Implementation | Requires skilled operation, setup can be complex | Requires specialized training, more complex setup | Simple setup, minimal training needed |

| Maintenance | Regular maintenance of equipment and media | Low maintenance, but requires water filtration | Low maintenance, but dry ice supply chain management is needed |

| Best Use Case | Heavy-duty cleaning and surface preparation | Precision cutting and shaping of materials | Cleaning delicate machinery or surfaces without residue |

Detailed Breakdown of Alternatives

Abrasive Waterjet Cutting

Abrasive waterjet cutting utilizes high-pressure water mixed with abrasive particles to cut through various materials. This method offers precision and versatility, making it suitable for industries such as aerospace and automotive. The primary advantage of waterjet cutting is its ability to work with a wide range of materials without thermal distortion. However, the initial investment is significantly higher due to the specialized equipment required, and the setup can be more complex, necessitating skilled operators.

Dry Ice Blasting

Dry ice blasting employs solid carbon dioxide pellets to clean surfaces. This method is particularly effective for delicate components, as it does not cause damage or leave residue. It is ideal for applications in the food industry, electronics, and historical restoration. The ease of setup and operation makes dry ice blasting an attractive option; however, the operational costs can be high due to the ongoing need for dry ice, which may not be readily available in all regions.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate surface preparation method depends on specific operational needs and constraints. B2B buyers should assess factors such as the type of materials being processed, the required precision, budget limitations, and the availability of skilled labor. While a sandblasting setup diagram provides a robust solution for heavy-duty applications, alternatives like abrasive waterjet cutting and dry ice blasting may offer better performance or cost-effectiveness for specialized tasks. By carefully evaluating these aspects, businesses can make informed decisions that align with their operational goals and budgetary considerations.

Illustrative image related to sandblasting setup diagram

Essential Technical Properties and Trade Terminology for sandblasting setup diagram

What Are the Essential Technical Properties of a Sandblasting Setup?

When evaluating a sandblasting setup, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some key properties that should be considered:

-

Pressure Rating (PSI)

– Definition: The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum pressure the system can handle safely.

– Importance: A higher PSI allows for more aggressive blasting, which can be essential for certain applications, such as heavy-duty cleaning or surface preparation. However, selecting the right pressure is critical to avoid damaging materials. -

Material Grade

– Definition: This refers to the quality and type of materials used in the construction of the sandblasting equipment, including pressure pots, hoses, and nozzles.

– Importance: High-grade materials ensure durability and resistance to wear from abrasive materials. For B2B buyers, investing in superior material grades can reduce long-term maintenance costs and downtime. -

Grit Size and Type

– Definition: Grit size is the measurement of the abrasive particles used in the sandblasting process, often specified in mesh size or microns.

– Importance: Different grit sizes are suitable for various applications, from delicate glass engraving to heavy metal stripping. Understanding grit specifications helps businesses select the right media for their specific needs, improving efficiency and results. -

Flow Rate

– Definition: The flow rate indicates how much abrasive material can be delivered per minute, usually measured in pounds per minute (PPM).

– Importance: A higher flow rate can lead to faster job completion times, which is essential for businesses aiming to maximize productivity. Buyers should ensure the flow rate aligns with their operational needs. -

Regulation Controls

– Definition: Regulation controls refer to the valves and regulators that manage air pressure and abrasive flow within the system.

– Importance: Precise control over these parameters is vital for consistent performance and quality of work. Systems with advanced regulation controls can improve safety and efficiency, making them more attractive to B2B buyers.

What Are Common Trade Terms Used in Sandblasting?

Familiarity with industry-specific terminology can enhance communication and negotiation between buyers and suppliers. Here are several key terms commonly used in the sandblasting sector:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships helps buyers identify the source of parts, which can impact quality and warranty considerations. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ is essential for B2B buyers to manage inventory costs effectively. High MOQs can lead to overstock situations, while low MOQs may allow for more flexibility in purchasing. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document used to solicit price quotes from suppliers for specific products or services.

– Significance: Issuing an RFQ allows businesses to compare prices and terms from multiple suppliers, ensuring they get the best deal possible. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Significance: Understanding Incoterms is crucial for B2B buyers involved in global trade, as they dictate aspects such as shipping, liability, and insurance. -

Aftermarket Parts

– Definition: Aftermarket parts are components made by companies other than the original manufacturer.

– Significance: These parts can offer cost savings and availability, but buyers must evaluate compatibility and quality compared to OEM parts.

By grasping these essential technical properties and industry terms, B2B buyers can navigate the sandblasting market more effectively, ensuring they make informed decisions that align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the sandblasting setup diagram Sector

What Are the Key Trends Shaping the Global Sandblasting Setup Diagram Market?

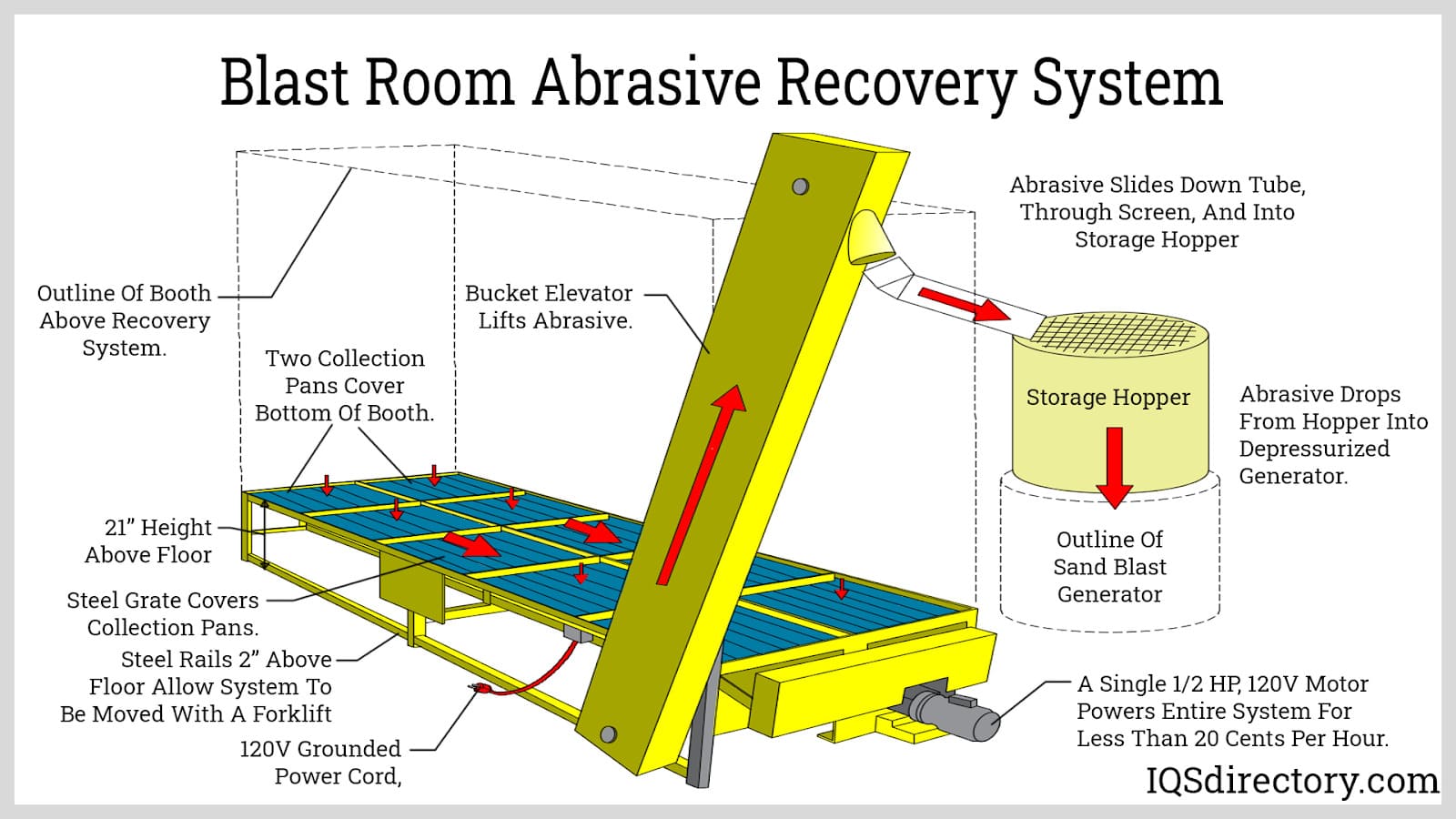

The sandblasting setup diagram market is experiencing significant evolution, driven by technological advancements and changing customer expectations. Global drivers such as industrialization, the need for surface preparation in manufacturing, and the growing demand for customized solutions are central to market dynamics. Emerging B2B technologies, including automation and IoT integration, are streamlining operations and enhancing efficiency. Buyers are increasingly seeking equipment that offers precision and reliability, particularly in regions such as Africa, South America, the Middle East, and Europe, where industries like construction, automotive, and aerospace are expanding.

Another notable trend is the shift towards modular and versatile systems. International buyers are looking for sandblasting setups that can be easily adapted for various applications, from glass engraving to stone and wood treatment. This flexibility reduces the need for multiple systems, ultimately lowering operational costs. Furthermore, manufacturers are increasingly focusing on user-friendly designs, enabling companies to implement these setups with minimal training.

Illustrative image related to sandblasting setup diagram

Sourcing trends also reflect a growing emphasis on local suppliers, particularly in emerging markets. Buyers are prioritizing partnerships with regional manufacturers to reduce lead times and shipping costs, while also fostering local economies. As competition intensifies, companies that can offer superior customer service and support will gain a competitive edge, making it essential for international buyers to evaluate potential suppliers thoroughly.

How Can Sustainability and Ethical Sourcing Impact the Sandblasting Setup Diagram Sector?

Sustainability is becoming a pivotal concern in the sandblasting setup diagram sector, influencing purchasing decisions across international markets. The environmental impact of traditional sandblasting methods, including dust emissions and the use of hazardous materials, has prompted buyers to seek greener alternatives. As a result, manufacturers are increasingly adopting eco-friendly practices and materials in their production processes.

Ethical sourcing is also gaining traction, with buyers demanding transparency in supply chains. They are looking for suppliers that adhere to environmental regulations and demonstrate a commitment to sustainable practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for companies aiming to enhance their market credibility.

Furthermore, the shift towards ‘green’ materials, such as recyclable abrasives and non-toxic cleaning agents, is reshaping product offerings. Suppliers that prioritize these materials not only appeal to environmentally conscious buyers but also stand to benefit from regulatory incentives and improved brand loyalty. As businesses increasingly recognize the importance of sustainability, aligning procurement strategies with these values will be crucial for long-term success in the sandblasting setup diagram market.

What Is the Historical Context of Sandblasting Setup Development?

The history of sandblasting can be traced back to the late 19th century when it was first introduced as a method for surface preparation and cleaning. Early systems used silica sand as an abrasive, which significantly improved efficiency in various industrial applications. Over the decades, the technology has evolved, with advancements in pneumatic systems and the introduction of different abrasive materials, including glass beads and garnet.

The evolution of sandblasting setups has paralleled technological innovations in manufacturing and construction, leading to the development of more sophisticated equipment that offers enhanced precision and control. As industries expanded globally, the need for effective surface treatment solutions became paramount, further driving the demand for advanced sandblasting setups.

Today, the market is characterized by a diverse array of systems designed to cater to specific applications, reflecting the ongoing commitment to improving efficiency and meeting the varied needs of international B2B buyers. This historical context not only underscores the importance of innovation but also highlights the need for sustainable practices in modern sandblasting solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of sandblasting setup diagram

1. How do I solve common issues with sandblasting setup diagrams?

To address issues with sandblasting setup diagrams, first ensure you have a clear understanding of the equipment layout and connections. Problems often arise from incorrect pressure settings or improper component connections. Review the diagram meticulously, focusing on the air supply, grit delivery, and control mechanisms. If issues persist, consult with the equipment manufacturer or a technical expert for troubleshooting assistance. Additionally, consider joining online forums or groups related to sandblasting to gain insights from other users’ experiences.

2. What is the best equipment for a sandblasting setup?

The best equipment for a sandblasting setup varies based on your specific needs, such as the materials you are working with and the scale of your operations. Generally, a reliable pressure pot, high-quality nozzle, and appropriate grit type are essential. For versatility, consider a system that allows for easy grit changes and has adjustable pressure settings. Research suppliers that offer robust equipment backed by warranties and technical support, ensuring you have access to reliable assistance as needed.

3. How can I customize my sandblasting setup to fit my specific needs?

Customization of your sandblasting setup can be achieved by selecting components that cater to your unique requirements. This includes choosing the right pressure pot size, nozzle types, and grit materials based on the surfaces you intend to treat. Collaborate with suppliers who offer tailored solutions and are willing to adapt their designs to your specifications. Additionally, consider integrating automation features, such as footswitch controls or automated grit delivery systems, to enhance efficiency and ease of use.

4. What are the minimum order quantities (MOQ) for sandblasting equipment?

Minimum order quantities for sandblasting equipment can vary significantly by supplier and product type. Many manufacturers offer flexible MOQs, particularly for B2B buyers, which can range from single units to larger batches based on your requirements. It’s advisable to communicate directly with suppliers to discuss your needs and negotiate terms that align with your purchasing strategy. Be aware that larger orders often lead to better pricing and favorable shipping terms.

5. How do I vet suppliers for sandblasting equipment?

Vetting suppliers is crucial for ensuring the quality and reliability of your sandblasting equipment. Start by researching potential suppliers online, checking their industry reputation, and reading reviews from other B2B buyers. Request references and case studies to gauge their experience and customer satisfaction. Additionally, assess their certifications and compliance with international standards, particularly if you are importing equipment. Engaging in direct communication and establishing rapport can also provide insights into their professionalism and reliability.

6. What payment terms should I expect when purchasing sandblasting equipment?

Payment terms for sandblasting equipment can vary widely among suppliers. Common options include upfront payments, partial payments upon order confirmation, or payment upon delivery. In international trade, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Discuss your preferred payment terms with suppliers early in negotiations to establish mutual understanding and avoid complications later in the transaction.

7. How do I ensure quality assurance in my sandblasting setup?

To ensure quality assurance in your sandblasting setup, it’s important to establish clear specifications and standards before procurement. Request detailed product documentation, including material certifications and performance data, from suppliers. Consider implementing an inspection process upon receiving the equipment to verify compliance with your specifications. Regular maintenance and operator training are also essential to uphold quality during operation, ensuring optimal performance and longevity of your sandblasting system.

Illustrative image related to sandblasting setup diagram

8. What logistics considerations should I keep in mind when importing sandblasting equipment?

When importing sandblasting equipment, logistics considerations include shipping methods, customs regulations, and potential tariffs. Determine the most cost-effective shipping option based on your timeline and budget, whether by air or sea. Familiarize yourself with the import regulations specific to your country, as compliance is critical to avoid delays or fines. Partnering with a logistics provider experienced in international trade can streamline the process, ensuring timely delivery and proper handling of your equipment.

Top 6 Sandblasting Setup Diagram Manufacturers & Suppliers List

1. Instructables – Footswitch Operated Sandblasting System

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Footswitch Operated Sandblasting System; Designed for glass engraving, wood, and stone products; Original system cost: $1,500 to $4,000; Purchased components for under $500; Footswitch model: FV320, 3 Way, 2 Position; Pinch valve assembly: 3/4 inch, made from glass filled nylon, bladder made from BUNA-N; Pinch valve assembly cost: $62.00; Replacement bladder cost: $22.50; Total cost for pinch valv…

2. Pinterest – Home-made Sand Blaster Machine

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Home-made Sand Blaster Machine Diagram

3. Harbor Freight – Large Sandblast Cabinet

Domain: gsg-art.com

Registered: 2013 (12 years)

Introduction: Sandblast cabinet from Harbor Freight, large model, uses venturi suction for sand control, features protective gloves, side door for glass access, requires compressed air, includes orange air hose for air intake, gray hose for sand delivery, exhaust system with filter, modifications for sealed dust collection and air inlet, in-line water removal device, larger cabinet with legs, bottom chute for s…

4. Mere Blasting – Key Components of a Sandblasting System

Domain: meremblasting.com

Registered: 2022 (3 years)

Introduction: Key Components of a Sandblasting System: 1. Compressor: Provides high-pressure air to propel abrasive materials. 2. Blasting Pot: Stores and mixes abrasive material with air, regulating flow for even distribution. 3. Hoses and Fittings: Connects compressor to blasting pot, preventing leaks and maintaining pressure. 4. Nozzle: Directs flow of abrasive material onto the surface, with various sizes a…

5. BlastOne – Blasting Equipment Solutions

Domain: blastone.com

Registered: 2002 (23 years)

Introduction: Step-by-Step Guide to Proper Blasting Equipment Setup, FREE SHIPPING ON ORDERS OVER $100, Blast Equipment categories include: Suction Guns, Small Blast Pots, Contractor Blast Pots, Specialty Blast Pots, MistBlaster Wet/Dry Pots, Mega Bulk Blasters, Robotic/Vertidrive Equipment, Track Blasters, Internal Pipe (ID) Systems, Blast Machine Accessories, Blast Rooms, Booths, various types of Blast Nozzle…

6. SandblasterInfo – Pressure Pot Plans

Domain: sandblasterinfo.com

Registered: 2009 (16 years)

Introduction: Pressure Pot Sandblaster Plans include diagrams and a video demonstrating the setup. The plans are designed for pressure pot modifications to address abrasive flow issues. The setup involves a tank filled with abrasive material, pressurized with air, and includes an abrasive mixing valve. The updated plans utilize an old propane tank with a welded top cap. The product also mentions various sandbla…

Strategic Sourcing Conclusion and Outlook for sandblasting setup diagram

In conclusion, the strategic sourcing of sandblasting setups can significantly enhance operational efficiency and cost-effectiveness for businesses across various industries. By investing in a thoughtfully designed sandblasting system, companies can streamline their processes, reduce material waste, and ensure versatility in handling different media. The insights gleaned from the sandblasting setup diagram highlight the importance of selecting high-quality components, such as pinch valves and pressure regulators, that align with specific operational requirements.

International buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to leverage these insights for informed purchasing decisions. Understanding the intricacies of sandblasting systems not only aids in optimizing performance but also fosters long-term partnerships with suppliers who can provide reliable, cost-effective solutions.

As the demand for customized sandblasting solutions continues to grow, now is the ideal time to evaluate your sourcing strategy. Embrace innovation and quality in your sandblasting setups to stay ahead in a competitive marketplace. Take the next step—invest in a strategic sourcing approach that supports your business goals and enhances your production capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.