The Definitive Guide to Tube Bending Services Near Me: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for tube bending services near me

In today’s competitive landscape, sourcing reliable tube bending services near me poses a significant challenge for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The complexities of ensuring quality, precision, and timely delivery can feel overwhelming, especially when navigating diverse suppliers and varying standards across different markets. This guide serves as a comprehensive resource, offering insights into various types of tube bending processes, their applications across industries, and critical factors to consider when vetting suppliers.

From understanding the nuances of mandrel and roll bending to exploring the advantages of using advanced technologies like Vector measuring machines, this guide equips you with the knowledge necessary to make informed purchasing decisions. We delve into essential aspects such as cost considerations, supplier certifications, and the importance of quality control measures, enabling you to identify partners who meet your specific requirements.

Whether you are in the petrochemical sector in Saudi Arabia or the automotive industry in Nigeria, our guide is designed to empower you with actionable insights, ensuring that your sourcing process is efficient and effective. By leveraging this information, you can confidently engage with tube bending service providers that align with your business goals, ultimately enhancing your operational efficiency and product quality.

Understanding tube bending services near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Bending | Uses heat to create controlled curves, minimizing distortion | Oil and gas, petrochemical, aerospace | Pros: High precision, minimal deformation; Cons: Higher initial setup costs. |

| Mandrel Bending | Maintains internal diameter during bends | Automotive, HVAC, construction | Pros: Smooth bends, preserves wall integrity; Cons: Requires specific tooling. |

| Roll Bending | Shapes tubes using rollers, effective for large diameters | Furniture, architectural designs, construction | Pros: Efficient for large volumes; Cons: Limited to certain shapes. |

| Helical Coil Bending | Creates seamless spirals, ideal for heat exchangers | Chemical processing, power generation | Pros: High dimensional accuracy; Cons: Can be complex and costly. |

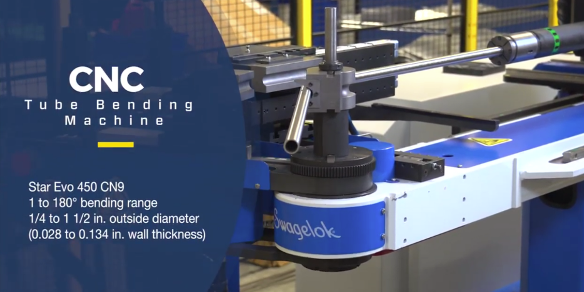

| CNC Tube Bending | Computer-controlled for precise, repeatable bends | Custom machinery, automotive, aerospace | Pros: Flexibility in design, high repeatability; Cons: Potentially longer lead times. |

What Are the Key Characteristics of Induction Bending Services?

Induction bending is characterized by its ability to create precise curves in tubes while minimizing material deformation. This method utilizes heat applied through induction coils, allowing for intricate designs without compromising the structural integrity of the tube. It is particularly suitable for applications in industries such as oil and gas, aerospace, and petrochemical sectors, where precision and strength are paramount. When considering induction bending, buyers should evaluate the initial setup costs against the long-term benefits of reduced material waste and enhanced performance in demanding environments.

How Does Mandrel Bending Maintain Tube Integrity?

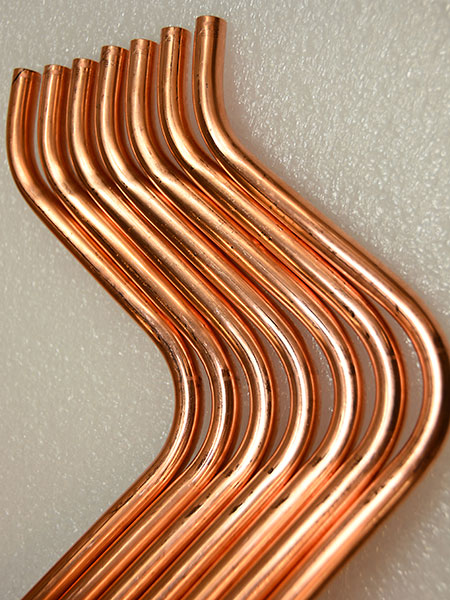

Mandrel bending is distinguished by its capability to preserve the internal diameter of tubes during the bending process. This method involves inserting a mandrel into the tube, which supports it and prevents collapse or deformation. It is widely used in automotive and HVAC applications, where maintaining the tube’s structural integrity is critical. Buyers should consider the specific tooling requirements and potential lead times associated with mandrel bending, as these factors can influence project timelines and costs.

Illustrative image related to tube bending services near me

What Are the Advantages of Roll Bending for Large Projects?

Roll bending is an efficient method for shaping large diameter tubes using a series of rollers. This technique is often employed in the furniture and construction industries, where large volumes of material need to be processed. The key advantage of roll bending lies in its speed and efficiency, making it ideal for mass production. However, buyers should be aware that this method is limited to certain shapes and may not offer the same level of precision as other bending techniques.

Why Choose Helical Coil Bending for Specialized Applications?

Helical coil bending is specifically designed to create seamless, uniform spirals in tubes, making it essential for applications like heat exchangers in chemical processing and power generation. This technique ensures high dimensional accuracy and can handle complex designs effectively. While it offers significant advantages in terms of performance, buyers should consider the complexity and potential costs associated with the setup of helical coil bending processes, especially for smaller projects.

How Does CNC Tube Bending Enhance Customization?

CNC tube bending leverages computer-controlled machinery to achieve precise and repeatable bends in various materials. This method is particularly beneficial for custom machinery and automotive applications, where unique specifications are often required. The flexibility offered by CNC technology allows for intricate designs and modifications, but buyers should be mindful of the potential for longer lead times, particularly when compared to more traditional bending methods. The investment in CNC capabilities can lead to significant long-term savings through reduced waste and improved product quality.

Key Industrial Applications of tube bending services near me

| Industry/Sector | Specific Application of tube bending services near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom tube bending for aircraft structures | Enhances structural integrity and weight reduction | Compliance with aviation standards, precision in tolerances |

| Automotive | Exhaust systems and chassis components | Improves performance and durability | Material specifications, rapid prototyping capabilities |

| Construction | Architectural features like handrails and frames | Aesthetic appeal and structural support | Design flexibility, adherence to local building codes |

| Energy | Piping systems for oil and gas applications | Ensures safety and efficiency in energy transport | Resistance to corrosion, adherence to industry regulations |

| HVAC | Ductwork and tubing for heating and cooling systems | Optimizes airflow and energy efficiency | Customization for specific system designs, thermal properties |

How Are Tube Bending Services Applied in the Aerospace Sector?

In the aerospace industry, tube bending services are critical for creating components that contribute to the structural integrity of aircraft. Custom bent tubes are often used in fuselage structures and fuel systems, where weight reduction is essential. Buyers in this sector must prioritize suppliers who comply with aviation standards and can deliver precise tolerances to ensure safety and performance. Additionally, the ability to work with specialized materials, such as titanium and aluminum alloys, is crucial for meeting stringent aerospace requirements.

What Role Does Tube Bending Play in the Automotive Industry?

The automotive sector extensively utilizes tube bending services for applications like exhaust systems and chassis components. These bent tubes not only enhance vehicle performance but also improve durability against vibrations and thermal stresses. For international buyers, especially from regions like Africa and South America, sourcing involves assessing the supplier’s capability for rapid prototyping and material specifications that align with local automotive standards. The ability to provide cost-effective solutions while maintaining high quality is a significant advantage.

Illustrative image related to tube bending services near me

Why Is Tube Bending Important in Construction?

In construction, tube bending services are employed to fabricate architectural features such as handrails, frames, and decorative elements. These custom bends add aesthetic appeal while ensuring structural support. Buyers must consider design flexibility and the supplier’s ability to adhere to local building codes, particularly in regions with specific architectural regulations. Ensuring that the materials used can withstand environmental factors, such as corrosion resistance for outdoor applications, is also essential for long-term durability.

How Does Tube Bending Benefit the Energy Sector?

In the energy sector, particularly in oil and gas, tube bending services are vital for creating efficient and safe piping systems. These bent tubes facilitate the transport of gases and liquids while minimizing pressure drops and ensuring safety. International buyers need to focus on sourcing suppliers that provide materials resistant to corrosion and capable of withstanding high-pressure environments. Compliance with industry regulations and standards is crucial to ensure the reliability and safety of these systems.

What Applications Exist for Tube Bending in HVAC Systems?

For HVAC systems, tube bending services are utilized to create ductwork and tubing that optimize airflow and energy efficiency. Properly bent tubes help maintain the system’s integrity while reducing energy costs. Buyers should look for suppliers that can customize designs to fit specific system requirements and offer materials with favorable thermal properties. Additionally, understanding the local climate and energy regulations can guide buyers in selecting the right solutions for their HVAC needs.

3 Common User Pain Points for ‘tube bending services near me’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality Across Orders

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing tube bending services. Variations in the hardness and properties of materials can lead to discrepancies in the bends produced, resulting in parts that do not meet specifications. This inconsistency can hinder production timelines, cause costly rework, and damage the buyer’s reputation with end customers. For businesses in sectors like automotive or aerospace, where precision is paramount, this can escalate into significant operational issues.

The Solution: To address this issue, B2B buyers should prioritize suppliers who utilize advanced quality control technologies, such as Vector Measuring Machines (VMM). When sourcing tube bending services, inquire about the quality assurance processes in place. Look for companies that employ VMM technology to measure and ensure the accuracy of bends against specified tolerances. This data-driven approach allows for real-time adjustments and provides a 3D representation of the tube, which enhances precision. Additionally, establishing a strong communication channel with the supplier can ensure that material variations are communicated and addressed proactively, reducing the risk of inconsistencies in future orders.

Scenario 2: Long Lead Times Affecting Project Deadlines

The Problem: A common frustration for B2B buyers is the long lead times associated with tube bending services, which can derail project timelines. Delays in receiving components can lead to bottlenecks in production, missed deadlines, and, ultimately, lost revenue. This issue is particularly acute in industries where rapid prototyping and just-in-time manufacturing are critical, such as in construction or manufacturing sectors.

The Solution: To mitigate lead time issues, buyers should seek out tube bending services that offer expedited processing options. During the sourcing phase, it’s beneficial to request a clear timeline for production and delivery. Look for companies with a reputation for quick turnaround times, ideally those that can provide same-day quotes and have a track record of on-time shipments. Furthermore, consider establishing a long-term relationship with a reliable supplier who can prioritize your orders based on historical needs and volume. Engaging in discussions about forecasting your requirements can also help suppliers allocate resources effectively, minimizing delays.

Scenario 3: Complexity in Custom Design Requirements

The Problem: Many B2B buyers encounter difficulties when their projects require custom tube bends that are not standard. Custom designs often involve complex specifications that can be hard to communicate, leading to misinterpretations and ultimately, the production of unusable parts. This scenario is especially common in industries that demand unique solutions for intricate applications, such as aerospace or specialized machinery.

The Solution: To successfully navigate custom design requirements, buyers should invest time in creating detailed specifications and visuals for their projects. When approaching tube bending service providers, provide them with comprehensive drawings, CAD models, or prototypes that clearly outline the required dimensions and angles. Engaging in collaborative discussions with the supplier’s technical team can enhance understanding and ensure that the final product meets expectations. Additionally, consider suppliers who offer prototyping services, allowing for initial tests of the custom bends before full-scale production. This iterative process not only saves time but also ensures that the final output aligns perfectly with your project specifications.

Strategic Material Selection Guide for tube bending services near me

What Are the Key Properties of Common Materials Used in Tube Bending Services?

When selecting materials for tube bending services, understanding the properties of various materials is crucial for ensuring optimal performance in specific applications. Here, we analyze four common materials: carbon steel, stainless steel, aluminum, and brass.

How Does Carbon Steel Perform in Tube Bending Applications?

Key Properties: Carbon steel is known for its strength and durability, making it suitable for high-pressure applications. It typically has a temperature rating of up to 500°F and can withstand significant mechanical stress.

Pros & Cons: The advantages of carbon steel include its high tensile strength and relatively low cost, making it a popular choice for structural applications. However, it is prone to corrosion unless properly coated or treated, which can increase manufacturing complexity.

Impact on Application: Carbon steel is ideal for applications involving gases and liquids but may not be suitable for corrosive environments without protective coatings.

Considerations for International Buyers: Compliance with ASTM standards is essential for carbon steel products. Buyers from regions like Africa and the Middle East should ensure that local regulations regarding material quality and safety are met.

Illustrative image related to tube bending services near me

What Are the Benefits of Using Stainless Steel for Tube Bending?

Key Properties: Stainless steel is highly resistant to corrosion, with a temperature rating that can exceed 1000°F. Its chromium content enhances its durability and makes it suitable for various environments.

Pros & Cons: The primary advantage of stainless steel is its corrosion resistance, which makes it ideal for food processing and chemical applications. However, it is generally more expensive than carbon steel and can be more challenging to bend due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for industries such as pharmaceuticals and petrochemicals.

Illustrative image related to tube bending services near me

Considerations for International Buyers: Buyers should be aware of compliance with DIN and JIS standards, particularly in Europe and Asia. The cost implications of importing stainless steel products should also be factored into procurement decisions.

Why Is Aluminum a Preferred Material for Tube Bending?

Key Properties: Aluminum is lightweight yet strong, with a temperature rating of around 600°F. It is also highly resistant to corrosion, thanks to its natural oxide layer.

Pros & Cons: The main advantage of aluminum is its low weight, which reduces shipping costs and makes it easier to handle. However, it has lower tensile strength compared to steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is suitable for applications in the automotive and aerospace industries, where weight reduction is critical. It is also compatible with various media, including water and air.

Considerations for International Buyers: Buyers should ensure that aluminum products meet ISO standards. In regions like South America, where aluminum is often imported, understanding local tariffs and regulations is crucial.

What Role Does Brass Play in Tube Bending Services?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and good thermal conductivity. Its temperature rating is similar to that of stainless steel.

Pros & Cons: Brass offers excellent machinability and is less prone to corrosion than other metals. However, it is more expensive than carbon steel and aluminum, which may deter some buyers.

Impact on Application: Brass is commonly used in plumbing and electrical applications due to its conductivity and resistance to corrosion.

Illustrative image related to tube bending services near me

Considerations for International Buyers: Compliance with relevant standards, such as ASTM B36 for brass tubing, is essential. Buyers from Europe and the Middle East should also consider the environmental impact of brass mining and processing.

Summary of Material Selection for Tube Bending Services

| Material | Typical Use Case for tube bending services near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications, automotive frames | High tensile strength | Prone to corrosion | Medium |

| Stainless Steel | Food processing, chemical applications | Excellent corrosion resistance | Higher cost and bending difficulty | High |

| Aluminum | Automotive, aerospace, lightweight structures | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Brass | Plumbing, electrical applications | Good machinability and conductivity | Higher cost compared to steel | High |

This guide serves as a foundational resource for international B2B buyers seeking tube bending services, enabling informed material selection based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tube bending services near me

What Are the Key Stages in the Tube Bending Manufacturing Process?

The manufacturing process for tube bending services typically encompasses several critical stages: material preparation, forming, assembly, and finishing. Each of these stages is essential for ensuring the precision and quality of the final product.

How Does Material Preparation Impact Tube Bending?

Material preparation is the foundation of the tube bending process. It involves selecting the right type of tube based on the intended application, which can range from mild steel to exotic alloys. Tubes may undergo pre-treatment processes such as cleaning, cutting, and deburring to ensure they are free from contaminants and defects. Properly prepared materials not only enhance the bending process but also significantly reduce the risk of failure during subsequent manufacturing stages.

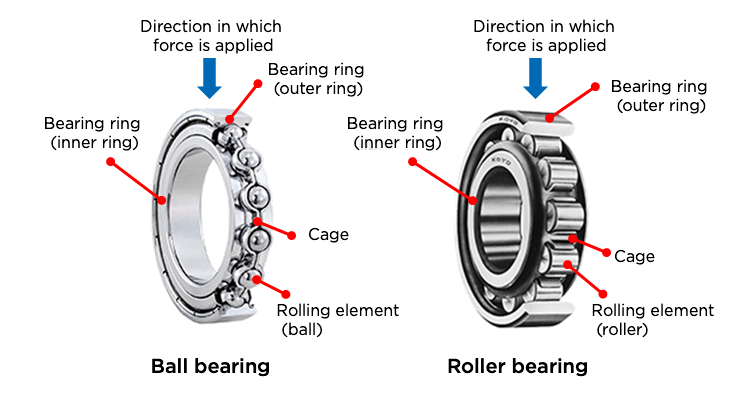

What Techniques Are Commonly Used in Tube Forming?

The forming stage is where the actual bending occurs, employing various techniques tailored to specific requirements. Common methods include:

-

Mandrel Bending: This technique involves inserting a mandrel inside the tube to maintain its internal diameter and prevent deformation during bending. It’s particularly useful for achieving tight bends without sacrificing structural integrity.

-

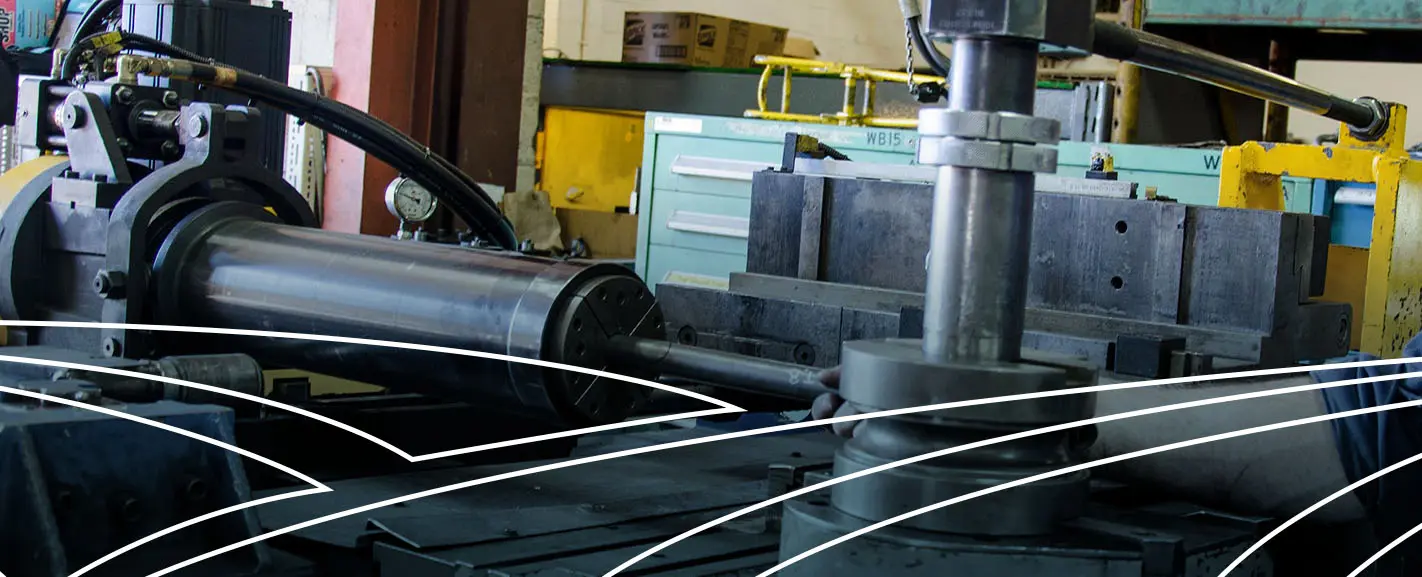

Induction Bending: This method uses heat to soften the material at the bending point, allowing for precise curves while minimizing cross-sectional distortion. It is ideal for larger diameter pipes and complex shapes.

-

Roll Bending: In this technique, the tube is passed through a set of rollers that gradually shape it into the desired curve. It is often used for larger radius bends and can accommodate various tube sizes and materials.

These techniques are chosen based on factors such as the tube material, desired bend radius, and end-use applications.

How Is Quality Assurance Implemented in Tube Bending Services?

Quality assurance (QA) is crucial in tube bending services to ensure that the final products meet both customer specifications and international standards. This involves multiple checkpoints throughout the manufacturing process.

What International Standards Should B2B Buyers Look for in Tube Bending?

International standards play a significant role in quality assurance for tube bending services. For instance, ISO 9001 certification indicates that a supplier has established a quality management system that meets global standards. Additionally, industry-specific certifications such as CE marking for European markets and API standards for the oil and gas sector ensure that products comply with relevant safety and performance criteria.

What Are the Common Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to maintaining product integrity. These include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production process. It ensures that materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring key parameters and dimensions to ensure that they align with design specifications. This may include regular inspections of bend angles and material properties.

-

Final Quality Control (FQC): The final inspection before product delivery, FQC verifies that the finished product meets all specifications and passes functional tests. This stage often includes dimensional checks and visual inspections for surface defects.

What Testing Methods Ensure Quality in Tube Bending Services?

To validate the quality of tube bends, several testing methods are commonly employed:

-

Dimensional Inspection: This involves using precise measuring tools to verify that the bends meet specified tolerances. Techniques such as Coordinate Measuring Machines (CMM) can provide accurate measurements of complex geometries.

-

Non-Destructive Testing (NDT): Methods like ultrasonic testing, radiographic testing, and magnetic particle inspection help identify internal and surface defects without damaging the product. These tests are particularly important in industries like aerospace and oil and gas, where safety is paramount.

-

Destructive Testing: In some cases, samples may undergo tensile strength tests to determine the material’s ability to withstand operational stresses. This is crucial for high-stakes applications where failure could lead to catastrophic consequences.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse international markets, verifying a supplier’s quality control practices is essential for ensuring reliable partnerships.

What Steps Can Buyers Take to Assess Supplier Quality?

-

Conduct Audits: Requesting an audit of the supplier’s facilities can provide insight into their manufacturing processes and quality assurance protocols. This can be done by either the buyer’s team or through third-party services.

-

Review Quality Reports: Suppliers should provide access to their quality control reports, which detail inspection results and compliance with relevant standards. This transparency can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging independent inspectors to evaluate the production process can offer an unbiased assessment of the supplier’s capabilities and adherence to quality standards.

What Are the Unique Challenges for International B2B Buyers in Quality Assurance?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may face specific challenges regarding quality assurance in tube bending services. These can include:

-

Regulatory Compliance: Different regions may have varying regulations and standards, making it vital for suppliers to be familiar with compliance requirements specific to the buyer’s location.

-

Cultural and Language Barriers: Effective communication is crucial for ensuring that quality expectations are clearly understood. Buyers should consider suppliers that offer multilingual support and cultural sensitivity.

-

Logistical Issues: Transportation and shipping can introduce risks to product integrity. Buyers should work with suppliers that have robust logistics solutions in place to ensure that products are delivered in optimal condition.

In conclusion, understanding the manufacturing processes and quality assurance practices for tube bending services is vital for B2B buyers. By focusing on material preparation, forming techniques, quality control checkpoints, and testing methods, buyers can make informed decisions and establish successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tube bending services near me’

Introduction

When sourcing tube bending services, especially for international projects, navigating the complexities of supplier selection is vital. This checklist serves as a practical guide for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that you select a reliable partner who meets your technical and logistical needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your project requirements. This includes the type of materials (e.g., steel, aluminum), dimensions, tolerances, and bending techniques needed (mandrel, roll bending, etc.). A well-defined specification helps suppliers provide accurate quotes and ensures that the final product meets your expectations.

Step 2: Research Local and Global Suppliers

Begin your search by identifying both local and international suppliers. While proximity can reduce shipping costs and lead times, global suppliers may offer specialized services or better pricing. Utilize online directories, trade associations, and industry forums to compile a list of potential vendors.

Step 3: Evaluate Potential Suppliers

Thoroughly vet each supplier on your list. Request company profiles, case studies, and references from clients in similar industries. Look for evidence of their experience with specific bending techniques and materials relevant to your project. Additionally, ensure they have a strong track record of on-time deliveries and quality assurance.

Step 4: Check Certifications and Compliance

Verify that suppliers hold necessary certifications relevant to your industry, such as ISO 9001 or ASME compliance. These certifications indicate adherence to quality management and safety standards, which are crucial for maintaining product integrity, particularly in regulated sectors like automotive or aerospace.

Step 5: Request Detailed Quotes

Once you have narrowed down your list, request detailed quotes from your top suppliers. Ensure the quotes include information on pricing, lead times, and payment terms. Compare these elements across suppliers to gauge which offers the best overall value, taking into account not just price, but also quality and service reliability.

Step 6: Assess Capabilities and Technology

Inquire about the technologies and equipment used by potential suppliers. Advanced machinery, such as Vector Measuring Machines (VMM) or CNC bending tools, can significantly enhance precision and consistency in tube bending. Understanding their capabilities will help you determine if they can meet your specific project needs.

Illustrative image related to tube bending services near me

Step 7: Negotiate Terms and Build Relationships

Once you select a supplier, engage in discussions about terms, including pricing, delivery schedules, and after-sales support. Establishing a strong relationship can lead to better service, flexibility in future orders, and potential cost savings as you continue to collaborate on projects.

By following this checklist, B2B buyers can confidently navigate the sourcing process for tube bending services, ensuring that they select the best partners for their business needs.

Comprehensive Cost and Pricing Analysis for tube bending services near me Sourcing

What Are the Key Cost Components of Tube Bending Services?

When assessing the cost structure for tube bending services, several components must be considered. The primary cost drivers include:

-

Materials: The type of material used significantly influences costs. Common materials like carbon steel are generally less expensive than specialized alloys or stainless steel. The material’s gauge and specifications also play a critical role in pricing.

-

Labor: Skilled labor is essential for tube bending operations. Labor costs can vary based on geographical location and the complexity of the bending required. Skilled technicians are necessary for precision work, particularly for custom bends.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility costs, and equipment maintenance. Efficient operations can help mitigate these overhead costs.

-

Tooling: Custom tooling may be required for specific projects, impacting initial setup costs. The use of advanced technologies, such as CNC machines, can also increase initial expenses but may reduce long-term costs through efficiency.

-

Quality Control (QC): Ensuring the precision and compliance of bends requires robust QC processes. This could involve inspection technologies like laser measuring systems, which add to the overall cost but are crucial for maintaining quality standards.

-

Logistics: Shipping and handling costs can vary significantly, particularly for international buyers. Factors such as distance, weight, and shipping method will influence logistics expenses.

-

Margin: Finally, suppliers typically add a margin to cover risks and generate profit. This margin can fluctuate based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Tube Bending Costs?

Several key factors influence the pricing of tube bending services:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Suppliers may offer discounts for higher volumes, making it financially advantageous for buyers with large requirements.

-

Specifications and Customization: Custom specifications, such as unique bends or tolerances, can increase costs due to the additional labor and tooling required. Standardized orders are generally more cost-effective.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., ASME, ISO) can lead to increased prices. Buyers should weigh the benefits of certified materials against their project requirements.

-

Supplier Factors: The supplier’s reputation, experience, and technological capabilities can affect pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will influence the total landed cost for international buyers. Understanding the implications of these terms is crucial for accurate budgeting.

What Are the Best Negotiation Strategies for Buyers?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, effective negotiation can lead to significant cost savings. Here are some strategies:

-

Leverage Volume: If you can commit to larger orders, use this as leverage to negotiate better pricing and terms.

-

Explore Alternative Materials: Discuss potential alternatives that meet your specifications but may be less expensive, thus lowering overall costs.

-

Total Cost of Ownership (TCO): Evaluate not just the upfront costs but the TCO, including maintenance, durability, and efficiency, to justify higher initial expenditures if they result in lower long-term costs.

-

Understand Local Market Dynamics: Familiarize yourself with local suppliers and their pricing structures. This knowledge can provide leverage when negotiating with international suppliers.

-

Be Candid About Expectations: Clearly communicate your needs and constraints. Suppliers may offer tailored solutions that fit your budget better if they understand your project’s scope.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must consider various pricing nuances when sourcing tube bending services:

-

Currency Fluctuations: Be mindful of currency exchange rates, as they can impact the total cost significantly.

-

Import Duties and Taxes: Factor in any import duties or taxes that may apply to your shipments, as these can add to the final costs.

-

Cultural Differences in Business Practices: Understanding and adapting to the local business culture of your suppliers can facilitate smoother negotiations and foster long-term relationships.

-

Regulatory Compliance: Ensure that the products meet local regulations and standards to avoid additional costs related to compliance or modifications.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on supplier, location, and market conditions. Always request detailed quotes from multiple suppliers to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing tube bending services near me With Other Solutions

Understanding Alternatives to Tube Bending Services

In the realm of manufacturing and fabrication, tube bending services are vital for creating components that meet specific design and functionality requirements. However, businesses often seek alternatives that might better fit their needs in terms of cost, efficiency, or production capabilities. This analysis will compare traditional tube bending services against alternative solutions, helping B2B buyers make informed decisions.

Illustrative image related to tube bending services near me

Comparison Table

| Comparison Aspect | Tube Bending Services Near Me | CNC Machining | 3D Printing |

|---|---|---|---|

| Performance | High precision with tailored bends | Excellent for complex shapes, limited to rigid materials | Versatile, can produce complex geometries but may lack strength in some materials |

| Cost | Moderate to high, depending on material and complexity | Generally high, especially for low volumes | Low to moderate, depending on material and design complexity |

| Ease of Implementation | Requires skilled labor and specific equipment | Requires setup and skilled operators | User-friendly for design, but post-processing may be needed |

| Maintenance | Low maintenance for service providers | Regular maintenance for machinery | Minimal, but material-specific requirements may arise |

| Best Use Case | Custom parts for various industries (automotive, aerospace) | High-precision parts with complex geometries | Prototyping and low-volume production of intricate designs |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a highly precise method of shaping materials, offering excellent performance for creating complex geometries. One of its primary advantages is its ability to work with various materials, including metals and plastics, making it versatile for different applications. However, the cost can be prohibitive for low-volume production runs, and the setup time can be lengthy. Additionally, skilled operators are essential to ensure the quality of the finished product, which can be a barrier for some businesses.

3D Printing

3D printing has emerged as a revolutionary technology in manufacturing, allowing for the rapid prototyping of complex designs without the need for extensive tooling or setup. This method is particularly beneficial for low-volume production and can produce intricate shapes that traditional bending methods cannot achieve. However, the mechanical properties of 3D-printed components can vary significantly depending on the material used, which may not meet the strength requirements for all applications. Furthermore, while the initial costs may be lower, post-processing steps could increase overall expenses.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating tube bending services versus alternative solutions like CNC machining and 3D printing, B2B buyers should consider their specific requirements, including production volume, material types, and the complexity of designs. Tube bending services offer high precision and are best suited for custom parts in industries requiring stringent specifications. On the other hand, CNC machining provides versatility for complex shapes, while 3D printing offers rapid prototyping capabilities. Ultimately, understanding the unique advantages and limitations of each option will guide buyers to the most suitable choice for their projects.

Essential Technical Properties and Trade Terminology for tube bending services near me

What Are the Key Technical Properties of Tube Bending Services?

When sourcing tube bending services, understanding the technical specifications is crucial for ensuring product quality and performance. Here are some essential properties to consider:

1. Material Grade

Material grade refers to the quality and type of metal used in tube fabrication, such as stainless steel, aluminum, or carbon steel. Each grade has specific mechanical properties, including tensile strength, corrosion resistance, and thermal conductivity. For B2B buyers, selecting the appropriate material grade is vital as it impacts the durability and suitability of the bent tubes for specific applications, such as automotive or construction.

2. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension. In tube bending, this often refers to how closely the final dimensions of the bent tube match the specified dimensions. Typical tolerances can range from ±0.01 inches to ±0.05 inches, depending on the material and application. Precise tolerances are essential for ensuring that components fit together correctly in assemblies, thereby reducing the risk of operational failures.

3. Bend Radius

The bend radius is the radius of the curvature of the bent tube. It significantly affects the tube’s structural integrity and flow characteristics. A smaller bend radius can increase the risk of kinking or weakening the material, while a larger radius may be necessary for maintaining flow efficiency in applications like piping. For B2B buyers, understanding the required bend radius is critical for ensuring functionality in specific systems.

4. Wall Thickness

Wall thickness refers to the thickness of the tube walls. Thicker walls provide greater strength and resistance to pressure, making them suitable for high-stress applications. Conversely, thinner walls may be adequate for less demanding uses and can reduce material costs. Buyers need to balance wall thickness against the required strength and weight considerations of their projects.

5. Finish Quality

Finish quality pertains to the surface treatment of the bent tubes, which can affect aesthetics, corrosion resistance, and friction characteristics. Common finishes include polished, anodized, or galvanized. For B2B buyers, specifying the finish is essential for meeting both functional requirements and design standards.

What Common Trade Terms Should I Know When Engaging Tube Bending Services?

Familiarity with industry jargon can streamline communication and negotiation processes with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In tube bending, OEMs often require specific bending specifications to meet their product standards. Understanding this term helps B2B buyers ensure they are sourcing from manufacturers who can meet OEM requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to produce or sell. This is crucial for B2B buyers to understand as it can affect budgeting and inventory management. Knowing the MOQ can help in planning purchases and managing cash flow.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for pricing and terms for specific products or services. For B2B buyers, crafting a detailed RFQ is essential for obtaining accurate and competitive quotes, ensuring that all potential suppliers understand the project requirements.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding the delivery of goods. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers involved in international transactions to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for B2B buyers to effectively manage project timelines and ensure that products are available when needed.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing tube bending services, ensuring that they meet their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the tube bending services near me Sector

What Are the Key Market Drivers and Trends Influencing Tube Bending Services?

The tube bending services sector is experiencing dynamic shifts driven by globalization, technological advancements, and evolving customer demands. B2B buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer precision-engineered solutions with rapid turnaround times. The demand for customized solutions is on the rise as industries such as automotive, aerospace, and construction continue to grow, necessitating high-quality, bespoke tube bending services.

Emerging technologies like automation and advanced manufacturing techniques are transforming the landscape. For instance, the integration of 3D modeling and simulation tools allows manufacturers to optimize designs before production, reducing waste and enhancing efficiency. Additionally, the rise of Industry 4.0 is pushing companies to invest in smart manufacturing capabilities, enabling real-time monitoring and quality control throughout the production process. This is particularly significant for international buyers who prioritize reliability and consistency in their supply chains.

Illustrative image related to tube bending services near me

Sourcing trends are also shifting towards a more collaborative approach, where buyers are looking for long-term partnerships with suppliers who can adapt to their changing needs. As competition intensifies, companies that can demonstrate agility and responsiveness will have a competitive edge in attracting international clients. Furthermore, the focus on transparency in the supply chain is becoming paramount, with buyers increasingly scrutinizing the practices of their suppliers.

How Is Sustainability Shaping the Future of Tube Bending Services?

The importance of sustainability and ethical sourcing in the tube bending services sector cannot be overstated. As global awareness of environmental issues increases, B2B buyers are actively seeking suppliers who prioritize sustainable practices. This includes the use of environmentally friendly materials, energy-efficient manufacturing processes, and waste reduction strategies. Companies that adopt sustainable practices not only reduce their environmental footprint but also appeal to a growing demographic of eco-conscious clients.

Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers aiming to establish credibility in the market. Buyers from regions like Europe, where regulatory standards are stringent, often require compliance with such certifications to ensure that their supply chains are ethically managed and environmentally responsible.

Moreover, the trend towards circular economy practices is gaining traction. This involves reusing materials and minimizing waste throughout the production process. For instance, suppliers who can offer recycled materials or demonstrate effective recycling processes enhance their appeal to international buyers looking to align with sustainable sourcing initiatives.

What Is the Historical Context of Tube Bending Services?

The evolution of tube bending services can be traced back to the early 20th century when manual bending techniques were prevalent. As industries grew and the demand for precision increased, the introduction of mechanized bending tools marked a significant turning point. By the mid-20th century, advancements in CNC (Computer Numerical Control) technology revolutionized the sector, allowing for high precision and repeatability in tube bending processes.

Today, tube bending services have evolved into a sophisticated field that combines traditional craftsmanship with cutting-edge technology. The focus has shifted from merely bending tubes to providing comprehensive solutions that meet the specific needs of diverse industries. As a result, suppliers are not only tasked with delivering high-quality bends but also with ensuring that their processes are efficient, sustainable, and adaptable to the ever-changing demands of the global marketplace.

In conclusion, B2B buyers looking for tube bending services must consider the interplay of market dynamics, sustainability practices, and the historical context of the industry to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of tube bending services near me

-

How do I choose the right tube bending service provider?

Selecting the right tube bending service provider involves evaluating their experience, capabilities, and quality standards. Look for a company with a strong track record in your industry, as they will better understand your specific requirements. Assess their technology, such as CNC bending machines and quality assurance processes, to ensure precision and consistency. Request samples or case studies to gauge their work quality, and consider customer reviews and testimonials for insights into their reliability and service levels. -

What are the common materials used in tube bending services?

Tube bending services typically work with a variety of materials, including carbon steel, stainless steel, aluminum, and brass. The choice of material depends on the application and required properties, such as strength, corrosion resistance, and weight. For example, stainless steel is preferred for environments requiring durability, while aluminum is favored for lightweight applications. Discuss your project needs with potential suppliers to identify the best material options that align with your specifications. -

What customization options are available for tube bending projects?

Most tube bending service providers offer extensive customization options, including various bending methods (e.g., mandrel bending, induction bending) and the ability to create unique shapes and sizes. You can specify dimensions, angles, wall thicknesses, and surface finishes based on your project requirements. Additionally, many companies can integrate secondary processes such as welding and coating to provide a complete solution. Always communicate your specific needs to ensure that the supplier can meet your expectations. -

What is the typical lead time for tube bending services?

Lead times for tube bending services can vary significantly based on factors like the complexity of the bends, material availability, and the supplier’s current workload. Generally, you can expect lead times ranging from a few days to several weeks. For urgent projects, some suppliers may offer expedited services, so it’s advisable to discuss your timeline requirements upfront. Establishing clear communication about deadlines will help ensure that your project remains on schedule. -

How do I verify the quality of tube bending services?

To verify the quality of tube bending services, inquire about the supplier’s quality assurance processes and certifications, such as ISO 9001. Request details on their inspection methods, including any technology used for measuring precision, such as Vector measuring machines or 3D modeling. Additionally, ask for samples of previous work or client testimonials to assess their performance. A reputable supplier should be transparent about their quality control measures and willing to provide documentation. -

What are the minimum order quantities (MOQs) for tube bending services?

Minimum order quantities (MOQs) for tube bending services can vary widely among suppliers, often influenced by the complexity of the bending process and material costs. Some companies may have MOQs as low as one unit for prototypes, while others may require larger quantities for production runs to justify setup costs. Discuss your project needs with potential suppliers to understand their MOQ policies and explore options for smaller batch production if necessary. -

What payment terms should I expect when sourcing tube bending services?

Payment terms for tube bending services can differ based on the supplier’s policies and the nature of your order. Common arrangements include upfront payments, deposits, or net payment terms (e.g., net 30 or net 60). For international transactions, consider additional factors like currency exchange rates, transaction fees, and any applicable tariffs. Always clarify payment terms before finalizing contracts to ensure that both parties have a mutual understanding. -

How does international shipping work for tube bending services?

International shipping for tube bending services involves several steps, including selecting a reliable logistics partner and understanding customs regulations. Suppliers often provide FOB (Free on Board) pricing, which includes shipping costs to the port of departure. Ensure you discuss shipping options, timelines, and any documentation required for customs clearance. It’s also wise to confirm the supplier’s experience in handling international orders to avoid potential delays or complications during transit.

Top 8 Tube Bending Services Near Me Manufacturers & Suppliers List

1. Jentsch Company – Tube Bending Services

Domain: jentschcompany.com

Registered: 2015 (10 years)

Introduction: Tube Bending capabilities range from 1/8″ to 4¼” OD tube. Services include: Hydraulic Tube Line Replication from 1/8″ to 2″, Heat Exchanger Tube Bending from 3/8″ to 2″ OD, Hydrostatic Testing of Heat Exchanger Tubes after Bending from 100 PSI to 5,000 PSI, Stress Relief Annealing on Heat Exchange Tubes. Pipe Bending capabilities range from ¼” through 4″, schedule 40, including various degree angl…

2. Tube Bending Specialists – Pipe and Tube Bending Services

Domain: tubebendingspecialists.com

Registered: 2000 (25 years)

Introduction: This company, Tube Bending Specialists – Pipe and Tube Bending Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Xometry – Precision Tube Bending Services

Domain: xometry.com

Registered: 2015 (10 years)

Introduction: Xometry offers precision tube bending services for round metal tube stock, including standard rotary draw and highly precise mandrel tube bending. The service includes instant online quoting, DFM, and competitive lead times. Material options include stainless steel (304 and 316), aluminum (6061), alloy steel (4130), and steel (A513 types). Tube bending sizes range from a minimum bendable diameter …

4. Sharpe Products – Custom Tube Bending & Laser Cutting

Domain: sharpeproducts.com

Registered: 1999 (26 years)

Introduction: Sharpe Products specializes in custom tube and pipe bending, laser cutting, and end forming services for various industries including aerospace, agriculture, automotive, construction, food and beverage, medical/healthcare, and recreation. They offer all-electric CNC tube bending and tube laser cutting for tubes with an outer diameter (OD) ranging from 1/2″ to 6″. Their services include precision e…

5. V.M. Choppy & Sons – Metal Forming Solutions

Domain: vmchoppyandsons.com

Registered: 2000 (25 years)

Introduction: V.M. Choppy & Sons specializes in metal forming, tube bending, and sheet rolling for various markets throughout the USA. They utilize a variety of equipment including: Safan Darley E-Brake 220 Ton x 12’, Bystronic PRDC 150 Ton x 10’ with 6 axis bg, Adira QHA 80-25 x 8’ 90 ton with nc bg, AMADA RG-25 25 Ton Press Brake, Roundo x 4’ Sheet Roller, Ercolina SB48 Pipe and Tube Bender, and Ercolina CE50…

6. PIRTEK – Custom Tube Bending and Fabrication Services

Domain: pirtekusa.com

Registered: 1997 (28 years)

Introduction: PIRTEK offers custom tube bending and fabrication services at select locations. The services include: Low and High-Pressure Hydraulic Tubes, Hydraulic Steel Tubes, Carbon and Stainless Tubes, Fittings in both Metric and Standard Tube, Tube Flaring, and Custom Tube Fabrication on New Equipment. Services are tailored to specific needs such as bend angle, tubing material, and tube thickness. Note tha…

7. Totten Tubes – Steel Tube Bending Services

Domain: tottentubes.com

Introduction: Totten Tubes offers steel tube and pipe bending services, celebrating 70 years in the industry. They provide high-quality, safe, and reliable tube bending services for both small and large structural pipes, accommodating short and long production runs. Applications for their tube bending services include elbows, u-joints, handrails, bike racks, chassis components, axles, fences, gates, furniture f…

8. Bassett Industries – Precision Tube Fabrication Services

Domain: bassettinc.com

Introduction: Bassett Industries offers tube bending and fabricating services with over 75 years of experience. They provide a range of precision tube fabrication processes, from pre-cutting raw materials to final production of finished tubular components and assemblies. Key features include:

– State-of-the-art CNC tube benders with touch screen controls for complex bent parts.

– 15 tube benders of various ty…

Strategic Sourcing Conclusion and Outlook for tube bending services near me

In today’s competitive global marketplace, the strategic sourcing of tube bending services is paramount for businesses seeking quality, efficiency, and cost-effectiveness. By leveraging advanced technologies such as Vector Measuring Machines and various bending methods—like induction and mandrel bending—companies can ensure precision and consistency in their projects. This not only enhances product quality but also fosters long-term partnerships with suppliers who can adapt to diverse industry requirements.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must prioritize suppliers who demonstrate a commitment to excellence, rapid turnaround times, and adherence to international standards. The ability to source locally while also considering global leaders in tube bending can provide a strategic advantage, optimizing supply chains and reducing lead times.

As you explore options for tube bending services, remember that investing in reliable partnerships will pay dividends in quality and service. Embrace the opportunity to connect with industry leaders who can support your unique needs and contribute to your business’s success. Start your sourcing journey today and position your company for future growth and innovation in tube fabrication.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.