Choosing Your Drawing Pump: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for drawing pump

In the competitive landscape of industrial equipment, sourcing the right drawing pump can be a formidable challenge for B2B buyers. With the diverse applications and varying specifications across different industries, understanding the nuances of drawing pumps is critical. This guide aims to demystify the global market for drawing pumps, equipping you with essential insights into the various types available, their applications, and the factors influencing pricing. Whether you’re operating in Africa, South America, the Middle East, or Europe, such as in Saudi Arabia or Nigeria, having a comprehensive understanding of these components is vital for making informed purchasing decisions.

Navigating the complexities of supplier vetting and ensuring compliance with regional standards can further complicate the sourcing process. This guide will detail best practices for evaluating suppliers, including their reliability, product quality, and customer support. We will also explore the cost implications and how to assess the total cost of ownership to ensure you make economically sound investments.

By addressing these key considerations, this guide empowers international B2B buyers to confidently navigate the intricacies of the drawing pump market. You will gain the knowledge needed to identify the right products that meet your operational requirements while optimizing your procurement strategies for enhanced business performance.

Understanding drawing pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Quick-Draw Pump | Hand-operated, reusable, compact, made from durable materials | Oil sampling, automotive maintenance | Pros: Cost-effective, easy to use, reusable tubing. Cons: Manual operation may be less efficient for large volumes. |

| RKI RP-3R Sample Drawing Pump | Battery-operated, motorized, compatible with gas detectors | Environmental monitoring, confined space safety | Pros: Long sampling range, quick disconnect, built-in filters. Cons: Requires batteries, higher initial investment. |

| Hydraulic Drawing Pump | Positive displacement, adjustable flow rates | Industrial fluid transfer, construction | Pros: High efficiency, suitable for various fluids. Cons: Complex installation, may require specialized maintenance. |

| Pneumatic Drawing Pump | Operates using compressed air, lightweight | Food processing, chemical handling | Pros: Clean operation, minimal maintenance. Cons: Dependent on air supply, may not be suitable for all fluids. |

| Electric Submersible Pump | Submersible design, electric-powered, capable of high flow rates | Wastewater management, agricultural irrigation | Pros: Efficient for large volumes, continuous operation. Cons: Requires electrical supply, potential for corrosion. |

What are the Key Characteristics of Quick-Draw Pumps?

Quick-Draw Pumps are designed for simplicity and efficiency in oil sampling applications. They are hand-operated and made from durable materials, often featuring reusable tubing that fits most vehicle dipsticks. These pumps are particularly suitable for automotive maintenance, where quick and accurate oil sampling is essential. Buyers should consider their ease of use and cost-effectiveness, though the manual operation may not suffice for larger volume requirements.

How Do RKI RP-3R Sample Drawing Pumps Enhance Safety in Confined Spaces?

The RKI RP-3R Sample Drawing Pump is a motorized device that attaches to gas detectors, allowing for efficient sampling in confined spaces. It offers a 100-foot sampling range and includes built-in dust and hydrophobic filters, enhancing safety during environmental monitoring. This pump is ideal for industries requiring compliance with safety regulations. While it boasts a user-friendly design, buyers must consider the ongoing costs of batteries and the initial investment.

What Makes Hydraulic Drawing Pumps Suitable for Industrial Applications?

Hydraulic Drawing Pumps operate on the principle of positive displacement, allowing for adjustable flow rates to accommodate different industrial fluids. These pumps are commonly used in construction and industrial fluid transfer due to their high efficiency and versatility. However, potential buyers should be aware of the complexity involved in installation and the need for specialized maintenance, which could impact overall operational costs.

Why Choose Pneumatic Drawing Pumps for Clean Operations?

Pneumatic Drawing Pumps utilize compressed air to operate, making them lightweight and easy to handle. They are particularly advantageous in food processing and chemical handling, where cleanliness and minimal maintenance are critical. The reliance on an air supply, however, may limit their application in settings without adequate infrastructure, which buyers should consider when assessing their operational needs.

What Advantages Do Electric Submersible Pumps Offer for Large Volume Applications?

Electric Submersible Pumps are designed to operate submerged in liquids, making them ideal for applications like wastewater management and agricultural irrigation. They provide high flow rates and continuous operation, making them efficient for large volume needs. However, buyers must consider their dependency on electrical supply and the risk of corrosion, which can influence long-term maintenance costs and operational reliability.

Key Industrial Applications of drawing pump

| Industry/Sector | Specific Application of Drawing Pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Oil Sampling and Testing | Enables accurate monitoring of oil quality and performance. | Ensure compatibility with various dipstick sizes and materials. |

| Environmental Monitoring | Air Quality Testing in Confined Spaces | Provides critical data for safety compliance and environmental assessments. | Look for pumps with battery operation and extended hose lengths. |

| Automotive | Engine Oil Sampling | Facilitates maintenance and performance analysis without oil changes. | Source durable, reusable components for cost efficiency. |

| Chemical Processing | Fluid Transfer and Sampling of Chemicals | Ensures precise measurement and handling of hazardous materials. | Verify chemical compatibility and safety certifications. |

| Agriculture | Fertilizer and Pesticide Application | Enhances efficiency in crop management and reduces wastage. | Consider pumps designed for corrosive substances and varying viscosities. |

How is a Drawing Pump Used in the Oil & Gas Industry?

In the oil and gas sector, drawing pumps are essential for oil sampling and testing. These pumps allow operators to extract oil samples directly from storage tanks or pipelines without the need for oil changes, ensuring accurate monitoring of oil quality and performance. This capability is crucial for maintaining regulatory compliance and optimizing production processes. Buyers should consider pumps that accommodate various dipstick sizes and are constructed from durable materials to withstand harsh environments.

What Role Does a Drawing Pump Play in Environmental Monitoring?

Drawing pumps are vital for air quality testing in confined spaces, such as storage tanks or processing facilities. They enable the extraction of air samples for analysis, providing critical data necessary for safety compliance and environmental assessments. International buyers, particularly in regions with stringent environmental regulations, should prioritize pumps with battery operation and extended hose lengths to facilitate sampling in hard-to-reach areas.

Why are Drawing Pumps Important for Automotive Applications?

In the automotive industry, drawing pumps are used for engine oil sampling, allowing technicians to assess oil condition without the need for oil changes. This process not only saves time and resources but also helps in identifying potential engine issues early. Buyers should focus on sourcing durable, reusable components to enhance cost efficiency and ensure compatibility with various engine designs.

How are Drawing Pumps Utilized in Chemical Processing?

Drawing pumps play a critical role in fluid transfer and sampling of chemicals in processing plants. They ensure precise measurement and handling of hazardous materials, which is essential for maintaining safety and efficiency. Buyers in this sector should verify the chemical compatibility of the pumps and ensure they meet safety certifications to minimize risks associated with chemical handling.

What Benefits Do Drawing Pumps Offer in Agriculture?

In the agricultural sector, drawing pumps are used for the application of fertilizers and pesticides. They enhance efficiency in crop management by enabling accurate and controlled distribution of inputs, thereby reducing wastage and improving yield. Buyers should consider pumps specifically designed to handle corrosive substances and varying viscosities to ensure optimal performance in diverse agricultural conditions.

3 Common User Pain Points for ‘drawing pump’ & Their Solutions

Scenario 1: Inconsistent Sampling Quality Leading to Misleading Results

The Problem: One of the primary challenges faced by B2B buyers of drawing pumps is the inconsistency in sampling quality, which can lead to misleading results. For industries such as oil and gas, environmental monitoring, or chemical processing, accurate sampling is critical. Users may encounter issues with the pump’s design or materials that compromise the integrity of the sample, especially if the pump is not compatible with the specific fluid being tested. This inconsistency can result in flawed data, affecting decision-making processes and potentially leading to costly errors.

The Solution: To ensure high-quality sampling, it is essential to select a drawing pump that is specifically designed for the type of fluid being handled. Buyers should thoroughly research and choose pumps with materials that are resistant to the chemicals involved, such as corrosion-resistant aluminum or high-grade plastics. Additionally, investing in pumps that feature advanced filtration systems can help eliminate contaminants that could skew results. Regular maintenance, including thorough cleaning of tubing and connections after each use, is also crucial to preserving sample integrity. Establishing a clear protocol for sampling procedures and training staff on best practices will further enhance the reliability of the data collected.

Scenario 2: Difficulty in Compatibility with Existing Equipment

The Problem: Another pain point for B2B buyers is the compatibility of drawing pumps with existing equipment, such as gas monitors or other sampling devices. Many businesses may already have a set of tools that they rely on, and introducing a new pump that does not integrate well can lead to inefficiencies and increased operational costs. For example, a pump designed to work with a specific gas monitor may not be compatible with other brands or models, leading to the need for additional purchases or modifications.

The Solution: When sourcing a drawing pump, it’s vital to consider not only the pump’s specifications but also its compatibility with existing equipment. Buyers should engage with suppliers who offer customizable options or provide detailed compatibility information for their products. Additionally, investing in modular pumps that can easily adapt to various systems can save time and resources. Conducting thorough testing of the pump with current equipment prior to full-scale implementation will also help identify potential issues early on. Building a strong relationship with suppliers can facilitate quicker resolutions should compatibility problems arise, ensuring that operations remain smooth and efficient.

Scenario 3: High Operational Costs Due to Inefficient Pumps

The Problem: Operational efficiency is a significant concern for B2B buyers, particularly in industries where time and cost management are crucial. Many organizations find that their existing drawing pumps are not only inefficient but also lead to higher operational costs due to excessive energy consumption or frequent breakdowns. This can result in unexpected downtime and repair expenses, which can severely impact productivity and profit margins.

The Solution: To combat high operational costs, businesses should invest in energy-efficient drawing pumps that meet modern efficiency standards. Conducting a comprehensive cost-benefit analysis when selecting pumps can help identify models that will save money in the long run through reduced energy consumption and maintenance needs. Buyers should also consider pumps with advanced features such as variable speed controls, which allow for better energy management based on specific application needs. Regular maintenance checks and monitoring performance metrics can help identify inefficiencies early, allowing for timely upgrades or replacements before they escalate into larger issues. By prioritizing efficiency in pump selection and maintenance, companies can significantly reduce operational costs and improve overall profitability.

Strategic Material Selection Guide for drawing pump

What Are the Key Materials Used in Drawing Pumps?

When selecting materials for drawing pumps, understanding the properties and suitability of various materials is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in the construction of drawing pumps, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Cast Aluminum

Key Properties:

Cast aluminum offers excellent strength-to-weight ratio, high corrosion resistance, and good thermal conductivity. It typically withstands moderate temperatures and pressures, making it suitable for a variety of applications.

Pros & Cons:

The durability of cast aluminum is commendable, as it resists rust and corrosion better than steel. However, it can be more expensive than some alternatives and may require more complex manufacturing processes, particularly for intricate designs.

Impact on Application:

Cast aluminum is compatible with various media, including oils and water-based fluids. However, it may not be suitable for aggressive chemicals, which could lead to degradation over time.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local standards for material safety and environmental regulations. Understanding ASTM and DIN standards can aid in selecting the right product.

2. Stainless Steel

Key Properties:

Stainless steel is known for its exceptional corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It is often used in environments where hygiene is paramount.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for harsh environments. However, it is generally more expensive than aluminum and may be heavier, which can impact portability.

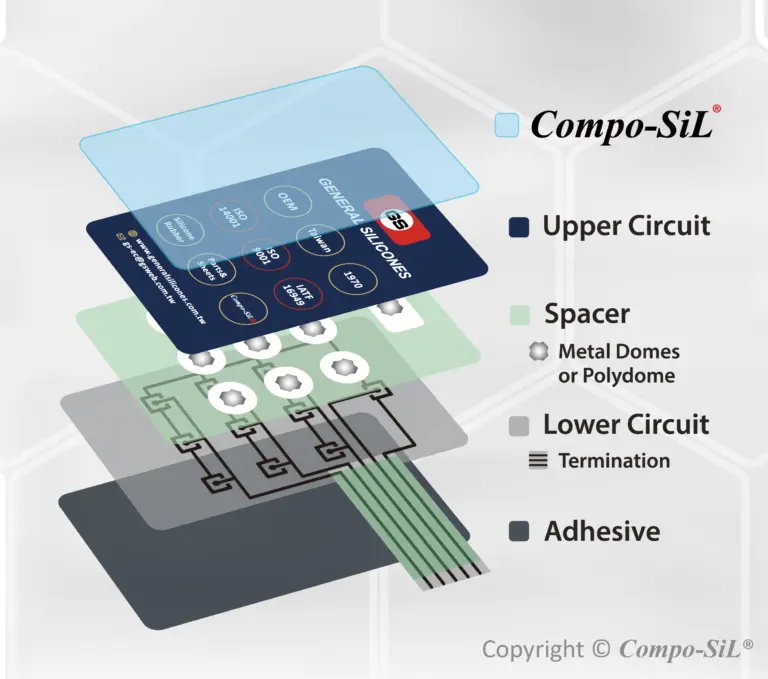

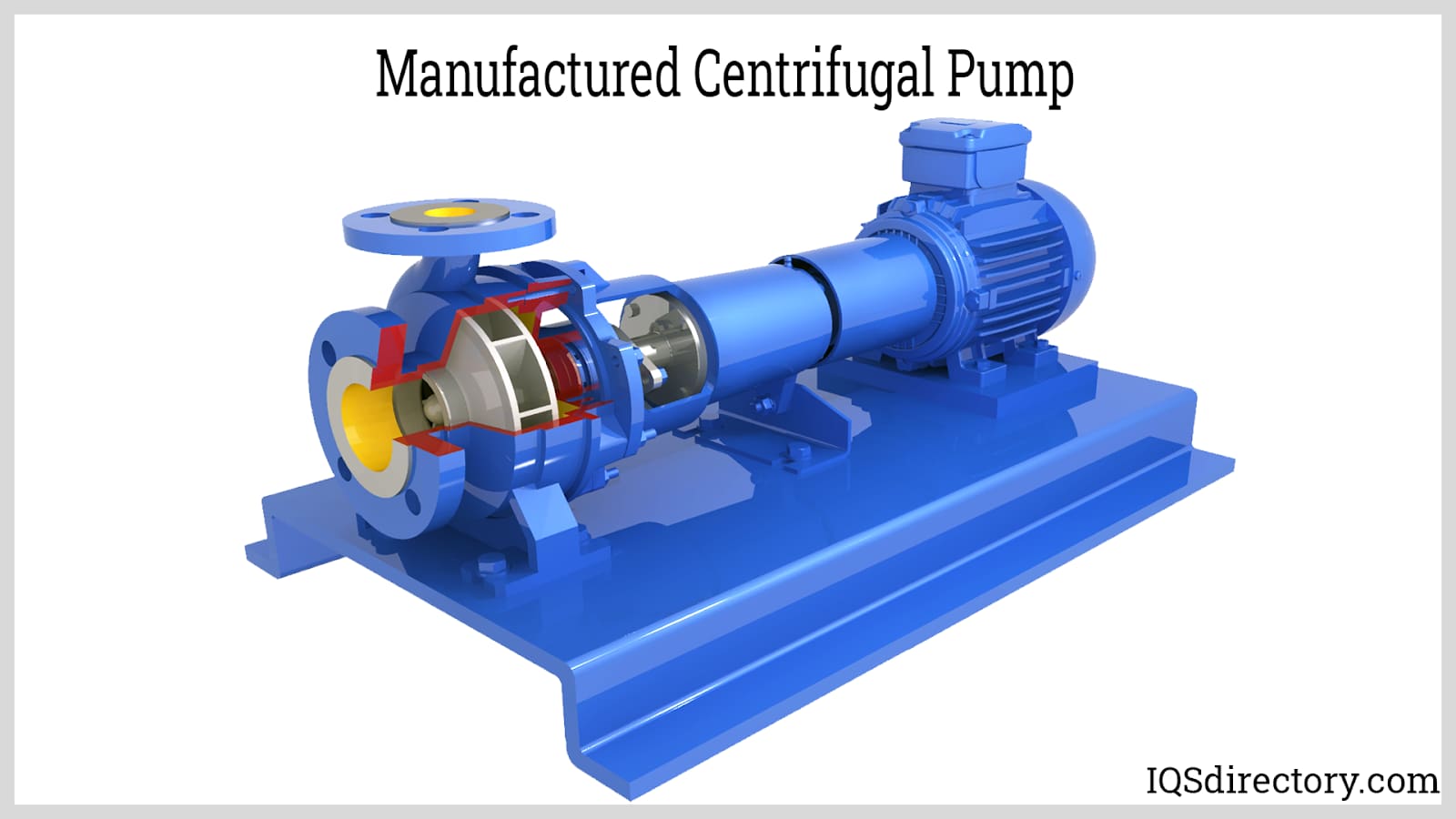

Illustrative image related to drawing pump

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances. This makes it a preferred choice in industries such as food processing and pharmaceuticals.

Considerations for International Buyers:

International buyers should be aware of the varying grades of stainless steel and their specific applications. Compliance with local regulations and standards, such as JIS in Japan or EN in Europe, is critical.

3. Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and good impact strength. It can handle a wide range of temperatures but is not suitable for high-pressure applications.

Pros & Cons:

The low cost and ease of manufacturing make polypropylene an attractive option for many applications. However, its lower temperature and pressure ratings limit its use compared to metals.

Impact on Application:

Polypropylene is highly compatible with acidic and alkaline substances, making it ideal for chemical handling. However, it may not perform well in high-temperature environments.

Considerations for International Buyers:

Buyers should consider the specific chemical compatibility of polypropylene with the intended media. Additionally, understanding local regulations regarding plastic materials can help ensure compliance.

4. Brass

Key Properties:

Brass is an alloy of copper and zinc, known for its excellent machinability, corrosion resistance, and good conductivity. It can handle moderate pressures and temperatures.

Pros & Cons:

Brass is durable and offers a good balance of cost and performance. However, it is susceptible to dezincification in certain environments, which can weaken the material over time.

Illustrative image related to drawing pump

Impact on Application:

Brass is compatible with a variety of fluids, including water and oils, but may not be suitable for aggressive chemicals. Its use is common in plumbing and hydraulic applications.

Considerations for International Buyers:

Buyers should be aware of the specific grades of brass and their properties. Compliance with international standards is essential, especially in regions with stringent material regulations.

Summary Table of Material Selection for Drawing Pumps

| Material | Typical Use Case for drawing pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Aluminum | General fluid sampling | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Stainless Steel | Food and pharmaceutical industries | Exceptional durability and hygiene | Higher cost and weight | High |

| Polypropylene | Chemical handling | Low cost and chemical resistance | Limited temperature and pressure ratings | Low |

| Brass | Plumbing and hydraulic applications | Good machinability and conductivity | Susceptible to dezincification | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions that align with their specific operational needs and compliance requirements across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for drawing pump

What Are the Key Manufacturing Processes for Drawing Pumps?

The manufacturing of drawing pumps involves several critical stages, each designed to ensure that the final product meets performance and durability standards. Understanding these processes is essential for B2B buyers looking to source reliable equipment.

What Materials Are Commonly Used in Drawing Pumps?

The primary materials used in the production of drawing pumps include high-grade metals such as cast aluminum, stainless steel, and various plastics. Cast aluminum is frequently chosen for its lightweight and corrosion-resistant properties, making it ideal for portable pumps. Stainless steel is often utilized in applications requiring enhanced durability and resistance to harsh environments, while plastics may be used in components where weight reduction is necessary.

How Are Drawing Pumps Formed and Assembled?

The manufacturing process typically includes the following stages:

-

Material Preparation: Raw materials are sourced and prepared according to specifications. This may involve cutting, machining, and treating materials to enhance their properties.

-

Forming Techniques: Common forming techniques include die casting for aluminum components and injection molding for plastic parts. Die casting allows for precise shapes and a smooth finish, while injection molding can produce complex geometries at high volumes.

-

Assembly: Once individual components are formed, they are assembled into the final pump configuration. This may involve mechanical fastening, welding, or the use of adhesives. Automated assembly lines are often employed to improve efficiency and consistency.

-

Finishing Processes: The final stage includes surface treatments such as anodizing for aluminum parts, which enhances corrosion resistance, and painting or powder coating for aesthetic and protective purposes.

What Quality Assurance Measures Are Essential in Drawing Pump Manufacturing?

Quality assurance is paramount in the manufacturing of drawing pumps to ensure reliability and safety. Adherence to international and industry-specific standards plays a crucial role in this process.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should look for suppliers who comply with relevant international quality standards such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) sets standards for various oil and gas-related equipment, which may be relevant depending on the application of the drawing pump.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon receipt to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to monitor compliance with quality standards. This includes dimensional checks, pressure tests, and visual inspections.

-

Final Quality Control (FQC): Once the assembly is complete, the final product undergoes rigorous testing to confirm that it meets performance specifications. This may involve functional testing, leak tests, and endurance tests.

What Testing Methods Are Commonly Used for Drawing Pumps?

To ensure the reliability and efficiency of drawing pumps, manufacturers employ various testing methods, including:

-

Hydraulic Testing: This involves subjecting the pump to pressure conditions to check for leaks and performance under operational stress.

-

Performance Testing: Evaluates the pump’s ability to perform as expected, including flow rate measurements and efficiency assessments.

-

Environmental Testing: Assesses the pump’s durability and functionality in extreme conditions, such as high temperatures or corrosive environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing drawing pumps, B2B buyers should be proactive in verifying the quality control practices of potential suppliers. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation, inspecting equipment, and interviewing staff.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed reports outlining their quality assurance processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This can be particularly useful for buyers operating in regions with stringent regulatory requirements.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions have unique regulatory requirements. Buyers should ensure that the supplier’s certifications are recognized in their target market.

-

Cultural Considerations: Communication styles and business practices can vary significantly across cultures. Understanding these differences can aid in establishing effective partnerships with suppliers.

-

Logistical Considerations: Shipping and customs regulations can impact the delivery of quality-assured products. Buyers should account for potential delays and ensure that the supplier has a reliable logistics strategy.

By understanding the manufacturing processes and quality assurance measures associated with drawing pumps, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drawing pump’

To assist B2B buyers in the procurement of drawing pumps, this practical sourcing guide outlines essential steps for a streamlined purchasing process. This checklist will enable you to ensure that you select the right equipment that meets your operational needs while also considering supplier reliability and product quality.

Step 1: Define Your Technical Specifications

Clearly outline the specifications you require for the drawing pump, including its intended use, capacity, and compatibility with existing systems. This is crucial as it establishes the baseline for your procurement needs. For example, consider whether you need a manual or motorized pump and the maximum sample range required.

- Key Considerations:

- Maximum flow rate and pressure.

- Material compatibility (e.g., aluminum, stainless steel).

- Size and weight constraints.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in drawing pumps. Look for companies with a robust portfolio and experience in your specific industry. This step is vital to ensure you are engaging with reliable sources that can meet your needs.

- Where to Look:

- Industry trade shows and exhibitions.

- Online B2B marketplaces.

- Recommendations from industry peers.

Step 3: Evaluate Supplier Certifications and Compliance

Before making any commitments, verify that potential suppliers hold necessary certifications and adhere to industry standards. This is essential for quality assurance and compliance with local regulations, especially in regions like Africa and the Middle East where standards may vary.

- What to Check:

- ISO certifications or equivalent.

- Compliance with local safety and environmental regulations.

- Product warranty and service agreements.

Step 4: Request Samples or Demonstrations

If possible, request samples or demonstrations of the drawing pumps you are considering. This hands-on experience allows you to assess the product’s performance, ease of use, and suitability for your applications.

- Considerations During Evaluation:

- Test the pump’s operational efficiency.

- Assess the user-friendliness of the design.

- Evaluate the quality of materials used in construction.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare them not only based on pricing but also on payment terms and delivery timelines. Understanding the total cost of ownership—including shipping, installation, and maintenance—will help you make a more informed decision.

- Key Aspects to Compare:

- Price per unit and bulk discounts.

- Payment options (e.g., upfront, installments).

- Expected lead times for delivery.

Step 6: Check References and Customer Reviews

Reach out to previous customers or check online reviews to gather insights about the supplier’s reliability and product performance. This step is critical to gauge the supplier’s reputation and the satisfaction level of other B2B buyers.

- What to Ask:

- How responsive is the supplier to inquiries?

- What has been the experience regarding product support?

- Are there any recurring issues with the product?

Step 7: Finalize the Agreement

Once you’ve selected a supplier, negotiate and finalize the terms of the purchase agreement. Ensure that all aspects of the transaction are clearly documented, including warranties, support services, and return policies.

Illustrative image related to drawing pump

- Key Points to Include:

- Delivery schedules.

- Terms of service and support.

- Clauses for returns and replacements.

By following these steps, you can ensure a thorough and effective procurement process for drawing pumps, minimizing risks and optimizing your investment.

Comprehensive Cost and Pricing Analysis for drawing pump Sourcing

What Are the Key Cost Components in Drawing Pump Production?

Understanding the cost structure of drawing pumps is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. For example, pumps made from durable cast aluminum may have a higher initial cost but offer better longevity, which can reduce replacement frequency and costs over time.

-

Labor: Labor costs vary widely based on location. Countries with lower labor costs may offer more competitive pricing but could also affect quality. Understanding labor market conditions in your sourcing region is vital.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Buyers should assess whether suppliers have optimized their operations to minimize these costs.

-

Tooling: Custom tooling for specialized pump designs can add to upfront costs. Buyers should consider whether standard designs meet their needs to avoid unnecessary expenses.

-

Quality Control (QC): Robust QC processes ensure product reliability but may increase costs. Suppliers with certifications (e.g., ISO) typically invest more in QC, which can lead to higher prices but potentially lower total costs in the long run due to fewer failures.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and Incoterms. Understanding these logistics can help buyers negotiate better terms and assess total expenses.

-

Margin: Supplier margins can fluctuate based on market competition and demand. Buyers should aim to understand the typical margins within their industry to identify reasonable pricing.

How Do Price Influencers Affect Drawing Pump Costs?

Several factors can influence the pricing of drawing pumps:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Buyers should evaluate their needs carefully to balance inventory costs against potential savings.

-

Specifications and Customization: Customized pumps that meet specific operational requirements typically incur higher costs. Buyers should assess whether the added features justify the price increase.

-

Quality and Certifications: Pumps that meet specific quality standards or have industry certifications may command higher prices. However, these certifications can also be indicators of reliability and efficiency, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more due to their proven track record, while newer players may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect overall costs.

What Negotiation Strategies Can Help Buyers Achieve Cost Efficiency?

B2B buyers can adopt several strategies to enhance cost efficiency when sourcing drawing pumps:

-

Conduct Market Research: Understanding market prices and competitor offerings can empower buyers during negotiations, enabling them to make informed decisions.

-

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time, as trust and reliability develop.

-

Leverage Total Cost of Ownership: Buyers should look beyond initial prices and consider long-term costs, including maintenance, warranty, and reliability, which can provide a clearer picture of value.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare prices and terms, creating leverage in negotiations.

-

Be Flexible with Specifications: If possible, opting for standard designs instead of custom solutions can reduce costs significantly.

What Additional Considerations Should International Buyers Keep in Mind?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding local regulations, import duties, and market conditions is essential. Currency fluctuations can also impact pricing. It’s advisable to work with local representatives or consultants who understand the regional market dynamics to navigate these complexities effectively.

Disclaimer on Indicative Prices

Please note that prices for drawing pumps can vary widely based on the factors discussed. The information provided here serves as a guideline, and buyers are encouraged to conduct thorough market research and consult with suppliers for precise quotations tailored to their specific needs.

Alternatives Analysis: Comparing drawing pump With Other Solutions

In the competitive landscape of industrial equipment, understanding the alternatives to a drawing pump is crucial for B2B buyers seeking optimal solutions for their operations. Drawing pumps serve essential functions in fluid sampling and transfer, yet various alternatives can offer distinct advantages depending on specific operational needs, budgets, and environmental conditions.

| Comparison Aspect | Drawing Pump | Quick-Draw Pump | RKI RP-3R Sample Drawing Pump |

|---|---|---|---|

| Performance | Effective for oil and fluid sampling; manual operation can limit speed | Efficient for fluid sampling without oil changes; reusable tubing improves sustainability | Compact and battery-operated; offers a sampling range of up to 100 feet |

| Cost | Varies widely based on brand and features | Approximately $42 | Approximately $380 |

| Ease of Implementation | Generally easy to use; manual effort required | Simple setup with reusable components; minimal training needed | Requires attachment to GX-3R gas monitor; some technical knowledge may be necessary |

| Maintenance | Regular cleaning needed; long-term durability dependent on usage | Minimal maintenance; tubing can be cleaned or replaced easily | Requires filter replacements and battery changes; rugged design reduces wear |

| Best Use Case | Ideal for general fluid sampling in various industries | Best for oil sampling in automotive applications | Suitable for confined space entry and gas detection environments |

What Are the Benefits and Drawbacks of the Quick-Draw Pump?

The Quick-Draw Pump is a user-friendly option designed primarily for fluid sampling without necessitating an oil change. Priced affordably, it appeals to businesses with limited budgets. Its reusable tubing enhances sustainability, allowing users to minimize waste. However, its manual operation may limit efficiency in high-volume environments, making it less suitable for large-scale applications where speed is critical.

How Does the RKI RP-3R Sample Drawing Pump Stand Out?

The RKI RP-3R Sample Drawing Pump is a motorized solution that integrates seamlessly with the GX-3R gas monitor, making it an excellent choice for confined space applications. Its battery-operated design allows for mobility and ease of use, providing a significant operational range. However, the higher price point may deter smaller businesses, and the need for compatibility with specific gas detection equipment could limit its broader applicability.

How Can B2B Buyers Choose the Right Solution?

When selecting a fluid sampling solution, B2B buyers should consider their specific operational requirements, including the nature of the fluids being sampled, frequency of use, and environmental conditions. Assessing the total cost of ownership, including maintenance and operational expenses, will provide a clearer picture of which solution aligns best with their needs. Ultimately, the choice between a drawing pump and its alternatives will depend on a careful evaluation of performance, cost, ease of implementation, and suitability for the intended application. By aligning these factors with their operational goals, buyers can ensure they select the most effective fluid sampling solution for their business.

Essential Technical Properties and Trade Terminology for drawing pump

What Are the Essential Technical Properties of a Drawing Pump?

When sourcing drawing pumps, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

-

Material Grade

Drawing pumps are typically made from materials such as cast aluminum or high-grade plastics. The choice of material affects durability, resistance to corrosion, and overall performance. For instance, pumps made from cast aluminum offer robustness, making them suitable for heavy-duty applications. Understanding material grades helps buyers assess the longevity and reliability of the equipment in various environments. -

Flow Rate

This specification indicates the volume of fluid the pump can move within a specific timeframe, usually measured in liters per minute (L/min). A higher flow rate may be essential for operations requiring quick sampling, such as in industrial settings. Buyers must match the flow rate with their operational needs to ensure efficiency and productivity. -

Power Source

Drawing pumps can be manually operated or powered by batteries or electricity. Battery-operated pumps, for example, provide flexibility in remote locations where electrical outlets are unavailable. Understanding the power source is important for evaluating operational feasibility, especially in regions with unstable electricity supply. -

Sampling Range

This refers to the maximum distance from which a pump can draw samples. For example, some pumps may have a sampling range of up to 100 feet. This property is particularly important for applications in large industrial sites or confined spaces, where access to sampling points may be limited. -

Operating Temperature Range

Each pump has a specified temperature range within which it operates effectively. Operating outside this range can lead to equipment failure or inaccurate sampling. Buyers should consider the environmental conditions in which the pump will be used to ensure optimal performance. -

Noise Level

The noise level produced by a drawing pump can impact workplace comfort and compliance with local regulations. Low-noise pumps are preferable in environments where noise pollution is a concern. Assessing noise levels is crucial for maintaining a conducive work environment.

What Are Common Trade Terminology Terms in the Drawing Pump Industry?

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some common terms used in the drawing pump market:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company. Understanding OEM relationships can help buyers identify quality products and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers, especially those with limited budgets or smaller operations, as it affects purchasing decisions and inventory management. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This document outlines the quantity, specifications, and delivery terms. Submitting an RFQ can lead to competitive pricing and better negotiation leverage. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight. Understanding Incoterms is essential for international buyers to clarify shipping costs, risks, and obligations during the transportation of drawing pumps. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. Recognizing lead times is crucial for planning inventory and ensuring that operations remain uninterrupted. -

Warranty Period

The warranty period is the timeframe during which a manufacturer will repair or replace defective products. Buyers should pay attention to warranty terms as they reflect the manufacturer’s confidence in their product and provide assurance for long-term investments.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and purchasing strategies.

Navigating Market Dynamics and Sourcing Trends in the drawing pump Sector

What Are the Key Market Dynamics and Trends Influencing the Drawing Pump Sector?

The drawing pump sector is experiencing notable growth, driven by several global factors including increasing industrial automation, rising demand for efficient fluid management systems, and the need for reliable sampling in various applications. Key markets in Africa, South America, the Middle East, and Europe are particularly focused on enhancing operational efficiency while minimizing downtime. As industries evolve, buyers are increasingly seeking advanced drawing pump technologies that feature automation capabilities, durability, and ease of maintenance.

Illustrative image related to drawing pump

Emerging trends include a shift towards electric and battery-operated pumps, which offer greater energy efficiency and reduced environmental impact. International B2B buyers are also prioritizing suppliers that provide comprehensive after-sales support and customization options to meet specific operational needs. The advent of Industry 4.0 technologies, such as IoT-enabled pumps, is further transforming the landscape, allowing for real-time monitoring and predictive maintenance, which can significantly reduce operational costs.

How Are Sustainability and Ethical Sourcing Shaping the Drawing Pump Market?

Sustainability is becoming a critical consideration for B2B buyers in the drawing pump sector. The environmental impact of manufacturing processes, as well as the lifecycle of products, are under increasing scrutiny. Buyers are urged to consider suppliers who prioritize sustainable practices, such as using eco-friendly materials and processes that minimize waste. Certifications like ISO 14001 for environmental management are becoming more relevant, as they demonstrate a commitment to sustainability.

Moreover, ethical sourcing is essential in establishing a responsible supply chain. Buyers should seek suppliers who maintain transparency in their sourcing practices, ensuring that raw materials are obtained responsibly and that labor standards are upheld. This not only enhances brand reputation but also aligns with the growing consumer demand for sustainable and ethically produced products. By focusing on these aspects, international buyers can contribute to a more sustainable future while ensuring compliance with regional regulations and standards.

How Has the Drawing Pump Sector Evolved Over Time?

The evolution of the drawing pump sector can be traced back to the early days of mechanical engineering, where rudimentary designs focused primarily on functionality. Over the decades, innovations in materials and technology have led to significant advancements in pump design, enhancing efficiency and reliability. The introduction of electric and battery-operated pumps revolutionized the industry, allowing for more versatile applications across various sectors, including automotive, industrial, and environmental monitoring.

In recent years, the integration of smart technology has further propelled the sector forward. Modern drawing pumps now incorporate sensors and IoT capabilities, enabling remote monitoring and data collection. This evolution reflects a broader trend towards automation and data-driven decision-making in industrial processes, making drawing pumps an integral component of contemporary fluid management systems. As the market continues to evolve, international B2B buyers must remain agile and informed about these changes to leverage new opportunities effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of drawing pump

-

How do I choose the right drawing pump for my application?

Selecting the appropriate drawing pump involves assessing your specific needs, such as the type of fluid being sampled, flow rate requirements, and environmental conditions. Consider factors like pump compatibility with your existing equipment, ease of use, and maintenance requirements. It’s also advisable to consult with suppliers about technical specifications and performance metrics to ensure the pump meets your operational standards. -

What is the best type of drawing pump for sampling oil and fuels?

For sampling oil and fuels, hand-operated vacuum pumps or motorized sample drawing pumps are typically recommended. Hand-operated pumps offer portability and ease of use, while motorized pumps provide efficiency and consistent performance, especially for larger volumes. Evaluate the compatibility of the pump with various engine types and ensure it includes necessary features, such as reusable tubing or built-in filters, for optimal performance. -

What are the minimum order quantities (MOQs) for drawing pumps?

Minimum order quantities for drawing pumps can vary significantly depending on the supplier and the specific model. Generally, suppliers may have MOQs ranging from a few units to several dozen. It’s beneficial to discuss your needs directly with suppliers, as they may offer flexibility, especially for first-time buyers or bulk orders. This can also lead to better pricing and terms. -

How can I verify the reliability of a drawing pump supplier?

To verify a drawing pump supplier’s reliability, conduct thorough research by checking their industry reputation, customer reviews, and years of experience. Request references from previous clients and assess their response times and customer service quality. Additionally, ensure they adhere to international quality standards and certifications, which can indicate their commitment to delivering high-quality products. -

What payment terms should I expect when sourcing drawing pumps internationally?

Payment terms can vary widely among suppliers. Common arrangements include advance payment, partial payment upon order confirmation, and balance upon delivery. It’s crucial to clarify these terms upfront and consider using secure payment methods, such as letters of credit or escrow services, especially for larger transactions. This helps mitigate risks associated with international trade. -

How does international shipping work for drawing pumps?

International shipping for drawing pumps typically involves selecting a reliable freight forwarder who can handle customs clearance, documentation, and logistics. Suppliers should provide information on shipping costs, estimated delivery times, and any applicable duties or taxes. Ensure that the supplier offers tracking options and insurance for your shipment to protect your investment during transit. -

What quality assurance measures should I look for in drawing pumps?

When sourcing drawing pumps, inquire about the supplier’s quality assurance processes. Look for manufacturers that conduct rigorous testing, including performance, safety, and durability assessments. Certifications such as ISO 9001 indicate adherence to quality management standards. Additionally, request documentation on warranty terms and after-sales support, which reflect the supplier’s confidence in their product quality. -

Can I customize a drawing pump to fit my specific requirements?

Many suppliers offer customization options for drawing pumps to meet specific operational needs. Customizations can include adjustments in size, material, or additional features such as extended hoses or specialized connectors. Discuss your requirements with the supplier early in the negotiation process to explore available options and any associated costs, ensuring that the final product aligns with your operational goals.

Top 7 Drawing Pump Manufacturers & Suppliers List

1. iStock – Water Pump Illustrations

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Water Pump Illustrations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. RKI – RP-3R Sample Drawing Pump

Domain: pksafety.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “RKI RP-3R Sample Drawing Pump For GX-3R”, “sku”: “RKI01-81-1197”, “price”: {“base_price”: 380.00, “hose_options”: [{“length”: “10 ft”, “price”: 445.00}, {“length”: “20 ft”, “price”: 455.00}, {“length”: “30 ft”, “price”: 460.00}]}, “description”: “Compact, battery-operated, motorized sample drawing pump that attaches to the GX-3R gas monitor to change it from diffusion operation t…

3. ConceptDraw – DIAGRAM

Domain: conceptdraw.com

Registered: 1999 (26 years)

Introduction: ConceptDraw DIAGRAM is a vector drawing software enhanced with a Mechanical Engineering solution that provides a wide set of drawing tools, predesigned mechanical drawing symbols, templates, samples, and examples. The ‘Hydraulic pumps and motors’ library contains 74 symbols for hydraulic pumps and motors used in engineering drawings of fluid power and hydraulic control systems. Hydraulic pumps can…

4. Pinterest – Vintage Gas Pump Graphics

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Gas pump drawing, vintage aesthetic, vector graphics, free vector download, retro style, automotive design, illustration, DIY projects, gas station coloring pages, oil canister icon, royalty-free clipart, pop art illustrations, transportation icons.

5. Reddit – Isometric Pump Drawing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Pump on isometric drawing, hand-drawn, includes suction and discharge flanges/nozzle and tag number.

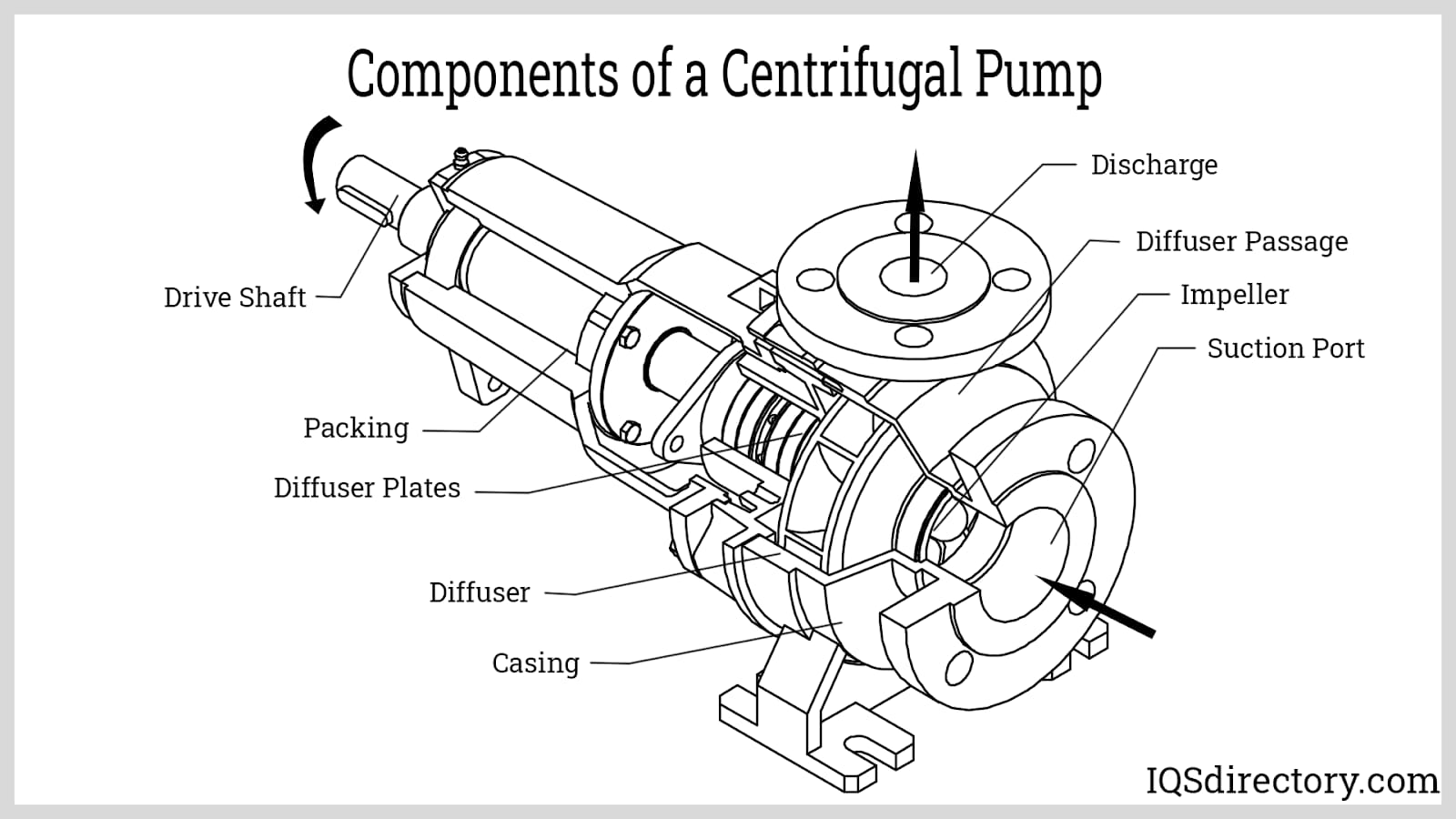

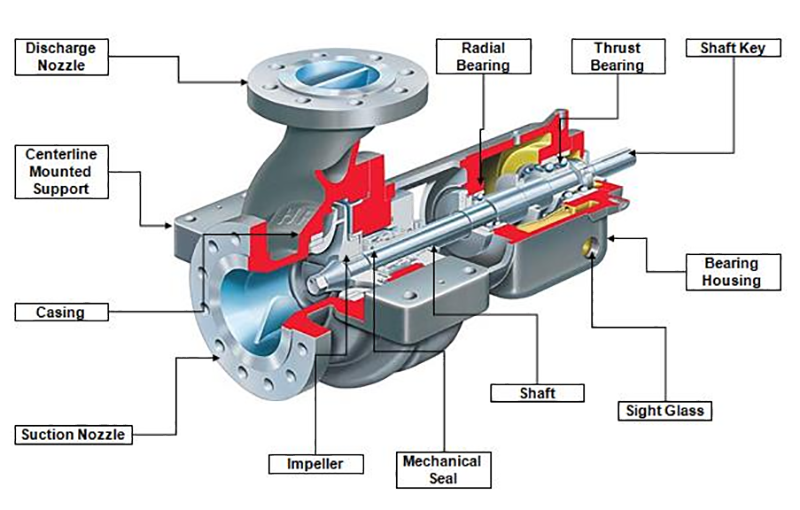

6. Shutterstock – Centrifugal Pump Illustration

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Centrifugal Pump Illustration, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. GrabCAD – Centrifugal Pump Impeller Tutorial

Domain: grabcad.com

Registered: 2008 (17 years)

Introduction: Tutorial for creating an impeller for a centrifugal pump using SOLIDWORKS. The tutorial includes 8 steps: 1) Understanding 2D drawing, 2) Sketching the left view on a plane, 3) Revolving the sketch, 4) Creation of hole for shaft, 5) Creating blade, 6) Creating 6 blades using circular pattern, 7) Final rendering, and 8) Video tutorial link. Skill level: Beginner. Created on March 19, 2019.

Strategic Sourcing Conclusion and Outlook for drawing pump

In the evolving landscape of industrial procurement, strategic sourcing for drawing pumps emerges as a pivotal process for businesses aiming to optimize operations and enhance productivity. Buyers should prioritize suppliers who offer durable, high-quality products tailored to specific needs, while also considering the total cost of ownership, including maintenance and operational efficiencies. This approach not only minimizes downtime but also fosters a sustainable supply chain, particularly in regions like Africa, South America, the Middle East, and Europe, where resource management is critical.

As industries worldwide face increasing pressure to enhance performance and reduce environmental impact, the importance of reliable drawing pumps cannot be overstated. Companies that engage in thoughtful sourcing will benefit from advanced technologies and innovative solutions that improve sampling processes and operational safety.

Looking ahead, international B2B buyers are encouraged to leverage this knowledge to forge strategic partnerships with reputable suppliers. By doing so, they can ensure access to cutting-edge equipment that meets regulatory standards and supports their operational goals. Embrace the opportunity to enhance your sourcing strategy today—your business’s efficiency and sustainability depend on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.